fluid CHEVROLET CAMARO 1967 1.G Chassis User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 71 of 659

HEATER AND AIR CONDITIONING 1A-48

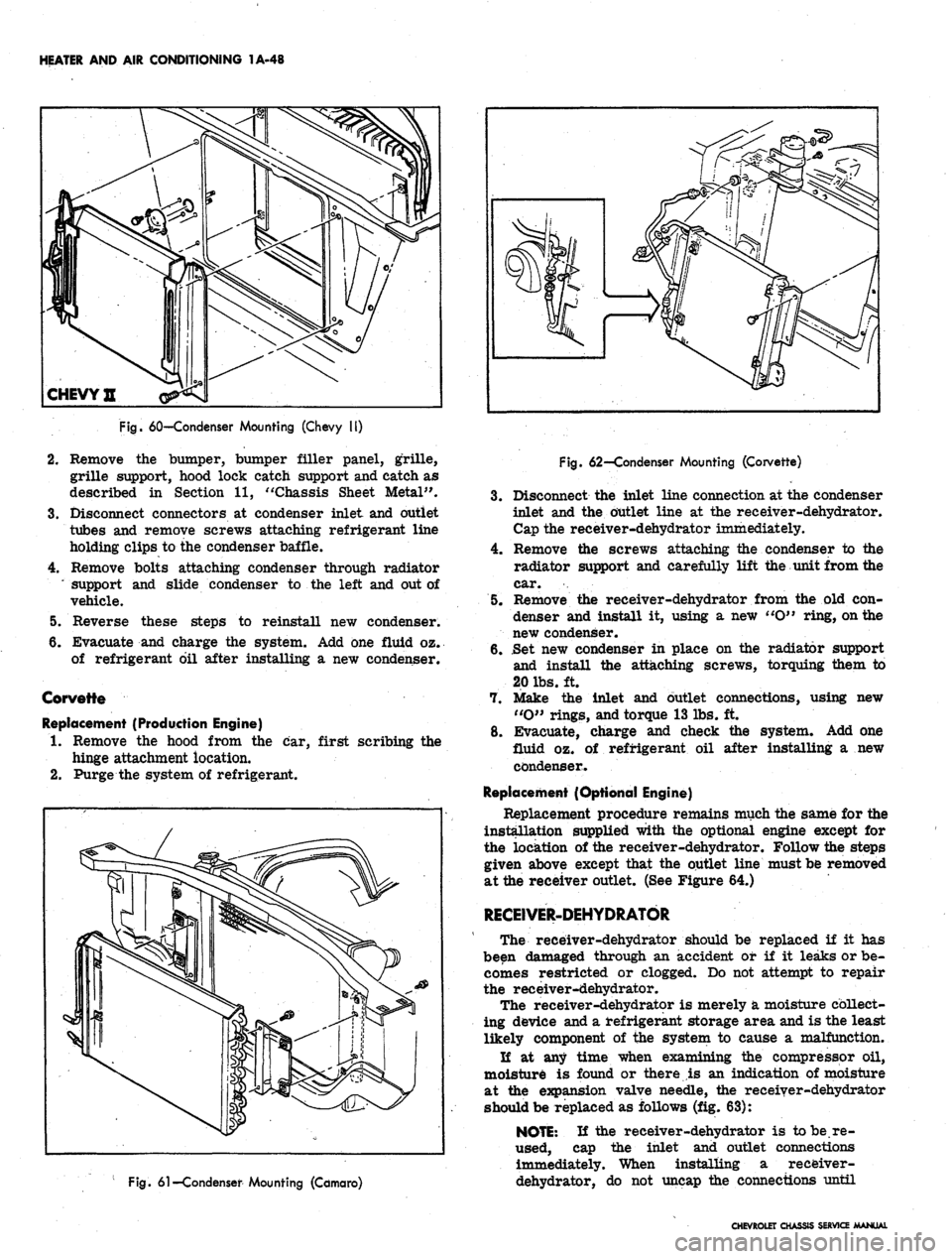

Fig.

60-Condenser Mounting (Chevy II)

2.

Remove the bumper, bumper filler panel, grille,

grille support, hood lock catch support and catch as

described in Section 11, "Chassis Sheet Metal".

3.

Disconnect connectors at condenser inlet and outlet

tubes and remove screws attaching refrigerant line

holding clips to the condenser baffle.

4.

Remove bolts attaching condenser through radiator

' support and slide condenser to the left and out of

vehicle.

5. Reverse these steps to reinstall new condenser.

6. Evacuate and charge the system. Add one fluid oz.

of refrigerant oil after installing a new condenser.

Corvette

Replacement (Production Engine)

1.

Remove the hood from the car, first scribing the

hinge attachment location.

2.

Purge the system of refrigerant.

Fig.

61—Condenser Mounting (Cdrnaro)

Fig.

62—Condenser Mounting (Corvette)

3.

Disconnect the inlet line connection at the condenser

inlet and the outlet line at the receiver-dehydrator.

Cap the receiver-dehydrator immediately.

4.

Remove the screws attaching the condenser to the

radiator support and carefully lift the unit from the

car.

5. Remove the receiver-dehydrator from the old con-

denser and install it, using a new "O" ring, on the

new condenser.

6. Set new condenser in place on the radiator support

and install the attaching screws, torquing them to

20 lbs. ft.

7. Make the inlet and outlet connections, using new

"O"

rings, and torque 13 lbs. ft.

8. Evacuate, charge and check the system. Add one

fluid oz. of refrigerant oil after installing a new

condenser.

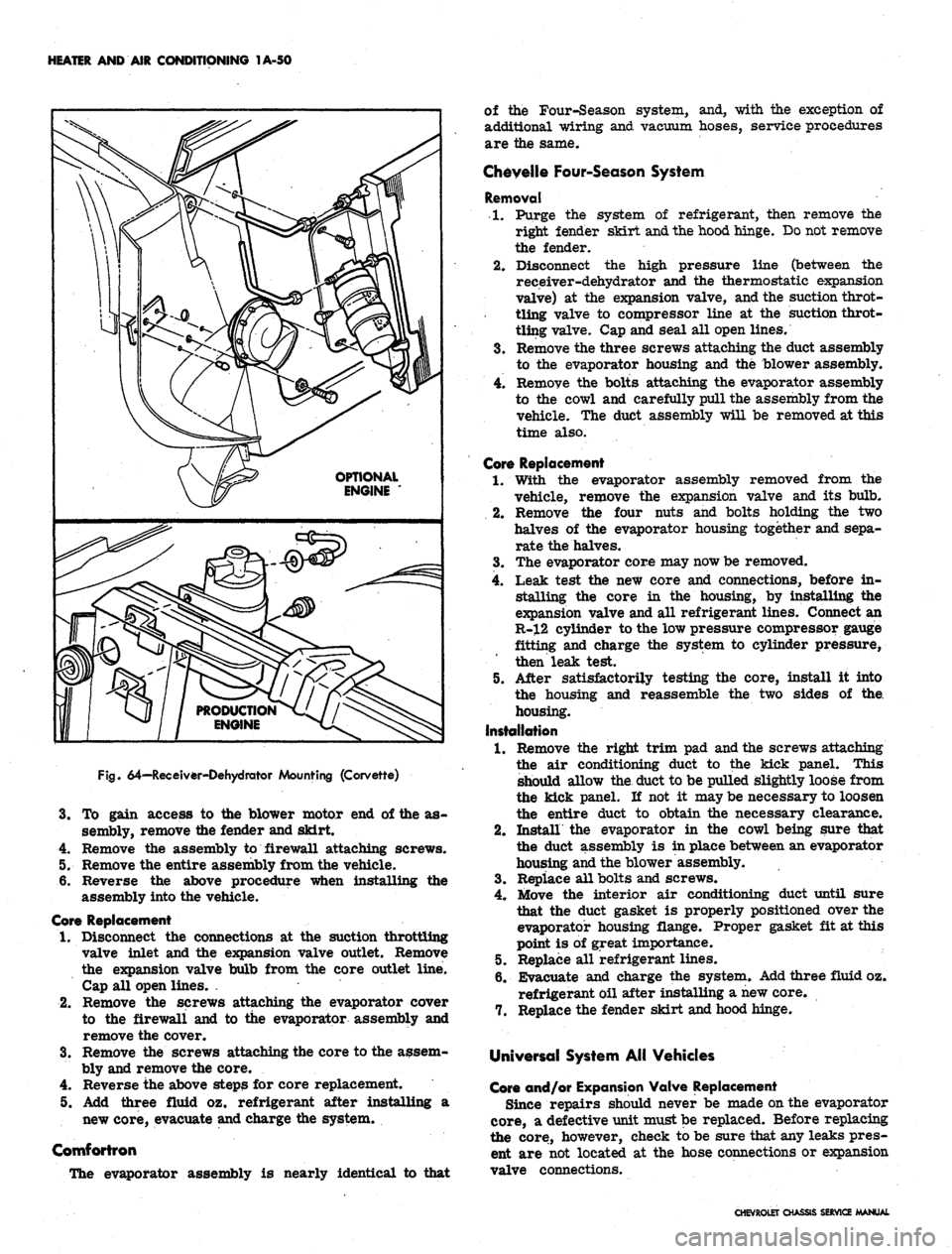

Replacement (Optional Engine)

Replacement procedure remains much the same for the

installation supplied with the optional engine except for

the location of the receiver-dehydrator. Follow the steps

given above except that the outlet line must be removed

at the receiver outlet. (See Figure 64.)

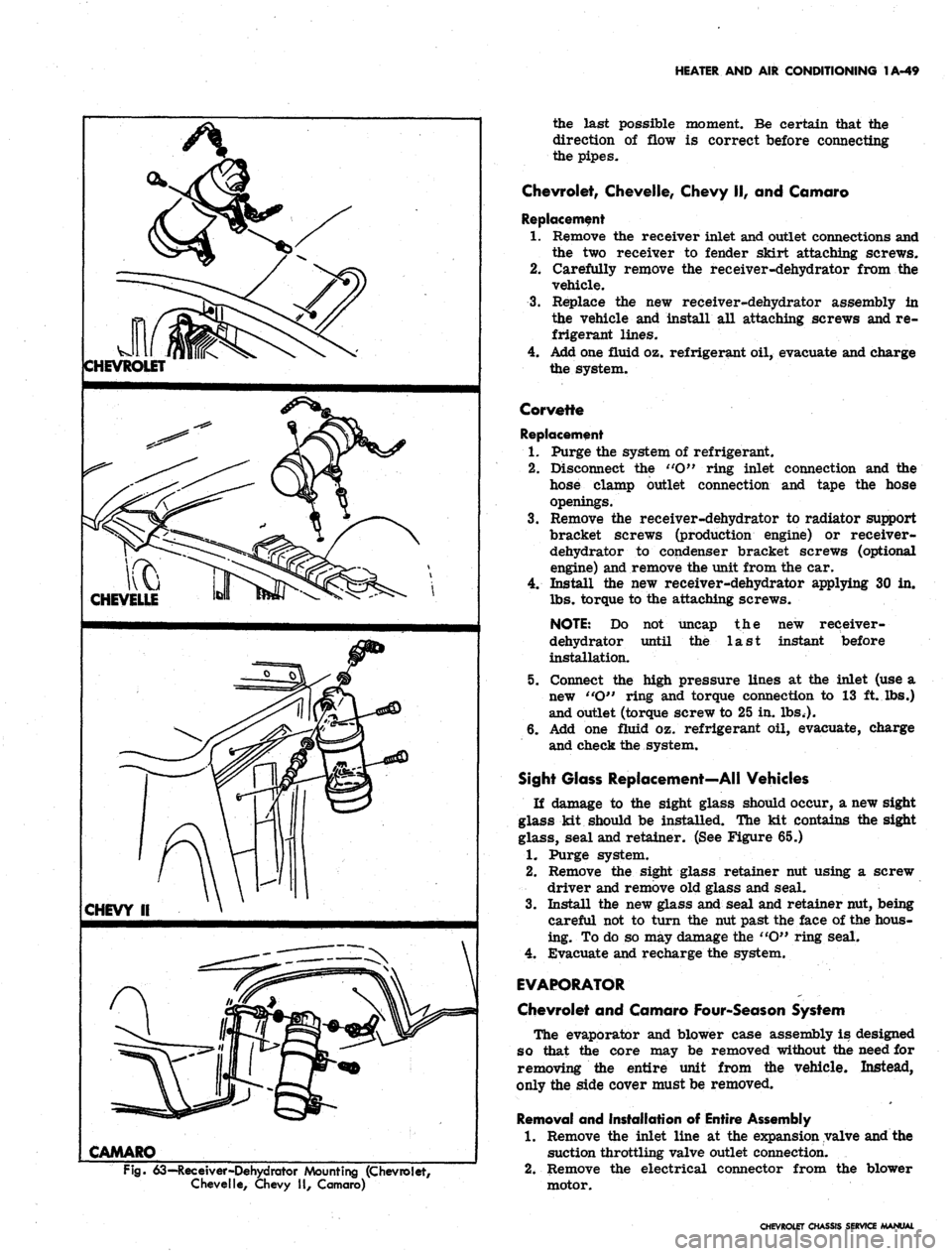

RECEIVER-DEHYDRATOR

The receiver-dehydrator should be replaced if it has

been damaged through an accident or if it leaks or be-

comes restricted or clogged. Do not attempt to repair

the receiver-dehydrator.

The receiver-dehydrator is merely a moisture collect-

ing device and a refrigerant storage area and is the least

likely component of the system to cause a malfunction.

If at any time when examining the compressor oil,

moisture is found or there is an indication of moisture

at the expansion valve needle, the receiver-dehydrator

should be replaced as follows (fig. 63):

NOTE:

If the receiver-dehydrator is to be re-

used, cap the inlet and outlet connections

immediately. When installing a receiver-

dehydrator, do not uncap the connections until

CHEVROLET CHASSIS SERVICE MANUAL

Page 72 of 659

HEATER AND AIR CONDITIONING 1A-49

CHEVROLET

CHEVELLE

CHEVY II

CAMARO

the last possible moment. Be certain that the

direction of flow is correct before connecting

the pipes.

Chevrolet, Chevelle, Chevy II, and Camaro

Replacement

1.

Remove the receiver inlet and outlet connections and

the two receiver to fender skirt attaching screws.

2.

Carefully remove the receiver-dehydrator from the

vehicle.

3.

Replace the new receiver~dehydrator assembly in

the vehicle and install all attaching screws and re-

frigerant lines.

4.

Add one fluid oz. refrigerant oil, evacuate and charge

the system.

Corvette

Replacement

1.

Purge the system of refrigerant.

2.

Disconnect the "O" ring inlet

hose clamp outlet connection

openings.

3.

Remove the receiver-dehydrator to radiator support

bracket screws (production engine) or receiver-

dehydrator to condenser bracket screws (optional

engine) and remove the unit from the car.

4.

Install the new receiver-dehydrator applying 30 in.

lbs.

torque to the attaching screws.

connection and the

and tape the hose

NOTE:

Do not uncap the new receiver-

dehydrator until the last instant before

installation.

5.

2.

3.

Fig.

63—

Receiver-Dehydrator Mounting (Chevrolet,

Chevelle/ Chevy II, Camaro)

Connect the high pressure lines at the inlet (use a

new "O" ring and torque connection to 13 ft. lbs.)

and outlet (torque screw to 25 in. lbs.).

6. Add one fluid oz. refrigerant oil, evacuate, charge

and check the system.

Sight Glass Replacement-All Vehicles

If damage to the sight glass should occur, a new sight

glass kit should be installed. The kit contains the sight

glass,

seal and retainer. (See Figure 65.)

1.

Purge system.

Remove the sight glass retainer nut using a screw

driver and remove old glass and seal.

Install the new glass and seal and retainer nut, being

careful not to turn the nut past the face of the hous-

ing. To do so may damage the "O" ring seal.

4.

Evacuate and recharge the system.

EVAPORATOR

Chevrolet and Camaro Four-Season System

The evaporator and blower case assembly is designed

so that the core may be removed without the need for

removing the entire unit from the vehicle. Instead,

only the side cover must be removed.

Removal and Installation of Entire Assembly

1.

Remove the inlet line at the expansion valve and the

suction throttling valve outlet connection.

2.

Remove the electrical connector from the blower

motor.

CHEVROLET CHASSIS SERVICE MANUAL

Page 73 of 659

HEATER AND AIR CONDITIONING 1A-50

Fig.

64—Receiver-Dehydrator Mounting (Corvette)

3.

4.

5.

6.

To gain access to the blower motor end of the as-

sembly, remove the fender and skirt.

Remove the assembly to firewall attaching screws.

Remove the entire assembly from the vehicle.

Reverse the above procedure when installing the

assembly into the vehicle.

Core Replacement

1.

Disconnect the connections at the suction throttling

valve inlet and the expansion valve outlet. Remove

the expansion valve bulb from the core outlet line.

Cap all open lines. .

Remove the screws attaching the evaporator cover

to the firewall and to the evaporator assembly and

remove the cover.

Remove the screws attaching the core to the assem-

bly and remove the core.

Reverse the above steps for core replacement.

Add three fluid oz. refrigerant after installing a

new core, evacuate and charge the system.

2.

3.

4.

5.

Comfortron

The evaporator assembly is nearly identical to that

of the Four-Season system, and, with the exception of

additional wiring and vacuum hoses, service procedures

are the same.

Chevelle Four-Season System

Removal

•

1.

Purge the system of refrigerant, then remove the

right fender skirt and the hood hinge. Do not remove

the fender.

2.

Disconnect the high pressure line (between the

receiver-dehydrator and the thermostatic expansion

valve) at the expansion valve, and the suction throt-

tling valve to compressor line at the suction throt-

tling valve. Cap and seal all open lines.

3.

Remove the three screws attaching the duct assembly

to the evaporator housing and the blower assembly.

4.

Remove the bolts attaching the evaporator assembly

to the cowl and carefully pull the assembly from the

vehicle. The duct assembly will be removed at this

time also.

Core Replacement

1.

With the evaporator assembly removed from the

vehicle, remove the expansion valve and its bulb.

2.

Remove the four nuts and bolts holding the two

halves of the evaporator housing together and sepa-

rate the halves.

3.

The evaporator core may now be removed.

4.

Leak test the new core and connections, before in-

stalling the core in the housing, by installing the

expansion valve and all refrigerant lines. Connect an

R-12 cylinder to the low pressure compressor gauge

fitting and charge the system to cylinder pressure,

then leak test.

5. After satisfactorily testing the core, install it into

the housing and reassemble the two sides of the.

housing.

Installation

1.

Remove the right trim pad and the screws attaching

the air conditioning duct to the kick panel. This

should allow the duct to be pulled slightly loose from

the kick panel. If not it may be necessary to loosen

the entire duct to obtain the necessary clearance.

2.

Install the evaporator in the cowl being sure that

the duct assembly is in place between an evaporator

housing and the blower assembly.

3.

Replace all bolts and screws.

4.

Move the interior air conditioning duct until sure

that the duct gasket is properly positioned over the

evaporator housing flange. Proper gasket fit at this

point is of great importance.

5. Replace all refrigerant lines.

6. Evacuate and charge the system. Add three fluid oz.

refrigerant oil after installing a new core.

7. Replace the fender skirt and hood hinge.

Universal System All Vehicles

Core and/or Expansion Valve Replacement

Since repairs should never be made on the evaporator

core, a defective unit must be replaced. Before replacing

the core, however, check to be sure that any leaks pres-

ent are not located at the hose connections or expansion

valve connections.

CHEVROLET CHASSIS SERVICE MANUAL

Page 76 of 659

HEATER AND AIR CONDITIONING 1A-53

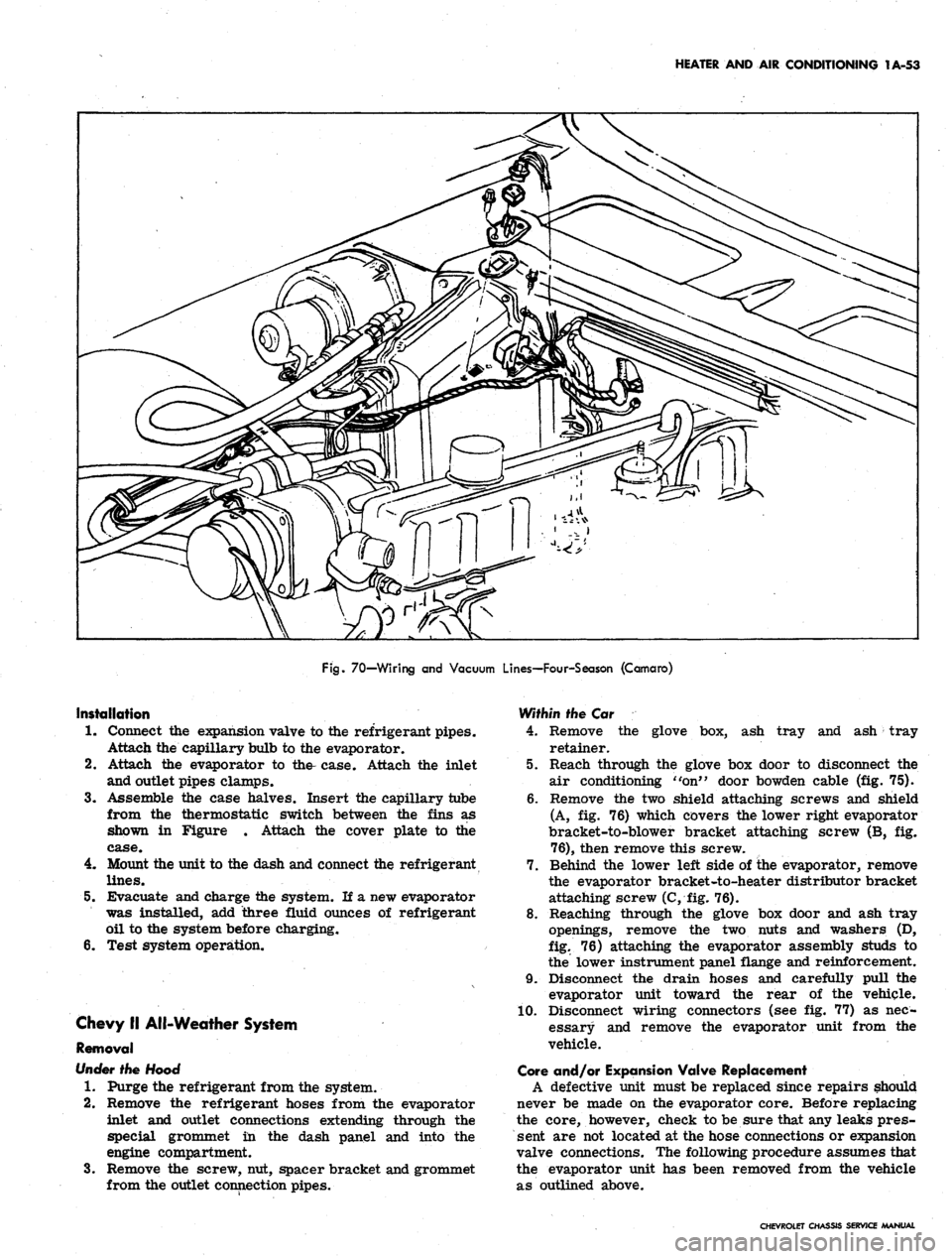

Fig.

70—Wiring and Vacuum Lines—Four-Season (Camaro)

Installation

1.

Connect the expansion valve to the refrigerant pipes.

Attach the capillary bulb to the evaporator.

2.

Attach the evaporator to the- case. Attach the inlet

and outlet pipes clamps.

3.

Assemble the case halves. Insert the capillary tube

from the thermostatic switch between the fins as

shown in Figure . Attach the cover plate to the

case.

4.

Mount the unit to the dash and connect the refrigerant

lines.

5.

Evacuate and charge the system. If a new evaporator

was installed, add three fluid ounces of refrigerant

oil to the system before charging.

6. Test system operation.

Chevy II All-Weather System

Removal

Under

the Hood

1.

Purge the refrigerant from the system.

2.

Remove the refrigerant hoses from the evaporator

inlet and outlet connections extending through the

special grommet in the dash panel and into the

engine compartment.

3.

Remove the screw, nut, spacer bracket and grommet

from the outlet connection pipes.

Within the Car

4.

Remove the glove box, ash tray and ash tray

retainer.

5.

Reach through the glove box door to disconnect the

air conditioning "on" door bowden cable (fig. 75).

6. Remove the two shield attaching screws and shield

(A, fig. 76) which covers the lower right evaporator

bracket-to-blower bracket attaching screw (B, fig.

76),

then remove this screw.

7.

Behind the lower left side of ihe evaporator, remove

the evaporator bracket-to-heater distributor bracket

attaching screw (C, fig. 76).

8. Reaching through the glove box door and ash tray

openings, remove the two nuts and washers (D,

fig.

76) attaching the evaporator assembly studs to

the lower instrument panel flange and reinforcement.

9. Disconnect the drain hoses and carefully pull the

evaporator unit toward the rear of the vehicle.

10.

Disconnect wiring connectors (see fig. 77) as nec-

essary and remove the evaporator unit from the

vehicle.

Gore and/or Expansion Valve Replacement

A defective unit must be replaced since repairs should

never be made on the evaporator core. Before replacing

the core, however, check to be sure that any leaks pres-

sent are not located at the hose connections or expansion

valve connections. The following procedure assumes that

the evaporator unit has been removed from the vehicle

as outlined above.

CHEVROLET CHASSIS SERVICE MANUAL

Page 79 of 659

HEATER AND AIR CONDITIONING 1A-56

BLACK & RED

IGNITION—-y^****

SWITCH -"A

/

BLOWER LEAD—^^^

RESISTOR—-" \^<

ASM.

f'

i

'fu^^^^A^^^^^r"G^OUH£>

WIRE

^^

k4

^EVAPORATOR HARNESS

' EVAPORATOR & BLOWER ASM.

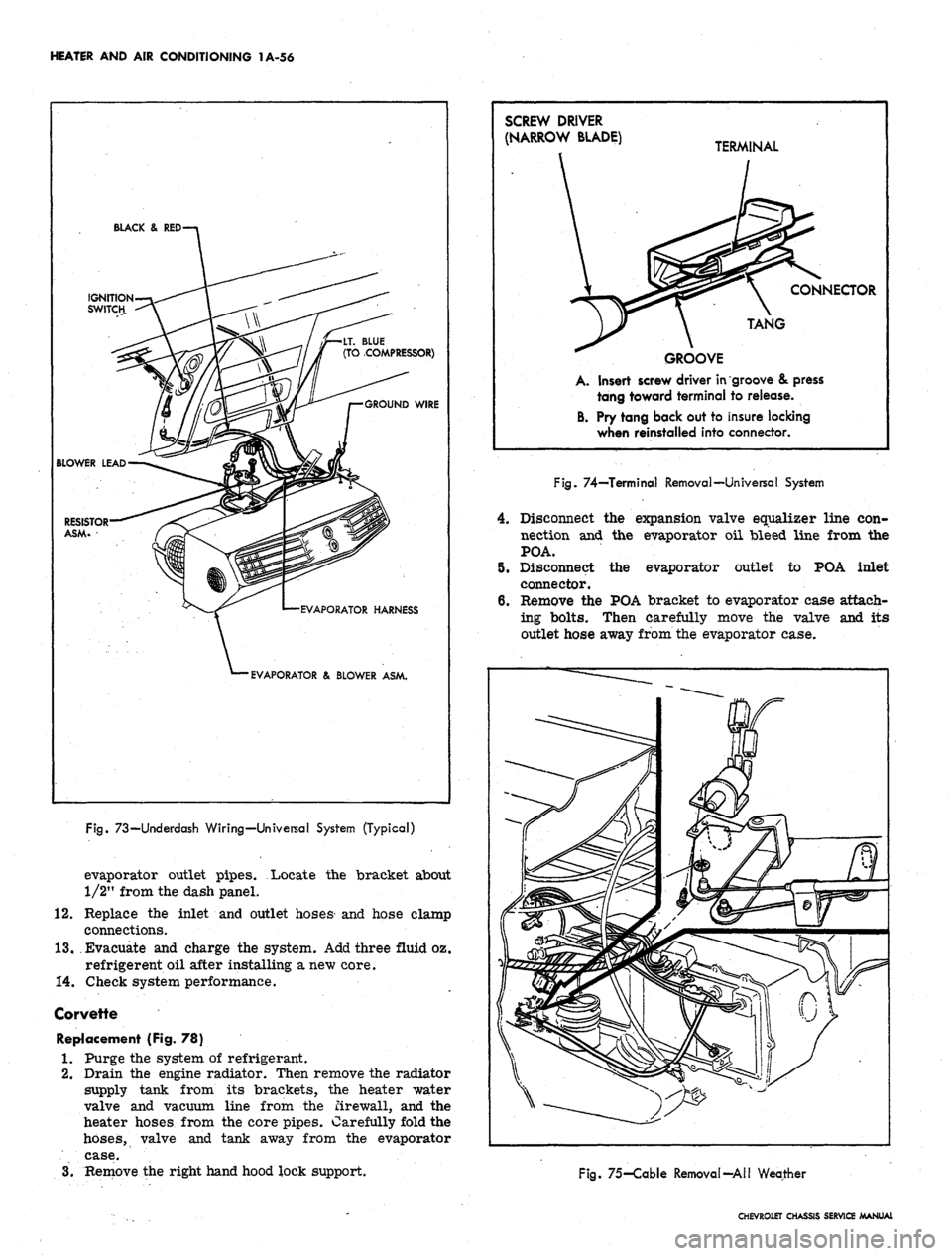

Fig.

73—Underdash Wiring—Universal System (Typical)

evaporator outlet pipes. Locate the bracket about

1/2" from the dash panel.

12.

Replace the inlet and outlet hoses and hose clamp

connections.

13.

Evacuate and charge the system. Add three fluid oz.

refrigerent oil after installing a new core.

14.

Check system performance.

Corvette

Replacement (Fig. 78)

1.

Purge the system of refrigerant.

2.

Drain the engine radiator. Then remove the radiator

supply tank from its brackets, the heater water

valve and vacuum line from the firewall, and the

heater hoses from the core pipes. Carefully fold the

hoses,

valve and tank away from the evaporator

case.

3.

Remove the right hand hood lock support.

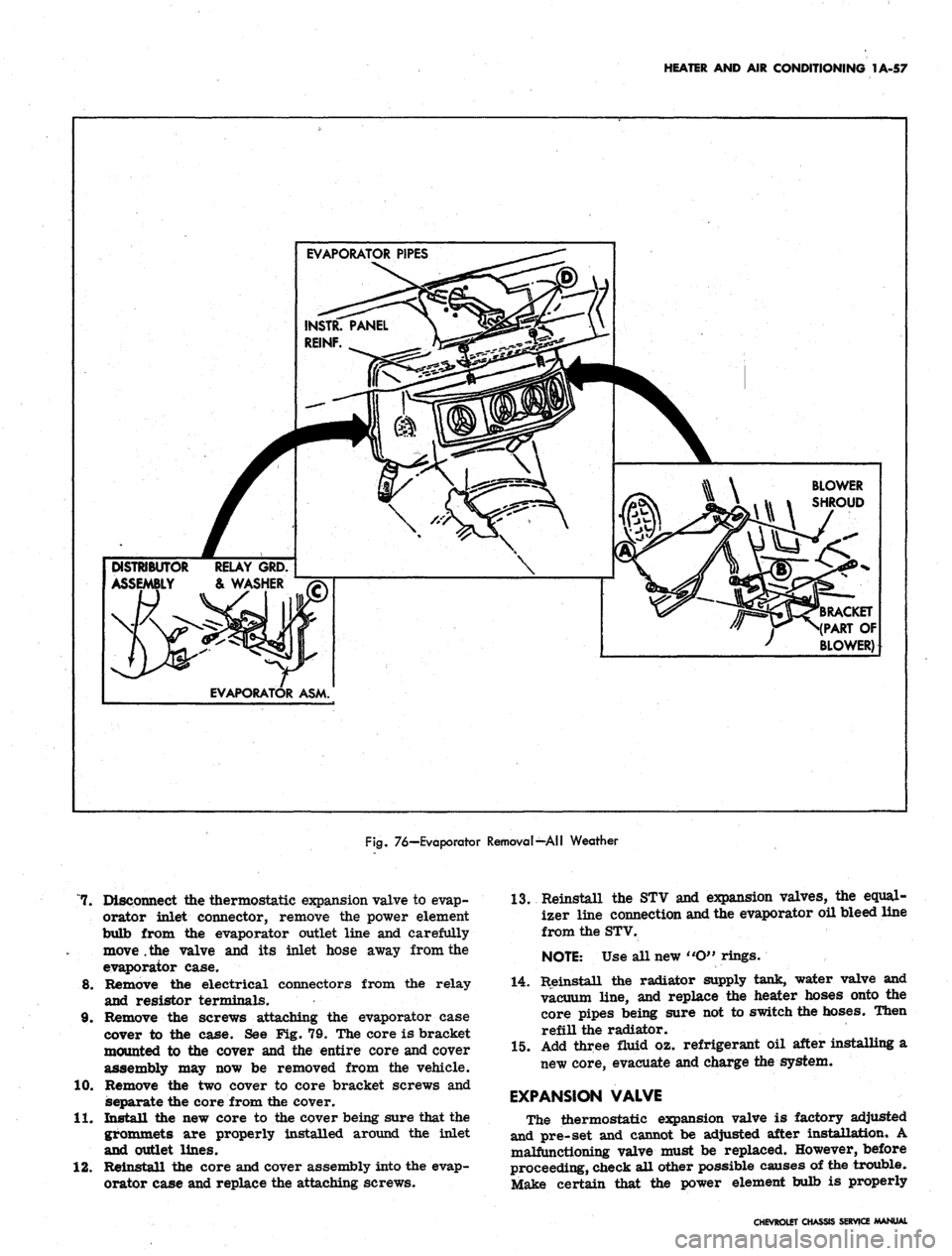

SCREW DRIVER

(NARROW BLADE) T£

GROOVE

A. Insert screw driver in

tang toward terminal

B. Pry tang back out to

when reinstalled into

RMINAL

\ CONNECTOR

TANG

groove & press

to release.

insure locking

connector.

Fig.

74—Terminal Removal—Universal System

4.

Disconnect the expansion valve equalizer line con-

nection and the evaporator oil bleed line from the

POA.

5.

Disconnect the evaporator outlet to POA inlet

connector.

6. Remove the POA bracket to evaporator case attach-

ing bolts. Then carefully move the valve and its

outlet hose away from the evaporator case.

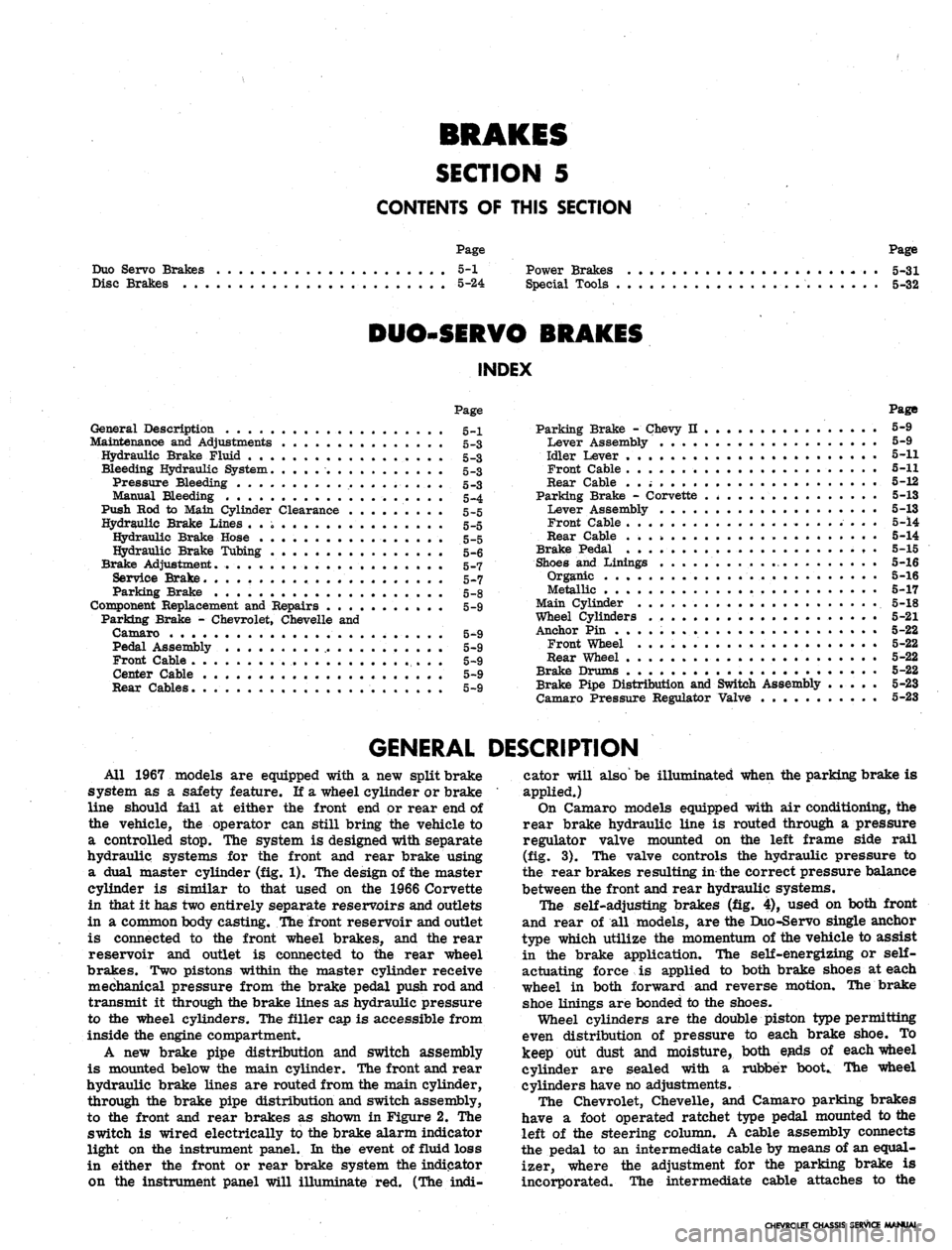

Fig.

75-Cable Removal-All Weather

CHEVROLET CHASSIS SERVICE MANUAL

Page 80 of 659

HEATER AND AIR CONDITIONING 1A-57

EVAPORATOR PIPES

DISTRIBUTOR RELAY GRD.

ASSEMBLY & WASHER

EVAPORATOR ASM.

BLOWER

SHROUD

(RACKET

(PART OF

BLOWER)

Fig.

76—Evaporator Removal—All Weather

7. Disconnect the thermostatic expansion valve to evap-

orator inlet connector, remove the power element

bulb from the evaporator outlet line and carefully

move .the valve and its inlet hose away from the

evaporator case.

8. Remove the electrical connectors from the relay

and resistor terminals.

9. Remove the screws attaching the evaporator case

cover to the case. See Fig. 79. The core is bracket

mounted to the cover and the entire core and cover

assembly may now be removed from the vehicle.

10.

Remove the two cover to core bracket screws and

separate the core from the cover.

11.

Install the new core to the cover being sure that the

grommets are properly installed around the inlet

and outlet lines.

12.

Reinstall the core and cover assembly into the evap-

orator case and replace the attaching screws.

13.

Reinstall the STV and expansion valves, the equal-

izer line connection and the evaporator oil bleed line

from the STV.

NOTE:

Use all new «O" rings.

14.

Reinstall the radiator supply tank, water valve and

vacuum line, and replace the heater hoses onto the

core pipes being sure not to switch the hoses. Then

refill the radiator.

15.

Add three fluid oz. refrigerant oil after installing a

new core, evacuate and charge the system.

EXPANSION VALVE

The thermostatic expansion valve is factory adjusted

and pre-set and cannot be adjusted after installation. A

malfunctioning valve must be replaced. However, before

proceeding, check all other possible causes of the trouble.

Make certain that the power element bulb is properly

CHEVROLET CHASSIS SERVICE MANUAL

Page 234 of 659

BRAKES

SECTION 5

CONTENTS OF THIS SECTION

Duo Servo Brakes

Disc Brakes

Page

5-1 Power Brakes

5-24 Special Tools

Page

5-31

5-32

DUO-SERVO BRAKES

INDEX

Page

General Description 5-1

Maintenance and Adjustments 5-3

Hydraulic Brake Fluid .. . 5-3

Bleeding Hydraulic System 5-3

Pressure Bleeding 5-3

Manual Bleeding 5_4

Push Rod to Main Cylinder Clearance 5-5

Hydraulic Brake Lines 5-5

Hydraulic Brake Hose 5-5

Hydraulic Brake Tubing 5-6

Brake Adjustment. .................... 5-7

Service Brake 5-7

Parking Brake 5-8

Component Replacement and Repairs 5-9

Parking Brake - Chevrolet, Chevelle and

Camaro 5^9

Pedal Assembly 5-9

Front Cable ,. . . 5-9

Center Cable 5-9

Rear Cables. . 5-9

Parking Brake - Chevy n 5-9

Lever Assembly 5-9

Idler Lever 5-11

Front Cable 5-11

Rear Cable . . ; 5-12

Parking Brake - Corvette 5-13

Lever Assembly . . . . 5-13

Front Cable 5-14

Rear Cable . . 5-14

Brake Pedal 5-15

Shoes and Linings 5-16

Organic 5-16

Metallic 5-17

Main Cylinder 5-18

Wheel Cylinders 5-21

Anchor Pin 5-22

Front Wheel 5-22

Rear Wheel 5-22

Brake Drums • 5-22

Brake Pipe Distribution and Switch Assembly . . . . . 5-23

Camaro Pressure Regulator Valve 5-23

GENERAL DESCRIPTION

All 1967 models are equipped with a new split brake

system as a safety feature. If a wheel cylinder or brake

line should fail at either the front end or rear end of

the vehicle, the operator can still bring the vehicle to

a controlled stop. The system is designed with separate

hydraulic systems for the front and rear brake using

a dual master cylinder (fig. 1). The design of the master

cylinder is similar to that used on the 1966 Corvette

in that it has two entirely separate reservoirs and outlets

in a common body casting. The front reservoir and outlet

is connected to the front wheel brakes, and the rear

reservoir and outlet is connected to the rear wheel

brakes. Two pistons within the master cylinder receive

mechanical pressure from the brake pedal push rod and

transmit it through the brake lines as hydraulic pressure

to the wheel cylinders. The filler cap is accessible from

inside the engine compartment.

A new brake pipe distribution and switch assembly

is mounted below the main cylinder. The front and rear

hydraulic brake lines are routed from the main cylinder,

through the brake pipe distribution and switch assembly,

to the front and rear brakes as shown in Figure 2. The

switch is wired electrically to the brake alarm indicator

light on the instrument panel. In the event of fluid loss

in either the front or rear brake system the indicator

on the instrument panel will illuminate red. (The indi-

cator will also' be illuminated when the parking brake is

applied.)

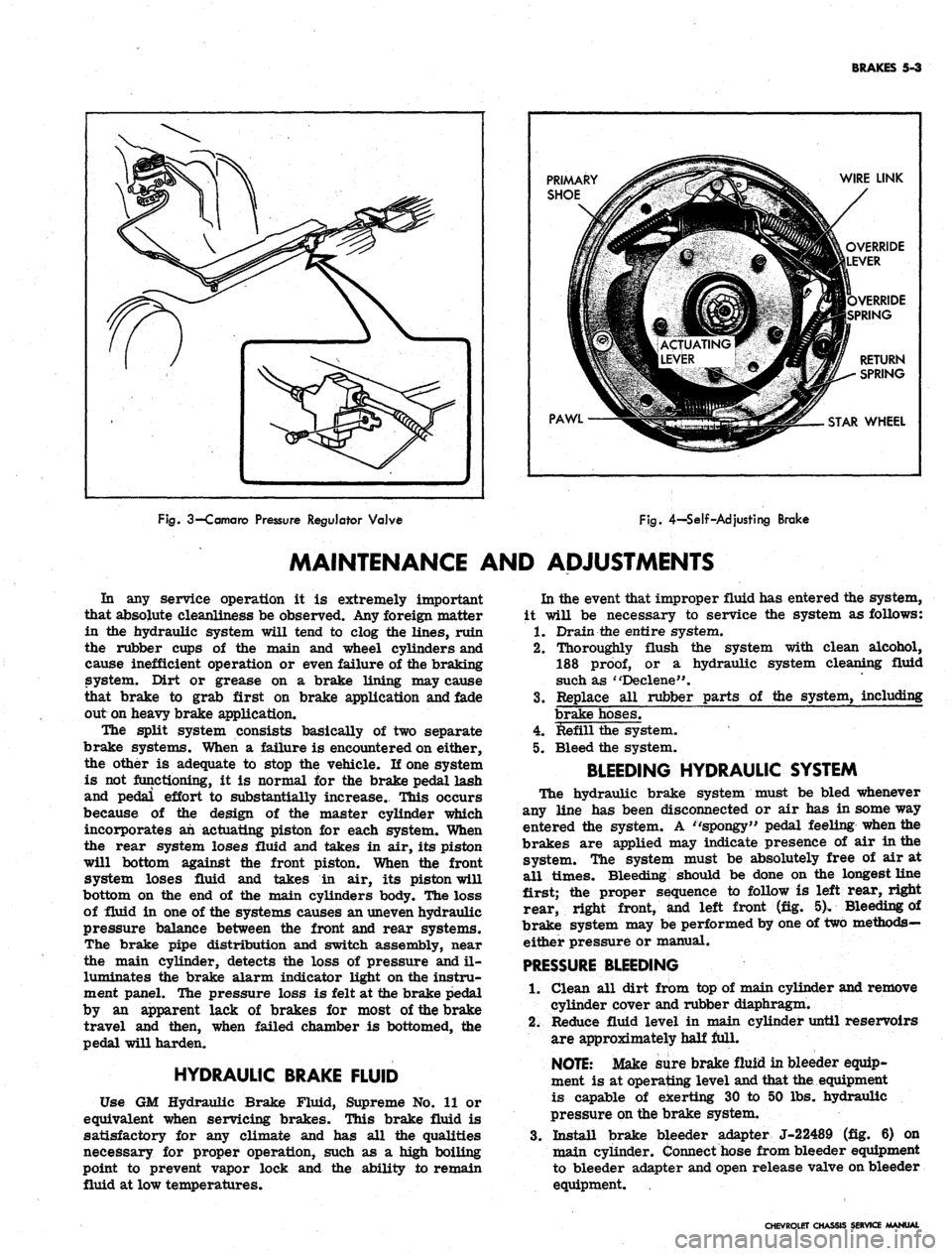

On Camaro models equipped with air conditioning, the

rear brake hydraulic line is routed through a pressure

regulator valve mounted on the left frame side rail

(fig. 3). The valve controls the hydraulic pressure to

the rear brakes resulting in the correct pressure balance

between the front and rear hydraulic systems.

The self-adjusting brakes (fig. 4), used on both front

and rear of all models, are the Duo-Servo single anchor

type which utilize the momentum of the vehicle to assist

in the brake application. The self-energizing or

self-

actuating force is applied to both brake shoes at each

wheel in both forward and reverse motion. The brake

shoe linings are bonded to the shoes.

Wheel cylinders are the double piston type permitting

even distribution of pressure to each brake shoe. To

keep out dust and moisture, both ejads of each wheel

cylinder are sealed with a rubber booC The wheel

cylinders have no adjustments.

The Chevrolet, Chevelle, and Camaro parking brakes

have a foot operated ratchet type pedal mounted to the

left of the steering column. A cable assembly connects

the pedal to an intermediate cable by means of an equal-

izer, where the adjustment for the parking brake is

incorporated. The intermediate cable attaches to the

CHEVROLET CHASSIS SERVICE MANUAL

Page 236 of 659

BRAKES

5-3

PRIMARY

SHOE

PAWL

WIRE LINK

OVERRIDE

LEVER

VERRIDE

SPRING

RETURN

SPRING

STAR

WHEEL

Fig.

3—Camaro

Pressure

Regulator

Valve

Fig.

4-Self-Adjusting

Brake

MAINTENANCE AND ADJUSTMENTS

In any service operation it is extremely important

that absolute cleanliness be observed. Any foreign matter

in the hydraulic system will tend to clog the lines, ruin

the rubber cups of the main and wheel cylinders and

cause inefficient operation or even failure of the braking

system. Dirt or grease on a brake lining may cause

that brake to grab first on brake application and fade

out on heavy brake application.

The split system consists basically of two separate

brake systems. When a failure is encountered on either,

the other is adequate to stop the vehicle. If one system

is not functioning, it is normal for the brake pedal lash

and pedal effort to substantially increase. This occurs

because of the design of the master cylinder which

incorporates ah actuating piston for each system. When

the rear system loses fluid and takes in air, its piston

will bottom against the front piston. When the front

system loses fluid and takes in air, its piston will

bottom on the end of the main cylinders body. The loss

of fluid in one of the systems causes an uneven hydraulic

pressure balance between the front and rear systems.

The brake pipe distribution and switch assembly, near

the main cylinder, detects the loss of pressure and il-

luminates the brake alarm indicator light on the instru-

ment panel. The pressure loss is felt at the brake pedal

by an apparent lack of brakes for most of the brake

travel and then, when failed chamber is bottomed, the

pedal will harden.

HYDRAULIC BRAKE FLUID

Use GM Hydraulic Brake Fluid, Supreme No. 11 or

equivalent when servicing brakes. This brake fluid is

satisfactory for any climate and has all the qualities

necessary for proper operation, such as a high boiling

point to prevent vapor lock and the ability to remain

fluid at low temperatures.

In the event that improper fluid has entered the system,

it will be necessary to service the system as follows:

1.

Drain the entire system.

2.

Thoroughly flush the system with clean alcohol,

188

proof,

or a hydraulic system cleaning fluid

such as "Declene".

3.

Replace all rubber parts of the system, including

brake hoses.

4.

Refill the system.

5. Bleed the system.

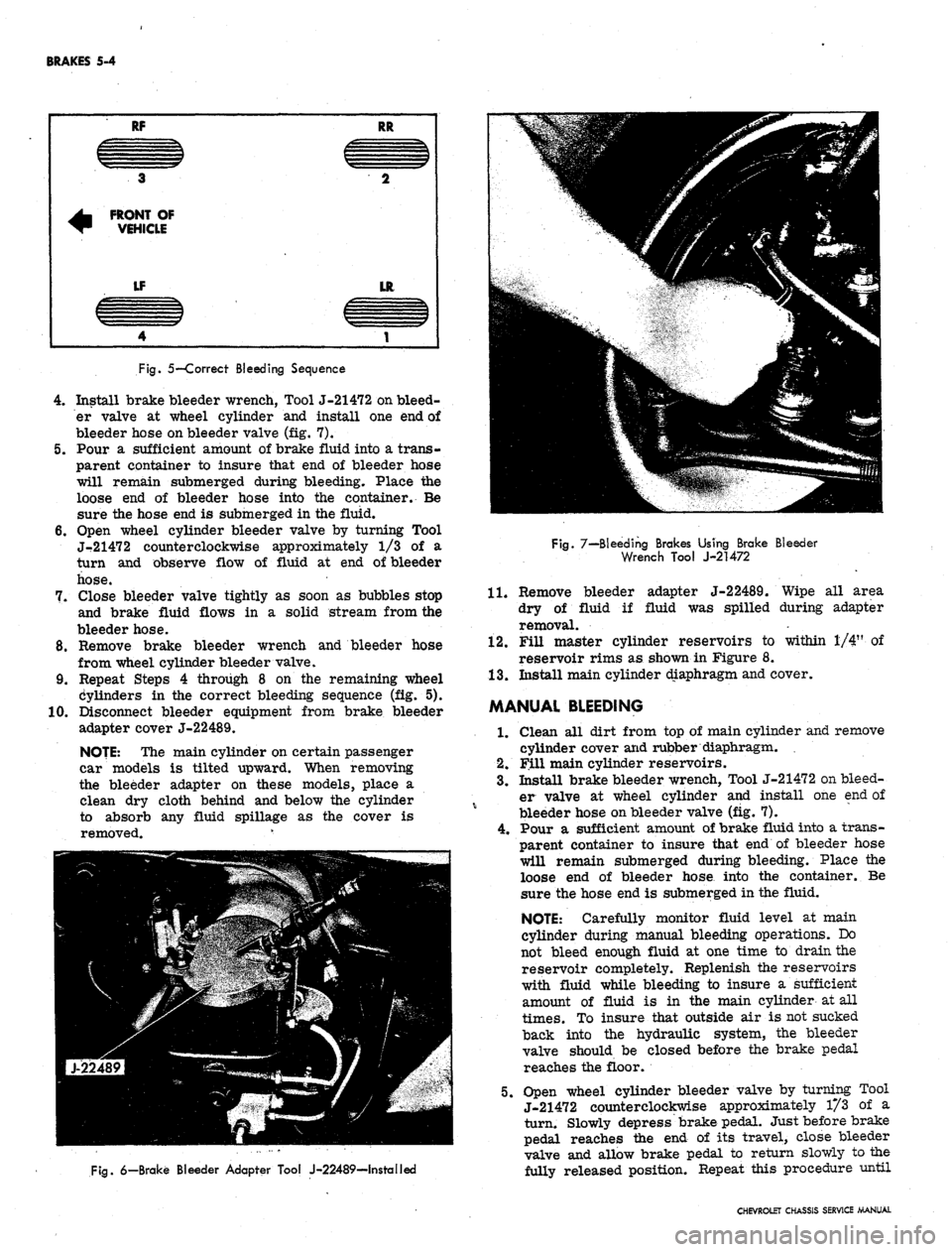

BLEEDING HYDRAULIC SYSTEM

The hydraulic brake system must be bled whenever

any line has been disconnected or air has in some way

entered the system. A ''spongy" pedal feeling when the

brakes are applied may indicate presence of air in the

system. The system must be absolutely free of air at

all times. Bleeding should be done on the longest line

first; the proper sequence to follow is left rear, right

rear, right front, and left front (fig. 5). Bleeding of

brake system may be performed by one of two methods—

either pressure or manual.

PRESSURE

BLEEDING

1.

Clean all dirt from top of main cylinder and remove

cylinder cover and rubber diaphragm.

2.

Reduce fluid level in main cylinder until reservoirs

are approximately half full.

NOTE:

Make sure brake fluid in bleeder equip-

ment is at operating level and that the. equipment

is capable of exerting 30 to 50 lbs. hydraulic

pressure on the brake system.

3.

Install brake bleeder adapter J-22489 (fig. 6) on

main cylinder. Connect hose from bleeder equipment

to bleeder adapter and open release valve on bleeder

equipment.

CHEVROLET CHASSIS SERVICE MANUAL

Page 237 of 659

BRAKES 5-4

RF

3

^ FRONT OF

~ VEHICLE

LF

4

RR

CZZZIZ3

2

LR

1

Fig.

5—Correct Bleeding Sequence

4.

Install brake bleeder wrench, Tool J-21472 on bleed-

er valve at wheel cylinder and install one end of

bleeder hose on bleeder valve (fig. 7).

5.

Pour a sufficient amount of brake fluid into a trans-

parent container to insure that end of bleeder hose

will remain submerged during bleeding. Place the

loose end of bleeder hose into the container. Be

sure the hose end is submerged in the fluid.

6. Open wheel cylinder bleeder valve by turning Tool

J-21472 counterclockwise approximately 1/3 of a

turn and observe flow of fluid at end of bleeder

hose.

7.

Close bleeder valve tightly as soon as bubbles stop

and brake fluid flows in a solid stream from the

bleeder hose.

8. Remove brake bleeder wrench and bleeder hose

from wheel cylinder bleeder valve.

9. Repeat Steps 4 through 8 on the remaining wheel

Cylinders in the correct bleeding sequence (fig. 5).

10.

Disconnect bleeder equipment from brake bleeder

adapter cover J-22489.

NOJE: The main cylinder on certain passenger

car models is tilted upward. When removing

the bleeder adapter on these models, place a

clean dry cloth behind and below the cylinder

to absorb any fluid spillage as the cover is

removed. v

Fig.

7—Bleeding Brakes Using Brake Bleeder

Wrench Tool J-21472

11.

adapter J-22489. Wipe all area

fluid was spilled during adapter

Fig.

6—Brake Bleeder Adapter Tool J-22489—Installed

Remove bleeder

dry of fluid if

removal.

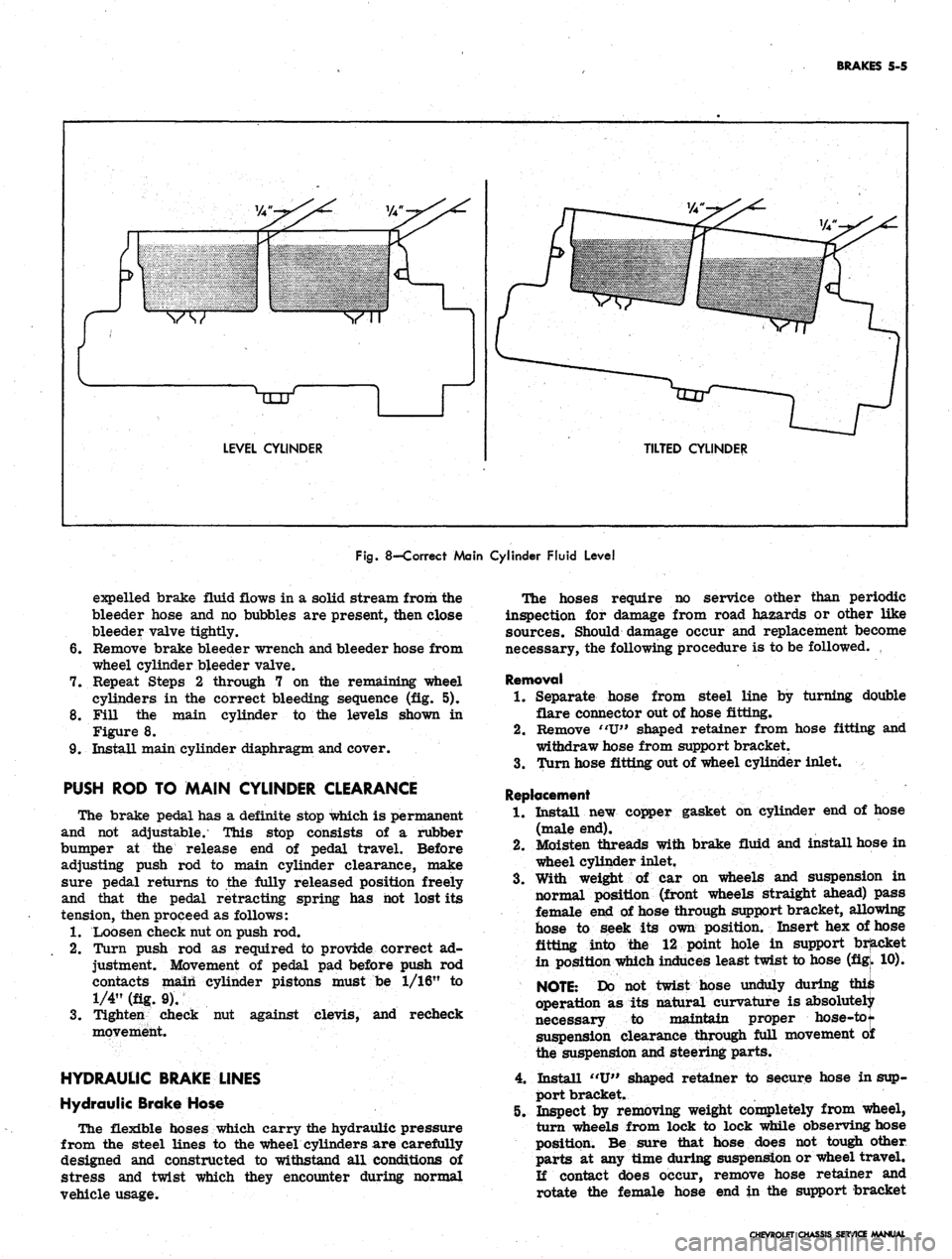

12.

Fill master cylinder reservoirs to within 1/4" of

reservoir rims as shown in Figure 8.

13.

Install main cylinder diaphragm and cover.

MANUAL BLEEDING

1.

Clean all dirt from top of main cylinder and remove

cylinder cover and rubber diaphragm.

2.

Fill main cylinder reservoirs.

3.

Install brake bleeder wrench, Tool J-21472 on bleed-

er valve at wheel cylinder and install one end of

bleeder hose on bleeder valve (fig. 7).

4.

Pour a sufficient amount of brake fluid into a trans-

parent container to insure that end of bleeder hose

will remain submerged during bleeding. Place the

loose end of bleeder hose into the container. Be

sure the hose end is submerged in the fluid.

NOTE: Carefully monitor fluid level at main

cylinder during manual bleeding operations. Do

not bleed enough fluid at one time to drain the

reservoir completely. Replenish the reservoirs

with fluid while bleeding to insure a sufficient

amount of fluid is in the main cylinder at all

times.

To insure that outside air is not sucked

back into the hydraulic system, the bleeder

valve should be closed before the brake pedal

reaches the floor.

5.

Open wheel cylinder bleeder valve by turning Tool

J-21472 counterclockwise approximately 1/3 of a

turn. Slowly depress brake pedal. Just before brake

pedal reaches the end of its travel, close bleeder

valve and allow brake pedal to return slowly to the

fully released position. Repeat this procedure until

CHEVROLET CHASSIS SERVICE MANUAL

Page 238 of 659

BRAKES 5-5

LEVEL CYLINDER

TILTED CYLINDER

Fig.

8—Correct Main Cylinder Fluid Level

expelled brake fluid flows in a solid stream from the

bleeder hose and no bubbles are present, then close

bleeder valve tightly.

6. Remove brake bleeder wrench and bleeder hose from

wheel cylinder bleeder valve.

7. Repeat Steps 2 through 7 on the remaining wheel

cylinders in the correct bleeding sequence (fig. 5).

8. Fill the main cylinder to the levels shown in

Figure 8.

9. Install main cylinder diaphragm and cover.

PUSH ROD TO MAIN CYLINDER CLEARANCE

The brake pedal has a definite stop which is permanent

and not adjustable. This stop consists of a rubber

bumper at the release end of pedal travel. Before

adjusting push rod to main cylinder clearance, make

sure pedal returns to the fully released position freely

and that the pedal retracting spring has hot lost its

tension, then proceed as follows:

1.

Loosen check nut on push rod.

2.

Turn push rod as required to provide correct ad-

justment. Movement of pedal pad before push rod

contacts main cylinder pistons must be 1/16" to

1/4" (fig. 9).

3.

Tighten check nut against clevis, and recheck

movement.

HYDRAULIC BRAKE LINES

Hydraulic Brake Hose

The flexible hoses which carry the hydraulic pressure

from the steel lines to the wheel cylinders are carefully

designed and constructed to withstand all conditions of

stress and twist which they encounter during normal

vehicle usage.

The hoses require no service other than periodic

inspection for damage from road hazards or other like

sources. Should damage occur and replacement become

necessary, the following procedure is to be followed.

Removal

1.

Separate hose from steel line by turning double

flare connector out of hose fitting.

2.

Remove "U" shaped retainer from hose fitting and

withdraw hose from support bracket.

3.

Turn hose fitting out of wheel cylinder inlet.

Replacement

1.

Install new copper gasket on cylinder end of hose

(male end).

2.

Moisten threads with brake fluid and install hose in

wheel cylinder inlet.

3.

With weight of car on wheels and suspension in

normal position (front wheels straight ahead) pass

female end of hose through support bracket, allowing

hose to seek its own position. Insert hex of hose

fitting into the 12 point hole in support bracket

in position which induces least twist to hose (figk 10).

NOTE:

Do not twist hose unduly during ^

operation as its natural curvature is absolutely

necessary to maintain proper hose-tot

suspension clearance through full movement o£

the suspension and steering parts.

4.

Install "U" shaped retainer to secure hose in sup-

port bracket.

5. Inspect by removing weight completely from wheel,

turn wheels from lock to lock while observing hose

position. Be sure that hose does not tough other

parts at any time during suspension or wheel travel.

If contact does occur, remove hose retainer and

rotate the female hose end in the support bracket

CHEVROLET CHASSIS SERVICE MANUAL