position CHEVROLET AVEO 2004 1.G Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2004, Model line: AVEO, Model: CHEVROLET AVEO 2004 1.GPages: 334, PDF Size: 2.35 MB

Page 189 of 334

Service

Your dealer knows your vehicle best and wants you to

be happy with it. We hope you will go to your dealer

for all your service needs. You will get genuine GM parts

and GM-trained and supported service people.

We hope you will want to keep your GM vehicle all GM.

Genuine GM parts have one of these marks:

California Proposition 65 Warning

Most motor vehicles, including this one, contain and/or

emit chemicals known to the State of California to

cause cancer and birth defects or other reproductive

harm. Engine exhaust, many parts and systems

(including some inside the vehicle), many fluids, and

some component wear by-products contain and/or emit

these chemicals.

5-3

Page 230 of 334

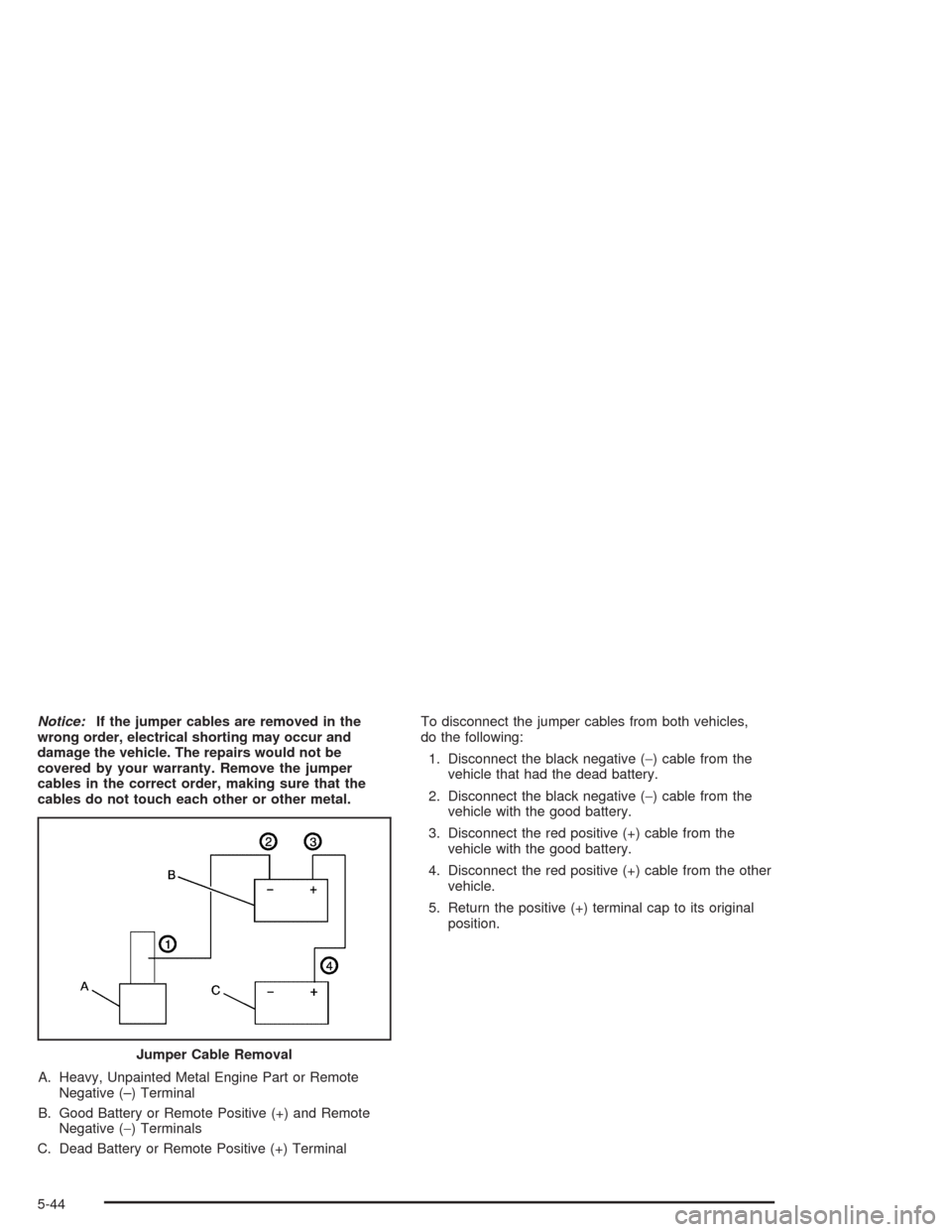

Notice:If the jumper cables are removed in the

wrong order, electrical shorting may occur and

damage the vehicle. The repairs would not be

covered by your warranty. Remove the jumper

cables in the correct order, making sure that the

cables do not touch each other or other metal.

A. Heavy, Unpainted Metal Engine Part or Remote

Negative (–) Terminal

B. Good Battery or Remote Positive (+) and Remote

Negative (−) Terminals

C. Dead Battery or Remote Positive (+) TerminalTo disconnect the jumper cables from both vehicles,

do the following:

1. Disconnect the black negative (−) cable from the

vehicle that had the dead battery.

2. Disconnect the black negative (−) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other

vehicle.

5. Return the positive (+) terminal cap to its original

position.

Jumper Cable Removal

5-44

Page 233 of 334

6. Pull the front turn signal bulb socket out of the lamp

housing.

7. Press the bulb inward and turn it counterclockwise

to remove it from the bulb socket.

8. Install the new bulb into the socket by pressing it in

and turning it clockwise.

9. Install the socket into the lamp housing by turning it

clockwise.

10. Reverse Steps 1 through 4 to install the assembly.

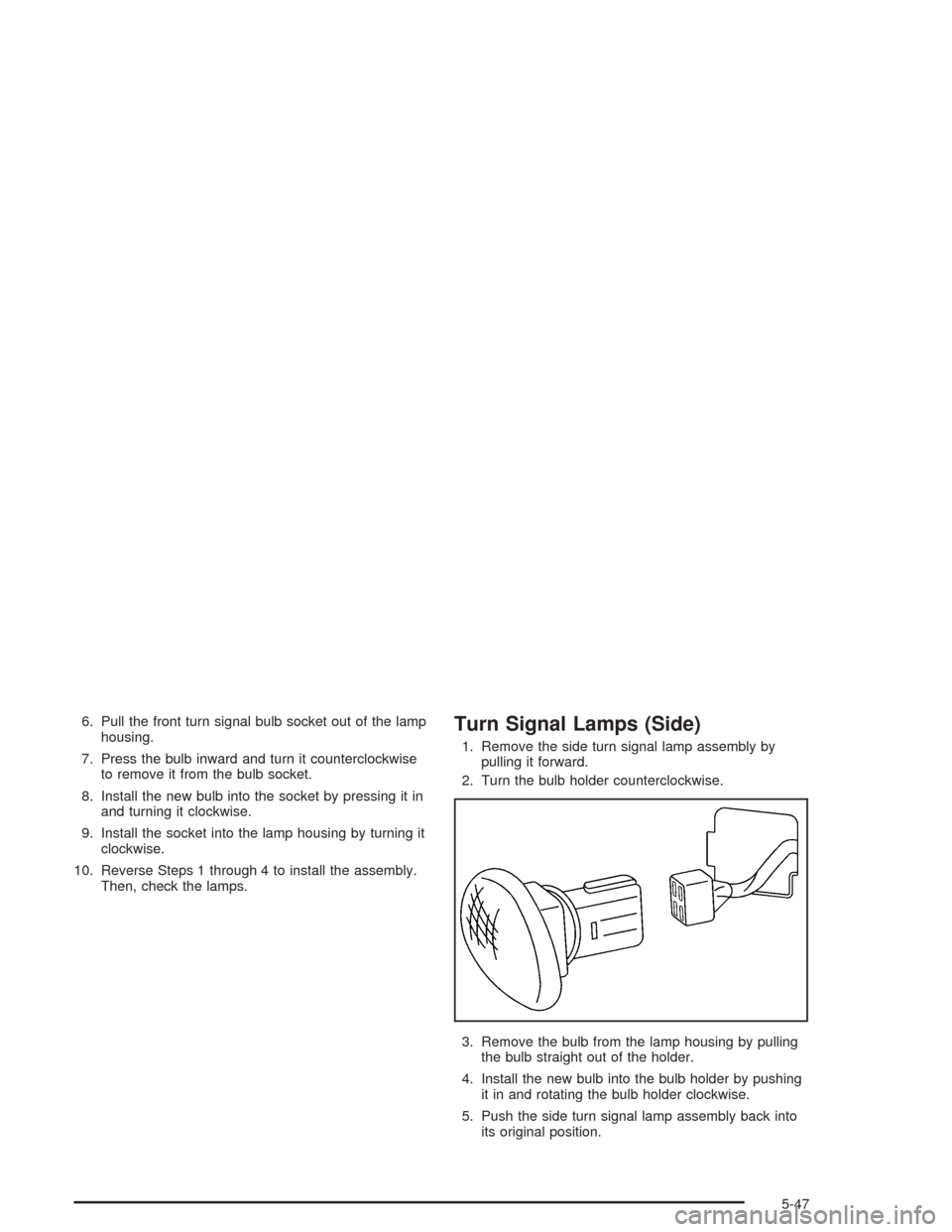

Then, check the lamps.Turn Signal Lamps (Side)

1. Remove the side turn signal lamp assembly by

pulling it forward.

2. Turn the bulb holder counterclockwise.

3. Remove the bulb from the lamp housing by pulling

the bulb straight out of the holder.

4. Install the new bulb into the bulb holder by pushing

it in and rotating the bulb holder clockwise.

5. Push the side turn signal lamp assembly back into

its original position.

5-47

Page 243 of 334

Intended Outboard Sidewall:The side of an

asymmetrical tire that must always face outward when

mounted on a vehicle.

Kilopascal (kPa):The metric unit for air pressure.

There are 6.9 kPa’s to one psi.

Light Truck (LT-Metric) Tire:A tire used on light duty

trucks and some multipurpose passenger vehicles.

Load Index:An assigned number ranging from 1 to 279

that corresponds to the load carrying capacity of a tire.

Maximum In�ation Pressure:The maximum cold

inflation pressure to which a tire may be inflated.

Maximum Load Rating:The load rating for a tire at

the maximum permissible inflation pressure for that tire.

Maximum Loaded Vehicle Weight:The sum of

curb weight; accessory weight; vehicle capacity weight;

and production options weight.

Normal Occupant Weight:The number of occupants a

vehicle is designed to seat multiplied by 150 pounds

(68 kg). SeeLoading Your Vehicle on page 4-32.

Occupant Distribution:Designated seating positions.Outward Facing Sidewall:The side of a asymmetrical

tire that has a particular side that faces outward

when mounted on a vehicle. The side of the tire that

contains a whitewall, bears white lettering or bears

manufacturer, brand and or model name molding that is

higher or deeper than the same moldings on the

other sidewall of the tire.

Passenger (P-Metric) Tire:A tire used on passenger

cars and some light duty trucks and multipurpose

vehicles.

Recommended In�ation Pressure:Vehicle

manufacturer’s recommended tire inflation pressure

shown on the tire placard. SeeInflation - Tire Pressure

on page 5-59andLoading Your Vehicle on page 4-32.

Radial Ply tire:A pneumatic tire in which the ply cords

that extend to the beads are laid at 90 degrees to the

centerline of the tread.

Rim:A metal support for a tire and upon which the tire

beads are seated.

Sidewall:The portion of a tire between the tread and

the bead.

5-57

Page 244 of 334

Speed Rating:An alphanumeric code assigned to a

tire indicating the maximum speed at which a tire

can operate.

Traction:The friction between the tire and the road

surface. The amount of grip provided.

Tread:The portion of a tire that comes into contact

with the road.

Treadwear Indicators:Narrow bands, sometimes

called “wear bars,” that show across the tread of a tire

when only 2/32 inch of tread remains. SeeWhen It

Is Time for New Tires on page 5-61.

Tread Width:The width of the tire’s tread.

UTQGS:Uniform Tire Quality Grading Standards,

a tire information system that provides consumers with

ratings for a tire’s traction, temperature and treadwear.

Ratings are determined by tire manufacturers using

government testing procedures. The ratings are molded

into the sidewall of the tire. SeeUniform Tire Quality

Grading on page 5-63.Vehicle Capacity Weight:The number of designated

seating positions multiplied by 150 pounds (68 kg)

plus the rated cargo load. SeeLoading Your Vehicle

on page 4-32.

Vehicle Maximum Load on the Tire:Load on an

individual tire due to curb weight, accessory weight,

occupant weight and cargo weight.

Vehicle Placard:A label permanently attached to a

vehicle showing original equipment tire size and

the recommended cold inflation pressure. SeeLoading

Your Vehicle on page 4-32.

5-58

Page 252 of 334

Tire Chains

Notice:Use tire chains only where legal and only

when you must. Use only SAE Class “S” type chains

that are the proper size for your tires. Install them on

the front tires and tighten them as tightly as possible

with the ends securely fastened. Drive slowly and

follow the chain manufacturer’s instructions. If you

can hear the chains contacting your vehicle, stop and

retighten them. If the contact continues, slow down

until it stops. Driving too fast or spinning the wheels

with chains on will damage your vehicle.

If a Tire Goes Flat

It’s unusual for a tire to “blowout” while you’re driving,

especially if you maintain your tires properly. If air goes

out of a tire, it’s much more likely to leak out slowly.

But if you should ever have a “blowout,” here are a few

tips about what to expect and what to do:

If a front tire fails, the flat tire will create a drag that

pulls the vehicle toward that side. Take your foot off the

accelerator pedal and grip the steering wheel firmly.

Steer to maintain lane position, and then gently brake to

a stop well out of the traffic lane.A rear blowout, particularly on a curve, acts much like a

skid and may require the same correction you’d use

in a skid. In any rear blowout, remove your foot from the

accelerator pedal. Get the vehicle under control by

steering the way you want the vehicle to go. It may be

very bumpy and noisy, but you can still steer. Gently

brake to a stop, well off the road if possible.

{CAUTION:

Lifting a vehicle and getting under it to do

maintenance or repairs is dangerous without

the appropriate safety equipment and training.

The jack provided with your vehicle is

designed only for changing a �at tire. If it is

used for anything else, you or others could be

badly injured or killed if the vehicle slips off

the jack. Use the jack provided with your

vehicle only for changing a �at tire.

If a tire goes flat, the next part shows how to use your

jacking equipment to change a flat tire safely.

5-66

Page 256 of 334

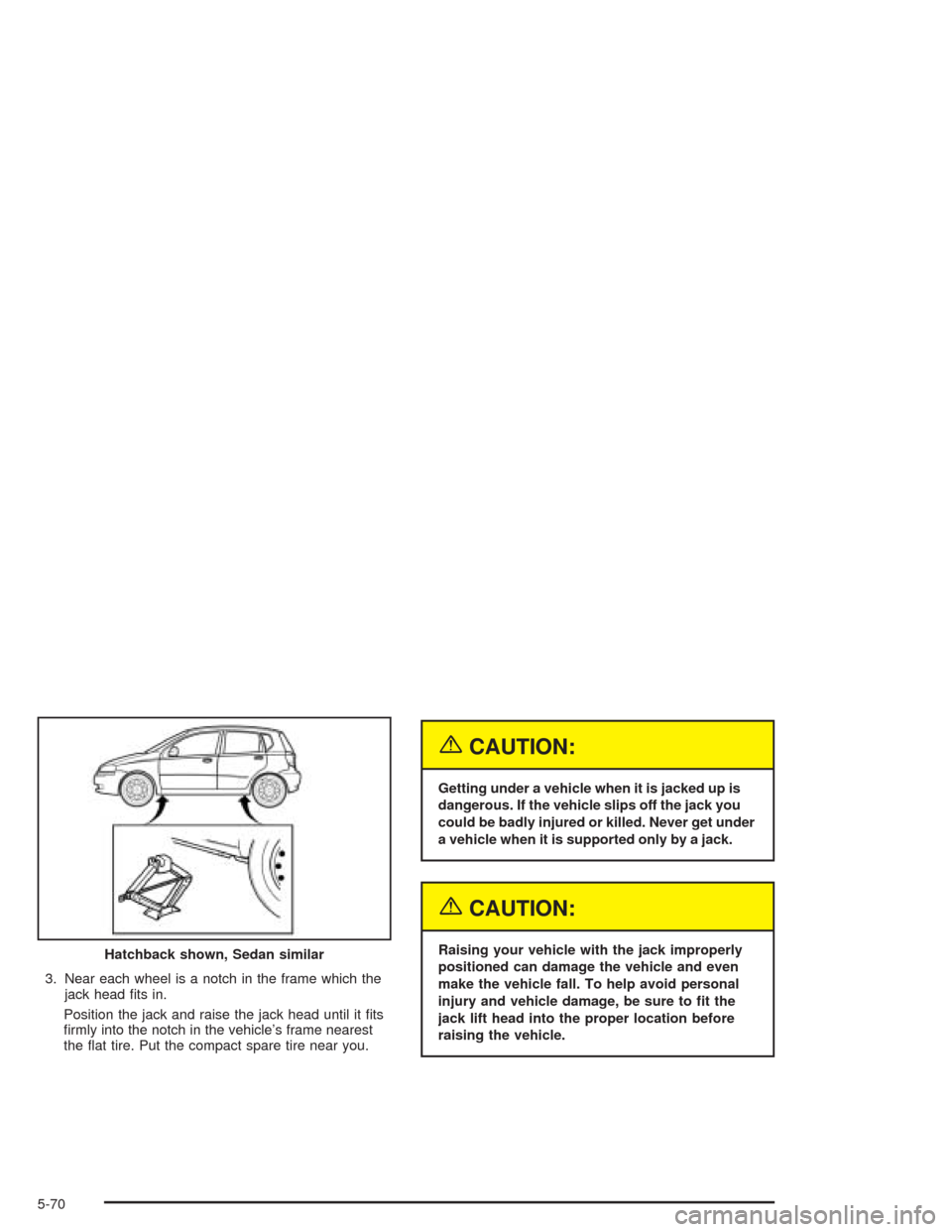

3. Near each wheel is a notch in the frame which the

jack head fits in.

Position the jack and raise the jack head until it fits

firmly into the notch in the vehicle’s frame nearest

the flat tire. Put the compact spare tire near you.

{CAUTION:

Getting under a vehicle when it is jacked up is

dangerous. If the vehicle slips off the jack you

could be badly injured or killed. Never get under

a vehicle when it is supported only by a jack.

{CAUTION:

Raising your vehicle with the jack improperly

positioned can damage the vehicle and even

make the vehicle fall. To help avoid personal

injury and vehicle damage, be sure to �t the

jack lift head into the proper location before

raising the vehicle. Hatchback shown, Sedan similar

5-70

Page 299 of 334

At Least Once a Year

Key Lock Cylinders Service

Lubricate the key lock cylinders with the lubricant

specified in Part D.

Body Lubrication Service

Lubricate all hood latch assemblies, secondary latch,

pivots, spring anchor, release pawl, hood and body

door hinges, rear compartment and any folding seat

hardware. Part D tells you what to use. More frequent

lubrication may be required when exposed to a corrosive

environment.

Starter Switch Check

{CAUTION:

When you are doing this inspection, the vehicle

could move suddenly. If the vehicle moves,

you or others could be injured.

1. Before you start, be sure you have enough room

around the vehicle.

2. Firmly apply both the parking brake and the regular

brake. SeeParking Brake on page 2-28if necessary.

Do not use the accelerator pedal, and be ready to

turn off the engine immediately if it starts.

3. On automatic transaxle vehicles, try to start the

engine in each gear. The starter should work only in

PARK (P) or NEUTRAL (N). If the starter works in

any other position, your vehicle needs service.

On manual transaxle vehicles, put the shift lever

in NEUTRAL (N), push the clutch down halfway and

try to start the engine. The starter should work only

when the clutch is pushed down all the way to the

floor. If the starter works when the clutch is not

pushed all the way down, your vehicle needs service.

6-21

Page 300 of 334

Automatic Transaxle Shift Lock Control

System Check

{CAUTION:

When you are doing this inspection, the vehicle

could move suddenly. If the vehicle moves, you

or others could be injured.

1. Before you start, be sure you have enough room

around the vehicle. It should be parked on a level

surface.

2. Firmly apply the parking brake. SeeParking Brake

on page 2-28if necessary.

Be ready to apply the regular brake immediately if

the vehicle begins to move.

3. With the engine off, turn the key to the RUN position,

but do not start the engine. Without applying the

regular brake, try to move the shift lever out of

PARK (P) with normal effort. If the shift lever moves

out of PARK (P), your vehicle needs service.

Ignition Transaxle Lock Check

While parked, and with the parking brake set, try to turn

the ignition key to LOCK in each shift lever position.

•With an automatic transaxle, the key should turn to

LOCK only when the shift lever is in PARK (P).

•With a manual transaxle, the key should turn to

LOCK only when you press the key release

button.

On all vehicles, the key should come out only in LOCK.

Turn the steering wheel to the left and to the right. It

should only lock when turned to the right.

6-22

Page 302 of 334

Part C: Periodic Maintenance

Inspections

Listed in this part are inspections and services which

should be performed at least twice a year (for instance,

each spring and fall).You should let your dealer’s

service department do these jobs. Make sure any

necessary repairs are completed at once.

Proper procedures to perform these services may be

found in a service manual. SeeService Publications

Ordering Information on page 7-11.

Steering, Suspension and Front

Drive Axle Boot and Seal Inspection

Inspect the front and rear suspension and steering

system for damaged, loose or missing parts, signs of

wear or lack of lubrication. Inspect the power steering

lines and hoses for proper hook-up, binding, leaks,

cracks, chafing, etc. Clean and then inspect the drive

axle boot seals for damage, tears or leakage. Replace

seals if necessary.

Exhaust System Inspection

Inspect the complete exhaust system. Inspect the body

near the exhaust system. Look for broken, damaged,

missing or out-of-position parts as well as open seams,

holes, loose connections or other conditions which

could cause a heat build-up in the floor pan or could let

exhaust fumes into the vehicle. SeeEngine Exhaust

on page 2-32.

6-24