battery replacement CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 7 of 659

GENERAL INFORMATION 0-5

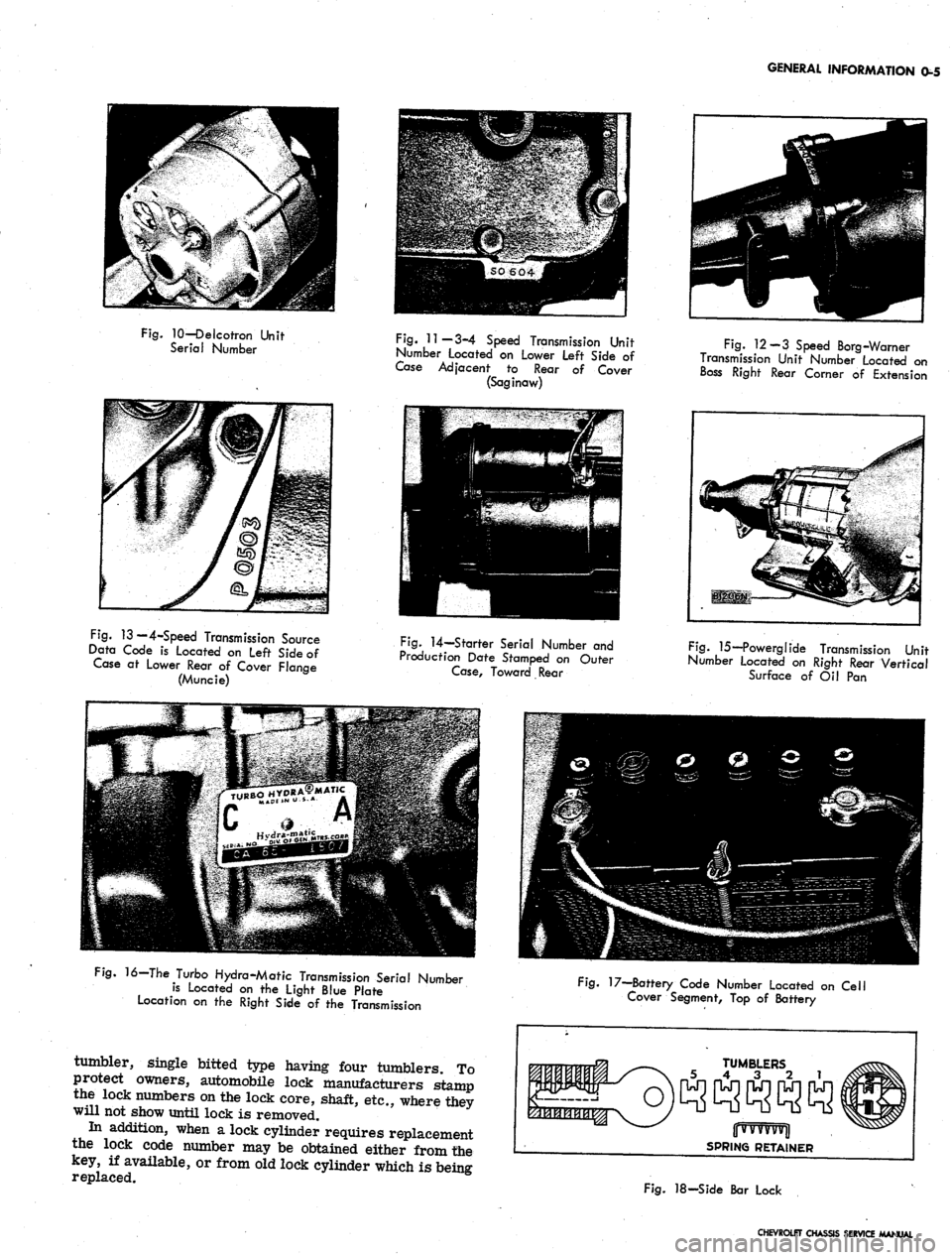

Fig.

10—Delcotron Unit

Serial Number

Fig.

11—3-4 Speed Transmission Unit

Number Located on Lower Left Side of

Case Adjacent to Rear of Cover

(Saginaw)

Fig.

12-3 Speed Borg-Warner

Transmission Unit Number Located on

Boss Right Rear Comer of Extension

Fig.

13 — 4-Speed Transmission Source

Data Code is Located on Left Side of

Case at Lower Rear of Cover Flange

(Muncie)

Fig.

14—Starter Serial Number and

Production Date Stamped on Outer

Case,

Toward Rear

Fig.

15—Powerglide Transmission Unit

Number located on Right Rear Vertical

Surface of Oil Pan

16—The Turbo Hydra-Matic Transmission Serial Number

is Located on the Light Blue Plate

Location on the Right Side of the Transmission

tumbler, single bitted type having four tumblers. To

protect owners, automobile lock manufacturers stamp

the lock numbers on the lock core, shaft, etc., where they

will not show until lock is removed.

In addition, when a lock cylinder requires replacement

the lock code number may be obtained either from the

key, if available, or from old lock cylinder which is being

replaced.

Fig.

17—Battery Code Number Located on Cell

Cover Segment, Top of Battery

TUMBLERS

5 4 3 2 1

jjwvvvvvjl

SPRING RETAINER

Fig.

18-Side Bar Lock

CHEVROLET CHASSIS SERVICE MANUAL

Page 26 of 659

HEATER AND AIR CONDITIONING 1A-3

linkage of this lever which will provide partial airflow

only to the defroster duct and which should be used for,

all normal defogging operations.

CORVETTE

Heater components are attached to the dash panel on

the right side of the vehicle with the air inlet assembly

on the engine side and the heater and air distributor

assemblies beneath the instrument panel within the pas-

senger compartment.

The heater operates on outside air only with the blower

receiving its air flow from the cowl vent plenum

chamber.

No water valve is utilized in the system. Therefore,

water flows through the heater core constantly while

the engine is running, keeping the core at maximum

temperature at all times.

Airflow through the system is shown in Figure 1.

Controls

Two knobs control all heater operations:

The FAN-TEMP knob is rotated to turn the blower

on and off and control blower speed and is pulled out

as desired to regulate heater temperature.

The AIR-DEF knob is the air on-and-off control as

well as the defroster control.

Temperature Damper: Door

At the heart of the heater operation is the temperature

damper door. Air from the blower follows parallel paths

through the distributor duct, with one path passing

through the heater core and the other path bypassing the

core.

The temperature damper door is placed in the duct

so that, when closed, the path of the heated air leaving

the heater core is blocked while the ambient air path

remains open. Positive closing of this door when no

heat is being called for is assured by a cam assembly

at the door operating lever. As the FAN-TEMP knob

is pulled out, the damper door is opened accordingly,

allowing varying proportions of heated air to mix with

the unheated airflow, thus providing heater outlet tem-

perature control. With the knob pulled fully out the

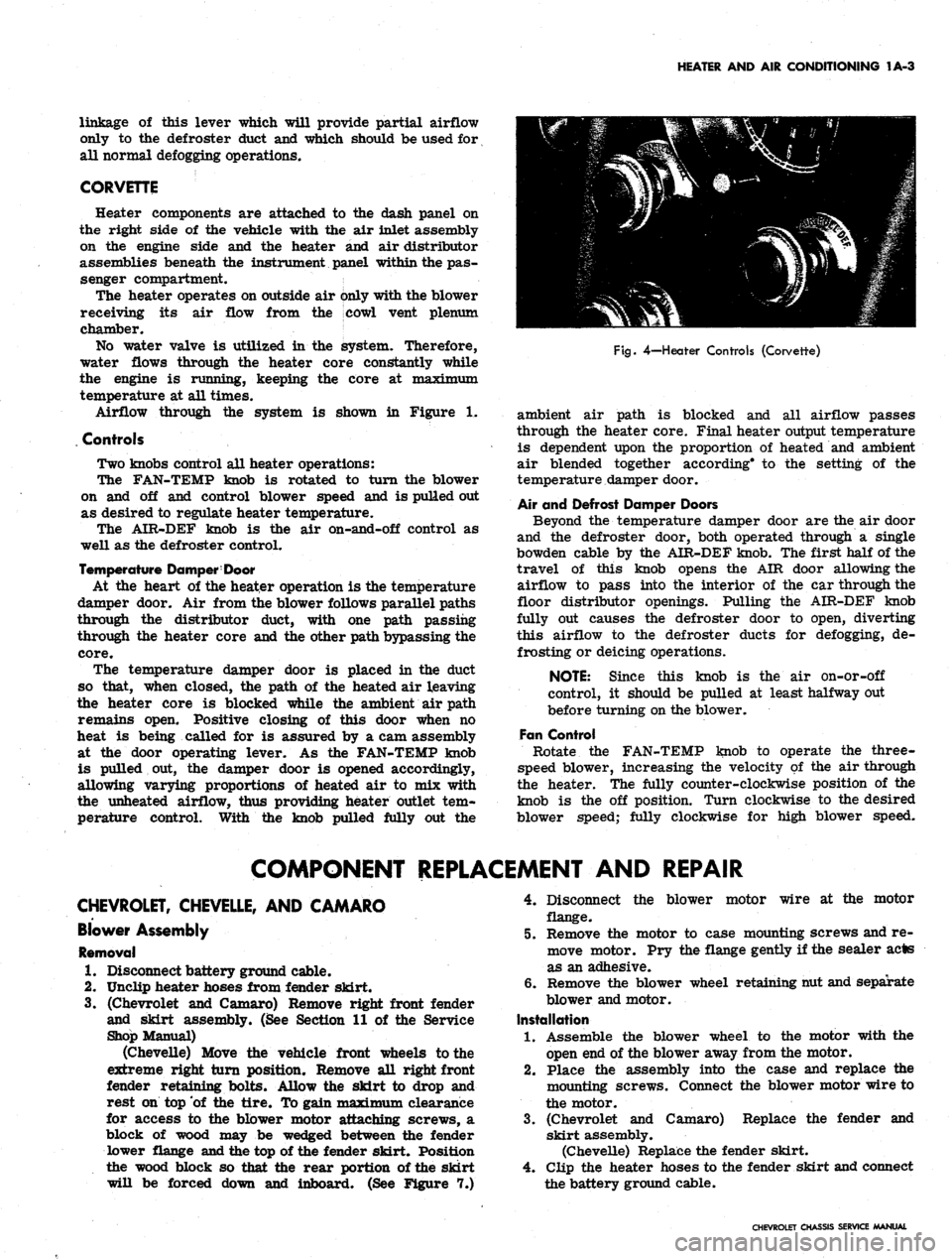

Fig.

4—Heater Controls (Corvette)

ambient air path is blocked and all airflow passes

through the heater core. Final heater output temperature

is dependent upon the proportion of heated and ambient

air blended together according* to the setting of the

temperature damper door.

Air and Defrost Damper Doors

Beyond the temperature damper door are the air door

and the defroster door, both operated through a single

bowden cable by the AIR-DEF knob. The first half of the

travel of this knob opens the AIR door allowing the

airflow to pass into the interior of the car through the

floor distributor openings. Pulling the AIR-DEF knob

fully out causes the defroster door to open, diverting

this airflow to the defroster ducts for defogging, de-

frosting or deicing operations.

NOTE: Since this knob is the air on-or-off

control, it should be pulled at least halfway out

before turning on the blower.

Fan Control

Rotate the FAN-TEMP knob to operate the three-

speed blower, increasing the velocity of the air through

the heater. The fully counter-clockwise position of the

knob is the off position. Turn clockwise to the desired

blower speed; fully clockwise for high blower speed.

COMPONENT REPLACEMENT AND REPAIR

CHEVROLET, CHEVELLE, AND CAMARO

Blower Assembly

Removal

1.

Disconnect battery ground cable.

2.

Unclip heater hoses from fender skirt.

3.

(Chevrolet and Camaro) Remove right front fender

and skirt assembly. (See Section 11 of the Service

Shop Manual)

(Chevelle) Move the vehicle front wheels to the

extreme right turn position. Remove all right front

fender retaining bolts. Allow the skirt to drop and

rest on top of the tire. To gain maximum clearance

for access to the blower motor attaching screws, a

block of wood may be wedged between the fender

lower flange and the top of the fender skirt. Position

the wood block so that the rear portion of the skirt

will be forced down and inboard. (See Figure 7.)

4.

Disconnect the blower motor wire at the motor

flange.

5.

Remove the motor to case mounting screws and re-

move motor. Pry the flange gently if the sealer acts

as an adhesive.

6. Remove the blower wheel retaining nut and separate

blower and motor.

Installation

1.

Assemble the blower wheel to the motor with the

open end of the blower away from the motor.

2.

Place the assembly into the case and replace the

mounting screws. Connect the blower motor wire to

the motor.

3.

(Chevrolet and Camaro) Replace the fender and

skirt assembly.

(Chevelle) Replace the fender skirt.

4.

Clip the heater hoses to the fender skirt and connect

the battery ground cable.

CHEVROLET CHASSIS SERVICE MANUAL

Page 29 of 659

HEATER AND AIR CONDITIONING 1A-6

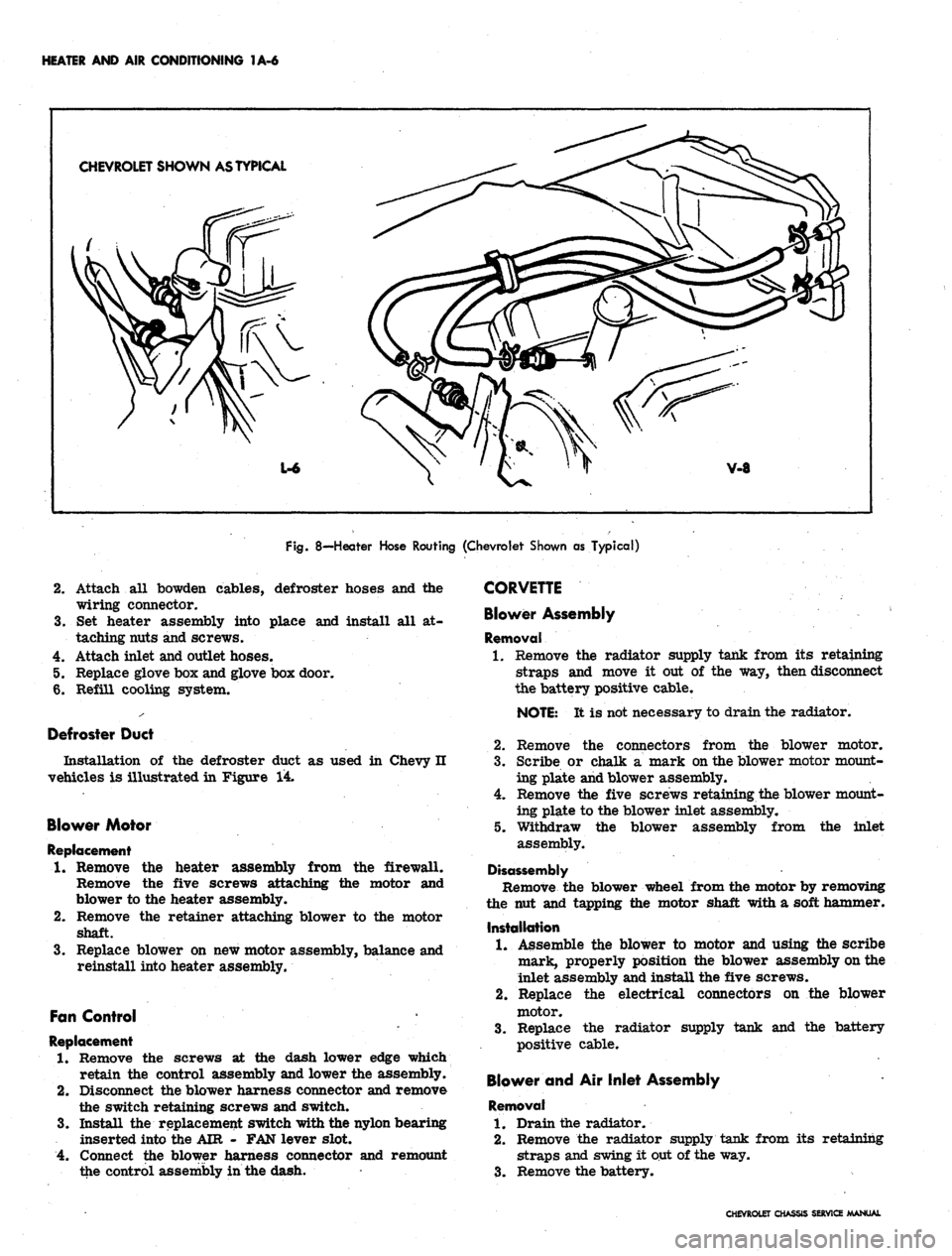

CHEVROLET SHOWN AS TYPICAL

Fig.

8—Heater Hose Routing (Chevrolet Shown as Typical)

cables, defroster hoses and the

place and install all at-

4.

5.

6.

Attach all bowden

wiring connector.

Set heater assembly into

taching nuts and screws.

Attach inlet and outlet hoses.

Replace glove box and glove box door.

Refill cooling system.

Defroster Duct

Installation of the defroster duct as used in Chevy H

vehicles is illustrated in Figure 14.

Blower Motor

Replacement

1.

Remove the heater assembly from the firewall.

Remove the five screws attaching the motor and

blower to the heater assembly.

2.

Remove the retainer attaching blower to the motor

shaft.

3.

Replace blower on new motor assembly, balance and

reinstall into heater assembly.

Fan Control

Replacement

1.

Remove the screws at the dash lower edge which

retain the control assembly and lower the assembly.

2.

Disconnect the blower harness connector and remove

the switch retaining screws and switch.

3.

Install the replacement switch with the nylon bearing

inserted into the AIR - FAN lever slot.

4.

Connect the blower harness connector and remount

the control assembly in the dash.

CORVETTE

Blower Assembly

Removal

1.

Remove the radiator supply tank from its retaining

straps and move it out of the way, then disconnect

the battery positive cable.

NOTE:

It is not necessary to drain the radiator.

2.

Remove the connectors from the blower motor.

3.

Scribe or chalk a mark on the blower motor mount-

ing plate and blower assembly.

4.

Remove the five screws retaining the blower mount-

ing plate to the blower inlet assembly.

Withdraw the blower assembly from the inlet

5.

assembly.

Disassembly

Remove the blower wheel from the motor by removing

the nut and tapping the motor shaft with a soft hammer.

Installation

1.

Assemble the blower to motor and using the scribe

mark, properly position the blower assembly on the

inlet assembly and install the five screws.

2.

Replace the electrical connectors on the blower

motor.

3.

Replace the radiator supply tank and the battery

positive cable.

Blower and Air Inlet Assembly

Removal

1.

Drain the radiator.

2.

Remove the radiator supply tank from its retaining

straps and swing it out of the way.

3.

Remove the battery.

CHEVROLET CHASSIS SERVICE MANUAL

Page 85 of 659

HEATER AND AIR CONDITIONING 1A-62

2.

Insert the evaporator assembly into the outlet case

half and mount the evaporator, thermostatic switch,

and cable to the case.

3.

Install the face plate to the case and install control

retaining nuts and knobs.

4.

Assemble the case halves and mount the evaporator

pipe clamp.

5. Install the evaporator assembly as previously

described under EVAPORATOR.

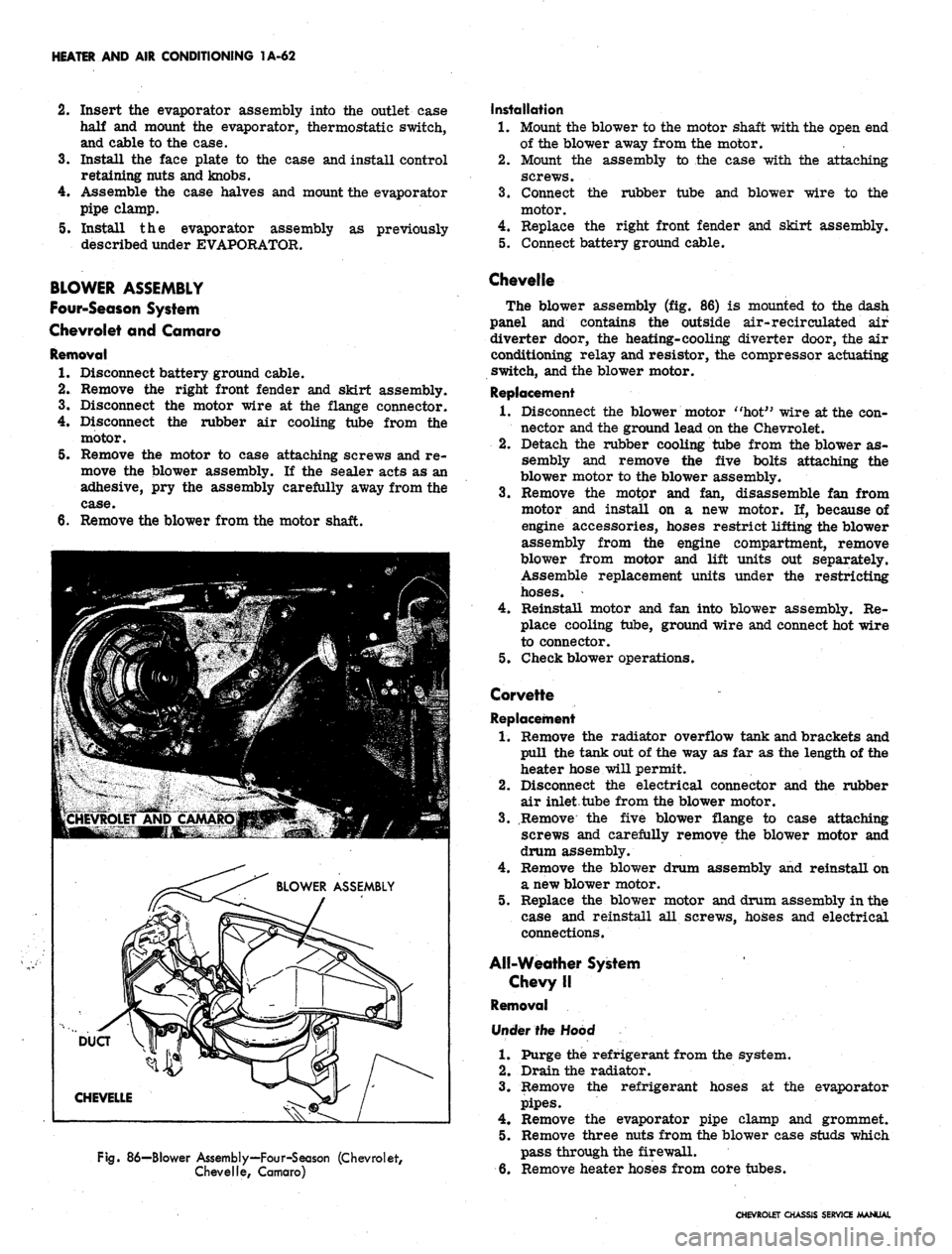

BLOWER ASSEMBLY

Four-Season System

Chevrolet and Camaro

Removal

1.

Disconnect battery ground cable.

2.

Remove the right front fender and skirt assembly.

3.

Disconnect the motor wire at the flange connector.

4.

Disconnect the rubber air cooling tube from the

motor.

5. Remove the motor to case attaching screws and re-

move the blower assembly. If the sealer acts as an

adhesive, pry the assembly carefully away from the

6. Remove the blower from the motor shaft.

Fig.

86—Blower Assembly—Four-Season (Chevrolet,

Chevelle, Camaro)

Installation

1.

Mount the blower to the motor shaft with the open end

of the blower away from the motor.

2.

Mount the assembly to the case with the attaching

screws.

3.

Connect the rubber tube and blower wire to the

motor.

4.

Replace the right front fender and skirt assembly.

5. Connect battery ground cable.

Chevelle

The blower assembly (fig. 86) is mounted to the dash

panel and contains the outside air-recirculated air

diverter door, the heating-cooling diverter door, the air

conditioning relay and resistor, the compressor actuating

switch, and the blower motor.

Replacement

1.

Disconnect the blower motor "hot" wire at the con-

nector and the ground lead on the Chevrolet.

2.

Detach the rubber cooling tube from the blower as-

sembly and remove the five bolts attaching the

blower motor to the blower assembly.

3.

Remove the motor and fan, disassemble fan from

motor and install on a new motor. If, because of

engine accessories, hoses restrict lifting the blower

assembly from the engine compartment, remove

blower from motor and lift units out separately.

Assemble replacement units under the restricting

hoses.

4.

Reinstall motor and fan into blower assembly. Re-

place cooling tube, ground wire and connect hot wire

to connector.

5. Check blower operations.

Corvette

Replacement

1.

Remove the radiator overflow tank and brackets and

pull the tank out of the way as far as the length of the

heater hose will permit.

2.

Disconnect the electrical connector and the rubber

air inlet tube from the blower motor.

3.

Remove the five blower flange to case attaching

screws and carefully remove the blower motor and

drum assembly.

4.

Remove the blower drum assembly and reinstall on

a new blower motor.

5. Replace the blower motor and drum assembly in the

case and reinstall all screws, hoses and electrical

connections.

All-Weather System

Chevy II

Removal

Under the Hood

1.

Purge the refrigerant from the system.

2.

Drain the radiator.

3.

Remove the refrigerant hoses at the evaporator

pipes.

4.

Remove the evaporator pipe clamp and grommet.

5. Remove three nuts from the blower case studs which

pass through the firewall.

6. Remove heater hoses from core tubes.

CHEVROLET CHASSIS SERVICE MANUAL

Page 91 of 659

HEATER AND AIR CONDITIONING 1A-68

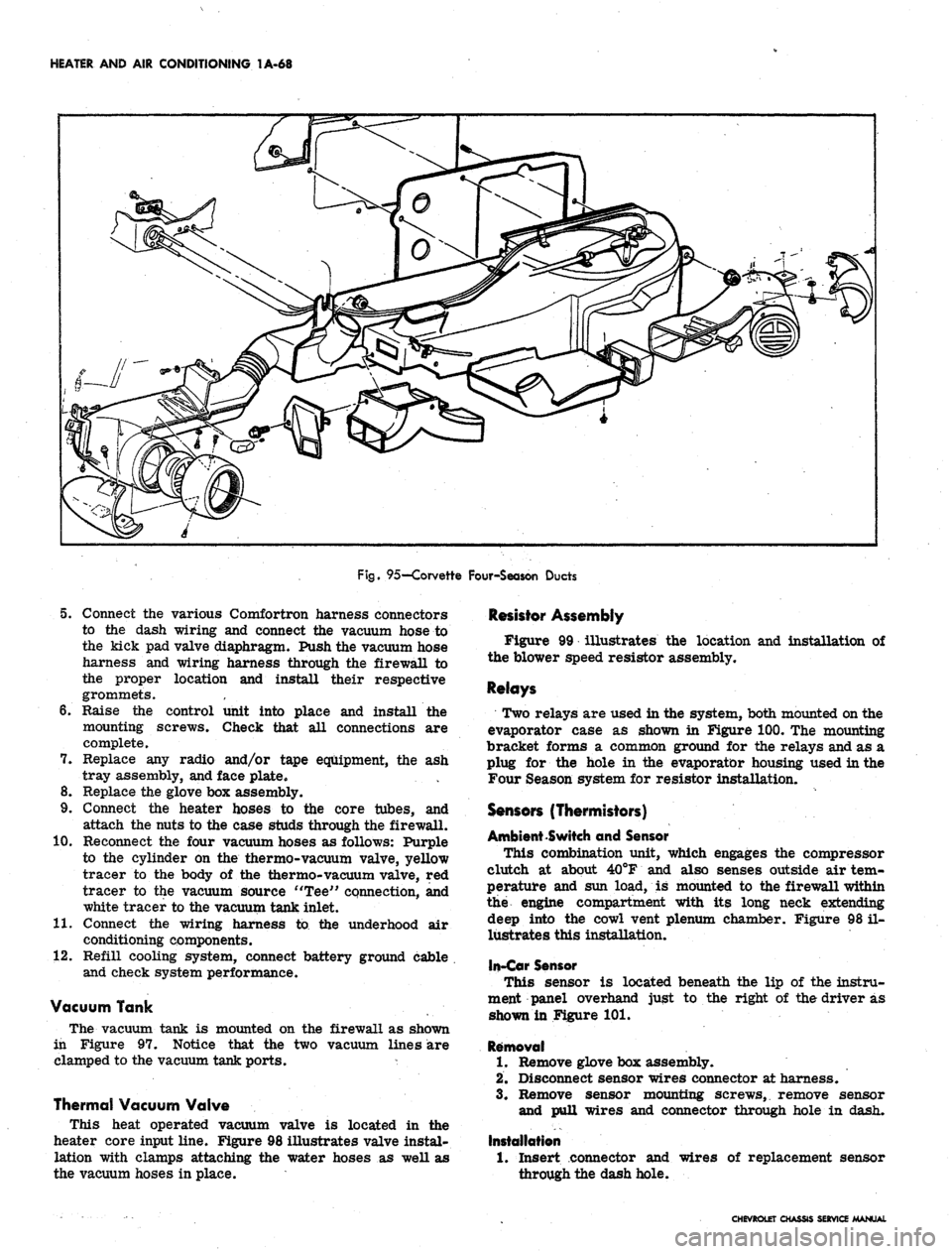

Fig.

95—Corvette Four-Season Ducts

5. Connect the various Comfortron harness connectors

to the dash wiring and connect the vacuum hose to

the kick pad valve diaphragm. Push the vacuum hose

harness and wiring harness through the firewall to

the proper location and install their respective

grommets.

6. Raise the control unit into place and install the

mounting screws. Check that all connections are

complete.

7. Replace any radio and/or tape equipment, the ash

tray assembly, and face plate.

8. Replace the glove box assembly.

9. Connect the heater hoses to the core tubes, and

attach the nuts to the case studs through the firewall.

10.

Reconnect the four vacuum hoses as follows: Purple

to the cylinder on the thermo-vacuum valve, yellow

tracer to the body of the thermo-vacuum valve, red

tracer to the vacuum source "Tee" connection, and

white tracer to the vacuum tank inlet.

11.

Connect the wiring harness to the underhood air

conditioning components.

12.

Refill cooling system, connect battery ground cable

and check system performance.

Vacuum Tank

The vacuum tank is mounted on the firewall as shown

in Figure 97. Notice that the two vacuum lines are

clamped to the vacuum tank ports. *

Thermal Vacuum Valve

This heat operated vacuum valve is located in the

heater core input line. Figure 98 illustrates valve instal-

lation with clamps attaching the water hoses as well as

the vacuum hoses in place.

Resistor Assembly

Figure 99 illustrates the location and installation of

the blower speed resistor assembly.

Relays

Two relays are used in the system, both mounted on the

evaporator case as shown in Figure 100. The mounting

bracket forms a common ground for the relays and as a

plug for the hole in the evaporator housing used in the

Four Season system for resistor installation.

Sensors (Thermistors)

Ambient Switch and Sensor

This combination unit, which engages the compressor

clutch at about 40°F and also senses outside air tem-

perature and sun load, is mounted to the firewall within

the engine compartment with its long neck extending

deep into the cowl vent plenum chamber. Figure 98 il-

lustrates this installation,

In-Car Sensor

This sensor is located beneath the lip of the instru-

ment panel overhand just to the right of the driver as

shown in Figure 101.

Removal

1.

Remove glove box assembly.

2.

Disconnect sensor wires connector at harness.

3.

Remove sensor mounting screws, remove sensor

and pull wires and connector through hole in dash.

Installation

1.

Insert connector and

through the dash hole.

wires of replacement sensor

CHEVROLET CHASSIS SERVICE MANUAL

Page 96 of 659

HEATER AND AIR CONDITIONING 1A-73

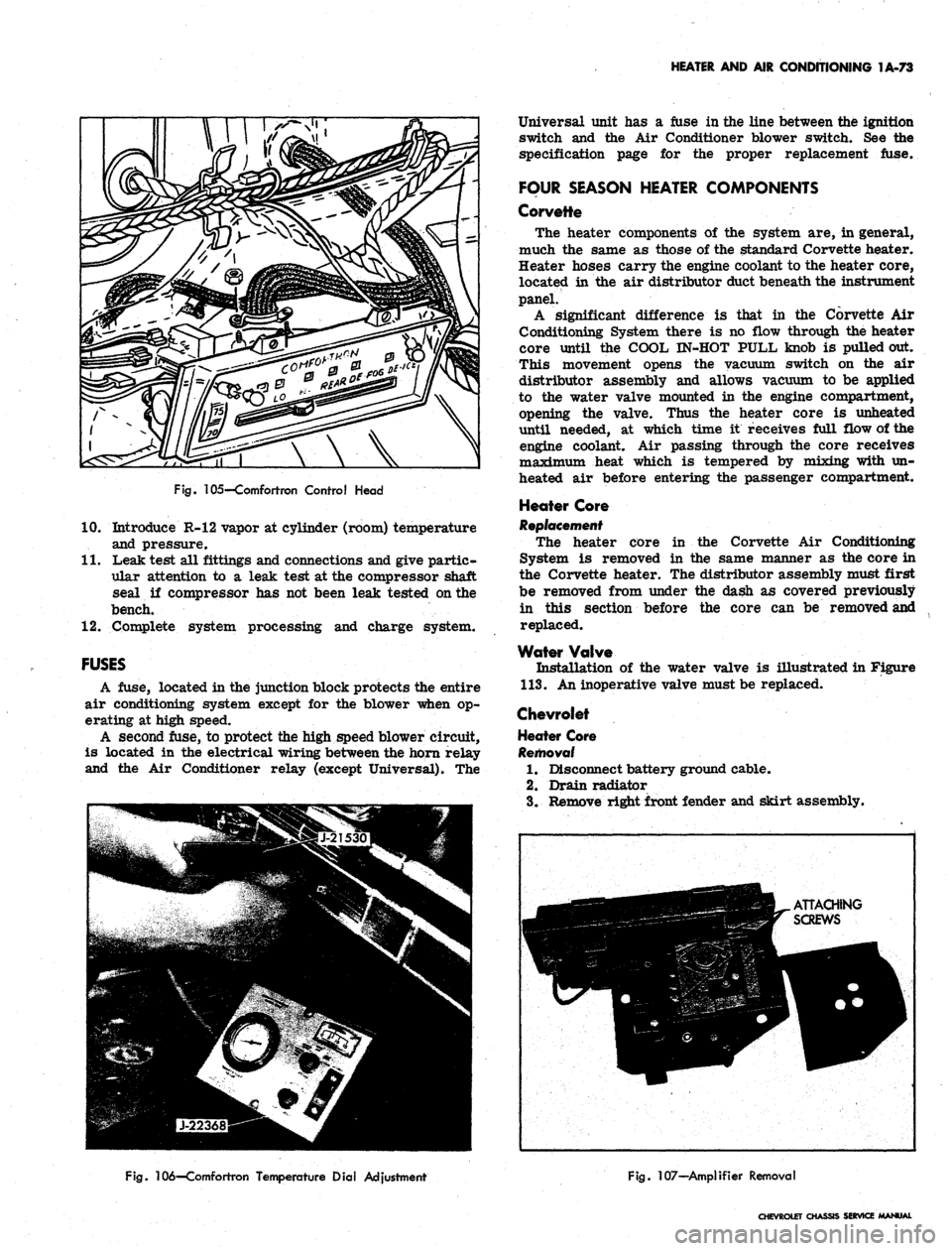

Fig.

105—Comfortron Control Head

10.

Introduce R-12 vapor at cylinder (room) temperature

and pressure.

11.

Leak test all fittings and connections and give partic-

ular attention to a leak test at the compressor shaft

seal if compressor has not been leak tested on the

bench.

12.

Complete system processing and charge system.

FUSES

A fuse, located in the junction block protects the entire

air conditioning system except for the blower when op-

erating at high speed.

A second fuse, to protect the high speed blower circuit,

is located in the electrical wiring between the horn relay

and the Air Conditioner relay (except Universal). The

Universal unit has a fuse in the line between the ignition

switch and the Air Conditioner blower switch. See the

specification page for the proper replacement fuse.

FOUR SEASON HEATER COMPONENTS

Corvette

The heater components of the system are, in general,

much the same as those of the standard Corvette heater.

Heater hoses carry the engine coolant to the heater core,

located in the air distributor duct beneath the instrument

panel.

A significant difference is that in the Corvette Air

Conditioning System there is no flow through the heater

core until the COOL IN-HOT PULL knob is pulled out.

This movement opens the vacuum switch on the air

distributor assembly and allows vacuum to be applied

to the water valve mounted in the engine compartment,

opening the valve. Thus the heater core is unheated

until needed, at which time it receives full flow of the

engine coolant. Air passing through the core receives

maximum heat which is tempered by mixing with un-

heated air before entering the passenger compartment.

Heater Core

Replacement

The heater core in the Corvette Air Conditioning

System is removed in the same manner as the core in

the Corvette heater. The distributor assembly must first

be removed from under the dash as covered previously

in this section before the core can be removed and

replaced.

Water Valve

Installation of the water valve is illustrated in Figure

113.

An inoperative valve must be replaced.

Chevrolet

Heater Core

Removal

1.

Disconnect battery ground cable.

2.

Drain radiator

3.

Remove right front fender and skirt assembly.

Fig.

106—Comfortron Temperature Dial Adjustment

Fig.

107—Amplifier Removal

CHEVROLET CHASSIS SERVICE MANUAL

Page 97 of 659

HEATER AND AIR CONDITIONING 1A-74

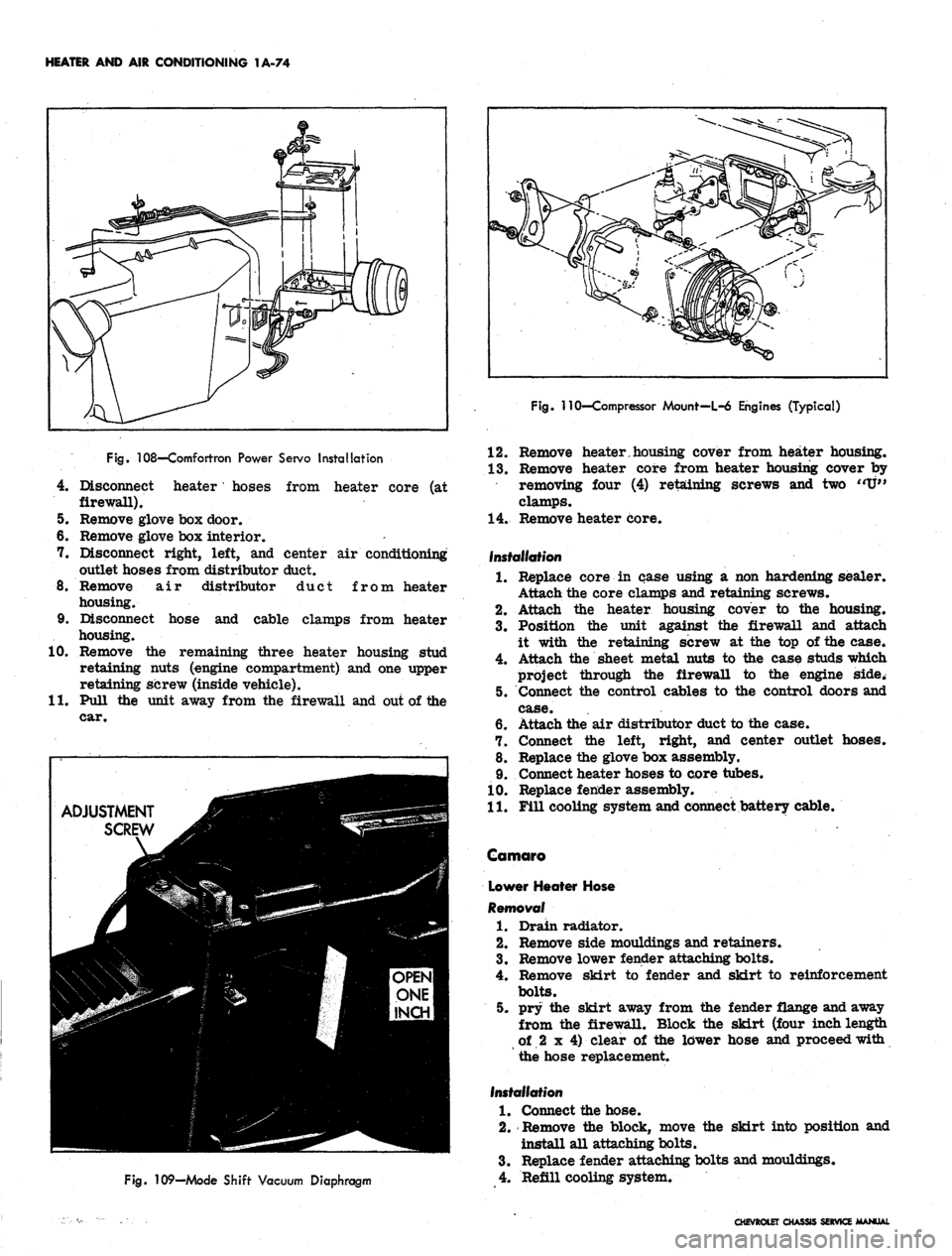

Fig.

108—Comfortron Power Servo Installation

4.

Disconnect heater' hoses from heater core (at

firewall).

5. Remove glove box door.

6. Remove glove box interior.

7. Disconnect right, left, and center air conditioning

outlet hoses from distributor duct.

8. Remove air distributor duct from heater

housing.

9. Disconnect hose and cable clamps from heater

housing.

10.

Remove the remaining three heater housing stud

retaining nuts (engine compartment) and one upper

retaining screw (inside vehicle).

11.

Pull the unit away from the firewall and out of the

car.

ADJUSTMENT

SCREW

Fig.

109—Mode Shift Vacuum Diaphragm

Fig. 110'—Compressor Mount—L-6 Engines (Typical)

12.

Remove heater.housing cover from heater housing.

13.

Remove heater core from heater housing cover by

removing four (4) retaining screws and two "U"

clamps.

14.

Remove heater core.

Installation

1.

Replace core in case using a non hardening sealer.

Attach the core clamps and retaining screws.

2.

Attach the heater housing cover to the housing.

3.

Position the unit against the firewall and attach

it with the retaining screw at the top of the case.

4.

Attach the sheet metal nuts to the case studs which

project through the firewall to the engine side.

5. Connect the control cables to the control doors and

case.

6. Attach the air distributor duct to the case.

7. Connect the left, right, and center outlet hoses.

8. Replace the glove box assembly.

9. Connect heater hoses to core tubes.

10.

Replace fender assembly.

11.

Fill cooling system and connect battery cable.

Camaro

Lower Heater Hose

Removal

1.

Drain radiator.

2.

Remove side mouldings and retainers.

3.

Remove lower fender attaching bolts.

4.

Remove skirt to fender and skirt to reinforcement

bolts.

5. pry the skirt away from the fender flange and away

from the firewall. Block the skirt (four inchlengtti

of 2 x 4) clear of the lower hose and proceed with

the hose replacement.

Installation

1.

Connect the hose.

2.

Remove the block, move the skirt into position and

install all attaching bolts.

3.

Replace fender attaching bolts and mouldings.

4.

Refill cooling system.

CHEVROLET CHASSIS SERVICE MANUAL

Page 242 of 659

BRAKES 5-9

COMPONENT REPLACEMENT AND REPAIRS

PARKING BRAKE-CHEVROLET, CHEVELLE AND

CAMARO (Figs. 19 and 20)

Pedal Assembly

Removal

NOTE:

Remove positive cable from battery to

eliminate the possibility of creating short cir-

cuits under dash.

1.

Place parking brake pedal in released position.

2.

Remove equalizer check nut, and separate cable

stud from equalizer.

3.

Remove two attaching nuts from mounting studs

located in engine compartment.

4.

Remove front cable .ball end from pedal assembly

swivel.

5. Remove pedal assembly to dash brace attaching

screw.

6. Remove pedal assembly by lowering rear slightly

to avoid scratching dash, and pulling, it out of the

firewall.

Installation

1.

Place pedal assembly in position with the two mount-

ing studs protruding through the holes provided in

the firewall.

2.

Install and tighten pedal assembly to dash brace

attaching screw.

3.

Position front cable ball end into pedal assembly

swivel.

4.

Install and tighten two attaching nuts on mounting

studs located in engine compartment.

5. Place

,

equalizer in position on center cable and

insert front cable stud through equalizer and secure

with check nut.

6. Adjust parking brake as outlined under Maintenance

and Adjustments in this section.

7. Connect positive battery cable.

Front Cable

Removal

NOTE:

Remove positive cable from battery to

eliminate the possibility of creating short cir-

cuits under dash.

1.

Place parking brake pedal in released position.

2.

Remove equalizer check nut, and separate cable

, stud from equalizer.

3.

Remove retainer from cable assembly at inner side

of frame rail.

4.

Remove ball end of cable from pedal assembly

swivel.

5. Compress expanded conduit locking fingers at toe

pan arid withdraw cable from car.

6. On Chevelle, if necessary, remove rubber tube

from front cable.

Installation

1.

On Chevelle, if necessary, replace rubber tube

over front cable.

2.

Position cable ball and conduit tip through cutout

in firewall. Make sure conduit locking fingers are

fully expanded and secured in cutout, then position

cable ball into pedal assembly swivel.

3.

Feed stud end of cable through frame rail and se-

cure with retainer on inner side of frame.

4.

Place one check nut on cable stud and insert stud

through equalizer, (make sure center cable is in

position), then place second check nut on stud.

5. Adjust parking brake as outlined in this section.

6. Connect positive battery cable.

Center Cable

Removal

1.

Place parking brake pedal in released position.

2.

Remove equalizer check nut and remove equalizer

from cable.

3.

Remove cable from cable guides.

4.

Disconnect center cable from rear cables at

connectors.

Installation

1.

Install cable ends into rear cable connectors.

2.

Place cable through equalizer and install equalizer

on to front cable stud, secure with check nut. (Do

not tighten.)

3.

Install cable in cable guides (figs. 19 and 20),

4.

Adjust parking brake as outlined in this section.

Rear Cables

Removal

1.

Place parking brake pedal in released position.

2.

Remove equalizer check nut and remove equalizer

from cable.

3.

Remove rear cable from connector.

4.

Remove retainer from rear cable at frame bracket.

Pull cable out of bracket.

5. Remove rear brake drum as outlined in this section.

6. Remove rear brake shoes as outlined in this section.

7. Remove cable end from parking brake actuating

lever.

8. Compress expanded conduit locking fingers at flange

plate entry hole and withdraw cable.

Installation

1.

Pass end of cable and conduit tip through flange

plate entry hole, making sure that conduit locking

fingers all expand fully.

2.

Connect cable end to actuating lever.

3.

Install rear brake shoes, drum and wheel as out-

lined in this section.

4.

Pass cable through frame bracket and install

retainer.

5. Install cable end into cable connector.

6. Position equalizer on center cable and place on

front cable stud, secure with check nut.

7. Make sure all center cable guides are in place

and adjust parking brake as outlined in this section.

PARKING BRAKE-CHEVY II (Fig. 21)

Lever Assembly

Removal

NOTE:

Remove positive cable from battery

to eliminate possibility of creating short cir-

cuits under dash.

CHEVROLET CHASSIS SERVICE MANUAL

Page 268 of 659

ENGINE

6-3

(ROUND) Y~~fll^H

CENTRIFUGAL

A ^k

ADVANCE--jflgKpl

MECHANISM

UB|

CAM

KSK^2

LUBRICATOR

VlSMi

REPLACEMENT

^BK

-^ADJUST

SQUARELY

AND

JUST

TOUCHING

LOBE

OF

CAM

/ROTOR

HBB

__

I^BH^F

?

(SOUARE)

^K^ I /—

CAM

jKft^J / LUBRICATOR

H^T^

CAUTION!

QV NEVER

OIL

•L-^

CAM LUBRICATOR-

REPLACE

WICK

WHEN

NECESSARY

LATERAL

MISALIGNMENT

PROPER

LATERAL ALIGNMENT

Fig.

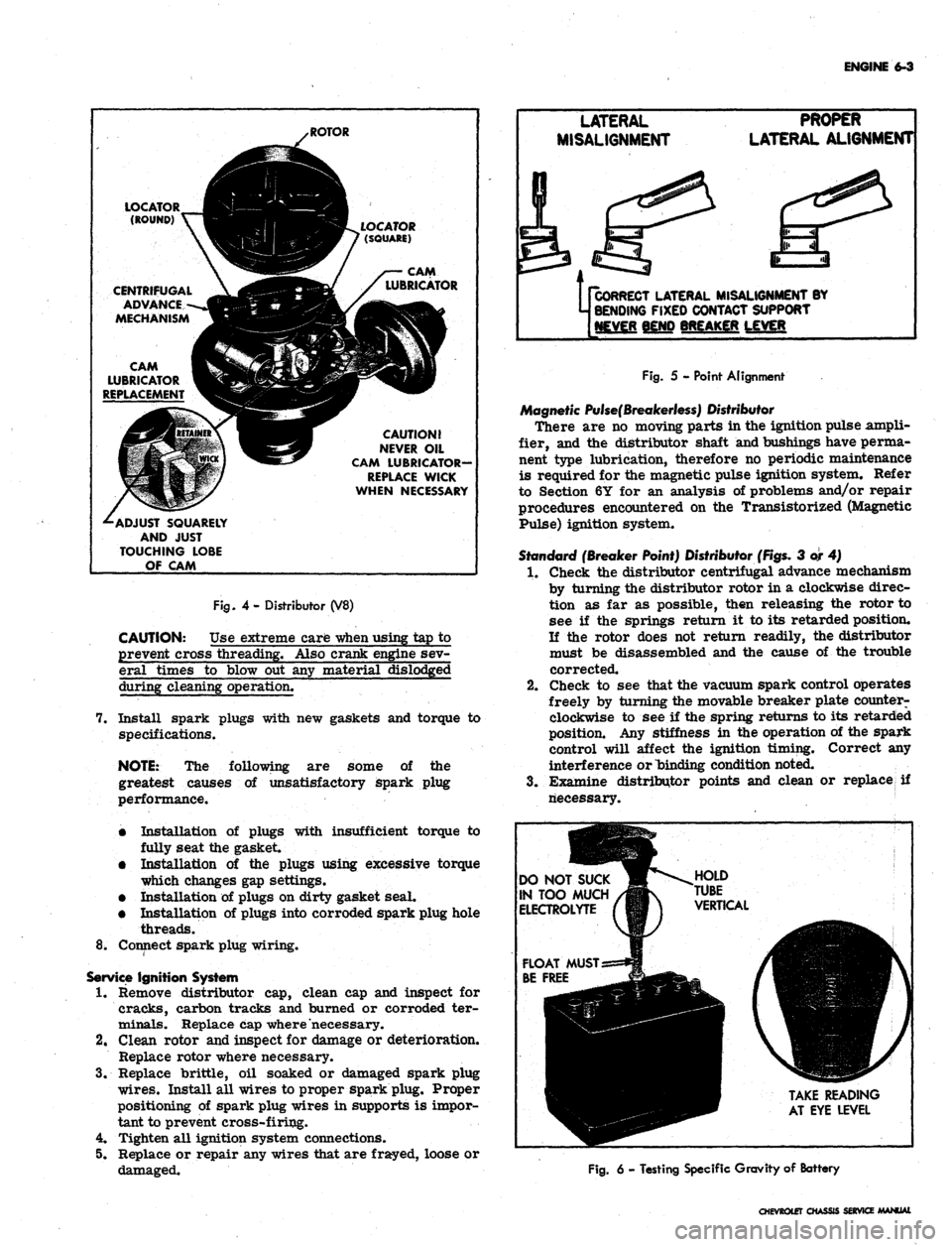

4- Distributor (V8)

CAUTION: Use extreme care

-when

using tap to

prevent cross threading. Also crank engine sev-

eral times to blow out any material dislodged

during cleaning operation.

7. Install spark plugs with new gaskets and torque to

specifications.

NOTE:

The following are some of the

greatest causes of unsatisfactory spark plug

performance.

•

Installation of plugs with insufficient torque to

fully seat the gasket.

•

Installation of the plugs using excessive torque

which changes gap settings.

•

Installation of plugs on dirty gasket seal.

•

Installation of plugs into corroded spark plug hole

threads.

8^ Connect spark plug wiring.

Service

Ignition System

1.

Remove distributor cap, clean cap and inspect for

cracks, carbon tracks and burned or corroded ter-

minals. Replace cap where necessary.

2.

Clean rotor and inspect for damage or deterioration.

Replace rotor where necessary.

3.

Replace brittle, oil soaked or damaged spark plug

wires.

Install all wires to proper spark plug. Proper

positioning of spark plug wires in supports is impor-

tant to prevent cross-firing.

4.

Tighten all ignition system connections.

5. Replace or repair any wires that are frayed, loose or

damaged.

Us

CORRECT

LATERAL MISALIGNMENT BY

j BENDING

FIXED CONTACT SUPPORT

[NEVER

BEND BREAKER LEVER

Fig.

5 - Point Alignment

Magnetic

Pulse(Breakerless)

Distributor

There are no moving parts in the ignition pulse ampli-

fier, and the distributor shaft and bushings have perma-

nent type lubrication, therefore no periodic maintenance

is required for the magnetic pulse ignition system. Refer

to Section 6Y for an analysis of problems and/or repair

procedures encountered on the Transistorized (Magnetic

Pulse) ignition system.

Standard

(Breaker Point) Distributor

(Figs.

3 or 4)

1.

Check the distributor centrifugal advance mechanism

by turning the distributor rotor in a clockwise direc-

tion as far as possible, then releasing the rotor to

see if the springs return it to its retarded position.

If the rotor does not return readily, the distributor

must be disassembled and the cause of the trouble

corrected.

2.

Check to see that the vacuum spark control operates

freely by turning the movable breaker plate counter-

clockwise to see if the spring returns to its retarded

position. Any stiffness in the operation of the spark

control will affect the ignition timing. Correct any

interference or binding condition noted.

3.

Examine distributor points and clean or replace if

riecessary.

DO

NOT SUCK

IN

TOO MUCH

ELECTROLYTE

TAKE

READING

AT

EYE LEVEL

Fig.

6 - Testing Specific Gravity of Battery

CHEVROtET

CHASSIS SERVICE MANUAL

Page 277 of 659

ENGINE

6-12

ENGINE

MECHANICAL

IN LINE

INDEX

Page

General Description . „ 6-12

Component Replacement and Adjustment 6-12

.Engine Assembly 6-12

Removal 6-12

Installation 6-13

Manifold Assembly 6-14

Removal . 6-14

Installation 6-14

Rocker Arm Cover . 6-14

Removal 6-14

mstallation . . . 6-14

Valve Mechanism

......

1 6-14

Removal 6-14

Installation and Adjustment . 6-14

Valve Lifters

..............

6-15

Locating Noisy Lifters

„.;....

6-15

Removal

.'.*...•

6-15

Installation . 6-15

Valve Stem Oil Seal and/or Valve Spring . 6-16

Replacement . 6-16

Cylinder Head Assembly . 6-16

Removal 6-16

Installation . 6-16

Oil Pan . » 6-17

Removal . . . ; . . 6-17

Installation

.........

. 6-17

Oil Pump . 6-18

Page

Removal . 6-18

Installation . 6-18

Oil Seal (Rear Main) . 6-19

Replacement 6-19

Crankshaft Pulley and Hub 6-19

Removal 6-19

Installation 6-19

Torsional Damper 6-19

Removal 6-19

Installation 6-19

Crankcase Front Cover . 6-20

Removal . 6-20

Installation 6-20

•

Oil Seal (Front Cover) 6-20

Replacement 6-20

Camshaft 6-21

Measuring Lobe Lift . ... .

.-.••.-.

6-21

Removal 6-21

Installation 6-22

Timing Gears

..••••.............••• 6—22

Replacement

6-22

Flywheel

6-22

Removal

* 6-22

Installation

6-22

Engine

Mounts

6-23

Replacement

(Front)

6-23

Replacement

(Rear)

. 6-23

GENERAL DESCRIPTION

The

In

Line engines

(fig. 1L)

covered

in

this section

are

the 1H3 cu. in. L4, the 194,

230

and

250

cu. in. L6,

regardless

of

which passenger vehicle they

are

used

in.

This section covers

the

removal

and

installation

of en-

gine assemblies;

the

removal, installation

and

adjustment

of some sub-assemblies

and

replacement

of

some

com-

ponents.

For

service

to all

components

and

sub-assem-

blies (after removal)

and

removal

of

some sub-assem-

blies,

refer

to

Section

6 of the

Chassis Overhaul Manual.

Because

of the

interchangeability

and

similarity

of

many engine sub-assemblies

and

engine parts, regardless

of which passenger vehicle they

are

used

in,

typical illus-

trations

and

procedures

are

used except where specific

illustrations

or

procedures

are

necessary

to

clarify

the

operation. Although illustrations showing bench opera-

tions

are

used, most single operations, when

not

part

of a

general overhaul, should

be

performed

(if

practical) with

the engine

in the

vehicle.

COMPONENT REPLACEMENT

AND

ADJUSTMENT

ENGINE ASSEMBLY

Removal

1.

Drain cooling system

and

engine

oil.

2.

Remove

air

cleaner

and

disconnect battery cables

at 7.

battery.

3.

Remove hood

as

outlined

in

Section 11.

4.

Remove radiator

and

radiator shroud

as

outlined

in

Section 13.

5.

Remove

fan

blade

and

pulley

as

outlined

in

Section

6K.

6. Disconnect wires

at:

• Starter Solenoid

8.

• Delcotron

9.

Temperature Switch

Oil Pressure Switch

Coil

Disconnect:

Accelerator linkage

at

manifold bellerank.

Exhaust pipe

at

manifold flange.

.

Fuel line (from tank)

at

fuel pump.

Vacuum line

to

power brake unit

at

manifold

(if

so equipped).

• Power steering pump lines

at

pump

end (if so

equipped).

Raise vehicle

and

place

on

jack stands.

Remove propeller shaft.

CHEVROLET CHASSIS SERVICE MANUAL