tow CHEVROLET CAMARO 1973 2.G User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1973, Model line: CAMARO, Model: CHEVROLET CAMARO 1973 2.GPages: 84, PDF Size: 32.64 MB

Page 43 of 84

Downloaded from www.Manualslib.com manuals search engine • Activate hazard warning flasher.

• Block both the front and back

of the wheel diagonally opposite

the jack position.

Remove

hubcap or wheel cover

with flat end of wheel

nut wrench

and loosen wheel nuts slightly.

Set

lever on jack to UP position.

Properly position load rest which

engages bumper by moving base of

NOTE: Base of jack column

should be slightly angled in toward

car since it will straighteri

as car is

raised.

jack slightly under car and engage

tang of

bracket in bumper notch,

then bring jack base back toward

upright position. Check that

l~ad

rest is positioned before operatmg

jack.

40

Jack Operation

After jack is positioned as noted

above use

wheel nut wrench as . ,

jack handle and raise car until tire

clears ground. Remove wheel nuts

and wheel, install spare and tighten

wheel nuts. Move jack lever to

DOWN and install hub cap or

wheel cover.

Page 45 of 84

Downloaded from www.Manualslib.com manuals search engine Cleaning Fabrics with

Cleaning

Fluid

This type of cleaner should be

used for cleaning stains containing

grease, oil or fats. Exces s stain

should be gently scraped off with

a clean dull knife

or scraper. Use

very little cleaner, light pressure,

and clean cloths (preferably cheese

cloths) . Cleaning action with cloth

should be from outside of stain to

wards center and constantly chang

ing to a clean section of cloth.

When stain

is cleaned from fabric,

immediately wipe

area briskly with

a clean absorbent towel or cheese

cloth to help dry area and prevent

a cleaning ring.

If ring forms, im

mediately clean entire area or panel

section of the trim assembly.

NOTE: Sometimes a difficult spot

may require a second application

of cleaning fluid followed immedi- ately

by a soft brush to completely

remove the spot.

Cleaning Fabrics with

Detergent Foam Cleaners

This type of cleaner is excellent

for cleaning general soilage from

fabrics and for cleaning a panel sec

tion where a minor cleaning ring

may be left from spot cleaning.

Vacuum area to remove excess

loose dirt. Always clean at least a

full trim panel or section of trim.

Mask adjacent trim along stitch or

weld lines. Mix detergent type foam

cleaners in strict accordance with

directions on label of container.

Use

foam only on a clean sponge or

soft bristle brush -Do not wet

fabric excessively or rub harshly

with brush. Wipe clean with a

slightly damp absorbent towel

or

cloth. Imm~diately after cleaning

fabric, dry fabric with a dry towel

42

or hair dryer. Rewipe fabric with

dry absorbent towel

or cloth to re

store the luster of the trim and to

eliminate any dried residue.

Seat Belt Care

• Clean only with mild soap solu

tion and lukewarm water.

• Do not bleach or dye belts since

this may severely weaken belts.

Removal of Specific Stains

Candy -Chocolate, use cloth

soaked in lukewarm water; other

than chocolate, use very hot water.

Dry.

If necessary, clean lightly with

fabric cleaning fluid.

Chewing Gum-Harden gum with

ice cube and scrape off with dull

knife. Moisten with fabric cleaning

fluid and scrape again.

Page 60 of 84

Downloaded from www.Manualslib.com manuals search engine and increased susceptibility to

damage by road impacts.

Tire pressures should be

checked when the tires are

"cold"

at least once a month (and pref

erably oftener) or before long

trips

or when heavily loaded. The

following points should be ob

served when checking and setting

tire pressures:

1. Cold tire pressure ratings are applic

able when a vehicle has been inopera

tive for 3 hours or more, or driven less than 1 mile.

2. Tire Inflation pressure may increase as

much as 6 pounds per square inch (psi)

when hot (after

vehicle has been driven 10 miles or at speeds of more than 60 miles per hour). Do not "bleed" or re

duce pressures when tires are hot from

driving.

3. For continuous high speed operation

(over 75 mph), Increase tire Inflation pressure 4 psi above the recommended

pressures up to a maximum of 32 psi cold pressure for load range B tires, or 40 psi for 0 load range tires. Sustained

speeds above 75 mph are not recommended when the 4 psi adjustment ,

would require pressures greater than

the above maximum pressures.

4. Always use a tire pressure gauge when

checking pressures as t,he appearance of a tire can be deceiving. For example,

radial ply fires, In comparison with bias ply tires at the same pressure, may have

the appearance of being under-inflated.

Vehicle Loading -Do not load

your vehicle beyond the vehicle

capacity (total pounds) shown on

the tire placard. This figure repre

sents the design capacity of the

ve

hicle, not merely of the tires.

When towing trailers, the allow

able pasenger and cargo load

must be reduced by an amount

equal to the trailer tongue load on

the trailer hitch.

(See "Trailer

Hauling"

in Section 1 of this man

ual.) Station wagon loads should

be distributed

as far forward as

possible. Vehicles equipped with

luggage racks do not have a

ve

hicle load capacity greater than

specified on the tire placard.

57

Tire Wear and Rotation -Un

even or abnormal tire wear is usu

ally the result of incorrect inflation

pressure, improper wheel align

ment, wheels being out-of-balance,

or poor driving habits. Underin

flation, incorrect toe or camber

and fast cornering produce differ

ent types of abnormal wear which

can be diagnosed by your dealer.

The original equipment tires in

corporate built-in tread wear

in

dicators to assist you in determin

ing when your tires ,have been

worn to the point of needing re

placement. These indicators ap

pear

as Ij2 inch wide bands when

tire tread depth

is 1/16 inch or

less. When the indicators appear

in two or more adjacent grooves,

tire replacement due to tread wear

is recommended.

To equalize wear, it

is recom

mended that the tires be rotated

every

6,000 miles (or sooner if

Page 63 of 84

Downloaded from www.Manualslib.com manuals search engine When driving on wet or slushy

roads, it

is possible for a wedge of

water to build up between the tire

and road surface. This phenom

enon, known

as hydroplaning.

may cause partial

or complete loss

of traction, which adversely affects

vehicle control and stopping abil

ity.

To reduce the possiblity of

traction loss, the following precau

tions should be observed:

1. Slow down during rainstorms or

when roads are slushy.

2. Slow down if road has standing

water

or puddles.

3. Replace tires when tread wear

indicators are visible .

4. Keep tires properly inflated.

For temporary assistance when

traction

is lost on ice or snow. the

use of AC Liquid Tire Chain is

recommended.

Inflation Instructions for

Space Saver Spare Tire

I. Install deflated space saver

spare

on car with valve stem at

the bottom and tighten all

five

lug nuts.

2. Remove valve qp and make

sure valve core is screwed tight

in valve stem.

3. Remove plastic cap from

in

flator.

4 . Place inflator over valve

stern

and push onto stem until sound

of gas entering tire can

be

heard .

5 . Keep pressure against valve and

hold can upright against wheel

to ensure complete draining of

fluid.

60

6 . Hold the inflator in position one

minute. After sound stops. then

remove inflator for disposal

in

proper receptacle.

7 . Replace valve cap.

NOTE: It is recommended that

the inflation pressure be checked

and adjusted to 28 psi

(Space

Saver Spare

only), as soon as pos

sible after installing tire on car.

To stow , deflate tire by remov

ing tire valve stem core with tool

on end of valve cap. Flatten tire

and replace core and cap. Do not

inhale gas.

Store tire in trunk com

partment. The

Space Saver Spare tire has

an approximate tread life of

2,000

miles; therefore, its continued use

other than for emergency purposes

is not recommended. The Space

Saver Spare

has the same warranty

as all original equipment tires.

Page 66 of 84

Downloaded from www.Manualslib.com manuals search engine The chart on the previous page, and the, information on the pages

which follow, contains information designed to aid the average

driver to discover, and possibly correct, conditions resulting in minor

mechanical difficulties

in his car. The chart, designed to point out

possible solutions to several

of the most common automotive malfunctions and point out a logical checking sequence, will lead step

by step to the most

likely causes and corrective procedures. If, after

making the checks and adjustments suggested, the source of the

trouble

has not been found and corrected, it is strongly recom

mended that an Authorized Chevrolet Dealer inspect the vehicle and make whatever repairs or adjustments are necessary.

FUEL SYSTEM AND ENGINE

If the ignition switch will cause the engine to "turn over" or

"crank" but the car will not start, check Steps A through 0 below.

NOTE: If continual ··f1ooding··, of the carburetor is evidenced by a

carburetor wet with fuel or black exhaust smoke, perform the

operation suggested in paragraph D only.

(A) The first and most obvious, and one of the most frequently

overlooked, items to check when

you have difficulty in starting your car is the amount of fuel in the

tank. Make it a habit to check the

FUEL GAUGE regularly and most

especially at a time when the engine will "turn over" but will not

start.

(8)

If the fuel tank is not empty,

you may check further to see

Checking Fuel Flow

63

whether the fuel is reaching the carburetor. Disconnect .the fuel line at the carburetor and remove the center wire (ground the secondary coil terminal or disconnect the primary wire from the coil to the

distributor at the coil) from the coil tower. Place a jar or cup under

the open line and briefly "crank" the engine by means of the

starter. If fuel spurts from the fitting, you may assume that the FUEL LINES are clear and the FUEL PUMP is operating properly. If no

fuel leaves the line, either the fuel

lines

or fuel pump are at fault.

See your Authorized Chevrolet

Dealer.

(C) Before reconnecting the fuel

line to the carburetor, remove

the

FUEL FILTER from the carburetor

inlet and check its condition. If it

appears to be clean, replace it

and recorinect the fuel line. Re

place the filter if it appears to be

plugged.

(D) If the fuel seems to be

reaching the carburetor properly, Fuel Filter

the problem may be: an EMPTY CARBURETOR BOWL caused by a "stuck shut" carburetor; a FLOODED CARBURETOR caused by a "stuck open" condition and evidenced by gasoline seeping around and down the outside of the carburetor; or a stuck CHOKE valve.

Remove the air cleaner from the carburetor. Check that the choke

valve moves freely and is not stuck. (Don't mistake normal spring

tension for a stuck valve.) Tap the side of the carburetor sharply

several times with a light tool such as a screwdriver handle or pliers. Replace the air cleaner and attempt to start the engine in the normal manner.

I

Page 68 of 84

Downloaded from www.Manualslib.com manuals search engine a bobby pin) between the rubber

cup at the end of the spark plug

wire and the tubular metal con

nector inside of it. If the spark

plug wire is wet or oily, wipe it

dry. Wrap a dry handkerchief or facial tissue, folded several thick.

nesses, around the wire at least three inches back from the end

and grasp the wire at this point.

Hold the bare wire about 1f4 inch

from the

bare tip of the spark

plug from which you removed the Checking Spark

wire. When the engine is "turned over" a spark should jump across

the V" inch space, indicating ample current supply. If no spark

jumps, the difficulty is probably caused by a defective ignition port

and should be corrected by your Authorized Chevrolet Dealer.

COOLING SYSTEM

When the cor will run but evidences serious overheating on the temperature gauge in the instrument panel, there are several items

which may be checked .

(L) Engine overheating will occur when the OIL lEVEL falls dangerously low. Check the oil level as a matter of course.

(M) Low COOLANT LEVEL will , of course, couse engine overheating. Determine . the cause of the low coolant level and have

it corrected if necessary.

(N) Check the RADIATOR CORE. Clean it if it is plugged with

bugs, leaves or other foreign material.

65

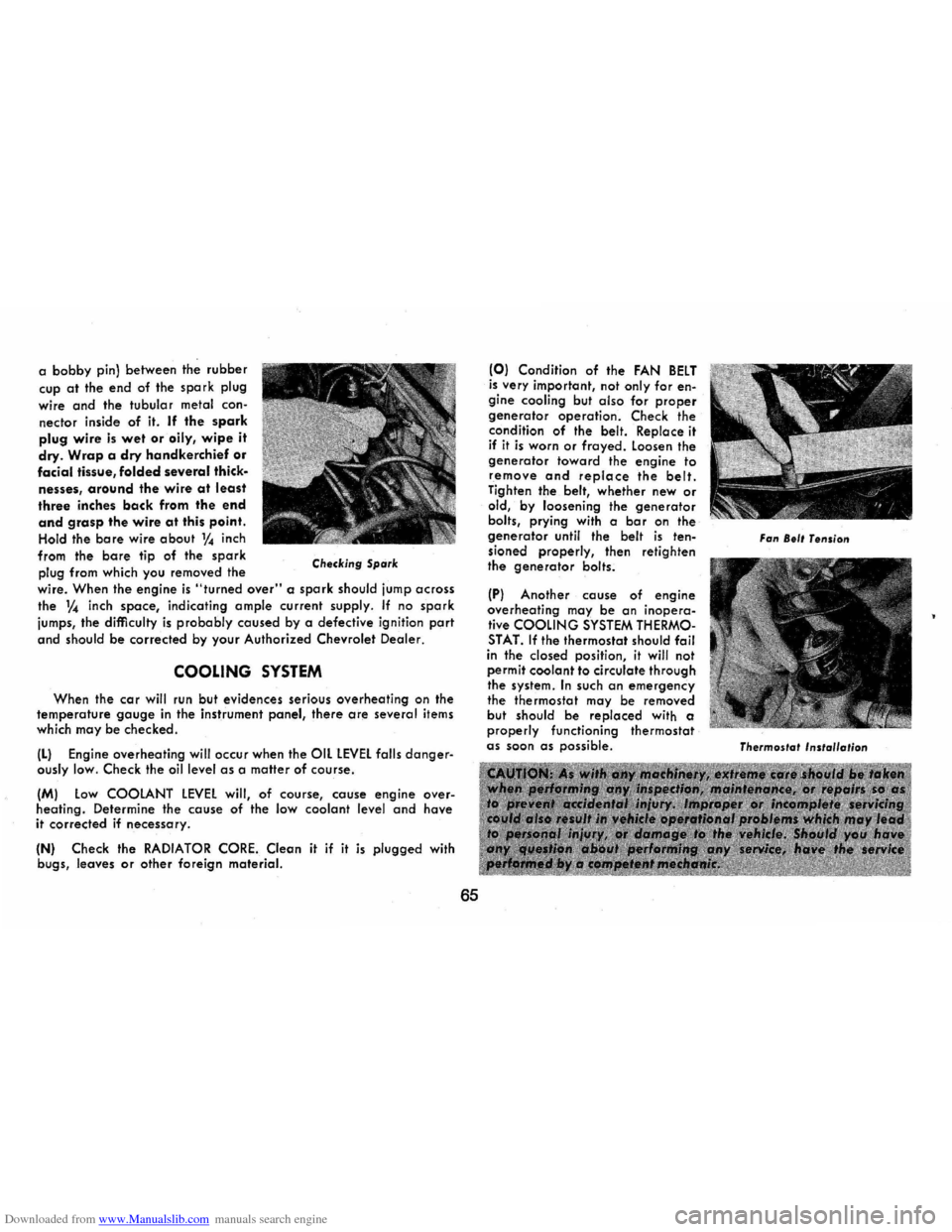

(0) Condition of the FAN BELT is very important, not only for engine cooling but also for proper generator operation. Check the

condition of the belt. Replace it if it is worn or frayed. Loosen the generator toward the engine to remove and replace the belt. Tighten the belt, whether new or old, by loosening the generator bolts, prying with a bar on the generator until the belt is tensioned properly, then retighten

the generator bolts.

(PI Another couse of engine ove rheating may be on inopera

tive COOLING SYSTEM THERMOSTAT. If the thermostat should foil in the closed position, it will not

perm it coolant to circulate through

the system . In such on emergency the thermostat may be removed

but should be replaced with a properly functioning thermostat as soon as possible.

Fan 8.11 Tension

Thermoslal Inslollo/ion

Page 75 of 84

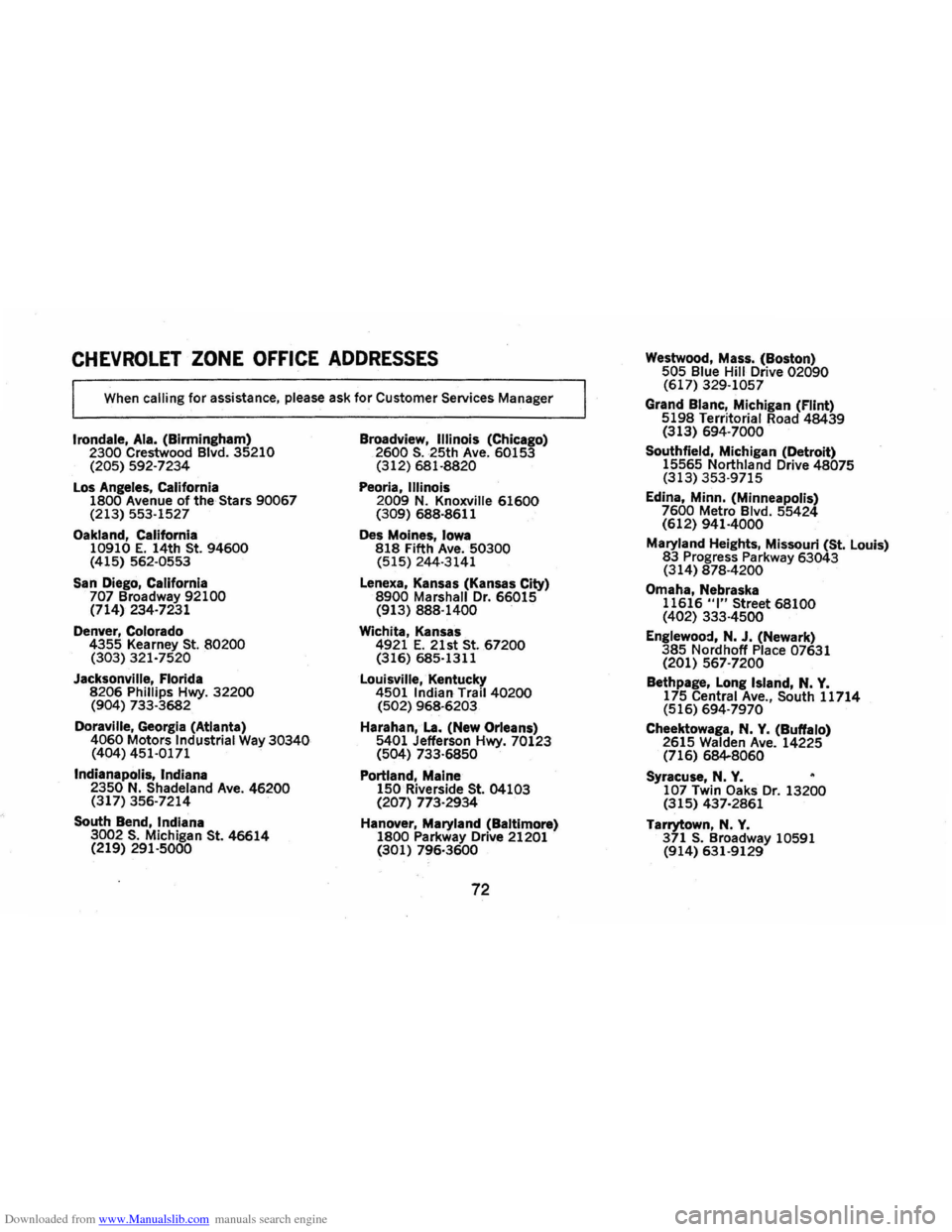

Downloaded from www.Manualslib.com manuals search engine CHEVROLET ZONE OFFICE ADDRESSES

When calling for assistance, please ask for Customer Services Manager

Irondale, Ala. (Birmingham) 2300 Crestwood Blvd. 35210

(205) 592-7234

Los Angeles,

California

1800 Avenue of the Stars 90067 (213) 553-1527

Oakland,

California

10910 E. 14th St. 94600 (415) 562·0553

San Diego, California

707 Broadway 92100 (714) 234-7231

Denver, Colorado

4355 Kearney

St. 80200

(303) 321-7520

Jacksonville, Florida 8206 Phillips Hwy. 32200

(904) 733-3682

Doraville, Georgia (Atlanta)

4060 Motors Industrial Way 30340 (404) 451-0171

Indianapolis, Indiana

2350

N. Shadeland Ave. 46200 (317) 356-7214

South Bend,

Indiana

3002 S. Michigan St. 46614

(219) 291-5000

Broadview, Illinois (Chicago) 2600 S. 25th Ave. 60153 (312) 681-8820

Peoria, Illinois

2009 N. Knoxville 61600 (309) 688-8611

Des Moines,

Iowa 818 Fifth Ave. 50300 (515) 244·3141

Lenexa, Kansas (Kansas City)

8900 Marshall Dr. 66015 (913) 888-1400

Wichita, Kansas

4921 E. 21st St .. 67200 (316) 685-1311

Louisville, Kentucky

4501 Indian Trail 40200

(502) 968-6203

Harahan,La. (New Orleans) 5401 Jefferson Hwy. 70123

(504) 733-6850

Portland, Maine 150 Riverside St. 04103

(207) 773-2934

Hanover, Maryland (Baltimore)

1800 Parkway Drive 21201

(301) 796·3600

72

Westwood, Mass. (Boston) 505 Blue Hill Drive 02090 (617) 329·1057

Grand Blanc, Michigan (Flint)

5198 Territorial Road 48439

(313)

694- 7000

Southfield,

Michigan (Detroit)

15565 Northland Drive 48075 (313) 353·9715

Edina, Minn. (Minneapolis)

7600 Metro Blvd. 55424

(612) 941-4000

Maryland Heights, Missouri (St. Louis)

83 Progress Parkway 63043 (314) 878·4200

Omaha, Nebraska

11616 "I" Street 68100

(402) 333·4500

Englewoo:t,

N. J. (Newark)

385 Nordhoff Place 07631

(201) 567·7200

Bethpage, Long Island, N. Y. 175 Central Ave., South 11714

(516) 694-7970

Cheektowaga, N. Y. (Buffalo) 2615 Walden Ave_ 14225

(716) 684--8060

Syracuse,

N. Y. 107 Twin Oaks Dr. 13200 (315) 437-2861

Tarrytown, N.

Y. 371 S. Broadway 10591 (914) 631·9129

Page 77 of 84

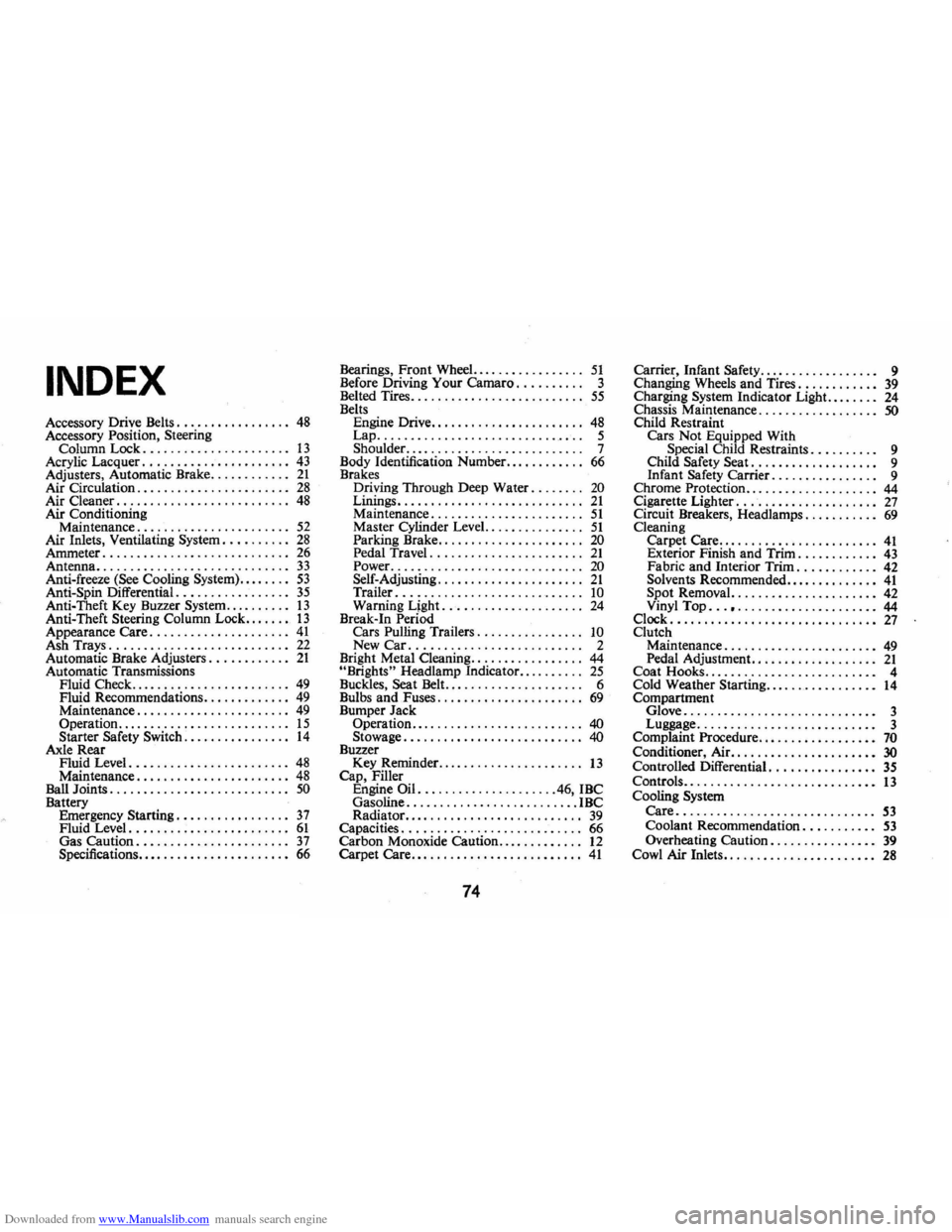

Downloaded from www.Manualslib.com manuals search engine INDEX

Accessory Drive Belts. . . . . . . . . . . . . . . .. 48 Accessory Position, Steering

Column Lock. .. . . . . .. . . .. . .. .. .... 13 Acrylic Lacquer. . . . . . . . . . . . . . . . . . . . .. 43 Adjusters, Automatic Brake ............ 21 Air Circulation . . . . . . . . . . . . . . . . . .. . ... 28 Air Cleaner. . . . . . . . . . . . . . . . . . . . . . . . .. 48 Air Conditioning

Maintenance. . . . . . . . . . . . . . . . . . . . . .. 52 Air Inlets, Ventilating System .......... 28 Ammeter ............................ 26 Antenna ................ ............. 33 Anti-freeze (See Cooling System). . . . . . .. 53 Anti-Spin Differential. . . . . . . . . . . . . . . .. 35 Anti-Theft Key Buzzer System .......... 13 Anti-Theft Steering Column Lock ....... 13 Appearance Care ..................... 41 Ash Trays. . . . . . . . . . . . . . . . . . . . . . . . . .. 22 Automatic Brake Adjusters. . . . . . . . . . .. 21 Automatic Transmissions

Fluid Check ........................ 49 Fluid Recommendations ............. 49 Maintenance. . . . . . . . . . . . . . . . . . . . . .. 49 Operation .......................... 15 Starter Safety Switch. . . . . . .. . . . . . ... 14 Axle Rear

Fluid Level. . . . . . . . . . . . . . . . . . . . . . .. 48 Maintenance. . . . . . . . . . . . . . . . . . . . . .. 48 Ball Joints ........................... 50 Battery

Emergency Starting. . . . . . . . . . . . . . . .. 37 Fluid Level. . . . . . . . . . . . . . . . . . . . . . .. 61 Gas Caution ....................... 37 Specifications. . . . . . . . . . . . . . . . . . . . . .. 66 Bearings,

Front Wheel.

................ 51 Before Driving Your Camaro . . . . . . . . . . 3

Belted Tires .......................... 55 Belts

Engine Drive. . . . . . . . . . . . . . . . . . . . . .. 48 Lap ................................ 5 Shoulder............ . .............. 7 Body Identification Number ............ 66 Brakes

D.riying Through Deep Water. . . . . . .. 20 Lmmgs ............................ 21 Maintenance ....................... 51 Master Cylinder Level. .............. 51 Parking Brake ...................... 20 Pedal Travel. . . . . . . . . . . . . . . . . . . . . .. 21 Power. .............. .............. 20 Self-Adjusting. . . . . . . . . . . . . . . . . . .. .. 21 Trailer ............................ 10 Warning Ljght. .. . . . . . . .. . . . . . . . . .. 24 Break-In Period Cars Pulling Trailers. . . . . . . . . . . . . . .. 10 New Car.......................... 2

Bright Metal Cleaning .......... '" .... 44 "Brights" Headlamp Indicator .......... 25 Buckles, Seat Belt.. . . . . . . . . . . . . . . . . . .. 6

Bulbs and Fuses . . . . . . . . . . . . . . . . . . . . .. 69 Bumper Jack

Operation ...... " .................. 40 Stowage ........................... 40 Buzzer Key Reminder.. .. .. .. .. .. . .. .. .. ... 13 Cap, Filler

Engine Oil. .................... 46, IBC

Gasoline .......................... IBC

Radiator. . . . . . . . . . . . . . . . . . . . . . . . . .. 39 Capacities. . . . . . . . . . . . . . . . . . . . . . . . . .. 66

Carbon Monoxide Caution ............. 12 Carpet Care .......................... 41

74

Carrier, Infant Safety.... . . . . . . .. .. . . .. 9

Changing Wheels and Tires. . . . . . . . . . .. 39 Charging System Indicator Light. . . . . . .. 24

Chassis Maintenance . . . . . . . . . . . . . . . . .. 50 Child Restraint

Cars Not Equipped With

Special Child Restraints. . . . . . . . . . 9

Child Safety Seat. . . . . . . . . . . . . . . . . . .

9 Infant Safety Carrier. . . . . . . . . . . . . . .. 9 Chrome Protection .................... 44

Cigarette Lighter. . . . . . . . . . . . . . . . . . . .. 27 Circuit Breakers, Headlamps. . . . . . . . . .. 69 Cleaning

Carpet Care. . . . . . . . . . . . . . . . . . . . . . .. 41 Exterior Finish and Trim. . . . . . . . . . .. 43 Fabric and Interior Trim ............ 42

Solvents Recommended .............. 41 Spot Removal. . . . . . . . . . . . . . . . . . . . .. 42 Vinyl Top ... , . . . . . . . . . . . . . . . . . . . .. 44

Clock ............................... 27 Clutch Maintenance. . . . . . . . . . . . . . . . . . . . . .. 49 Pedal Adjustment ................... 21 Coat Hooks........ ...... ........ .... 4

Cold Weather Starting ................. 14 Compartment

Glove ............................. 3

Luggage. .......... ................ 3

Complaint Procedure .................. 70 Conditioner, Air ...................... 30 Controlled Differential. . . . . . . . . . . . . . .. 35 Controls ............................. 13 Cooling System

Care ........... ................... 53 Coolant Recommendation. . . . . . . . . .. 53 Overheating Caution. . . . . . . . . . . . . . .. 39 Cowl Air Inlets ....................... 28

Page 81 of 84

Downloaded from www.Manualslib.com manuals search engine Steering Column Controls. . . . . . . . . . . . . . . . . .. 13 Column Lock. . . . . . . . . . . . . . . . . . . . .. 13 Gear Lubricant. .................... 51 Linkage Inspection. . . . . . . . . . . . . . . . .. 48 Maintenance. . . . . . . . . . . . . . . . . . . . . .. 48 Power ....................... ...... 18 Wheel, Tilt ......................... 19 Straps, Safety (See Seat Belts) Storage Of Items..... . .. . . . . . . . . . . . . .. 5 Suspension Maintenance. . . . . . . . . . . . . .. 50 Tape System, Stereo. . . . . . . . . . . . . . . . . .. 34 Temperature ........... ............ " 29 Control , Cooling.. . .. . . . . . . . . . . . . . .. 29 Control, Heating. . . . . . . . . . . . . . . . . . .. 29 Indicator Light/Gauge. . . . . . . . . . . . . .. 26 Thermostat ....... ................... 55 Tilt Steering Wheel.. . . . . . . . . . . . . . . . . .. 19 Tire

Belted .. ........................... 55 Care ........................ ...... 55 Changing ........................ " 39 Full Rated Load ............ ....... . 57 High Speed Operation ............... 56 Hydroplaning. . . . . . . . . . . . . .. . . . . . .. 58 Inflation Pressure ............. ... , .. 56 Inspection ............ ... ........ " 57 Load Limit. . . . . . . . . . . . . . . . . . . . . . .. 56 Rotation ..... ............ .......... 58 Space Saver ........................ 60 Traction ............. .............. 59 Tread Wear Indicators .... ... ....... 57 Usage and Options... . . . . . . . . . . . . . .. 55 Towing

Caution ........... ................ . 36

Disabled Vehicle .................... 36 To Start. .... ........ .............. 36 Toxic

Cleaning Solvents ................... 41 Exhaust Fumes ..................... 12 Traction, Wet Roads. . . . . . . . . . . . . . . . . . 5

Traffic Hazard Flasher. . . . . . . . . . . . . . .. 36 Trailer Hauling.. . . . . . . . . . . . .. . . . . .. .. 10 Break-In Period .................... 11 Cautions . . . . . . . . . . . . . . . . . . . . . . . . . .. 11 Equipment.. . . . . . . . . . . . . . . . . . . . . . .. 10 Special Maintenance ............. .... 10 Tire Inflation ......... .............. 10 Trailer Tongue Load. . . . . . . . . . . . . . .. 10 Transmission 3-Speed Manual. . . . . . . . . . . . . . . . . . .. 17 Automatic .................. ....... 15 Braking Effect On Hills .............. 16 Checking Fluid Level. . . . . . . . . . . . . . .. 49 Fluid And Strainer.. . . . . . . . . . . . . . . .. 49 Fluid Change Interval. . . . . . . . . . . . . . . 49 Maintenance. . . . . . . . . . . . . . . . . . . . . .. 49 Shift Controls.. . . . . . . .. .. . . . . . . . ... 50 Shift Indicator

Turbo Hydramatic .................. 50 Tread Wear Indicators ................ 57 Trim Care, Interior .................. , 41 Trunk

Driving With Trunk Open ........... 12 Turbo-Hydramatic . . . . . . . . . . . . . . . . . . .. 50 Maintenance. . . . . . . . . . . . . . . . . . . . . .. 50 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . 15 Turn Signals and Lane Change

Feature ................. ........... 17 Underbody Maintenance. . . . . . . . . . . . . . . 61

78

Upholstery And Carpet Care ........... 41 Vehicle Identification Number .......... 66 Vehicle Loading ................... '" 57 Ventilating Blower .................... 26 Ventilating Grilles .................... 26 Vents Outside Air ..................... 26 Vinyl Fabric Care Interior ........... .. .... 41 Roof Care. . . . . . . . . . . . . . . . . . . . . . . .. 43 Volatile Cleaning Solvents. . . . . . . . . . . .. 41 Caution ........................... 41 Volume Control, Radio ................ 33 Warning Flasher, Hazard .............. 36 Warning Lights. . . . . . . . . . . . . . . . . . . . . .. 23 Brake ............................. 24 Engine Temperature ....... .......... 24 Generator .......................... 24 Oil Pressure.. . . . . . . . . . . . . . . . . . . . . .. 23 Warranty (See Warranty Folder)

Washers

Windshield

...................... '" 27 Washing ............................. 43 Waxing And Polishing.. .. . . . .. . . . . .. .. 43 Wheel Bearings , Front .... . . . . . . . . . . . .. 51 Wheel Changing. . . . . . . . . . . . . . . . . . . . .. 39 Wheel Discs, Replacement. . . . . . . . . . . .. 39 Wheel, Tilt Steering ................... 19 Windshield

Defrosting and

Defogging . . . . . . . . . . . . . . . . . . . . .

.. 29 Washer Use In Cold Weather ........ 27 Washer Solution ............ .......• 27 Wipers And Washers.. . . . . . . . . . . . . .. 27 Wrecker, Towing. . . . . . . . . . . . . . . . . . . .. 36 Zone Offices ......... ............ .. 72, 73