light CHEVROLET CAMARO 1971 2.G User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1971, Model line: CAMARO, Model: CHEVROLET CAMARO 1971 2.GPages: 88, PDF Size: 34.8 MB

Page 35 of 88

Downloaded from www.Manualslib.com manuals search engine • Drum brake adjustment is made

automatically

as the brakes are

applied while car

is moving back

wards.

• Disc brake adjustment is made

automatically with each brake

application.

• If excess brake pedal travel de

velops, drive alternately back

ward and forward (several

times) and apply brakes firmly

in each direction.

• See your dealer if normal pedal

travel

is not restored, or if there

is a

rapid increase in pedal

travel, which could be a sign of

other brake trouble.

Clutch Adjustment

Clutch adjustment should be

checked and adjusted periodically

as necessary to compensate for

clutch facing wear. To check,

de

press pedal by hand until resistance

is felt. Free travel of pedal should

be approximately one inch; if very little

or no free travel

is evident,

clutch adjustment

is required.

Headlight Beam Switch

"High" and "low" headlight

beams are controlled by the floor

button at your left foot. The

indi

cator, located in the speedometer

dial, will light up when the high

beams are in use.

OTHER CONTROLS AND FEATURES

Positraction Rear Axle

The optional Positraction pro

vides additional traction on snow,

ice, mud, sand, and gravel,

par

ticularly when one rear wheel is on

a surface providing poor traction.

During normal driving and

cor

nering, the Positraction unit func

tions as a standard differential.

32

When one wheel encounters a slip

pery surface, however, the Positrac

tion directs driving force to the rear

wheel having the better traction.

Page 36 of 88

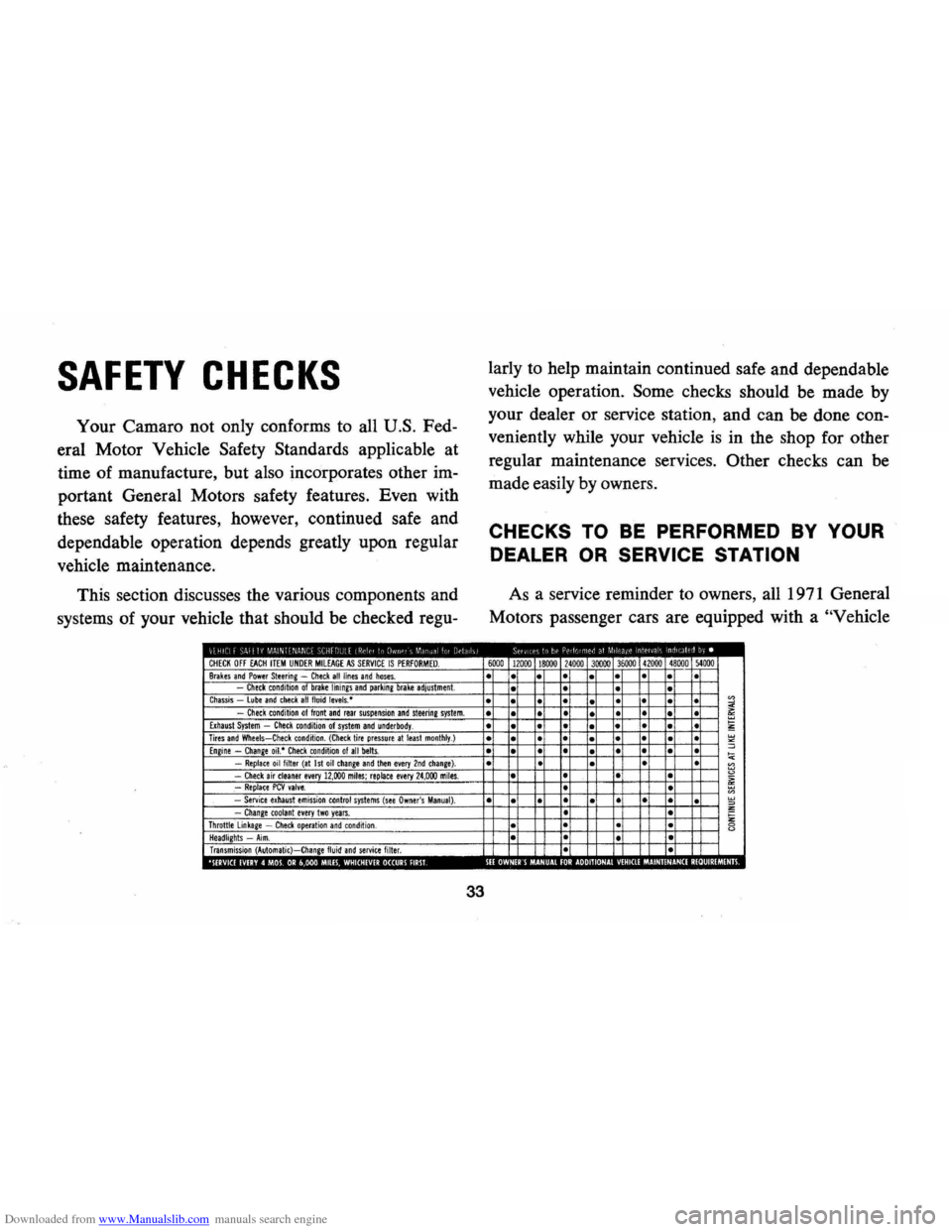

Downloaded from www.Manualslib.com manuals search engine SAFETY CHECKS

Your Camaro not only conforms to all U.S. Fed

eral Motor Vehicle

Safety Standards applicable at

time of manufacture, but also incorporates other im

portant General Motors safety features. Even with

these safety features, however, continued safe and

dependable operation depends greatly upon regular

vehicle maintenance.

This section discusses the various components and

systems of your vehicle that should be checked regu-

CHECK OFF EACH ITEM UNDER MIlEAGE AS SERVICE IS PERFORMED. Brakes and Power Steering -Check all lines and hoses. Check condition of brake linings and parking brake adjustment. Chassis lube and check all fluid levels,· Check condition of front and rear suspension and steerine system. Exhaust System -Check condition of system and underbody. Tires and Wheels-Check condition. (Check tire pressure at least monthly.) Engine -Change oil.· Check condition 01 all belts. -Replace oil filter (at 1st oil change and tllen every 2nd chanie). -Check air cleaner every 12,000 miles; replace every 24,000 miles. .-Replace PCV valve. -Service exhaust emission control systems (see Owner's Manual). -Change toolanl every Iwo years. Throttle linkage -Check operation and condition . Headlights -Aim. Transmission (Automatic)-Change fluid and service filter. 0 ,', III · 0

33

larly to help maintain continued safe and dependable

vehicle operation.

Some checks should be made by

your dealer or service station, and can be done con

veniently while your vehicle

is in the shop for other

regular maintenance services.

Other checks can be

made easily by owners.

CHECKS TO BE PERFORMED BY YOUR

DEALER OR SERVICE STATION

As a service reminder to owners, all 1971 General

Motors passenger cars are equipped with a

"Vehicle

6000 12000 18000 24000 30000 36000 41000 48000 )4000

• •

• •

• • • •

• • •

• •

• • • • • • •

• • • • • • • • • • •

• • • •

• • •

• •

• • • •

• • • • • • •

• • • • •

• •

• •

• • •

• •

• • • • •

• • • • • •

•

• • •

· • · •

• • • • •

• 0 o· 00 0 ·

0

Page 38 of 88

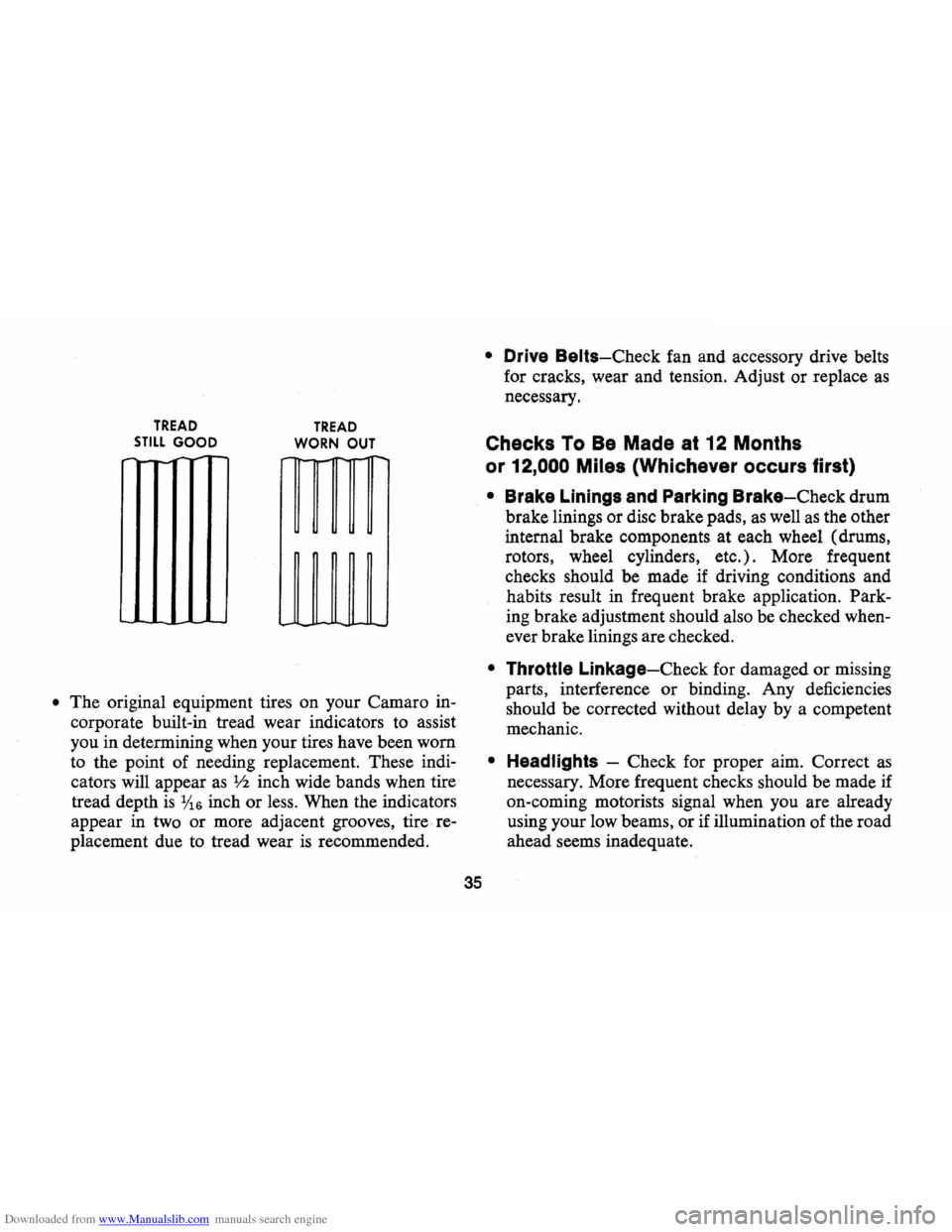

Downloaded from www.Manualslib.com manuals search engine TREAD STILL GOOD

-

TREAD

WORN OUT

• The original equipment tires on your Camaro in

corporate built-in tread wear indicators to assist

you in detennining when your tires have been worn

to the point of needing replacement. These indi

cators will appear

as V2 inch wide bands when tire

tread depth

is 1;16 inch or less. When the indicators

appear in two or more adjacent grooves, tire re

placement due to tread wear

is recommended.

35

• Drive Belts-Check fan and accessory drive belts

for cracks, wear and tension. Adjust or replace

as

necessary.

Checks To Be Made at 12 Months

or

12,000 Miles (Whichever occurs first)

• Brake Linings and Parking Brake-Check drum

brake linings or disc brake pads,

as well as the other

internal brake components at each wheel (drums,

rotors, wheel cylinders, etc.) . More frequent

checks should be made if driving conditions and

habits result in frequent brake application. Park

ing brake adjustment should also be checked when

ever brake linings are checked.

• Throttle Linkage-Check for damaged or missing

parts, interference or binding. Any deficiencies

should be corrected without delay by a competent

mechanic.

• Headlights -Check for proper aim. Correct as

necessary. More frequent checks should be made if

on-coming motorists signal when you are already

using your low beams, or if illumination of the road

ahead seems inadequate.

Page 39 of 88

Downloaded from www.Manualslib.com manuals search engine For further details on the engine and transmission

items listed on the

"Vehicle Safety Maintenance

Schedule," and for other recommended maintenance,

refer

to the "Service and Maintenance" and "Air

Pollution. Control" Sections of this manual.

CHECKS lOBE PERFORMED

BY OWNER

Listed below are the safety checks that should be

made by the owner . These checks should be made at

least every 4 months or

6,000 miles, whichever occurs

first , or more often when so indicated . Any

deficien

cies should be brought to the attention of your dealer

or service station, so the advice of a qualified mech

anic is available regarding the need for repairs or

replacements.

• Anti-Theft Lock-Check for proper operation by

attempting to turn key to

LOCK position in the

various transmission gears with

car stationary. Key

should

tum to LOCK position only when trans

mission control is in PARK on automatic trans

mission models or in REVERSE on manual trans

mission models.

• Seat Belts-Check lap and shoulder belts as well

as buckles, retractors and anchors for loose con-

36

nections, damage and positive latching action.

• Windshield Wipers and Washers-Check con

dition and alignment of wiper blades. Check

amount and direction of fluid sprayed by washers

during use.

• Defrosters-Check performance by turning con

trols to "de-ice" and "Hi" fan speed and noting

amount of air directed against the windshield.

• Wheel Alignment and Balance-In addition to

abnormal tire wear the need for wheel alignment

service may be indicated by a pull to the right or

left when driving on a straight level road. The need

for wheel balancing may be indicated by a

vibra

tion at the steering wheel while driving.

• Parking Brake and "Park" Mechanism-Check

parking brake holding ability by parking on a fairly

steep hill and restraining the vehicle with the

parking brake only.

On cars with automatic trans

missions, check the holding ability of the "Park"

mechanism by releasing all brakes after the trans

mission selector lever has been placed in the "P"

position.

• Lights -Check license plate lights, side marker

lights , headlamps, parking lamps, tail lamps , brake

Page 40 of 88

Downloaded from www.Manualslib.com manuals search engine lights, turn signals, backup lamps, and hazard

warning flashers. Have someone observe operation

of each light while you activate the controls.

• Starter Safety Switch (Automatic Transmis

sion Cars)

CAUTION: Before making the following check, be sure to have a clear distance ahead and behind the car, set the parking brake and firmly apply the foot brake. Do not depress accelerator pedal. Be prepared to turn ott ignition switch immediately if engine should start.

Check starter safety switch by placing the transmis

sion in each of the driving gears while attempting to

start the engine. The starter should operate only in the

Park ("P") or Neutral ("N") positions.

• Starter Interlock (Manual Transmission Cars)

-To check a manual transmission equipped car,

depress the clutch halfway, place the transmission

in neutral, and attempt to start.

The starter should

operate only when clutch

is fully depressed.

• Transmission Shift Indicator-Check to be sure

shift indicator accurately indicates the shift posi

tion selected.

• Horn-Blow the horn occasionally to be sure that

it works.

37

• Seat Back LatcheS-Check to see that seat bac k

latches are holding by pulling forward on the seat

back top.

• Rearview Mirrors and Sun Visors-Check that

friction joints are properly adjusted so mirrors and

sun visors stay in the selected position.

• Door LatcheS-Check for positive closing, la tch

ing and locking.

• Hood Latches-Check to make sure hood closes

firmly . Check also for broken , d amaged or missing

parts which might prevent secure latching.

• Fluid LeakS-Check for fuel, water, oil or other

fluid leaks by observing the ground beneath the

vehicle after it has been parked for a while . (Water

dripping from air conditioning system after use

is

normal). If gasoline fumes are noticed at any time,

the cause should be determined

and corrected with

out delay because of the possibility of fire.

• Exhaust System-See engine exhaust gas caution

at beginning of starting and operating section of

this manual for suggested driver observations and

checks.

Page 41 of 88

Downloaded from www.Manualslib.com manuals search engine I n Case of Emergency

Four Way Hazard

Warning

Flasher

• Use the warning flasher to warn

other drivers any time your

ve

hicle becomes a traffic hazard,

day or night.

• Avoid stopping on the roadway

if possible.

• Turn on the hazard warning

flasher, with engine ignition off

or on, by pushing in on the but

ton located just below the steer

ing wheel.

• If the brake pedal is depressed,

the lights will not flash

but will

glow continuously instead.

• To cancel the flasher, pull the

button outward.

"Rocking" Car

If it becomes necessary to rock

the car to free it from sand, mud or

snow, move the selector lever

from

"D" to "R" in a repeat pattern

while simultaneously applying

moderate pressure to the accelera

tor. Do not race engine. A void

spinning wheels when trying to free

car.

Towing

Proper lifting or towing equip

ment

is necessary to prevent dam

age to the vehicle during any tow

ing operation. Detailed towing in

formation is available at your

dealer and has been provided to

tow truck operators responsible for

movement of disabled or locked

ve

hicles. State and local laws appli

cable to vehicles in tow must also

be followed.

Your Camaro may be towed on

all four wheels, at speeds of less

than 35 MPH, for distances up to

38

50 miles, provided driveIine, axle

and transmission are otherwise nor

mally operable.

For such towing,

parking brake must be released,

and transmission must be in neu

tral (ignition lock turned to

OFF

position). Attachments must be to

main structural members of the car,

not to bumpers or bracketing,

Safety chains or cables should be

used. Remember that power steer

ing assist will not be available when

engine

is inoperative.

Emergency Starting

• Never tow the car to start

because the surge forward when

the engine starts could cause a

collision with the tow vehicle.

• Engines in vehicles with auto

matic transmissions cannot be

started by pushing the car.

Page 43 of 88

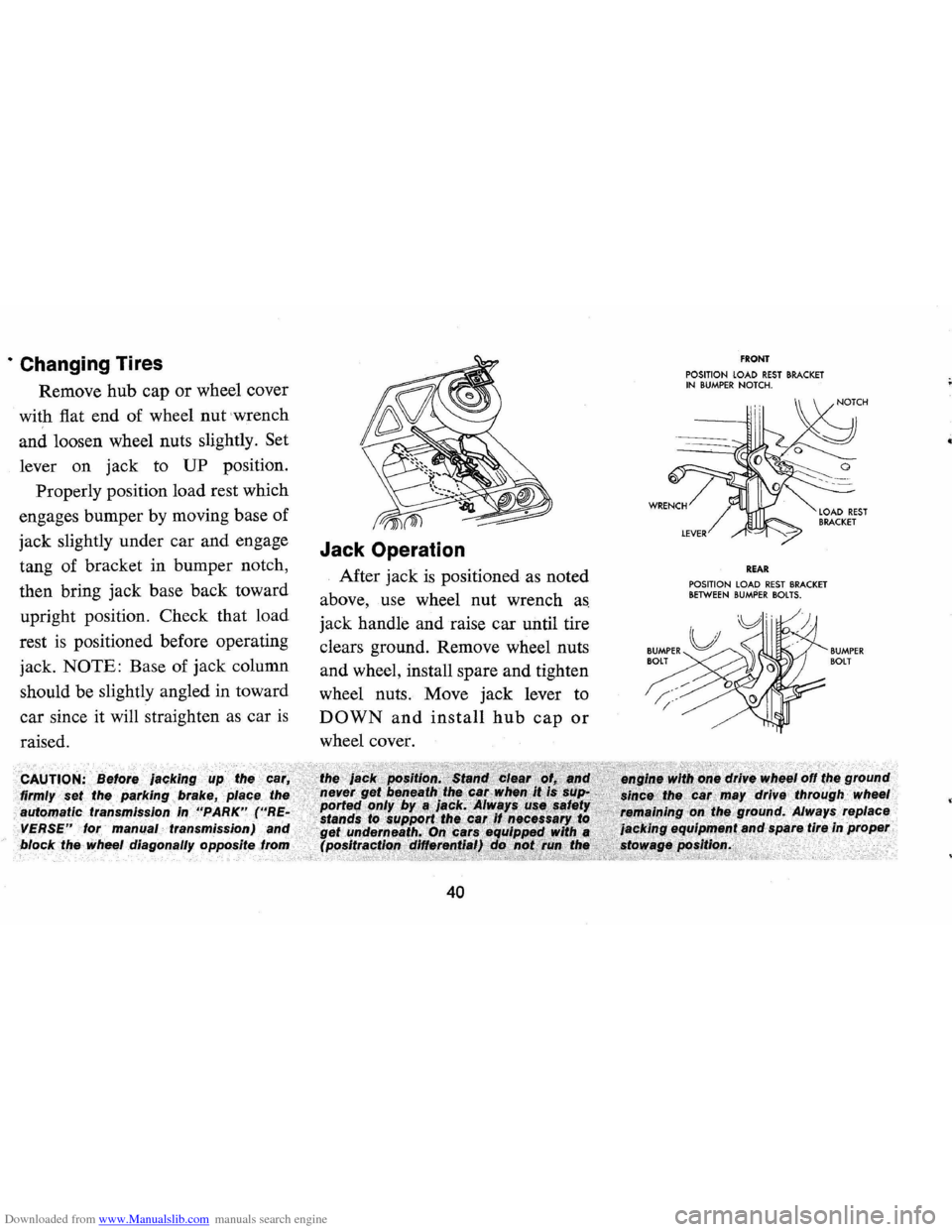

Downloaded from www.Manualslib.com manuals search engine · Changing Tires

Remove hub cap or wheel cover

with fiat end of wheel

nut wrench

and loosen wheel nuts slightly.

Set

lever on jack to UP position.

Properly position load rest which

engages bumper by moving base of

jack slightly under car and engage

tang of bracket in bumper notch,

then bring jack base back toward

upright position. Check that load

rest is positioned before operating

jack.

NOTE: Base of jack column

should be slightly angled in toward

car since it will straighten as car

is

raised.

firmly

automatic rralrlSOIlSSlon

VERSE" lor manual transmission)

Jack Operation

After jack is positioned as noted

above, use wheel nut wrench

as

jack handle and raise car until tire

clears ground. Remove wheel nuts

and wheel, install spare and tighten

wheel nuts. Move jack lever to

DOWN and install hub cap or

wheel cover.

block the wheel diagonally opposite .. _.... .,.. __

40

FRONT POSITION LOAD REST BRACKET IN BUMPER NOTCH.

REAR POSITION LOAD REST BRACKET BETWEEN BUMPER BOLTS.

BUMPER BOlT

Page 44 of 88

Downloaded from www.Manualslib.com manuals search engine WHAT YOU SHOULD KNOW ABOUT

AIR POLLUTION CONTROL SYSTEMS

AND THE SERVICE THEY REQUIRE

Source of Emissions

During the combustion process in an automotive

engine, some of the fuel (hydrocarbons) fails to

bum

completely and is discharged into the engine crank

case or exhaust system. Additional hydrocarbons are

emitted into the atmosphere through evaporation of

gasoline vapors from the fuel tank and carburetor.

Of the total hydrocarbons coming from uncontrolled

automobiles, about

20% are emitted from the crank

case,

20% from the fuel system and 60% from the

engine exhaust.

In addition to hydrocarbons, carbon monoxide

and oxides of nitrogen are also formed during the

41

combustion process. These are also discharged into

the exhaust system.

What General Motors Has Done

Since research on the control of vehicle emissions

first began some

20 years ago, General Motors has

developed a number of control systems which are

highly effective in reducing undesirable emissions.

(These systems are discussed in some detail in the

following pages of this section). The progress made

is evidenced by a reduction in hydrocarbon emissions

of

80% since 1960. Control of hydrocarbon emis

sions

is important since, when subjected to sunlight

Page 49 of 88

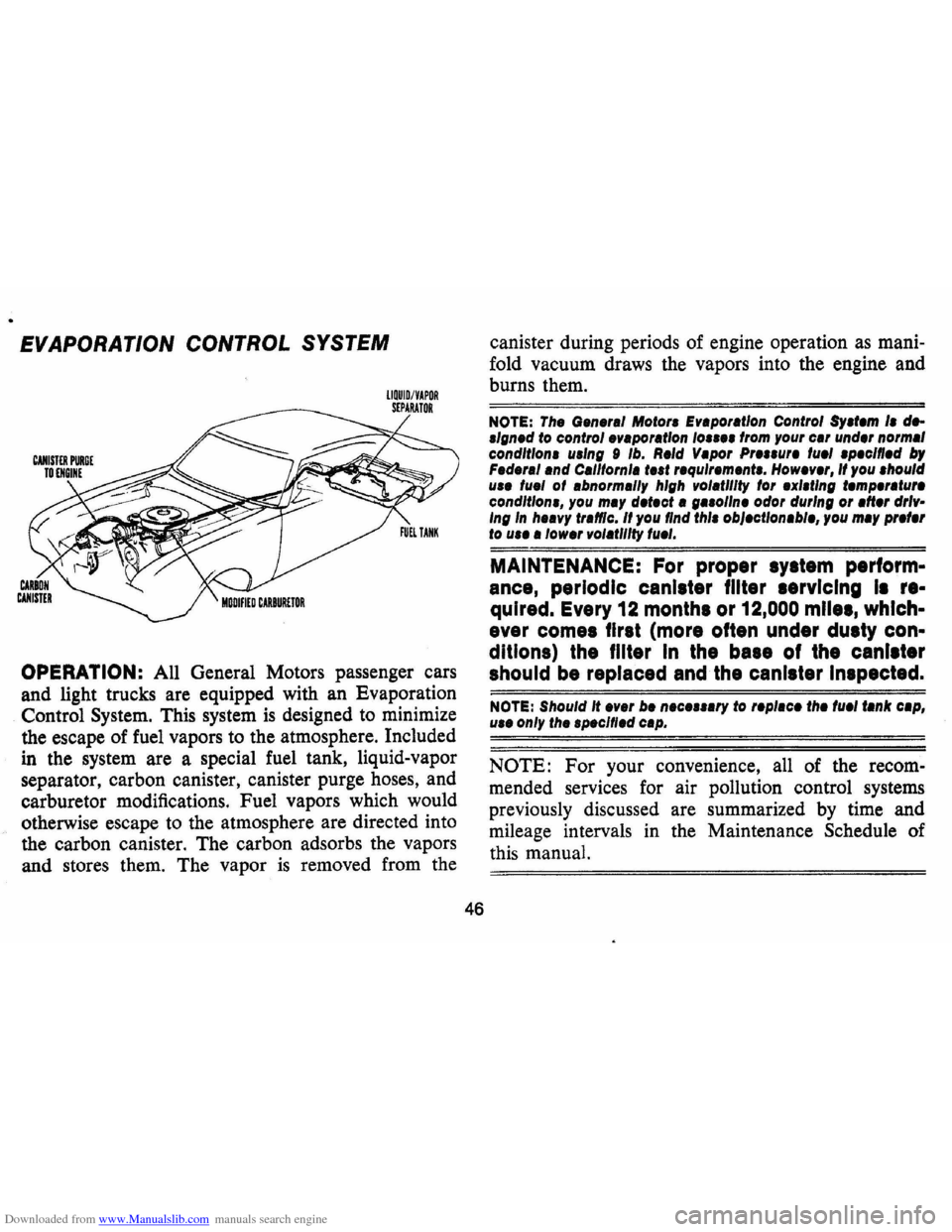

Downloaded from www.Manualslib.com manuals search engine EVAPORATION CONTROL SYSTEM

LIQUID/VAPOR SEPARATOR

OPERATION: All General Motors passenger cars

and light trucks are equipped with an Evaporation

Control

System. This system is designed to minimize

the escape of fuel vapors to the atmosphere. Included

in the system are a special fuel tank, liquid-vapor

separator, carbon canister, canister purge hoses, and

carburetor modifications. Fuel vapors which would

otherwise escape to the atmosphere are directed into

the carbon canister. The carbon adsorbs the vapors

and stores them. The vapor

is removed from the

46

canister during periods of engine operation as mani

fold vacuum draws the vapors into the engine and

burns them.

NOTE: Th. G.n.r.' Motora E".por.tlon Control Sy.t.m I. de.'gn.d to control ."aporatlon 10 •••• trom your c.r und.r normal condition. u.'ng 9 lb. R.ld Vapor Pr ••• ur. tu.' .p.cltl.d by F.d.r.' .nd C.lltorn/a t •• t r.qulr.m.nt •. How.".r, It 'Iou .hould u.. tu.' ot .bnorm.lly high "o/.tlllty tor .x/.tlnll t.mperatur.

condition., you may d.t.ct • ga.olln. odor during or att.r dr/,,· Ing In h •• "y tr.mc. It 'Iou find thl. obJ.ctlonabl., you may pr.t.r to u ••• low.r "o/atlllty tu.'.

MAINTENANCE: For proper system perform

ance, periodic canister tllter servicing II re

quired. Every

12 months or 12,000 miles, which

ever comes first (more often under dusty con

ditions) the filter

In the base of the can liter

should be replaced and the canister Inspected.

NOTE: Should It .".r b. n.c •••• ry to r.pl.c. the tu.' tank cap, u •• only the .peclfl.d c.p.

NOTE: For your convenience, all of the recom

mended services for air pollution control systems

previously discussed are summarized

by time and

mileage intervals in the Maintenance Schedule of

this manual.

Page 51 of 88

Downloaded from www.Manualslib.com manuals search engine Cleaning Fabrics with

Cleaning Fluid

This type of cleaner should be

used for cleaning stains containing

grease, oil

or fats. Excess stain

should be gently scraped off with

a clean dull knife

or scraper. Use

very little cleaner, light pressure,

and clean cloths (preferably cheese

cloths). Cleaning action with cloth

should be from outside of stain to

wards center and constantly chang

ing to a clean section of cloth.

When stain

is cleaned from fabric,

immediately wipe area briskly with

a clean absorbent towel

or cheese

cloth to help dry area and prevent

a cleaning ring.

If ring forms, im

mediately clean entire area

or panel

section of the trim assembly.

NOTE: Sometimes a difficult spot

may require a second application

of cleaning fluid followed immedi

ately by a soft brush to completely

remove the spot.

Cleaning Fabrics with

Detergent Foam

Cleaners

This type of cleaner is excellent

for cleaning general soilage from

fabrics and for cleaning a panel sec

tion where a minor cleaning ring

may be left from spot cleaning.

Vacuum area to remove excess

loose dirt. Always clean at least a

full trim panel

or section of trim.

Mask adjacent trim along stitch

or

weld lines. Mix detergent type foam

cleaners in strict accordance with

directions

on label of container.

Use foam only on a clean sponge or

48

soft bristle brush - Do not wet

fabric excessively or rub harshly

with brush. Wipe clean with a

slightly damp absorbent towel

or

cloth. Immediately after cleaning

fabric, dry fabric with a dry towel

or hair dryer. Rewipe fabric with

dry absorbent towel

or cloth to re

store the luster of the trim and to

eliminate any dried residue.

Removal of Specific Stains

Candy -Chocolate, use cloth

soaked in lukewarm water; other

than chocolate, use very hot water.

Dry.

If necessary, clean lightly with

fabric cleaning fluid.

Chewing Gum-Harden gum with

ice cube and scrape off with dull

knife. Moisten with fabric cleaning

fluid

and scrape again.