lock CHEVROLET CAMARO 1974 2.G User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1974, Model line: CAMARO, Model: CHEVROLET CAMARO 1974 2.GPages: 85, PDF Size: 32.84 MB

Page 26 of 85

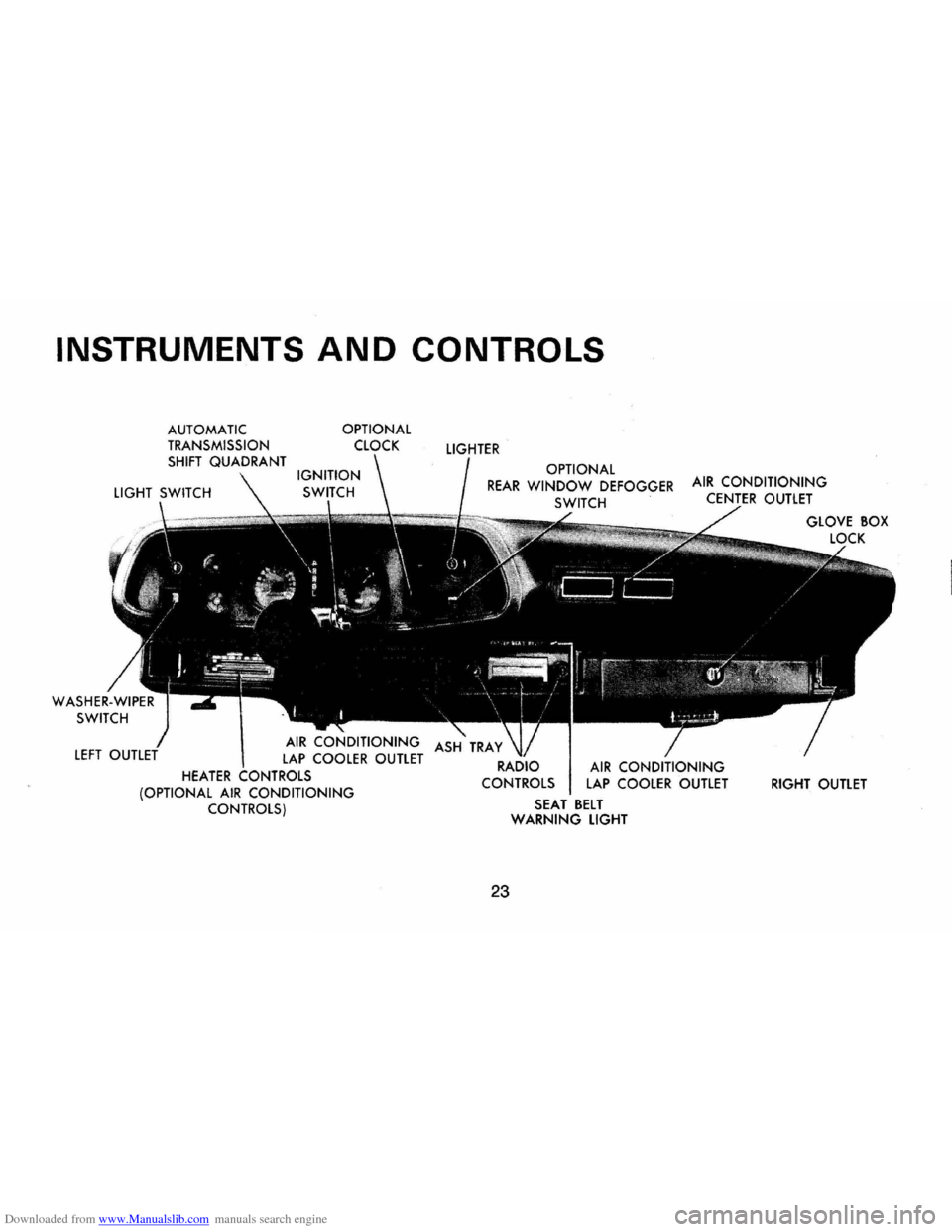

Downloaded from www.Manualslib.com manuals search engine INSTRUMENTS AND CONTROLS

AUTOMATIC TRANSMISSION

SHIFT QUADRANT

HEATER ,-,.., ... ,T,,,,",'

OPTIONAL

CLOCK

(OPTIONAL

AIR CONDITIONING CONTROLS)

LIGHTER

OPTIONAL REAR WINDOW DEFOGGER AIR CONDITIONING SWITCH CENTER OUTLET

ASH TRAY

RADIO

CONTROLS

23

SEAT BELT WARNING LIGHT

GLOVE BOX

RIGHT

OUTLET

Page 29 of 85

Downloaded from www.Manualslib.com manuals search engine What to do:

1. Check that the parking brake is

released. If it is ...

2. Pull off the road and stop, care

fully-remembering that:

• Stopping distances may be

greater.

• Greater pedal effort may be re

quired.

• Pedal travel may be greater.

3.

Tryout brake operation by

starting and stopping on road

shoulder-then:

• If you judge such operation to

be safe, proceed cautiously at a

safe speed to nearest dealer for

repair.

• Or have car towed to dealer for

repair.

Continued operation of the car

in this condition

is dangerous .

. Headlight Beam Indicator

Light

The headlights of your car have

high and low beams to provide you with

proper night-time visibility

for most driving conditions. The

"low" beams are used during most

city driving. The

"high" beams are

especially useful when driving on

dark roads since they provide ex

cellent long range illumination.

The headlight beam indicator will

be on whenever the high beams or

"brights" are in use. The Headlight

Beam

Switch controls the headlight

beams (see Page 22) .

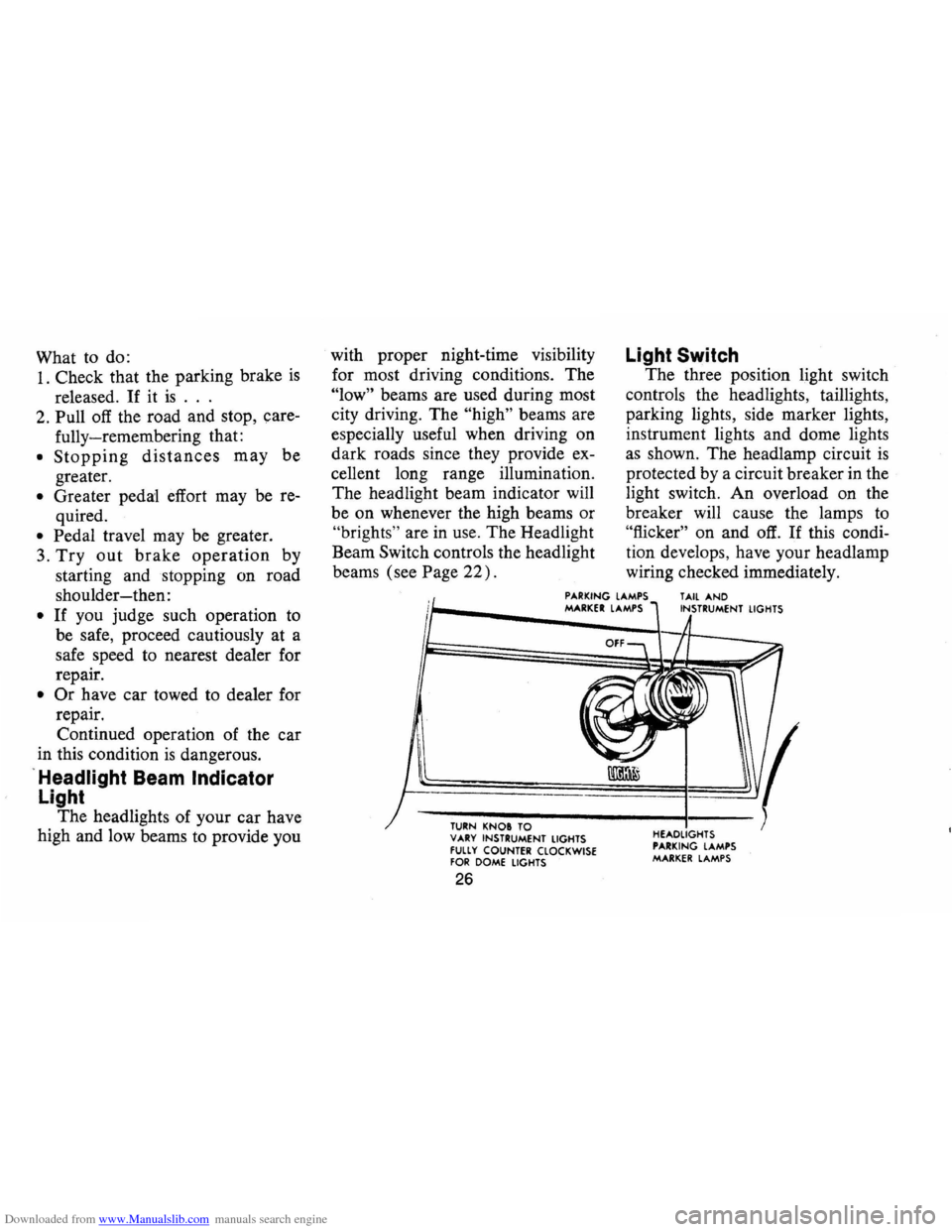

Light Switch

The three position light switch

controls the headlights, taillights,

parking lights, side marker lights,

instrument lights and dome lights

as shown. The headlamp circuit is

protected by a circuit breaker in the

light switch. An overload on the

breaker will cause the lamps

to

"flicker" on and off. If this condi

tion develops, have your headlamp

wiring checked immediately.

PARKING LAMPS

MARKER LAMPS

TURN KNOB TO

VARY INSTRUMENT LIGHTS

FULL Y COUNTER CLOCKWISE FOR DOME LIGHTS

26

HEADLIGHTS PARKING LAMI'S

MARKER LAMPS

Page 31 of 85

Downloaded from www.Manualslib.com manuals search engine Clock

Reset the clock, if your car is so

equipped, by pulling

out the knob

and turning

the hands clockwise if

slow, counterclockwise if fast. This

will,

if the clock error is five min

utes

or more, automatically com

pensate for time gain

or lag. Sev

eral resettings, several days apart,

may be needed to properly adjust

the clock mechanism. Have your

clock cleaned

and oiled by a com

petent clock serviceman at least

every two years.

Cigarette Lighter

The accessory cigarette lighter is

located on the instrument panel

face.

To operate, push it in. When

it becomes heated,

it automatically

pops

out ready for use.

Windshield Wiper

and Washer

The windshield wiping system

operates

at two speeds and is de

signed to wipe clear designated areas

of the

windshield under most

inclement weather conditions.

The

windshield wipers work electrically

and are not affected by engine op

eration.

Push the control lever to the

right to

start the electric windshield

wiper .

The two-speed electric wiper

has both a

"low" and a "high" speed

po sition.

Pressing the control will send a

measured amount of water

or other

cleaning agent onto the windshield

and will also cause the wiper lever

to move, thus starting the wiper .

motor. The wiper will then con

tinue to operate until manually

turned off at the wiper lever.-

Fill the washer

jar only % full

during the winter to allow for ex

pansion if the temperature should

fall low enough to freeze the so

lution.

• Check washer fluid level regu

larly-do it frequently when the

weather is bad.

28

• Use fluid such as GM

OPTIKLEEN to preventfreez

ingdamage, and to provide bet

ter cleaning.

• Do not use radiator anti-freeze in

windshield washer; it could

cause paint damage.

• In cold weather, warm the wind

shield with defrosters before us

ing

washer-to help prevent ic

ing that may seriously obscure

vision.

Ventilation System

Your Camaro incorporates a

ventilation system

that provides

ventilation comfort, made possible

by the addition of air vent provi

sions in the rear body lock pillar.

Another feature of the system

is

continuous low-speed operation of

the air conditioner blower, result

ing in an uninterrupted supply

of

outside air flow into the car when-

Page 34 of 85

Downloaded from www.Manualslib.com manuals search engine • Keep all windows and vents

closed to reduce dust, road and

wind noise and uncomfortable

drafts .

• For most satisfactory heater op

eration and air circulation, oper

ate fan on low or medium speeds

for normal operation and high

speed for quick warm-up and

during extremely low tempera

tures.

• For adequate rear seat heating,

the area beneath the front seat

must not be blocked by carpet

ing, rags, paper

or other mate

rial and fan should operate on

.high blower.

• For additional summer ventila

tion move the

AIR lever to mid

position and the

DEFROSTER

lever to DEE If greater air

flow is desired, move the FAN

lever down to operate the three

speed blower.

Rear Window Defroster

To insure clear vision through

the rear window during

incH:ment

weather, the Rear Window De

froster has become established

as a

popular accessory . This unit draws in

air from the passenger compart

ment and direct s it against the back

window to remove frost or mois

ture. Its blower has a two-speed

control switch on the instrument

panel.

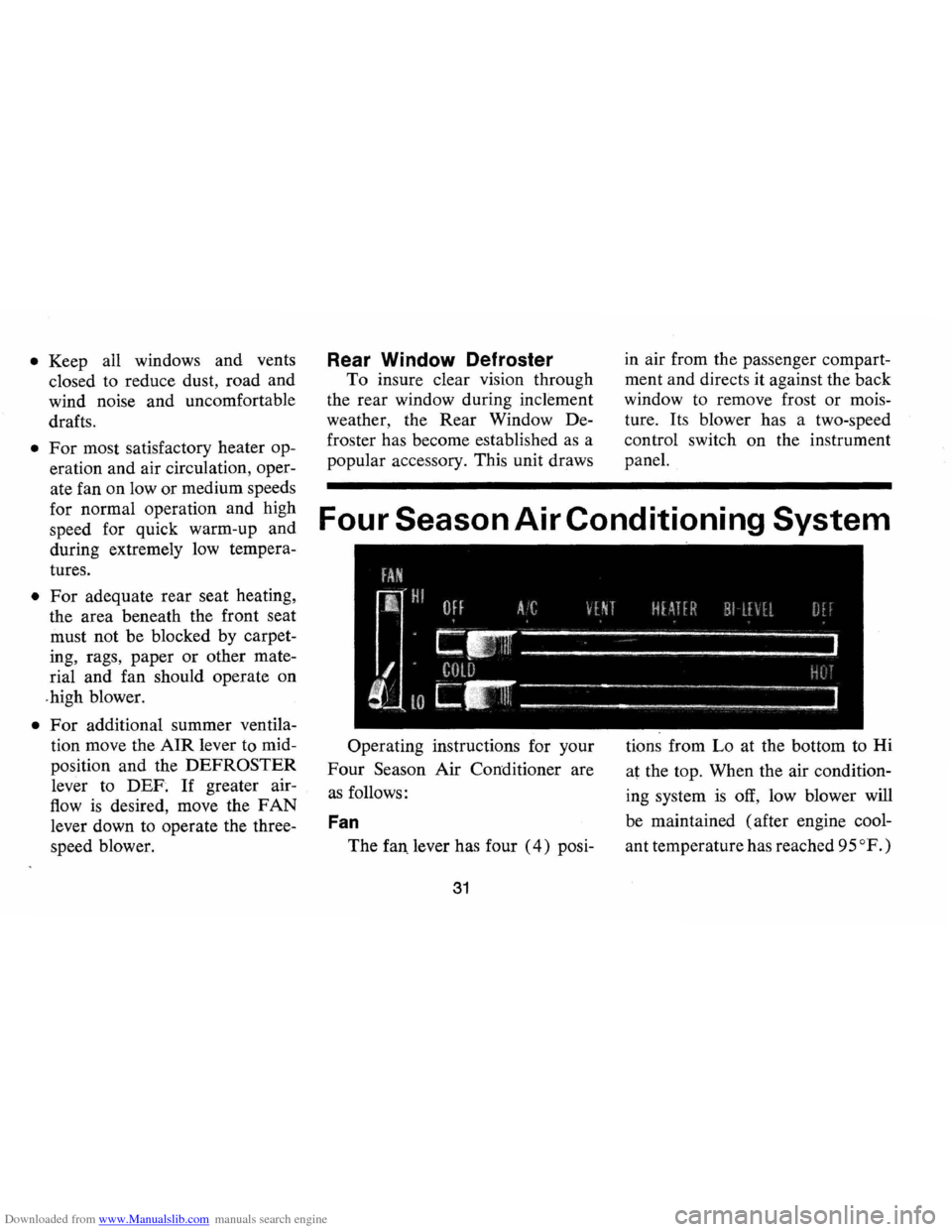

Four Season Air Conditioning System

Operating instructions for your

Four Season Air Conditioner are

as follows:

Fan

The fan. lever has four (4) posi-

31

tions from Lo at the bottom to Hi

at the top. When the air condition

ing system

is off, low blower will

be maintained (after engine cool

ant temperature has reached

95 of.)

Page 38 of 85

Downloaded from www.Manualslib.com manuals search engine OTHER CONTROLS AND FEATURES

Positraction Rear Axle

The optional Positraction pro

vides additional traction on snow ,

ice , mud, sand, and gravel, par

ticularly when one rear wheel

is on

a surface providing poor traction.

During normal driving and cor

nering, the Positraction unit

func~

tions as a standard differential.

When one wheel encounters a slip

pery surface, however , the Positrac

tion directs driving force to the rear

wheel having the better traction.

Power Windows

Power windows have an ignition

interlock so the windows cannot be

operated unless the ignition switch

is in the "on" position.

REMINDER: Remove the ignition

key when the vehicle

is not at

tended by a responsible person.

A master control for both win

dows

is provided at the driver's

position. Also, an individual switch

is provided under right window for

passenger use.

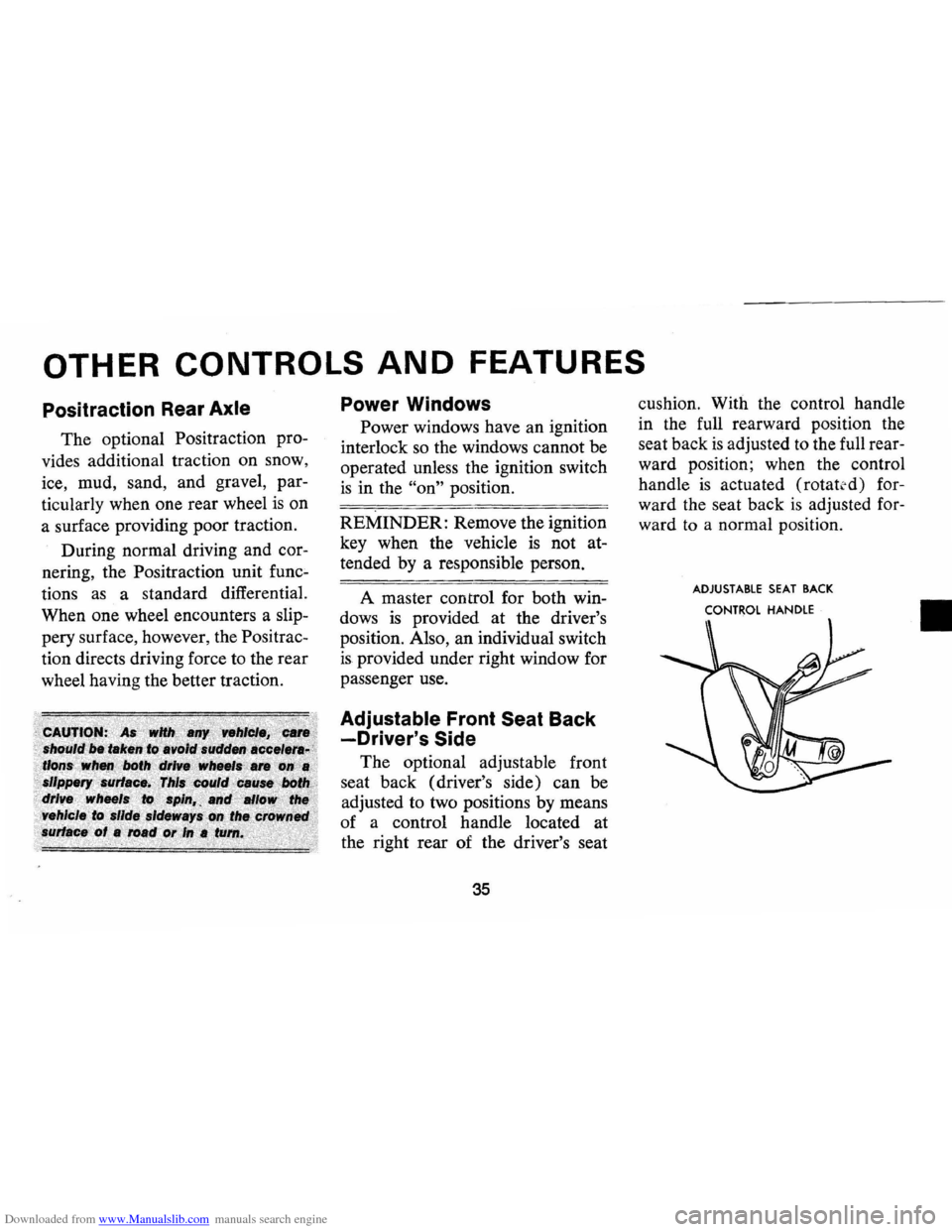

Adjustable Front Seat Back

-Driver's Side

The optional adjustable front

seat back (driver's side) can be

adjusted to two positions by means

of a control handle located at

the right rear of the driver's seat

35

cushion. With the control handle

in the full rearward position the

seat back

is adjusted to the full rear

ward position; when the control

handle

is actuated (rotat td) for

ward the seat back

is adjusted for

ward

to a normal position .

ADJUSTABLE SEAT BACK

CONTROL

HANDLE

II

Page 40 of 85

Downloaded from www.Manualslib.com manuals search engine than 35 mph, for distances up to

50 miles, provided the drive-line,

axle, transmission, and steering

system are otherwise normally op

erable.

Use only towing equipment

specifically designed for this pur

pose following the instructions of

the towing equipment manufac

turer. A separate safety chain sys

tem must be used.

For such towing

the steering must be unlocked,

transmission in neutral and the

parking brake released. Attach

ments must be made to main struc

tural members of the car. Do not

attach to bumpers

or associated

brackets. Remember that power

brake and power steering assists

will not be available when engine

is inoperative.

Emergency Starting

• Engines in vehicles with auto

matic transmissions cannot be started

by pushing

or towing the

car.

• Never tow a manual transmis

sion-equipped

car to start be

cause the surge forward when

the engine starts could cause a

collision with the tow vehicle.

• A car with a discharged battery

may be started by transferring

electrical power from a battery

in another car -called

"jump

starting."

Jump Starting

37

• The battery in the other vehicle

must be of the

same nominal

voltage

(12 volts), and must be

negatively grounded. (All Gen

eral Motors cars, light trucks

(10,000 GVWR and under),

and motor homes use 12-volt,

negatively grounded electrical

systems and

can be used to jump

start one another.) The nominal

voltage and grounding of the

other vehicle's battery may be

determined by checking the spec

ifications

in its owner's manual.

Use of a booster battery of a

higher nominal voltage,

or which

is positively grounded may re

sult

in serious personal injury or

property damage.

• The battery in your car must be a

Delco battery (the original,

or a

replacement) which

is equipped

with flame arrestor type filler/

vent caps

on all filler openings, or

a sealed-type battery which does

Page 42 of 85

Downloaded from www.Manualslib.com manuals search engine tive terminal (black color, "-" Engine Coolant

or "N") of the battery in the other

vehicle, and

THEN the other

end of the same cable to the nega

tive terminal of your battery in

this car. Take care that clamps

from one cable do not inadver

tently touch the clamps on the

other cable. Do not lean over the

battery when making this con

nection.

5. Start the engine in the vehicle

that

is providing the jump start

(if it

was not running). Let run

a

few minutes, then start the en-

gine in the car with the dis-

Jacking Instructions

charged battery.

6. Reverse the above sequence ex

actly when removing the jumper

cables. Reinstall vent caps and

dispose in a safe manner of any

cloths used to cover vent wells,

as

the cloths may have corrosive

acid on them.

39

Preparation

• Park on level surface and set

parking brake firmly.

• Set automatic transmission in

park. (Manual transmission in

reverse).

• Activate hazard warning flasher.

Instructions

1. After removing spare wheel

and tire, jack, jack

base,and

jack handle (wheel nut wrench),

proceed with changing the

wheel

as follows:

2. Remove hub cap

or wheel

cover with flat end of wheel

nut wrench and loosen, but do

not remove nuts, by turning

counterclockwise.

3. With column assembly seated

in base and lever in

"UP" posi

tion,

insert jack hook in

bumper slot.

Page 50 of 85

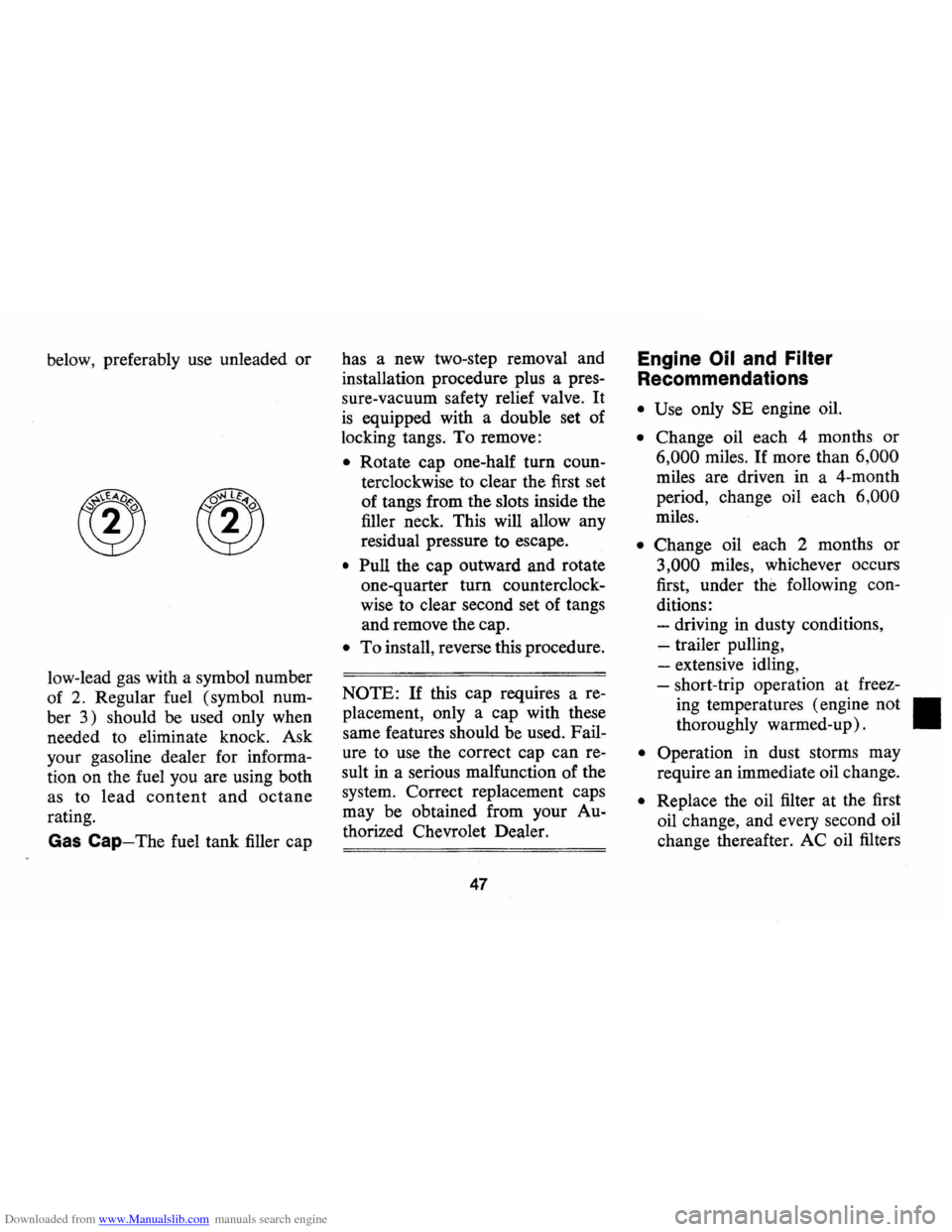

Downloaded from www.Manualslib.com manuals search engine below, preferably use unleaded or

low-lead gas with a symbol number

of

2. Regular fuel (symbol num

ber

3) should be used only when

needed to eliminate knock. Ask

your gasoline dealer for informa

tion on the fuel you are using both

as to

lead content and octane

rating.

Gas Cap-The fuel tank filler cap has

a new two-step removal and

installation procedure plus a pres

sure-vacuum safety relief valve. It

is equipped with a double set of

locking tangs. To remove:

• Rotate cap one-half turn coun

terclockwise to clear the first set

of tangs from the slots inside the

filler neck. This will allow any

residual pressure to escape.

• Pull the cap outward and rotate

one-quarter turn counterclock

wise to clear second set of tangs

and remove the cap.

• To install, reverse this procedure.

NOTE: If this cap requires a re

placement, only a cap with these

same features should be used. Fail

ure to use the correct cap can re

sult in a serious malfunction of the

system. Correct replacement caps

may be obtained from your Au

thorized Chevrolet Dealer.

47

Engine Oil and Filter

Recommendations

• Use only SE engine oil.

• Change oil each 4 months or

6,000 miles. If more than 6,000

miles are driven in a 4-month

period, change oil each

6,000

miles.

• Change oil each 2 months or

3,000 miles, whichever occurs

first, under the following con

ditions: - driving in dusty conditions,

-trailer pulling,

- extensive idling,

- short-trip operation at freez-

ing temperatures (engine not

II

thoroughly warmed-up).

• Operation in dust storms may

require an immediate oil change.

• Replace the oil filter at the first

oil change, and every second oil

change thereafter. AC oil filters

Page 56 of 85

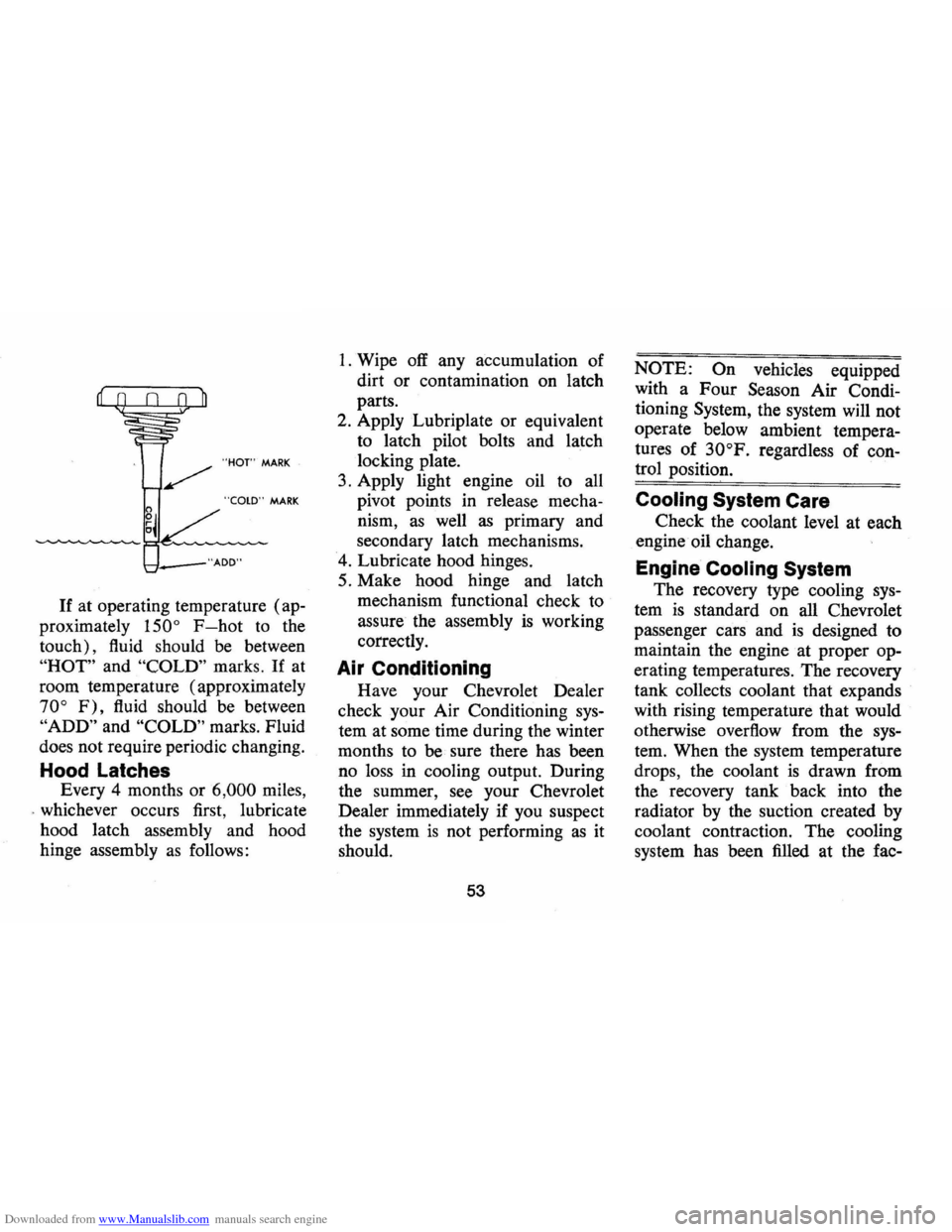

Downloaded from www.Manualslib.com manuals search engine "HOT" MARK

"COLD" MARK

>-f.. __ "AOO"

If at operating temperature (ap

proximately

150° F-hot to the

touch), fluid should be between

"HOT" and "COLD" marks. If at

room temperature (approximately

70° F), fluid should be between

"ADD" and "COLD" marks. Fluid

does not require periodic changing.

Hood Latches

Every 4 months or 6,000 miles,

. whichever occurs first, lubricate

hood latch assembly and hood

hinge assembly

as follows:

1. Wipe off any accumulation of

dirt or contamination on latch

parts.

2. Apply Lubriplate or equivalent

to latch pilot bolts and latch

locking plate.

3. Apply light engine oil to all

pivot points in release mecha

nism,

as well as primary and

secondary latch mechanisms.

4. Lubricate hood hinges.

5. Make hood hinge and latch

mechanism functional check to

assure the assembly

is working

correctly.

Air Conditioning

Have your Chevrolet Dealer

check your Air Conditioning

sys

tem at some time during the winter

months to

be sure there has been

no loss in cooling output. During

the summer,

see your Chevrolet

Dealer immediately if you suspect

the system

is not performing as it

should.

53

NOTE: On vehicles equipped

with a Four Season Air Condi

tioning System, the system will not

operate below ambient tempera

tures of

30°F. regardless of con

trol position.

Cooling System Care

Check the coolant level at each

engine · oil change.

Engine Cooling System

The recovery type cooling sys

tem is standard on all Chevrolet

passenger cars and

is designed to

maintain the engine at proper op

erating temperatures.

The recovery

tank collects coolant that expands

with rising temperature that would

otherwise overflow from the

sys

tem. When · the system temperature

drops, the coolant

is drawn from

the recovery tank back into the

radiator by the suction created by

coolant contraction. The cooling

system has been filled at the fac-

Page 58 of 85

Downloaded from www.Manualslib.com manuals search engine clockwise to detent (do not

press down while rotating).

• Wait until any residual pres

sure (indicated by a hissing

sound)

is relieved.

• After all hissing ceases, press

down on cap while continuing

to rotate counterclockwise.

CAUTION: To ,a~()/d' thedange, .• olbfling "l)~ned;tlo n(Jtl'entoveradiator «aP while

, engipe and radiator are ,stlll hot because $ca/ding ' flU./d·antlsteam' will be blown .

(1utunder pressure.

2. If necessary, run engine, with

radiator cap removed, until nor

mal operating temperature

is

reached and upper radiator hose

is hot (indicates thermostat

is

open).

3. Stop engine and open radiator

drain valve to drain coolant. (To

speed this operation, the drain

plugs in the block can also be

removed.) 4.

Close valve (install block drain

plugs, if removed) and add suf

ficient water to

fill system .

5. Run engine, drain and refill the

system, as described in steps

1,

2, 3, and 4, a sufficient number

of times until the drained liquid

is nearly colorless.

6. Allow system to drain com

pletely and then close radiator

drain valve tightly. (Install

block drain plugs, if removed.)

7. Remove recovery cap leaving

hoses in place. Remove coolant

recovery tank and empty of

fluid. Flush tank with clean

water , drain and reinstall.

8. Add sufficient ethylene glycol

coolant , meeting GM specifica

tion 1899-M, to provide the re

quired freezing and corrosion

protection-at least a 44 percent

solution

(-20°F). Fill radiator

to the base of the radiator filler

55

neck and add sufficient coolant

to the recovery tank to raise level

to the

"FULL HOT" mark. Re

install recovery tank cap.

9. Run engine , with radiator cap

removed, until normal operat

ing

temperature is reached.

(Radiator upper hose becomes

hot.)

10. With engine idling, add cool

ant until level reaches bottom

of filler neck and install radia

tor cap making certain arrows

line up with overflow tube.

It is the owner's responsibility

to keep the freeze protection at a

level commensurate with the tem

peratures which may occur in the

area of vehicle operation .

• Maintain cooling system freeze

protection at

-20 °F or below

to ensure protection against cor

rosion and loss of coolant from

boiling even though freezing