lock CHEVROLET AVEO 2009 1.G Manual Online

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2009, Model line: AVEO, Model: CHEVROLET AVEO 2009 1.GPages: 354, PDF Size: 2.07 MB

Page 295 of 354

Headlamp Wiring

The headlamp wiring is protected by fuses in the fuse

block. An electrical overload will cause the lamps to turn

off. If this happens, have the headlamp wiring checked

right away.

Windshield Wiper Fuses

The windshield wiper motor is protected by a circuit

breaker and a fuse. If the motor overheats due to heavy

snow, etc., the wiper will stop until the motor cools. If

the overload is caused by some electrical problem, have

it �xed.

Power Windows and Other Power

Options

Circuit breakers in the fuse block protect the power

windows and other power accessories. When the current

load is too heavy, the circuit breaker opens and

closes, protecting the circuit until the problem is �xed or

goes away.

Fuses and Circuit Breakers

The wiring circuits in the vehicle are protected from

short circuits by a combination of fuses, circuit breakers

and fusible thermal links. This greatly reduces the

chance of �res caused by electrical problems.

Look at the silver-colored band inside the fuse. If the

band is broken or melted, replace the fuse. Be sure you

replace a bad fuse with a new one of the identical

size and rating.

Fuses of the same amperage can be temporarily

borrowed from another fuse location, if a fuse goes out.

Replace the fuse as soon as you can.

5-87

Page 296 of 354

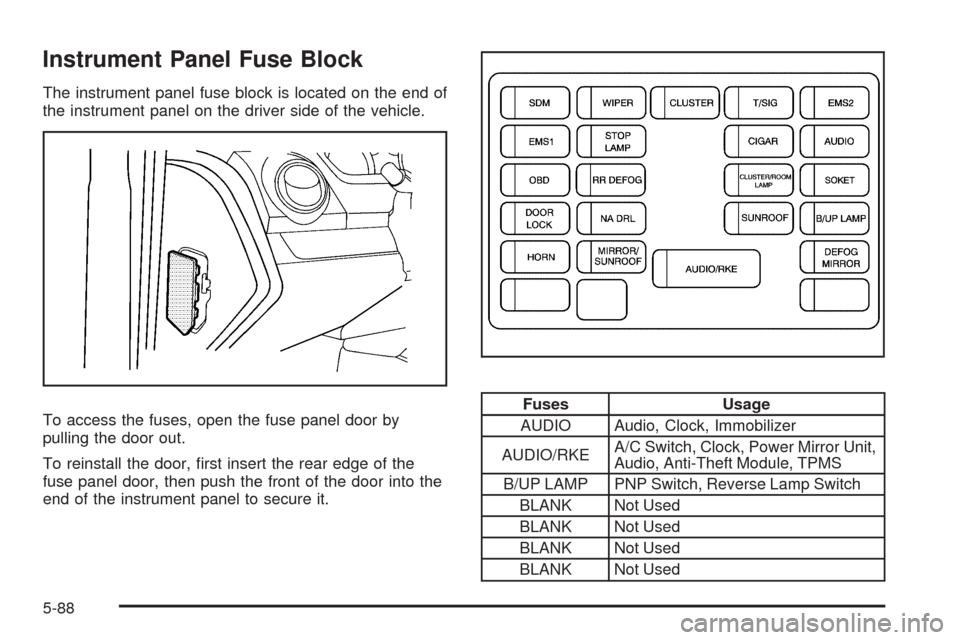

Instrument Panel Fuse Block

The instrument panel fuse block is located on the end of

the instrument panel on the driver side of the vehicle.

To access the fuses, open the fuse panel door by

pulling the door out.

To reinstall the door, �rst insert the rear edge of the

fuse panel door, then push the front of the door into the

end of the instrument panel to secure it.

Fuses Usage

AUDIO Audio, Clock, Immobilizer

AUDIO/RKEA/C Switch, Clock, Power Mirror Unit,

Audio, Anti-Theft Module, TPMS

B/UP LAMP PNP Switch, Reverse Lamp Switch

BLANK Not Used

BLANK Not Used

BLANK Not Used

BLANK Not Used

5-88

Page 297 of 354

Fuses Usage

CIGAR Cigar Lighter

CLUSTERBrake Switch, TPMS, Anti-Theft

Module

DEFOG

MIRRORPower Mirror Unit, A/C Switch

RR DEFOG Rear Defog

DOOR LOCK Door Lock

NA DRL NA DRL Circuit

MIRROR/

SUNROOFMirror Control Switch, Room Lamp,

A/C Switch

EMS 1Engine Room Fuse Block, TCM,

VSS, Fuel Pump

EMS 2 Stoplamp Switch

HORN Horn

OBD DLC, Immobilizer

CLUSTER/

ROOM LAMPTrunk Room Lamp, Trunk Open

Switch, IPC, Room Lamp

SDM Sensing and Diagnostic Module

SOKET Power JackFuses Usage

STOP LAMP Brake Switch

SUNROOF Sunroof Module (Option)

T/SIG Hazard Switch

WIPER Wiper Switch, Wiper Motor

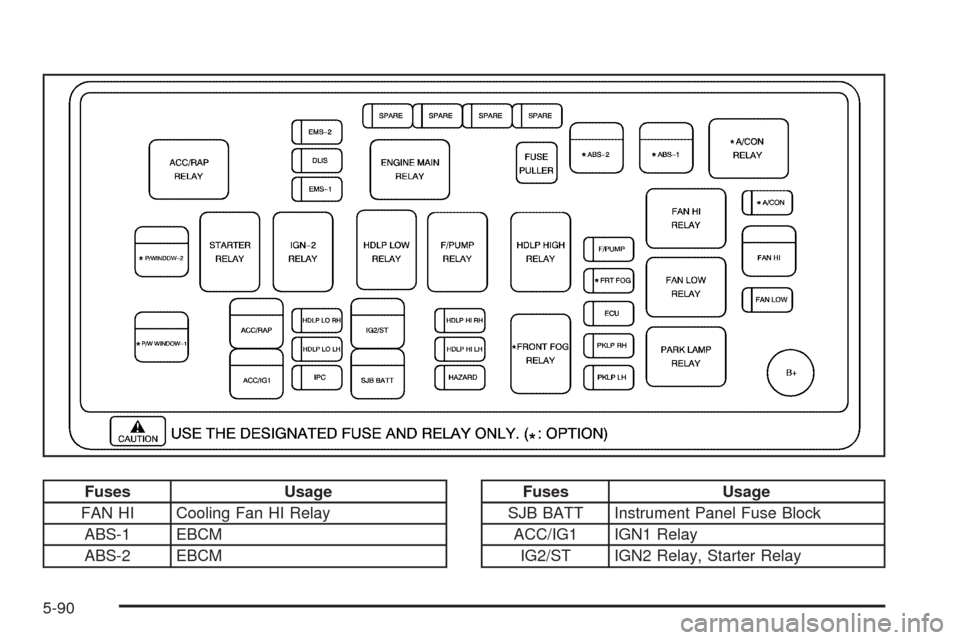

Engine Compartment Fuse Block

The engine compartment fuse block is located on the

driver side of the vehicle, near the battery. See

Engine Compartment Overview on page 5-14for more

information on location.

Notice:Spilling liquid on any electrical components

on the vehicle may damage it. Always keep the

covers on any electrical component.

To access the fuses, press in the side �aps to release

the cover. To reinstall the cover, push the cover until it is

secure.

5-89

Page 298 of 354

Fuses Usage

FAN HI Cooling Fan HI Relay

ABS-1 EBCM

ABS-2 EBCMFuses Usage

SJB BATT Instrument Panel Fuse Block

ACC/IG1 IGN1 Relay

IG2/ST IGN2 Relay, Starter Relay

5-90

Page 299 of 354

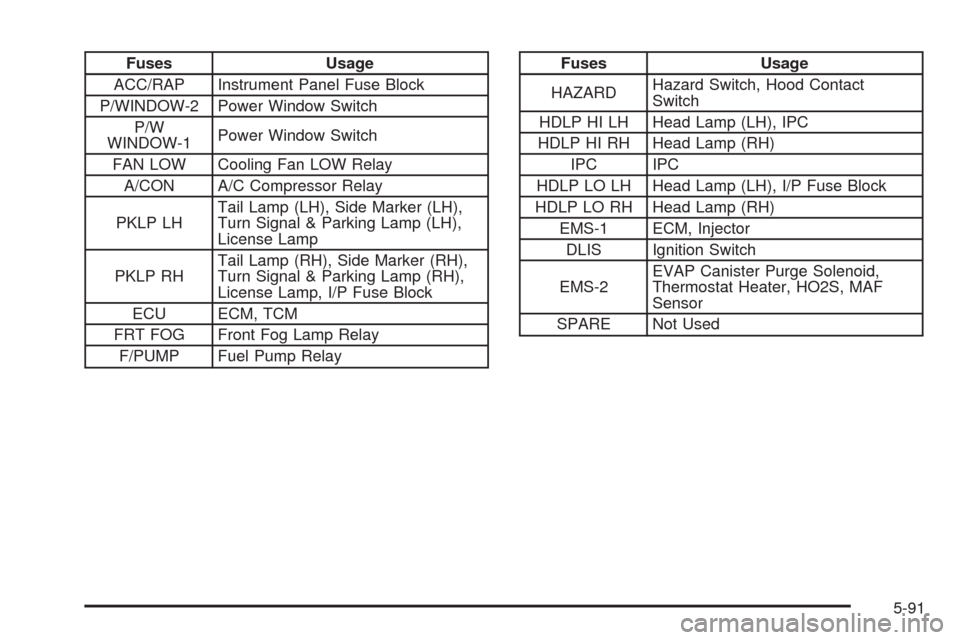

Fuses Usage

ACC/RAP Instrument Panel Fuse Block

P/WINDOW-2 Power Window Switch

P/W

WINDOW-1Power Window Switch

FAN LOW Cooling Fan LOW Relay

A/CON A/C Compressor Relay

PKLP LHTail Lamp (LH), Side Marker (LH),

Turn Signal & Parking Lamp (LH),

License Lamp

PKLP RHTail Lamp (RH), Side Marker (RH),

Turn Signal & Parking Lamp (RH),

License Lamp, I/P Fuse Block

ECU ECM, TCM

FRT FOG Front Fog Lamp Relay

F/PUMP Fuel Pump RelayFuses Usage

HAZARDHazard Switch, Hood Contact

Switch

HDLP HI LH Head Lamp (LH), IPC

HDLP HI RH Head Lamp (RH)

IPC IPC

HDLP LO LH Head Lamp (LH), I/P Fuse Block

HDLP LO RH Head Lamp (RH)

EMS-1 ECM, Injector

DLIS Ignition Switch

EMS-2EVAP Canister Purge Solenoid,

Thermostat Heater, HO2S, MAF

Sensor

SPARE Not Used

5-91

Page 300 of 354

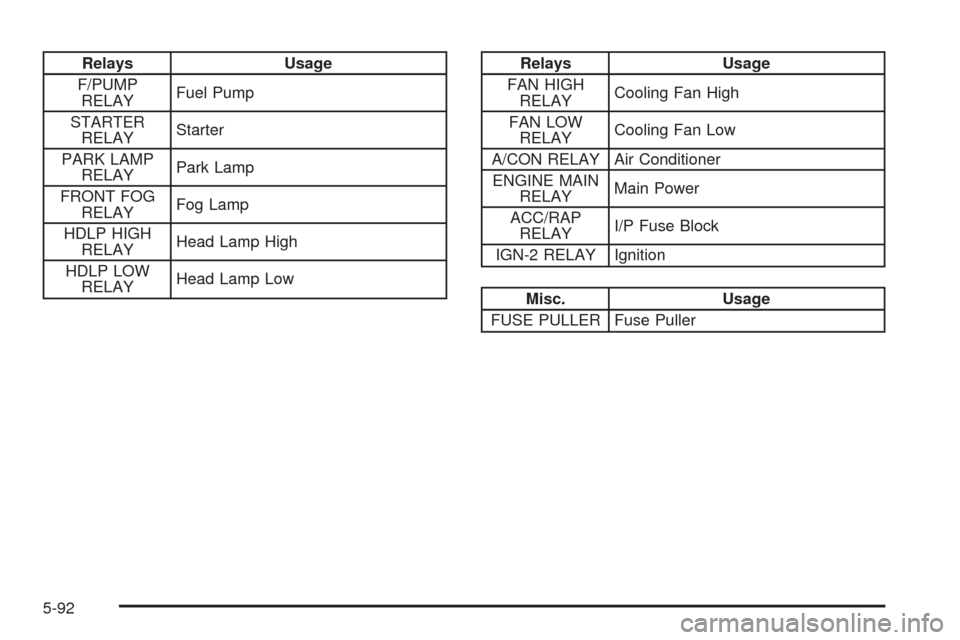

Relays Usage

F/PUMP

RELAYFuel Pump

STARTER

RELAYStarter

PARK LAMP

RELAYPark Lamp

FRONT FOG

RELAYFog Lamp

HDLP HIGH

RELAYHead Lamp High

HDLP LOW

RELAYHead Lamp LowRelays Usage

FAN HIGH

RELAYCooling Fan High

FAN LOW

RELAYCooling Fan Low

A/CON RELAY Air Conditioner

ENGINE MAIN

RELAYMain Power

ACC/RAP

RELAYI/P Fuse Block

IGN-2 RELAY Ignition

Misc. Usage

FUSE PULLER Fuse Puller

5-92

Page 310 of 354

Maintenance Footnotes

†The U.S. Environmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will not nullify

the emission warranty or limit recall liability prior to

the completion of the vehicle’s useful life. We, however,

urge that all recommended maintenance services be

performed at the indicated intervals and the

maintenance be recorded.

(a)Visually inspect brake lines and hoses for proper

hook-up, binding, leaks, cracks, chafing, etc. Inspect

disc brake pads for wear and rotors for surface

condition. Inspect drum brake linings/shoes for wear or

cracks. Inspect other brake parts, including drums,

wheel cylinders, calipers, parking brake, etc.

(b)Visually inspect front and rear suspension and

steering system for damaged, loose, or missing parts

or signs of wear. Inspect power steering cables for

proper hook-up, binding, cracks, chafing, etc.

(c)Visually inspect hoses and have them replaced if

they are cracked, swollen, or deteriorated. Inspect

all pipes, fittings and clamps; replace with genuine

parts as needed. To help ensure proper operation,

a pressure test of the cooling system and pressure cap

and cleaning the outside of the radiator and air

conditioning condenser is recommended at least

once a year.(d)Inspect wiper blades for wear, cracking, or

contamination. Clean the windshield and wiper blades,

if contaminated. Replace wiper blades that are worn

or damaged. See Windshield Wiper Blade Replacement

on page 5-50 and Windshield and Wiper Blades on

page 5-84 for more information.

(e)Make sure the safety belt reminder light and safety

belt assemblies are working properly. Look for any

other loose or damaged safety belt system parts. If you

see anything that might keep a safety belt system

from doing its job, have it repaired. Have any torn or

frayed safety belts replaced. Also see Checking

the Restraint Systems on page 1-75.

(f)Lubricate all key lock cylinders, door hinges and

latches, hood hinges and latches, and trunk lid hinges

and latches. More frequent lubrication may be required

when exposed to a corrosive environment. Applying

silicone grease on weatherstrips with a clean cloth will

make them last longer, seal better, and not stick or

squeak.

(g)Visually inspect belt for fraying, excessive cracks, or

obvious damage. Replace belt if necessary.

6-8

Page 313 of 354

At Least Once a Year

Starter Switch Check

{CAUTION:

When you are doing this inspection, the vehicle

could move suddenly. If the vehicle moves, you or

others could be injured.

1. Before starting this check, be sure there is enough

room around the vehicle.

2. Firmly apply both the parking brake and the regular

brake. SeeParking Brake on page 2-28if necessary.

Do not use the accelerator pedal, and be ready to

turn off the engine immediately if it starts.

3. For automatic transmission vehicles, try to start the

engine in each gear. The starter should work only

in P (Park) or N (Neutral). If the starter works in any

other position, your vehicle needs service.

For manual transmission vehicles, put the shift lever

in Neutral, push the clutch pedal down halfway,

and try to start the engine. The starter should work

only when the clutch pedal is pushed down all

the way to the �oor. If the starter works when the

clutch pedal is not pushed all the way down,

your vehicle needs service.

Automatic Transmission Shift Lock

Control System Check

{CAUTION:

When you are doing this inspection, the vehicle

could move suddenly. If the vehicle moves, you or

others could be injured.

1. Before starting this check, be sure there is enough

room around the vehicle. It should be parked on a

level surface.

2. Firmly apply the parking brake. SeeParking Brake

on page 2-28if necessary.

Be ready to apply the regular brake immediately if

the vehicle begins to move.

3. With the engine off, turn the ignition to ON/RUN,

but do not start the engine. Without applying the

regular brake, try to move the shift lever out

of P (Park) with normal effort. If the shift lever

moves out of P (Park), your vehicle needs service.

6-11

Page 314 of 354

Ignition Transmission Lock Check

While parked, and with the parking brake set, try to turn

the ignition to LOCK/OFF in each shift lever position.

For automatic transmission vehicles, the ignition

should turn to LOCK/OFF only when the shift

lever is in P (Park).

For manual transmission vehicles, the ignition

should turn to LOCK/OFF only when you press the

key release button.

On all vehicles, the ignition key should come out only

in LOCK/OFF.

Turn the steering wheel to the left and to the right.

It should only lock when turned to the right.

Parking Brake and Automatic

Transmission P (Park) Mechanism

Check

{CAUTION:

When you are doing this check, the vehicle could

begin to move. You or others could be injured and

property could be damaged. Make sure there is

room in front of the vehicle in case it begins to roll.

Be ready to apply the regular brake at once

should the vehicle begin to move.

6-12

Page 316 of 354

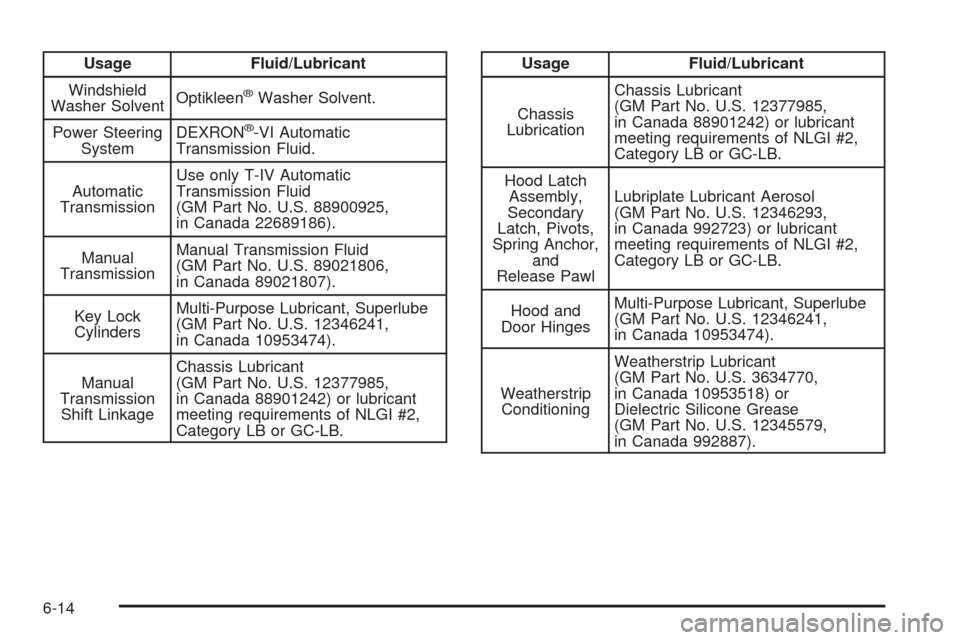

Usage Fluid/Lubricant

Windshield

Washer SolventOptikleen

®Washer Solvent.

Power Steering

SystemDEXRON

®-VI Automatic

Transmission Fluid.

Automatic

TransmissionUse only T-IV Automatic

Transmission Fluid

(GM Part No. U.S. 88900925,

in Canada 22689186).

Manual

TransmissionManual Transmission Fluid

(GM Part No. U.S. 89021806,

in Canada 89021807).

Key Lock

CylindersMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474).

Manual

Transmission

Shift LinkageChassis Lubricant

(GM Part No. U.S. 12377985,

in Canada 88901242) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

Usage Fluid/Lubricant

Chassis

LubricationChassis Lubricant

(GM Part No. U.S. 12377985,

in Canada 88901242) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

Hood Latch

Assembly,

Secondary

Latch, Pivots,

Spring Anchor,

and

Release PawlLubriplate Lubricant Aerosol

(GM Part No. U.S. 12346293,

in Canada 992723) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

Hood and

Door HingesMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474).

Weatherstrip

ConditioningWeatherstrip Lubricant

(GM Part No. U.S. 3634770,

in Canada 10953518) or

Dielectric Silicone Grease

(GM Part No. U.S. 12345579,

in Canada 992887).

6-14