stop start CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 739 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 739

3. Make sure the ignition switch has

been in the OFF position for at least 10

seconds and that all accessories are OFF.

4. Turn the ignition switch ON and the pump will run for about 2 seconds.

Note the system pressure with t he pump running, it should be between

40-47 psi.

The ignition switch may have to be cycled to the ON position more than once to

obtain maximum pressure. It is also norma l for the pressure to drop slightly

when the pump first stops, but it should then hold steady.

5. If the pressure is not as specified, verify that fuel pump operation is

heard in the tank.

6. If fuel pump operation is not heard, inspect the fuel pump relay and

wiring.

7. If fuel pump operation is heard, inspect the filter and lines for restriction.

8. Start the engine and make sure the pr essure decreases about 3-10 psi at

idle.

9. If fuel pressure does not decrease, inspect the fuel pressure regulator

and hose.

10. Disconnect the fuel pressure gauge.

THROTTLE BODY

REMOVAL & INSTALLATION 1. Disconnect the negative (-) battery c able and partially drain the radiator.

2. Remove the air inlet duct and unplug the IAC and TPS electrical connectors.

3. Label and disconnect the vacuum and coolant lines.

4. Disconnect the accelerator, thro ttle valve (transmission control) and

cruise control cables, as applicable.

5. Remove the throttle body attaching bolts, then separate the throttle body from the plenum.

6. Discard the gasket.

To install: 7. Install the throttle body to the plenum using a new gasket. Tighten the \

bolts to specification.

8. Engage the accelerator, throttle valve and cruise control cables, as

necessary. Make sure that the link ages do not hold the throttle open.

9. Connect the vacuum and coolant lines.

10. Install the air inlet duct and plug the IAC and TPS electrical connectors

into their sockets.

11. Connect the negative (-) battery cable and refill the radiator.

12. With the engine OFF, check to s ee that the accelerator pedal is free.

Depress the pedal to the floor and release.

Page 743 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 743

MINIMUM IDLE SPEED

The minimum idle speed should onl

y be adjusted under two conditions:

If the throttle body has been replaced.

After every other possible cause for the in correct idle speed has been explored.

There are many possible causes for incorre ct idle speed, most of which require

a high level of diagnostic skill as well as expensive testing equipment. Check

the vehicle for vacuum leaks, incorrect valve or ignition timing, deposit

accumulation in the throttle bore or valve, sticking throttle linkage or bent throttle

valves. If the vehicle will still not idle pr operly after checking these areas, it

should be diagnosed by a professional.

1. Pierce the idle stop screw with an awl. Apply leverage to remove it.

2. Make sure the IAC valve is connect ed. Short the A and B terminals of the

ALDL connector together with a length of wire.

3. Turn the ignition to the ON positi on, but do not start the engine. Wait at

least 30 seconds before proceeding.

4. With the ignition ON, disconnect the IAC valve connector.

5. Separate the set-timing connector. Th is eliminates the possibility of

changes in engine speed due to variations of engine timing.

6. Start the engine and remove t he wire shorting the A and B terminals

together. It may be necessary to hold the throttle open slightly to prevent

the engine from stalling.

7. Allow the engine to reach no rmal operating temperature.

8. Adjust the idle speed to the following: a. 2.8L Engines - 450-550 rp m A/T or 550-650 rpm M/T

b. 3.1L Engines - Refer to the underhood emissions sticker

c. 5.0L and 5.7L TPI engines - 400-450 rpm.

If these figures differ from t hose on the underhood emissions

sticker, always follow the specifications on the emissions sticker.

9. Turn the ignition OFF and connect the IAC valve harness. On models up

to 1989, adjust the Throttle Position Sensor.

THROTTLE POSITION SENSOR (TPS) 1. Install three jumper wires betw een the TPS and the harness connector.

2. Use a digital voltmeter connected to terminals A and B of the TPS.

3. Turn the ignition switch ON , but do not start the engine.

4. Loosen the TPS attaching screws and adj ust the sensor to the following:

a. 2.8L Engines - 0.50-0.60 volts

b. 5.0L and 5.7L TPI Engines - 0.47-0.61 volts

5. Tighten the attaching screws, then check that the reading has not been

disturbed.

6. With the ignition OFF, remove the jumper wires. Reconnect the TPS

harness.

Page 868 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 868

3. Rotate the stub shaft and drain the

power steering fluid into a suitable

container.

4. Turn the Pitman shaft adjuster screw counterclockwise until fully

extended, then turn back 1 full turn.

5. Rotate the stub shaft from stop-to -stop and count the number of turns.

6. Starting at either stop, turn the stub shaft back half the total number of

turns. This is the "Center" posit ion of the gear. When the gear is

centered, the flat on the stub sha ft should face upward and be parallel

with the side cover, and the master spline on the Pitman shaft should be\

in line with the adjuster screw.

7. Rotate the stub shaft 45 degrees each side of the center using a suitable

torque wrench with the hand le in the vertical position. Record the worm

bearing preload measured on or near the center gear position.

8. Adjust the over-center drag torque by loosening the adjuster locknut and

turning the Pitman shaft adjuster screw clockwise until the correct drag

torque is obtained: Add 6-10 inch lbs. (0.7-1.1 Nm) of torque to the

previously measured wo rm bearing preload torque. Tighten the adjuster

locknut to 20 ft. lbs. (27 Nm). Prev ent the adjuster screw from turning

while tightening the adju ster screw locknut.

9. Install the steering gear and c onnect the negative battery cable.

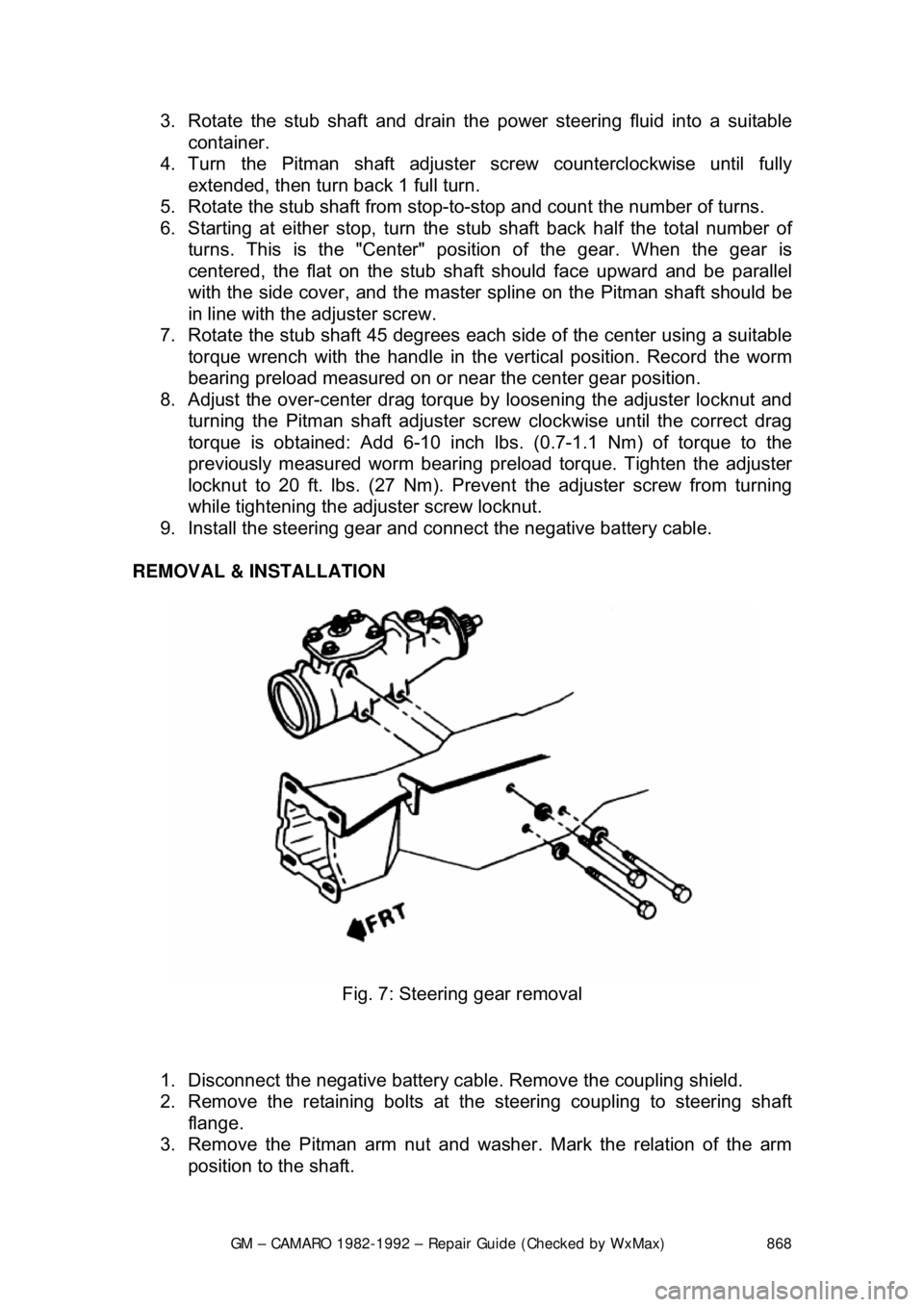

REMOVAL & INSTALLATION

Fig. 7: Steering gear removal

1. Disconnect the negative battery cabl e. Remove the coupling shield.

2. Remove the retaining bolts at t he steering coupling to steering shaft

flange.

3. Remove the Pitman arm nut and wa sher. Mark the relation of the arm

position to the shaft.

Page 871 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 871

6. Refill the pump with fluid and

bleed by turning the pulley

counterclockwise (viewed from the front). Stop the bleeding when air

bubbles no longer appear.

7. Install the pump belt on the pulley and adjust the tension.

SYSTEM BLEEDING 1. Fill the reservoir with power steering fluid.

The use of automatic transmission flui d in the power steering system is NOT

recommended.

2. Allow the reservoir and fluid to sit undisturbed for a few minutes.

3. Start the engine, allow it to run for a mome nt, then turn it off.

4. Check the reservoir fluid level and add fluid if necessary.

5. Repeat the above steps until the fluid level stabilizes.

6. Raise the front of the vehicle so that the wheels are off of the ground.

7. Start the engine and increase t he engine speed to about 1500 rpm.

8. Turn the front wheels right to le ft (and back) several times, lightly

contacting the wheel stops at the ends of travel.

9. Check the reservoir fluid level. Add fluid as required.

10. Repeat step 8 until the fluid leve l in the reservoir stabilizes.

11. Lower the vehicle and repeat steps 8 and 9.