oil level CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 15 of 659

LUBRICATION 0-13

LUBRICATION

INDEX

Page

Engine Crankcase Oil . 0-13

Crankcase Capacities. . 0-13

Lubrication . ,

•

o-13

SAE Viscosity Oils 0-13

Types of Oils 0-14

Maintaining Oil Level 0-14

Oil and Filter Change Intervals 0-14

Oil.

. . ...:.. 0-14

Filter o-14

Crankcase Dilution . 0-14

Automatic Control Devices to Minimize

Crankcase Dilution 0-14

Crankcase Breather Cap 0-14

Crankcase Ventilation System 0-15

Valve Type 0-15

Fuel Filter 0-15

Air Cleaner . 0-15

Polyurethane Type 0-15

Oil Wetted Paper Element Type 0-15

Battery Terminal Washers 0-15

Page

Distributor 0-15

Rear Axle and 3-Speed and Overdrive

4-Speed Transmission 0-15

Recommended Lubricants 0-15

Multi-Purpose Gear Lubricants 0-15

Lubricant Additions 0-15

Lubricant Changes 0-15

Powerglide Transmission 0-15

Turbo Hydra-Matic 0-16

Front Wheel Bearings 0-16

Manual Steering Gear . . . . 0-16

Power Steering 0-16

Air Conditioning 0-16

Brake Master Cylinder. 0-16

Parking Brake 0-16

Clutch Cross-Shaft , 0-16

Chassis Lubrication 0-16

Lubrication Diagrams . . 0-19

Body Lubrication (Chevrolet, Chevelle, Chevy n, Camaro). 0-20

Body Lubrication Points (Corvette) . 0-21

The selection of the proper lubricant and its correct

application at regular intervals does much to increase the

life and operation of all moving parts of the vehicle.

Consequently, it is important that the correct grade of

oil or grease, as noted in the following pages, be used.

ENGINE CRANKCASE OIL

Crankcase Capacity

4 Cylinder 4 qt.

6 Cylinder 4 qt.

8 Cylinder (283) 4 qt.

8 Cylinder (327) 4 qt.

8 Cylinder (350) 4 qt.

8 Cylinder (396) 4 qt.

8 Cylinder (427) Chevrolet 4 qt.

8 Cylinder (427) Corvette 5 qt.

For 4 Cyl. Add .5 qt. with filter change;

1 qt. for 6 and 8 Cyl. engines.

Lubrication

Crankcase oil should be selected to give the best per-

formance under the climatic and driving conditions in the

territory in which the vehicle is driven.

During warm or hot weather, an oil which will provide

adequate lubrication under high operating temperatures

is required.

During the colder months of the year* an oil which will

permit easy starting at the lowest atmospheric tempera-

ture likely to be encountered, should be used.

When the crankcase is drained and refilled, the crank-

case oil should be selected, not on the basis of the exist-

ing temperature at the time of the change, but on the

lowest temperature anticipated for the period during

which the oil is to be used.

Unless the crankcase oil is selected on the basis of

viscosity or fluidity of the anticipated temperature, dif-

ficulty in starting will be experienced at each sudden

drop in temperature.

SAE Viscosity Oils

SAE Viscosity Numbers indicate only the viscosity or

body of the oil, that is, whether an oil is a light or a

heavy body oil, and do not consider or include other

properties or quality factors.

The lower SAE Viscosity Numbers, such as SAE 5W

and SAE 10W which represent the light body oils, are

recommended for use during cold weather to provide

easy starting and instant lubrication. The higher SAE

Viscosity Numbers such as SAE 20 and SAE 20W, which

represents heavier body oils, are recommended for use

during warm or hot weather to provide improved oil

economy and adequate lubrication under high operating

temperatures.

Oils are available which are designed to combine the

easy starting characteristics of the lower SAE Viscosity

Number with the warm weather operating characteristics

of the higher SAE Viscosity Number. These are termed

"multi-viscosity oils," SAE 5-10W, SAE 5W-20, SAE

10W-20W, and SAE 10W-30.

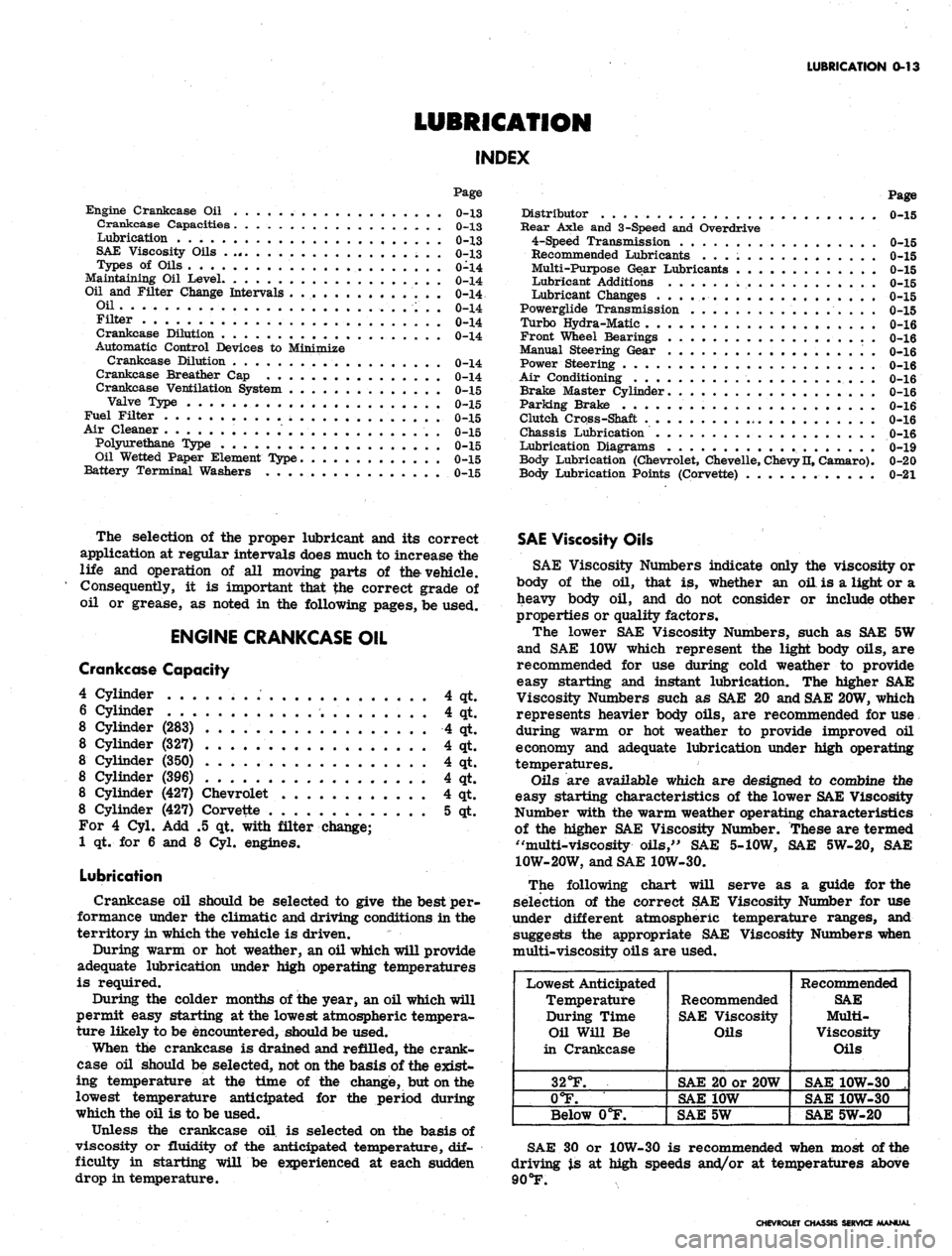

The following chart will serve as a guide for the

selection of the correct SAE Viscosity Number for use

under different atmospheric temperature ranges, and

suggests the appropriate SAE Viscosity Numbers when

multi-viscosity oils are used.

Lowest Anticipated

Temperature

During Time

Oil Will Be

in Crankcase

32°F.

0°F.

Below 0°F.

Recommended

SAE Viscosity

Oils

SAE 20 or 20W

SAE 10W

SAE 5W

Recommended

SAE

Multi-

Viscosity

Oils

SAE 10W-30 .

SAE 10W-30

SAE 5W-20

SAE 30 or 10W-30 is recommended when most of the

driving is at high speeds and/or at temperatures above

90

°F.

CHEVROLET CHASSIS SERVICE MANUAL

Page 16 of 659

LUBRICATION 0-14

SAE 5W-30 oils may be used during periods when

temperatures of 32° and below are to be expected.

Types of Oils

In service, crankcase oils may form sludge and varnish

and under some conditions, corrosive acids unless pro-

tected against oxidation.

To minimize the formation of these harmful products

and to assure the use of oil best suited for present day

operating conditions, automobile manufacturers have de-

veloped a series of sequence tests designed to evaluate

the ability of any oil to properly lubricate automobile

engines.

It is recommended that only those oils which are

certified by their suppliers as meeting or exceeding the

maximum severity requirements of these sequence tests

(or GM Standard 4745-M) be used in Chevrolet engines.

Certified sequence tested oils will be described as such

on their containers.

Maintaining Oil Level

The oil gauge rod is marked "Full" and "Add Oil."

These notations have broad arrows pointing to the level

lines.

The oil level should be maintained between the

two lines, neither going above the "Full" line nor under

the "Add Oil" line. DO NOT OVERFILL. After operating

vehicle allow a few minutes for oil to return to crankcase

before checking oil level.

Check the oil level frequently and add oil when

necessary.

Oil and Filter Change Intervals

NOTE:

Under prolonged dusty driving condi-

tions,

it is recommended that these operations

be performed more often.

OIL

To insure continuation of best performance, low main-

tenance cost and long engine life, it is necessary to

change the crankcase oil whenever it becomes contami-

nated with harmful foreign materials. Under normal

driving conditions draining the crankcase and refilling

with fresh oil every 60 days or every 6000 miles which-

ever occurs first, is recommended.

It is always advisable to drain the crankcase only after

the engine has become thoroughly warmed up or reached

normal operating temperature. The benefit of draining is,

to a large extent, lost if the crankcase is drained when

the engine is cold, as some of the suspended foreign

material will cling to the sides of the oil pan and will not

drain out readily with the cold, slower moving oil.

OIL FILTER

Change engine oil filter every 6000 miles or every 6

months, whichever occurs first.

NOTE:

For Vehicles in heavy duty operation

involving continuous start-stop or prolonged idl-

ing, engine oil should be changed after 2500-

3000 miles of operation. The filter should be

changed after 5000-6000 miles of operation.

Crankcase Dilution

Probably the most serious phase of engine oil deterio-

ration is that of crankcase dilution which is the thinning

of the oil by fuel vapor leaking by pistons and rings and

mixing with the oil and by condensation of water on the

cylinder walls and crankcase.

Leakage of fuel, or fuel vapors, into the oil pan occurs

mostly during the "warming up" period when the fuel is

not thoroughly vaporized and burned. Water vapor enters

the crankcase through normal engine ventilation and

through exhaust gas blow-by. When the engine is not

completely warmed up, these vapors condense, combine

with the condensed fuel and exhaust gases and form acid

compounds in the crankcase.

As long as the gases and internal walls of the crank-

case are hot enough to keep water vapor from con-

densing, no harm will result. However, when the engine

is run in low temperatures moisture will collect and

unite with the gases formed by combustion resulting in

an acid formation. The acid thus formed is likely to

cause serious etching or pitting which will manifest itself

in excessively rapid wear on piston pins, camshaft

bearings and other moving parts of the engine, oftentimes

causing the owner to blame the car manufacturer or the

lubricating oil when in reality the trouble may be traced

back to the character of fuel used, or a condition of the

engine such as excessive blowby or improper carburetor

adjustment.

Automatic Control Devices to Minimize

Crankcase Dilution

All engines are equipped with automatic devices which

aid greatly in minimizing the danger of crankcase

dUution.

The thermostat, mounted in the cylinder head water

outlet, restricts the flow of water to the radiator until a

predetermined temperature is reached, thus minimizing

the length of time required to reach efficient operating

temperature, reducing the time that engine temperatures

are conducive to vapor condensation.

A water by-pass is included in the cooling system,

utilizing a hole in the front of, the cylinder block. This

allows a limited circulation of coolant, bypassing the

thermostat until thermostat opening temperatures are

reached. This system provides a uniform coolant tem-

perature throughout the engine, eliminating localized

hot-spots, improving exhaust valve life, provides fast

warmrup of lubricating oil and fast temperature rise in

the coolant which provides fast heater operation in cold

weather.

A thermostatic heat control on the exhaust manifold

during the warming up period, automatically directs the

hot exhaust gases against the center of the intake mani-

fold, greatly aids in proper vaporization of the fuel.

An automatic choke reduces the danger of raw or

unvaporized fuel entering the combustion chamber and

leaking into the oil reservoir.

An.

efficient crankcase ventilating system drives off

fuel vapors and aids in the evaporation of the raw fuel

and water which may find its way into the oil pan.

CRANKCASE BREATHER CAP

Clean and re-oil at every oil change..

CHEVROLET CHASSIS SERVICE MANUAL

Page 17 of 659

LUBRICATION 0-15

CRANKCASE VENTILATION VALVE

VALVE TYPE

NOTE: Under prolonged dusty driving condi-

tions,

it is recommended that these operations

be performed more often. Every 12,000 miles

or 12 months the valve should be replaced.

Connecting hoses, fittings, flame arrestor and

crankcase breather cap (where used) should be

cleaned. At every oil change the system should

be tested for proper function and serviced, if

necessary.

FUEL FILTER

Replace filter element located in carburetor inlet if

flooding occurs, if engine surges during constant speed

operation (pulsating effect) or if poor performance is

experienced during acceleration or at higher speeds.

AIR CLEANER

NOTE: Under prolonged dusty driving condi-

tions,

it is recommended that these operations

be performed more often.

POLYURETHANE TYPE-

Every 12,000 miles clean element in solvent, squeeze

out solvent, then soak in engine oil and squeeze out

excess.

OIL WETTED PAPER ELEMENT TYPE-

First 12,000 miles inspect or test element; if satis-

factory, re-use element but recheck every 6,000 miles

until replaced. Element must not be washed, oiled,

tapped or cleaned with an air hose.

BATTERY TERMINAL WASHERS

Battery terminals have felt washers between top of

case and cable connections to minimize corrosive action

of battery acid. These felt washers should be saturated

with engine oil every 6,000 miles.

DISTRIBUTOR

4 and 6-Cylinder Engine—Remove distributor cap and

rotate lubricator 1/2 turn at 12,000 mile intervals. Re-

place at 24,000 mile intervals.

8-Cylinder Engine—Change cam lubricator end for end

at 12,000 mile intervals. Replace at 24,000 mile

intervals.

REAR AXLE AND 3-SPEED AND

OVERDRIVE, 4-SPEED TRANSMISSIONS

The passenger car operates under the most severe

lubrication conditions at high speed and requires a hypoid

lubricant which will meet this condition.

Recommended Lubricants

Standard Rear Axles—SAE 90 "Multi-Purpose" gear

lubricant.

Positraction Rear Axles—Use special Positraction

lubricant.

CAUTION: Straight Mineral Oil gear lubricants

must not be used in hypoid rear axles.

Transmissions—SAE 90 "Multi-Purpose" gear

lubricant.

The SAE 90 viscosity grade is recommended for year

round use. However, when extremely low temperatures

are encountered for protracted periods during the winter

months, the SAE 80 viscosity grade may be used.

"Multi-Purpose" Gear Lubricants

Gear lubricants that will satisfactorily lubricate hypoid

rear axles have been developed and are commonly re-

ferred to as ' 'Multi-Purpose" gear lubricants meeting

U.S.

Army Ord. Spec. MIL-L-2105B.

These lubricants can also be satisfactorily used in

manual transmissions.

CAUTION: With Positraction rear axles use

special Positraction lubricant.

"Multi-Purpose" gear lubricants must be manufac-

tured under carefully controlled conditions and the

lubricant manufacturer must be responsible for the

satisfactory performance of his product. His reputation

is the best indication of quality.

Lubricant Additions

The lubricant level in the axle and transmission hous-

ings should be checked periodically. (Every 6,000 miles.)

It is recommended that any additions required to bring

up the lubricant level be made using the same type lubri-

cant already in the housing.

When checking lubricant level in transmission or rear

axle the unit being cheeked should be at operating

temperature. With unit at operating temperature the

lubricant should be level with bottom of the filler plug

hole.

If the lubricant level is checked with the unit cold

the lubricant level should be 1/2 inch below the filler

plug hole.

Lubricant Changes

The rear axle lubricant does not require changing for

the life of the vehicle. If additions are needed, or when

refilling the axle after service procedures, use lubricants

described above.

POWERGLIDE TRANSMISSION

NOTE: Every 12,000 miles, it is recommended

that the Powerglide low band be adjusted as

specified in Section 7 of this manual.

Every 6,000 miles--Check fluid level on dipstick with

engine idling, selector lever in neutral position, parking

brake set and transmission at operating temperature. If

fluid level is below full mark on dip stick, adding a small

amount of Automatic Transmission Fluid, General Motors

Automatic Transmission Fluid (Part Numbers 1050568-

69,

70) is recommended. If this fluid is not obtainable,

use Automatic Transmission Fluid Type 'A' bearing the

mark AQ-ATF followed by a number and the suffix letter

'A'.

Recheck fluid level on dip stick and again add a

small amount of fluid if needed to bring level to full

mark. DO NOT OVERFILL.

CHEVROLET CHASSIS SERVICE MANUAL

Page 54 of 659

HEATER

AND AIR

CONDITIONING

1A-31

FIVE

AMP

TIME DELAY

FUSE

CORD

TO

110

AC

SOURCE

PUMP

INLET

PUMP DISCHARGE

OUTLET

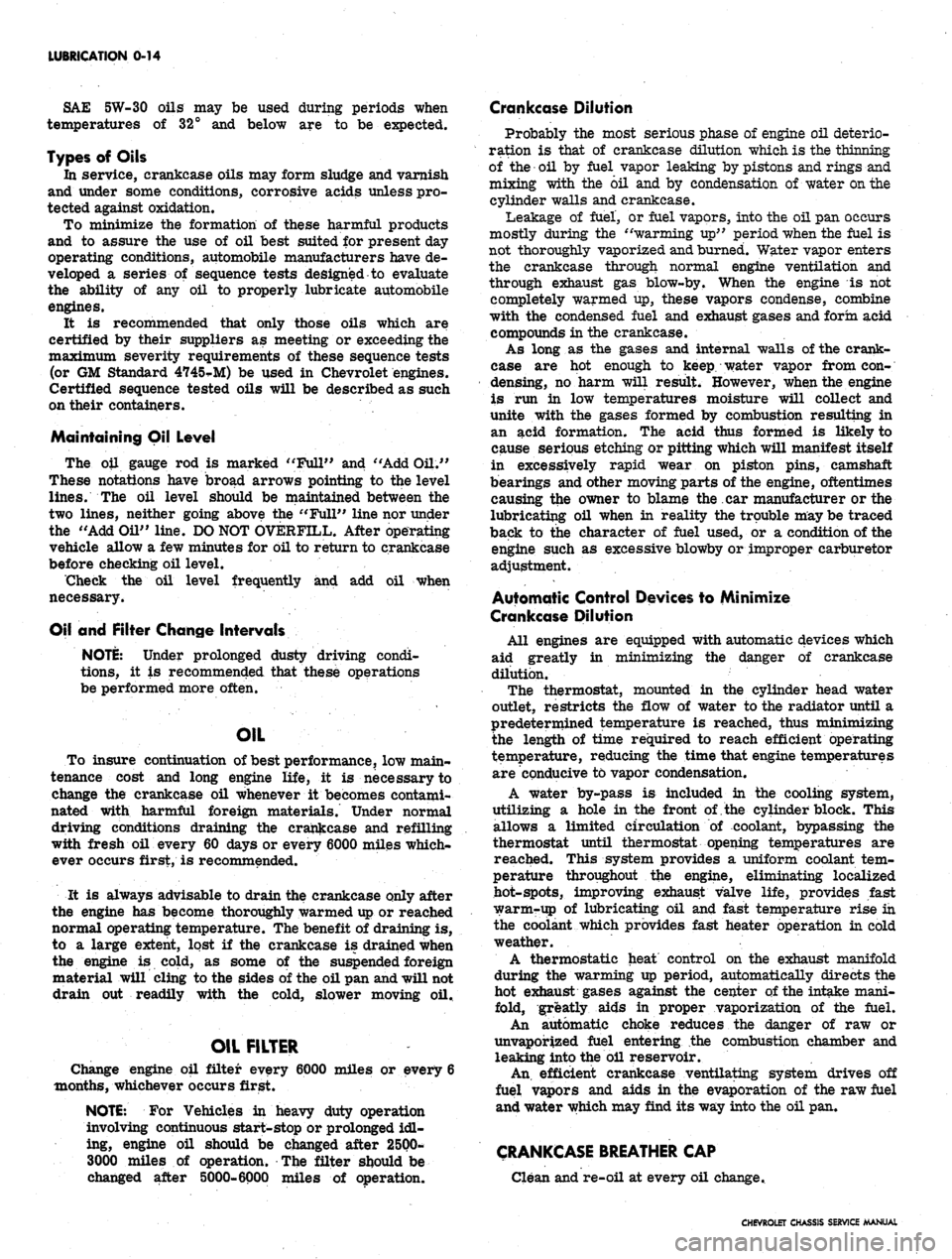

Fig.

44—Vacuum Pump

the use of weighing equipment necessary with the larger

drum. The single can Valve J-6271 can be used for com-

pleting the charge and for miscellaneous operations such

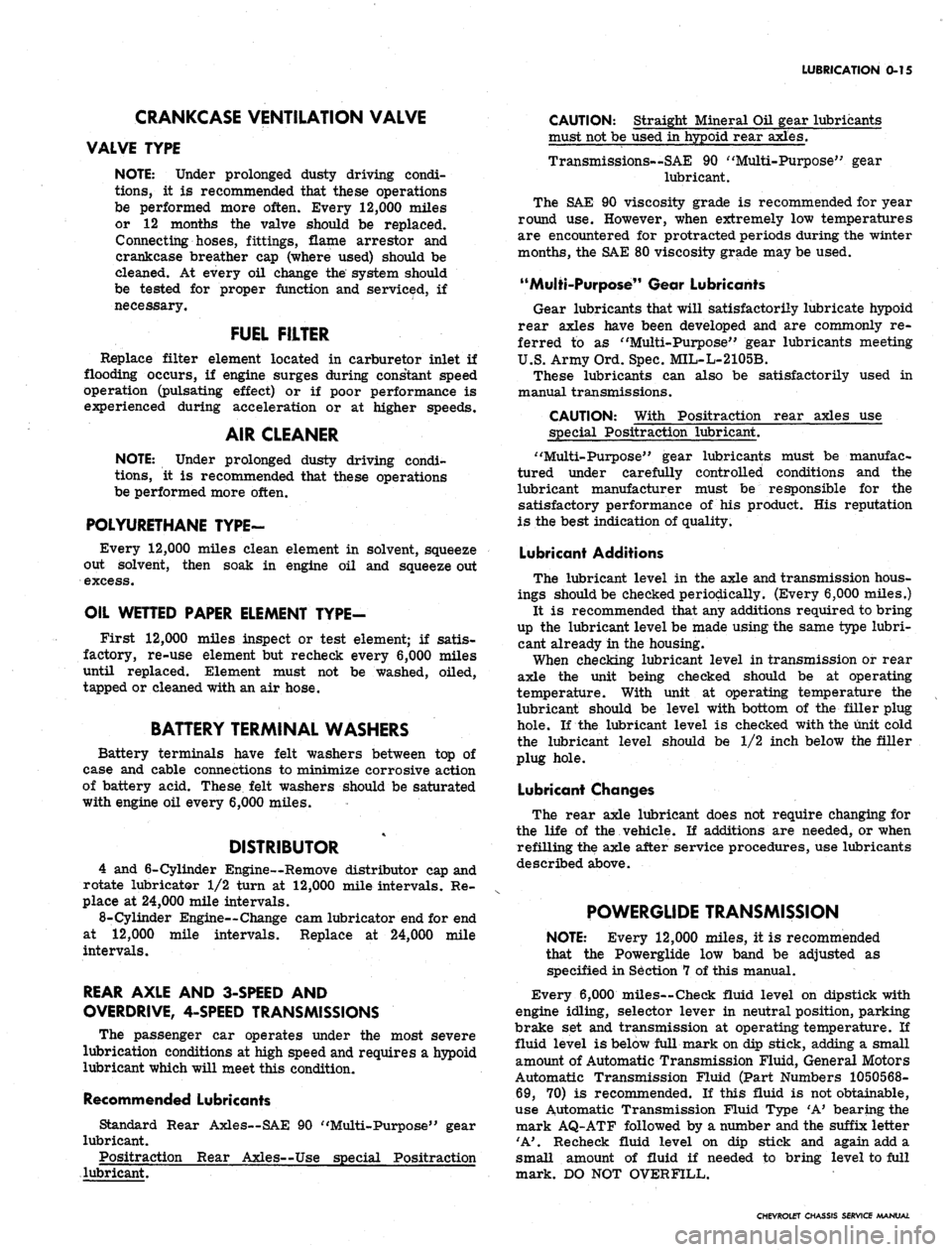

Fig.

45-R-12 Disposable Cans

as flushing. The valves are installed by piercing the top

seal of the cans.

Evacuating and charging procedures later in this sec-

tion will make use of the J-8393 Charging Station which

uses the 25 lb. drum of refrigerant.

COMPRESSOR OIL

Special refrigeration lubricant should be used in the

system. It is available in 1 quart graduated bottles

through Parts Stock. This oil is as free from moisture

and contaminants as it is possible to attain by commercial

processes. This condition should be preserved by im-

mediately capping the bottle when not in use.

See "Air Conditioning System Capacities" for the

total system oil capacity.

Due to the porosity of the refrigerant hoses and con-

nections, the system refrigerant level will show a definite

drop after a period of time. Since the compressor oil is

carried throughout the entire system mixed with the

refrigerant a low refrigerant level will cause a dangerous

lack of lubrication. Therefore the refrigerant charge in

the system has a definite tie-in with the amount of oil

found in the compressor and an insufficient charge may

eventually lead to an oil build-up in the evaporator.

COMPRESSOR SERIAL NUMBER

The compressor serial number is located on the serial

number plate on top of the compressor. The serial num-

ber consists of a series of numbers and letters. This

serial number should be referenced on all forms and

correspondence related to the servicing of this part.

INSPECTION AND PERIODIC SERVICE

PRE-DELIVERY INSPECTION

1.

Check that engine exhaust is suitably ventilated.

2.

Check the belt for proper tension.

3.

With controls positioned for operation of the system,

operate the unit for ten minutes at approximately

2000 rpm. Observe the clutch pulley bolt to see that

compressor is operating at the same speed as the

clutch pulley. Any speed variation indicates clutch

slippage.

Before turning off the engine, check the sight glass

to see that the.unit has a sufficient Refrigerant

charge. The glass should be clear, although during

milder weather it may show traces of bubbles. Foam

in.

the flow indicates a low charge. No liquid visible

indicates no charge.

CHEVROLET CHASSIS SERVICE MANUAL

Page 55 of 659

HEATER AND AIR CONDITIONING 1A-32

5.

Check hose clamp connections. If clamp screw torque

is less than 10 lb. in., retighten to 20-25 lb. in. Do

not tighten to new hose specifications or hose leak-

age may occur.

6. If there is evidence of an oil leak, check the com-

pressor to see that the oil charge is satisfactory.

7.

Check the system controls for proper operation.

6000 MILE INSPECTION

1.

Check unit for any indication of a refrigerant leak.

2.

If there is an indication of an oil leak, check the

compressor proper oil charge.

3.

Check sight glass for proper charge of Refrigerant-

12.

4.

Tighten the compressor brace and support bolts and

check the belt tension.

5.

Check hose clamp connections as in step 5 above.

6. Check thermostatic switch setting (Universal and

All-Weather Systems.)

PERIODIC SERVICE

• Inspect condenser regularly to be sure that it is not

plugged with leaves or other foreign material.

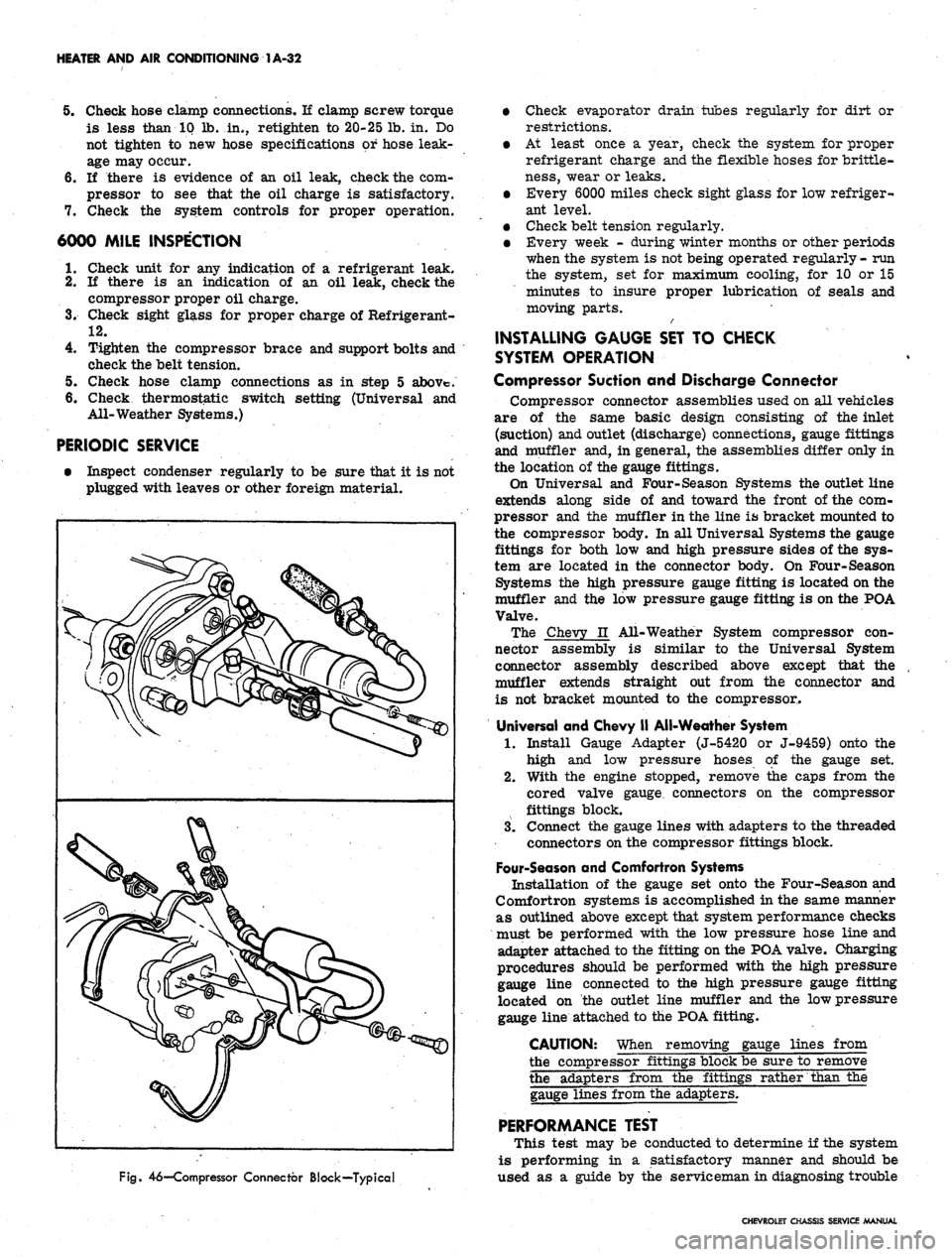

Fig.

46—Compressor Connector Block—Typical

• Check evaporator drain tubes regularly for dirt or

restrictions.

• At least once a year, check the system for proper

refrigerant charge and the flexible hoses for brittle-

ness,

wear or leaks.

• Every 6000 miles check sight glass for low refriger-

ant level.

• Check belt tension regularly.

• Every week - during winter months or other periods

when the system is not being operated regularly- run

the system, set for maximum cooling, for 10 or 15

minutes to insure proper lubrication of seals and

moving parts.

INSTALLING GAUGE SET TO CHECK

SYSTEM OPERATION

Compressor Suction and Discharge Connector

Compressor connector assemblies used on all vehicles

are of the same basic design consisting of the inlet

(suction) and outlet (discharge) connections, gauge fittings

and muffler and, in general, the assemblies differ only in

the location of the gauge fittings.

On Universal and Four-Season Systems the outlet line

extends along side of and toward the front of the com-

pressor and the muffler in the line is bracket mounted to

the compressor body. In all Universal Systems the gauge

fittings for both low and high pressure sides of the sys-

tem are located in the connector body. On Four-Season

Systems the high pressure gauge fitting is located on the

muffler and the low pressure gauge fitting is on the POA

Valve.

The Chevy n All-Weather System compressor con-

nector assembly is similar to the Universal System

connector assembly described above except that the

muffler extends straight out from the connector and

is not bracket mounted to the compressor.

Universal and Chevy II All-Weather System

1.

Install Gauge Adapter (J-5420 or J-9459) onto the

high and low pressure hoses of the gauge set.

2.

With the engine stopped, remove the caps from the

cored valve gauge, connectors on the compressor

fittings block.

3.

Connect the gauge lines with adapters to the threaded

connectors on the compressor fittings block.

Four-Season and Comfortron Systems

Installation of the gauge set onto the Four-Season and

Comfortron systems is accomplished in the same manner

as outlined above except that system performance checks

must be performed with the low pressure hose line and

adapter attached to the fitting on the POA valve. Charging

procedures should be performed with the high pressure

gauge line connected to the high pressure gauge fitting

located on the outlet line muffler and the low pressure

gauge line attached to the POA fitting.

CAUTION: When removing gauge lines from

the compressor fittings block be sure to remove

the adapters from the fittings rather than the

gauge lines from the adapters.

PERFORMANCE TEST

This test may be conducted to determine if the system

is performing in a satisfactory manner and should be

used as a guide by the serviceman in diagnosing trouble

CHEVROLET CHASSIS SERVICE MANUAL

Page 60 of 659

HEATER AND AIR CONDITIONING 1A-37

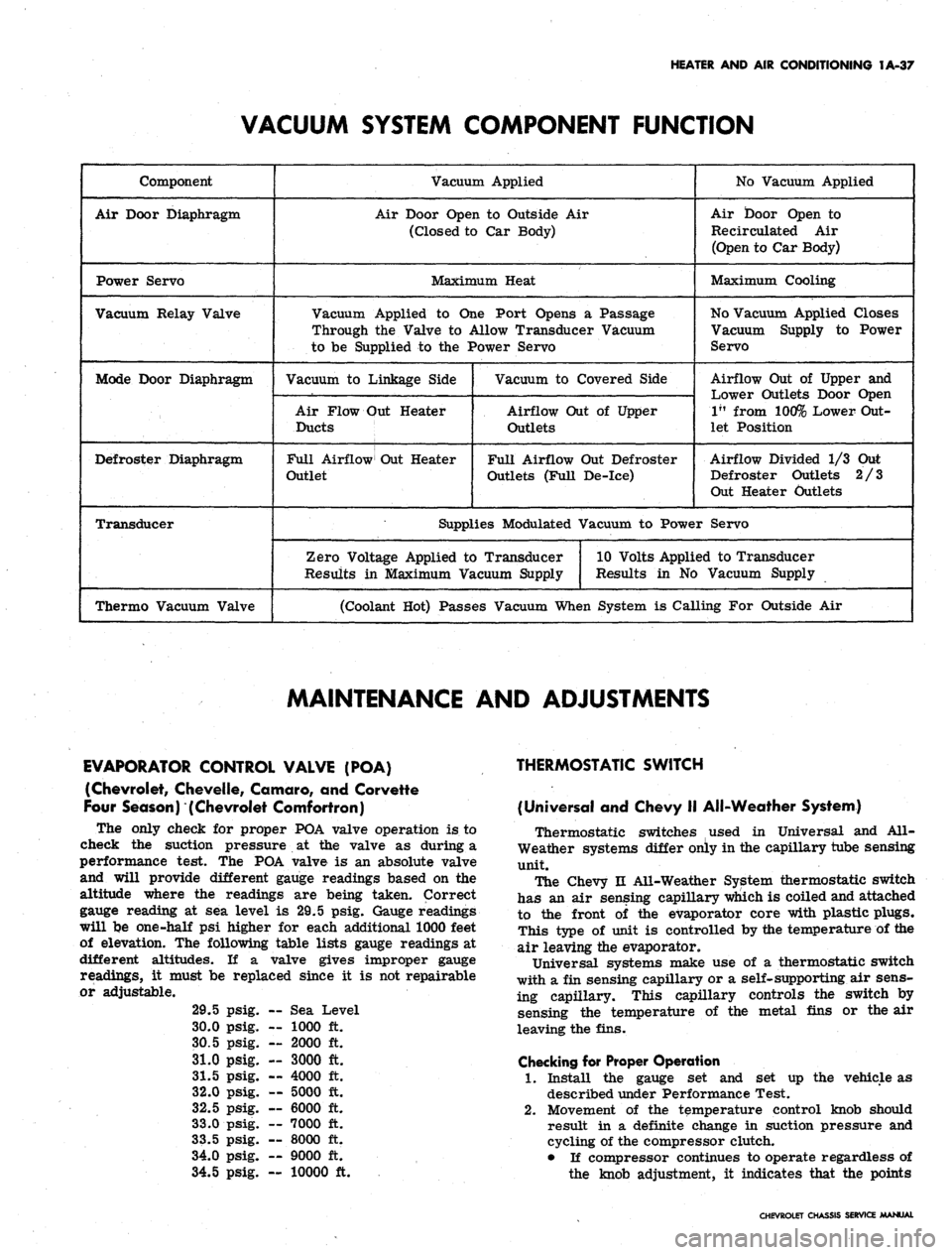

VACUUM SYSTEM COMPONENT FUNCTION

Component

Air Door Diaphragm

Power Servo

Vacuum Relay Valve

Mode Door Diaphragm

Defroster Diaphragm

Transducer

Thermo Vacuum Valve

Vacuum Applied

Air Door Open to Outside Air

(Closed to Car Body)

Maximum Heat

Vacuum Applied to One Port Opens a Passage

Through the Valve to Allow Transducer Vacuum

to be Supplied to the Power Servo

Vacuum to Linkage Side

Air Flow Out Heater

Ducts

Full Airflow Out Heater

Outlet

Vacuum to Covered Side

Airflow Out of Upper

Outlets

Full Airflow Out Defroster

Outlets (Full De-ice)

No Vacuum Applied

Air Door Open to

Re circulated Air

(Open to Car Body)

Maximum Cooling

No Vacuum Applied Closes

Vacuum Supply to Power

Servo

Airflow Out of Upper and

Lower Outlets Door Open

1"

from 100% Lower Out-

let Position

Airflow Divided 1/3 Out

Defroster Outlets 2/3

Out Heater Outlets

Supplies Modulated Vacuum to Power Servo

Zero Voltage Applied to Transducer

Results in Maximum Vacuum Supply

10 Volts Applied to Transducer

Results in No Vacuum Supply

(Coolant Hot) Passes Vacuum When System is Calling For Outside Air

MAINTENANCE AND ADJUSTMENTS

EVAPORATOR CONTROL VALVE (POA)

(Chevrolet, Chevelle, Comoro, and Corvette

Four Season) (Chevrolet Comfortron)

The only check for proper POA valve operation is to

check the suction pressure at the valve as during a

performance test. The POA valve is an absolute valve

and will provide different gauge readings based on the

altitude where the readings are being taken. Correct

gauge reading at sea level is 29.5 psig. Gauge readings

will be one-half psi higher for each additional 1000 feet

of elevation. The following table lists gauge readings at

different altitudes. If a valve gives improper gauge

readings, it must be replaced since it is not repairable

or adjustable.

29.5

30.0

30.5

31.0

31.5

32.0

32.5

33.0

33.5

34.0

34.5

psig.

psig.

psig.

psig.

psig.

psig.

psig.

psig.

psig.

psig.

psig.

— Sea 1

— 1000

— 2000

— 3000

— 4000

— 5000

— 6000

— 7000

— 8000

— 9000

Level

ft.

ft.

ft.

ft.

ft.

ft.

ft.

ft.

ft.

— 10000 ft.

THERMOSTATIC SWITCH

(Universal and Chevy II All-Weather System)

Thermostatic switches used in Universal and All-

Weather systems differ only in the capillary tube sensing

unit.

The Chevy n All-Weather System thermostatic switch

has an air sensing capillary which is coiled and attached

to the front of the evaporator core with plastic plugs.

This type of unit is controlled by the temperature of the

air leaving the evaporator.

Universal systems make use of a thermostatic switch

with a fin sensing capillary or a self-supporting air sens-

ing capillary. This capillary controls the switch by

sensing the temperature of the metal fins or the air

leaving the fins.

Checking for Proper Operation

1.

Install the gauge set and set up the vehicle as

described under Performance Test.

2.

Movement of the temperature control knob should

result in a definite change in suction pressure and

cycling of the compressor clutch.

• If compressor continues to operate regardless of

the knob adjustment, it indicates that the points

CHEVROLET CHASSIS SERVICE MANUAL

Page 66 of 659

HEATER AND AIR CONDITIONING 1A-43

LOW PRESSURE

CONTROL

HIGH PRESSURE

CONTROL

3

VACUUM

CONTROL

4

FREON

CONTROL

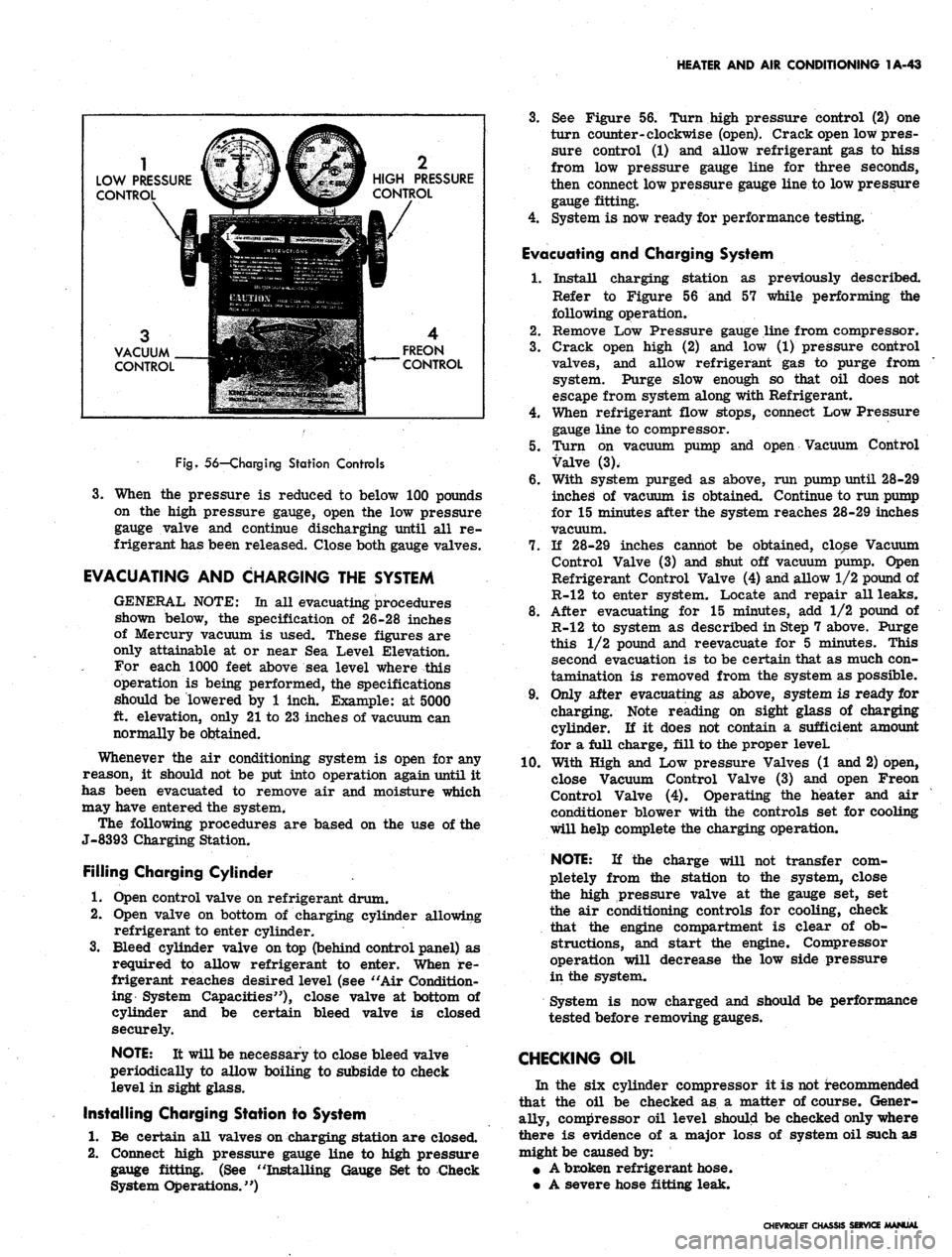

Fig,

56—Charging Station Controls

3.

When the pressure is reduced to below 100 pounds

on the high pressure gauge, open the low pressure

gauge valve and continue discharging until all re-

frigerant has been released. Close both gauge valves.

EVACUATING AND CHARGING THE SYSTEM

GENERAL NOTE: La all evacuating procedures

shown below, the specification of 26-28 inches

of Mercury vacuum is used. These figures are

only attainable at or near Sea Level Elevation.

For each 1000 feet above sea level where this

operation is being performed, the specifications

should be lowered by 1 inch. Example: at 5000

ft. elevation, only 21 to 23 inches of vacuum can

normally be obtained.

Whenever the air conditioning system is open for any

reason, it should not be put into operation again until it

has been evacuated to remove air and moisture which

may have entered the system.

The following procedures are based on the use of the

J-8393 Charging Station.

Filling Charging Cylinder

1.

Open control valve on refrigerant drum.

2.

Open valve on bottom of charging cylinder allowing

refrigerant to enter cylinder.

3.

Bleed cylinder valve on top (behind control panel) as

required to allow refrigerant to enter. When re-

frigerant reaches desired level (see "Air Condition-

ing System Capacities"), close valve at bottom of

cylinder and be certain bleed valve is closed

securely.

NOTE: It will be necessary to close bleed valve

periodically to allow boiling to subside to check

level in sight glass.

Installing Charging Station to System

1.

Be certain all valves on charging station are closed.

2.

Connect high pressure gauge line to high pressure

gauge fitting. (See "Installing Gauge Set to Check

System Operations.")

3.

See Figure 56. Turn high pressure control (2) one

turn counter-clockwise (open). Crack open low pres-

sure control (1) and allow refrigerant gas to hiss

from low pressure gauge line for three seconds,

then connect low pressure gauge line to low pressure

gauge fitting.

4.

System is now ready for performance testing.

Evacuating and Charging System

1.

Install charging station as previously described.

Refer to Figure 56 and 57 while performing the

following operation.

2.

Remove Low Pressure gauge line from compressor.

3.

Crack open high (2) and low (1) pressure control

valves, and allow refrigerant gas to purge from

system. Purge slow enough so that oil does not

escape from system along with Refrigerant.

4.

When refrigerant flow stops, connect Low Pressure

gauge line to compressor.

5.

Turn on vacuum pump and open Vacuum Control

Valve (3).

6. With system purged as above, run pump until 28-29

inched of vacuum is obtained. Continue to run pump

for 15 minutes after the system reaches 28-29 inches

vacuum.

7.

If 28-29 inches cannot be obtained, close Vacuum

Control Valve (3) and shut off vacuum pump. Open

Refrigerant Control Valve (4) and allow 1/2 pound of

R-12 to enter system. Locate and repair all leaks.

8. After evacuating for 15 minutes, add 1/2 pound of

R-12 to system as described in Step 7 above. Purge

this 1/2 pound and reevacuate for 5 minutes. This

second evacuation is to be certain that as much con-

tamination is removed from the system as possible.

9. Only after evacuating as above, system is ready for

charging. Note reading on sight glass of charging

cylinder. If it does not contain a sufficient amount

for a full charge, fill to the proper leveL

10.

With High and Low pressure Valves (1 and 2) open,

close Vacuum Control Valve (3) and open Freon

Control Valve (4). Operating the heater and air

conditioner blower with the controls set for cooling

will help complete the charging operation.

NOTE: If the charge will not transfer com-

pletely from the station to the system, close

the high pressure valve at the gauge set, set

the air conditioning controls for cooling, check

that the engine compartment is clear of ob-

structions, and start the engine. Compressor

operation will decrease the low side pressure

in the system.

System is now charged and should be performance

tested before removing gauges.

CHECKING OIL

In the six cylinder compressor it is not recommended

that the oil be checked as a matter of course. Gener-

ally, compressor oil level should be checked only where

there is evidence of a major loss of system oil such as

might be caused by:

• A broken refrigerant hose.

• A severe hose fitting leak.

CHEVROLET CHASSIS SERVICE MANUAL

Page 68 of 659

HEATER AND AIR CONDITIONING 1A-45

• A very badly leaking compressor seal.

• Collision damage to the system components.

As a quick check on compressor oil charge, with the

engine off, carefully crack open the oil drain plug on the

bottom of the compressor. If oil comes out, the com-

pressor has the required amount of oil To further check

the compressor oil charge, should the above test show

insufficient oil, it is necessary to remove the compressor

from the vehicle, drain and measure the oil.

Checking Compressor Oil Charge

1.

Run the system for 10 minutes at 500-600 engine

rpm with controls set for maximum cooling and

high blower speed.

2.

Turn off engine, discharge the system, remove

compressor from vehicle, place it in a horizontal

position with the drain plug downward. Remove the

drain plug and, tipping the compressor back and

forth and rotating the compressor shaft, drain the

oil into a clean container, measure and discard the

oiL

3.

a. If the quantity drained was 4 fluid oz. or more,

add the same amount of new refrigerant oil to

the replacement compressor.

b.

If the quantity drained was less than 4 fluid oz.,

add 6 fluid oz. of new refrigeration oil to the

replacement compressor.

c. If a new service compressor is being installed,

drain all oil from it and replace only the amount

specified in Steps 3a and 3b above.

d. If a field repaired compressor is being installed,

add an additional 1 fluid oz. to the compressor.

4.

In the event that it is not possible to idle the com-

pressor as outlined in Step 1 to effect oil return to

it, proceed as follows:

a. Remove the compressor, drain, measure and

discard the oil.

b.

If the amount drained is more than 1-1/2 fluid

oz.

and the system shows no signs of a major

leak, add the same amount to the replacement

compressor.

c. If the amount drained is less than 1-1/2 fluid oz.

and the system appears to have lost an excessive

amount of oil add 6 fluid oz. of clean refrigeration

oil to replacement compressor, 7 fluid oz. to a

repaired compressor.

If the oil contains chips or other foreign ma-

terial, replace the receiver-dehydrator and flush

or replace all component parts as necessary. Add

the full specified volume of new refrigeration oil

to the system.

5.

Add additional oil in the following amounts for any

system components being replaced.

Evaporator 3 fluid oz.

Condenser . . . . ... . . . . . . 1 fluid oz.

Receiver-Dehydrator ....... 1 fluid oz.

NOTE: When adding oil to the compressor, it

will be necessary to tilt the rear end of the

compressor up so that the oil will not run out

of the suction and discharge ports. Do not set

the compressor on the shaft end.

Adding Oil to the System

The system should be completely assembled and un-

charged before adding oil. Use only uncontaminated

refrigerant oil (525 viscosity) and add as follows:

1.

Connect the low pressure line from the gauge set

to the low pressure gauge fitting on the P.O.A.

valve (Four-Season) or low pressure fitting on the

compressor connector Mock (Universal System).

2.

Connect the high pressure line from the charging

station gauge set to the compressor muffler or high

pressure side of the connector block.

3.

Disconnect the high pressure line from the gauge set,

make certain that the line is clean, and place the

end in a graduated container.

4.

Pour enough refrigerant oil into the container so

that the required volume may be drawn into the

system by the high pressure hose.

5.

Close the high pressure valve at the gauge set,

and open the low pressure valve.

6. Operate the vacuum pump to drop the pressure within

the system and cause atmospheric pressure to force

oil through the high pressure line into the system.

When the oil level has dropped the required volume,

pull the line out of the oil container and continue

vacuum pump operation to force the oil contained

in the line into the system.

7.

Shut off the vacuum pump and connect ttye high

pressure line to the gauge set. Open the high

pressure valve and evacuate the system through

the high and low pressure sides of the system.

Complete the charging operation as outlined in Step

10 under "Evacuating and Charging System".

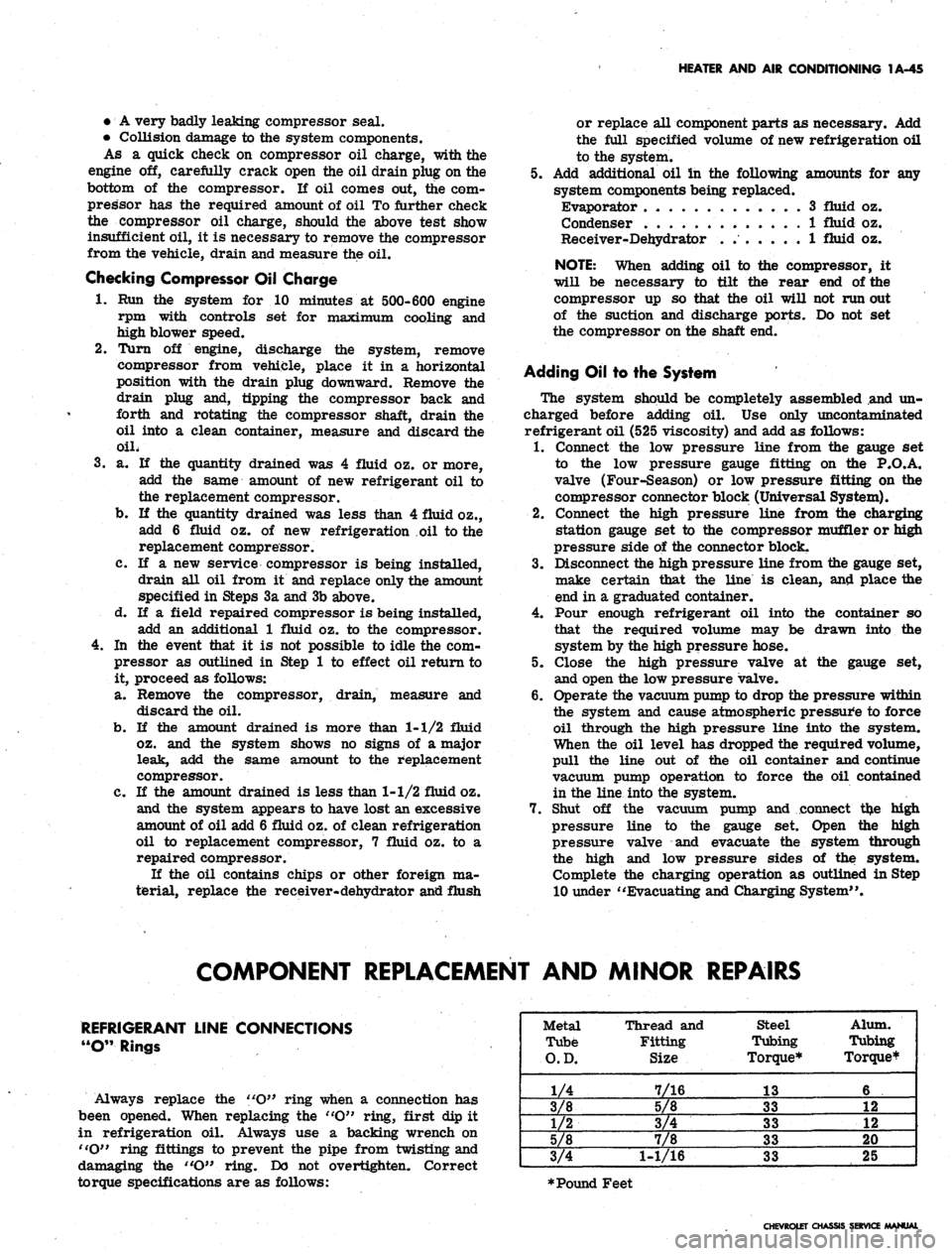

COMPONENT REPLACEMENT AND MINOR REPAIRS

REFRIGERANT LINE CONNECTIONS

"O"

Rings

Always replace the "O" ring when a connection has

been opened. When replacing the "O" ring, first dip it

in refrigeration oil. Always use a backing wrench on

"O"

ring fittings to prevent the pipe from twisting and

damaging the "O" ring. Do not overtighten. Correct

torque specifications are as follows:

Metal

Tube

O.D.

1/4

3/8

1/2

5/8

3/4

Thread and

Fitting

Size

7/16

5/8

3/4

7/8

1-1/16

Steel

Tubing

Torque*

13

33

33

33

33

Alum.

Tubing

Torque*

6

12

12

20

25

* Pound Feet

CHEVROLET CHASSIS SERVICE

Page 217 of 659

REAR SUSPENSION AND DRIVE LINE 4-27

SHIM AND

SERVICE

12

14

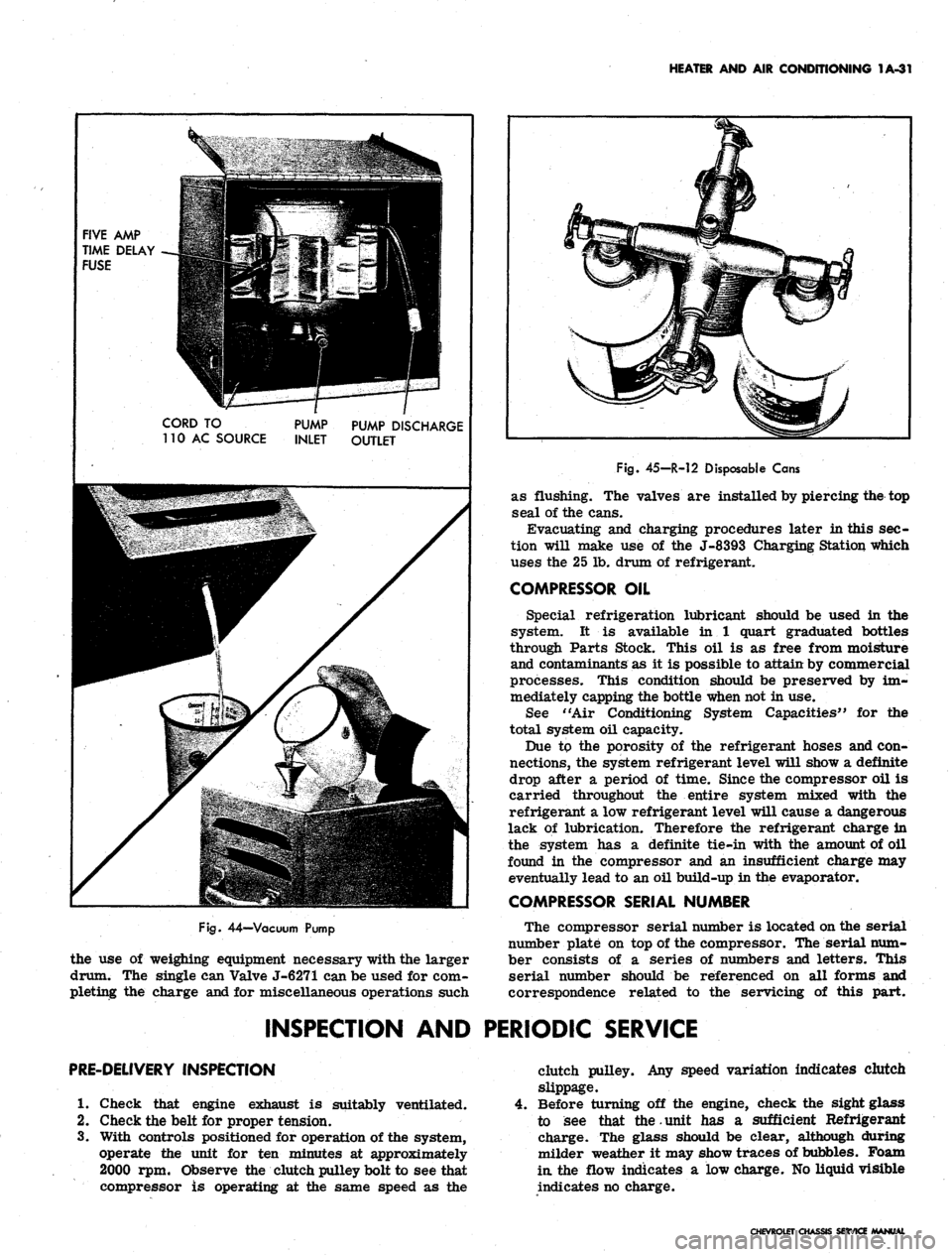

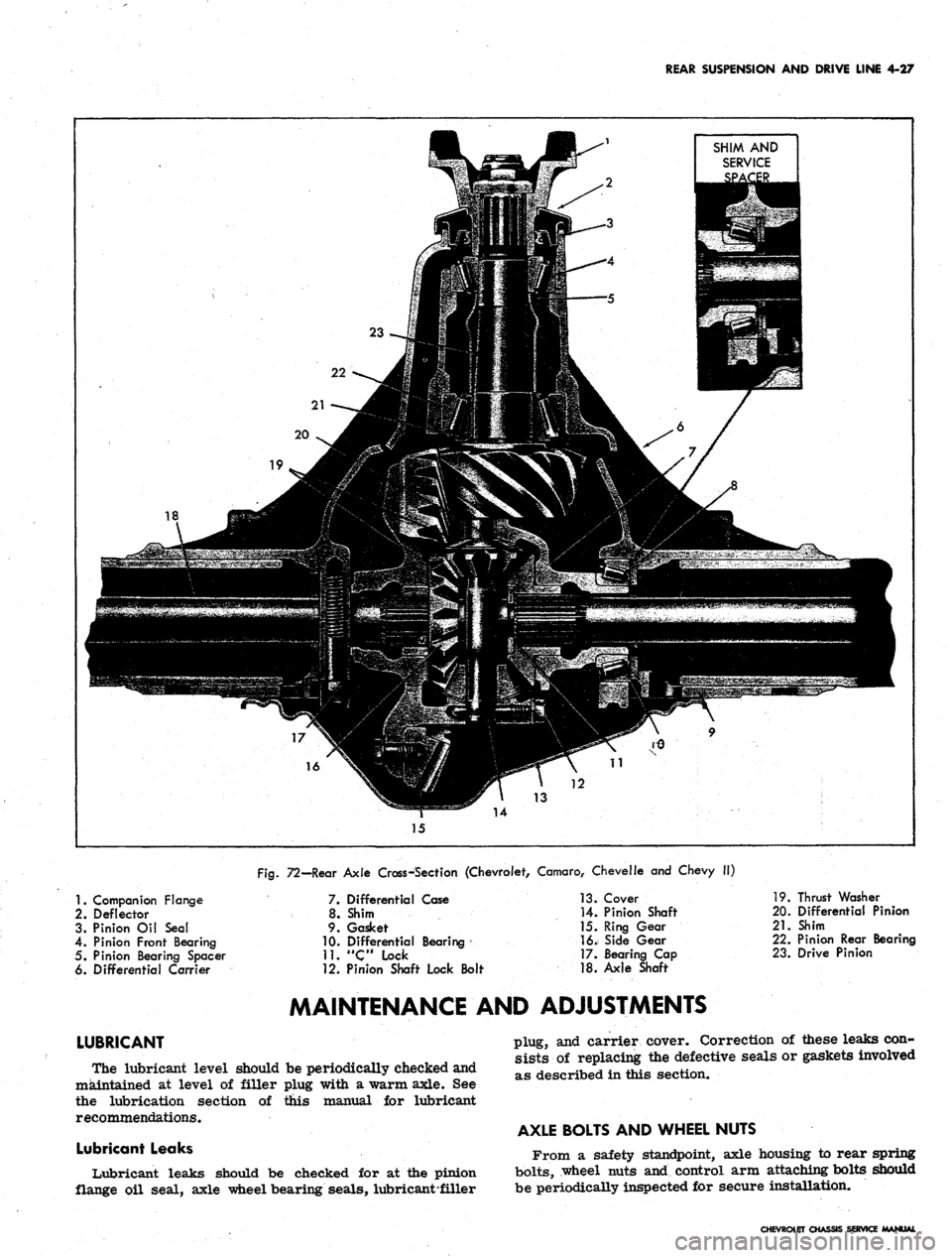

Fig.

72—Rear Axle Cross-Section (Chevrolet, Camaro, Chevelle and Chevy II)

1.

Companion Flange

2.

Deflector

3. Pinion Oil Seal

4.

Pinion Front Bearing

5. Pinion Bearing Spacer

6. Differential Carrier

LUBRICANT

7. Differential Case

8. Shim

9. Gasket

10.

Differential Bearing

11.

"Clock

12. Pinion Shaft Lock Bolt

13.

Cover

14.

Pinion Shaft

15.

Ring Gear

16.

Side Gear

17.

Bearing Cap

18.

Axle Shaft

19.

Thrust Washer

20.

Differential Pinion

21.

Shim

22.

Pinion Rear Bearing

23.

Drive Pinion

MAINTENANCE AND ADJUSTMENTS

The lubricant level should be periodically checked and

maintained at level of filler plug with a warm axle. See

the lubrication section of this manual for lubricant

recommendations.

Lubricant Leaks

Lubricant leaks should be checked for at the pinion

flange oil seal, axle wheel bearing seals, lubricant-filler

plug, and carrier cover. Correction of these leaks con-

sists of replacing the defective seals or gaskets involved

as described in this section.

AXLE BOLTS AND WHEEL NUTS

From a safety standpoint, axle housing to rear spring

bolts,

wheel nuts and control arm attaching bolts should

be periodically inspected for secure installation.

CHEVROLET CHASSIS SERVICE MANUAL

Page 222 of 659

REAR SUSPENSION AND DRIVE LINE 4-32

HP?

Fig.

81

—Whed Bearing and/or Oil Seal Installation

4.

Install brake components on flange and connect

hydraulic line to wheel cylinder inlet. See Section 5

for brake assembly procedure.

5. Install axle shaft, brake drum and wheel and tire

assembly.

6. Bleed and. adjust brakes as outlined in Section 5.

Installation

1.

Slide axle shaft into place.

CAUTION: Exercise care that splines on end

of shaft do not damage oil seal and that they

engage with splines of differential side gear/

2.

Install axle shaft "C" lock on button end of axle-

shaft and push shaft outward so that shaft lock seats

in counterbore of differential side gear.

3.

Position differential pinion shaft through case and

pinions, aligning hole in shaft with lock screw hole.

Install lock screw and torque to specifications.

4.

Using a new gasket, install carrier cover and torque

bolts to specifications.

CAUTION: Make sure both gasket surfaces on

carrier and cover are clean before installing

new gasket. Torque carrier cover bolts in a

crosswise pattern to ensure uniform draw on

cover gasket.

5. Fill axle with lubricant to a level even with bottom

of filler hole. See Section 0 for proper lubricant.

6. Install brake drum and wheel and tire assembly.

7. Lower vehicle and test operation of axle.

PINION FLANGE, DUST DEFLECTOR

AND/OR OIL SEAL

Replacement

1.

Raise rear of vehicle and place stand jacks under

frame side rails so that axle hangs freely to allow

sufficient working room.

2.

Check wheels for freedom of rotation.

3.

Separate rear universal joint, tape trunnion bearings

to joint, position propeller shaft to one side and tie

it to frame side rail.

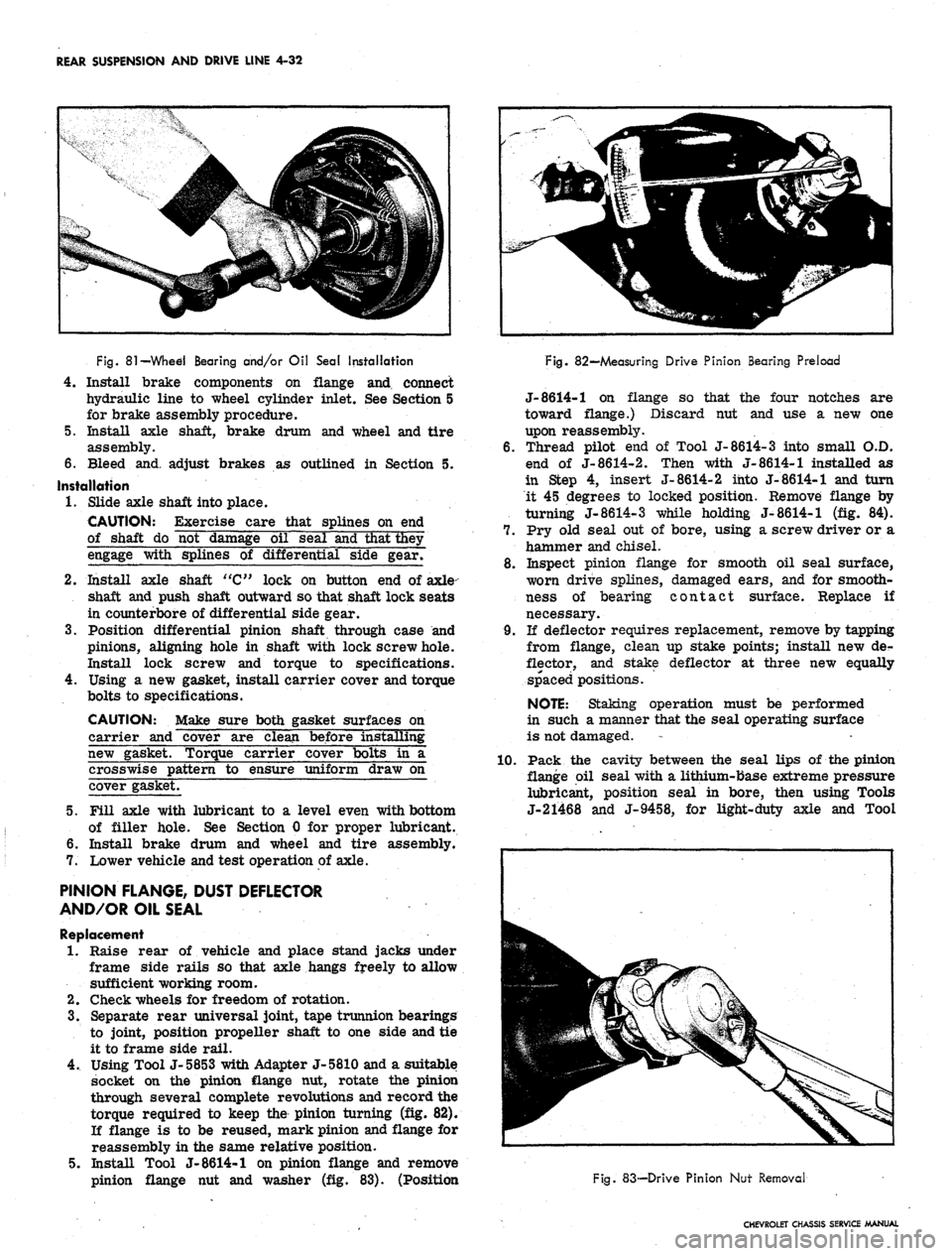

4.

Using Tool J-5853 with Adapter J-5810 and a suitable

socket on the pinion flange nut, rotate the pinion

through several complete revolutions and record the

torque required to keep the pinion turning (fig. 82).

If flange is to be reused, mark pinion and flange for

reassembly in the same relative position.

5. Install Tool J-8614-1 on pinion flange and remove

pinion flange nut and washer (fig. 83). (Position

Fig. 82—Measuring Drive Pinion Bearing Preload

J-8614-1 on flange so that the four notches are

toward flange.) Discard nut and use a new one

upon reassembly.

6. Thread pilot end of Tool J-8614-3 into small O.D.

end of J-8614-2. Then with J-8614-1 installed as

in Step 4, insert J-8614-2 into J-8614-1 and turn

it 45 degrees to locked position. Remove flange by

turning J-8614-3 while holding J-8614-1 (fig. 84).

7. Pry old seal out of bore, using a screw driver or a

hammer and chisel.

8. Inspect pinion flange for smooth oil seal surface,

worn drive splines, damaged ears, and for smooth-

ness of bearing contact surface. Replace if

necessary.

9. If deflector requires replacement, remove by tapping

from flange, clean up stake points; install new de-

flector, and stake deflector at three new equally

spaced positions.

NOTE:

Staking operation must be performed

in such a manner that the seal operating surface

is not damaged.

1.0. Pack the cavity between the seal lips of the pinion

flange oil seal with a lithium-base extreme pressure

lubricant, position seal in bore, then using Tools

J-21468 and J-9458, for light-duty axle and Tool

Fig. 83-—Drive Pinion Nut Removal

CHEVROLET CHASSIS SERVICE MANUAL