gauges CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 52 of 659

HEATER AND AIR CONDITIONING 1A-29

time as possible will be required to perform the

operation. Don't leave the system open any longer

than is necessary.

• Finally, after the operation has been completed and

the system sealed again, air and moisture should be

evacuated from the system before recharging.

GAUGE SET

The gauge set (fig. 41) is used when purging, evacua-

ting, charging or diagnosing trouble in the system. The

gauge at the left is known as the low pressure gauge.

The face is graduated into pounds of pressure and, in

the opposite direction, in inches of vacuum. This is the

gauge that should always be used in checking pressures

on the low pressure side of the system. When all parts of

the system are functioning properly the refrigerant

pressure on the low pressure side never fails below 0

pounds pressure. However, several abnormal conditions

can occur that will cause the low pressure to fall into a

partial vacuum. Therefore, a low pressure gauge is

required.

The high pressure gauge is used for checking pres-

sures on the high pressure side of the system.

The connection at the left is for attaching the low

pressure gauge line and the one at the right the high

pressure gauge line. The center connector is common to

both and is for the purpose of attaching a line for adding

refrigerant, discharging refrigerant, evacuating the sys-

tem and other uses. When not required, this line or

connection should be capped.

NOTE:

Gauge fitting connections should be in-

stalled hand tight only and the connections leak

tested before proceeding.

The hand shutoff valves on the gauge manifold do not

control the opening or closing off of pressure to the

gauges. They merely close each opening to the center

connector and to each other. During most diagnosing

and service operation, the valves must be closed. The

only occasion for opening both at the same time would be

to bypass refrigerant vapor from the high pressure to

the low pressure side of the system, or in evacuating

both sides of the system.

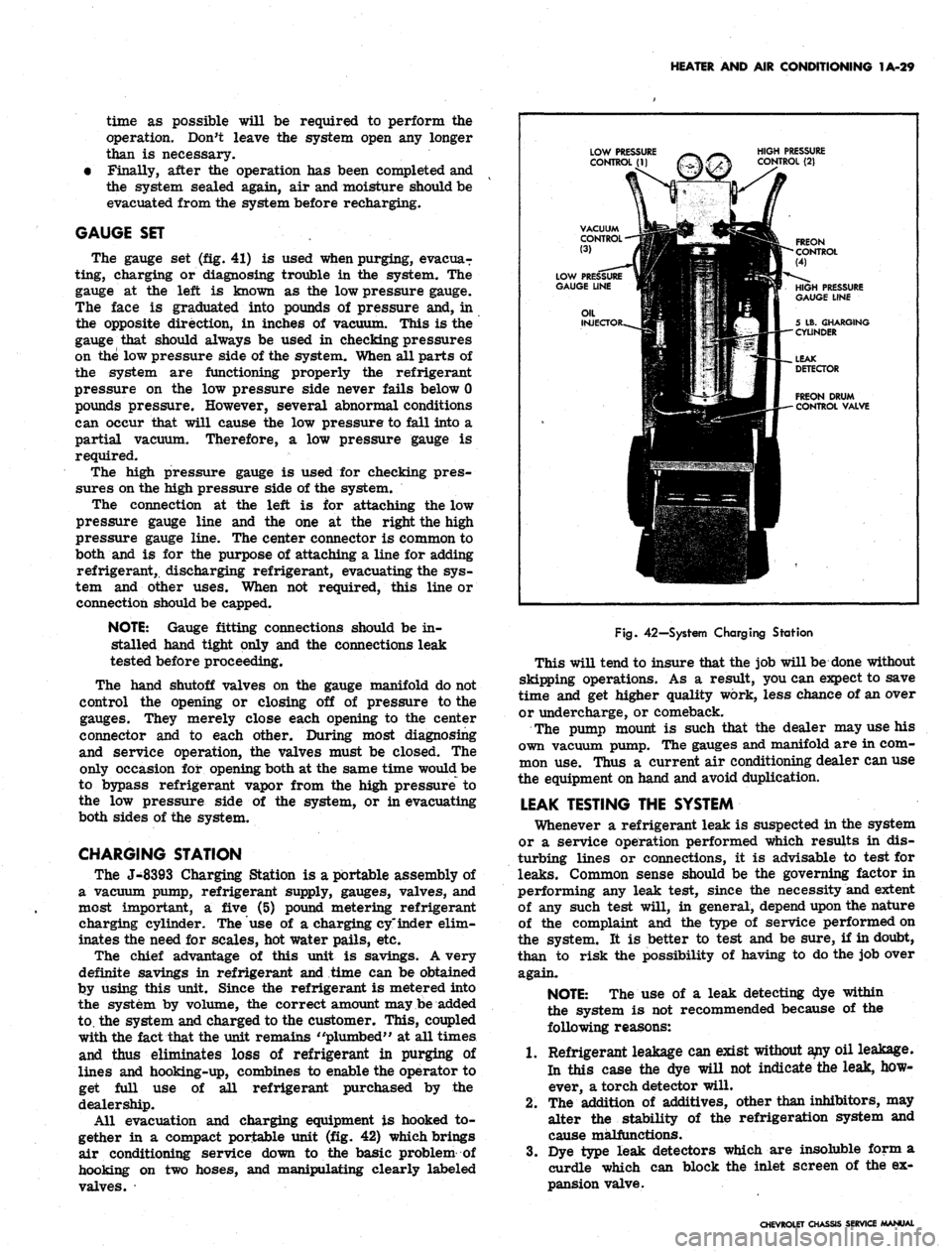

CHARGING STATION

The J-8393 Charging Station is a portable assembly of

a vacuum pump, refrigerant supply, gauges, valves, and

most important, a five (5) pound metering refrigerant

charging cylinder. The use of a charging ey'inder elim-

inates the need for scales, hot water pails, etc.

The chief advantage of this unit is savings. A very

definite savings in refrigerant and time can be obtained

by using this unit. Since the refrigerant is metered into

the system by volume, the correct amount may be added

to.

the system and charged to the customer. This, coupled

with the fact that the unit remains "plumbed" at all times

and thus eliminates loss of refrigerant in purging of

lines and hooking-up, combines to enable the operator to

get full use of all refrigerant purchased by the

dealership.

All evacuation and charging equipment is hooked to-

gether in a compact portable unit (fig. 42) which brings

air conditioning service down to the basic problem of

hooking on two hoses, and manipulating clearly labeled

valves.

Fig.

42—System Charging Station

This will tend to insure that the job will be done without

skipping operations. As a result, you can expect to save

time and get higher quality work, less chance of an over

or undercharge, or comeback.

The pump mount is such that the dealer may use his

own vacuum pump. The gauges and manifold are in com-

mon use. Thus a current air conditioning dealer can use

the equipment on hand and avoid duplication.

LEAK TESTING THE SYSTEM

Whenever a refrigerant leak is suspected in the system

or a service operation performed which results in dis-

turbing lines or connections, it is advisable to test for

leaks.

Common sense should be the governing factor in

performing any leak test, since the necessity and extent

of any such test will, in general, depend upon the nature

of the complaint and the type of service performed on

the system. It is better to test and be sure, if in doubt,

than to risk the possibility of having to do the job over

again.

NOTE:

The use of a leak detecting dye within

the system is not recommended because of the

following reasons:

1.

Refrigerant leakage can exist without any oil leakage.

In this case the dye will not indicate the leak, how-

ever, a torch detector will.

2.

The addition of additives, other than inhibitors, may

alter the stability of the refrigeration system and

cause malfunctions.

3.

Dye type leak detectors which are insoluble form a

curdle which can block the inlet screen of the ex-

pansion valve.

CHEVROLET CHASSIS SERVICE MANUAL

Page 66 of 659

HEATER AND AIR CONDITIONING 1A-43

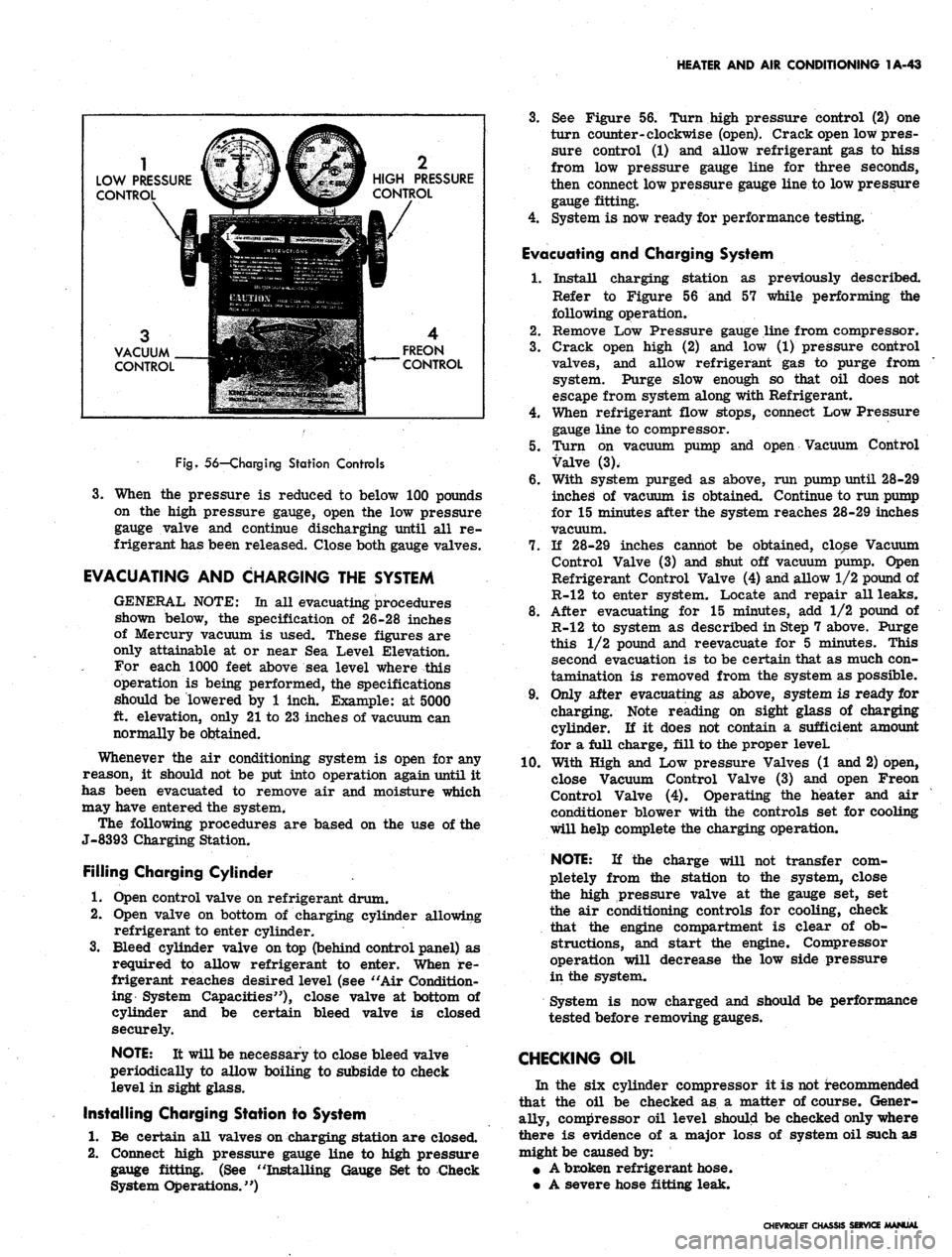

LOW PRESSURE

CONTROL

HIGH PRESSURE

CONTROL

3

VACUUM

CONTROL

4

FREON

CONTROL

Fig,

56—Charging Station Controls

3.

When the pressure is reduced to below 100 pounds

on the high pressure gauge, open the low pressure

gauge valve and continue discharging until all re-

frigerant has been released. Close both gauge valves.

EVACUATING AND CHARGING THE SYSTEM

GENERAL NOTE: La all evacuating procedures

shown below, the specification of 26-28 inches

of Mercury vacuum is used. These figures are

only attainable at or near Sea Level Elevation.

For each 1000 feet above sea level where this

operation is being performed, the specifications

should be lowered by 1 inch. Example: at 5000

ft. elevation, only 21 to 23 inches of vacuum can

normally be obtained.

Whenever the air conditioning system is open for any

reason, it should not be put into operation again until it

has been evacuated to remove air and moisture which

may have entered the system.

The following procedures are based on the use of the

J-8393 Charging Station.

Filling Charging Cylinder

1.

Open control valve on refrigerant drum.

2.

Open valve on bottom of charging cylinder allowing

refrigerant to enter cylinder.

3.

Bleed cylinder valve on top (behind control panel) as

required to allow refrigerant to enter. When re-

frigerant reaches desired level (see "Air Condition-

ing System Capacities"), close valve at bottom of

cylinder and be certain bleed valve is closed

securely.

NOTE: It will be necessary to close bleed valve

periodically to allow boiling to subside to check

level in sight glass.

Installing Charging Station to System

1.

Be certain all valves on charging station are closed.

2.

Connect high pressure gauge line to high pressure

gauge fitting. (See "Installing Gauge Set to Check

System Operations.")

3.

See Figure 56. Turn high pressure control (2) one

turn counter-clockwise (open). Crack open low pres-

sure control (1) and allow refrigerant gas to hiss

from low pressure gauge line for three seconds,

then connect low pressure gauge line to low pressure

gauge fitting.

4.

System is now ready for performance testing.

Evacuating and Charging System

1.

Install charging station as previously described.

Refer to Figure 56 and 57 while performing the

following operation.

2.

Remove Low Pressure gauge line from compressor.

3.

Crack open high (2) and low (1) pressure control

valves, and allow refrigerant gas to purge from

system. Purge slow enough so that oil does not

escape from system along with Refrigerant.

4.

When refrigerant flow stops, connect Low Pressure

gauge line to compressor.

5.

Turn on vacuum pump and open Vacuum Control

Valve (3).

6. With system purged as above, run pump until 28-29

inched of vacuum is obtained. Continue to run pump

for 15 minutes after the system reaches 28-29 inches

vacuum.

7.

If 28-29 inches cannot be obtained, close Vacuum

Control Valve (3) and shut off vacuum pump. Open

Refrigerant Control Valve (4) and allow 1/2 pound of

R-12 to enter system. Locate and repair all leaks.

8. After evacuating for 15 minutes, add 1/2 pound of

R-12 to system as described in Step 7 above. Purge

this 1/2 pound and reevacuate for 5 minutes. This

second evacuation is to be certain that as much con-

tamination is removed from the system as possible.

9. Only after evacuating as above, system is ready for

charging. Note reading on sight glass of charging

cylinder. If it does not contain a sufficient amount

for a full charge, fill to the proper leveL

10.

With High and Low pressure Valves (1 and 2) open,

close Vacuum Control Valve (3) and open Freon

Control Valve (4). Operating the heater and air

conditioner blower with the controls set for cooling

will help complete the charging operation.

NOTE: If the charge will not transfer com-

pletely from the station to the system, close

the high pressure valve at the gauge set, set

the air conditioning controls for cooling, check

that the engine compartment is clear of ob-

structions, and start the engine. Compressor

operation will decrease the low side pressure

in the system.

System is now charged and should be performance

tested before removing gauges.

CHECKING OIL

In the six cylinder compressor it is not recommended

that the oil be checked as a matter of course. Gener-

ally, compressor oil level should be checked only where

there is evidence of a major loss of system oil such as

might be caused by:

• A broken refrigerant hose.

• A severe hose fitting leak.

CHEVROLET CHASSIS SERVICE MANUAL

Page 273 of 659

ENGINE

6-8

Check

and

Adjust Ignition Timing

(Fig. 13)

1.

Disconnect

the

distributor spark advance hose

and

plug

the

vacuum source opening.

2.

Start engine

and run at

idle speed

(see

tune

up

chart).

3.

Aim

timing light

at

timing

tab.

NOTE:

- The

markings

on the

tabs

are in 2°

increments

(the

greatest number

of

markings

on

the

"A"

side

of the "O"). the "O"

markings

is

TDC

of

#1 cylinder

and all

BTDC settings fall

on

the

"A"

(advance) side

of "O".

4.

Adjust

the

timing

by

loosening

the

distributor clamp

and

,

rotating

the

distributor body

as

required, then

tighten

the

clamp.

5.

Stop engine

and

remove timing light

and

reconnect

the spark advance hose.

Adjust Idle Speed

and

Mixture

(Fig. 14)

(Except when

equipped with

Air

Injection Reactor System)

1.

As a

preliminary adjustment, turn idle mixture

screws lightly

to

seat

and

back

out 2

turns.

CAUTION:

Do not

turn idle mixture screw

tightly against seat

or

damage

may

result.

2.

With engine running

at

operating temperature (choke

wide open) adjust idle speed screw

to

bring idle

speed

to

specified

rpm

(automatic transmission

in

drive, manual transmission

in

neutral).

3.

Adjust idle mixture screw

to

obtain highest steady

idle speed

(1/4

turn

out

from lean roll).

4.

Repeat Steps

2 and 3 as

needed

for

final adjustment.

5.

Shut down

the

engine, remove gauges

and

install

air

cleaner.

Adjust Idle Speed

and

Mixture

(Fig. 14)

(With

Air

Injection Reactor System)

The recommended adjustment procedure

for Air

Injec-

tion Reactor System equipped engines

is as

follows:

1.

As a

preliminary adjustment, turn idle mixture

screws lightly

to

seat

and

than back

out 3

turns.

CAUTION:

Do not

turn idle mixture screw

tightly against seat

or

damage

may

result.

2.

With engine running

at

operating temperature, choke

wide open,

and

parking brake applied, adjust idle

specified idle speed (automatic

"drive"-manual transmission

in

to

in

screw

transmission

"neutral").

;3.

Adjust idle mixture screw (turn

in) to

"lean roll"

position; then turn screw

out 1/4

turn

(1/4

turn rich

from "lean roll").

The

definition

of

"lean roll" point

is

a 20 to 30 rpm

drop

in

engine speed, obtained

by

leaning

the

idle mixture.

4.

Repeat Steps

2 and 3 as

needed

for

final adjustments.

ADDITIONAL CHECKS

AND

ADJUSTMENTS

Testing Crankcase Ventilation Valve

(Fig. 15) 0

1.

Connect tachometer

and

vacuum gauge

as for

idle

speed

and

mixture adjustment.

2.

Set

parking brake, start engine

and

adjust idle speed

and mixture.

3.

Disconnect ventilation hose

at

valve, block opening

of

valve

and

read engine

rpm

change.

4.

A

change

of

less than

50 rpm

indicates

a

plugged

ventilation valve

-

replace

the

valve.

Cylinder Balance Test

(Fig. 16)

It

is

often difficult

to

locate

a

weak cylinder.

A com-

pression test,

for

example, will

not

locate

a

leaky intake

manifold,

a

valve

not

opening properly

due to a

worn

camshaft,

or a

defective spark plug.

With

the

cylinder balance test,

the

power output

of one

cylinder

may be

checked against another, using

a set of

grounding leads. When

the

power output

of

each cylinder

is

not

equal,

the

engine will lose power

and run

roughly.

Perform

a

cylinder balance test

as

follows:

1.

Connect

the

tachometer

and

vacuum gauge.

2.

Start engine

and run at 1500 rpm.

3.

Ground large clip

of

grounding leads

and

connect

in-

dividual leads

to all

spark plugs except

the

pair being

tested.

Divide

the

firing order

in

half

and

arrange

one

half

over

the

other.

The

cylinders

to be

tested together

ap-

pear

one

over

the

other.

L4 Firing Order

V8 Firing Order

1-8-4-3-6-5-7-2

1-6, 8-5, 4-7, 3-2

1-3-4-2

= 1-3

4-2

L6 Firing Order

1-5-3-6-2-4

=

=

1-4. 3-2

1-5-3

6-2-4

1-6, 5-2, 3-4

1-8-4-3

6-5-7-2

4.

Operate engine

on

each pair

of

cylinders

in

turn

and

note engine

rpm and

manifold vacuum

for

each pair.

A variation

of

more than

1

inch

of

vacuum

or 40 rpm

between pairs

of

cylinders being tested indicates that

the cylinders

are off

balance.

Battery

The battery should

be

checked with special testing

equipment

and to the

equipment manufacturers specifica-

tions.

See

Section 6Y

for

complete information

on

battery

tests.

Ignition

The following additional ignition checks

may be

made

with

any of

several pieces

of

equipment available

for un-

covering

the

source

of

engine difficulties.

The

specific

operating instructions

of the

equipment manufacturer

should

be

followed:

Cranking voltage

Ignition switch

Distributor resistance

Secondary resistance

Ignition output

and

secondary leakage

Cranking Voltage

(Fig. 17)

1.

Disconnect coil primary lead

at the

coil negative

terminal

to

prevent engine from firing during

cranking.

2.

Connect voltmeter between primary terminal

of coi|

(resistance wire side)

and

ground.

3.

Operate starting motor.

CHEVROLET CHASSIS SERVICE MANUAL

Page 309 of 659

SECTION 6M

ENGINE FUEL

CONTENTS OF THIS SECTION

Page

Carburetors 6M-1 Fuel Pumps .

Air Cleaners 6M-7 Special Tools

Page

6M-10

6M-12

CARBURETORS

INDEX

Page

General Description 6M-1

Service Procedures 6M-1

Preliminary Checks 6M-1

Idle Speed and Mixture Adjustment ........... 6M-1

Fast Idle Adjustment .................. 6M-3

Choke Adjustment 6M-3

Float Adjustment 6M-4

Page

Additional Adjustments 6M-4

Removal 6M-4

Test Before Installation 6M-5

Installation 6M-5

Fuel Filter Maintenance 6M-5

Choke Coil Replacement 6M-5

Throttle Linkage Adjustment . . 6M-6

GENERAL DESCRIPTION

Various carburetors (fig. lc) are used with Chevrolet,

Chevelle, Chevy II, Camaro and Corvette passenger

vehicles. These carburetors are designed to meet the

particular requirements of engines, transmissions and

vehicles, therefore carburetors that look alike are not

always interchangeable. (Refer to carburetor part num-

ber and/or specifications.)

Because many service procedures for the various

carburetors are similar, typical illustrations and pro-

cedures are used except where specific illustrations or

procedures are necessary to clarify the operation.

This section covers removal, installation and adjust-

ments (on engine) of carburetors. Also covered in this

section are maintenance procedures for choke coils,

throttle linkage and fuel filters. For carburetor .over-

haul procedures and additional adjustments (bench), re-

fer to Section 6M of the Overhaul Manual under the

carburetor being serviced.

Specifications for carburetors are located in the back

of this manual.

SERVICE PROCEDURES

Preliminary Checks

1.

Thoroughly warm-up engine. If the engine is cold,

allow to run for at least 15 minutes.

2.

Inspect torque of carburetor to intake manifold bolts

and intake manifold to cylinder head bolts to exclude

the possibility of air leaks.

3.

Inspect manifold heat control valve (if used) for free-

dom of action and correct spring tension.

Idle Speed and Mixture Adjustment (Except Air Injection

Reactor System)

NOTE:

This adjustment should be performed

with engine at operating temperature and park-

ing brake applied.

1.

Remove Air Cleaner.

2.

Connect tachometer and vacuum gauge to engine, then

set hand brake and shift transmission into neutral.

3.

As a preliminary adjustment, turn idle mixture

screws lightly to seat and back out 1-1/2 turns.

CAUTION: Do not turn idle mixture screw

tightly against seat or damage may result.

4.

With engine running (choke wide open) adjust idle

speed screw to specified idle speed, (automatic

transmission in drive, synchronized transmission in

neutral).

5. Adjust idle mixture screw to obtain highest steady

vacuum at specified idle speed.

NOTE:

On air conditioned vehicles, turn air

conditioning to the "on" position and hold the

hot idle compensator valve closed while adjust-

ing idle speed and idle mixture screws.

NOTE:

On Rochester BV carburetors the idle

mixture screw should be turned out 1/4 turn

from the "lean roll" position. The definition

of "lean roll" point is a 20 to 30 rpm drop

in engine speed obtained by leaning the idle

mixture.

6. Repeat Steps 4 and5 as needed for final adjustment.

NOTE:

If necessary, final adjustment of the \

carburetor may be made with the air cleaner

installed.

7. Turn engine off, remove gauges and install air

clearer.

CHEVROLET CHASSIS SERVICE MANUAL

Page 311 of 659

ENGINE FUEL 6M-3

Idle Speed and Mixture Adjustment (With Air Injection

Reactor System)

The following is the recommended procedure for Air

Injection Reactor System equipped engines.

NOTE: This adjustment should be performed

with engine at operating temperature and parking

brake applied.

1.

Remove air cleaner.

2.

Connect tachometer to engine, then set hand brake

and shift transmission into neutral.

3.

As a preliminary adjustment, turn idle mixture

screws lightly to seat and back out 3 turns.

CAUTION: Do not turn idle mixture screw

tightly against seat or damage may result."

4.

With engine running (choke wide open) adjust idle

speed screw to specified idle speed. (Automatic

transmission in dirve, synchronized transmission in

neutral).

5.

Adjust idle mixture screw (turn in) to "lean roll"

position; then turn screw out 1/4 turn (1/4 turn

rich from "lean roll"). The definition of "lean

roll" point is a 20 to 30 rpm drop in engine speed,

obtained by leaning the idle mixture.

NOTE: On air conditioned vehicles, turn air

conditioning "OFF" on in-line, 283, 327, and'

350 cu. in. engines, and turned "ON" and hot

idle compensator held closed on 396 and 427 cu.

in. engines.

6. Repeat Steps 4 and 5 as needed for final adjustment.

NOTE: If necessary, final adjustment of the

carburetor may be made with air cleaner

installed.

7.

Shut down the engine, remove gauges and install air

cleaner. *

Fast Idle Adjustment

Rochester

4MV and Holley

With fast idle lever on high step of cam and choke valve

open (engine warm) set fast idle to give specified engine

rpm. Adjust sejrew on Rochester 4MV and bend fast

idle lever *pn Holley. .

Choke Adjustment

With Remote Choke (Fig. 2c)

1.

Remove air cleaner and check to see that choke

valve and rod move freely.

2.

Disconnect choke rod at choke lever.

3.

Check choke adjustment as follows:

On all except 275 and 300 h.p. 327 cu. in. engines,

hold choke valve closed and pull.rod up against stop.

The top of choke rod end should be 1/2-1 rod diame-

ter above top of hole in choke valve lever.

On 275 and 300 h.p. 327 cu. in. engines, hold choke

valve closed and push rod down against stop on ther-

mostat bracket. The top of the choke rod should be

1/2-1 rod diameter below the top of the hole in the

choke lever.

4.

If necessary, adjust rod length by bending rod at

offset bend. (Bend must be such that rod enters

choke lever hole freely and squarely).

5.

Connect rod at choke lever and install air cleaner.

With Manual Choke (Carter YF)

1.

Remove air cleaner.

CHOKE VALVE

COMPLETELY

CLOSED

PULL UPWARD ON

ROD TO END OF

TRAVEL

BEND ROD

TO ADJUST

ROD IN BOTTOM

OF SLOT

BOTTOM OF

ROD SHOULD

BE EVEN WITH

TOP OF

HOLE

CHOKE VALVE

CLOSED

BOTTOM OF

ROD SHOULD

BE EVEN WITH

TOP OF HOLE

TOP OF ROD

SHOULD BE EVEN

WITH BOTTOM

OF HOLE (CHOKE

CLOSED)

BEND ROD TO

ADJUST

PULL DOWNWARD'

ON ROD TO CON-

TACT STOP

L6 (TYPICAL)

[

V8 327-275 HP

V8 350-295 HP

BEND ROD

TO ADJUST

PULL UPWARD ON

ROD TO CONTACT

STOP ON BRACKET

ALL V8 (EXCEPT 327-275 HP

AND 350-295 HP)

Fig.

2C—Remote Choke Adjustment

CHEVROLET CHASSIS SERVICE MANUAL

Page 392 of 659

CLUTCH AND TRANSMISSIONS 7-33

from rolling. The pointer on the indicator quadrant

should line up properly with the range indicators in all

ranges.

OIL LEAKS

Before attempting to correct an oil leak, the actual

source of the leak must be determined. In many cases

the source of the leak can be deceiving due to "wind flow1 f

around the engine and transmission.

The suspected area should be wiped clean of all oil

before inspecting for the source of the leak. Red dye is

used in the transmission oil at the assembly plant and

will indicate if the oil leak is from the transmission.

The use of a "black light"* to identify the oil at the

source of leak is also helpful. Comparing the oil from

the leak to that on the engine or transmission dip stick

(when viewed by black light) will determine the source

of the leak.

Oil leaks around the engine and transmission are gen-

erally carried toward the rear of the car by the air

stream. For example, a transmission "oil filter tube

to case leak" will sometimes appear as a leak at the

rear of the transmission. In determining the source of

an oil leak it is most helpful to keep the engine running.

The mating surfaces of servo cover, converter housing,

transmission case and transmission case extension

should be carefully examined for signs of leakage. The

vacuum modulator must also be checked to insure that

the diaphragm has not ruptured as this would allow trans-

mission oil to be drawn into the intake manifold. Us-

ually, the exhaust will be excessively smoky if the

diaphragm ruptures due to the transmission oil added to

the combustion. The transmission case extension rear

oil seal should also be checked. All test plugs should be

checked to make sure that they are tight and that there

is no sign of leakage at these points. The converter

underpan should also be removed. Any appreciable quan-

tity of oil in this area would indicate leakage at the pump

square seal ring, pump seal assembly, or pump bolt

sealing washers.

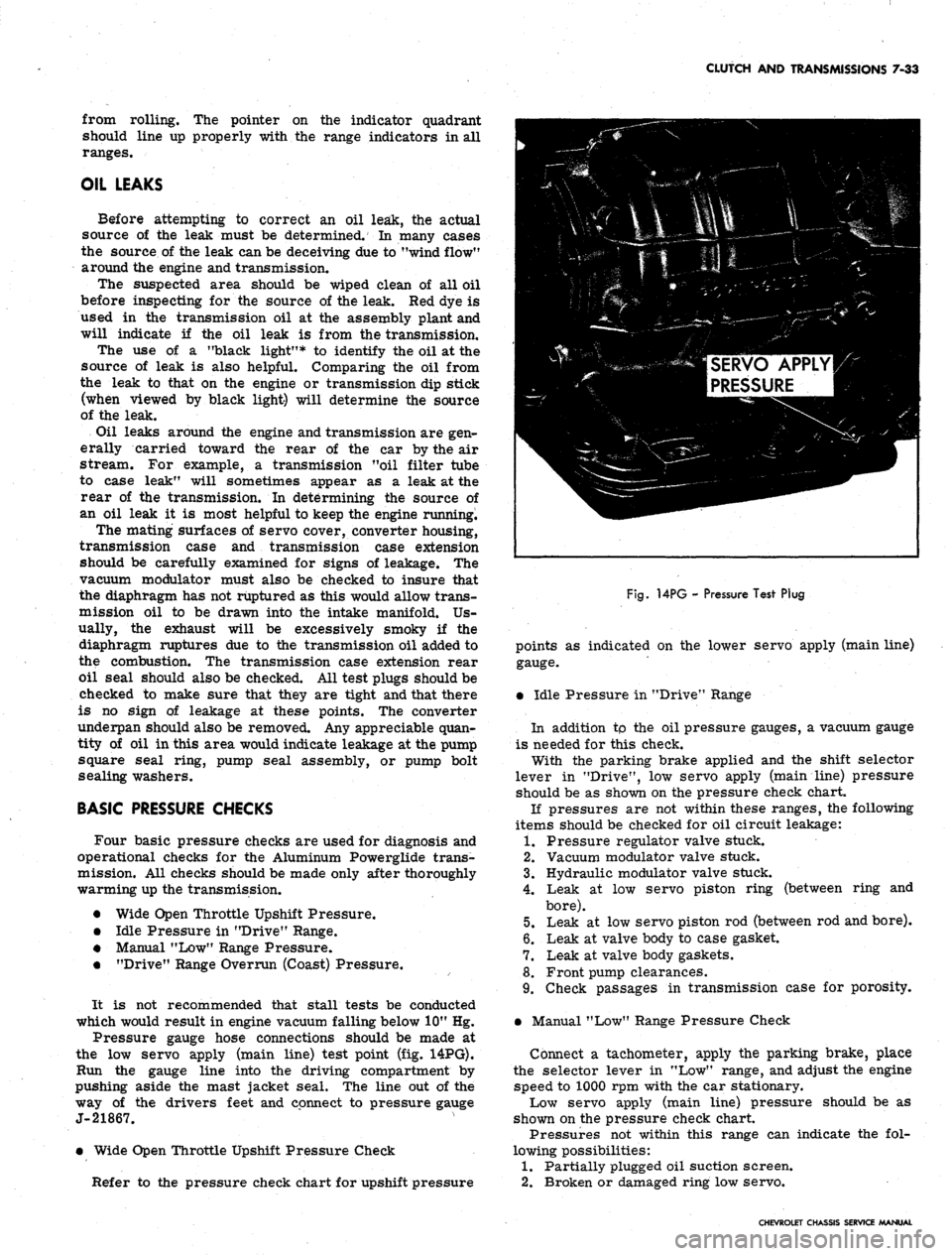

BASIC PRESSURE CHECKS

Four basic pressure checks are used for diagnosis and

operational checks for the Aluminum Powerglide trans-

mission. All checks should be made only after thoroughly

warming up the transmission.

• Wide Open Throttle Upshift Pressure.

• Idle Pressure in "Drive" Range.

• Manual "Low" Range Pressure.

• "Drive" Range Overrun (Coast) Pressure.

It is not recommended that stall tests be conducted

which would result in engine vacuum falling below 10" Hg.

Pressure gauge hose connections should be made at

the low servo apply (main line) test point (fig. 14PG).

Run the gauge line into the driving compartment by

pushing aside the mast jacket seal. The line out of the

way of the drivers feet and connect to pressure gauge

J-21867.

• Wide Open Throttle Upshift Pressure Check

Refer to the pressure check chart for upshift pressure

SERVO APPLY

PRESSURE

Fig.

14PG - Pressure Test Plug

points as indicated on the lower servo apply (main line)

gauge.

• Idle Pressure in "Drive" Range

In addition tp the oil pressure gauges, a vacuum gauge

is needed for this check.

With the parking brake applied and the shift selector

lever in "Drive", low servo apply (main line) pressure

should be as shown on the pressure check chart.

If pressures are not within these ranges, the following

items should be checked for oil circuit leakage:

1.

Pressure regulator valve stuck.

2.

Vacuum modulator valve stuck.

3.

Hydraulic modulator valve stuck.

4.

Leak at low servo piston ring (between ring and

bore).

5.

Leak at low servo piston rod (between rod and bore).

6. Leak at valve body to case gasket.

7.

Leak at valve body gaskets.

8. Front pump clearances.

9. Check passages in transmission case for porosity.

• Manual "Low" Range Pressure Check

Connect a tachometer, apply the parking brake, place

the selector lever in "Low" range, and adjust the engine

speed to 1000 rpm with the car stationary.

Low servo apply (main line) pressure should be as

shown on the pressure check chart.

Pressures not within this range can indicate the fol-

lowing possibilities:

1.

Partially plugged oil suction screen.

2.

Broken or damaged ring low servo.

CHEVROLET CHASSIS SERVICE MANUAL

Page 513 of 659

SECTION 12

ELECTRICAL-BODY AND CHASSIS

CONTENTS

OF

THIS

SECTION

Page

Page

System 12-1

Instruments and Gauges 12-21

Directional Signal 12r40

Windshield Wipers and Washers 12-44

Wiring Diagrams 12-56

Special Tools 12-60

LIGHTING SYSTEM

INDEX

Page

General Description

!2-i

Maintenance and Adjustments

•.................. 12-2

Headlamp Adjustment......................

12-3

Headlamp Panel Travel Adjustment.

12-5

Service Operations.

. . .. 12-5

Front Lighting

12-5

Headlamp

. 12_5

Parking Lamp

12-5

Fender Lamp

. 12_^

Headlamp Panel

12-8

Headlamp Panel Motor

^2-9

Rear Lighting

l2-10

Tail, Stop and Directional Lamps

12-10

Page

Backing Lamps

12-14

License Plate Lamp

12-14

Automatic Transmission Quadrant Lamp

12-14

Seat Separator Console Lamps

. 12-15

Lighting Switch

. . 12-15

Wiper Switch.

12-15

Stoplight Switch

12-15

Dimmer Switch

12-15

Backing Lamp Switches

12-15

Neutral Safety Switches

12-17

Parking Brake Alarm Switch

................. 12-19

Instrument Panel Compartment Lamp/Switch

12-19

Cirgarette Lighter

12-19

GENERAL DESCRIPTION

.

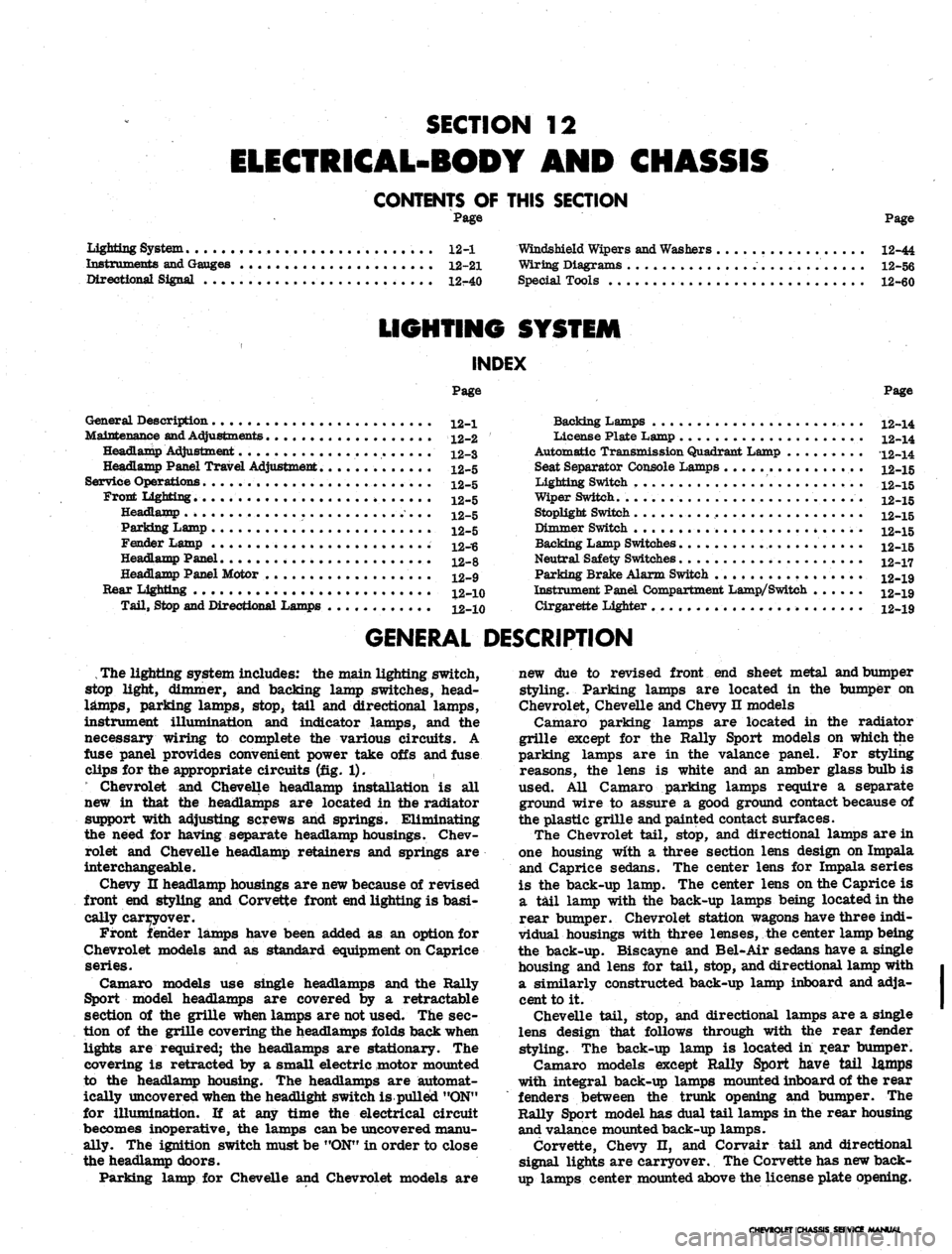

The lighting system includes: the main lighting switch,

stop light, dimmer, and backing lamp switches, head-

lamps, parking lamps, stop, tail and directional lamps,

instrument illumination and indicator lamps, and the

necessary wiring to complete the various circuits. A

fuse panel provides convenient power take offs and fuse

clips for the appropriate circuits (fig. 1).

Chevrolet and Chevelle headlamp installation is all

new in that the headlamps are located in the radiator

support with adjusting screws and springs. Eliminating

the need for having separate headlamp housings. Chev-

rolet and Chevelle headlamp retainers and springs are

interchangeable.

Chevy n headlamp housings are new because of revised

front end styling and Corvette front end lighting is basi-

cally carryover.

Front fender lamps have been added as an option for

Chevrolet models and as standard equipment on Caprice

series.

Camaro models use single headlamps and the Rally

Sport model headlamps are covered by a retractable

section of the grille when lamps are not used. The sec-

tion of the grille covering the headlamps folds back when

lights are required; the headlamps are stationary. The

covering is retracted by a small electric motor mounted

to the headlamp housing. The headlamps are automat-

ically uncovered when the headlight switch is pulled "ON"

for illumination. If at any time the electrical circuit

becomes inoperative, the lamps can be uncovered manu-

ally. The ignition switch must be

"ON"

in order to close

the headlamp doors.

Parking lamp for Chevelle and Chevrolet models are

new due to revised front end sheet metal and bumper

styling. Parking lamps are located in the bumper on

Chevrolet, Chevelle and Chevy n models

Camaro parking lamps are located in the radiator

grille except for the Rally Sport models on which the

parking lamps are in the valance panel. For styling

reasons, the lens is white and an amber glass bulb is

used. All Camaro parking lamps require a separate

ground wire to assure a good ground contact because of

the plastic grille and painted contact surfaces.

The Chevrolet tail, stop, and directional lamps are in

one housing with a three section lens design on Impala

and Caprice sedans. The center lens for Impala series

is the back-up lamp. The center lens on the Caprice is

a tail lamp with the back-up lamps being located in the

rear bumper. Chevrolet station wagons have three indi-

vidual housings with three lenses, the center lamp being

the back-up. Biscayne and Bel-Air sedans have a single

housing and lens for tail, stop, and directional lamp with

a similarly constructed back-up lamp inboard and adja-

cent to it.

Chevelle tail, stop, and directional lamps are a single

lens design that follows through with the rear fender

styling. The back-up lamp is located in r.ear bumper.

Camaro models except Rally Sport have tail lamps

with integral back-up lamps mounted inboard of the rear

fenders between the trunk opening and bumper. The

Rally Sport model has dual tail lamps in the rear housing

and valance mounted back-up lamps.

Corvette, Chevy n, and Corvair tail and directional

signal lights are carryover. The Corvette has new back-

up lamps center mounted above the license plate opening.

CHEVROLET CHASSIS SERVICE

Page 514 of 659

ELECTRICAL-BODY AND CHASSIS 12-2

FJg.

1 - Fuse Panel Assembly

All power window and tailgate circuits require the igni-

tion switch to be "ON" to open or close the windows un-

like past model designs which were operated independ-

ently of the ignition switch.

The windshield wiper and washer switch is new in that

washer button in the center of the knob has been deleted

and its function will be accomplished by pushing the knob.

A set screw is used to retain the knob to the shaft.

In addition to fuses, the wiring harness incorporates

fusible links to protect the wiring. Links are used rather

than a fuse in wiring circuits that are not normally fused,

such as the ignition circuit. Fusible links in the Chevro-

let wiring are four gauge sizes smaller than the cable it

is designed to protect. The links are marked on the

insulation with wire gauge size because of the heavy insu-

lation which makes the link appear a heavier gauge than it

actually is.

Engine compartment wiring harness incorporate sev-

eral fusible links. Each link is identified with its gauge

size.

A fusible link is a length of special wire (normally

four wire gauges smaller than the circuit it is protecting)

used in wiring circuits that are not normally fused, such

as the ignition circuit. The same size wire with a spe-

cial hypalon insulation must be used when replacing a

fusible link.

The links are:

1.

The pigtail lead at the battery positive cable (except

Corvette) is a 14 gauge, brown fusible link protecting

the 10 gange battery charging circuit. This wire is

an integral part of the battery cable assembly and

servicing requires replacing the complete battery

cable assembly. On Corvette models this link is

installed as a molded splice at the solenoid "Bat"

terminal and servicing requires splicing in a new

link.

2.

A 16 gauge black fusible link is located at horn relay

to protect all unfused wiring of 12 gauge or larger.

It is a serviceable piece with an in-line connector

and is not integral with the wiring harness.

3.

The generator warning light and field circuitry (16

gauge wire) is protected by a fusible link (20 gauge

orange wire) used in the "battery feed to voltage

regulator #3 terminal" wire. The link is installed

as a molded splice in the generator and forward lamp

harness and is serviced by splicing in a new 20 gauge

wire as required.

4.

The ammeter circuit on all models is protected by

two orange, 20 gauge wire fusible links installed as

molded splices in the circuit at the junction block or

the solenoid "Bat" terminal (Corvette only) and at the

horn relay. Each link is serviced by splicing in a

new 20 gauge wire as required.

The wiring harnesses use a standarized. color code

common to all Chevrolet vehicles. Under the color code,

the color of the wire designates a particular circuit. The

harness title indicates the type of harness, single of mul-

tiple wire, and also describe the location of the harness.

The body harness is a flat, solid wire assembly and is

routed through the vehicle near the center of the body.

Composite wiring diagrams (figs. 104 thru 124) are in-

cluded at the end of this section.

MAINTENANCE AND ADJUSTMENTS

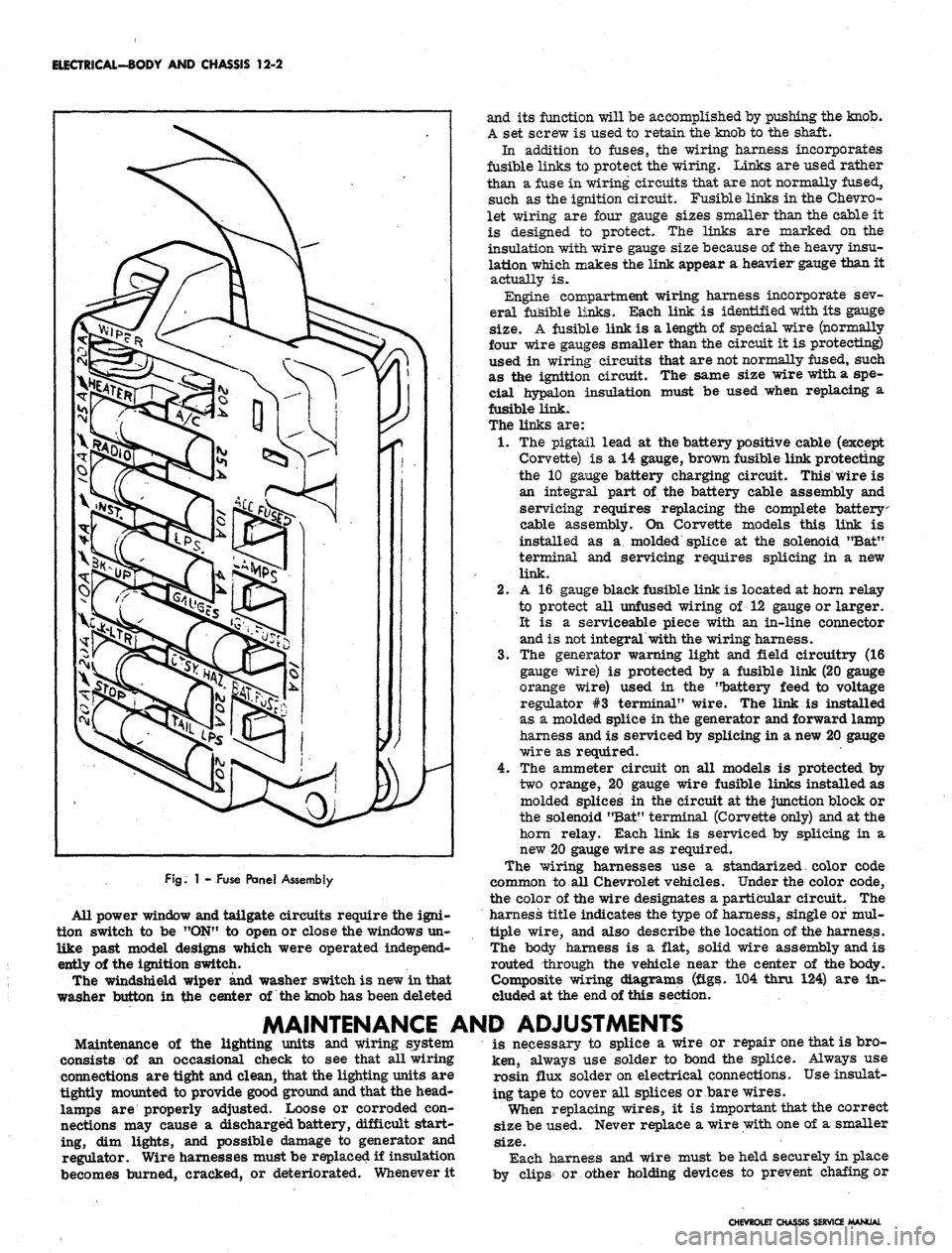

Maintenance of the lighting units and wiring system

consists of an occasional check to see that all wiring

connections are tight and clean, that the lighting units are

tightly mounted to provide good ground and that the head-

lamps are properly adjusted. Loose or corroded con-

nections may cause a discharged battery, difficult start-

ing, dim lights, and possible damage to generator and

regulator. Wire harnesses must be replaced if insulation

becomes burned, cracked, or deteriorated. Whenever it

is necessary to splice a wire or repair one that is bro-

ken, always use solder to bond the splice. Always use

rosin flux solder on electrical connections. Use insulat-

ing tape to cover all splices or bare wires.

When replacing wires, it is important that the correct

size be used. Never replace a wire with one of a smaller

size.

Each harness and wire must be held securely in place

by clips or other holding devices to prevent chafing or

CHEVROLET CHASSIS SERVICE MANUAL

Page 533 of 659

ELECTRICAL-BODY AND CHASSIS 12-21

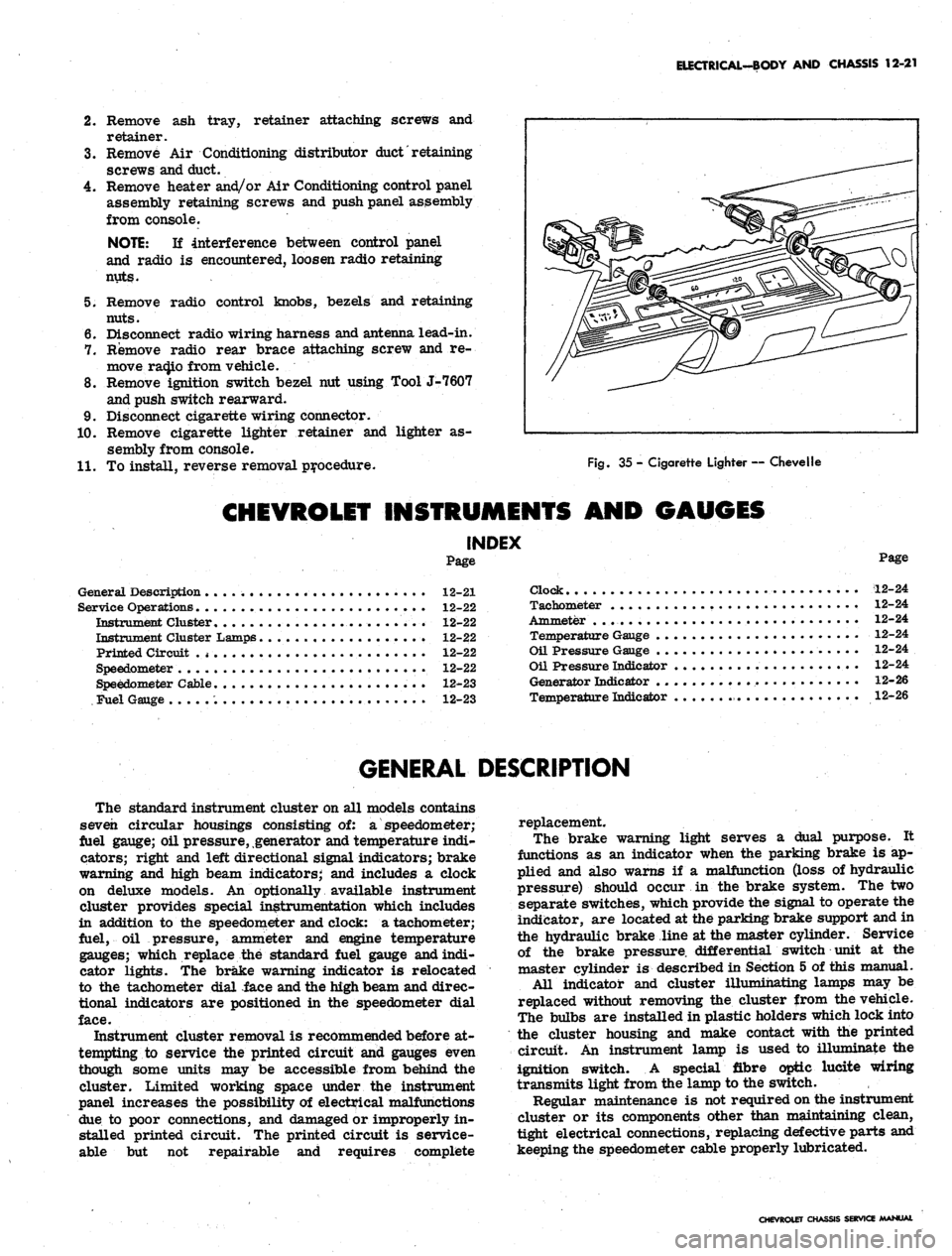

2.

Remove ash tray, retainer attaching screws and

retainer.

3.

Remove Air Conditioning distributor

duct'

retaining

screws and duct.

4.

Remove heater and/or Air Conditioning control panel

assembly retaining screws and push panel assembly

from console.

NOTE:

If interference between control panel

and radio is encountered, loosen radio retaining

nuts.

5. Remove radio control knobs, bezels and retaining

nuts.

6. Disconnect radio wiring harness and antenna lead-in.

7. Remove radio rear brace attaching screw and re-

move ra(Jio from vehicle.

8. Remove ignition switch bezel nut using Tool J-7607

and push switch rearward.

9. Disconnect cigarette wiring connector.

10.

Remove cigarette lighter retainer and lighter as-

sembly from console.

11.

To install, reverse removal procedure.

Fig.

35 - Cigarette Lighter — Chevelle

CHEVROLET INSTRUMENTS AND GAUGES

INDEX

Page

General Description 12-21

Service Operations 12-22

Instrument Cluster........................ 12-22

Instrument Cluster Lamps 12-22

Printed Circuit .

* •

12-22

Speedometer 12-22

Speedometer Cable 12-23

Fuel Gauge 12-23

Page

Clock 12-24

Tachometer 12-24

Ammeter . . 12-24

Temperature Gauge 12-24

Oil Pressure Gauge 12-24

Oil Pressure Indicator 12-24

Generator Indicator 12-26

Temperature Indicator 12-26

GENERAL DESCRIPTION

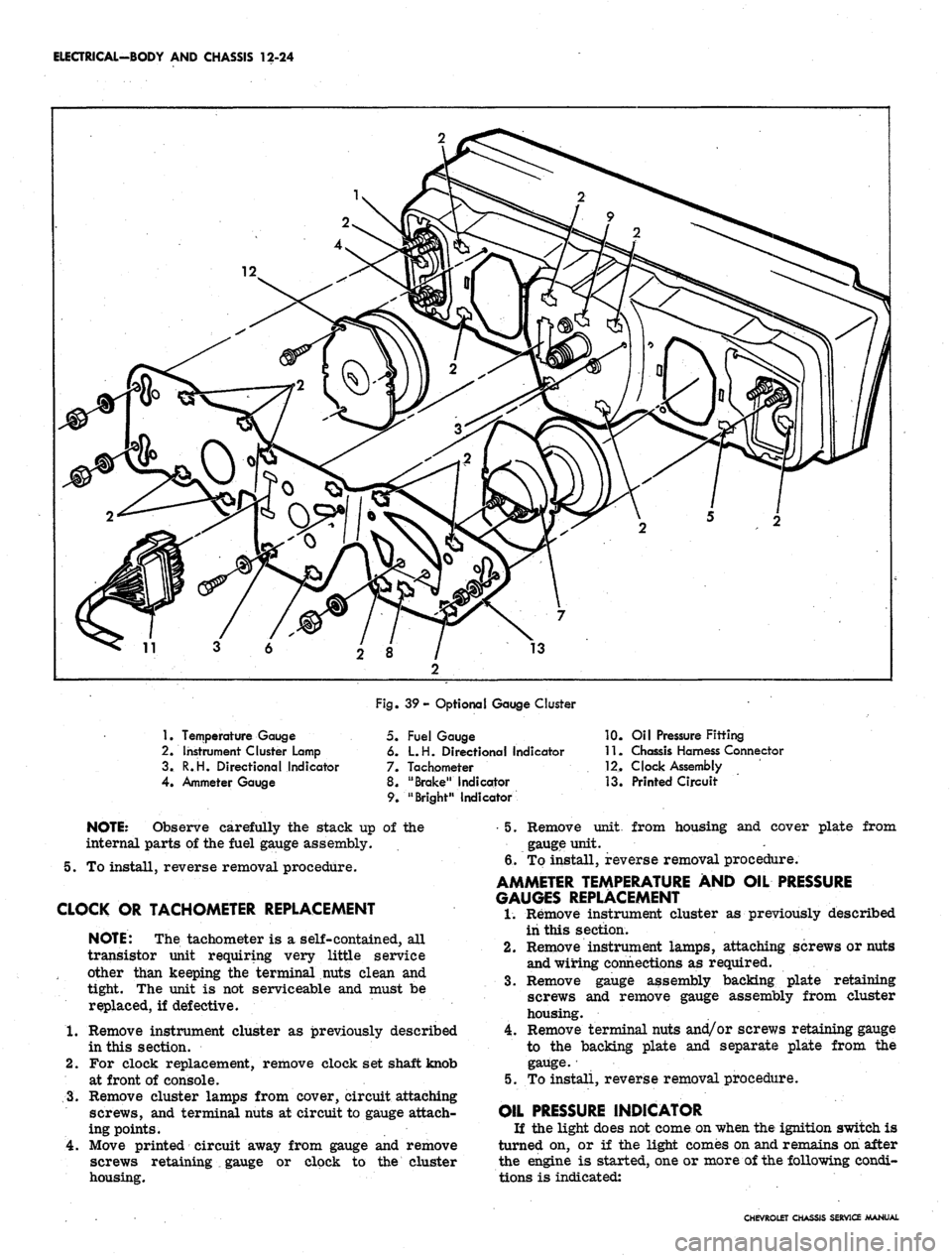

The standard instrument cluster on all models contains

seven circular housings consisting of: a speedometer;

fuel gauge; oil pressure, generator and temperature indi-

cators; right and left directional signal indicators; brake

warning and high beam indicators; and includes a clock

on deluxe models. An optionally available instrument

cluster provides special instrumentation which includes

in addition to the speedometer and clock: a tachometer;

fuel, oil pressure, ammeter and engine temperature

gauges; which replace the standard fuel gauge and indi-

cator lights. The brake warning indicator is relocated

to the tachometer dial face and the high beam and direc-

tional indicators are positioned in the speedometer dial

face.

Instrument cluster removal is recommended before at-

tempting to service the printed circuit and gauges even

though some units may be accessible from behind the

cluster. Limited working space under the instrument

panel increases the possibility of electrical malfunctions

due to poor connections, and damaged or improperly in-

stalled printed circuit. The printed circuit is service-

able but not repairable and requires complete

replacement.

The brake warning light serves a dual purpose. It

functions as an indicator when the parking brake is ap-

plied and also warns if a malfunction (loss of hydraulic

pressure) should occur in the brake system. The two

separate switches, which provide the signal to operate the

indicator, are located at the parking brake support and in

the hydraulic brake line at the master cylinder. Service

of the brake pressure, differential switch unit at the

master cylinder is described in Section 5 of this manual.

All indicator and cluster illumihating lamps may be

replaced without removing the cluster from the vehicle.

The bulbs are installed in plastic holders which lock into

the cluster housing and make contact with the printed

circuit. An instrument lamp is used to illuminate the

ignition switch. A special fibre optic lucite wiring

transmits light from the lamp to the switch.

Regular maintenance is not required on the instrument

cluster or its components other than maintaining clean,

tight electrical connections, replacing defective parts and

keeping the speedometer cable properly lubricated.

CHEVROLET CHASSIS SERVICE MANUAL

Page 536 of 659

ELECTRICAL-BODY AND CHASSIS 12-24

1.

Temperature Gauge

2.

Instrument Cluster Lamp

3.

R.H. Directional Indicator

4.

Ammeter Gauge

Fig. 39- Optional Gauge Cluster

5. Fuel Gauge

6. L.H. Directional Indicator

7. Tachometer

8. "Brake" Indicator

9. "Bright" Indicator

10.

Oil Pressure Fitting

11.

Chassis Harness Connector

12.

Clock Assembly

13.

Printed Circuit

NOTE:

Observe carefully the stack up of the

internal parts of the fuel gauge assembly.

5. To install, reverse removal procedure.

CLOCK OR TACHOMETER REPLACEMENT

NOTE:

The tachometer is a self-contained, all

transistor unit requiring very little service

other than keeping the terminal nuts clean and

tight. The unit is not serviceable and must be

replaced, if defective.

1.

Remove instrument cluster as previously described

in this section.

2.

For clock replacement, remove clock set shaft knob

at front of console.

3.

Remove cluster lamps from cover, circuit attaching

screws, and terminal nuts at circuit to gauge attach-

ing points.

4.

Move printed circuit away from gauge and remove

screws retaining

•_

gauge or clock to the cluster

housing.

•5.

Remove unit, from housing and cover plate from

gauge unit.

6/To install, reverse removal procedure.

AMMETER TEMPERATURE AND OIL PRESSURE

GAUGES REPLACEMENT

1.

Remove instrument cluster as previously described

iii this section.

2.

Remove instrument lamps, attaching screws or nuts

and wiring connections as required.

3.

Remove gauge assembly backing plate retaining

screws and remove gauge assembly from cluster

housing.

4.

Remove terminal nuts and/or screws retaining gauge

to the backing plate and separate plate from the

gauge.

•

5. To install, reverse removal procedure.

OIL PRESSURE INDICATOR

If the light does not come on when the ignition switch is

turned on, or if the light comes on and remains on after

the engine is started, one or more of the following condi-

tions is indicated:

CHEVROLET CHASSIS SERVICE MANUAL