fuel tank removal CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 277 of 659

ENGINE

6-12

ENGINE

MECHANICAL

IN LINE

INDEX

Page

General Description . „ 6-12

Component Replacement and Adjustment 6-12

.Engine Assembly 6-12

Removal 6-12

Installation 6-13

Manifold Assembly 6-14

Removal . 6-14

Installation 6-14

Rocker Arm Cover . 6-14

Removal 6-14

mstallation . . . 6-14

Valve Mechanism

......

1 6-14

Removal 6-14

Installation and Adjustment . 6-14

Valve Lifters

..............

6-15

Locating Noisy Lifters

„.;....

6-15

Removal

.'.*...•

6-15

Installation . 6-15

Valve Stem Oil Seal and/or Valve Spring . 6-16

Replacement . 6-16

Cylinder Head Assembly . 6-16

Removal 6-16

Installation . 6-16

Oil Pan . » 6-17

Removal . . . ; . . 6-17

Installation

.........

. 6-17

Oil Pump . 6-18

Page

Removal . 6-18

Installation . 6-18

Oil Seal (Rear Main) . 6-19

Replacement 6-19

Crankshaft Pulley and Hub 6-19

Removal 6-19

Installation 6-19

Torsional Damper 6-19

Removal 6-19

Installation 6-19

Crankcase Front Cover . 6-20

Removal . 6-20

Installation 6-20

•

Oil Seal (Front Cover) 6-20

Replacement 6-20

Camshaft 6-21

Measuring Lobe Lift . ... .

.-.••.-.

6-21

Removal 6-21

Installation 6-22

Timing Gears

..••••.............••• 6—22

Replacement

6-22

Flywheel

6-22

Removal

* 6-22

Installation

6-22

Engine

Mounts

6-23

Replacement

(Front)

6-23

Replacement

(Rear)

. 6-23

GENERAL DESCRIPTION

The

In

Line engines

(fig. 1L)

covered

in

this section

are

the 1H3 cu. in. L4, the 194,

230

and

250

cu. in. L6,

regardless

of

which passenger vehicle they

are

used

in.

This section covers

the

removal

and

installation

of en-

gine assemblies;

the

removal, installation

and

adjustment

of some sub-assemblies

and

replacement

of

some

com-

ponents.

For

service

to all

components

and

sub-assem-

blies (after removal)

and

removal

of

some sub-assem-

blies,

refer

to

Section

6 of the

Chassis Overhaul Manual.

Because

of the

interchangeability

and

similarity

of

many engine sub-assemblies

and

engine parts, regardless

of which passenger vehicle they

are

used

in,

typical illus-

trations

and

procedures

are

used except where specific

illustrations

or

procedures

are

necessary

to

clarify

the

operation. Although illustrations showing bench opera-

tions

are

used, most single operations, when

not

part

of a

general overhaul, should

be

performed

(if

practical) with

the engine

in the

vehicle.

COMPONENT REPLACEMENT

AND

ADJUSTMENT

ENGINE ASSEMBLY

Removal

1.

Drain cooling system

and

engine

oil.

2.

Remove

air

cleaner

and

disconnect battery cables

at 7.

battery.

3.

Remove hood

as

outlined

in

Section 11.

4.

Remove radiator

and

radiator shroud

as

outlined

in

Section 13.

5.

Remove

fan

blade

and

pulley

as

outlined

in

Section

6K.

6. Disconnect wires

at:

• Starter Solenoid

8.

• Delcotron

9.

Temperature Switch

Oil Pressure Switch

Coil

Disconnect:

Accelerator linkage

at

manifold bellerank.

Exhaust pipe

at

manifold flange.

.

Fuel line (from tank)

at

fuel pump.

Vacuum line

to

power brake unit

at

manifold

(if

so equipped).

• Power steering pump lines

at

pump

end (if so

equipped).

Raise vehicle

and

place

on

jack stands.

Remove propeller shaft.

CHEVROLET CHASSIS SERVICE MANUAL

Page 290 of 659

ENGINE 6-25

refer to Section 6 of the Chassis Overhaul Manual.

Because of the interchangeability and similarity of

many engines, engine sub-assemblies and engine parts,

regardless of which passenger vehicle they are used in,

typical illustrations and procedures are used except

where specific illustrations or procedures are necessary

to clarify the operation. Although illustrations showing

bench operations are used, most single operations, when

not part of a general overhaul, should be performed (if

practical) with the engine in the vehicle.

COMPONENT REPLACEMENT AND ADJUSTMENT

ENGINE ASSEMBLY

Removal

• .1. Drain cooling system and engine oil.

2.

Remove air cleaner and disconnect battery cables at

battery.

3.

Remove hood as outlined in Section 11.

4.

Remove radiator and shroud as outlined in Sec-

tion 13.

5. Remove fan blade and pulley as outlined in Sec-

tion 6K.

6. Disconnect wires at:

• Starter solenoid

• Delcotron

• Temperature switch

• Oil pressure switch

• Coil

7. Disconnect:

• Accelerator linkage at pedal lever.

• Exhaust pipes at manifold flanges.

• Vacuum line to power brake unit at manifold (if

so equipped),

• Power steering pump lines at pump end (if so

equipped).

• Fuel line (from tank) at fuel pump.

• Engine cooler lines (if so equipped).

• Oil pressure gauge line (if so equipped).

8. Raise vehicle and place on jack stands.

9. Remove propeller shaft.

NOTE:

If plug for propeller shaft opening

in transmission is not available, drain

transmission.

10.

Disconnect:

• Shift linkage at transmission.

• Speedometer cable at transmission.

• Transmission cooler lines (if so equipped).

11.

On synchromesh equipped vehicles, disconnect clutch

linkage at cross-shaft then remove cross-shaft en-

gine bracket.

12.

Remove rocker arm covers as outlined, then attach

engine lifting adapter at the proper cylinder head bolt

locations.

13.

Remove front mount bolts.

14.

Attach lifting device and raise engine to take weight

off front mounts, then remove rear mount bolts.

15.

Raise engine to take weight off rear mount, then re-

move crossmember.

NOTE:

On Chevrolets it will be necessary to

remove mount from transmission before cross-

member can be removed.

16.

Remove engine-transmission assembly from vehicle

as a unit.

17.

Remove transmission (and clutch):

Synchromesh Transmission

a. Remove clutch housing cover plate screws.

b.

Remove bolts attaching the clutch housing to en-

gine block then remove transmission and clutch

housing as a unit.

NOTE:

Support the transmission as the last

mounting bolt is removed, and as it is being

pulled away from the engine (to prevent damage

to clutch disc).

c. Remove starter and clutch housing rear cover

plate.

d. Loosen clutch mounting bolts a turn at a time (to

prevent distortion of clutch cover) until the spring

pressure is released. Remove all bolts, clutch

disc and pressure plate assembly.

Automatic

Transmission

a. Lower engine, secured by the hoist, and support

engine on blocks.

b.

Remove starter and converter housing underpan.

c. Remove flywheel-to-converter attaching bolts.

d. Support transmission on blocks.

e. Remove transmission-to-engine mounting bolts.

f. With the hoist attached, remove blocks from the

engine only and slowly guide the engine from the

transmission.

18.

Mount engine in stand.

Installation

1.

Attach lifting device to engine and remove engine

from engine stand.

2.

Install transmission (and clutch):

Synchromesh Transmission

a. Install the clutch on flywheel as outlined in Sec-

tion 7.

b.

Install clutch housing rear cover and starter.

c. Install transmission and clutch housing as out-

lined in Section 7.

d. Install clutch housing cover screws and tighten

securely.

Automatic

Transmissions

a. Position engine adjacent to the transmission and

align the converter with the flywheel.

b.

Bolt transmission to engine, then raise engine and

transmission assembly and install flywheel to

converter attaching bolts.

c. Install converter housing underpan and starter.

3.

Tilt and lower engine and transmission assembly into

the chassis as a unit, guiding engine to align front

mounts with frame supports.

4.

Install front mount bolts and torque to specifications.

5. Raise engine enough to install rear crossmember,

then install crossmember, install rear mount, lower

engine and torque rear mount to specifications.

CHEVROLET CHASSIS SERVICE MANUAL

Page 318 of 659

ENGINE FUEL

6M-10

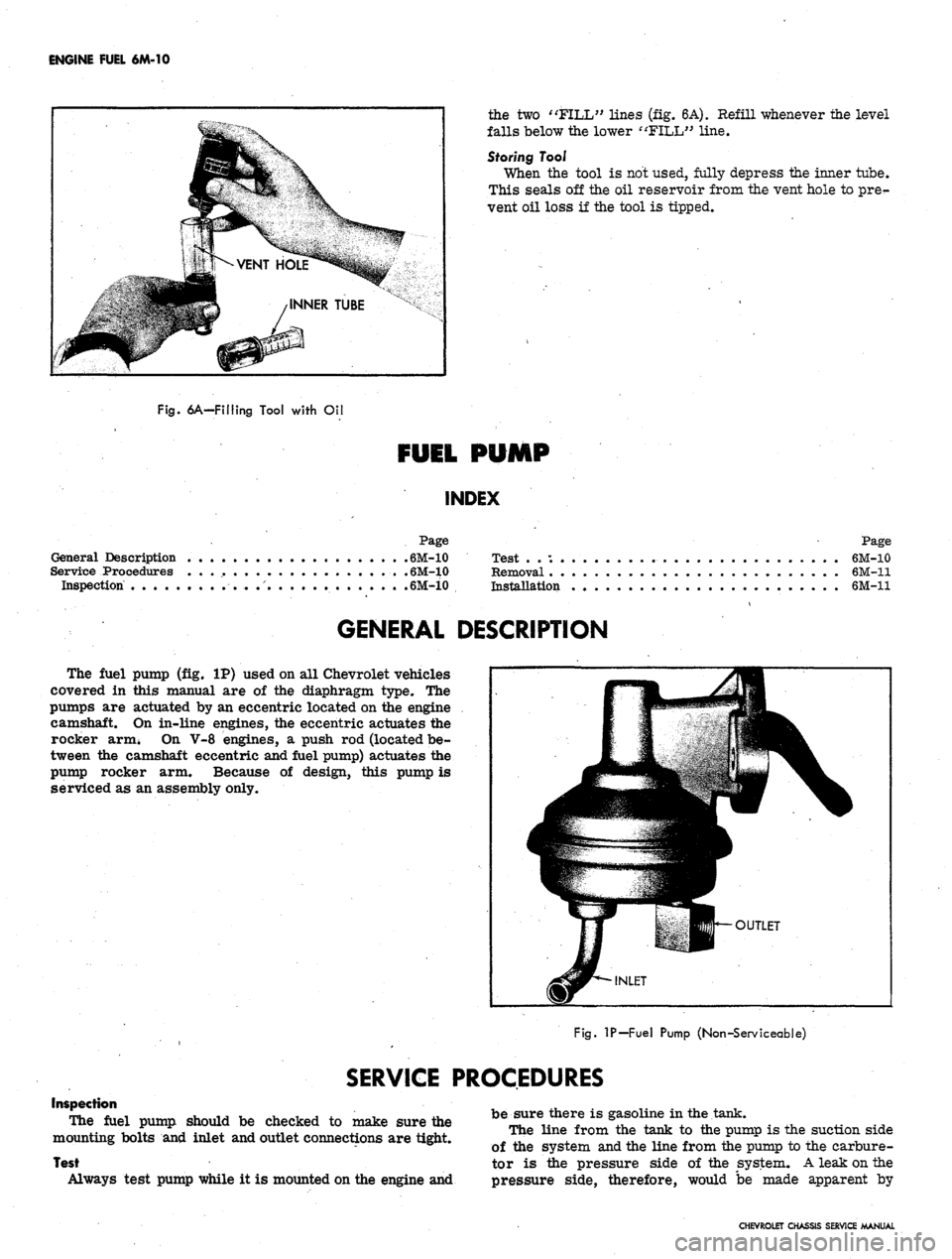

the

two

"FILL71 lines

(fig.

6A). Refill whenever

the

level

falls below the lower

<'FILL"

line.

Storing Tool

When

the

tool

is

not used, fully depress

the

inner tube.

This seals

off

the

oil

reservoir from the vent hole

to pre-

vent

oil

loss

if

the tool

is

tipped.

Fig. 6A-Filling Tool with

Oil

FUEL PUMP

INDEX

Page

General Description

. . . . 6M-10

Service Procedures .6M-10

Inspection .6M-10

Page

Test

. . ; 6M-10

Removal

6M-11

Installation

6M-11

GENERAL DESCRIPTION

The fuel pump

(fig. IP)

used

on all

Chevrolet vehicles

covered

in

this manual

are of the

diaphragm type.

The

pumps

are

actuated

by an

eccentric located on

the

engine

camshaft.

On

in-line engines,

the

eccentric actuates

the

rocker arm*

On V-8

engines,

a

push

rod

(located be-

tween

the

camshaft eccentric and fuel pump) actuates

the

pump rocker

arm.

Because

of

design, this pump

is

serviced

as an

assembly only.

Fig.

IP—Fuel Pump (Non-Serviceable)

SERVICE PROCEDURES

Inspection

The fuel pump should

be

checked

to

make sure

the

mounting bolts

and

inlet and outlet connections

are

tight.

Test

Always test pump while

it is

mounted on the engine

and

be sure there

is

gasoline

in

the tank.

The line from

the

tank

to the

pump

is the

suction side

of

the

system and the line from the pump

to the

carbure-

tor

is the

pressure side

of the

system.

A

leak on

the

pressure side, therefore, would

be

made apparent

by

CHEVROLET CHASSIS SERVICE MANUAL

Page 319 of 659

ENGINE FUEL 6M-11

dripping fuel, but a leak on the suction would not be ap-

parent except for its effect of reducing volume of fuel on

the pressure side.

1.

Tighten any loose line connections and look for bends

or kinks in lines.

2.

Disconnect fuel pipe at carburetor. Disconnect dis-

tributor to coil primary wire so that engine can be

cranked without firing. Place suitable container at

end of pipe and crank engine a few revolutions. If

little or no gasoline flows from open end of pipe then

fuel pipe is clogged or pump is inoperative. Before

removing pump disconnect fuel pipe at gas tank and

outlet pipe and blow through them with an air hose

to make sure they are clear. Reconnect pipes and

retest while cranking engine.

CAUTION: Whenever the engine is cranked re-

motely at the starter, with a special jumper

cable or other means, the primary distributor

lead must be disconnected from the negative

post on the coil and the ignition switch must be

in the "ON" position. Failure to do this will

result in a damaged grounding circuit in the

ignition switch.

3.

If fuel flows from pump in good volume from pipe

at carburetor, check fuel delivery pressure to be

certain that pump is operating withint specified limits

as follows:

a. Attach a fuel pump pressure test gauge to dis-

connect end of pump to carburetor pipe.

b.

Run engine at approximately 450-1,000 rpm (on

gasoline in carburetor bowl) and note reading on

pressure gauge.

c. If pump is operating properly the pressure will

be within specifications and will remain constant

at speeds between 450-1,000 rpm. If pressure

is too low, too high, or varies materially at dif-

ferent speeds, the pump should be replaced.

Removal

1.

Disconnect fuel inlet and outlet pipes at fuel pump.

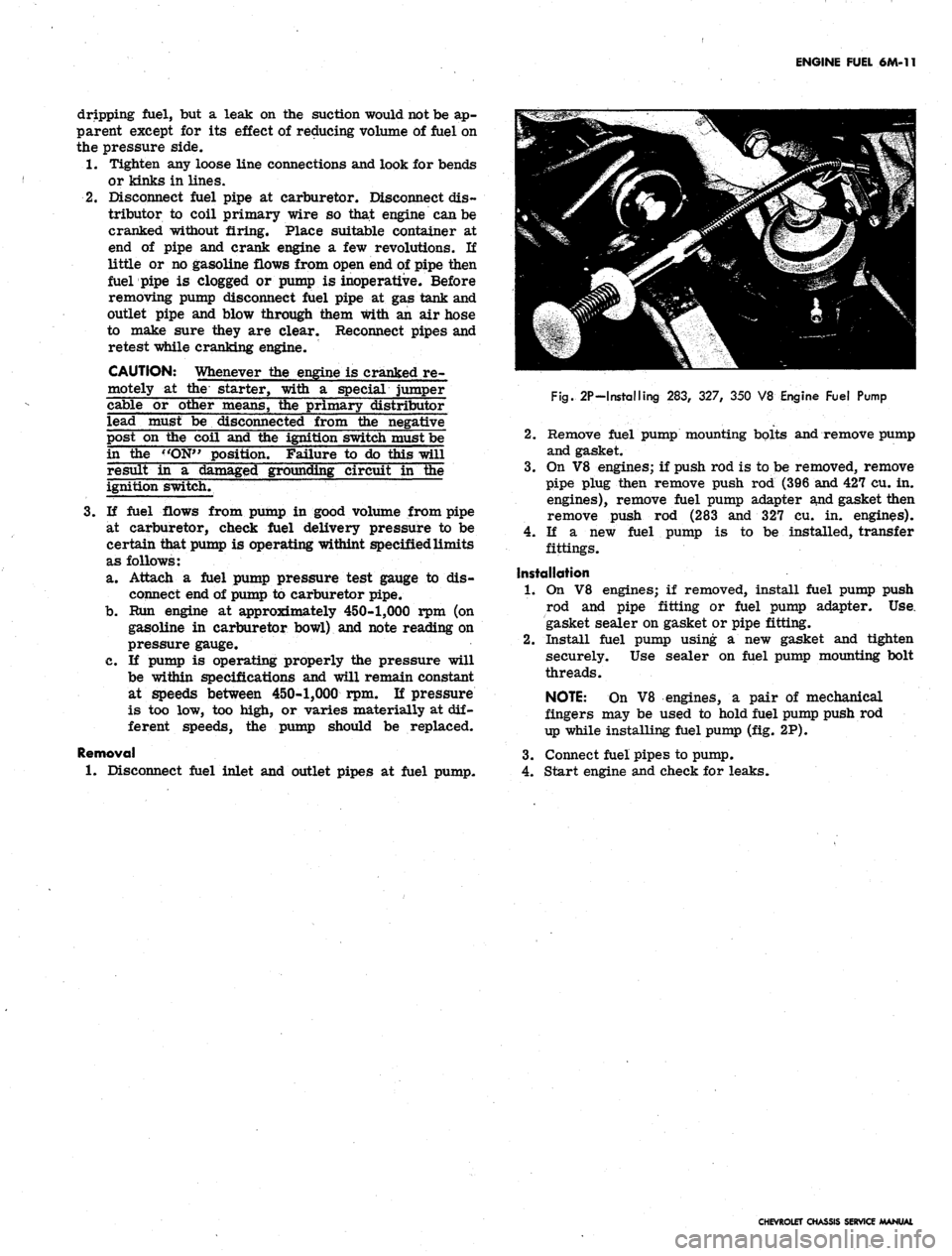

Fig.

2P-Installing 283, 327, 350 V8 Engine Fuel Pump

2.

Remove fuel pump mounting bolts and remove pump

and gasket.

3.

On V8 engines; if push rod is to be removed, remove

pipe plug then remove push rod (396 and 427 cu. in.

engines), remove fuel pump adapter and gasket then

remove push rod (283 and 327 cu. in. engines).

4.

If a new fuel pump is to be installed, transfer

fittings.

Installation

1.

On V8 engines; if removed, install fuel pump push

rod and pipe fitting or fuel pump adapter. Use.

gasket sealer on gasket or pipe fitting.

2.

Install fuel pump using a new gasket and tighten

securely. Use sealer on fuel pump mounting bolt

threads.

NOTE:

On V8 engines, a pair of mechanical

fingers may be used to hold fuel pump push rod

up while installing fuel pump (fig. 2P).

3.

Connect fuel pipes to pump.

4.

Start engine and check for leaks.

CHEVROLET CHASSIS SERVICE MANUAL

Page 409 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-3

CAUTION: Always drain gasoline from com-

plete fuel system including carburetor, fuel

pump and all fuel lines and fuel tank if the vehi-

cle is to be stored for any appreciable length of

time. This precaution will prevent accumulation

of gum formation and resultant poor engine

performance.

Removal and Installation (Except Station Wagon)

1.

Drain fuel tank.

2.

Raise vehicle.

3.

Disconnect fuel pickup line, ground wire.

4.

Disconnect meter wire at rear harness connector.

5. Disconnect vent pipe hose.

6. Remove tank support straps and lower tank carefully.

7. To install, reverse the removal procedure.

Removal and Installation (Station Wagon)

1.

Drain fuel tank.

2.

Raise vehicle.

3.

Remove gas tank shield at the back of the left rear

wheel; remove all screws including the screw

attachment at the bottom of the quarter panel.

4.

Disconnect fuel pickup line and gauge wires from

tank unit.

5. Remove ground wire attaching bolt at body location.

6. Remove strap assembly nut and carefully lower tank.

7. Reverse removal procedure to install.

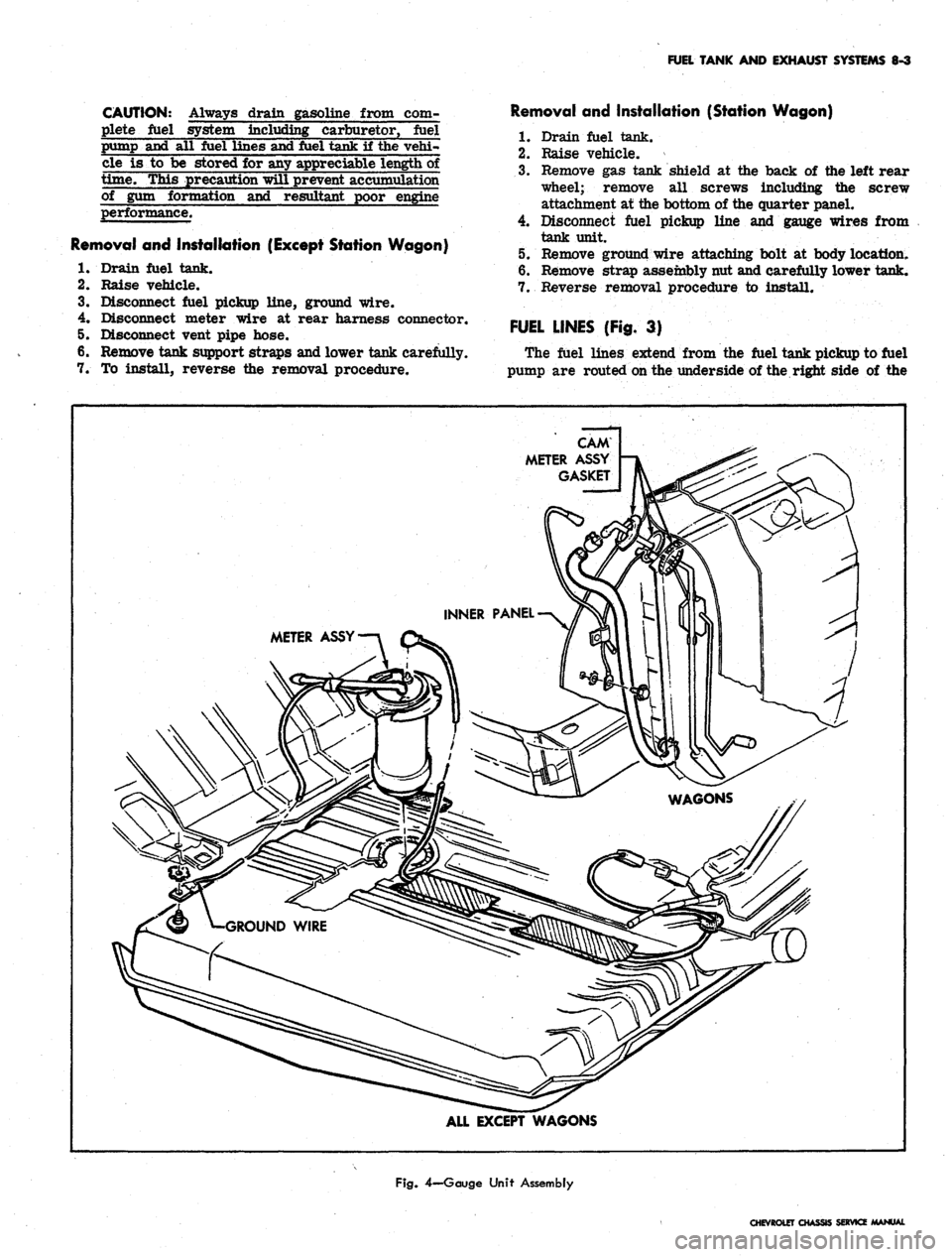

FUEL LINES (Fig. 3)

The fuel lines extend from the fuel tank pickup to fuel

pump are routed on the underside of the right side of the

CAM

METER ASSY

GASKET

METER ASSY

ALL EXCEPT WAGONS

Fig.

4—Gauge Unit Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 410 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-4

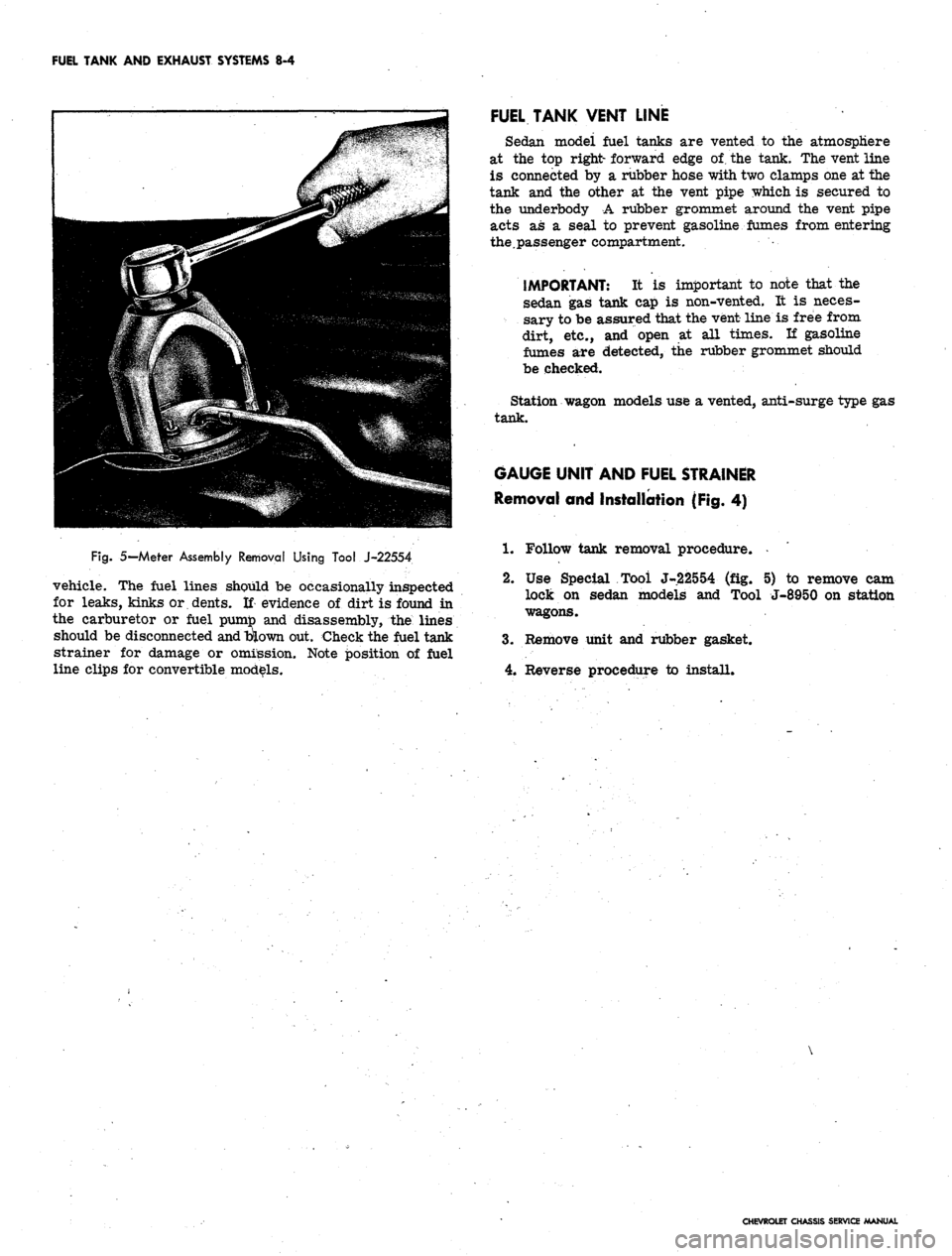

Fig.

5— Meter Assembly Removal Using Tool J-22554

vehicle. The fuel lines should be occasionally inspected

for leaks, kinks or dents. If evidence of dirt is found in

the carburetor or fuel pumto and disassembly, the lines

should be disconnected

and

blown out. Check the fuel tank

strainer for damage or omission. Note position of fuel

line clips for convertible models.

FUEL TANK VENT LINE

Sedan modei fuel tanks are vented to the atmosphere

at the top right- forward edge of. the tank. The vent line

is connected by a rubber hose with two clamps one at the

tank and the other at the vent pipe which is secured to

the underbody A rubber grommet around the vent pipe

acts as a seal to prevent gasoline fumes from entering

the.passenger compartment.

IMPORTANT: It is important to note that the

sedan gas tank cap is non-vented. It is neces-

sary to be assured that the vent line is free from

dirt, etc., and open at all times. If gasoline

fumes are detected, the rubber grommet should

be checked.

Station wagon models use a vented, anti-surge type gas

tank.

GAUGE UNIT AND FUEL STRAINER

Removal and Installation (Fig. 4)

1.

Follow tank removal procedure.

2.

Use Special Tool J-22554 (fig. 5) to remove cam

lock on sedan models and Tool J-8950 on station

wagons.

3.

Remove unit and rubber gasket.

4.

Reverse procedure to install.

CHEVROLET CHASSIS SERVICE MANUAL

Page 414 of 659

FUEL TANK AND EXHAUST SYSTEMS

8-8

CHEVELLE

FUEL TANKS

INDEX

Page

General Description.

g.g

Component Part Replacement

8-8

Fuel Tanks

. 8-8

Fuel Lines

8-8

Metering Units (Gauge, Sending Unit)

Fuel Tank Filler Neck Caps.

. .

Fuel Tank Vent Lines

Page

8-8

8-8

8-9

GENERAL DESCRIPTION

All models

use a 20

gallon capacity (approx.) fuel tank

mounted between

the

frame rails behind

the

rear axle.

The fuel tanks

are

basically

the

same

for

sedan, 2-seat

station wagon

and

pickup models except

for

filler neck

location

and

venting

(fig. 8).

All fuel tanks

are

vented

to the

atmosphere. Sedan

model tanks have

an

external vent hose and pipe assem-

bly

(fig. 11) and use a

non-vented fuel cap. Station wagon

and pickup model tanks

are

vented through

a

hose

and

vent pipe assembly

to the

filler neck

(fig. 8)

and

use a

vented, anti-surge type

gas cap. The

fuel caps

are two

different designs conforming

to SAE

standards

and are

not interchangeable.

The filler neck assembly

on

sedan models

is a

rear

fill design located behind

the

center

bar of the

bumper.

Station wagon

and

sedan pickup model filler neck assem-

blies

are

located

in

the left rear quarter panel.

The fuel pickup pipe

is

built integrally with

the

tank

gauge, located

at the

top-front center

of

the tank.

A

fine

mesh screen

is

located

at

the bottom-end

of the

fuel pick-

up pipe

to

prevent

the

entrance

of

foreign material into

the fuel system.

The sedan fuel tanks

are

held

in

place

by

two metal

straps attached individually

to the

underbody

at

each

end.

The straps hinge

at the

forward end and secure

the

tank

at

the

rear with

an

adjustable bolt

and nut

assembly.

The station wagon

and

pickup models have

a

frame

mounted fuel tank secured with straps

to

front and rear

supports.

COMPONENT PART REPLACEMENT

FUEL TANK

Draining Tank

The absence

of a

drain plug

in the gas

tanks makes

it

necessary

to

siphon fuel from

the

tank when draining

is

needed. Refer

to the

recommended draining procedures

previously outlined under Chevrolet Models

in

this

section.

Removal

and

Installation (Sedan Models)

1.

Raise vehicle.

2.

Drain fuel tank.

3.

Disconnect fuel pickup line

and

gauge wires from

tank unit.

4.

Disconnect vent hose from tank.

5. Remove tank support straps and lower tank carefully.

6.

To

install, reverse

the

removal procedure.

Removal

and

Installation

(Station Wagon

and

Pickup)

1.

Follow Steps

1

thru

3

outlined under sedan models.

2.

Remove tank support straps.

3.

Remove frame screw attachments from

the

front

support

(fig. 8).

4.

Guide tank forward

and

remove.

5.

To

install, reverse removal procedure.

FUEL LINES

The fuel lines, extending from fuel tank toiiuelpump,

are routed

on the

underside

of the

underbody along

the

right side

of the

vehicle opposite

the

single exhaust

sys-

tem.

The

fuel lines should occasionally

be

inspected

for

leaks,

kinks,

or

dents.

If

evidence

of

dirt

is

found

in the

carburetor

or

fuel pump

on

disassembly,

the

lines should

be disconnected

and

blown

out.

Check

the

fuel tank

strainer

for

damage

or

omission. Fuel lines

are of 5/16"

diameter tubing with beaded type ends

for

connections

of

hoses.

FUEL PIPE RETAINER

CUP

Removal

and

Installation

If fuel pipes

and

retainer clips

are

removed, Tool

J-7777 should

be

used

to

install

new

retainer clips

(fig.

10).

After removal

of the old

clip from

the

frame, position

the

new

clip

in the

location

of the old

clip. Index

the

"blind rivet"

and

press hard (hand pressure should

do)

to expand rivet.

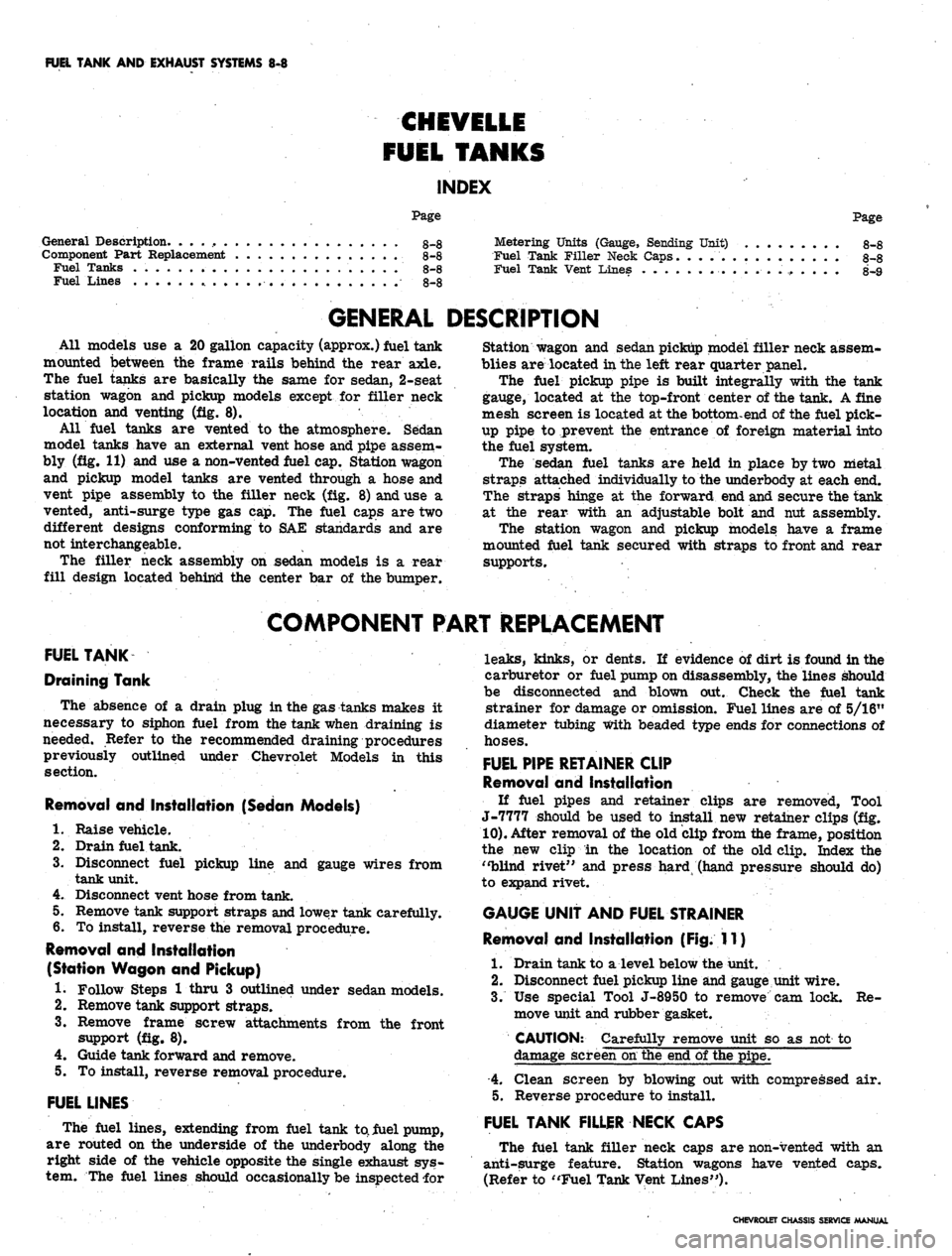

GAUGE UNIT

AND

FUEL STRAINER

Removal

and

Installation

(Fig. 11)

1.

Drain tank

to a

level below

the

unit.

2.

Disconnect fuel pickup line

and

gauge unit wire.

3.

Use

special Tool J-8950

to

remove

cam

lock.

Re-

move unit

and

rubber gasket.

CAUTION: Carefully remove unit

so as not to

damage screen

on the end of

the pipe.

4.

Clean screen

by

blowing

out

with compressed

air.

5. Reverse procedure

to

install.

FUEL TANK FILLER NECK CAPS

The fuel tank filler neck caps

are

non-vented with

an

anti-surge feature. Station wagons have vented caps.

(Refer

to

"Fuel Tank Vent Lines").

CHEVROLET CHASSIS SERVICE MANUAL

Page 416 of 659

FUEL TANK

AND

EXHAUST SYSTEMS

8-10

Fig.

11—Gauge Unit Assembly

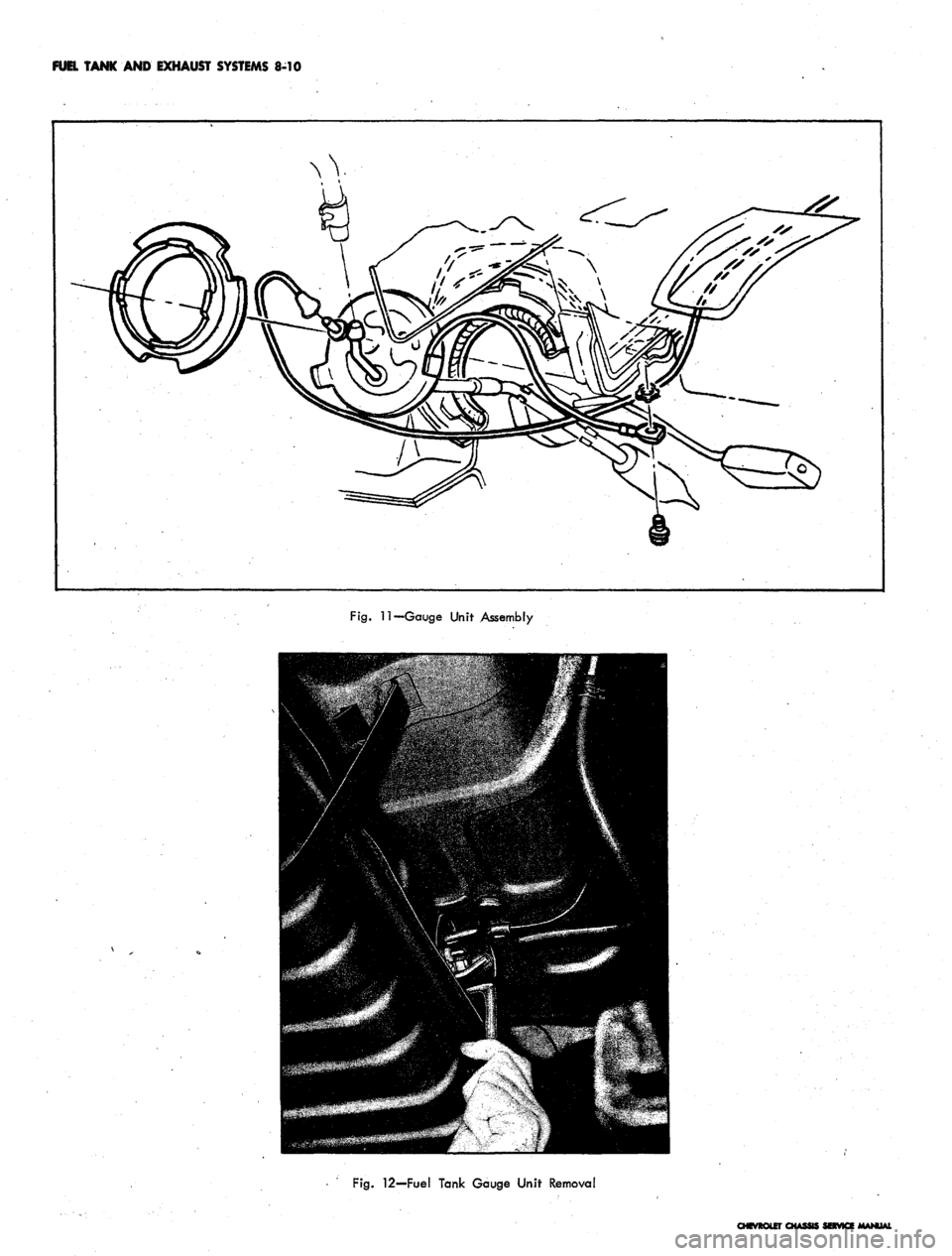

Fig.

12—Fuel Tank Gauge Unit Removal

CHEVROLET CHASSIS SERVICE

Page 419 of 659

FUEL TANK

AND

EXHAUST SYSTEMS

8-13

CHEVY II

FUEL TANKS

INDEX

Page

Page

General Description.

8-13

Component Part Replacement

8-13

Fuel Tanks

8-13

Fuel Lines

8-14

Metering Units (Gauge Sending Unit)

8-13

Fuel Tank Filler- Neck Caps.

. . 8-14

Fuel Tank Vent Lines .......

8-14

GENERAL DESCRIPTION

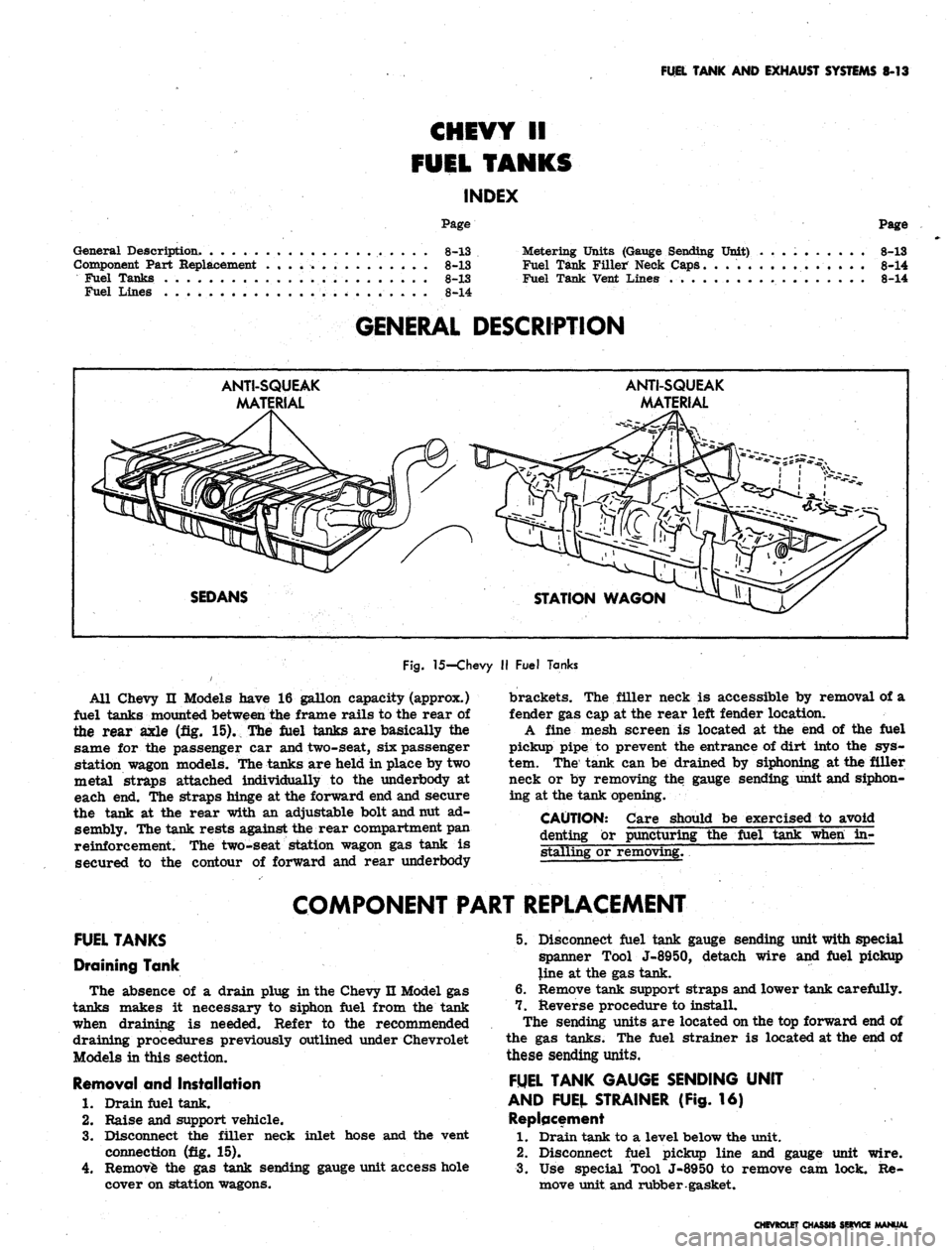

ANTI-SQUEAK

MA'

ANTI-SQUEAK

MATERIAL

SEDANS

STATION WAGON

Fig.

15-Chevy

II

Fuel Tanks

All Chevy

II

Models have

16

gallon capacity (approx.)

fuel tanks mounted between

the

frame rails

to the

rear

of

the rear axle

(fig. 15). The

fuel tanks

are

basically

the

same

for the

passenger

car

and two-seat,

six

passenger

station wagon models. The tanks

are

held

in

place

by two

metal straps attached individually

to the

underbody

at

each

end. The

straps hinge

at the

forward

end

and secure

the tank

at the

rear with

an

adjustable bolt and nut

ad-

sembly. The tank rests against the rear compartment

pan

reinforcement.

The

two-seat station wagon

gas

tank

is

secured

to the

contour

of

forward

and

rear underbody

brackets.

The

filler neck

is

accessible

by

removal

of a

fender

gas cap at the

rear left fender location.

A fine mesh screen

is

located

at the end of the

fuel

pickup pipe

to

prevent

the

entrance

of

dirt into

the sys-

tem.

The

tank

can be

drained

by

siphoning

at the

filler

neck

or by

removing

the

gauge sending unit and siphon-

ing

at the

tank opening.

CAUTION: Care should

be

exercised

to

avoid

denting

or

puncturing

the

fuel tank when

in-

stalling

or

removing.

~

COMPONENT PART REPLACEMENT

FUEL TANKS

Draining Tank

The absence

of a

drain plug

in

the Chevy

n

Model

gas

tanks makes

it

necessary

to

siphon fuel from

the

tank

when draining

is

needed. Refer

to the

recommended

draining procedures previously outlined under Chevrolet

Models

in

this section.

Removal

and

Installation

1.

Drain fuel tank.

2.

Raise

and

support vehicle.

3.

Disconnect

the

filler neck inlet hose

and the

vent

connection

(fig. 15).

4.

Remove

the gas

tank sending gauge unit access hole

cover

on

station wagons.

5. Disconnect fuel tank gauge sending unit with special

spanner Tool J-8950, detach wire

and

fuel pickup

line

at the gas

tank.

6. Remove tank support straps and lower tank carefully.

7. Reverse procedure

to

install.

The sending units

are

located on

the top

forward

end of

the

gas

tanks.

The

fuel strainer

is

located

at the end of

these sending units.

FUEL TANK GAUGE SENDING UNIT

AND FUEL STRAINER

(Fig. 16)

Replacement

1.

Drain tank

to a

level below

the

unit.

2.

Disconnect fuel pickup line

and

gauge unit wire.

3.

Use

special Tool J-8950

to

remove

cam

lock.

Re-

move unit and rubber gasket.

CHEVROLET CHASSIS SERVICE MANUAL

Page 424 of 659

FUEL TANK

AND

EXHAUST SYSTEMS

8-18

CORVETTE

FUEL TANK

INDEX

Page

General Description.

. 8-18

Service Operations

8-18

Fuel Tank

8-18

Gauge Sending Unit

8-20

Fuel Lines.

8-20

GENERAL DESCRIPTION

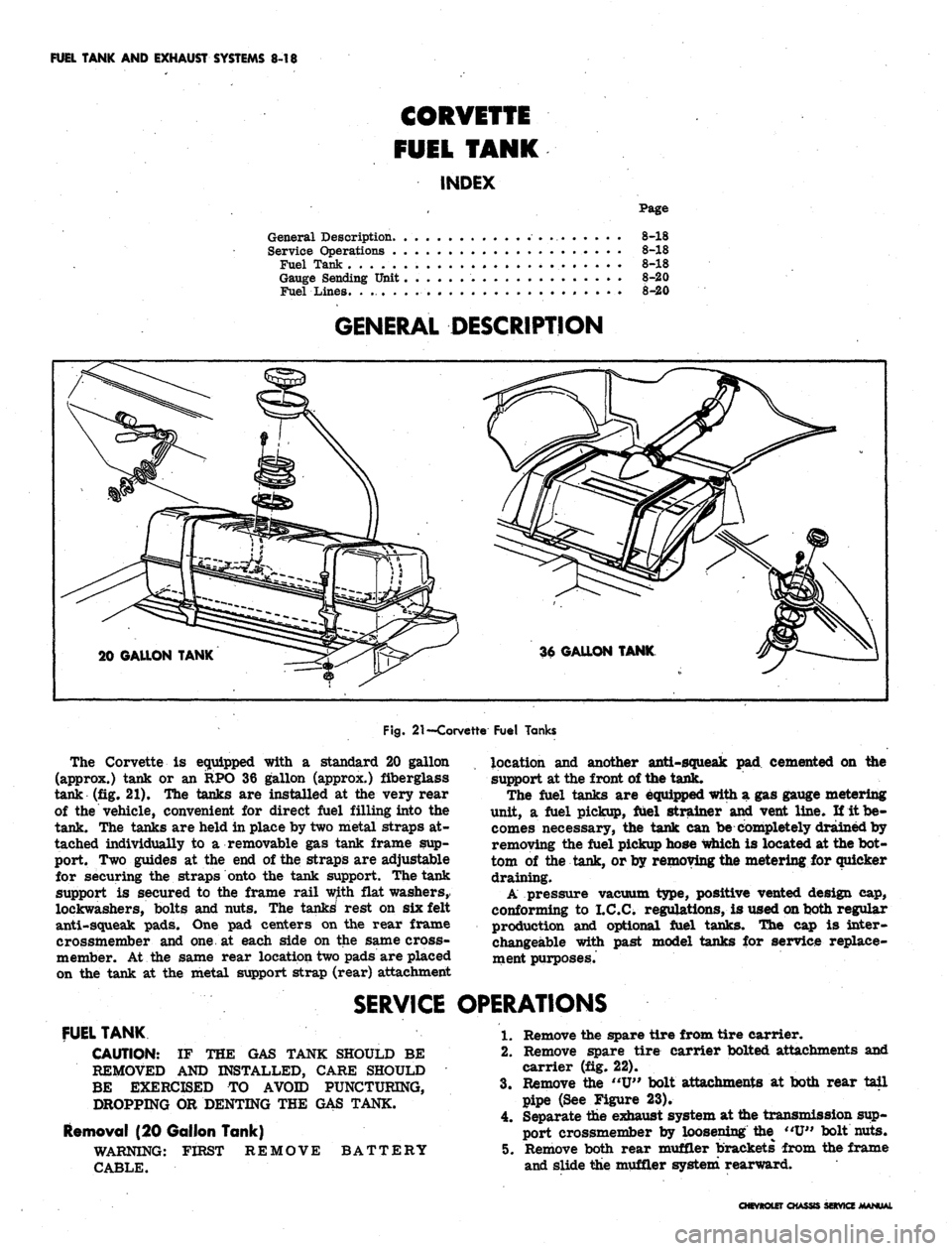

20 GALLON TANK

Fig.

21

—Corvette Fuel Tanks

The Corvette

is

equipped with

a

standard

20

gallon

(approx.) tank

or an RPO 36

gallon (approx.) fiberglass

tank

(fig. 21). The

tanks

are

installed

at the

very rear

of

the

vehicle, convenient

for

direct fuel filling into

the

tank.

The

tanks

are

held

in

place

by

two metal straps

at-

tached individually

to a

removable

gas

tank frame

sup-

port.

Two

guides

at the end of

the straps

are

adjustable

for securing

the

straps onto

the

tank support. The tank

support

is

secured

to the

frame rail with flat washers,

lockwashers, bolts

and

nuts.

The

tanks' rest

on six

felt

anti-squeak pads.

One pad

centers

on the

rear frame

crossmember

and one at

each side

on the

same cross-

member.

At the

same rear location two pads

are

placed

on

the

tank

at the

metal support strap (rear) attachment

location

and

another anti-squeak

pad

cemented

on the

support

at

the front

of

the tank.

The fuel tanks

are

equipped with

a gas

gauge metering

unit,

a

fuel pickup, fuel strainer

and

vent line.

If it be-

comes necessary,

the

tank

can be

completely drained

by

removing

the

fuel pickup hose which

is

located

at

the

bot-

tom

of the

tank,

or

by removing the metering

for

quicker

draining.

A pressure vacuum type, positive vented design

cap,

conforming

to

I.C.C. regulations,

is

used on both regular

production

and

optional fuel tanks.

The cap is

inter-

changeable with past model tanks

for

service replace-

ment purposes.

SERVICE OPERATIONS

FUEL TANK

CAUTION:

IF THE GAS

TANK SHOULD

BE

REMOVED

AND

INSTALLED, CARE SHOULD

BE EXERCISED

TO

AVOID PUNCTURING,

DROPPING

OR

DENTING

THE GAS

TANK.

Removal

(20

Gallon Tank)

WARNING: FIRST REMOVE BATTERY

CABLE.

1.

Remove

the

spare tire from tire carrier.

2.

Remove spare tire carrier bolted attachments

and

carrier

(fig. 22).

3.

Remove

the "U"

bolt attachments

at

both rear tail

pipe

(See

Figure

23).

4.

Separate

the

exhaust system

at

the transmission sup-

port crossmember

by

loosening

the "U"

bolt nuts.

5. Remove both rear muffler brackets from

the

frame

and slide

the

muffler system rearward.

CHEVROLET CHASSIS SERVICE MANUAL