engine coolant CHERY TIGGO 2009 Service Manual PDF

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 780 of 1903

Downloaded from www.Manualslib.com manuals search engine 3.CHECK ENGINE COOLANT TEMPERATURE (ECT) SENSOR SIGNAL CIRCUIT FOR AN OPEN OR SHORT

• Turn ignition switch on.

• Check reference voltage between sensor terminal 2

and ground in the sensor electrical connector

E-068.

• 4.5 - 4.9 V should exist.

Is the check result normal?

Ye s>>Go to step 5.

No

>>Go to the next step.

4.DETECT MALFUNCTIONING PART

• Turn ignition switch off.

• Disconnect ECM connector.

• Check harness for an open or short between ECT connector terminal 2 and ECM connector E-054, terminal 67.

Is the check result normal?

Ye s>>Replace the ECM.

No

>>Repair circuit for an open or short in harness or connectors.

5.CHECK ECT SENSOR GROUND CIRCUIT FOR AN OPEN AND SHORT

• Check harness continuity between following terminals.

ECT SENSOR TERMINAL ECM TERMINAL

17 6

• Continuity should exist.

• Also check harness for short to power and short to ground.

Is the check result normal?

Ye s>>Go to the next step.

No

>>Repair circuit for an open or short to power or short to ground in harness or connectors.

DIAGNOSIS & TESTING

LTSMD030008

03–496Chery Automobile Co., Ltd.

Page 815 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

Engine Coolant Temperature (ECT) Sensor

Description

The Engine Coolant Temperature (ECT) Sensor is beside the thermostat. The ECT Sensor is a negative thermal

coefficient sensor.

Operation

The ECT sensor provides an input signal to the ECM. As temperature increases, resistance of the sensor decreases.

As coolant temperature varies, the ECT sensor resistance changes resulting in a different voltage value at the ECT

sensor signal circuit. The ECM uses the input to control air-fuel mixture, timing, and radiator fan on/off times.

Removal & Installation

1. Disconnect and isolate the negative battery cable.

2. Release the coolant system pressure.

WARNING!

Never remove the radiator pressure relief cap under any conditions while the engine is operating or hot. Failure

to follow these instructions could result in personal injury or damage to the cooling system or engine. To avoid

having scalding hot coolant or steam blow out of the cooling system, use extreme care when removing the pres-

sure relief cap. Wait until the engine has cooled, then wrap a thick cloth around the pressure relief cap and turn

it slowly one turn (counterclockwise). Step back while the pressure is released from the cooling system. When

you are certain all the pressure has been released, (with a cloth) turn and remove the pressure relief cap. Failure

to follow these instructions may result in serious personal injury.

3. Disconnect the coolant temperature sensor electrical connector.

CAUTION:

Remove the coolant temperature sensor when the engine is cold.

03

03–531Chery Automobile Co., Ltd.

Page 816 of 1903

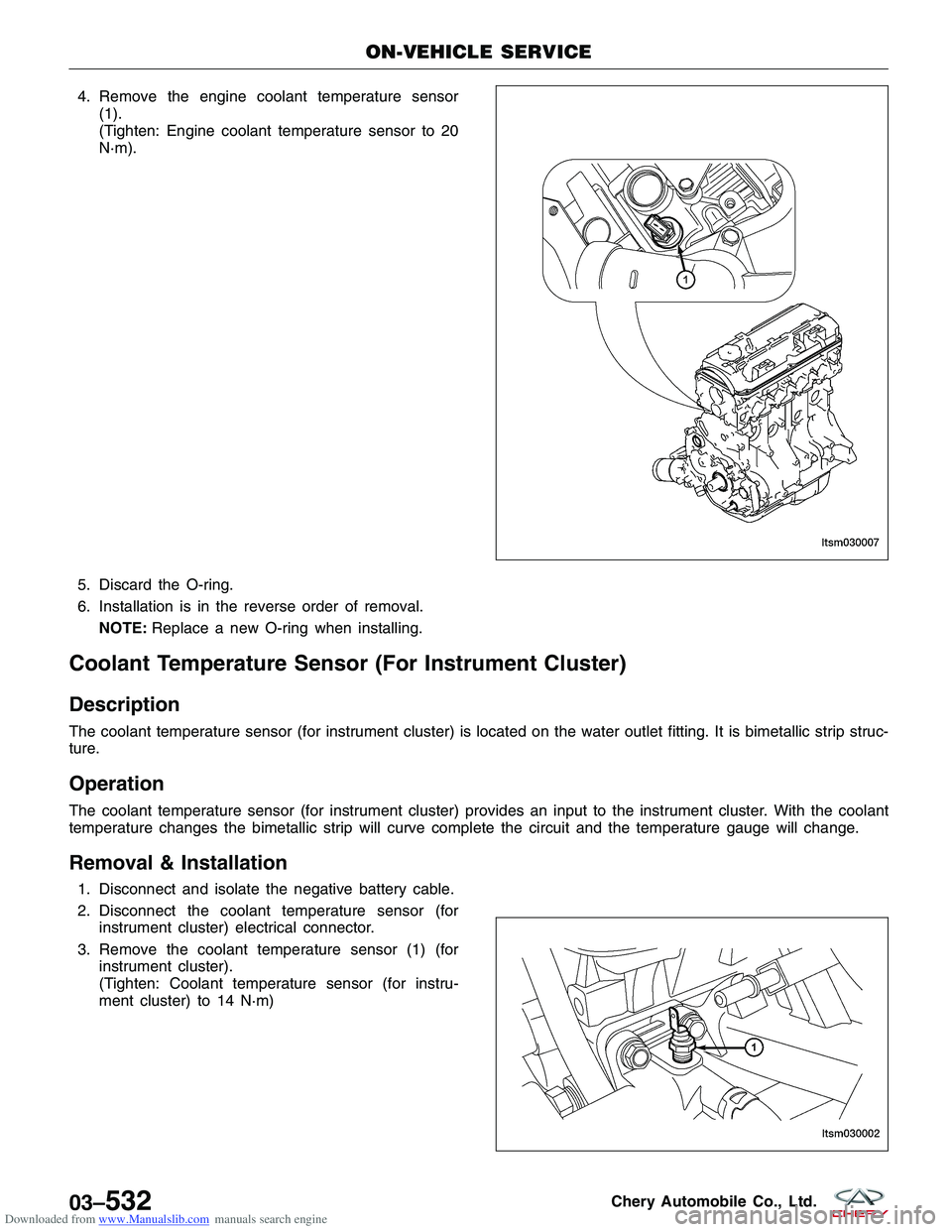

Downloaded from www.Manualslib.com manuals search engine 4. Remove the engine coolant temperature sensor(1).

(Tighten: Engine coolant temperature sensor to 20

N·m).

5. Discard the O-ring.

6. Installation is in the reverse order of removal. NOTE: Replace a new O-ring when installing.

Coolant Temperature Sensor (For Instrument Cluster)

Description

The coolant temperature sensor (for instrument cluster) is located on the water outlet fitting. It is bimetallic strip struc-

ture.

Operation

The coolant temperature sensor (for instrument cluster) provides an input to the instrument cluster. With the coolant

temperature changes the bimetallic strip will curve complete the circuit and the temperature gauge will change.

Removal & Installation

1. Disconnect and isolate the negative battery cable.

2. Disconnect the coolant temperature sensor (for

instrument cluster) electrical connector.

3. Remove the coolant temperature sensor (1) (for instrument cluster).

(Tighten: Coolant temperature sensor (for instru-

ment cluster) to 14 N·m)

ON-VEHICLE SERVICE

LTSM030007

LTSM030002

03–532Chery Automobile Co., Ltd.

Page 817 of 1903

Downloaded from www.Manualslib.com manuals search engine 4. Installation is in the reverse order of removal.

CAUTION:

Before removing the coolant temperature sensor (for instrument cluster), release the coolant pres-

sure and make sure the engine is cold.

Knock Sensor

Description

The knock sensor is attached to the cylinder block. The knock sensor is designed to detect engine vibration that is

caused by detonation.

Operation

When the knock sensor detects a knock in one of the cylinders, it sends an input signal to the ECM. In response, the

ECM retards ignition timing for all cylinders by a scheduled amount.

Knock sensors contain a piezoelectric material which constantly vibrates and sends an input voltage (signal) to the

ECM while the engine operates. As the intensity of the vibration increases, the knock sensor output voltage also

increases.

The voltage signal produced by the knock sensor increases with the amplitude of vibration. The ECM receives an

input knock sensor voltage signal. If the signal rises above a predetermined level, the ECM will store that value in

memory and retard ignition timing to reduce engine knock. If the knock sensor voltage exceeds a present value, the

ECM retards ignition timing for all cylinders. It is not a selective cylinder retard.

The ECM ignores knock sensor input signal during engine idle conditions. Once the engine speed exceeds a spec-

ified value, knock retard is allowed.

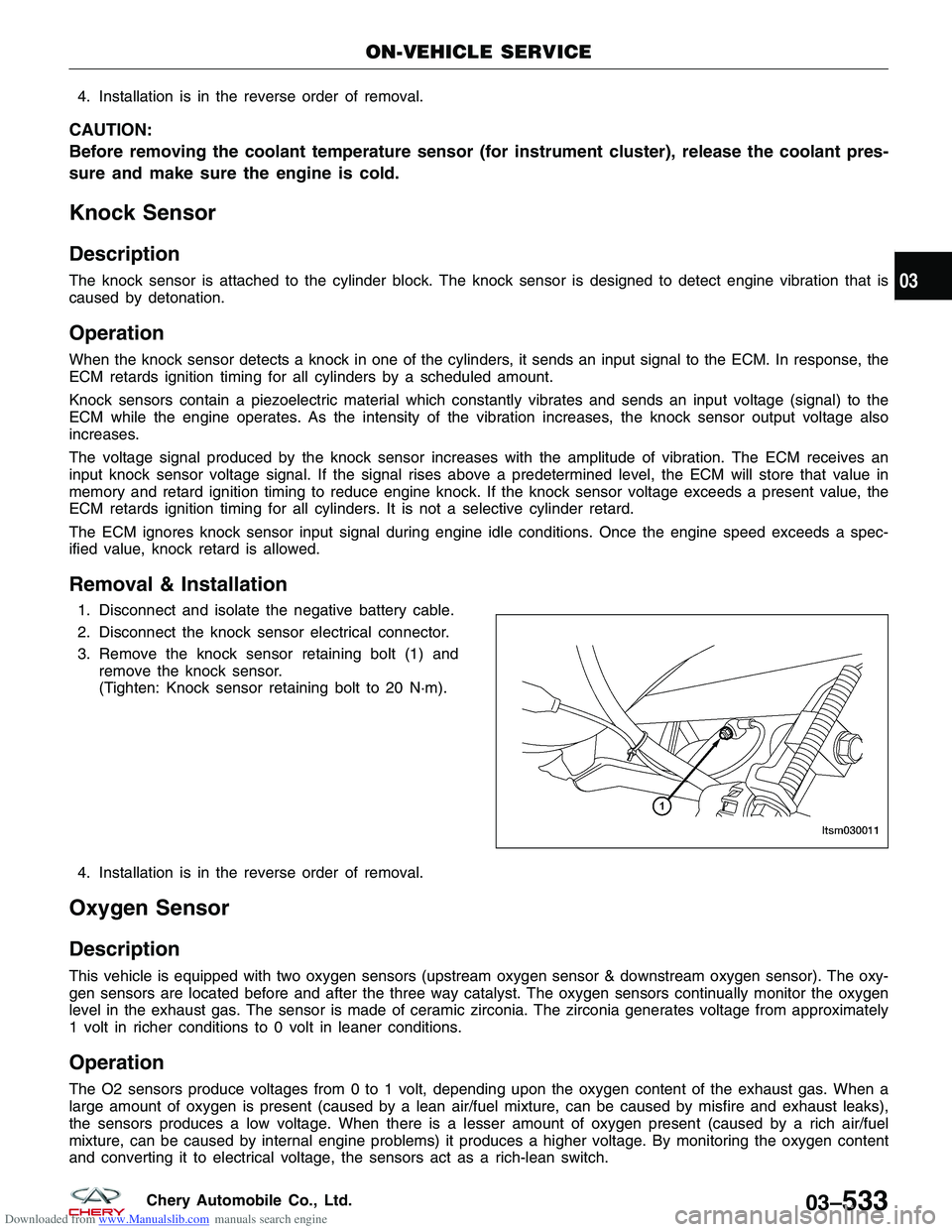

Removal & Installation

1. Disconnect and isolate the negative battery cable.

2. Disconnect the knock sensor electrical connector.

3. Remove the knock sensor retaining bolt (1) andremove the knock sensor.

(Tighten: Knock sensor retaining bolt to 20 N·m).

4. Installation is in the reverse order of removal.

Oxygen Sensor

Description

This vehicle is equipped with two oxygen sensors (upstream oxygen sensor & downstream oxygen sensor). The oxy-

gen sensors are located before and after the three way catalyst. The oxygen sensors continually monitor the oxygen

level in the exhaust gas. The sensor is made of ceramic zirconia. The zirconia generates voltage from approximately

1 volt in richer conditions to 0 volt in leaner conditions.

Operation

The O2 sensors produce voltages from 0 to 1 volt, depending upon the oxygen content of the exhaust gas. When a

large amount of oxygen is present (caused by a lean air/fuel mixture, can be caused by misfire and exhaust leaks),

the sensors produces a low voltage. When there is a lesser amount of oxygen present (caused by a rich air/fuel

mixture, can be caused by internal engine problems) it produces a higher voltage. By monitoring the oxygen content

and converting it to electrical voltage, the sensors act as a rich-lean switch.

ON-VEHICLE SERVICE

LTSM030011

03

03–533Chery Automobile Co., Ltd.

Page 872 of 1903

Downloaded from www.Manualslib.com manuals search engine EGR Valve 2.4L

Description

The EGR valve (1) is located on the underside of the

idle air control motor. It is controlled by the vacuum

hose.

Operation

The EGR valve can heighten the intake air temperature and reduce the NOx content in the exhaust. It is controlled

by the coolant temperature sensor and the throttle position sensor.

ON-VEHICLE SERVICE

LTSM030033

03–588Chery Automobile Co., Ltd.

Page 916 of 1903

Downloaded from www.Manualslib.com manuals search engine COOLING

06

CONTENTSpage

Cooling System ...................................................................... 06-1

COOLING SYSTEM

GENERAL INFORMATION06-2

Description 06-2

Operation 06-4

Specifications 06-5

Special Tools 06-5

Electrical Schematics 06-6

DIAGNOSIS AND TESTING06-11

Cooling System Pressure Test 06-11

Cooling System Concentration Test 06-11

Cooling System Troubleshooting Chart 06-12

ON-VEHICLE SERVICE06-13

Cooling System Draining and Filling 06-13

Cooling System Draining Procedure 06-13

Cooling System Filling Procedure 06-13

Thermostat 06-14

Description 06-14

Operation 06-14 Removal & Installation - 1.6L & 1.8L &

2.0L 06-14

Removal & Installation - 2.4L 06-15

Thermostat Inspection 06-16

Coolant Pump 06-16

Removal & Installation - 1.6L & 1.8L &

2.0L 06-16

Removal & Installation - 2.4L 06-17

Coolant Pump Inspection 06-17

Radiator 06-17

Description 06-17

Operation 06-17

Removal & Installation 06-17

Cooling Fan 06-18

Description 06-18

Operation 06-19

Removal & Installation 06-19

Cooling Fan Inspection 06-19

06

06–1Chery Automobile Co., Ltd.

Page 918 of 1903

Downloaded from www.Manualslib.com manuals search engine The cooling system regulates engine operating temperature. It allows the engine to reach normal operating temper-

ature as soon as possible, maintains normal operating temperature and prevents overheating.

The cooling system also provides a means of heating the passenger compartment. The cooling system is pressurized

and uses a centrifugal water pump to circulate coolant throughout the system.

The cooling system consists of the following components:

•Radiator

• Coolant

• Coolant pump

• Electric cooling fans

• Electric cooling fans control module

• Thermostat

• Coolant reservoir

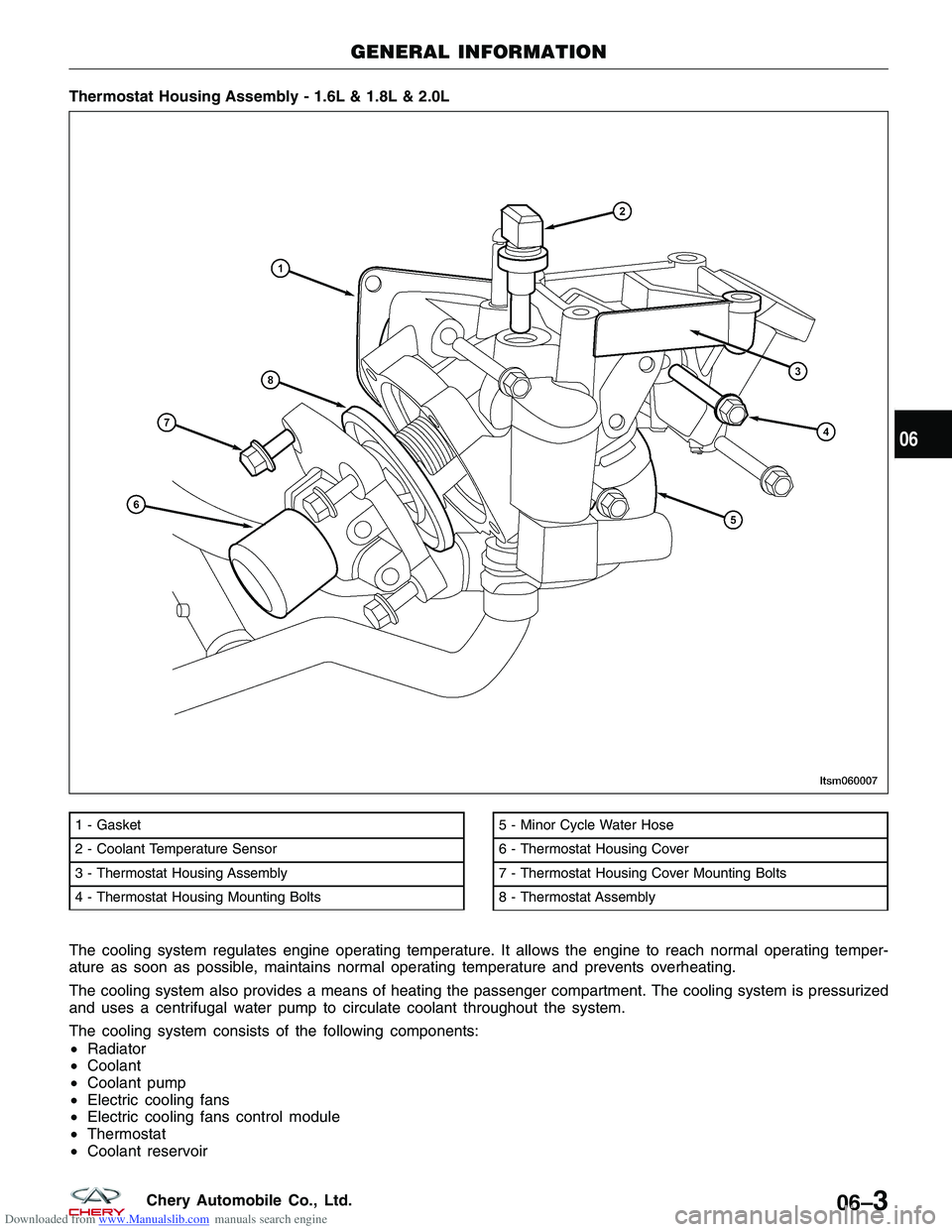

Thermostat Housing Assembly - 1.6L & 1.8L & 2.0L

1 - Gasket

2 - Coolant Temperature Sensor

3 - Thermostat Housing Assembly

4 - Thermostat Housing Mounting Bolts5 - Minor Cycle Water Hose

6 - Thermostat Housing Cover

7 - Thermostat Housing Cover Mounting Bolts

8 - Thermostat Assembly

GENERAL INFORMATION

LTSM060007

06

06–3Chery Automobile Co., Ltd.

Page 919 of 1903

Downloaded from www.Manualslib.com manuals search engine •Hoses and clamps

• Coolant temperature sensor

• Coolant temperature sensor (for instrument cluster) (with 2.4L engine)

• Heater core

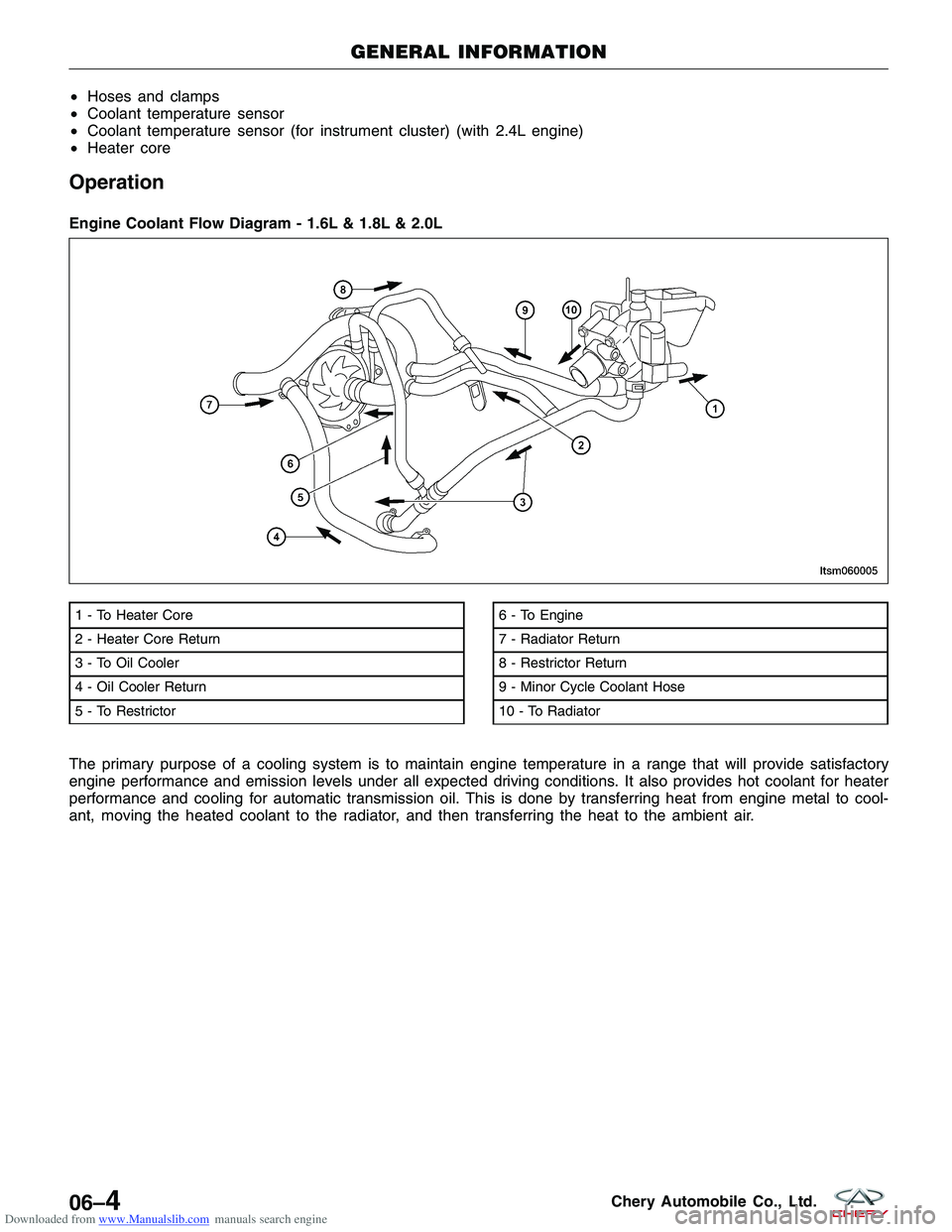

Operation

The primary purpose of a cooling system is to maintain engine temperature in a range that will provide satisfactory

engine performance and emission levels under all expected driving conditions. It also provides hot coolant for heater

performance and cooling for automatic transmission oil. This is done by transferring heat from engine metal to cool-

ant, moving the heated coolant to the radiator, and then transferring the heat to the ambient air. Engine Coolant Flow Diagram - 1.6L & 1.8L & 2.0L

1 - To Heater Core

2 - Heater Core Return

3 - To Oil Cooler

4 - Oil Cooler Return

5 - To Restrictor6 - To Engine

7 - Radiator Return

8 - Restrictor Return

9 - Minor Cycle Coolant Hose

10 - To Radiator

GENERAL INFORMATION

LTSM060005

06–4Chery Automobile Co., Ltd.

Page 920 of 1903

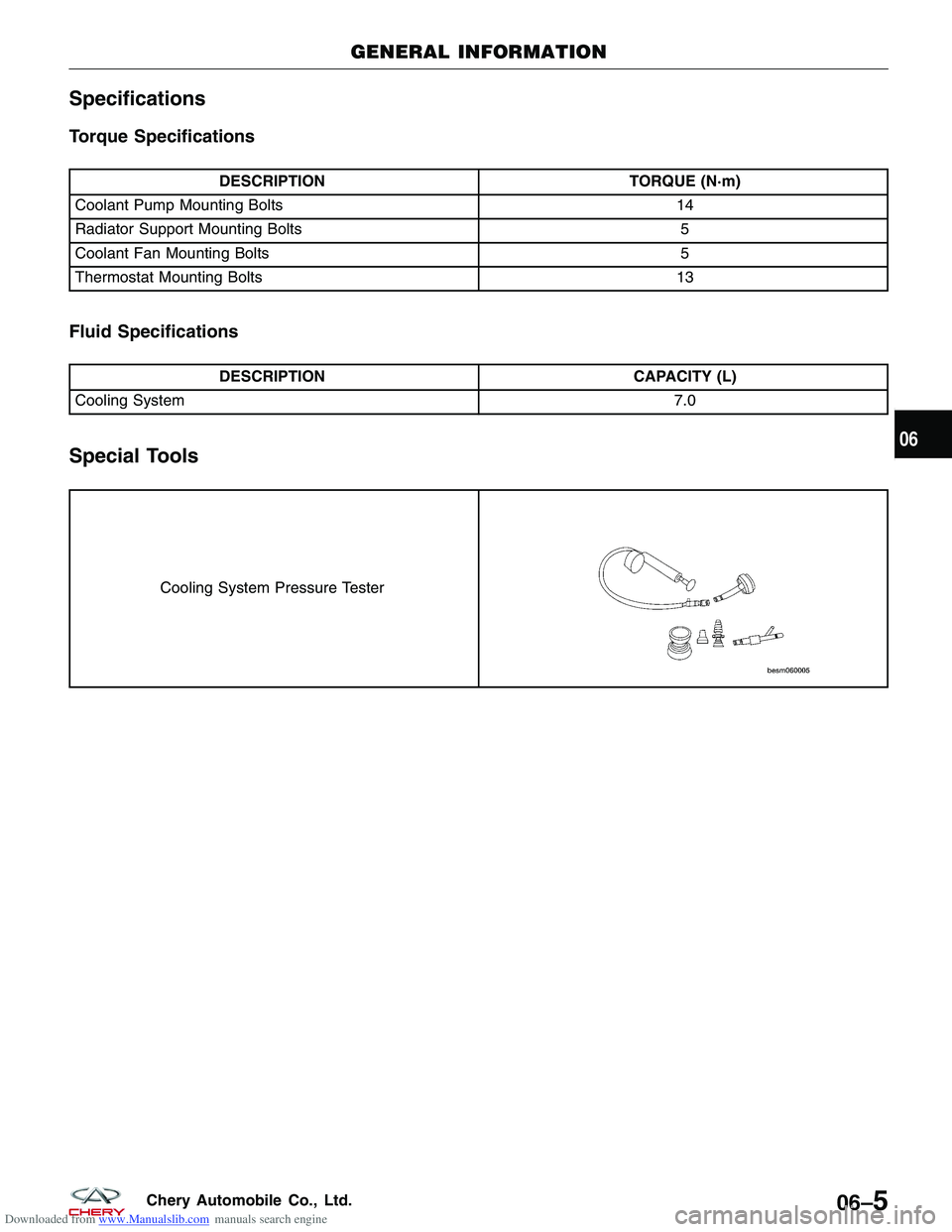

Downloaded from www.Manualslib.com manuals search engine Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Coolant Pump Mounting Bolts 14

Radiator Support Mounting Bolts 5

Coolant Fan Mounting Bolts 5

Thermostat Mounting Bolts 13

Fluid Specifications

DESCRIPTIONCAPACITY (L)

Cooling System 7.0

Special Tools

Cooling System Pressure Tester

GENERAL INFORMATION

06

06–5Chery Automobile Co., Ltd.

Page 926 of 1903

Downloaded from www.Manualslib.com manuals search engine DIAGNOSIS AND TESTING

Cooling System Pressure Test

WARNING!

Always allow the engine to cool before opening the cooling system. Do not remove the coolant pressure relief

cap when the engine is operating or the cooling system is hot. The cooling system is under pressure; steam and

hot liquid can come out forcefully when the cap is loosened slightly. Failure to follow these instructions may

result in serious personal injury.

CAUTION:

Do not pressurize the cooling system beyond the maximum pressure listed in the specifications

table in this section, or cooling system components can be damaged.

1. Turn the engine off.

2. Check the engine coolant level. Adjust the coolant level as necessary.

3. Attach the pressure tester to the coolant recovery reservoir. Install a pressure test pump to the quick-connectfitting of the test adapter.

4. Pressurize the engine cooling system to 111 kPa. Observe the gauge reading for approximately 2 minutes. Pres- sure should not drop during this time. If the pressure drops within this time, inspect for leaks and repair as nec-

essary.

5. If no leaks are found and the pressure drops, the pressure relief cap may be leaking. Install a new pressure relief cap and retest the system.

6. If no leaks are found after a new pressure relief cap is installed, and the pressure drops, the leak may be inter- nal to the radiator transmission cooler (if equipped). Inspect the coolant for transmission fluid and the transmis-

sion fluid for coolant. Repair as necessary.

7. If there is no contamination of the coolant or transmission fluid, the leak may be internal to the engine. Inspect the coolant for engine oil and the engine oil for coolant.

8. Release the system pressure by loosening the pressure relief cap. Check the coolant level and adjust as nec- essary.

Cooling System Concentration Test

CAUTION:

Do not mix types of coolant, corrosion protection will be severely reduced.

Coolant concentration should be checked when any additional coolant is added to the cooling system or after a cool-

ant drain, flush and refill. The coolant mixture offers optimum engine cooling and protection against corrosion when

mixed to a freeze point of -37°C to -46°C. The use of a hydrometer or a refractometer can be used to test coolant

concentration.

06

06–11Chery Automobile Co., Ltd.