lock CHEVROLET ASTRO PASSENGER 1994 1.G Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1994, Model line: ASTRO PASSENGER, Model: CHEVROLET ASTRO PASSENGER 1994 1.GPages: 340, PDF Size: 16.86 MB

Page 260 of 340

Downloaded from www.Manualslib.com manuals search engine Air Conditioning

Every now and then have your dealership check your air conditioning

system to be sure it has not

lost any cooling ability. If you think the system

is not working properly, have your dealership

check it out as soon as

possible.

The air conditioning will not work when the temperature is below

40°F

(4 O C).

Lubrication

Accelerator Control System

Refer to the Maintenance Schedule to determine how often the accelerator

linkage pivot points must be lubricated and what type of lubricant

to use.

Accelerator cables and cruise control cables should not be lubricated. Any

cables that are worn or are hard to pull should be replaced.

When cleaning the engine compartment with water or steam, avoid directing

the flow onto the throttle linkage in a manner that would cau\

se moisture

to

enter the cables.

Hood Latches and Hood Hinge

Refer to the Maintenance Schedule to determine how to lubricate the hood

latch and hood hinge assembly.

Sliding Door Tracks

Your vehicle’s sliding door has three tracks which need lubrication.

For the upper and lower tracks, open the door, wipe the track\

clean and then lubricate with Lubriplate

TM White Grease.

For the outside middle track, close

the door after you finish the upper and

lower tracks. Then, wipe

the track clean and lubricate with

Lubriplate

TM White Grease.

Body

Normal use of your vehicle will cause metal to metal wear at some points on

the cab and body

if they are not lubricated.

For exposed surfaces, such as door checks, door lock bolts, lock striker

plates, dovetail bumper wedges, etc., a thin film

of engine oil should be

applied.

Where oil holes are provided in the body or cab, a dripless oil can be used.

The seat adjusters and seat track should be lubricated with chassis grease.

6-42

Page 261 of 340

Downloaded from www.Manualslib.com manuals search engine Door weatherstrips and rubber hood bumpers should be wiped clean with a

wet cloth and lightly coated with a rubber lubricant.

Never use too much of any lubricant and be sure

to wipe up any extra

lubricant when you are finished.

Some parts

that need lubricating are hard to get at. Window regulators and

controls are inside the doors. You can get to these by removing

the trim

panels.

Refer to the Maintenance Schedule to determine how often to lubricate

these items and what type

of lubricant to use.

Lock Cylinders

To be sure your locks operate properly, they must be lubricated.

Refer to the Maintenance Schedule to determine how often to lubricate them

and what type of lubricant to use.

You should not use penetrating oils because they could wash out

the factory

installed lubricant and cause the lock to bind. De-icers which contain

alcohol could also

wash away the lubricant, so be sure to lubricate the lock

after using a de-icer of this type.

Exhaust System

To help prevent damage to your exhaust system, do not continue to drive

your vehicle if you notice:

Engine misfiring

Loss of performance

Other unusual operating conditions

Have your engine and exhaust system serviced regularly.

Three- Way Catalytic Converter

Your vehicle’s three-way catalytic converter is designed to reduce the

pollutants in your vehicle’s exhaust. Use only unleaded fuel in your vehicle.

If you use leaded fuel, you could damage your three-way catalytic converter

and other engine components.

Engine Control Module System

This system has an oxygen (02) sensor that helps keep your engine’s

air-fuel mixture at a proper level. Use only unleaded fuel in your vehicle.

If

you use leaded fuel, you could damage your oxygen (02) sensor and affect

your vehicle’s emissions.

6-43

Page 284 of 340

Downloaded from www.Manualslib.com manuals search engine Fuses and Circuit Breakers

The wiring circuits in your vehicle are protected from short circuits by a

combination of fuses, circuit breakers, and fusible thermal

links in the

wiring itself. This greatly reduces the chance of fires caused by electrical

problems. See “Fuses and Circuit Breakers”

in the Index for more

information.

Headlights

The headlight wiring is protected by a circuit breaker in the light switch. An

electrical overload will cause the lights

to go on and off, or in some cases to

remain off. If this happens, have your headlight wiring checked right away.

Windshield Wipers

The windshield wiper motor is protected by a circuit breaker and a fuse. If

the motor overheats

due to heavy snow, etc., the wiper will stop until the

motor cools. If the overload is caused

by some electrical problem and not

snow, etc., be sure to get it fixed.

Power Windows and Other Power Options

Circuit breakers in the fuse panel protect the power windows and other

power accessories. When the current load is too heavy, the circuit breaker

opens and closes, protecting the circuit until the problem is fixed or goes

away.

Trailer Wiring Harness

The optional seven-wire trailer wiring harness is protected by an in-line

fuse

in the battery feed wire. This fuse is near the junction block. See

“Trailer Wiring Harness”

in the Index.

6-66

Page 285 of 340

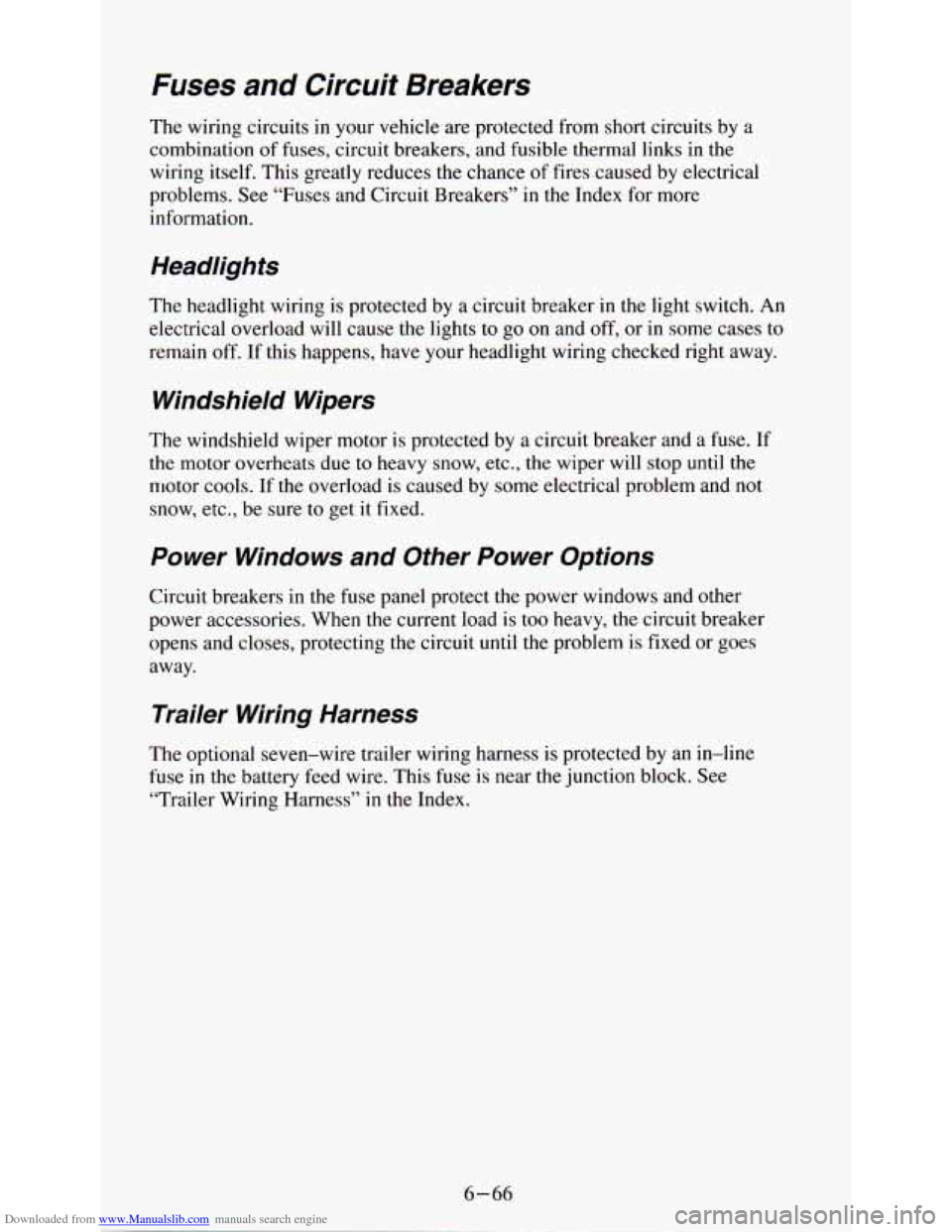

Downloaded from www.Manualslib.com manuals search engine ruse Block

The fuse block is

under the instrument

panel

on the driver’s

side. Remove the

cover with

a

screwdriver.

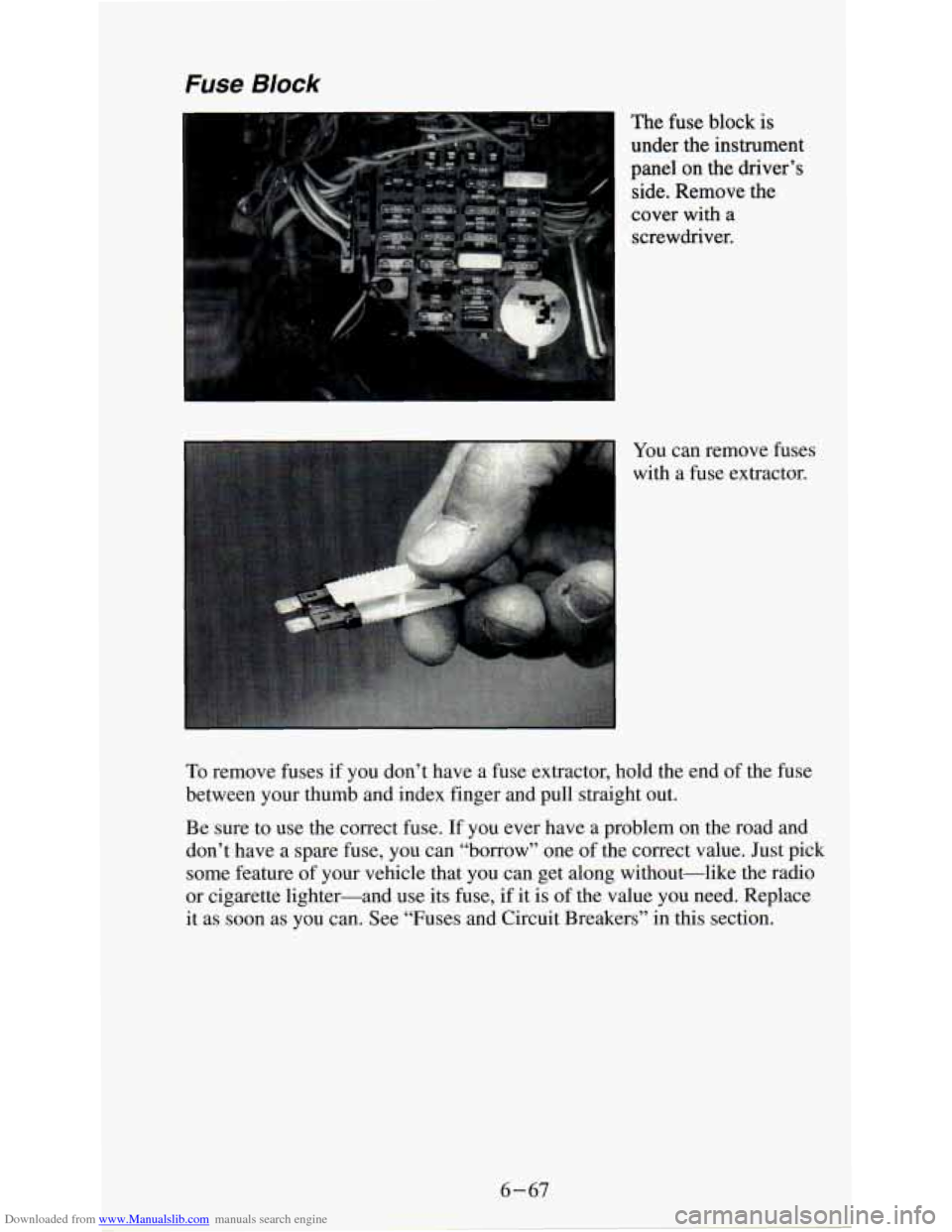

To remove fuses if you don’t have a fuse extractor, hold the end of the fuse

between your thumb and index finger and pull straight out.

Be sure to use the correct fuse.

If you ever have a problem on the road and

don’t have a spare fuse, you can “borrow” one

of the correct value. Just pick

some feature of your vehicle that you can get along without-like the radio

or cigarette lighter-and use its fuse, if it is of the value you need. Replace

it as

soon as you can. See “Fuses and Circuit Breakers” in this section.

6-67

Page 289 of 340

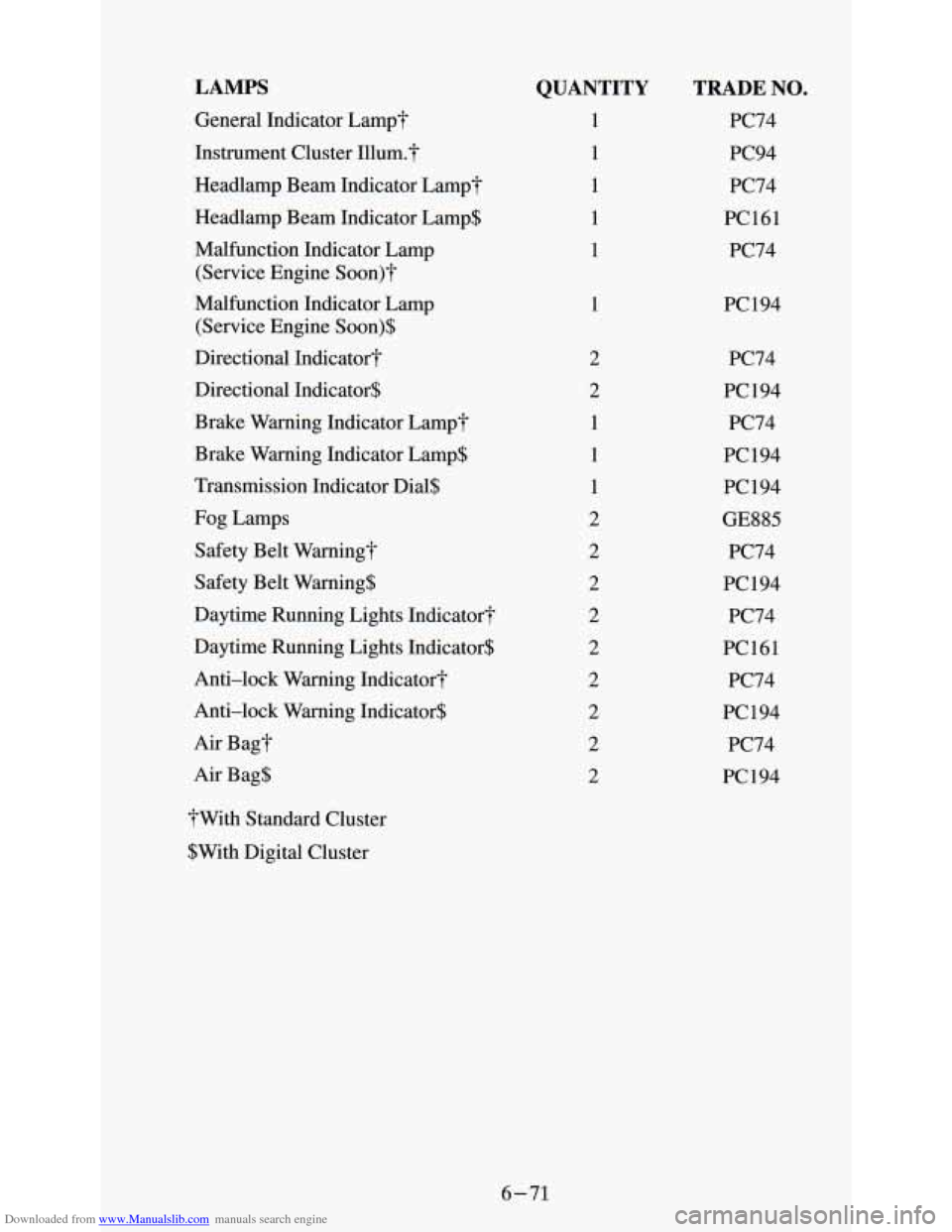

Downloaded from www.Manualslib.com manuals search engine LAMPS

General Indicator Lamp?

Instrument Cluster Illum.?

Headlamp Beam Indicator Lamp?

Headlamp Beam Indicator Lamp$

Malfunction Indicator Lamp (Service Engine Soon)?

Malfunction Indicator Lamp

(Service Engine Soon)$

Directional Indicator?

Directional Indicator$

Brake Warning Indicator Lamp?

Brake Warning Indicator Lamp$

Transmission Indicator Dial$

Fog Lamps

Safety Belt Warning?

Safety Belt Warning$

Daytime Running Lights Indicator?

Daytime Running Lights Indicator$

Anti-lock Warning Indicator?

Anti-lock Warning Indicator$

Air Bag?

Air Bag$

QUANTITY TRADE NO.

1 PC74

1 PC94

1 PC74

1 PC161

1 PC74

1

2

2

1

1

1

2

2

2

2

2

2

2

2

2

PC 194

PC74

PC 194

PC74

PC 194

PC 194

GE885 PC74

PC 194

PC74

PC161 PC74

PC 194

PC74

PC 194

?With Standard Cluster

$With Digital Cluster

6-71

Page 291 of 340

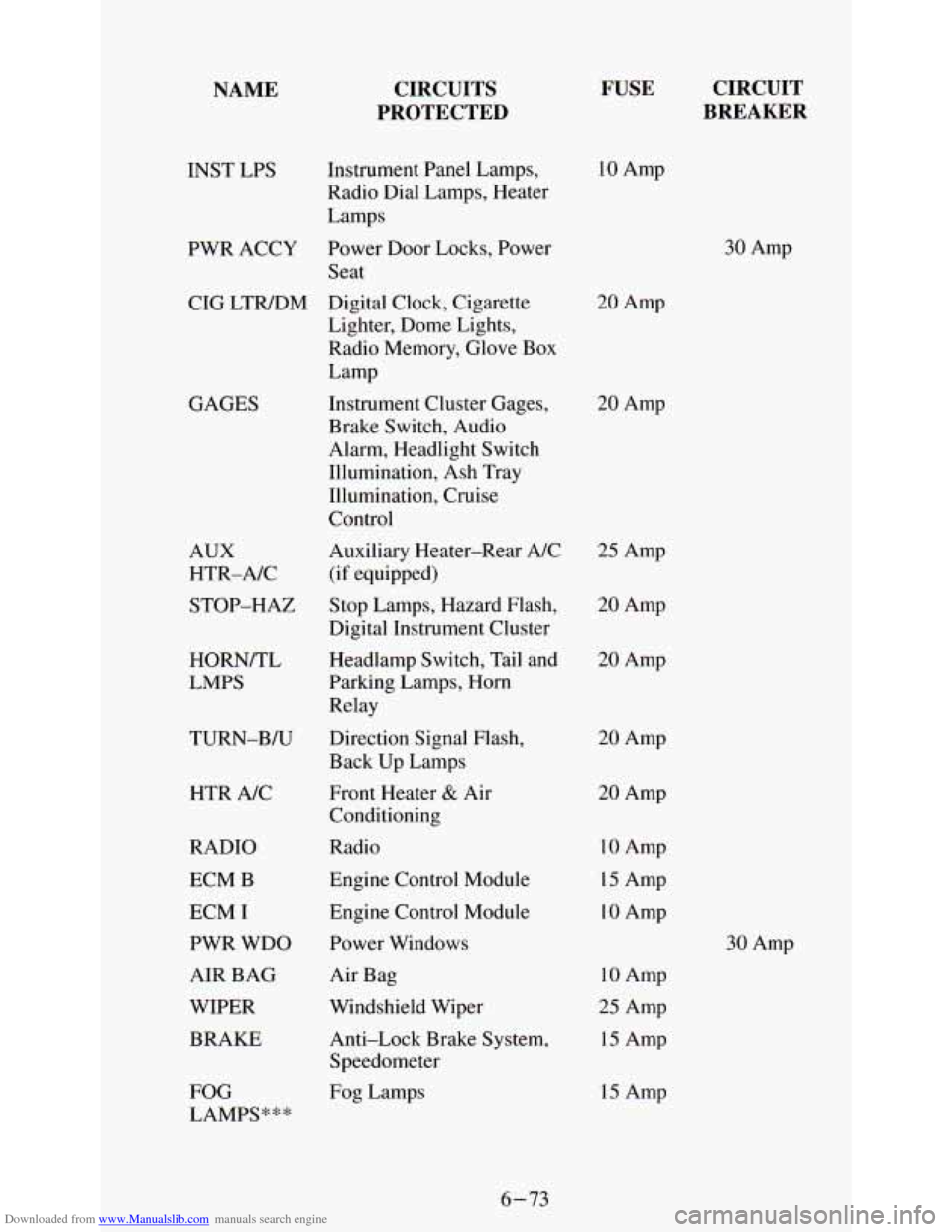

Downloaded from www.Manualslib.com manuals search engine NAME

INST LPS

CIRCUITS

PROTECTED

Instrument Panel Lamps,

Radio Dial Lamps, Heater

Lamps

PWR ACCY Power Door Locks, Power

CIG LTWDM Digital Clock, Cigarette Seat

Lighter,

Dome Lights,

Radio Memory, Glove Box

Lamp

GAGES

AUX

HTR-A/C STOP-HAZ Instrument Cluster Gages,

Brake

Switch, Audio

Alarm, Headlight Switch

Illumination, Ash Tray

Illumination, Cruise

Control

Auxiliary Heater-Rear A/C (if equipped)

Stop Lamps, Hazard Flash,

Digital Instrument Cluster

HORN/TL Headlamp Switch, Tail and

LMPS Parking Lamps, Horn

Relay

TURN-B/U Direction Signal Flash,

Back Up Lamps

HTR A/C

RADIO

ECM B

ECM I

PWR WDO

AIR BAG

WIPER

BRAKE

FOG

LAMPS*** Front Heater

& Air

Conditioning

Radio

Engine Control Module

Engine Control Module

Power Windows

Air Bag

Windshield Wiper

Anti-Lock Brake System, Speedometer

Fog Lamps

FUSE

10 Amp

CIRCUIT

BREAKER

30 Amp

20 Amp

20 Amp

25 Amp

20 Amp

20 Amp

20 Amp

20 Amp

10 Amp

15 Amp

10 Amp

30 Amp

10 Amp

25 Amp

15 Amp

15 Amp

6-73

Page 303 of 340

Downloaded from www.Manualslib.com manuals search engine 13. TIRE AND WHEEL ROTATION AND INSPECTION - For

proper wear and maximum tire life, rotate tires at the first

6,000 miles

(10

000 kilometers) for Schedule I or 7,500 miles (12 500 kilometers)

for Schedule I1 and

then every 15,000 miles (25 000 kilometers)

thereafter. Follow the instructions and patterns shown in Sectio\

n

6.

Check tires for uneven wear or damage. If irregular or premature wear

is apparent, check wheel alignment. Also, check for damaged wheels.

See “Tires” in the Index for more information.

14.

DRIVE AXLE SERVICE - Check readfront axle fluid level and add

as needed. Check constant velocity joints and axle seals for leaking.

Locking Differential - Drain fluid at first oil change and refill.

Check fluid level and add as needed at subsequent oil changes. In

dusty areas or trailer towing applications, drain fluid at every

15,000 miles (24 135 kilometers) and refill.?

Standard Differential - Check fluid level and add as needed at

every oil change. In dusty areas or trailer towing applications\

,

drain fluid every

15,000 miles (24 135 kilometers) and refill.?

15. BRAKE SYSTEM INSPECTION - When the engine oil is changed,

inspect the lines and hoses for proper hookup, binding, leaks, cracks,

chafing, etc. Check the parking brake adjustment, and the fluid\

level in the master cylinder. A low fluid level can indicate

worn disc brake pads

which may need to be serviced.?

When the wheels are removed for rotation, inspect disc brake pads for

wear and rotors for surface condition. Also inspect drum brake linings

for wear and cracks. Inspect other brake parts, including drums, wh\

eel

cylinders, parking brake, etc. at the same time.

Inspect brakes more often if driving habits or conditions resul\

t in

frequent braking.

-f A fluid loss in these systems may indicate a problem. Have them inspected a\

nd

repaired at once.

7-9

Page 304 of 340

Downloaded from www.Manualslib.com manuals search engine Owner Checks and Services

Listed below are owner checks and services which would be made at the

time period specified

to help ensure proper safety, emission performance,

and dependability

of your vehicle.

Be sure

any necessary repairs are completed at once. Whenever any fluids

or lubricants are added to your vehicle, make sure they are t\

he proper ones,

as shown in this section.

At Least Once a Month

Tire Inflation Pressure Check - Check the tires for proper inflation. If

they

are low, inflate them to the level specified on the Certification label.

See “Inflation-Tire Pressure” in

the Index.

At Least Once a Year

Key Lock Cylinder Lubrication - Lubricate key lock cylinders with one

of the lubricants recommended in this section.

Transmission Neutral or Clutch Start Switch Operation -

1. Before you start, be sure you have enough room around the veh\

icle.

2. Firmly apply both the manual parking brake, and the regular br\

ake. See

“Brakes” and “Parking Brake”

in the Index. Do not use the accelerator

pedal.

3. Be ready to turn off the engine immediately if it starts.

4. Try to start the engine in each gear. The starter should work only in “P”

(Park) or “N’ (Neutral).

7- 10

Page 305 of 340

Downloaded from www.Manualslib.com manuals search engine Steering Column Lock Operation - While parked, try to turn the key to

LOCK in each gear shift position.

0 The key should turn to LOCK only when the gear shift is in “P”

(Park).

On all vehicles, the key should come out only in

LOCK.

Parking Brake and Transmission

“P’ (Park) Mechanism Operation -

-

Park on a fairly steep hill, with the vehicle facing downhill. Keeping your

foot on the regular brake, set the manual parking brake.

0 To check the parking brake: With the engine running and the

transmission in

“N’ (Neutral), slowly remove foot pressure from the

regular brake pedal.

Do this until the vehicle is held by the parking

brake only.

0 To check the “P” (Park) mechanism’s holding ability: Apply the regular

brake and shift

to T“ (Park). Release the manual parking brake, then

slowly release the regular brake.

Lap and Shoulder Belts Condition and Operation - Inspect belt system,

including: webbing, buckles, latch plates, retractors, guide loops and

anchors. Have a belt assembly replaced if the webbing has been cut or

otherwise damaged.

Body Lubrication Service - Lubricate all body door hinges. Lubricate the

body hood, fuel door and rear compartment hinges, latches and locks

including interior

glove box and console doors, and any moving seat

hardware. Lubricate the hood safety lever pivot and prop rod pivot. More

frequent lubrication may be required when exposed

to a corrosive

environment.

7-11

Page 307 of 340

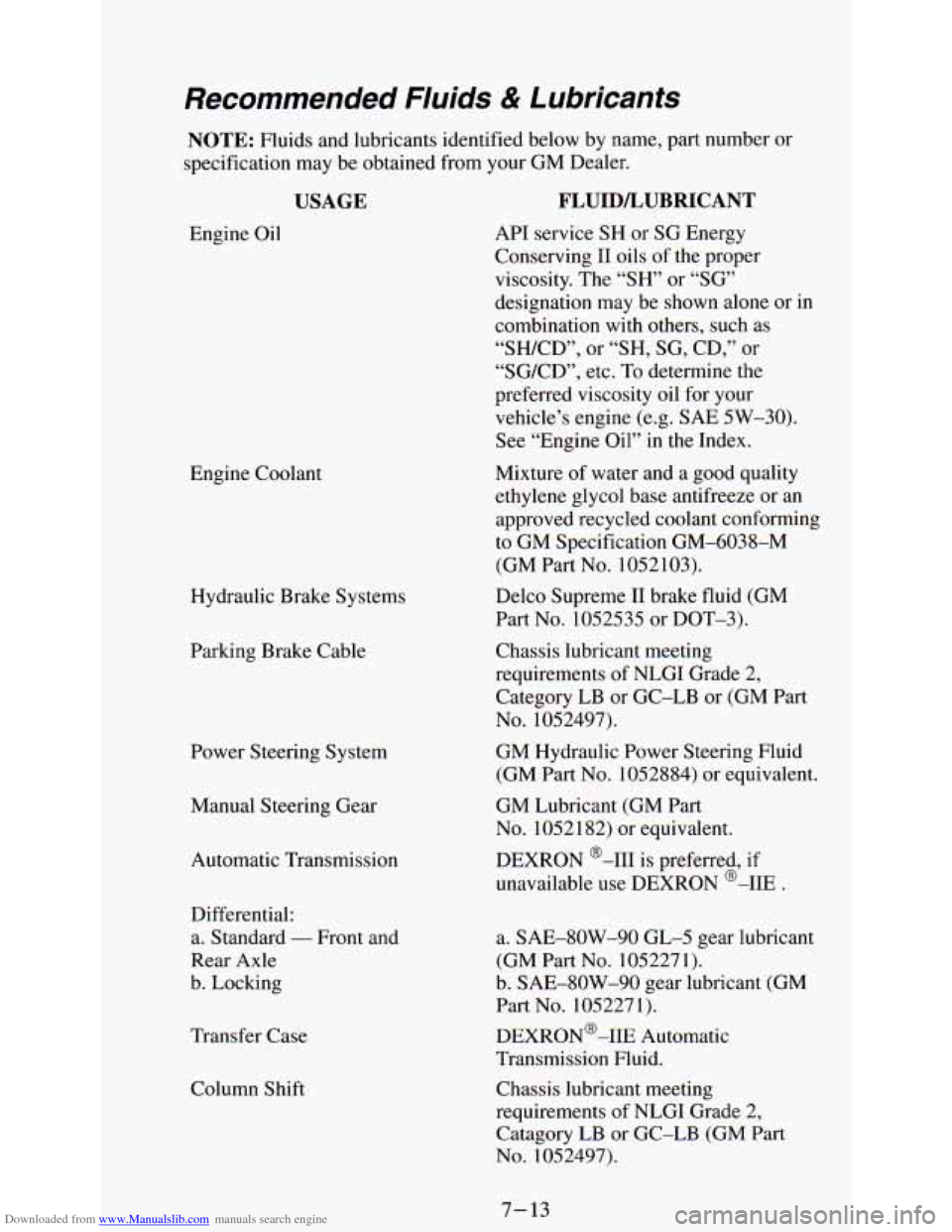

Downloaded from www.Manualslib.com manuals search engine Recommended Fluids & Lubricants

NOTE: Fluids and lubricants identified below by name, part number or

specification may be obtained from your GM Dealer.

USAGE

Engine Oil

Engine Coolant Hydraulic Brake Systems

Parking Brake Cable

Power Steering System

Manual Steering Gear

Automatic Transmission

Differential: a. Standard

- Front and

Rear Axle

b. Locking

Transfer Case Column Shift

FLUIDLUBRICANT

API service SH or SG Energy

Conserving I1 oils

of the proper

viscosity. The “SH” or

“SG’

designation may be shown alone or in

combination with others, such as

“SWCD”, or

“SH, SG, CD,” or

“SGKD”, etc. To determine the

preferred viscosity oil for your

vehicle’s engine (e.g. SAE 5W-30).

See “Engine Oil”

in the Index.

Mixture of water and a good quality

ethylene glycol base antifreeze or an

approved recycled coolant conforming

to GM Specification GM-6038-M

(GM Part No. 1052103).

Delco Supreme I1 brake fluid

(GM

Part No. 1052535 or DOT-3).

Chassis lubricant meeting

requirements of NLGI Grade 2,

Category LB or GC-LB or (GM Part

No. 1052497).

GM Hydraulic Power Steering Fluid

(GM Part No. 1052884) or equivalent.

GM Lubricant (GM Part

No. 10521 82) or equivalent.

DEXRON @-I11

is preferred, if

unavailable use DEXRON @-IIE .

a. SAE-80W-90 GL-5 gear lubricant

(GM Part

No. 105227 1).

b. SAE-80W-90 gear lubricant (GM

Part

No. 1052271).

DEXRON@-IIE Automatic

Transmission Fluid.

Chassis lubricant meeting

requirements of NLGI Grade 2,

Catagory LB or GC-LB

(GM Part

No. 1052497).

7- 13