service CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 3 of 659

SECTION O

INFORMATION AND LUBRICATION

CONTENTS OF THIS SECTION

Page

General Information o-l

Lubrication 0-13

GENERAL INFORMATION

Model Identification and Vehicle Dimensions

Chevrolet

Chevelle

Chevy n

Corvette

Camaro

Page

0-1

0-1

0-2

0-2

0-3

0-3

Page

Unit and Serial Numbers o-3

Engine Number o-3

Vehicle Serial Number 0r3

Keys and Locks 0-4

Pushing,Towing and Lifting 0-7

Series

Biscayne

Bel Air

Tmpala.

Impala

Super Sport

Caprice

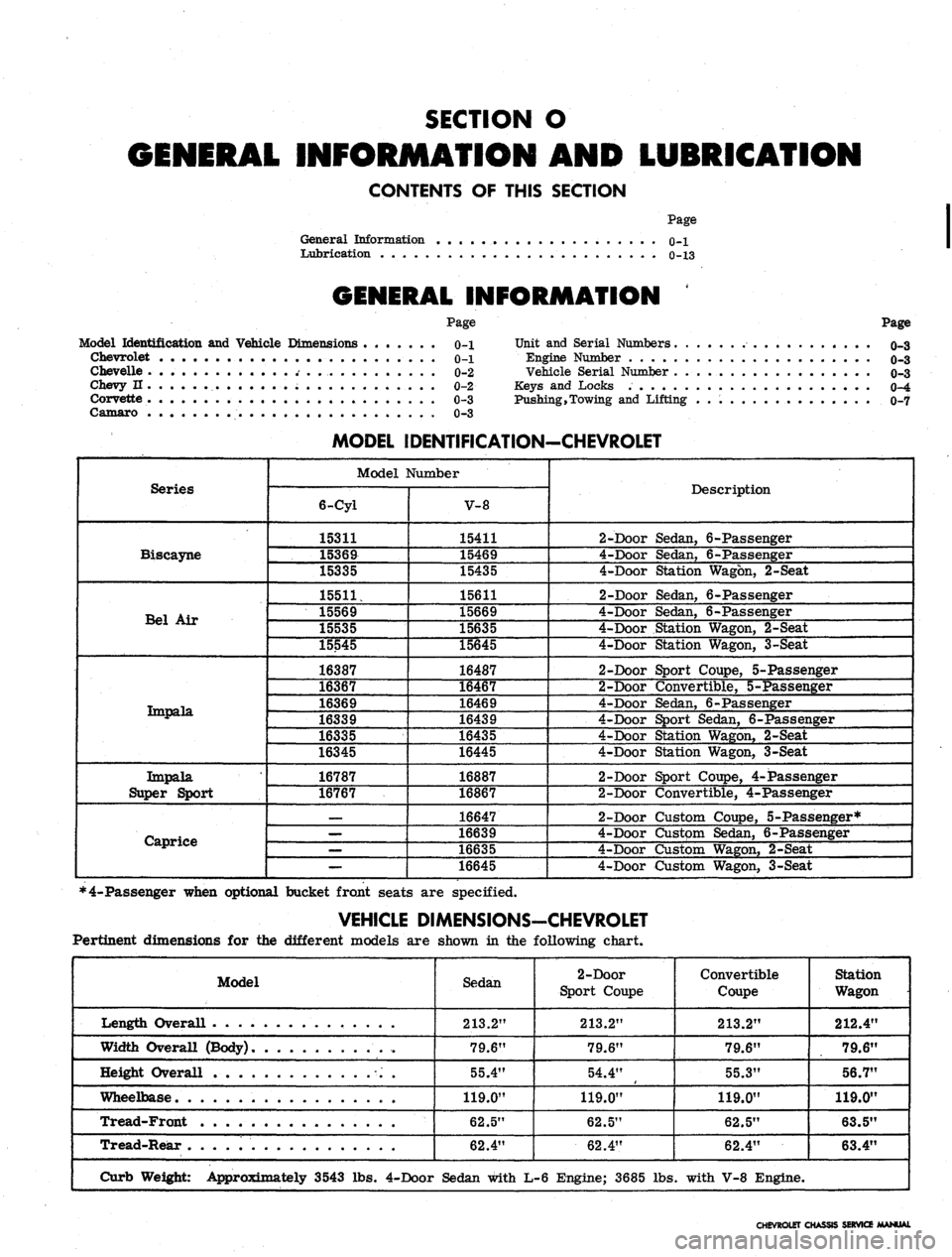

MODEL IDENTIFICATION-CHEVROLET

Model Number

6-Cyl

15311

15369

15335

15511,

15569

15535

15545

16387

16367

16369

16339

16335

16345

16787

16767

—

—

—

—

V-8

15411

15469

15435

15611

15669

15635

15645

16487

16467

16469

16439

16435

16445

16887

16867

16647

16639

16635

16645

Description

2-Door Sedan, 6-Passenger

4-Door Sedan, 6-Passenger

4-Door Station Wagon, 2-Seat

2-Door Sedan, 6-Passenger

4-Door Sedan, 6-Passenger

4-Door Station Wagon, 2-Seat

4-Door Station Wagon, 3-Seat

2-Door Sport Coupe, 5-Passenger

2-Door Convertible, 5-Passenger

4-Door Sedan, 6-Passenger

4-Door Sport Sedan, 6-Passenger

4-Door Station Wagon, 2-Seat

4-Door Station Wagon, 3-Seat

2-Door Sport Coupe, 4-Passenger

2-Door Convertible, 4-Passenger

2-Door Custom Coupe, 5-Passenger*

4-Door Custpm Sedan, 6-Passenger

4-Door Custom Wagon, 2-Seat

4-Door Custom Wagon, 3-Seat

*4-Passenger when optional bucket front seats are specified.

VEHICLE DIMENSIONS-CHEVROLET

Pertinent dimensions for the different models are shown in the following chart.

Model

Length Overall . .

Width Overall (Body)

Height Overall

Wheelbase

Tread-Front

Tread-Rear

Curb Weight: Approximately 3543 lbs.

Sedan

213.2"

79.6"

55.4"

119.0"

62.5"

62.4"

4-Door Sedan with

2-Door

Sport Coupe

213.2"

79.6"

54.4"

119.0"

62.5"

62.4"

L-6 Engine; 3685 lbs

Convertible

Coupe

213.2"

79.6"

55.3"

119.0"

62.5"

62.4"

. with V-8 Engine.

Station

Wagon

212.4"

79.6"

56.7"

119.0"

63.5"

63.4"

CHEVROLET CHASSIS SERVICE MANUAL

Page 4 of 659

GENERAL INFORMATION 0-2

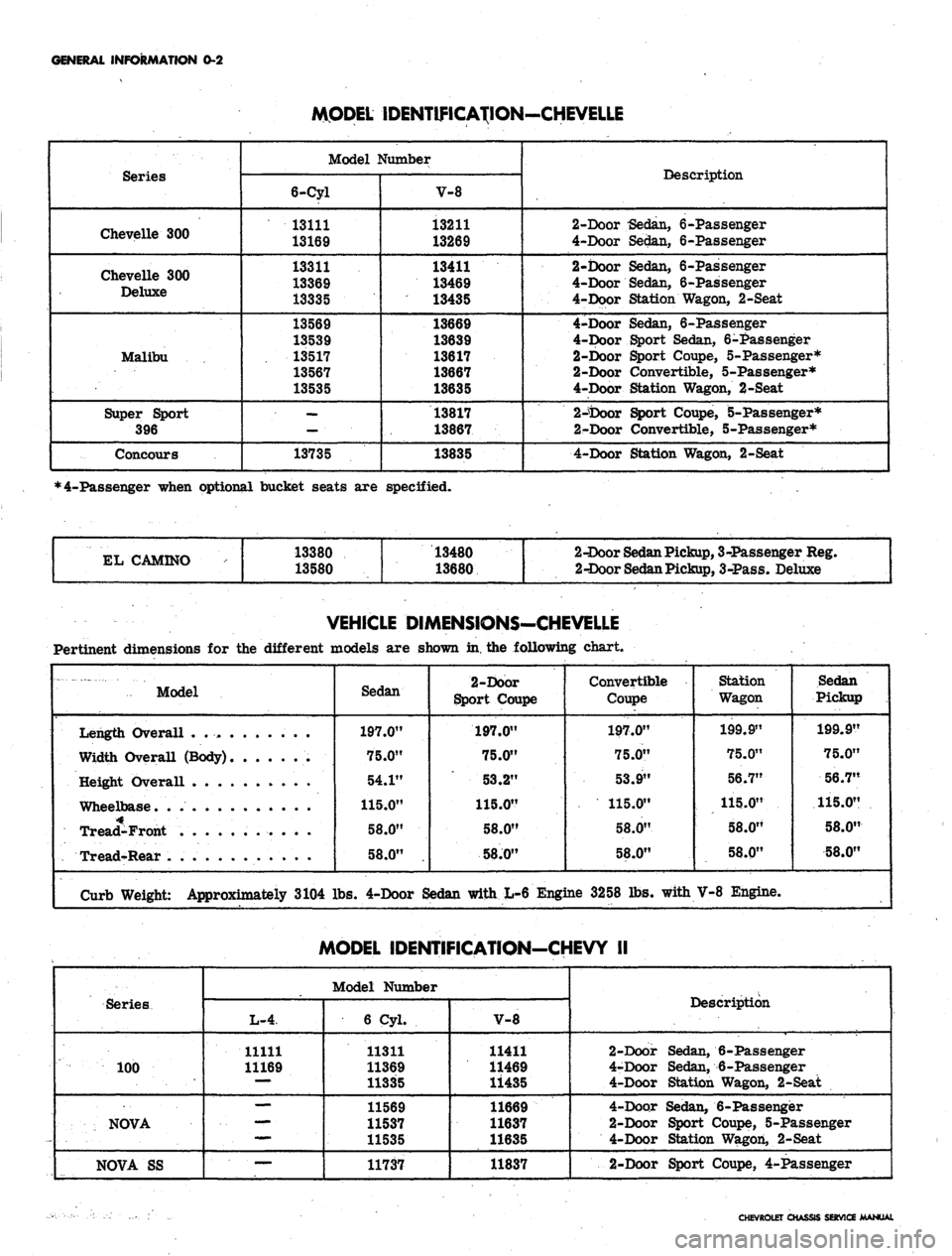

MODEL IDENTIFICATION-CHEVELLE

Series

Chevelle 300

Chevelle 300

Deluxe

Malibu

Super Sport

396

Concours

Model Number

6-Cyl

13111

13169

13311

13369

13335

13569

13539

13517

13567

13535

—

13735

V-8

13211

13269

13411

13469

13435

13669

13639

13617

13667

13635

13817

13867

13835

Description

2-Door -Sedan, 6-Passenger

4-Door Sedan, 6-Passenger

2-Door Sedan, 6-Passenger

4-Door Sedan, 6-Passenger

4-Door Station Wagon, 2-Seat

4-Door Sedan, 6-Passenger

4-Door Sport Sedan, 6-Passenger

2-Door Sport Coupe, 5-Passenger*

2-Door Convertible, 5-Passenger*

4-Door Station Wagon, 2-Seat

2-tooor Sport Coupe, 5-Passenger*

2-Door Convertible, 5-Passenger*

4-Door Station Wagon, 2-Seat

*4-Passenger when optional bucket seats are specified.

EL CAMINO

13380

13580

13480

13680

2-Door

Sedan

Pickup,

3-Passenger Reg.

2-Door

Sedan

Pickup,

3-Pass. Deluxe

VEHICLE DIMENSIONS-CHEVELLE

Pertinent dimensions for the different models are shown in, the following chart.

Model

Sedan

197.0"

75.0"

54.1"

115.0"

58.0"

58.0"

2-Door

Sport Coupe

197.0"

75.0"

53.2"

115.0"

58.0"

58J0"

Convertible

Coupe

197.0"

75.0"

53.9"

115.0"

58.0"

58.0"

Station

Wagon

199.9"

75.0"

56.7"

115.0"

58.0"

58.0"

Sedan

Pickup

199.9"

75.0"

56.7"

115.0"

58.0"

58.0"

Length Overall .

Width Overall (Body)

Height Overall . . .

Wheelbase. .

Tread-Front

Tread-Rear .

Curb Weight: Approximately 3104 lbs. 4-Door Sedan with L-6 Engine 3258 lbs. with V-8 Engine.

MODEL IDENTIFICATION-CHEVY II

Series

100

NOVA

NOVA SS

Model Number

L-4

11111

11169

mmm.

—

6 Cyl.

11311

11369

11335

11569

11537

11535

11737

V-8

11411

11469

11435

11669

11637

11635

11837

Description

2-Door Sedan, 6-Passenger

4-Door Sedan, 6-Passenger

4-Door Station Wagon, 2-Seat

4-Door Sedan, 6-Passenger

2-Door Sport Coupe, 5-Passenger

4-Door Station Wagon, 2-Seat

2-Door Sport Coupe, 4-Passenger

CHEVROLET CHASSIS SERVICE MANUAL

Page 5 of 659

GENERAL INFORMATION 0-3

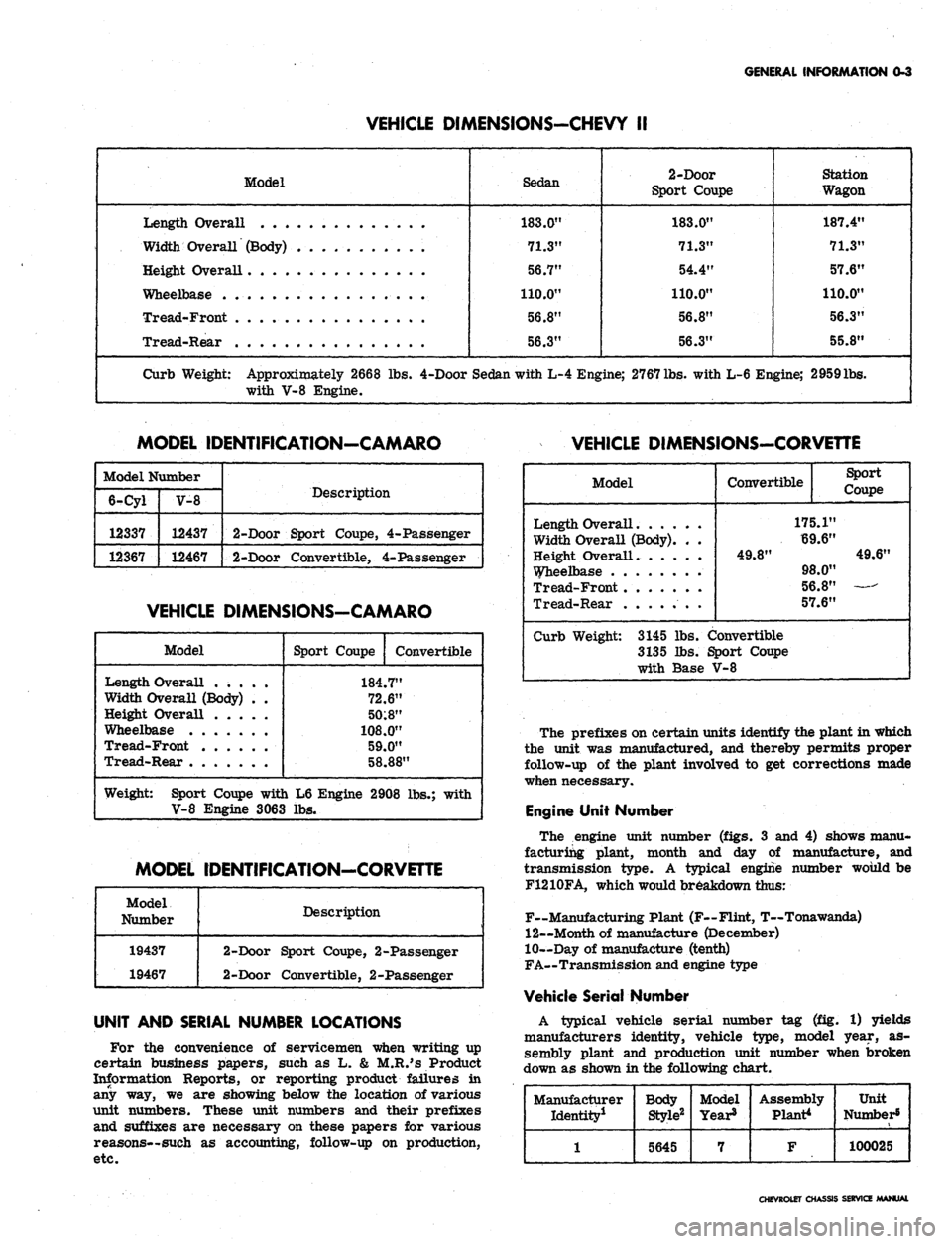

VEHICLE DIMENSIONS-CHEVY II

Model

Length Overall

Width Overall (Body) . . . .

Height Overall

Wheelbase

Tread-Front

Tread-Rear . . .

Sedan

183.0"

71.3"

56.7"

110.0"

56.8"

56.3"

2-Door

Sport Coupe

183.0"

71.3"

54.4"

110.0"

56.8"

56.3"

Station

Wagon

187.4"

71.3"

57.6"

110.0"

56.3"

55.8"

Curb Weight: Approximately 2668 lbs. 4-Door Sedan with L-4 Engine; 2767

lbs.

with L-6 Engine; 2959lbs.

with V-8 Engine.

MODEL IDENTIFICATION-CAMARO

VEHICLE DIMENSIONS-CORVEnE

Model Number

6-Cyl

12337

12367

V-8

12437

12467

Description

2-Door Sport Coupe, 4-Passenger

2-Door Convertible, 4-Passenger

VEHICLE DIMENSIONS-CAMARO

Model

Length Overall .....

Width Overall (Body) . .

Height Overall

Wheelbase

Tread-Front

Tread-Rear

Sport Coupe

Convertible

184.7"

72.6"

50:8"

108.0"

59.0"

58.88"

Weight: Sport Coupe with L6 Engine 2908 lbs.; with

V-8 Engine 3063 lbs.

MODEL IDENTIFICATION-CORVETTE

Model

Number

19437

19467

Description

2-Door Sport Coupe, 2-Passenger

2-Door Convertible, 2-Passenger

UNIT AND SERIAL NUMBER LOCATIONS

For the convenience of servicemen when writing up

certain business papers, such as L. & M.R.'s Product

Information Reports, or reporting product failures in

any way, we are showing below the location of various

unit numbers. These unit numbers and their prefixes

and suffixes are necessary on these papers for various

reasons—such as accounting, follow-up on production,

etc.

Model

Length Overall

Width Overall (Body). . .

Height Overall.

Wheelbase

Tread-Front

Tread-Rear .

Convertible

Sport

Coupe

175.1"

69.6"

49.8"

49.6"

98.0"

56.8"

57.6"

Curb Weight: 3145 lbs. Convertible

3135 lbs. Sport Coupe

with Base V-8

The prefixes on certain units identify the plant in which

the unit was manufactured, and thereby permits proper

follow-up of the plant involved to get corrections made

when necessary.

Engine Unit Number

The engine unit number (figs. 3 and 4) shows manu-

facturing plant, month and day of manufacture, and

transmission type. A typical engine number would be

F1210FA, which would breakdown thus:

F~Manufacturing Plant (F—Flint, T—Tonawanda)

12—Month of manufacture (December)

10—Day of manufacture (tenth)

FA—Transmission and engine type

Vehicle Serial Number

A typical vehicle serial number tag (fig. 1) yields

manufacturers identity, vehicle type, model year, as-

sembly plant and production unit number when broken

down as shown in the following chart.

Manufacturer

Identity1

1

Body

Style2

5645

Model

Year8

7

Assembly

Plant*

F

Unit

Number5

100025

CHEVROLET CHASSIS SERVICE /MANUAL

Page 6 of 659

GENERAL INFORMATION 0-4

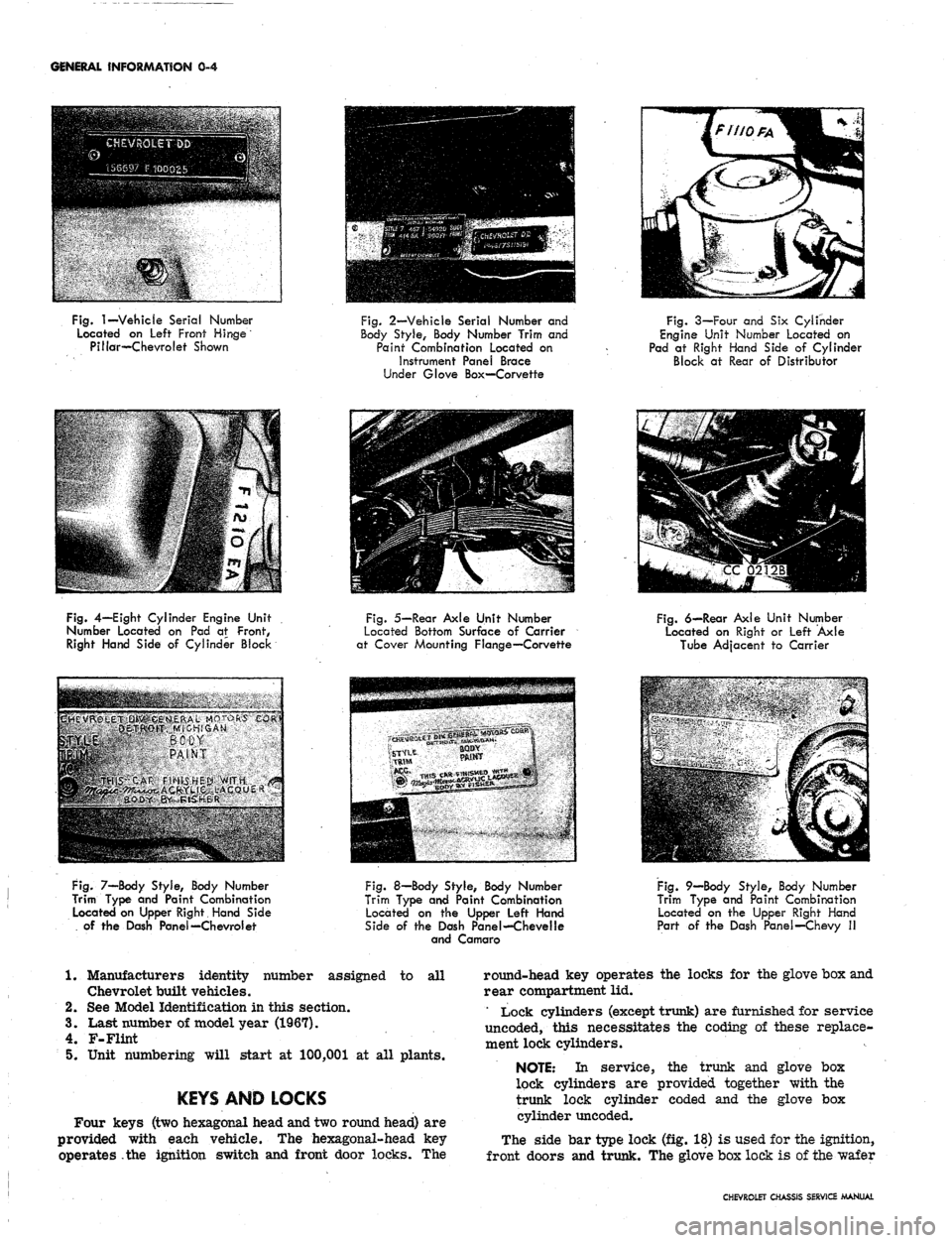

Fig.

1—Vehicle

Serial Number

Located on Left Front Hinge

Pillar—Chevrolet Shown

Fig.

2—Vehicle Serial Number and

Body Style, Body Number Trim and

Paint Combination Located on

Instrument Panel Brace

Under Glove Box—Corvette

Fig. 3—Four and Six Cylinder

Engine Unit Number Located on

Pad at Right Hand Side of Cylinder

Block at Rear of Distributor

Fig.

4—Eight Cylinder Engine Unit

Number Located on Pad at Front,

Right Hand Side of Cylinder Block

Fig.

5—Rear Axle Unit Number

Located Bottom Surface of Carrier

at Cover Mounting Flange—Corvette

Fig.

6—Rear Axle Unit Number

Located on Right or Left Axle

Tube Adjacent to Carrier

BSHfi^;^

PAINT

HRIKI5"tM>

fIHIsS

HE|St.>MfT*

^^ * *•'"

•<"'

Fig.

7—Body Style, Body Number

Trim Type and Paint Combination

Located on Upper Right Hand Side

of the Dash Panel—Chevrol et

Fig.

8—Body Style, Body Number

Trim Type and Paint Combination

Located on the Upper Left Hand

Side of the Dash Panel—Chevelle

and Camaro

Fig.

9—Body Style, Body Number

Trim Type and Paint Combination

Located on the Upper Right Hand

Part of the Dash Panel—Chevy II

1. Manufacturers identity number assigned to all

Chevrolet built vehicles.

2.

See Model Identification in this section.

3.

Last number of model year (1967).

4.

F-Flint

5.

Unit numbering will start at 100,001 at all plants.

KEYS AND LOCKS

Four keys (two hexagonal head and two round head) are

provided with each vehicle. The hexagonal-head key

operates the ignition switch and front door locks. The

round-head key operates the locks for the glove box and

rear compartment lid.

' Lock cylinders (except trunk) are furnished for service

uncoded, this necessitates the coding of these replace-

ment lock cylinders.

NOTE: In service, the trunk and glove box

lock cylinders are provided together with the

trunk lock cylinder coded and the glove box

cylinder uncoded.

The side bar type lock (fig. 18) is used for the ignition,

front doors and trunk. The glove box lock is of the wafer

CHEVROLET CHASSIS SERVICE MANUAL

Page 7 of 659

GENERAL INFORMATION 0-5

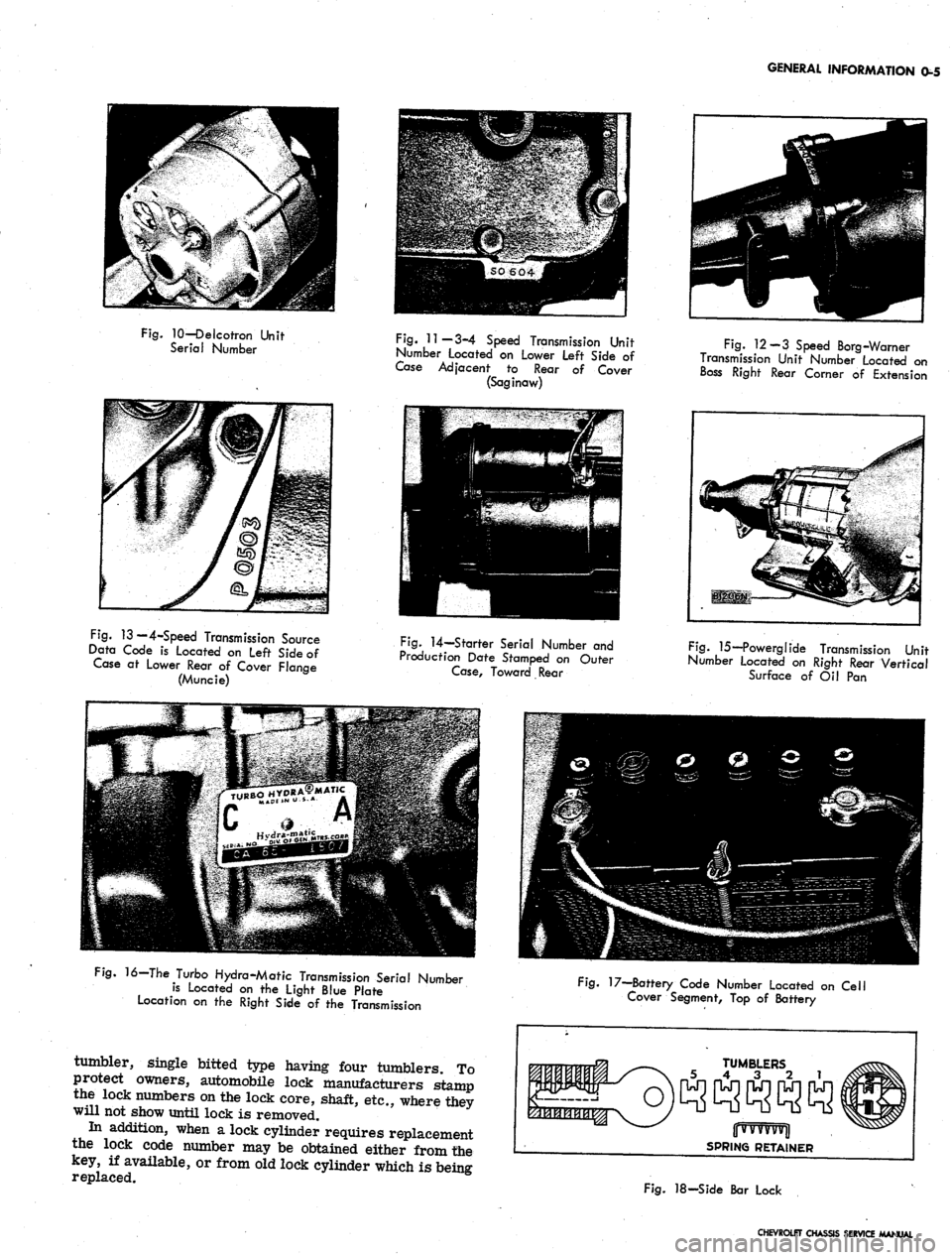

Fig.

10—Delcotron Unit

Serial Number

Fig.

11—3-4 Speed Transmission Unit

Number Located on Lower Left Side of

Case Adjacent to Rear of Cover

(Saginaw)

Fig.

12-3 Speed Borg-Warner

Transmission Unit Number Located on

Boss Right Rear Comer of Extension

Fig.

13 — 4-Speed Transmission Source

Data Code is Located on Left Side of

Case at Lower Rear of Cover Flange

(Muncie)

Fig.

14—Starter Serial Number and

Production Date Stamped on Outer

Case,

Toward Rear

Fig.

15—Powerglide Transmission Unit

Number located on Right Rear Vertical

Surface of Oil Pan

16—The Turbo Hydra-Matic Transmission Serial Number

is Located on the Light Blue Plate

Location on the Right Side of the Transmission

tumbler, single bitted type having four tumblers. To

protect owners, automobile lock manufacturers stamp

the lock numbers on the lock core, shaft, etc., where they

will not show until lock is removed.

In addition, when a lock cylinder requires replacement

the lock code number may be obtained either from the

key, if available, or from old lock cylinder which is being

replaced.

Fig.

17—Battery Code Number Located on Cell

Cover Segment, Top of Battery

TUMBLERS

5 4 3 2 1

jjwvvvvvjl

SPRING RETAINER

Fig.

18-Side Bar Lock

CHEVROLET CHASSIS SERVICE MANUAL

Page 8 of 659

GENERAL INFORMATION

0-6

Once the code number of the lock is obtained look up

this number in a key cutting book.

All side bar locks (except trunk) furnished to the field

by the Parts' Department are uncoded, that is, they are

furnished without tumblers, springs or spring retainers,

these parts are serviced separately. The tumblers come

in five different depths, indicated by numbers.

The side bar locks have six tumbler positions, and in

looking up the cutting code, the following may be used as

an example. After key code number is determined, either

from key or from number stamped on lock cylinder refer

to your code book and record the key cutting information

as follows:

Key of Lock

Code Number

0V11

Cutting or Tumbler

position from head

of lock

Key Cutting

Code Numerical

545431

123456

NOTE:

Key blanks used for ignition and door

locks are stamped with an "A" while rear com-

partment and glove box blanks are stamped with

a "B".

The number that is written above the cutting or tumbler

position indicates each different tumbler which is to be

dropped into each tumbier slot of the lock.

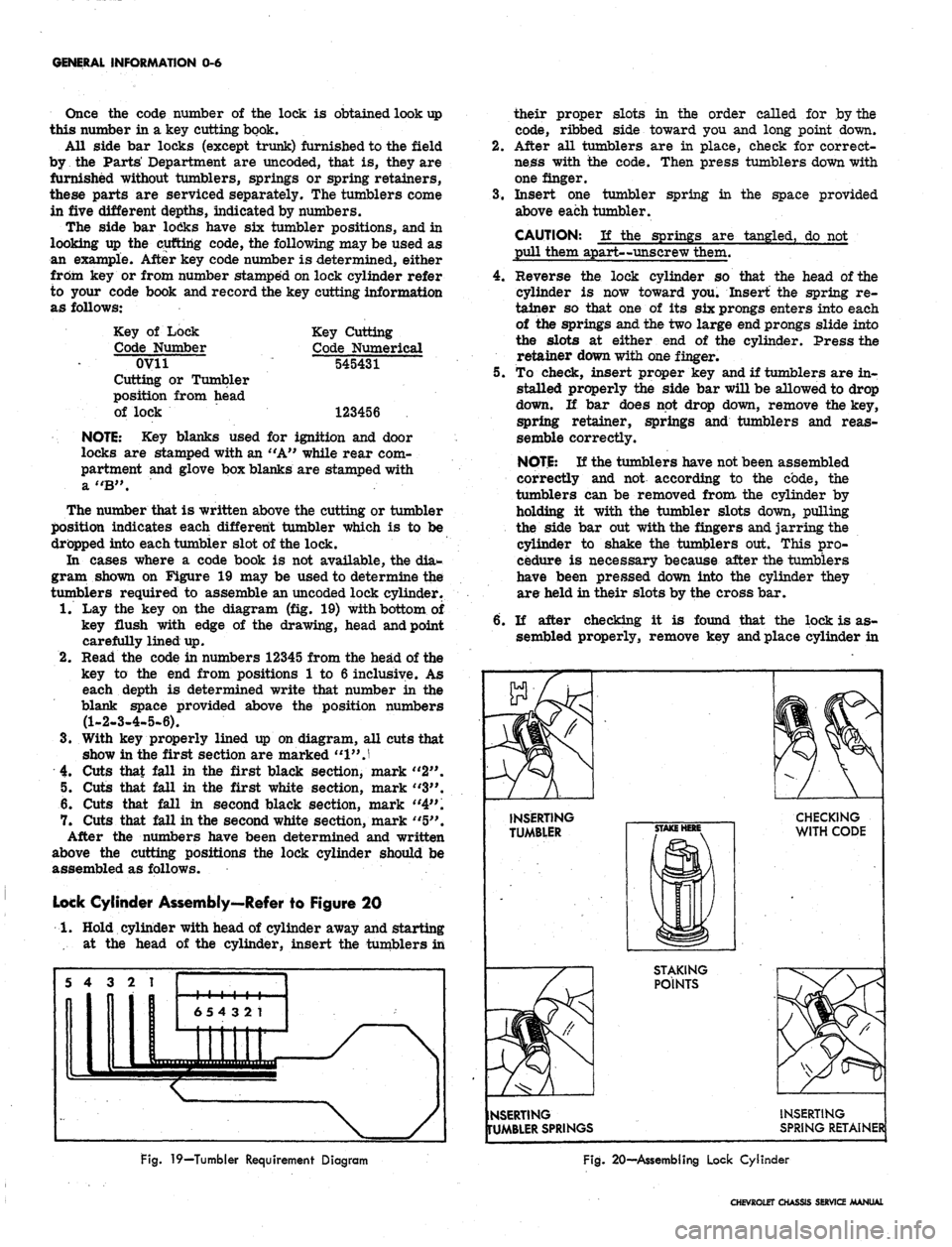

In cases where a code book is not available, the dia-

gram shown on Figure 19 may be used to determine the

tumblers required to assemble an uncoded lock cylinder.

1.

Lay the key on the diagram (fig. 19) with bottom of

key flush with edge of the drawing, head and point

carefully lined up.

2.

Read the code in numbers 12345 from the head of the

key to the end from positions 1 to 6 inclusive. As

each depth is determined write that number in the

blank space provided above the position numbers

(1-2-3-4-5-6).

3.

With key properly lined up on diagram, all cuts that

show in the first section are marked

"1"

J

4.

Cuts that fall in the first black section, mark "2".

5. Cuts that fall in the first white section, mark "3".

6. Cuts that fall in second black section, mark "4".

7. Cuts that fall in the second white section, mark "5".

After the numbers have been determined and written

above the cutting positions the lock cylinder should be

assembled as follows.

Lock Cylinder Assembly—Refer to Figure 20

1.

Hold cylinder with head of cylinder away and starting

•... at the head of the cylinder, insert the tumblers in

their proper slots in the order called for by the

code, ribbed side toward you and long point down.

2.

After all tumblers are in place, check for correct-

ness with the code. Then press tumblers down with

one finger.

3.

Insert one tumbler spring in the space provided

above each tumbler.

CAUTION: If the springs are tangled, do not

pull them apart—unscrew them.

4.

Reverse the lock cylinder so that the head of the

cylinder is now toward you. Insert the spring re-

tainer so that one of its six prongs enters into each

of the springs and the two large end prongs slide into

the slots at either end of the cylinder. Press the

retainer down with one finger.

5. To check, insert proper key and if tumblers are in-

stalled properly the side bar will be allowed to drop

down. If bar does not drop down, remove the key,

spring retainer, springs and tumblers and reas-

semble correctly.

NOTE:

If the tumblers have not been assembled

correctly and not according to the code, the

tumblers can be removed from the cylinder by

holding it with the tumbler slots down, pulling

the side bar out with the fingers and jarring the

cylinder to shake the tumblers out. This pro-

cedure is necessary because after the tumblers

have been pressed down into the cylinder they

are held in their slots by the cross bar.

6. If after checking it is found that the lock is as-

sembled properly, remove key and place cylinder in

INSERTING

TUMBLER

CHECKING

WITH CODE

STAKING

POINTS

NSERTING

TUMBLER SPRINGS

INSERTING

SPRING RETAINER

Fig.

19—Tumbler Requirement Diagram

Fig.

20—Assembling Lock Cylinder

CHEVROLET CHASSIS SERVICE MANUAL

Page 9 of 659

GENERAL INFORMATION 0-7

a vise using leather or wood on each side to prevent

damage to the cylinder,

7. Stake the retainer securely in place by staking the

cylinder metal over both edges of the retainer ends

using a suitable staking tool at right angles to the

top of the retainer and from the cast metal of the

cylinder over the retainer at each corner.

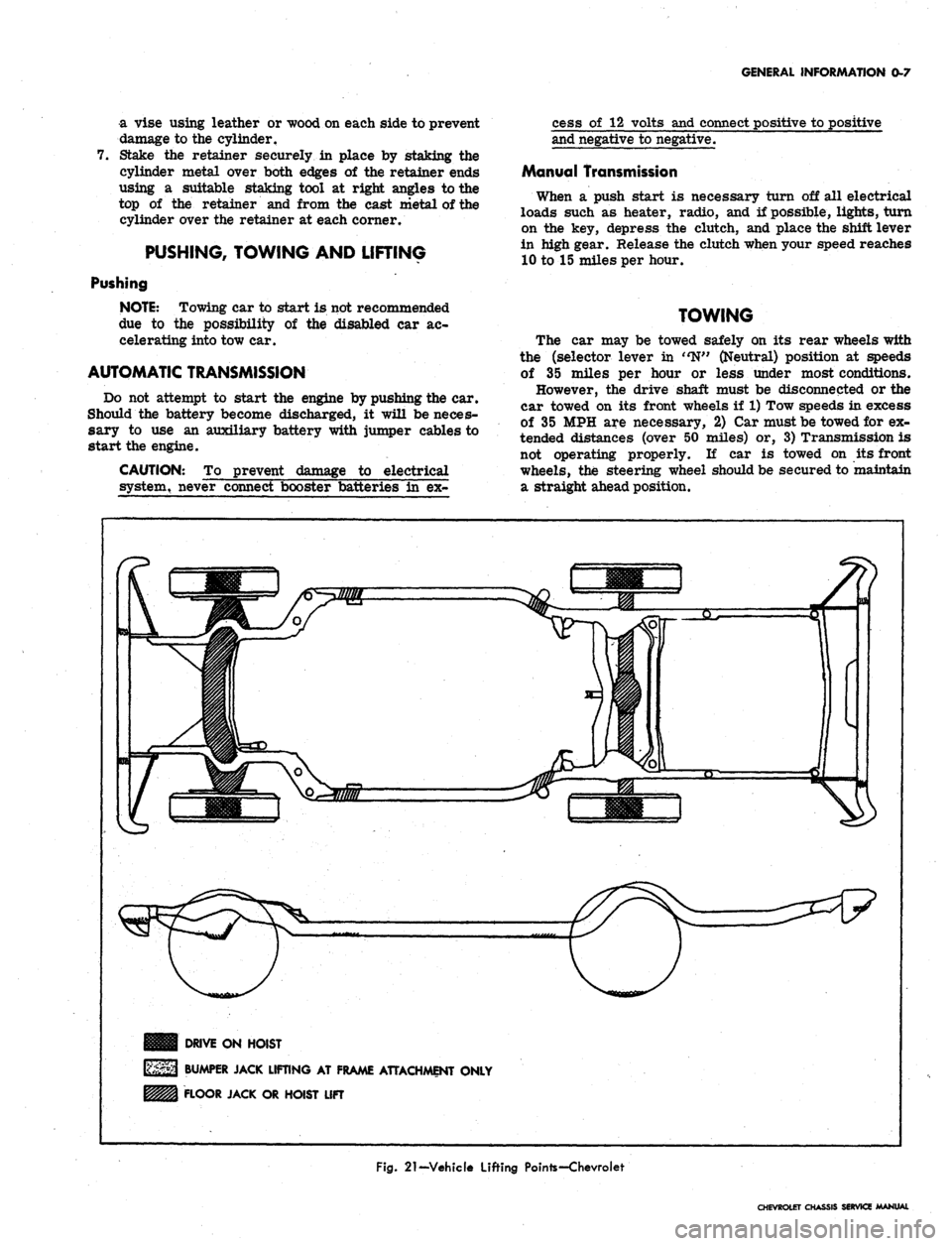

PUSHING, TOWING AND LIFTING

Pushing

NOTE:

Towing car to start is not recommended

due to the possibility of the disabled car ac-

celerating into tow car.

AUTOMATIC TRANSMISSION

Do not attempt to start the engine by pushing the car.

Should the battery become discharged, it will be neces-

sary to use an auxiliary battery with jumper cables to

start the engine.

CAUTION: To prevent damage to electrical

system, never connect booster batteries in ex-

cess of 12 volts and connect positive to positive

and negative to negative.

Manual Transmission

When a push start is necessary turn off all electrical

loads such as heater, radio, and if possible, lights, turn

on the key, depress the clutch, and place the shift lever

in high gear. Release the clutch when your speed reaches

10 to 15 miles per hour.

TOWING

The car may be towed safely on its rear wheels with

the (selector lever in "N" (Neutral) position at speeds

of 35 miles per hour or less under most conditions.

However, the drive shaft must be disconnected or the

car towed on its front wheels if 1) Tow speeds in excess

of 35 MPH are necessary, 2) Car must be towed for ex-

tended distances (over 50 miles) or, 3) Transmission is

not operating properly. If car is towed on its front

wheels, the steering wheel should be secured to maintain

a straight ahead position.

DRIVE ON HOIST

BUMPER JACK LIFTING AT FRAME ATTACHMENT ONLY

FLOOR JACK OR HOIST LIFT

Fig.

21-Vehicle Lifting Pointe-Chevroiet

CHEVROLET CHASSIS SERVICE MANUAL

Page 10 of 659

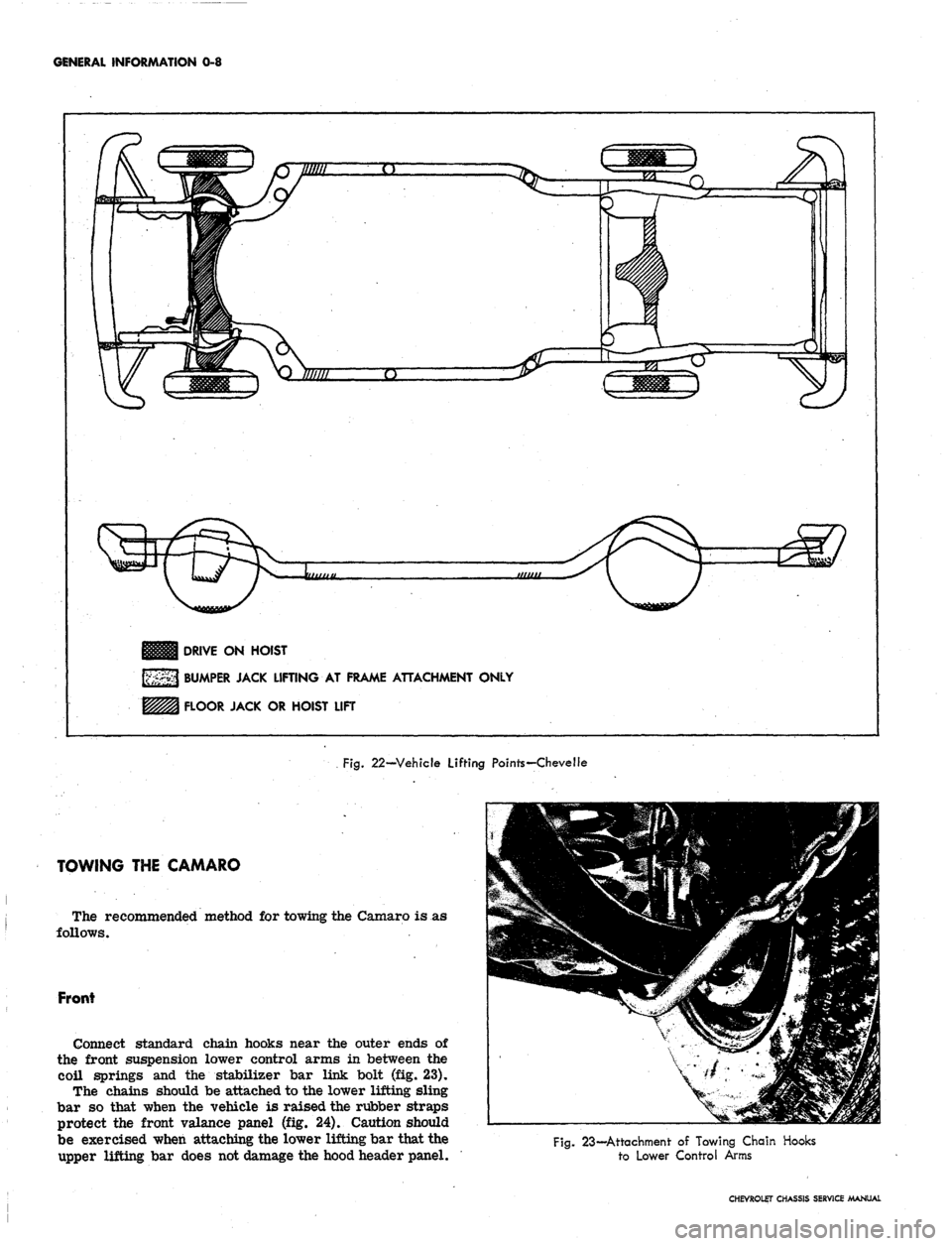

GENERAL INFORMATION 0-8

nun

Illllfl Q

i,,,,,,,,

DRIVE ON HOIST

BUMPER JACK LIFTING AT FRAME ATTACHMENT ONLY

FLOOR JACK OR HOIST LIFT

Fig.

22—Vehicle Lifting Points—Chevelle

TOWING THE CAMARO

The recommended method for towing the Camaro is

follows.

Front

Connect standard chain hooks near the outer ends of

the front suspension lower control arms in between the

coil springs and the stabilizer bar link bolt (fig. 23).

The chains should be attached to the lower lifting sling

bar so that when the vehicle is raised the rubber straps

protect the front valance panel (fig. 24). Caution should

be exercised when attaching the lower lifting bar that the

upper lifting bar does not damage the hood header panel.

Fig. 23—Attachment of Towing Chain Hooks

to Lower Control Arms

CHEVROLET CHASSIS SERVICE MANUAL

Page 11 of 659

GENERAL INFORMATION

0-9

Fig.

25—Attachment

of

Towing Chain Hooks

to

Axle Tube

Fig.

24—Towing Sling Attachment—Front

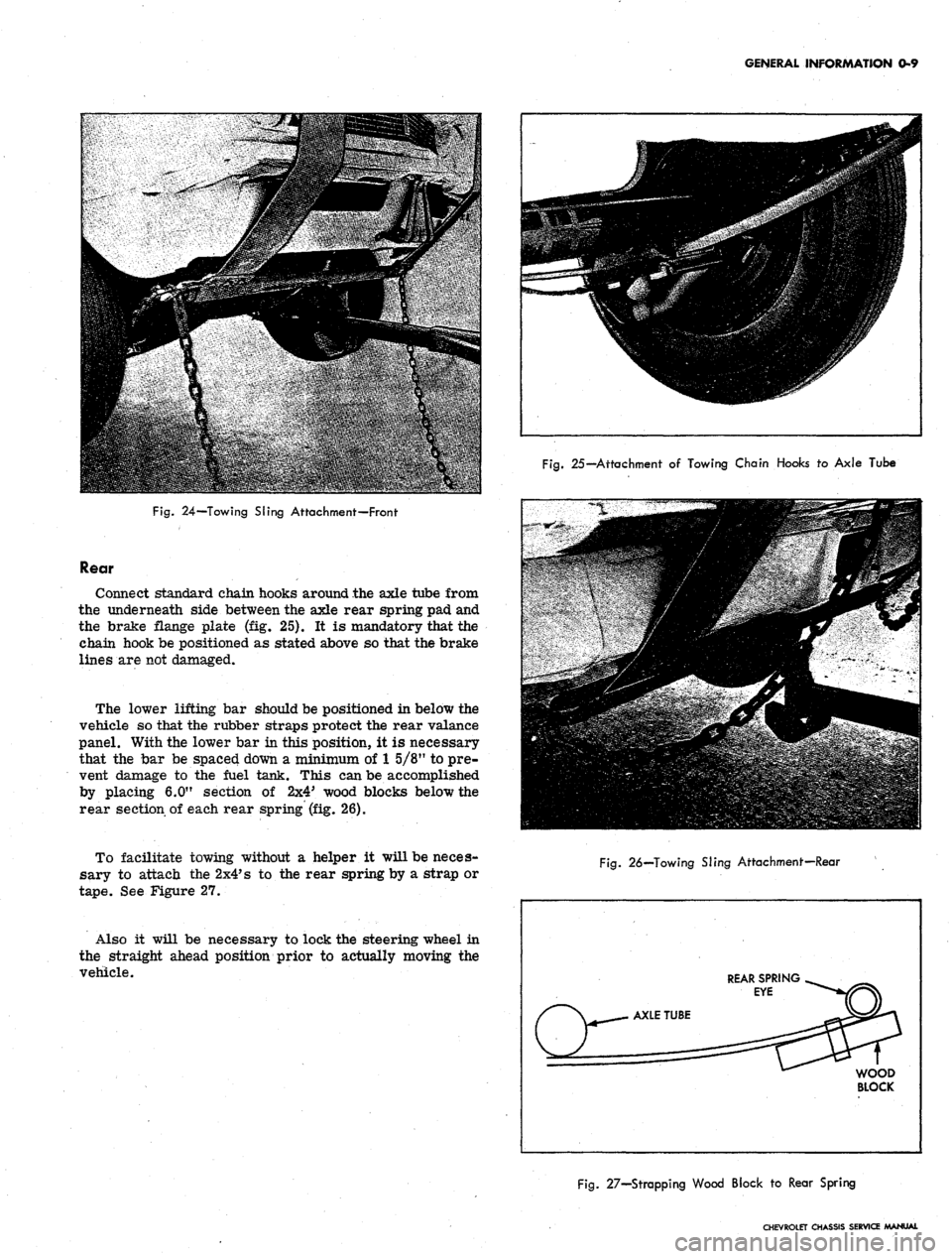

Rear

Connect standard chain hooks around the axle tube from

the underneath side between the axle rear spring pad and

the brake flange plate (fig. 25). It is mandatory that the

chain hook be positioned as stated above so that the brake

lines are not damaged.

The lower lifting bar should be positioned in below the

vehicle so that the rubber straps protect the rear valance

panel. With the lower bar in this position, it is necessary

that the bar be spaced down a minimum of

1

5/8" to pre-

vent damage to the fuel tank. This can be accomplished

by placing 6.0" section of 2x4' wood blocks below the

rear section of each rear spring (fig. 26).

To facilitate towing without a helper it will be neces-

sary to attach the

2x4*

s to the rear spring by a strap or

tape.

See Figure 27.

Also it will be necessary to lock the steering wheel in

the straight ahead position prior to actually moving the

vehicle.

Fig.

26—Towing SJing Attachment—Rear

REAR SPRING

EYE

WOOD

BLOCK

Fig.

27—Strapping Wood Block

to

Rear Spring

CHEVROLET CHASSIS SERVICE MANUAL

Page 12 of 659

GENERAL INFORMATION 0-10

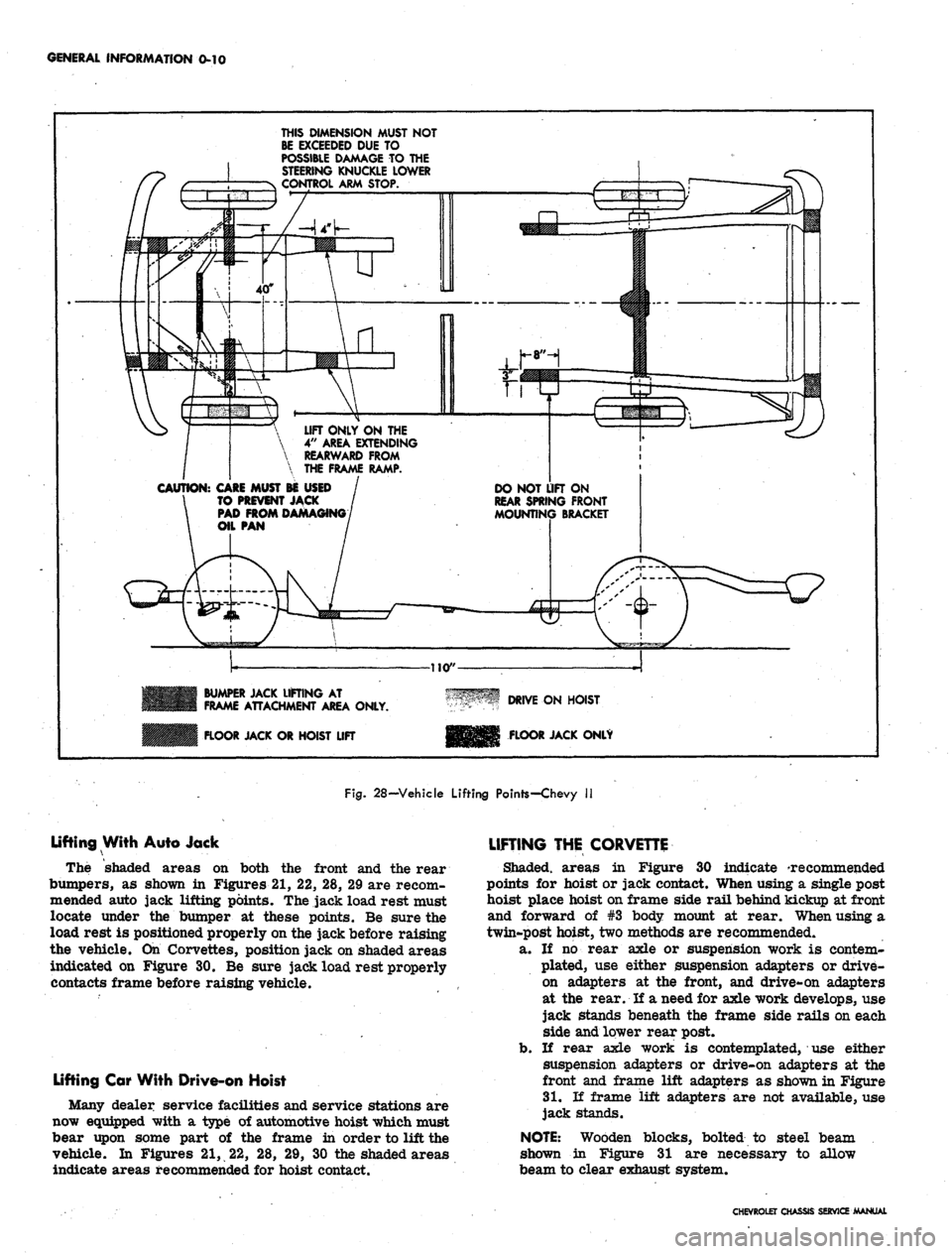

THIS DIMENSION MUST NOT

BE EXCEEDED DUE TO

POSSIBLE DAMAGE TO THE

STEERING KNUCKLE LOWER

CONTROL ARM STOP.

LIFT ONLY ON THE

4"

AREA EXTENDING

REARWARD FROM

THE FRAME RAMP.

CAUTION:

CARE MUST BE USED

TO PREVENT JACK

PAD FROM DAMAGING

DO NOT LIFT ON

REAR SPRING FRONT

MOUNTING BRACKET

BUMPER JACK LIFTING AT

FRAME ATTACHMENT AREA ONLY.

FLOOR JACK OR HOIST LIFT

DRIVE ON HOIST

FLOOR JACK ONLY

Fig.

28-Vehicle Lifting Points-Chevy II

Lifting With Auto Jack

The shaded areas on both the front and the rear

bumpers, as shown in Figures 21, 22, 28, 29 are recom-

mended auto jack lifting points. The jack load rest must

locate under the bumper at these points. Be sure the

load rest is positioned properly on the jack before raising

the vehicle. On Corvettes, position jack on shaded areas

indicated on Figure 30. Be sure jack load rest properly

contacts frame before raising vehicle.

Lifting Car With Drive-on Hoist

Many dealer service facilities and service stations are

now equipped with a type of automotive hoist which must

bear upon some part of the frame in order to lift the

vehicle. In Figures 21, 22, 28, 29, 30 the shaded areas

indicate areas recommended for hoist contact.

LIFTING THE CORVETTE

Shaded, areas in Figure 30 indicate 'recommended

points for hoist or jack contact. When using a single post

hoist place hoist on frame side rail behind kickup at front

and forward of #3 body mount at rear. When using a

twin-post hoist, two methods are recommended.

a. If no rear axle or suspension work is contem-

plated, use either suspension adapters or drive-

on adapters at the front, and drive-on adapters

at the rear. If a need for axle work develops, use

jack stands beneath the frame side rails on each

side and lower rear post.

b.

If rear axle work is contemplated, use either

suspension adapters or drive-on adapters at the

front and frame lift adapters as shown in Figure

31.

If frame lift adapters are not available, use

jack stands.

NOTE:

Wooden blocks, bolted to steel beam

shown in Figure 31 are necessary to allow

beam to clear exhaust system.

CHEVROLET CHASSIS SERVICE MANUAL