ABS CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 397 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 397

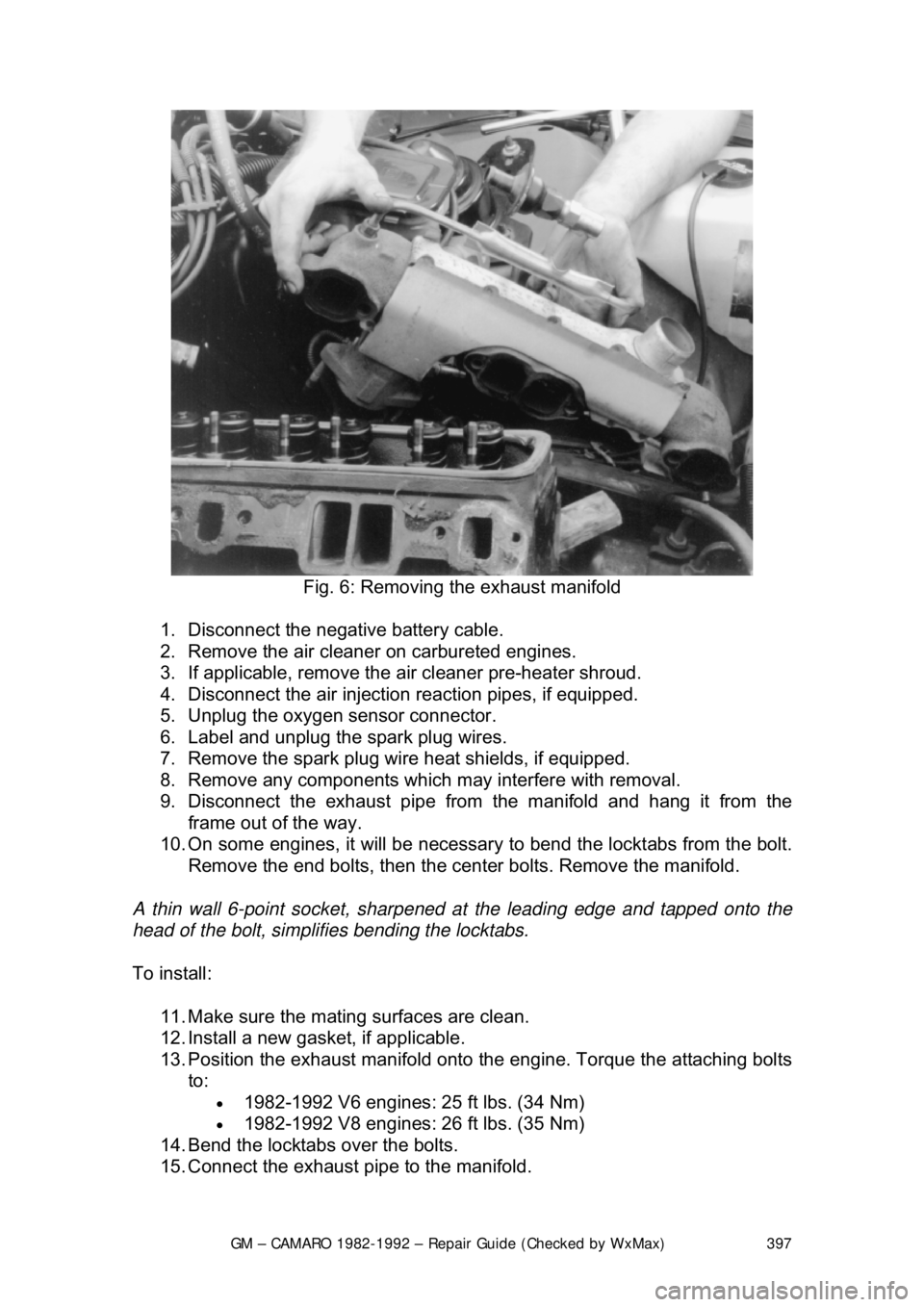

Fig. 6: Removing the exhaust manifold

1. Disconnect the negative battery cable.

2. Remove the air cleaner on carbureted engines.

3. If applicable, remove the ai r cleaner pre-heater shroud.

4. Disconnect the air injecti on reaction pipes, if equipped.

5. Unplug the oxygen sensor connector.

6. Label and unplug the spark plug wires.

7. Remove the spark plug wire heat shields, if equipped.

8. Remove any components which may interfere with removal.

9. Disconnect the exhaust pipe from the manifold and hang it from the

frame out of the way.

10. On some engines, it will be necessary to bend the locktabs from the bolt.

Remove the end bolts, then the center bolts. Remove the manifold.

A thin wall 6-point socket, sharpened at the leading edge and tapped onto the

head of the bolt, simplifies bending the locktabs.

To install:

11. Make sure the mating surfaces are clean.

12. Install a new gasket, if applicable.

13. Position the exhaust manifold onto the engine. Torque the attaching bolts

to:

• 1982-1992 V6 engines: 25 ft lbs. (34 Nm)

• 1982-1992 V8 engines: 26 ft lbs. (35 Nm)

14. Bend the locktabs over the bolts.

15. Connect the exhaust pipe to the manifold.

Page 409 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 409

When servicing the engine, be absolutely sure to mark vacuum hoses and

wiring so that these items

may be properly reconnected during installation. Also,

when disconnecting fittings of metal lines (fuel, power brake vacuum), always

use two flare nut (or line) wrenches. Ho ld the wrench on the large fitting with

pressure on the wrench as if you were tightening the fitting (clockwise), THEN

loosen and disconnect the smaller fitting fr om the larger fitting. If this is not

done, damage to the line will result.

CAUTION - When draining the coolant, keep in mind that cats and dogs are

attracted by the ethylene gl ycol antifreeze, and are quite likely to drink any that

is left in an uncovered container or in puddles on the ground. This will prove

fatal in sufficient quantity. Always drai n the coolant into a sealable container.

Coolant should be reused unless it is contaminated or several years old.

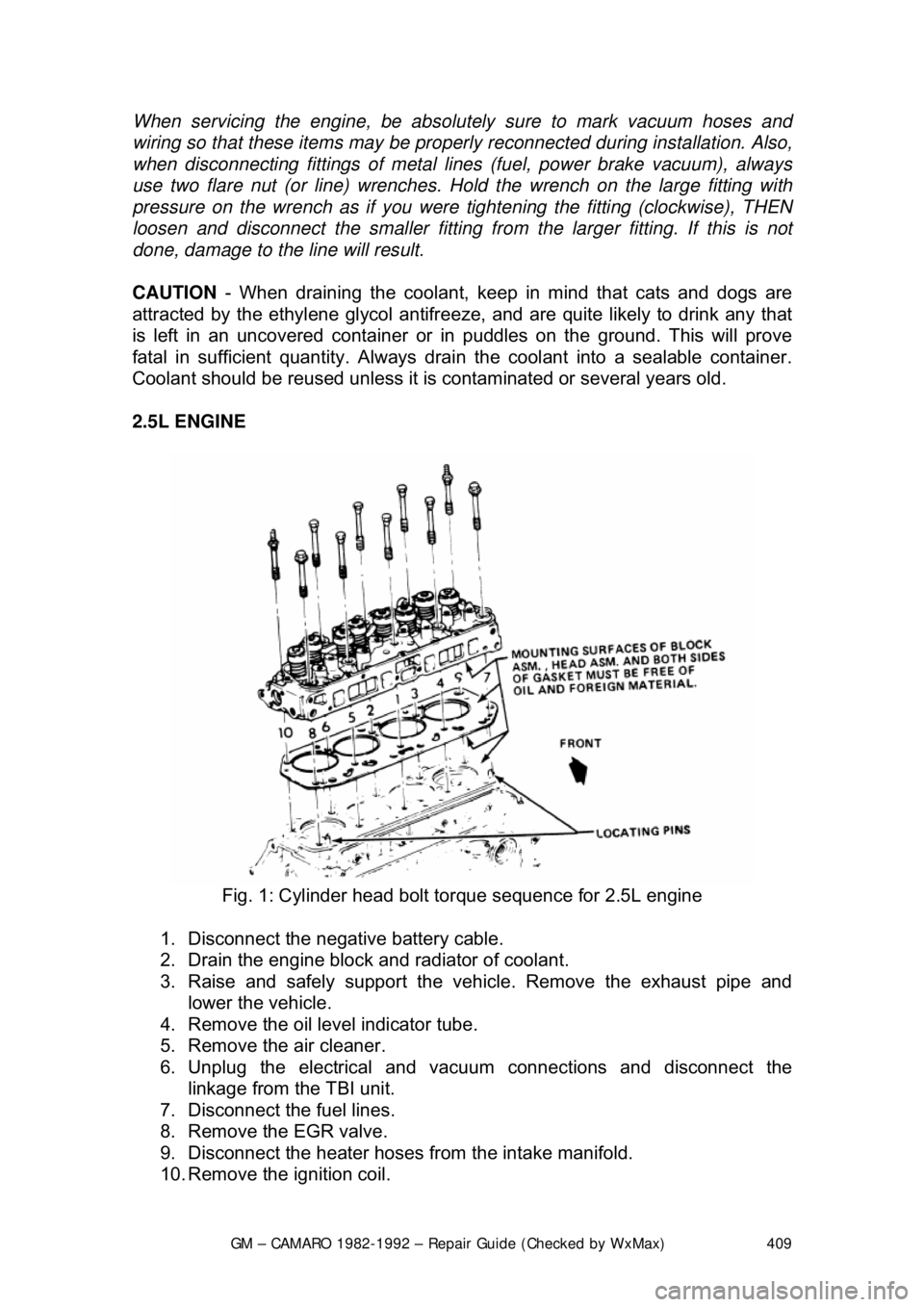

2.5L ENGINE

Fig. 1: Cylinder head bolt torque sequence for 2.5L engine

1. Disconnect the negative battery cable.

2. Drain the engine block and radiator of coolant.

3. Raise and safely support the vehi cle. Remove the exhaust pipe and

lower the vehicle.

4. Remove the oil level indicator tube.

5. Remove the air cleaner.

6. Unplug the electrical and vac uum connections and disconnect the

linkage from the TBI unit.

7. Disconnect the fuel lines.

8. Remove the EGR valve.

9. Disconnect the heater hoses from the intake manifold.

10. Remove the ignition coil.

Page 430 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 430

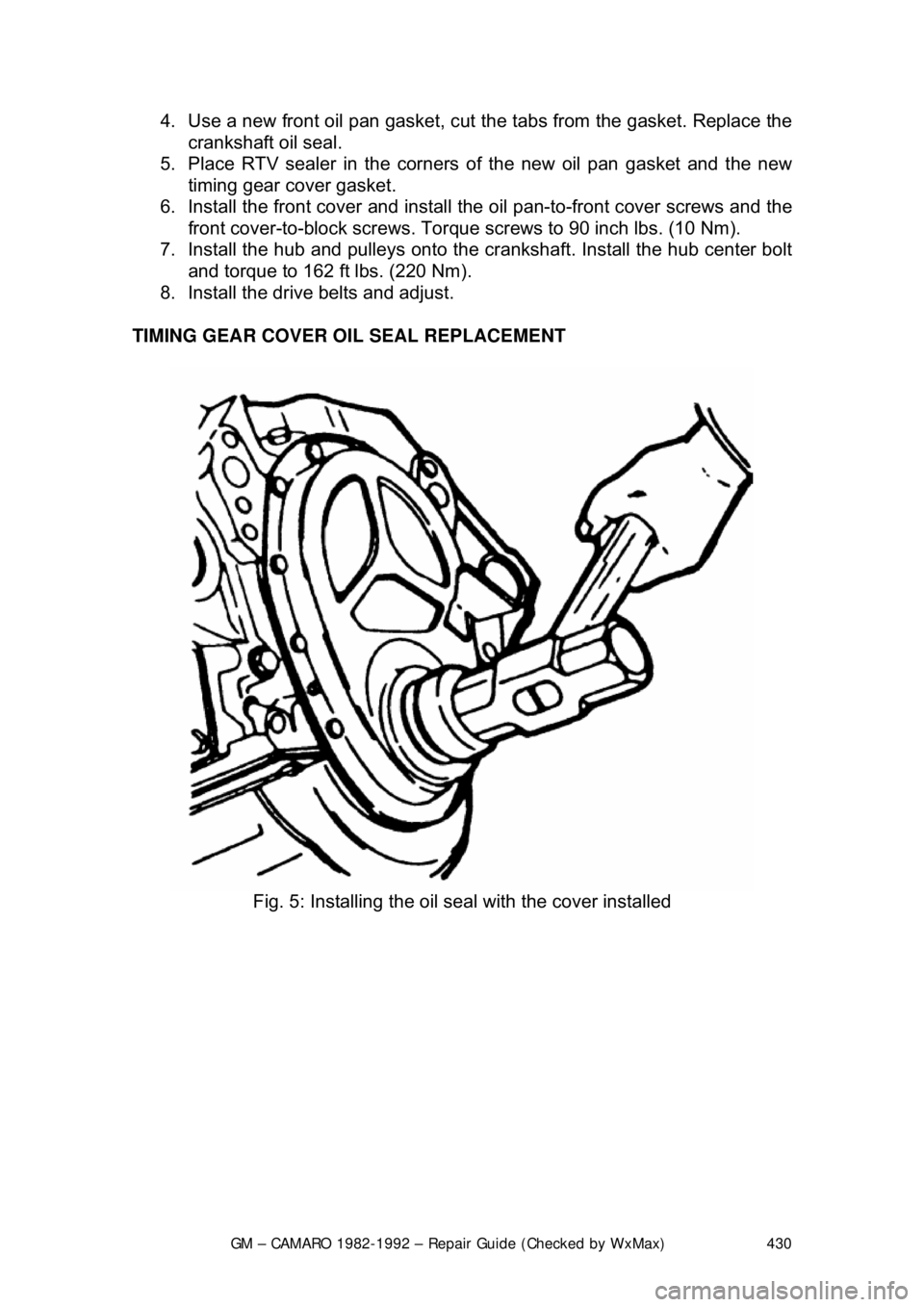

4. Use a new front oil pan gasket, cut

the tabs from the gasket. Replace the

crankshaft oil seal.

5. Place RTV sealer in the corners of the new oil pan gasket and the new

timing gear cover gasket.

6. Install the front cove r and install the oil pan-to -front cover screws and the

front cover-to-block screws. Torque scr ews to 90 inch lbs. (10 Nm).

7. Install the hub and pulle ys onto the crankshaft. Install the hub center bolt

and torque to 162 ft lbs. (220 Nm).

8. Install the drive belts and adjust.

TIMING GEAR COVER OIL SEAL REPLACEMENT

Fig. 5: Installing the oil seal with the cover installed

Page 549 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 549

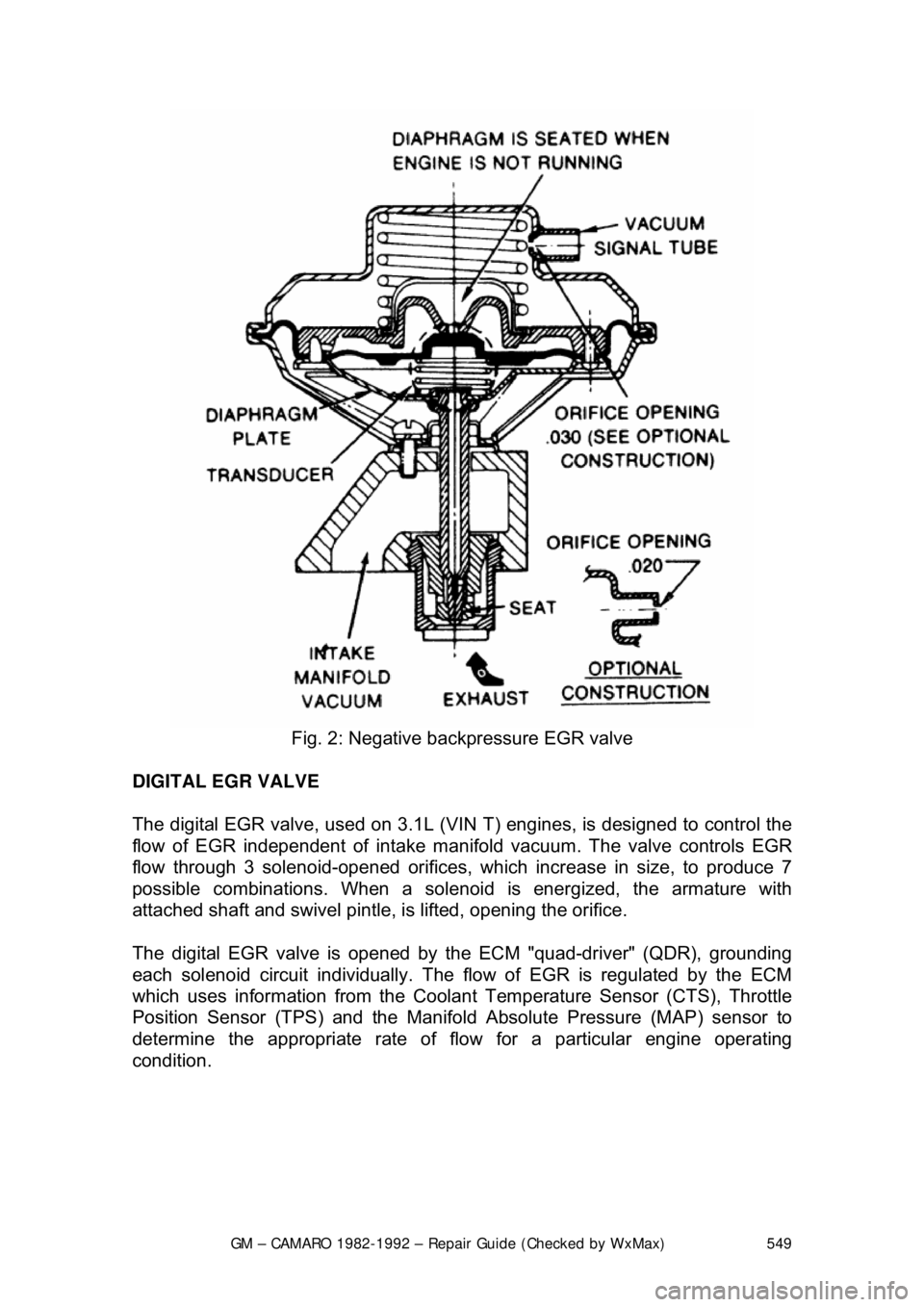

Fig. 2: Negative backpressure EGR valve

DIGITAL EGR VALVE

The digital EGR valve, used on 3.1L (VIN T) engines, is designed to control the

flow of EGR independent of intake mani fold vacuum. The valve controls EGR

flow through 3 solenoid- opened orifices, which increa se in size, to produce 7

possible combinations. When a solenoid is energized, the armature with

attached shaft and swivel pintle, is lifted, opening the orifice.

The digital EGR valve is opened by t he ECM "quad-driver" (QDR), grounding

each solenoid circuit individually. The fl ow of EGR is regulated by the ECM

which uses information from the Coolant Temperature Sensor (CTS), Throttle

Position Sensor (TPS) and the Manifold Absolute Pressure (MAP) sensor to

determine the appropriate rate of flow for a particular engine operating

condition.

Page 561 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 561

3. Apply at least 7 in. Hg of vacuum

to the damper diaphragm unit. The

door should close. If it doesn't, che ck the diaphragm linkage for binding

and correct hookup.

4. With the vacuum still applied and t he door closed, clamp the tube to trap

the vacuum. If the door doesn't remain closed, there is a leak in the

diaphragm assembly.

REMOVAL & INSTALLATION

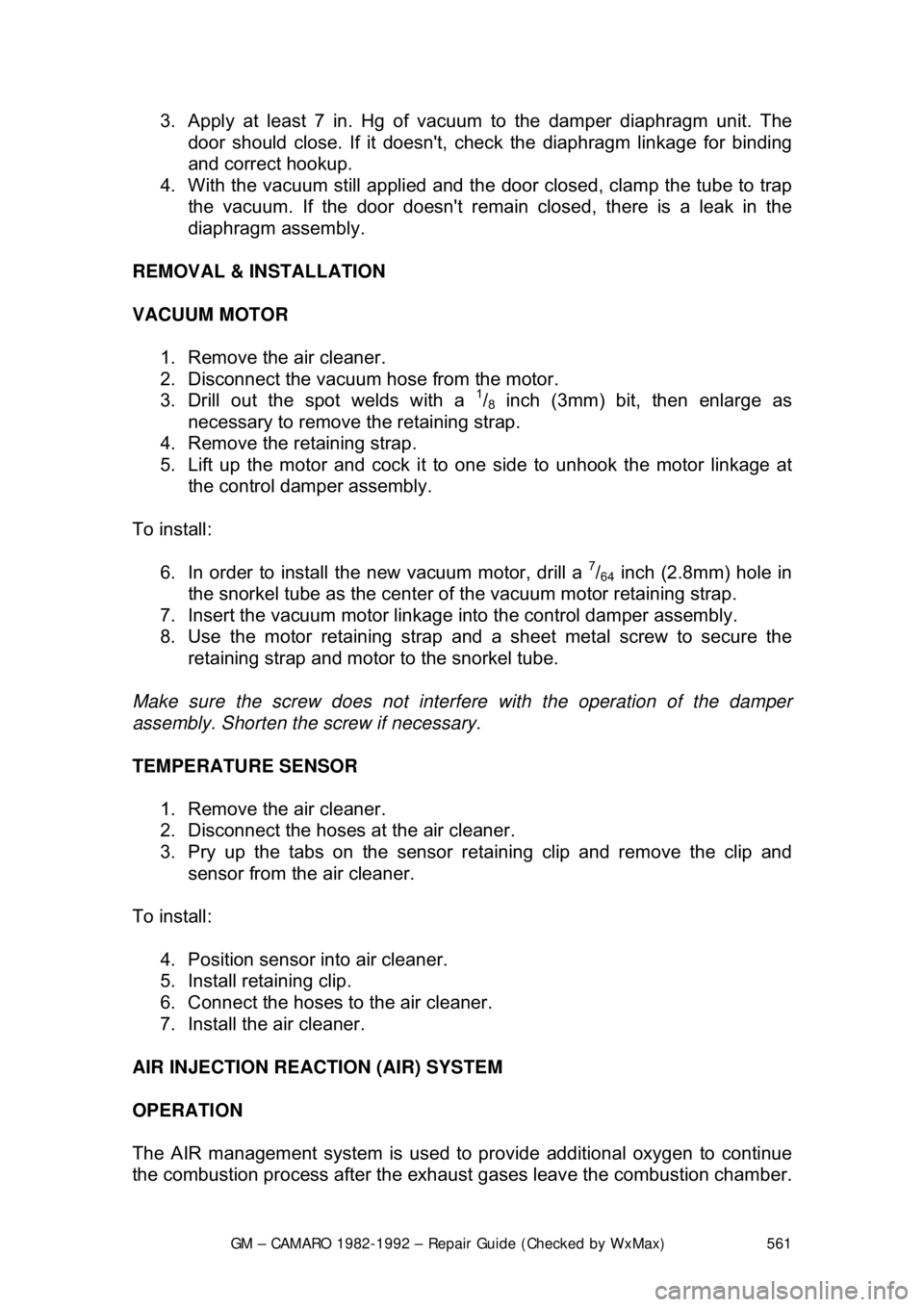

VACUUM MOTOR 1. Remove the air cleaner.

2. Disconnect the vacuum hose from the motor.

3. Drill out the spot welds with a

1/8 inch (3mm) bit, then enlarge as

necessary to remove the retaining strap.

4. Remove the retaining strap.

5. Lift up the motor and cock it to o ne side to unhook the motor linkage at

the control damper assembly.

To install: 6. In order to install t he new vacuum motor, drill a

7/64 inch (2.8mm) hole in

the snorkel tube as the c enter of the vacuum motor retaining strap.

7. Insert the vacuum motor linkage into the control damper assembly.

8. Use the motor retaining strap and a sheet metal screw to secure the

retaining strap and motor to the snorkel tube.

Make sure the screw does not interf ere with the operation of the damper

assembly. Shorten the screw if necessary.

TEMPERATURE SENSOR 1. Remove the air cleaner.

2. Disconnect the hoses at the air cleaner.

3. Pry up the tabs on the sensor reta ining clip and remove the clip and

sensor from the air cleaner.

To install: 4. Position sensor into air cleaner.

5. Install retaining clip.

6. Connect the hoses to the air cleaner.

7. Install the air cleaner.

AIR INJECTION REACTION (AIR) SYSTEM

OPERATION

The AIR management system is used to prov ide additional oxygen to continue

the combustion process after the exhaus t gases leave the combustion chamber.

Page 567 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 567

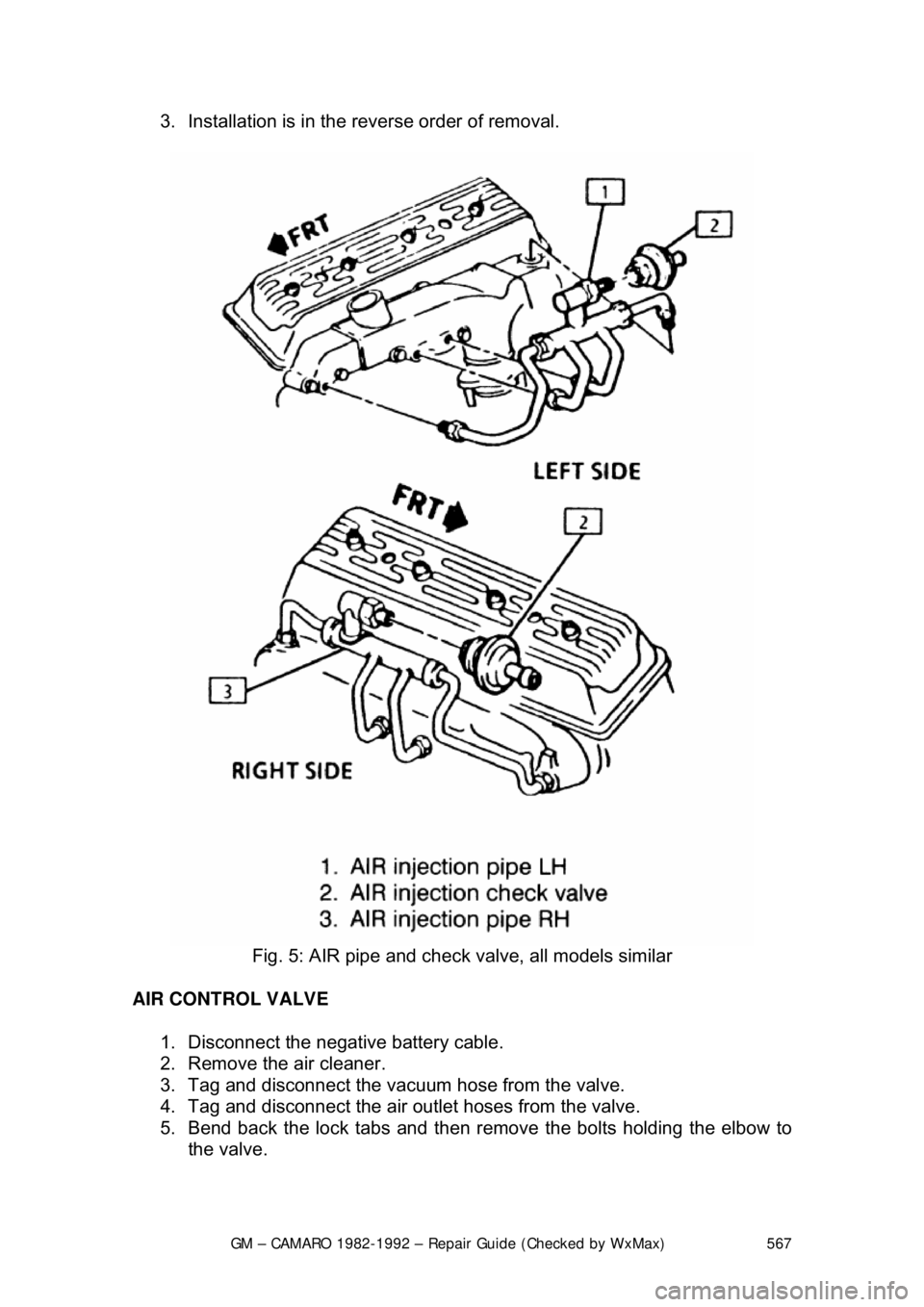

3. Installation is in the reverse order of removal.

Fig. 5: AIR pipe and check valve, all models similar

AIR CONTROL VALVE 1. Disconnect the negative battery cable.

2. Remove the air cleaner.

3. Tag and disconnect the vacuum hose from the valve.

4. Tag and disconnect the air outle t hoses from the valve.

5. Bend back the lock tabs and then remo ve the bolts holding the elbow to

the valve.

Page 568 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 568

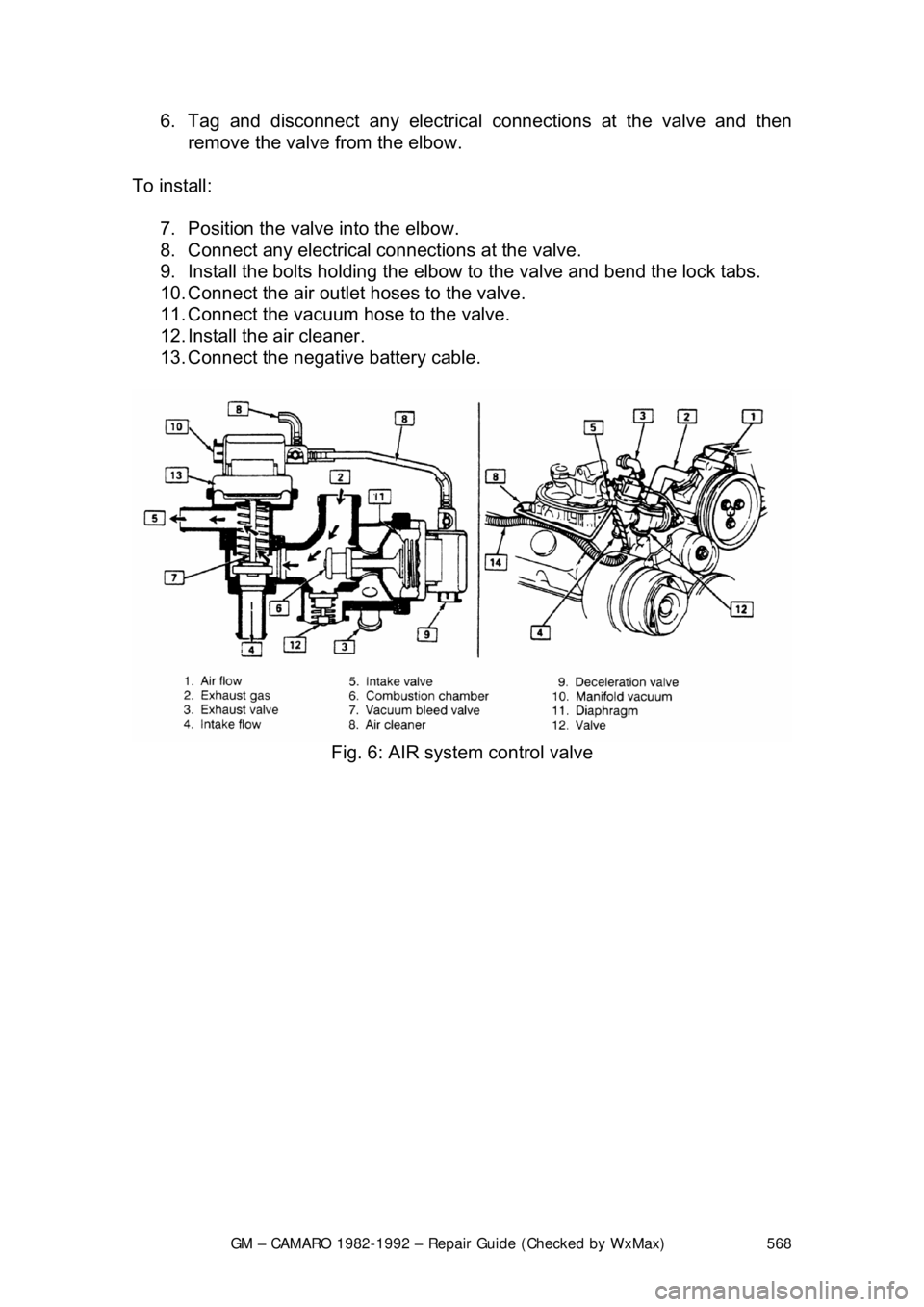

6. Tag and disconnect any electrical

connections at the valve and then

remove the valve from the elbow.

To install: 7. Position the valve into the elbow.

8. Connect any electrical c onnections at the valve.

9. Install the bolts holding the elbow to the valve and bend the lock tabs.

10. Connect the air outlet hoses to the valve.

11. Connect the vacuum hose to the valve.

12. Install the air cleaner.

13. Connect the negative battery cable.

Fig. 6: AIR system control valve

Page 585 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 585

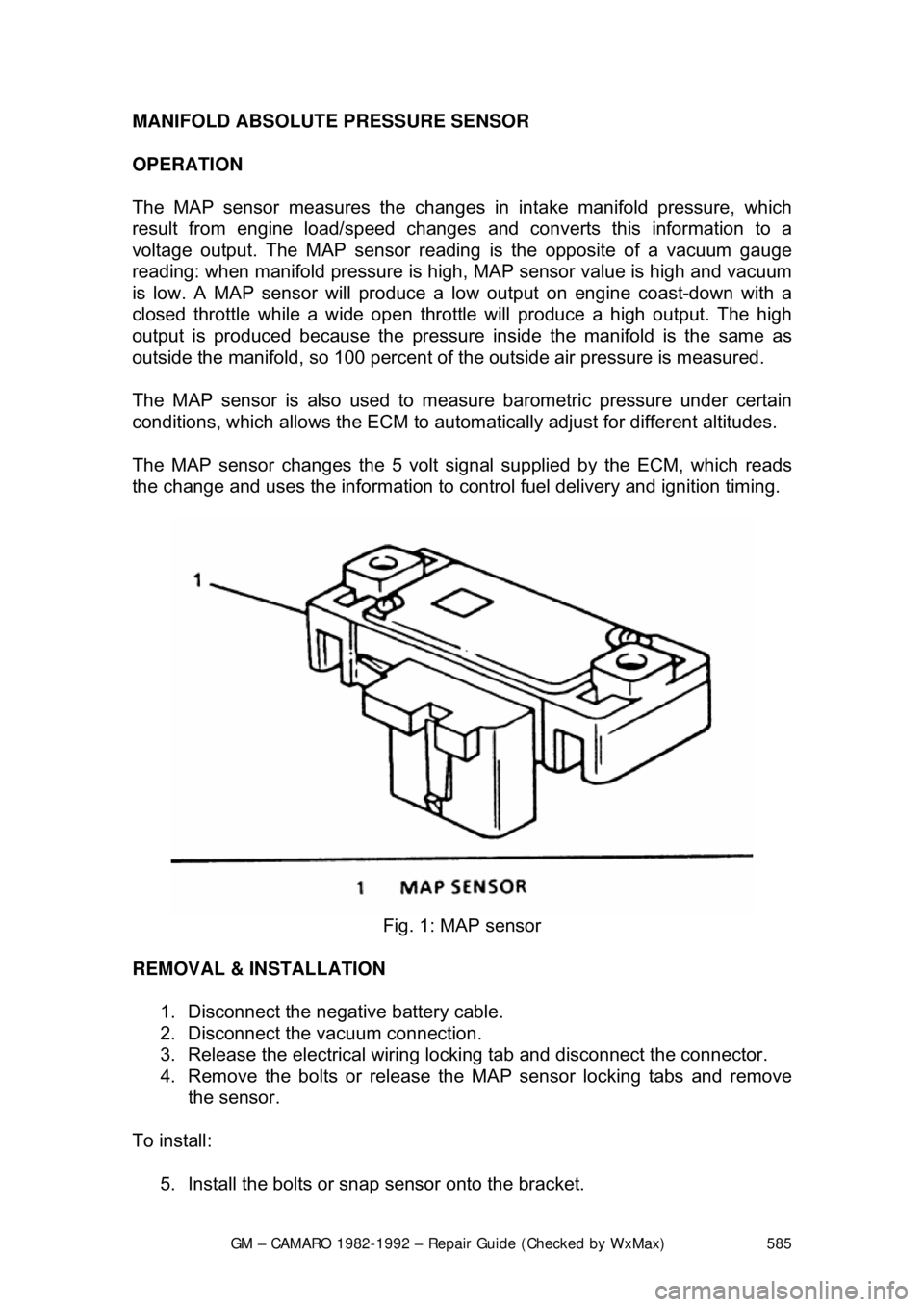

MANIFOLD ABSOLUTE PRESSURE SENSOR

OPERATION

The MAP sensor measures the changes in

intake manifold pressure, which

result from engine load/ speed changes and converts this information to a

voltage output. The MAP sensor reading is the opposite of a vacuum gauge

reading: when manifold pressu re is high, MAP sensor value is high and vacuum

is low. A MAP sensor will produce a low output on engine coast-down with a

closed throttle while a wide open throttle will produce a high output. The high

output is produced because the pressure inside the manifold is the same as

outside the manifold, so 100 percent of t he outside air pressure is measured.

The MAP sensor is also used to meas ure barometric pressure under certain

conditions, which allows the ECM to autom atically adjust for different altitudes.

The MAP sensor changes the 5 volt signal supplied by the ECM, which reads

the change and uses the information to cont rol fuel delivery and ignition timing.

Fig. 1: MAP sensor

REMOVAL & INSTALLATION 1. Disconnect the negative battery cable.

2. Disconnect the vacuum connection.

3. Release the electrical wiring lo cking tab and disconnect the connector.

4. Remove the bolts or release the MAP sensor locking tabs and remove

the sensor.

To install: 5. Install the bolts or snap sensor onto the bracket.

Page 628 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 628

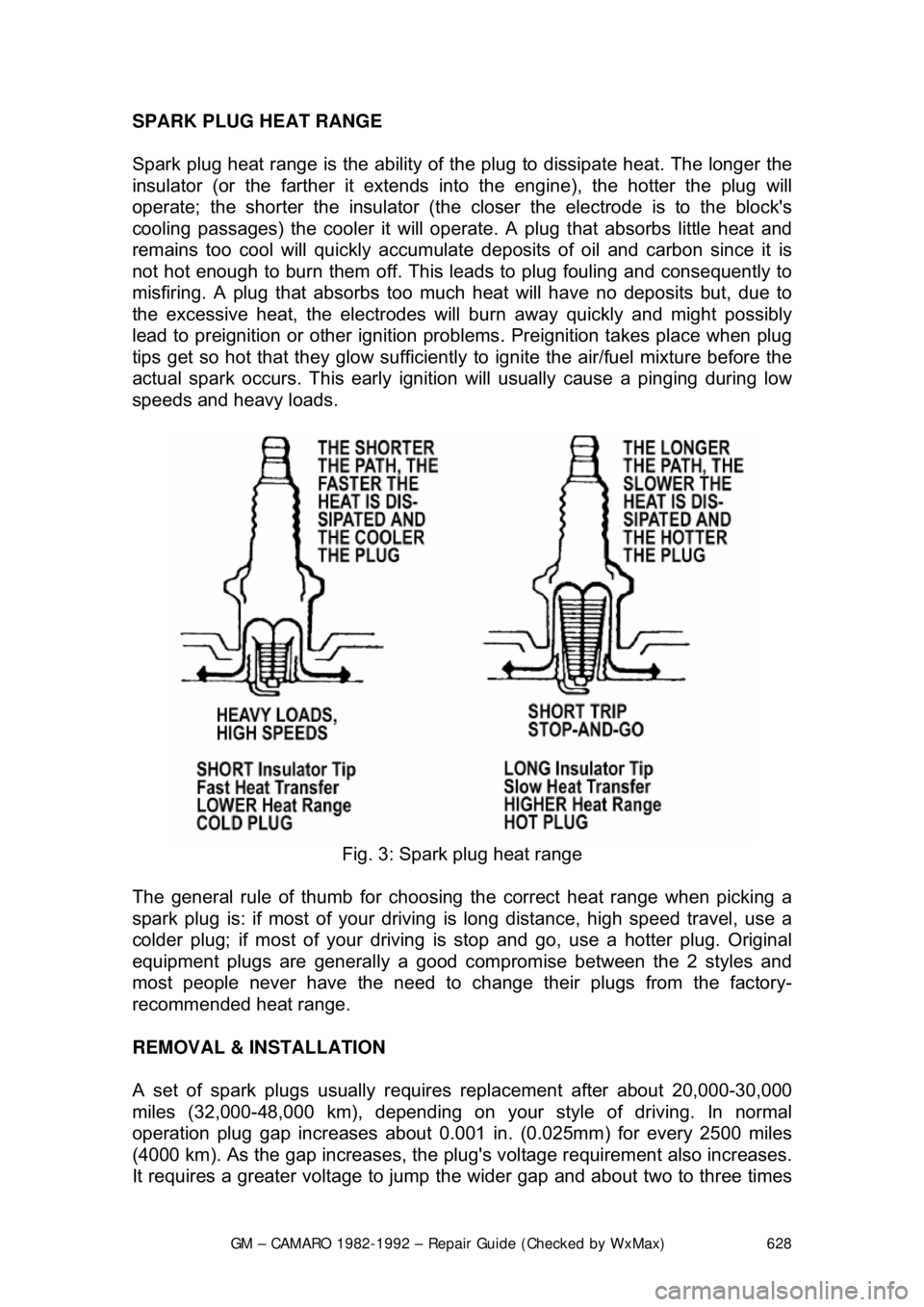

SPARK PLUG HEAT RANGE

Spark plug heat range is

the ability of the plug to dissipate heat. The longer the

insulator (or the farther it extends in to the engine), the hotter the plug will

operate; the shorter the insulator (the cl oser the electrode is to the block's

cooling passages) the cooler it will operate. A plug that absorbs little heat and

remains too cool will quickly accumulate deposits of oil and carbon since it is

not hot enough to burn them off. This leads to plug fouling and consequently to

misfiring. A plug that absorbs too much heat will have no deposits but, due to

the excessive heat, the electrodes will burn away quickly and might possibly

lead to preignition or other ignition probl ems. Preignition takes place when plug

tips get so hot that they gl ow sufficiently to ignite the air/fuel mixture before the

actual spark occurs. This early igniti on will usually cause a pinging during low

speeds and heavy loads.

Fig. 3: Spark plug heat range

The general rule of thumb for choosing the correct heat range when picking a

spark plug is: if most of your driving is long distanc e, high speed travel, use a

colder plug; if most of your driving is stop and go, use a hotter plug. Original

equipment plugs are general ly a good compromise between the 2 styles and

most people never have the need to change their plugs from the factory-

recommended heat range.

REMOVAL & INSTALLATION

A set of spark plugs usually requi res replacement after about 20,000-30,000

miles (32,000-48,000 km), depending on y our style of driving. In normal

operation plug gap increases about 0.001 in. (0.025mm) for every 2500 miles

(4000 km). As the gap increases, the plug' s voltage requirement also increases.

It requires a greater voltage to jump t he wider gap and about two to three times

Page 630 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 630

WARNING

- Do not use the spark plug socke t to thread the plugs. Always

carefully thread the plug by hand or us ing an old plug wire to prevent the

possibility of crossthreading and damaging the cylinder head bore.

8. Carefully tighten the spark plug. If the plug you are installing is equipped

with a crush washer, seat the plug, then tighten about

1/4 turn to crush

the washer. If you are installing a t apered seat plug, tighten the plug to

specifications provided by the vehicle or plug manufacturer.

9. Apply a small amount of silicone di electric compound to the end of the

spark plug lead or inside the spark pl ug boot to prevent sticking, then

install the boot to the spark plug and pus h until it clicks into place. The

click may be felt or hear d, then gently pull back on the boot to assure

proper contact.

INSPECTION & GAPPING

Check the plugs for deposits and wear. If they are not going to be replaced,

clean the plugs thoroughly. Remember t hat any kind of deposit will decrease

the efficiency of the plug. Plugs can be cleaned on a spark plug cleaning

machine, which can sometimes be found in service stations, or you can do an

acceptable job of cleaning with a stiff br ush. If the plugs are cleaned, the

electrodes must be filed flat. Use an igni tion points file, not an emery board or

the like, which will leave deposits. The electrodes must be filed perfectly flat

with sharp edges; rounded edges reduce the s park plug voltage by as much as

50%.

Check spark plug gap before installati on. The ground electrode (the L-shaped

one connected to the body of the plug) mu st be parallel to the center electrode

and the specified size wire gauge (please refer to the Tune-Up Specifications

chart for details) must pass between t he electrodes with a slight drag.

NEVER adjust the gap on a used platinum type spark plug .

Always check the gap on new plugs as they are not always set correctly a\

t the

factory. Do not use a flat feeler g auge when measuring the gap on a used plug,

because the reading may be inaccurate. A round-wire type gapping tool is the

best way to check the gap. The co rrect gauge should pass through the

electrode gap with a slight drag. If you're in doubt, try one size smaller and one

larger. The smaller gauge should go through easily, while the larger one\

shouldn't go through at all. Wire gapping tools usually have a bending tool

attached. Use that to adjust the side electrode until the proper distance is

obtained. Absolutely never attempt to bend the center electrode. Also, be

careful not to bend the side electrode too fa r or too often as it may weaken and

break off within the engine, requiring remova l of the cylinder head to retrieve it.