check engine CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 622 of 659

ACCESSORIES 15-13

SYSTEM TEST

CHECKS AND ADJUSTMENTS

Automatic Level Control Test Gauge (Fig. 15)

A complete system test includes on and off-the-car

component tests.. '

On the car tests are:

Quick check of Automatic Level Control System

Compressor output test

Regulator test and adjustment

Control valve test

Time delay test

Line and fitting leak test

Trim adjustment

Off-the-car operations include:

Control valve replacement

Compressor repair

Component leak tests

a. Compressor, reservoir, and regulator

b.

Control valve

c. Superlifts

Quick Check-On Car (Reservoir Pressure at 150 PSI)

1.

Fill the fuel tank or simulate at the rate of 6 lbs./

gal.

- otherwise car should be empty.

2.

Turn engine off.

3.

Add a 2 passenger load to the rear bumper or tail-

gate.

Maintain the load until the -car lifts or AT

LEAST 20 SECONDS.

4.

After car lifts remove the load and observe until the

car lowers.

FILL VALVE

J-21999

CONNECTORS

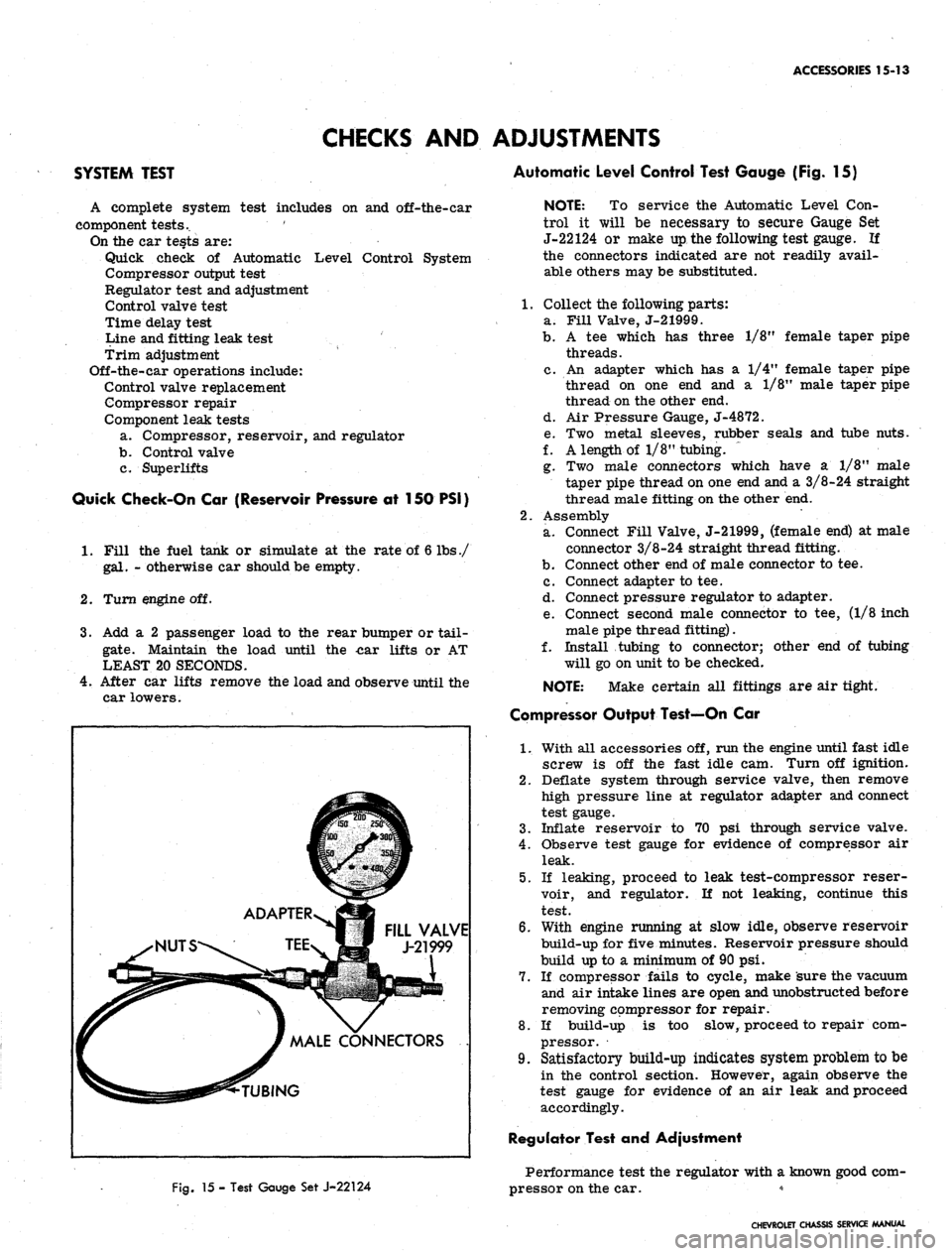

Fig.

15 - Test Gauge Set J-22124

NOTE: To service the Automatic Level Con-

trol it will be necessary to secure Gauge Set

J-22124 or make up the following test gauge. If

the connectors indicated are not readily avail-

able others may be substituted.

1.

Collect the following parts:

a. Fill Valve, J-21999.

b.

A tee which has three 1/8M female taper pipe

threads.

c. An adapter which has a 1/4" female taper pipe

thread on one end and a 1/8" male taper pipe

thread on the other end.

d. Air Pressure Gauge, J-4872.

e. Two metal sleeves, rubber seals and tube nuts.

f. A length of 1/8" tubing. ~

g. Two male connectors which have a 1/8" male

taper pipe thread on one end and a 3/8-24 straight

thread male fitting on the other end.

2.

Assembly

a. Connect Fill Valve, J-21999, (female end) at male

connector 3/8-24 straight thread fitting.

b.

Connect other end of male connector to tee.

c. Connect adapter to tee.

d. Connect pressure regulator to adapter.

e. Connect second male connector to tee, (1/8 inch

male pipe thread fitting).

f. Install tubing to connector; other end of tubing

will go on unit to be checked.

NOTE:

Make certain all fittings are air tight.

Compressor Output Test—On Car

1.

With all accessories off, run the engine until fast idle

screw is off the fast idle cam. Turn off ignition.

2.

Deflate system through service valve, then remove

high pressure line at regulator adapter and connect

test gauge.

3.

Inflate reservoir to 70 psi through service valve.

4.

Observe test gauge for evidence of compressor air

leak.

5.

If leaking, proceed to leak test-compressor reser-

voir, and regulator. If not leaking, continue this

test.

6. With engine running at slow idle, observe reservoir

build-up for five minutes. Reservoir pressure should

build up to a minimum of 90 psi.

7.

If compressor fails to cycle, make sure the vacuum

and air intake lines are open and unobstructed before

removing compressor for repair.

8. If build-up is too slow, proceed to repair com-

pressor.

9. Satisfactory build-up indicates system problem to be

in the control section. However, again observe the

test gauge for evidence of an air leak and proceed

accordingly.

Regulator Test and Adjustment

Performance test the regulator with a known good com-

pressor on the car. *

CHEVROLET CHASSIS SERVICE MANUAL

Page 623 of 659

ACCESSORIES 15-14

Deflate system through service valve and disconnect

line at pressure regulator valve. Install test gauge on

regulator valve high pressure fitting.

Inflate system through service valve to maximum

available pressure.

NOTE: If available pressure is less than 140

psi,

start engine to build-up reservoir to this

pressure.

Regulated pressure should build-up to and hold

steady at 100-130 psi on test gauge.

Check regulated pressure by momentarily (not more

than one second) depressing valve core on test gauge

arid observe gauge reading.

If regulated pressure now reads less than 100 psi,

replace regulator assembly.

If regulated pressure exceeds 130 psi, replace regu-

lator assembly.

Control Valve Test

Exhaust (Superlifts Inflated)

1.

Disconnect control valve lever from link.

2.

Hold lever down in exhaust position until Superlifts

deflate or for a minimum of 18 seconds.

3.

If Superlifts deflate, perform Intake Check.

4.

If Superlifts do not deflate, remove exhaust adapter

from control valve and hold lever down as in Step 2.

Replace adapter, O-ring and filter if this deflates

Superlifts.

5.

Replace control valve if none of the above steps solve

problem.

Intake (Reservoir Pressure 125 psi Minimum)

1.

Disconnect overtravel lever from link.

2.

Hold lever up in intake position until Superlifts in-

Fig.

16 - Assembly Leak Test Preparation

flate or for a minimum of fifteen seconds.

3.

If Superlifts inflate and hold, proceed to Time Delay

Check. '•

4.

If Superlifts inflate and then leak down, perform leak

test on lines and fittings and then on Superlifts and

control valve. Repair or replace as indicated.

Time Delay Test (Reservoir Pressure 125 psi Minimum)

1.

Record rear trim height of empty car (rear bumper

to ground).

2.

Add weight equivalent to two passenger load to rear

of car. Car should begin to level in 4-18 seconds.

3.

Remove weight. After 4-18 seconds car should begin

to settle.

4.

Replace valve if time delay is not within the 4-18

seconds.

Trim Adjustment—On Car

Trim adjustment should be performed with a full fuel

tank (or the equivalent in load at the rate of 6 lbs

./gal-

lon)

,

but no other load.

Abbreviated Adjustment

1.

Fill the compressor at the service valve with the

available air line pressure.

2.

Disconnect link from height control valve lever.

Move the height control valve lever upward until air

fills the Superlifts.

3.

Move lever downward and hold until air stops escap-

ing from the exhaust port of the height control valve.

The Superlifts will now automatically hold 8 to 15

PSI.

;

4.

Let lever go to its neutral position> and loosen the

lever adjustment nut.

5.

Assemble the link to the height control valve lever

and tighten the lever adjustment nut.

NOTE: Do not move control valve lever and

overtravel body while tightening nut.

Leak Tests

Compressor, Reservoir and Regulator

1.

Remove assembly intact.

2.

Connect test gauge to regulator. Inflate reservoir

through service valve to 80-110 psi.

3.

Route an 8" rubber hose between vacuum and vent

ports,

(fig. 16).

4.

Submerge in water and observe for air leaks at:

Reservoir weld seam.

Reservoir to compressor O-ring.

Regulator to compressor O-ring.

Regulator boot-defective internal.O-rihg.

Diaphragm between first and second stage housings.

' Tightening through bolts may correct the leak.

Cover gasket and retainer screw. A few bubbles here

is not a leak. A continuous stream indicates defec-

tive compressor check valves.

Service valve.

Test gauge connections.

5.

Correct any leaks detected by either tightening

screws or replacing parts.

CHEVROLET CHASSIS SERVICE MANUAL

Page 639 of 659

SPECIFICATIONS

12

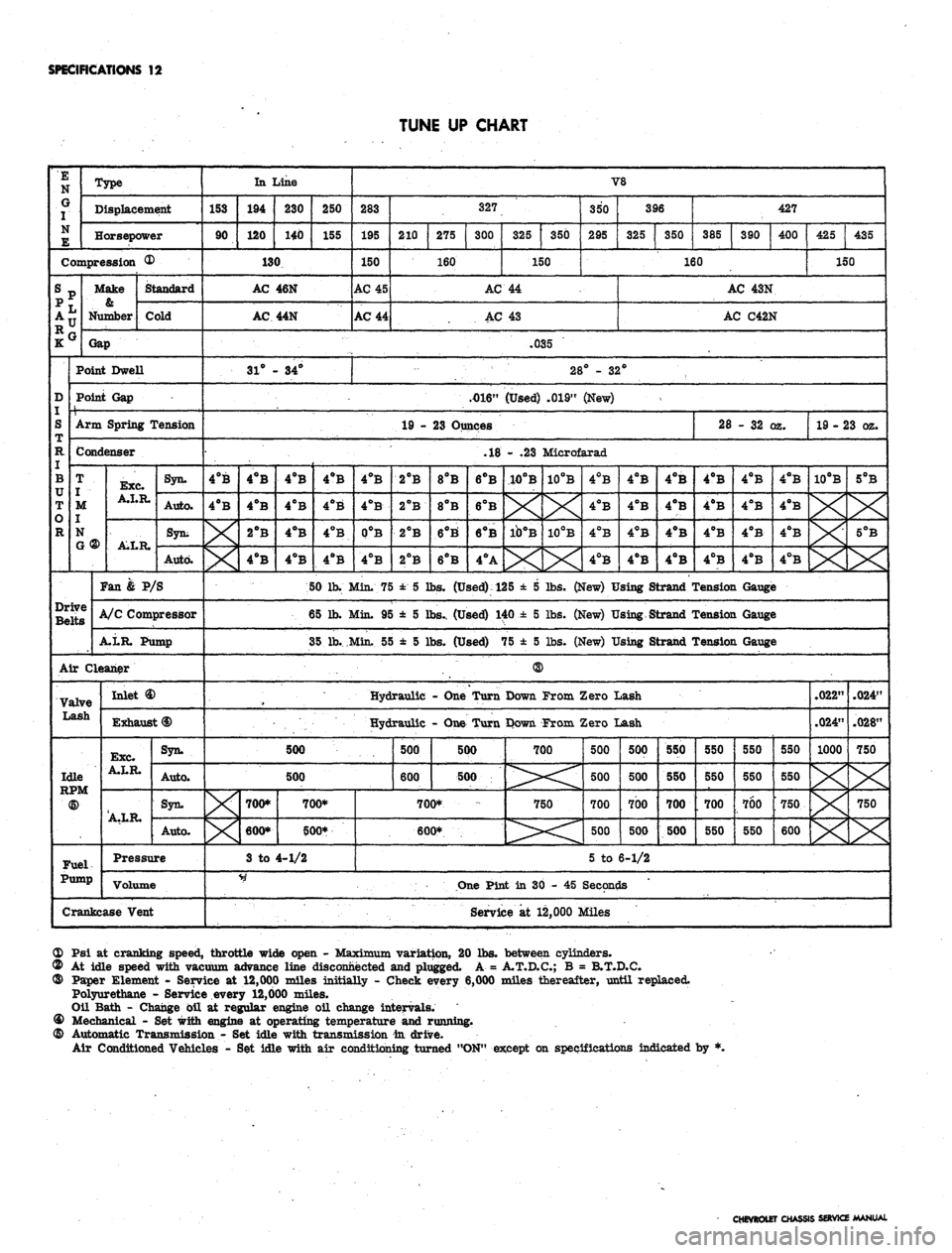

TUNE UP CHART

E

N

G

I

N

E

Type

Displacement

Horsepower

Compression ®

srp

;•

D

S

R

I

B

TT

T

o

R

Make

0.

Number

Standard

Cold

Gap

Point Dwell

Point Gap

1 ,

Arm Spring Tension

Condenser

T

I

M

j

N

G ®

Drive

Belts

Exc.

A.I.R.

AXR.

Syn.

Auto.

Syn;

Auto.

Fan & P/S

A/C Compressor

A.LR. Pump

Air Cleaner

Valve

Lash

Idle

<§>

Fuel.

Pump

Inlet

Exhaust

<§)

Exc.

A.LR.

A.LR.

Syn.

Auto.

Syn.

Auto.

Pressure

Volume

Crankcase Vent

In Line

153

90

194

120

230

140

250

155

130

AC

AC

31° -

46N

44N

• 34°

V8

283

195

150

AC 45

AC 44

327

210

275

300

160

325

350

150

350

295

396

325

350

427

385

390

400

160

AC 44

AC 43

425

435

150

AC 43N

AC C42N

.035

28° - 32°

.4)16"

(Used) .019" (New)

<

19 - 23 Ounces

4°B

4°B

4°B

4°B

2°B

4°B

4°B

4°B

4°B

4°B

28

- 32 (

yz.

19 - 23 oz.

.18 - .23 Microfarad

4°B

4°B

4°B

4ftB

4°B

4°B

0°B

4°B

50 lb. Min. 75

65 Jh. Min. 95

35 lb..Min. 5£

500

2°B

2°B

2°B

2°B

8PB

8°B

6°B'

6°B

6°B

6°B

6°B

4°A

10°B

X

ib°B

X

10PB

X

10°B

X

4°B

4°B

4°B

4°B

4°B

4°B

4°B

4°B

4°B

4°B

4°B

4°B

± 5 lbs.

(Used):

125 ± 5 lbs. (New) Using Strand '

± 5 lbs.. (Used) 140 ± 5 lbs. (New) Using Strand '

>

± 5 lbs. (Used) 75 ± 5 lbs. (New) Using Strand r

Hydraulic - One Turn Down From Zero Lash

Hydraulic - One Turn Down From Zero Lash

500

X

700*

600*

3 to

700*

500*

4-1/2

500

600

500

500

700*

600*

700

750

500

500

700

500

500

500

700

500

550

550

700

500

4°B

4°B

4°B

4°B

4°B

4°B

4°B

4°B

4°B

4°B

4°B

4°B

Tension Gauge

Tension Gauge

Tension Gauge

550

550

700

550

550

550

700

550

550

550

750

600

10°B

5°B

X

X

.022"

.024"

1000

X

X

X

.024"

.028"

750

X

750

X

5 to 6-1/2

One Pint in 30 - 45 Seconds

Service at 12,000 Miles

OD Psi at cranking speed, throttle wide open - Maximum variation, 20 lbs. between cylinders.

© At idle speed with vacuum advance line disconnected and plugged. A = A.T.D.C.; B = B.T.D.C.

® Paper Element - Service at 12,000 miles initially - Check every 6,000 miles thereafter, until replaced.

Polyurethane - Service every 12,000 miles.

Oil Bath - Change oil at regular engine oil change intervals.

® Mechanical - Set with engine at operating temperature and running.

@ Automatic Transmission - Set idle with transmission in drive.

Air Conditioned Vehicles - Set idle with air conditioning turned "ON" except on specifications indicated by *.

CHEVROLET CHASSIS SERVICE MANUAL