headlamp CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 136 of 659

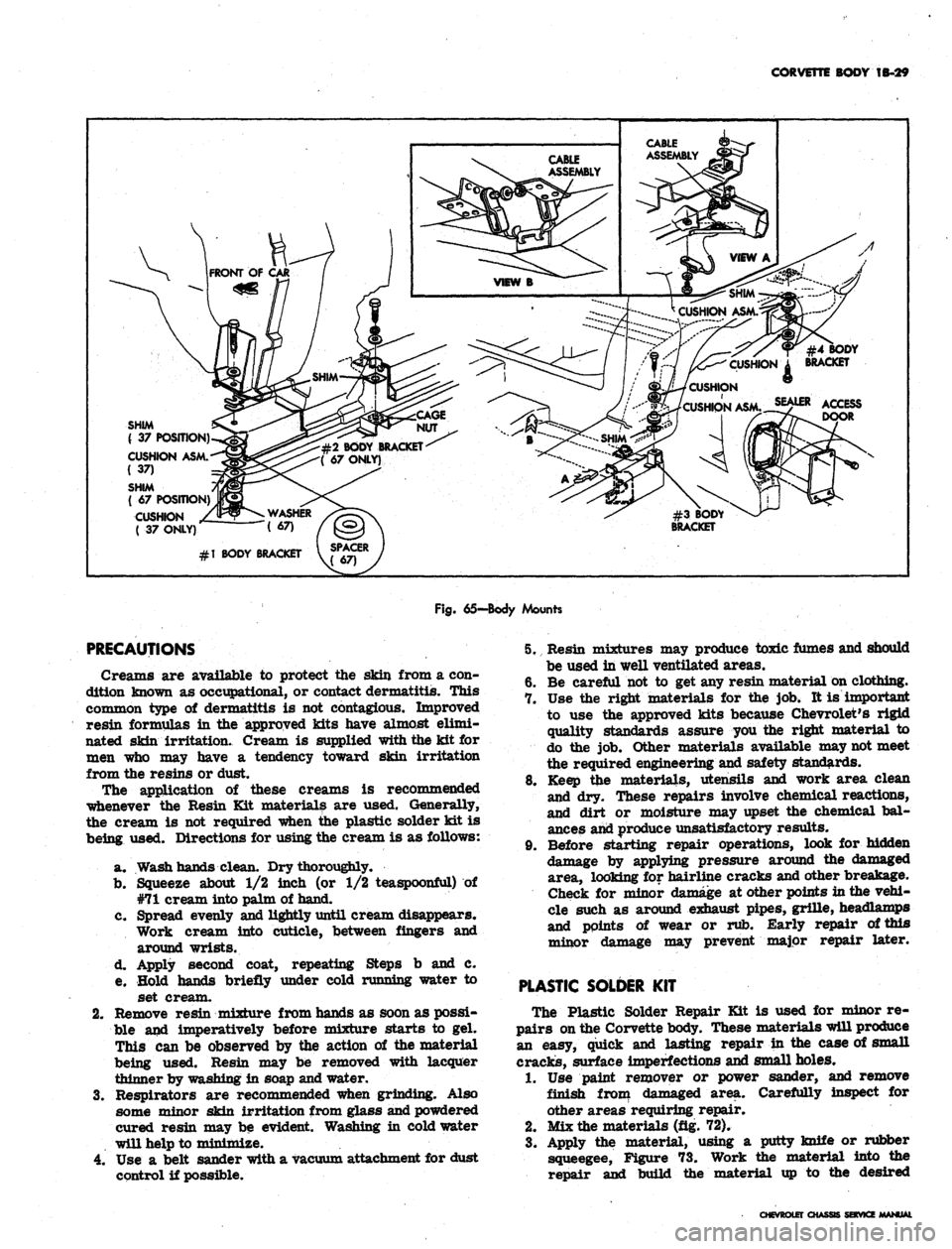

CORVETTE BODY 1B-29

CUSHION

CUSHION ASNi.^ty** ACCESS

#2 BODY BRACKET

( 67 ONLY)

SHIM

( 37 POSITION).

CUSHION ASM.

( 37)

SHIM

( 67 POSITION)

CUSHION

( 37 ONLY)

#1 BODY BRACKET

Fig.

65—Body Mounts

PRECAUTIONS

Creams are available to protect the skin from a con-

dition known as occupational, or contact dermatitis. This

common type of dermatitis is not contagious. Improved

resin formulas in the approved kits have almost elimi-

nated skin irritation. Cream is supplied with the kit for

men who may have a tendency toward skin irritation

from the resins or dust.

The application of these creams is recommended

whenever the Resin Kit materials are used. Generally,

the cream is not required when the plastic solder kit is

being used. Directions for using the cream is as follows:

a. Wash hands clean. Dry thoroughly.

b.

Squeeze about 1/2 inch (or 1/2 teaspoonful) of

#71 cream into palm of hand.

c. Spread evenly and lightly until cream disappears.

Work cream into cuticle, between fingers and

around wrists.

d. Apply second coat, repeating Steps b and c.

e. Hold hands briefly under cold running water to

set cream.

2.

Remove resin mixture from hands as soon as possi-

ble and imperatively before mixture starts to gel.

This can be observed by the action of the material

being used. Resin may be removed with lacquer

thinner by washing in soap and water.

3.

Respirators are recommended when grinding. Also

some minor skin irritation from glass and powdered

cured resin may be evident. Washing in cold water

will help to minimize.

4.

Use a belt sander with a vacuum attachment for dust

control if possible.

5. Resin mixtures may produce toxic fumes and should

be used in well ventilated areas.

6. Be careful not to get any resin material on clothing.

7. Use the right materials for the job. It is important

to use the approved kits because Chevrolet's rigid

quality standards assure you the right material to

do the job. Other materials available may not meet

the required engineering and safety standards.

8. Keep the materials, utensils and work area clean

and dry. These repairs involve chemical reactions,

and dirt or moisture may upset the chemical bal-

ances and produce unsatisfactory results.

9. Before starting repair operations, look for hidden

damage by applying pressure around the damaged

area, looking for hairline cracks and other breakage.

Check for minor damage at other points in the vehi-

cle such as around exhaust pipes, grille, headlamps

and points of wear or rub. Early repair of this

minor damage may prevent major repair later.

PLASTIC SOLDER

KIT

The Plastic Solder Repair Kit is used for minor re-

pairs on the Corvette body. These materials will produce

an easy, quick and lasting repair in the case of small

cracks, surface imperfections and small holes.

1.

Use paint remover or power sander, and remove

finish from damaged area. Carefully inspect for

other areas requiring repair.

2.

Mix the materials (fig. 72).

3.

Apply the material, using a putty knife or rubber

squeegee, Figure 73. Work the material into the

repair and build the material up to the desired

CHEVROLET CHASSIS SERVICE

Page 491 of 659

CHASSIS SHEET METAL 11-4

FENDERS

Fenders are adjustable with shims at the cowl and

rocker panel. To add or remove shims, loosen bolts at

shim locations (fig. 7) and carefully apply force with pry

bar to provide clearance for shim removal or installa-

tion.

SHEET METAL ADJUSTMENTS

For proper operation of doors and hood, and for pre-

sentable appearance, adjust front sheet metal to the tol-

erances shown in Figures

4-

and 5.

COMPONENT PART REPLACEMENT

NOTE: When replacing sheet metal compo-

nents on Chevrolet or Chevelle, note position and

attachment of all seals and dust shielding and

replace as necessary.

BATTERY TRAY

Removal

1.

Disconnect battery cables.

2.

Remove screw retaining battery hold down clamp and

remove battery from vehicle.

3.

Remove screws retaining battery tray to fender skirt

and radiator support.

4.

On Chevrolet, remove headlamp bezel and remove

screw retaining tray to radiator support.

5.

Remove battery tray from vehicle.

Installation

Reverse removal procedure.

RADIATOR SUPPORT

Removal

1.

Remove front bumper (Section 14).

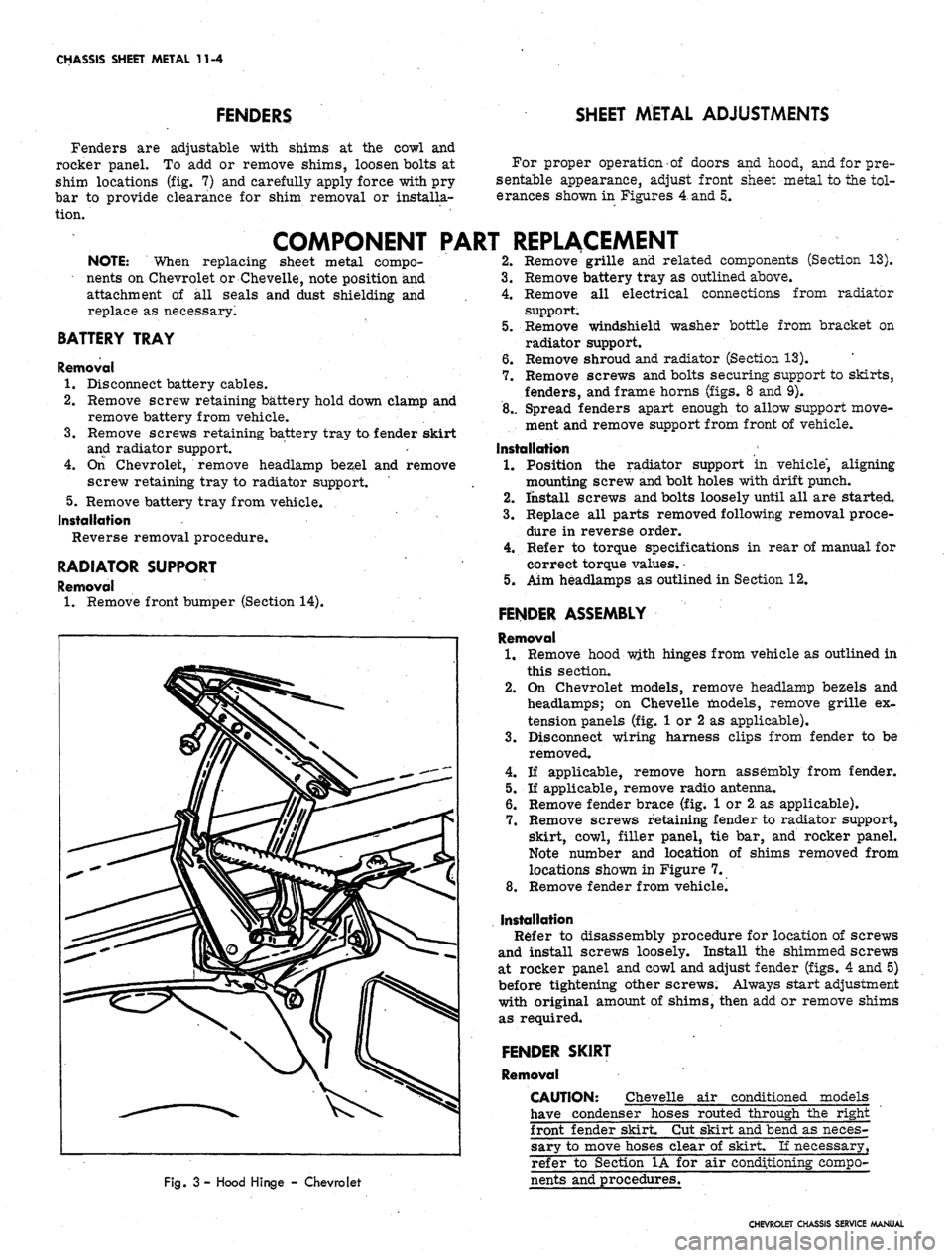

Fig.

3 - Hood Hinge - Chevrolet

2.

Remove grille and related components (Section 13).

3.

Remove battery tray as outlined above.

4.

Remove all electrical connections from radiator

support.

5.

Remove windshield washer bottle from bracket on

radiator support.

6. Remove shroud and radiator (Section 13).

7.

Remove screws and bolts securing support to skirts,

fenders, and frame horns (figs. 8 and 9).

8.. Spread fenders apart enough to allow support move-

ment and remove support from front of vehicle.

Installation

1.

Position the radiator support in vehicle", aligning

mounting screw and bolt holes with drift punch.

2.

install screws and bolts loosely until all are started.

3.

Replace all parts removed following removal proce-

dure in reverse order.

4.

Refer to torque specifications in rear of manual for

correct torque values.

•

5.

Aim headlamps as outlined in Section 12.

FENDER ASSEMBLY

Removal

1.

Remove hood with hinges from vehicle as outlined in

this section.

2.

On Chevrolet models, remove headlamp bezels and

headlamps; on Chevelle models, remove grille ex-

tension panels (fig. 1 or 2 as applicable).

3.

Disconnect wiring harness clips from fender to be

removed.

4.

If applicable, remove horn assembly from fender.

5.

If applicable, remove radio antenna.

6. Remove fender brace (fig. 1 or 2 as applicable).

7.

Remove screws retaining fender to radiator support,

skirt, cowl, filler panel, tie bar, and rocker panel.

Note number and location of shims removed from

locations shown in Figure 7.

8. Remove fender from vehicle.

Installation

Refer to disassembly procedure for location of screws

and install screws loosely. Install the shimmed screws

at rocker panel and cowl and adjust fender (figs. 4 and 5)

before tightening other screws. Always start adjustment

with original amount of shims, then add or remove shims

as required.

FENDER SKIRT

Removal

CAUTION: Chevelle air conditioned models

have condenser hoses routed through the right

front fender skirt. Cut skirt and bend as neces-

sary to move hoses clear of skirt. If necessary,

refer to Section 1A for air conditioning compo-

nents and procedures.

CHEVROLET CHASSIS SERVICE MANUAL

Page 498 of 659

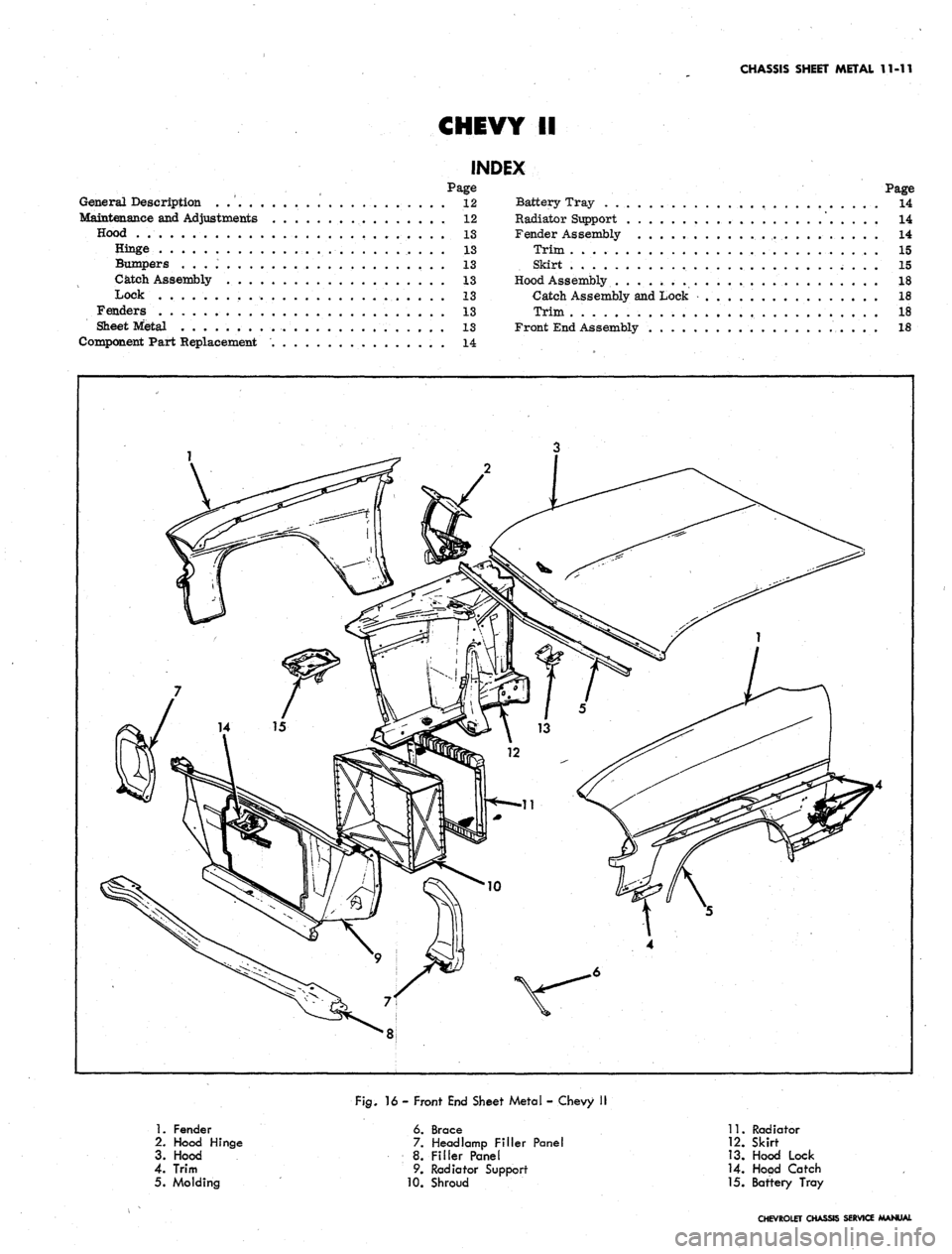

CHASSIS SHEET METAL 11-11

CHEVY II

INDEX

Page

General Description 12

Maintenance and Adjustments 12

Hood ........ 13

Hinge 13

Bumpers 13

Catch Assembly . . . 13

Lock 13

Fenders . 13

Sheet Metal 13

Component Part Replacement 14

Page

Battery Tray 14

Radiator Support 14

Fender Assembly ...................... 14

Trim 15

Skirt 15

Hood Assembly 18

Catch Assembly and Lock • 18

Trim 18

Front End Assembly 18

1.

Fender

2.

Hood Hinge

3. Hood

4.

Trim

5. Molding

Fig.

16 - Front End Sheet Metal - Chevy II

6. Brace

7. Headlamp Filler Panel

8. Filler Panel

9. Radiator Support

10.

Shroud

11.

Radiator

12.

Skirt

13.

Hood Lock

14.

Hood Catch

15.

Baftery Tray

CHEVROLET CHASSIS SERVICE MANUAL

Page 501 of 659

CHASSIS SHEET METAL 11-14

location is shimmed; thus keeping the fender mount-

ing bolts from crushing in the fender mounting

flange.

If shimming is done without the fenders being disas-

asembled, it is suggested that fender mounting bolts

rearward of radiator support be loosened while shims

are inserted and sheet metal fit is checked. Tighten

shimmed mounting bolts first, then all others.

COMPONENT PART REPLACEMENT

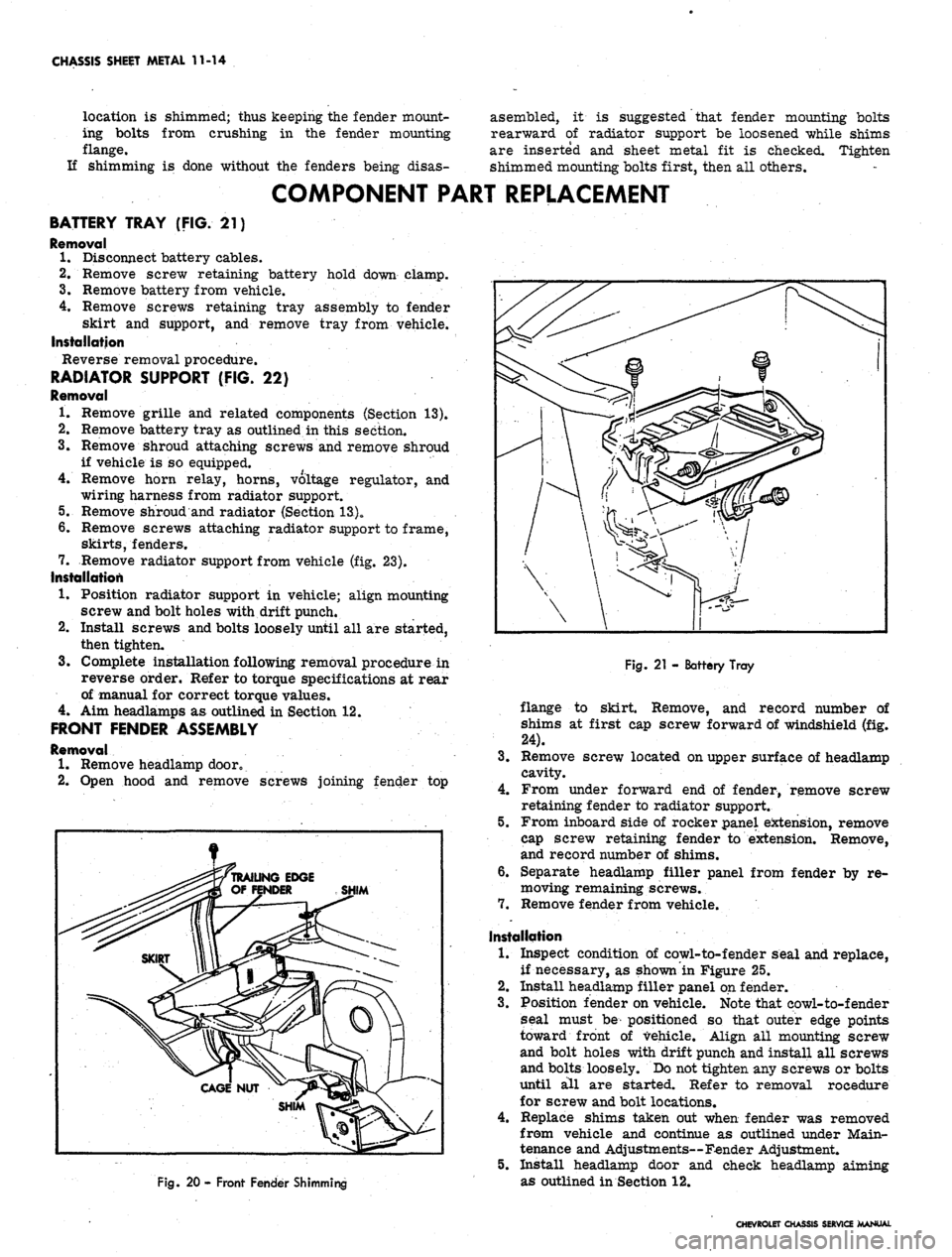

BATTERY TRAY (FIG. 21)

Removal

1.

Disconnect battery cables.

2.

Remove screw retaining battery hold down clamp.

3.

Remove battery from vehicle.

4.

Remove screws retaining tray assembly to fender

skirt and support, and remove tray from vehicle.

Installation

Reverse removal procedure.

RADIATOR SUPPORT (FIG. 22)

Removal

1.

Remove grille and related components (Section 13).

Remove battery tray as outlined in this section.

Remove shroud attaching screws and remove shroud

if vehicle is so equipped.

Remove horn relay, horns, voltage regulator, and

wiring harness from radiator support.

Remove shroud and radiator (Section 13)o

Remove screws attaching radiator support to frame,

skirts,

fenders.

Remove radiator support from vehicle (fig. 23).

Installation

1.

Position radiator support in vehicle; align mounting

screw and bolt holes with drift punch.

Install screws and bolts loosely until all are started,

then tighten.

3.

Complete installation following removal procedure in

reverse order. Refer to torque specifications at rear

of manual for correct torque values.

4.

Aim headlamps as outlined in Section 12.

FRONT FENDER ASSEMBLY

Removal

1*

Remove headlamp dooro

2.

Open hood and remove screws joining fender top

2.

Fig. 20 - Front Fender Shimming

Fig.

21 - Battery Tray

flange to skirt. Remove, and record number of

shims at first cap screw forward of windshield (fig.

24).

3.

Remove screw located on upper surface of headlamp

cavity.

4.

From under forward end of fender, remove screw

retaining fender to radiator support.

5.

From inboard side of rocker panel extension, remove

cap screw retaining fender to extension. Remove,

and record number of shims.

6. Separate headlamp filler panel from fender by re-

moving remaining screws.

7.

Remove fender from vehicle.

Installation

1.

Inspect condition of cowl-to-fender seal and replace,

if necessary, as shown in Figure 25.

2.

Install headlamp filler panel on fender.

3.

Position fender on vehicle. Note that eowl-to-fender

seal must be positioned so that outer edge points

toward front of vehicle. Align all mounting screw

and bolt holes with drift punch and install all screws

and bolts loosely. Do not tighten any screws or bolts

until all are started. Refer to removal rocedure

for screw and bolt locations.

4.

Replace shims taken out when fender was removed

from vehicle and continue as outlined under Main-

tenance and Adjustments—Fender Adjustment.

5.

Install headlamp door and cheek headlamp aiming

as outlined in Section 12.

CHEVROLET CHASSIS SERVICE MANUAL

Page 505 of 659

CHASSIS SHEET METAL 11-18

b.

Check and adjust front wheel alignment as out-

lined in Section 3.

c. Check and adjust headlamp aiming as outlined in

Section 12.

HOOD ASSEMBLY

Hood may be removed either with or without hinges.

To shorten aligning time, hood hinge plates may be lo-

cated by scribing a mark on hood and/or body which

outlines entire plate. See Maintenance and Adjustments -

Hood Hinge for hood adjustment procedure. Hood hinge

springs may be easily and safely removed and installed.

through the use of Tool J-9559 as follows:

1.

With hood opened only far enough to allow passage of

mechanic's arm between hood and fender, insert ends

of J-9559 (through bolt removed) between coils of

spring until barrel of tool contacts outer diameter

of spring.

2.

Open hood fully while still holding spring (with tool

installed) in hand; when hood is near fully opened

position, spring may be removed as shown in Figure

28.

3.

As soon as spring is removed, insert long bolt sup-

plied with J-9559 through holes in end of tool, pass-

ing it through spring, and install nut on bolt.

Spring may be removed from J-9559 or J-9559 may be

installed in a new spring by the following method:

1.

Place a closed 6 or 8 inch "C" clamp in a vise or

fasten it to a heavy bench top (bench should be fas-

tened to floor).

2.

Hook one end of spring in clamp and the other end

in hook of a hoist as shown in Figure 29.

3.

Stretch the spring enough to allow insertion of

J-9559. Install through bolt if spring is not to be

installed on hinge at once.

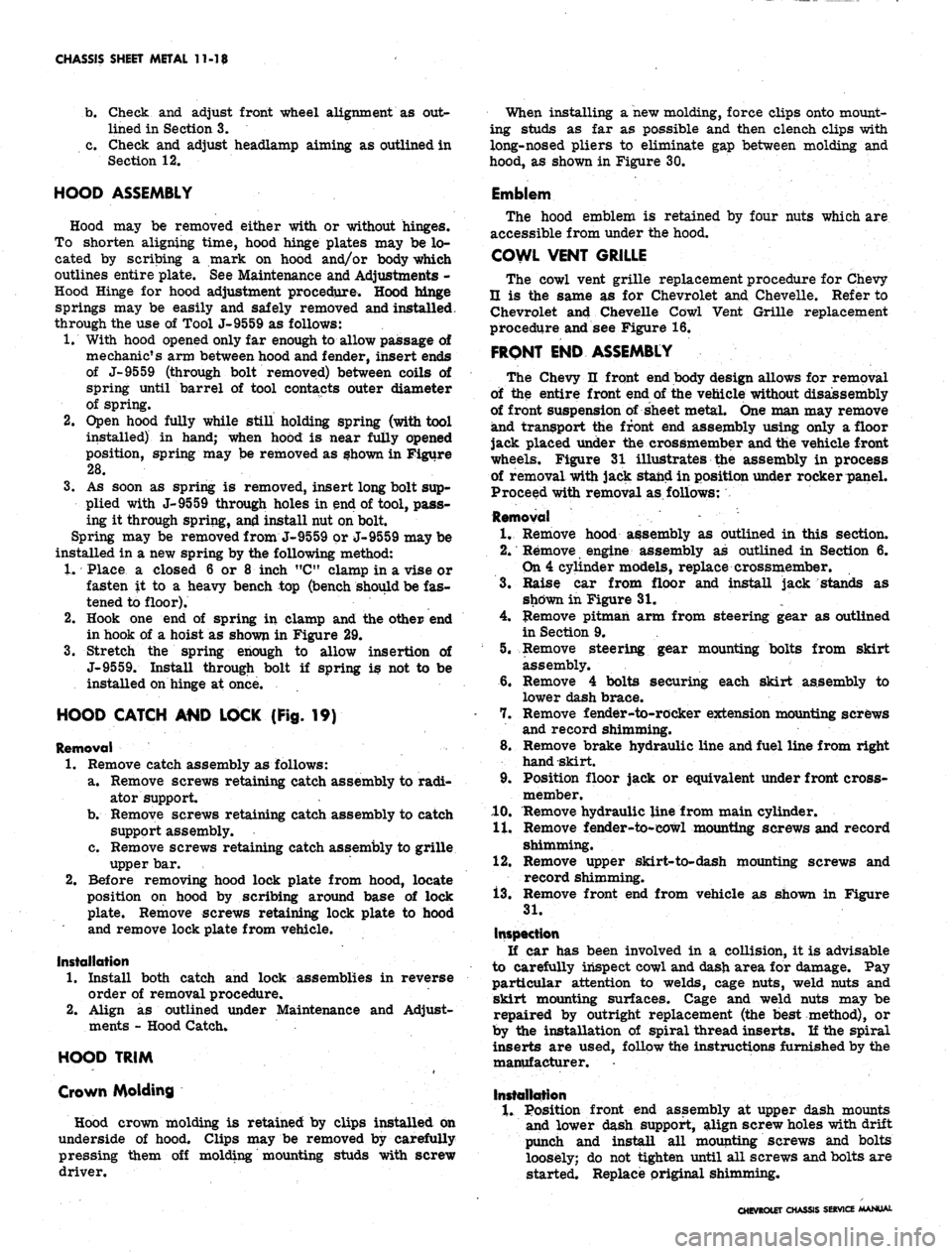

HOOD CATCH AMD LOCK (Fig. 19)

Removal

1.

Remove catch assembly as follows:

a. Remove screws retaining catch assembly to radi-

ator support.

b.

Remove screws retaining catch assembly to catch

support assembly.

c* Remove screws retaining catch assembly to grille

upper bar.

2.

Before removing hood lock plate from hood, locate

position on hood by scribing around base of lock

plate. Remove screws retaining lock plate to hood

and remove lock plate from vehicle.

Installation

1.

Install both catch and lock assemblies in reverse

order of removal procedure.

2.

Align as outlined under Maintenance and Adjust-

ments - Hood Catch.

HOOD TRIM

Crown Molding

Hood crown molding is retained by clips installed on

underside of hood. Clips may be removed by carefully

pressing them off molding mounting studs with screw

driver.

When installing a new molding, force clips onto mount-

ing studs as far as possible and then clench clips with

long-nosed pliers to eliminate gap between molding and

hood, as shown in Figure 30.

Emblem

The hood emblem is retained by four nuts which are

accessible from under the hood.

COWL VENT GRILLE

The cowl vent grille replacement procedure for Chevy

U is the same as for Chevrolet and Chevelle. Refer to

Chevrolet and Chevelle Cowl Vent Grille replacement

procedure and see Figure 16.

FRONT END ASSEMBLY

The Chevy n front end body design allows for removal

of the entire front end of the vehicle without disassembly

of front suspension of sheet metal. One man may remove

and transport the front end assembly using only a floor

jack placed under the crossmember and the vehicle front

wheels. Figure 31 illustrates the assembly in process

of removal with jack stand in position under rocker panel.

Proceed with removal

as.

follows:

Removal

1.

Remove hood assembly as outlined in this section.

2.

Remove engine assembly as outlined in Section 6.

On 4 cylinder models, replace crossmember.

3.

Raise car from floor and install jack stands as

shown in Figure 31.

4.

Remove pitman arm from steering gear as outlined

in Section 9.

5.

Remove steering gear mounting bolts from skirt

assembly.

6. Remove 4 bolts securing each skirt assembly to

lower dash brace.

7.

Remove fender-to-rocker extension mounting screws

and record shimming.

8. Remove brake hydraulic line and fuel line from right

hand skirt.

9. Position floor jack or equivalent under front cross-

member.

10.

Remove hydraulic line from main cylinder.

11.

Remove fender-to-cowl mounting screws and record

shimming.

12.

Remove upper skirt-to-dash mounting screws and

record shimming.

13.

Remove front end from vehicle as shown in Figure

31.

Inspection

If car has been involved in a collision, it is advisable

to carefully inspect cowl and dash area for damage. Pay

particular attention to welds, cage nuts, weld nuts and

skirt mounting surfaces. Cage and weld nuts may be

repaired by outright replacement (the best method), or

by the installation of spiral thread inserts. If the spiral

inserts are used, follow the instructions furnished by the

manufacturer. -

Installation

%, position front end assembly at upper dash mounts

and lower dash support, align screw holes with drift

punch and install all mounting screws and bolts

loosely; do not tighten until all screws and bolts are

started. Replace original shimming.

CHEVROLET CHASSIS SERVICE MANUAL

Page 509 of 659

CHASSIS SHEET METAL 11-22

wiring harness, and washer bottle from radiator

support.

5.

Remove screw connecting battery tray to radiator

support.

6. Remove shroud from vehicle if so equipped.

7.

Remove shroud and radiator (Section 13).

8. Remove screws securing support to frame, skirts,

and fenders.

9. Remove radiator support from vehicle.

Installation

Install radiator support following the removal pro-

cedure in reverse order. Refer to torque specifications

in rear of manual for correct torque values for radiator

supportj grille, and bumper.

FENDER AND SKIRT ASSEMBLY

Removal

1.

Remove front bumper (Section 14).

2.

Remove hood and hood.hinges (two men).

3.

Remove bolts securing brace to skirt and dash panel

and remove brace (fig. 32).

4.

Disconnect any components attached to fender and

skirt such as cruise control, hoses, electrical har-

ness etc.

5.

Remove screws securing radiator support to fender

and skirt.

6. Remove headlamp bezel and headlamp.

7.

Remove screws securing fender and skirt assembly

to header panel, headlamp housing and valance panel.

Remove screw securing fender extension to valance

panel.

8. Remove screws securing fender and skirt assembly

to vehicle and remove fender and skirt assembly.

9. If necessary, remove screws attaching fender ex-

tension and bumper bracket to fender and remove

extension and bracket. Replace fender trim if nec-

essary.

Installation

Install fender anci skirt assembly following the removal

procedure in reverse order. Refer to torque specifi-

cations in rear of manual for correct torque values.

HOOD ASSEMBLY

Procedures for hood removal and installation for

Camaro are the same as for Chevrolet and Chevelle.

Refer to Chevrolet and Chevelle hood removal and in-

stallation procedures, Figure 35 for Camaro hood catch,

support, and lock plate, and Figure 37 for Camaro hood

and insulator.

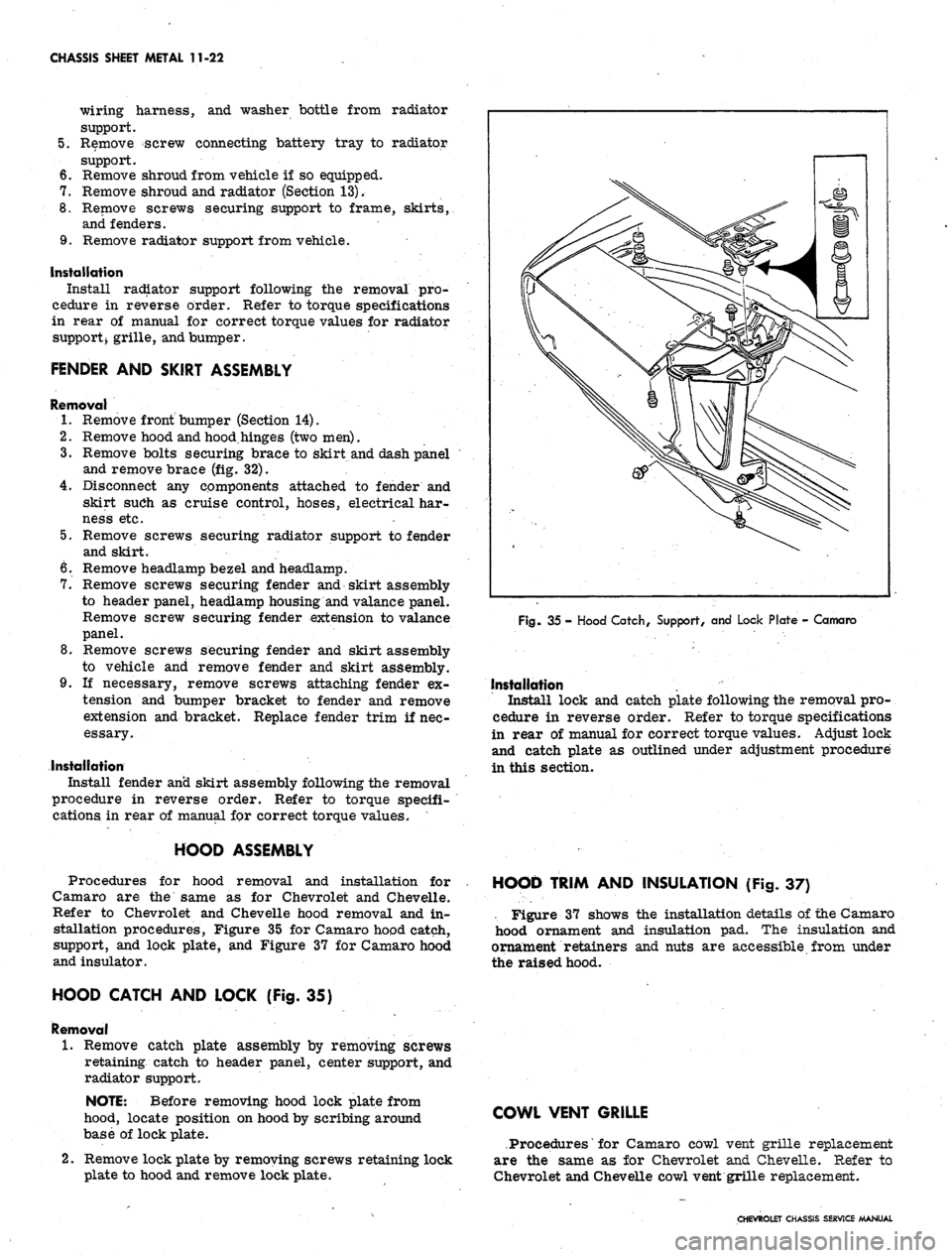

HOOD CATCH AND LOCK (Fig. 35)

Removal

1.

Remove catch plate assembly by removing screws

retaining catch to header panel, center support, and

radiator support.

NOTE: Before removing hood lock plate from

hood, locate position on hood by scribing around

base of lock plate.

2.

Remove lock plate by removing screws retaining lock

plate to hood and remove lock plate.

Fig.

35 - Hood Catch, Support, and Lock Plate - Camaro

Installation

Install lock and catch plate following the removal pro-

cedure in reverse order. Refer to torque specifications

in rear of manual for correct torque values. Adjust lock

and catch plate as outlined under adjustment procedure

in this section.

HOOD TRIM AND INSULATION (Fig. 37}

. Figure 37 shows the installation details of the Camaro

hood ornament and insulation pad. The insulation and

ornament retainers and nuts are accessible from under

the raised hood.

COWL VENT GRILLE

.Procedures'for Camaro cowl vent grille replacement

are the same as for Chevrolet and Chevelle. Refer to

Chevrolet and Chevelle cowl vent grille replacement.

CHEVROLET CHASSIS SERVICE MANUAL

Page 513 of 659

SECTION 12

ELECTRICAL-BODY AND CHASSIS

CONTENTS

OF

THIS

SECTION

Page

Page

System 12-1

Instruments and Gauges 12-21

Directional Signal 12r40

Windshield Wipers and Washers 12-44

Wiring Diagrams 12-56

Special Tools 12-60

LIGHTING SYSTEM

INDEX

Page

General Description

!2-i

Maintenance and Adjustments

•.................. 12-2

Headlamp Adjustment......................

12-3

Headlamp Panel Travel Adjustment.

12-5

Service Operations.

. . .. 12-5

Front Lighting

12-5

Headlamp

. 12_5

Parking Lamp

12-5

Fender Lamp

. 12_^

Headlamp Panel

12-8

Headlamp Panel Motor

^2-9

Rear Lighting

l2-10

Tail, Stop and Directional Lamps

12-10

Page

Backing Lamps

12-14

License Plate Lamp

12-14

Automatic Transmission Quadrant Lamp

12-14

Seat Separator Console Lamps

. 12-15

Lighting Switch

. . 12-15

Wiper Switch.

12-15

Stoplight Switch

12-15

Dimmer Switch

12-15

Backing Lamp Switches

12-15

Neutral Safety Switches

12-17

Parking Brake Alarm Switch

................. 12-19

Instrument Panel Compartment Lamp/Switch

12-19

Cirgarette Lighter

12-19

GENERAL DESCRIPTION

.

The lighting system includes: the main lighting switch,

stop light, dimmer, and backing lamp switches, head-

lamps, parking lamps, stop, tail and directional lamps,

instrument illumination and indicator lamps, and the

necessary wiring to complete the various circuits. A

fuse panel provides convenient power take offs and fuse

clips for the appropriate circuits (fig. 1).

Chevrolet and Chevelle headlamp installation is all

new in that the headlamps are located in the radiator

support with adjusting screws and springs. Eliminating

the need for having separate headlamp housings. Chev-

rolet and Chevelle headlamp retainers and springs are

interchangeable.

Chevy n headlamp housings are new because of revised

front end styling and Corvette front end lighting is basi-

cally carryover.

Front fender lamps have been added as an option for

Chevrolet models and as standard equipment on Caprice

series.

Camaro models use single headlamps and the Rally

Sport model headlamps are covered by a retractable

section of the grille when lamps are not used. The sec-

tion of the grille covering the headlamps folds back when

lights are required; the headlamps are stationary. The

covering is retracted by a small electric motor mounted

to the headlamp housing. The headlamps are automat-

ically uncovered when the headlight switch is pulled "ON"

for illumination. If at any time the electrical circuit

becomes inoperative, the lamps can be uncovered manu-

ally. The ignition switch must be

"ON"

in order to close

the headlamp doors.

Parking lamp for Chevelle and Chevrolet models are

new due to revised front end sheet metal and bumper

styling. Parking lamps are located in the bumper on

Chevrolet, Chevelle and Chevy n models

Camaro parking lamps are located in the radiator

grille except for the Rally Sport models on which the

parking lamps are in the valance panel. For styling

reasons, the lens is white and an amber glass bulb is

used. All Camaro parking lamps require a separate

ground wire to assure a good ground contact because of

the plastic grille and painted contact surfaces.

The Chevrolet tail, stop, and directional lamps are in

one housing with a three section lens design on Impala

and Caprice sedans. The center lens for Impala series

is the back-up lamp. The center lens on the Caprice is

a tail lamp with the back-up lamps being located in the

rear bumper. Chevrolet station wagons have three indi-

vidual housings with three lenses, the center lamp being

the back-up. Biscayne and Bel-Air sedans have a single

housing and lens for tail, stop, and directional lamp with

a similarly constructed back-up lamp inboard and adja-

cent to it.

Chevelle tail, stop, and directional lamps are a single

lens design that follows through with the rear fender

styling. The back-up lamp is located in r.ear bumper.

Camaro models except Rally Sport have tail lamps

with integral back-up lamps mounted inboard of the rear

fenders between the trunk opening and bumper. The

Rally Sport model has dual tail lamps in the rear housing

and valance mounted back-up lamps.

Corvette, Chevy n, and Corvair tail and directional

signal lights are carryover. The Corvette has new back-

up lamps center mounted above the license plate opening.

CHEVROLET CHASSIS SERVICE

Page 515 of 659

ELECTRICAL-BODY AND CHASSIS 12-3

Fig.

2 - T-3 Safety Aimer

wearing away the insulation due to vibration.

By referring to the wiring diagrams, circuits may be

tested for continuous circuit or shorts with a conventional

test lamp or low reading volt meter.

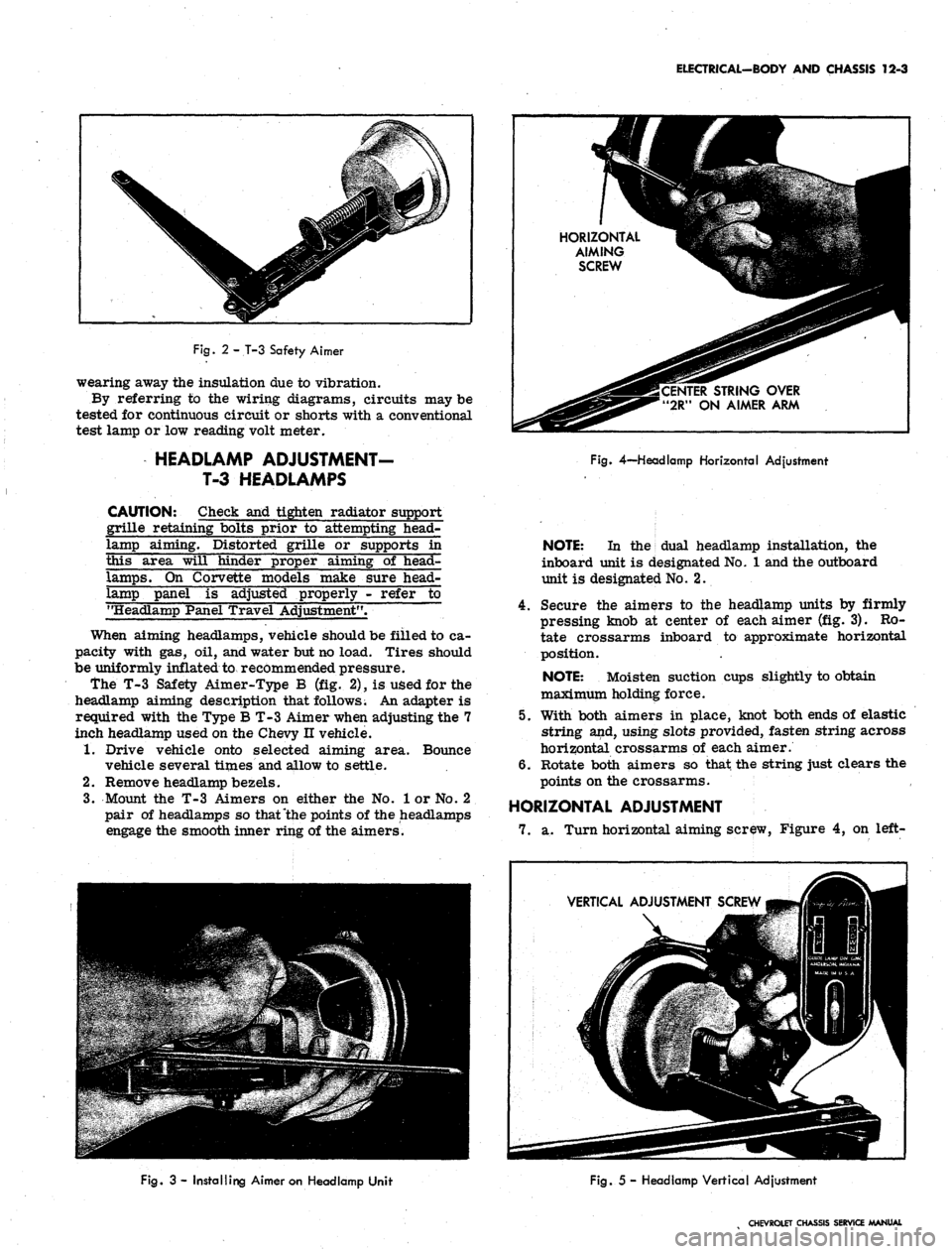

HEADLAMP ADJUSTMENT-

T-3 HEADLAMPS

CAUTION: Check and tighten radiator support

grille retaining bolts prior to attempting head-

lamp aiming. Distorted grille or supports in

this area will hinder proper aiming of head-

lamps. On Corvette models make sure head-

lamp panel is adjusted properly - refer to

"Headlamp Panel Travel Adjustment".

When aiming headlamps, vehicle should be filled to ca-

pacity with gas, oil, and water but no load. Tires should

be uniformly inflated to recommended pressure.

the T-3 Safety Aimer-Type B (fig. 2), is used for the

headlamp aiming description that follows. An adapter is

required with the Type B T-3 Aimer when adjusting the 7

inch headlamp used on the Chevy n vehicle.

1.

Drive vehicle onto selected aiming area. Bounce

vehicle several times and allow to settle.

2.

Remove headlamp bezels.

3.

Mount the T-3 Aimers on either the No. 1 or No. 2

pair of headlamps so that "the points of the headlamps

engage the smooth inner ring of the aimers.

HORIZONTAL

AIMING

SCREW

STRING OVER

"2R" ON AIMER ARM

Fig.

4—-Headlamp Horizontal Adjustment

NOTE:

In the dual headlamp installation, the

inboard unit is designated No. 1 and the outboard

unit is designated No. 2.

4.

Secure the aimers to the headlamp units by firmly

pressing knob at center of each aimer (fig. 3). Ro-

tate crossarms inboard to approximate horizontal

position.

NOTE:

Moisten suction cups slightly to obtain

maximum holding force.

5. With both aimers in place, knot both ends of elastic

string and, using slots provided, fasten string across

horizontal crossarms of each aimer.

6. Rotate both aimers so that the string just clears the

points on the crossarms.

HORIZONTAL ADJUSTMENT

7. a. Turn horizontal aiming screw, Figure 4, on left-

VERTICAL ADJUSTMENT SCREW

Fig.

3 - Installing Aimer on Headlamp Unit

Fig.

5 - Headlamp Vertical Adjustment

CHEVROLET CHASSIS SERVICE MANUAL

Page 516 of 659

ELECTRICAL-BODY AND CHASSIS 12-4

b.

hand lamp until the string is positioned over the

crossarm centerline. Turn the screw clockwise

in making the final adjustment to take up play in

the headlamp mechanism.

Repeat the above procedure on the right-hand

lamp to complete the horizontal adjustment of the

headlamps.

VERTICAL ADJUSTMENT

8. a. Numeral "2" (fig. 5) should appear in the "down"

window of each aimer. If not, loosen knob at

underside of aimer arm and slide back and forth

until the numeral does appear.

NOTE:

This setting will give a 2" drop of the

headlamp high beam spot centerline on a screen

placed 25 feet forward of the vehicle. Check

state laws for proper vertical setting.

b.

Turn headlamp vertical aim screw (fig. 5) on left-

hand unit counter-clockwise until the bubble is at

the inner end of the glass tube. Then turn screw

clockwise until bubble is centered in tube.

c. Repeat this procedure on right-hand headlamp

unit to complete vertical adjustment of lamps.

9. Recheck the string at the ends of each crossarm for

correct setting and the bubble on each aimer for

centered position.

10.

Remove the aimers by pulling on the suction cup tabs

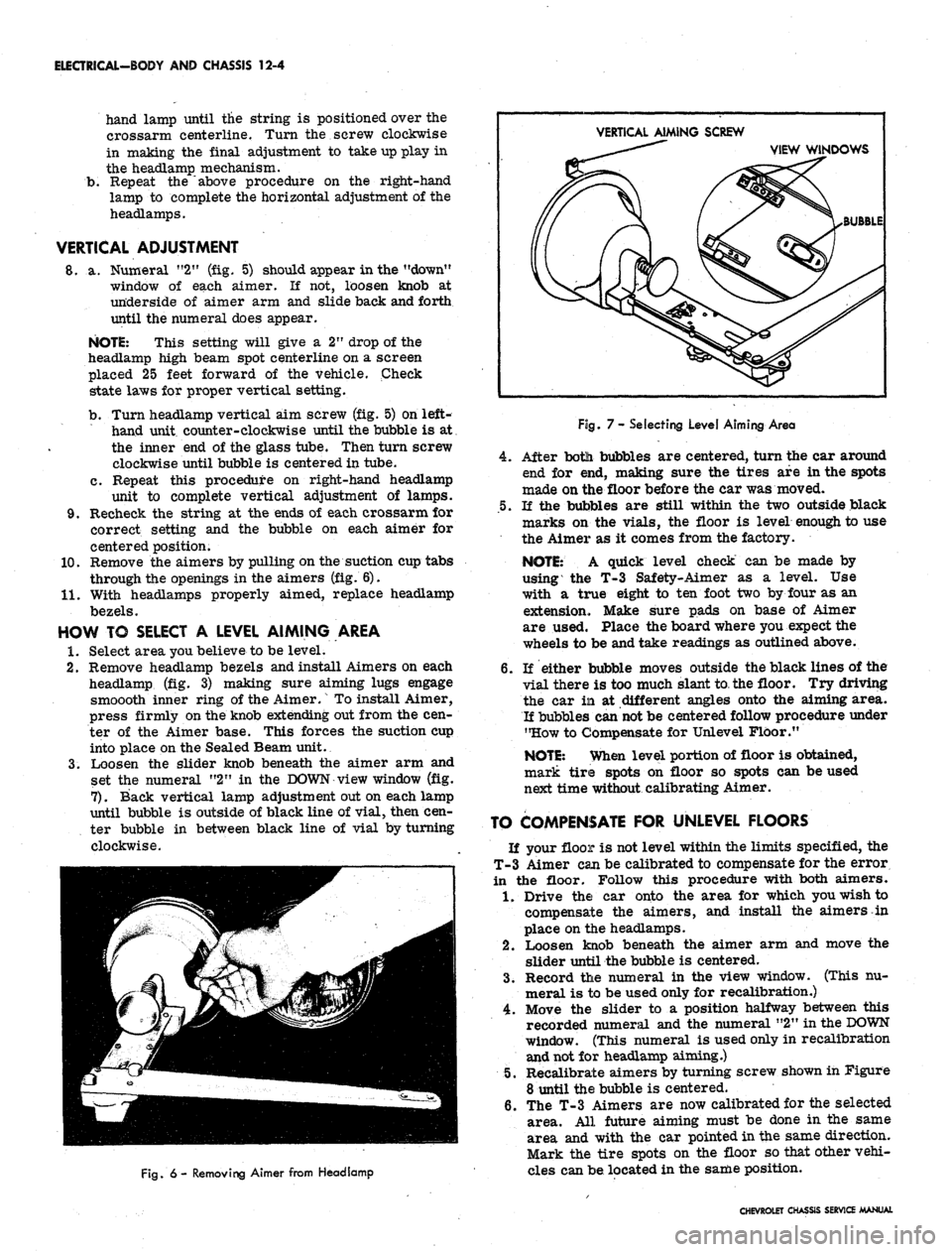

through the openings in the aimers (fig. 6).

11.

With headlamps properly aimed, replace headlamp

bezels.

HOW TO SELECT A LEVEL AIMING AREA

1.

Select area you believe to be level.

2.

Remove headlamp bezels and install Aimers on each

headlamp (fig. 3) making sure aiming lugs engage

smoooth inner ring of the Aimer.

"

To install Aimer,

press firmly on the knob extending out from the cen-

ter of the Aimer base. This forces the suction cup

into place on the Sealed Beam unit.:

3.

Loosen the slider knob beneath the aimer arm and

set the numeral "2" in the DOWN view window (fig.

7).

Back vertical lamp adjustment out on each lamp

until bubble is outside of black line of vial, then cen-

ter bubble in between black line of vial by turning

clockwise.

VERTICAL AIMING SCREW

VIEW WINDOWS

BUBBLE

Fig.

6 - Removing Aimer from Headlamp

Fog.

7- Selecting Level Aiming Area

4.

After botli bubbles are centered, turn the car around

end for end, making sure the tires are in the spots

made on the floor before the car was moved.

.5.

If the bubbles are still within the two outside black

marks on the vials, the floor is level enough to use

the Aimer as it comes from the factory.

NOTE:

A quick level check can be made by

using the T-3 Safety-Aimer as a level. Use

with a true eight to ten foot two by four as an

extension. Make sure pads on base of Aimer

are used. Place the board where you expect the

wheels to be and take readings as outlined above.

6. If either bubble moves outside the black lines of the

vial there is too much slant to the floor. Try driving

the car in at different angles onto the aiming area.

If bubbles can

not

be centered follow procedure under

"How to Compensate for Unlevel Floor."

NOTE:

When level portion of floor is obtained,

mark tire spots on floor so spots can be used

next time without calibrating Aimer.

TO COMPENSATE FOR UNLEVEL FLOORS

If your floor is not level within the limits specified, the

T-3 Aimer can be calibrated to compensate for the error

in the floor. Follow this procedure with both aimers.

1.

Drive the car onto the area for which you wish to

compensate the aimers, and install the aimers in

place on the headlamps.

2.

Loosen knob beneath the aimer arm and move the

slider until the bubble is centered.

3.

Record the numeral in the view window. (This nu-

meral is to be used only for recalibration.)

4.

Move the slider to a position halfway between this

recorded numeral and the numeral "2" in the

DOWN

window. (This numeral is used only in recalibration

and not for headlamp aiming.)

5.

Recalibrate aimers by turning screw shown in Figure

8 until the bubble is centered.

6. The T-3 Aimers are now calibrated for the selected

area. All future aiming must be done in the same

area and with the car pointed in the same direction.

Mark the tire spots on the floor so that other vehi-

cles can be located in the same position.

CHEVROLET CHASSIS SERVICE MANUAL

Page 517 of 659

ELECTRICAL-BODY AND CHASSIS 12-5

Fig.

8—Turning Level Adjusting Screw to Calibrate Aimer

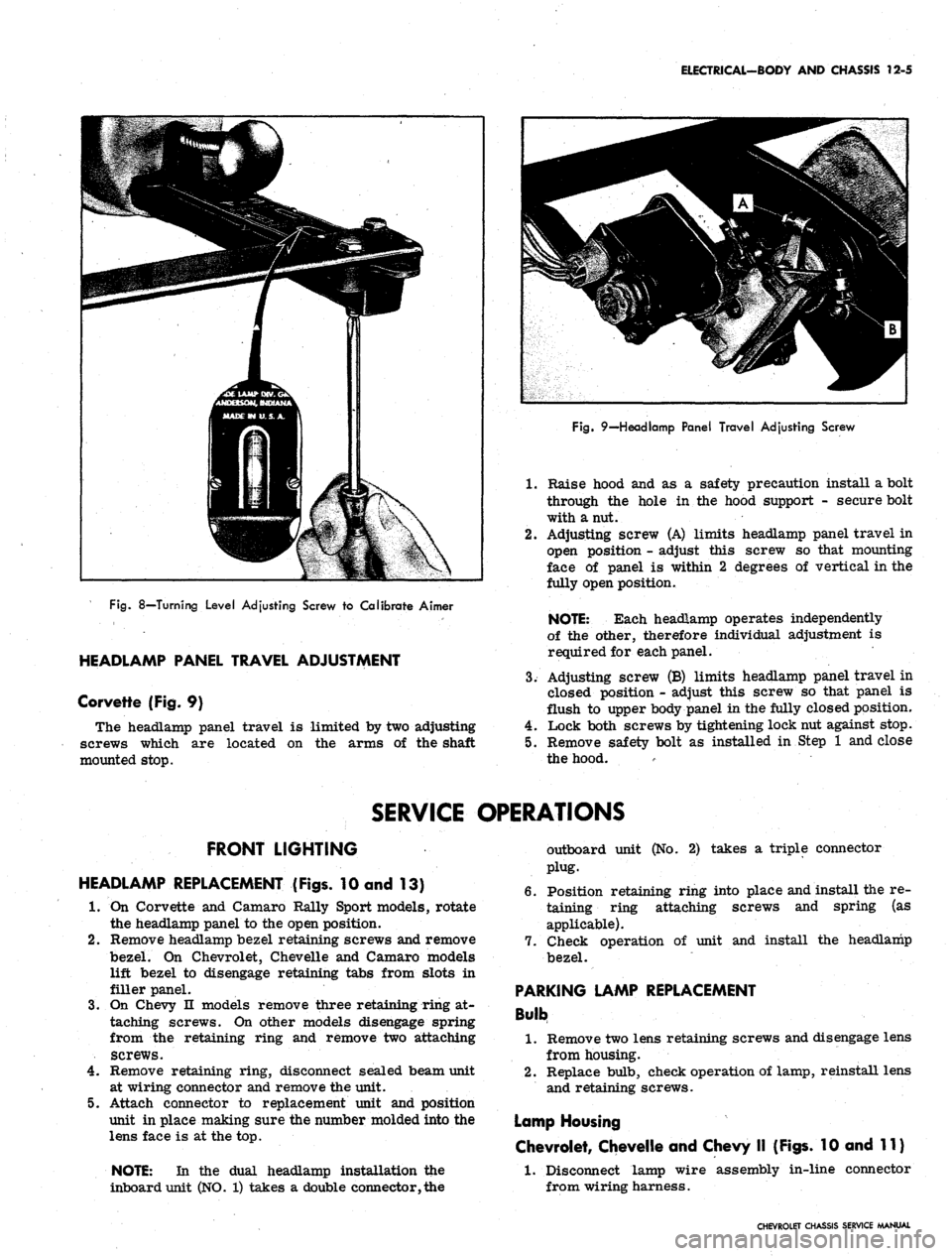

HEADLAMP PANEL TRAVEL ADJUSTMENT

Corvette (Fig. 9)

The headlamp panel travel is limited by two adjusting

screws which are located on the arms of the shaft

mounted stop.

Fig.

9—Headlamp Panel Travel Adjusting Screw

1.

Raise hood and as a safety precaution install a bolt

through the hole in the hood support - secure bolt

with a nut.

2.

Adjusting screw (A) limits headlamp panel travel in

open position - adjust this screw so that mounting

face of panel is within 2 degrees of vertical in the

fully open position.

NOTE: Each headlamp operates independently

of the other, therefore individual adjustment is

required for each panel.

3.

Adjusting screw (B) limits headlamp panel travel in

closed position - adjust this screw so that panel is

flush to upper body panel in the fully closed position.

4.

Lock both screws by tightening lock nut against stop.

5.

Remove safety bolt as installed in Step 1 and close

the hood.

SERVICE OPERATIONS

FRONT LIGHTING

HEADLAMP REPLACEMENT (Figs. 10 and 13)

1.

On Corvette and Camaro Rally Sport models, rotate

the headlamp panel to the open position.

2.

Remove headlamp bezel retaining screws and remove

bezel. On Chevrolet, Chevelle and Camaro models

lift bezel to disengage retaining tabs from slots in

filler panel.

3.

On Chevy n models remove three retaining ring at-

taching screws. On other models disengage spring

from the retaining ring and remove two attaching

screws.

4.

Remove retaining ring, disconnect sealed beam unit

at wiring connector and remove the unit.

5.

Attach connector to replacement unit and position

unit in place making sure the number molded into the

lens face is at the top.

NOTE: In the dual headlamp installation the

inboard unit (NO. 1) takes a double connector, the

outboard unit (No. 2) takes a triple connector

plug.

6. Position retaining ring into place and install the re-

taining ring attaching screws and spring (as

applicable).

7.

Check operation of unit and install the headlamp

bezel.

PARKING LAMP REPLACEMENT

Bulb

1.

Remove two lens retaining screws and disengage lens

from housing.

2.

Replace bulb, check operation of lamp, reinstall lens

and retaining screws.

Lamp Housing

Chevrolet, Chevelle and Chevy II (Figs. 10 and 11)

1.

Disconnect lamp wire assembly in-line connector

from wiring harness.

CHEVROLET CHASSIS SERVICE MANUAL