ESP CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 492 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 492

It is always recommended that you remo

ve any cylinder ridges before removing

the piston and connecting rod assemblies . If you know that new pistons are

going to be installed and the engine bl ock will be bored oversize, you may be

able to forego this step. However, some ridges may actually prevent the

assemblies from being remove d, necessitating its removal.

There are several different types of ridge reamers on the market, none of which

are inexpensive. Unless a great deal of engine rebuild ing is anticipated, borrow

or rent a reamer.

1. Turn the crankshaft until the piston is at the bottom of its travel.

2. Cover the head of the piston with a rag.

3. Follow the tool manufacturers in structions and cut away the ridge,

exercising extreme care to avoid cutting too deeply.

4. Remove the ridge reamer, the r ag and as many of the cuttings as

possible. Continue until all of the cylinder ridges have been removed.

DISASSEMBLY

The engine disassembly instructions fo llowing assume that you have the engine

mounted on an engine stand. If not, it is easiest to disassemble the engine on a

bench or the floor with it resting on t he bellhousing or transmission mounting

surface. You must be able to access the connecting rod fasteners and turn the

crankshaft during disassembly. Also, all en gine covers (timing, front, side, oil

pan, whatever) should have already been removed. Engines which are seized

or locked up may not be able to be co mpletely disassembled, and a core

(salvage yard) engine should be purchased.

If not done during the cylinder head removal, remove the pushrods and li\

fters,

keeping them in order for assembly. Remove the timing gears and/or timing

chain assembly, then remove the oil pu mp drive assembly and withdraw the

camshaft from the engine block. Remove the oil pick-up and pump assembly. If

equipped, remove any balanc e or auxiliary shafts. If necessary, remove the

cylinder ridge from the top of the bore. See the cylinder ridge removal

procedure earlier in this section.

Rotate the engine over so that the cr ankshaft is exposed. Use a number punch

or scribe and mark each connecting rod wit h its respective cylinder number. The

cylinder closest to the front of t he engine is always number 1. However,

depending on the engine placemen t, the front of the engine could either be the

flywheel or damper/pulley end. Generally the front of the engine faces the front

of the vehicle. Use a number punch or scribe and also mark the main bearing

caps from front to rear wit h the front most cap being nu mber 1 (if there are five

caps, mark them 1 through 5, front to rear).

Page 495 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 495

Again, rotate the engine, this time

to position the number one cylinder bore

(head surface) up. Turn the crankshaft until the number one piston is at the

bottom of its travel, this should allow t he maximum access to its connecting rod.

Remove the number one co nnecting rods fasteners and cap and place two

lengths of rubber hose over the rod bolts/studs to protect the crankshaft from

damage. Using a sturdy wooden dowel and a hammer, push the connecting rod

up about 1 in. (25mm) from the cranks haft and remove the upper bearing insert.

Continue pushing or tapping the connecti ng rod up until the piston rings are out

of the cylinder bore. Remove the piston and rod by hand, put the upper half of

the bearing insert back into the rod, in stall the cap with its bearing insert

installed, and hand-tighten the cap fasteners. If the parts are kept in order in this

manner, they will not get lost and you wil l be able to tell which bearings came

form what cylinder if any problems are discovered and diagnosis is necessary.

Remove all the other piston assemblie s in the same manner. On V-style

engines, remove all of the pistons from one bank, then reposition the engine

with the other cylinder bank head surface up, and remo ve that banks piston

assemblies.

The only remaining component in the engine block should now be the

crankshaft. Loosen the main bearing ca ps evenly until the fasteners can be

turned by hand, then remove them and the caps. Remove the crankshaft fro\

m

the engine block. Thoroughly clea n all of the components.

INSPECTION

Now that the engine block and all of its components ar e clean, it's time to

inspect them for wear and/or damage. To accurately inspect them, you will need

some specialized tools:

• Two or three separate micromet ers to measure the pistons and

crankshaft journals

• A dial indicator

• Telescoping gauges for the cylinder bores

• A rod alignment fixture to check for bent connecting rods

If you do not have access to the proper tools, you may want to bring the

components to a shop that does.

Generally, you shouldn't expect cracks in the engine block or its components

unless it was known to leak, consume or mix engine fluids, it was severely

overheated, or there was ev idence of bad bearings and/or crankshaft damage.

A visual inspection should be performed on all of the components, but just

because you don't see a crack does not mean it is not there. Some more

reliable methods for inspecting for cracks include Magnaflux, a magnetic

process or Zyglo, a dye penetrant. M agnaflux is used only on ferrous metal

(cast iron). Zyglo uses a spray on fluoresce nt mixture along with a black light to

reveal the cracks. It is strongly recommended to have your engine block

checked professionally for cracks, especia lly if the engine was known to have

overheated and/or leaked or consumed coolant. Contact a local shop for

availability and pricing of these services.

Page 500 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 500

within specifications, install new bear

ings in the rod and take another

measurement. If the clearance is still out of specifications, and the crankshaft is

not, the rod will need to be reconditioned by a machine shop.

You can also use Plastigage to check the bearing clearances. The assembling

section has complete instructions on its use.

CAMSHAFT

Inspect the camshaft and lifters/followers as described earlier in this section.

BEARINGS

All of the engine bearings should be visua lly inspected for wear and/or damage.

The bearing should look evenly worn a ll around with no deep scores or pits. If

the bearing is severely worn, scored, pi tted or heat blued, then the bearing, and

the components that use it, should be brought to a machine shop for inspection.

Full-circle bearings (used on most camshafts, auxiliary shafts, balance shafts,

etc.) require specialized tools for re moval and installation, and should be

brought to a machine shop for service.

OIL PUMP

The oil pump is responsible for provid ing constant lubrication to the whole

engine and so it is re commended that a new oil pump be installed when

rebuilding the engine.

Completely disassemble the oil pump and thoroughly clean all of the

components. Inspect the oil pump gears and housing for wear and/or damage.

Insure that the pressure relief valve oper ates properly and there is no binding or

sticking due to varnish or debris. If all of the parts are in proper working

condition, lubricate the gears and relie f valve, and assemble the pump.

REFINISHING

Almost all engine block refinishing must be performed by a machine shop. If the

cylinders are not to be rebored, then t he cylinder glaze can be removed with a

ball hone. When removing cylinder glaz e with a ball hone, use a light or

penetrating type oil to lubricate the hone. Do not allow the hone to run dry as

this may cause excessive scoring of t he cylinder bores and wear on the hone. If

new pistons are required, t hey will need to be installed to the connecting rods.

This should be performed by a machine shop as the pistons must be installed in

the correct relationship to the rod or engine damage can occur.

Page 510 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 510

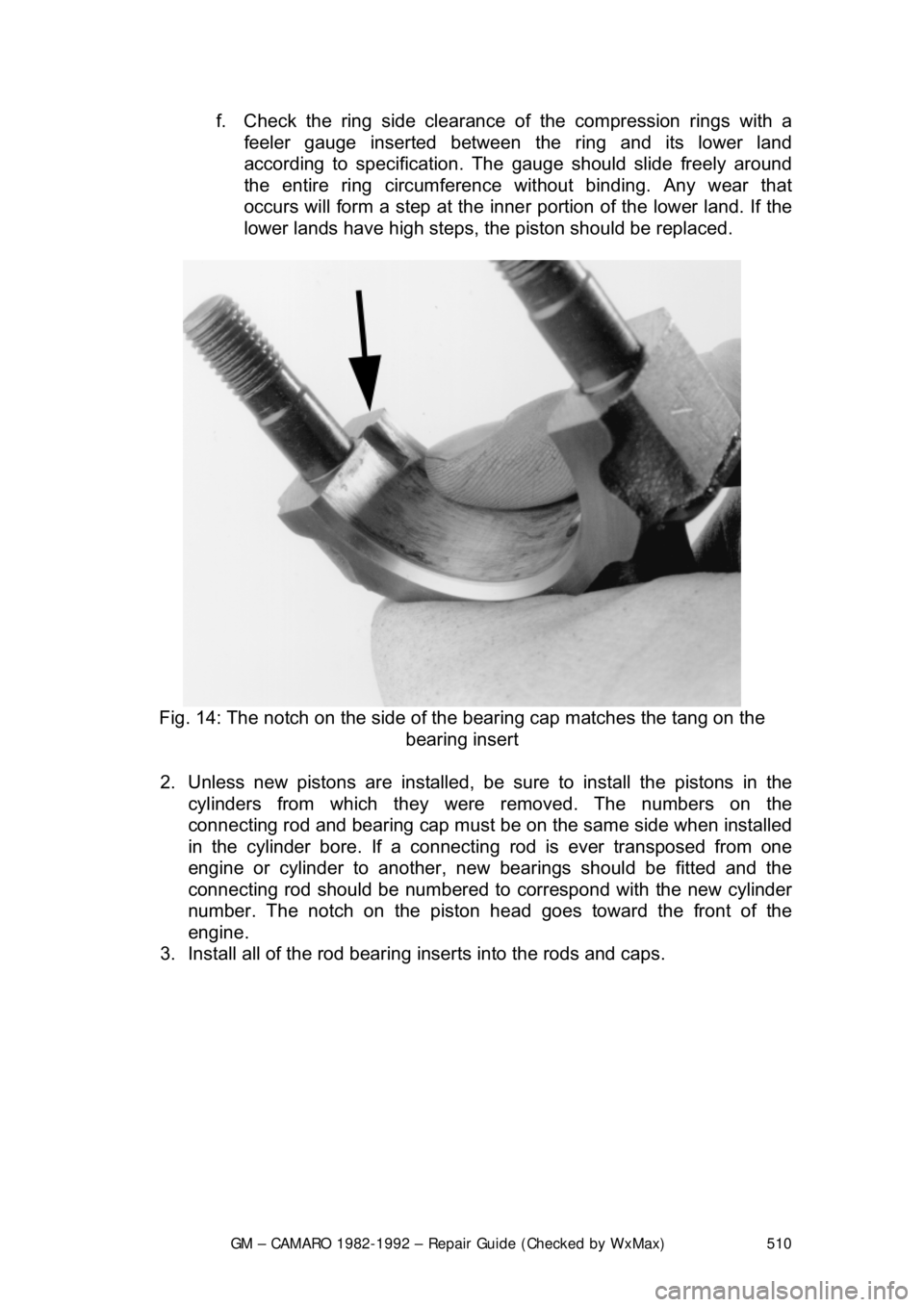

f. Check the ring side clearance of the compression rings with a

feeler gauge inserted between the ring and its lower land

according to specification. The gauge should slide freely around

the entire ring circumference wit hout binding. Any wear that

occurs will form a step at the inne r portion of the lower land. If the

lower lands have high steps, t he piston should be replaced.

Fig. 14: The notch on the side of t he bearing cap matches the tang on the

bearing insert

2. Unless new pistons are installed, be sure to install the pistons in the

cylinders from which they were removed. The numbers on the

connecting rod and bearing cap must be on the same side when installed

in the cylinder bore. If a connecting rod is ever transposed from one

engine or cylinder to another, new bear ings should be fitted and the

connecting rod should be numbered to correspond with the new cylinder

number. The notch on the piston head goes toward the front of the

engine.

3. Install all of the rod bearing inserts into the rods and caps.

Page 547 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 547

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

OPERATION

All models are equipped with

this system, which consists of a metering valve, a

vacuum line to the carburet or or intake manifold, and cast-in exhaust passages

in the intake manifold. The EGR valve is controlled by vacuum, which opens

and closes in response to the vacuum signals to admit exhaust gases into the

air/fuel mixture. The exhaust gases lower peak combustion temperatures,

reducing the formation of NOx. The valve is closed at idle and wide open

throttle, but is open between the two extreme positions.

There are actually four types of EGR systems: Ported, Positive Back-Pressure,

Negative Backpressure and Digital. The pr inciple of all the systems are the

same; the only difference is in the me thod used to control how the EGR valve

opens.

Too much EGR flow at idle, cruise or during cold operation may result in the

engine stalling after cold start, the engine stalling at idle after deceleration,

vehicle surge during cruise and rough idle . If the EGR valve is always open, the

vehicle may not idle. Too little or no EGR flow allows combustion temperatures

to rise, which could result in spar k knock (detonation), engine overheating

and/or emission test failure.

A Thermal Vacuum Switch (TVS) or vacuum control solenoid may sometimes\

be used in combination with the EGR va lve. The TVS will close off vacuum

during cold operation. A va cuum control solenoid uses Pulse Width Modulation

(PWM) to turn the solenoid ON and OFF numerous times a second and varies

the amount of ON time (pulse width) to vary the amount of ported vacuum

supplied the EGR valve.

PORTED VALVE

In the ported system, the amount of ex haust gas admitted into the intake

manifold depends on a ported vacuum signal. A ported vacuum signal is one

taken from the carburetor above the th rottle plates; thus, the vacuum signal

(amount of vacuum) is dependent on how far the throttle plates are opened.

When the throttle is closed (idle or dec eleration) there is no vacuum signal.

Thus, the EGR valve is closed, and no exhaust gas enters the intake mani\

fold.

As the throttle is opened, a vacuum is produced, which opens the EGR valve,

admitting exhaust gas into the intake manifold.

POSITIVE BACKPRE SSURE VALVE

This valve operates the same as the ported, except, it has an internal air bleed

that acts as a vacuum regulator. T he bleed valve controls the amount of

vacuum inside the vacuum chamber duri ng operation. When the valve receives

sufficient exhaust backpressure through the hollow shaft, it closes the bleed; at

this point the EGR valve opens.

Page 581 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 581

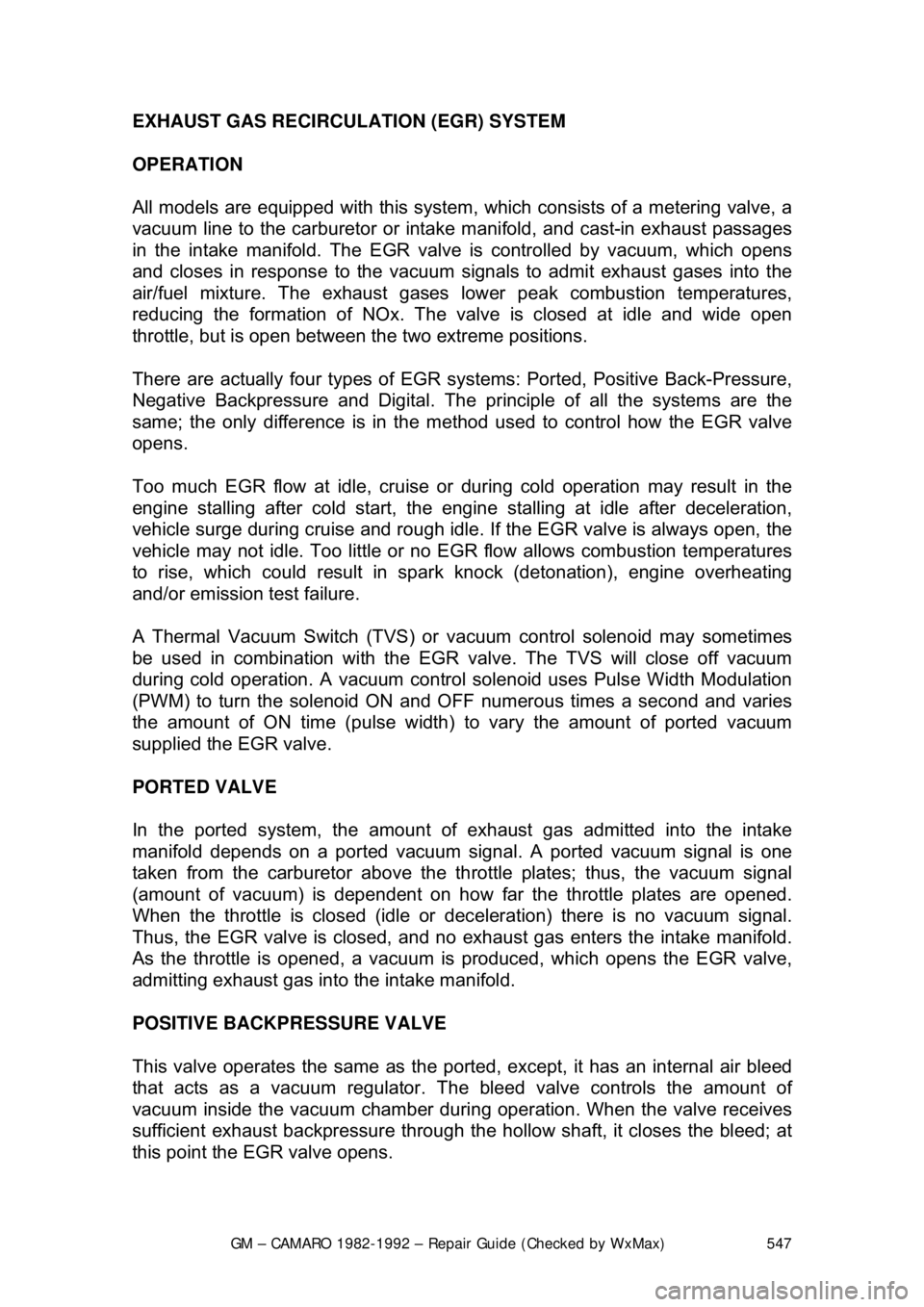

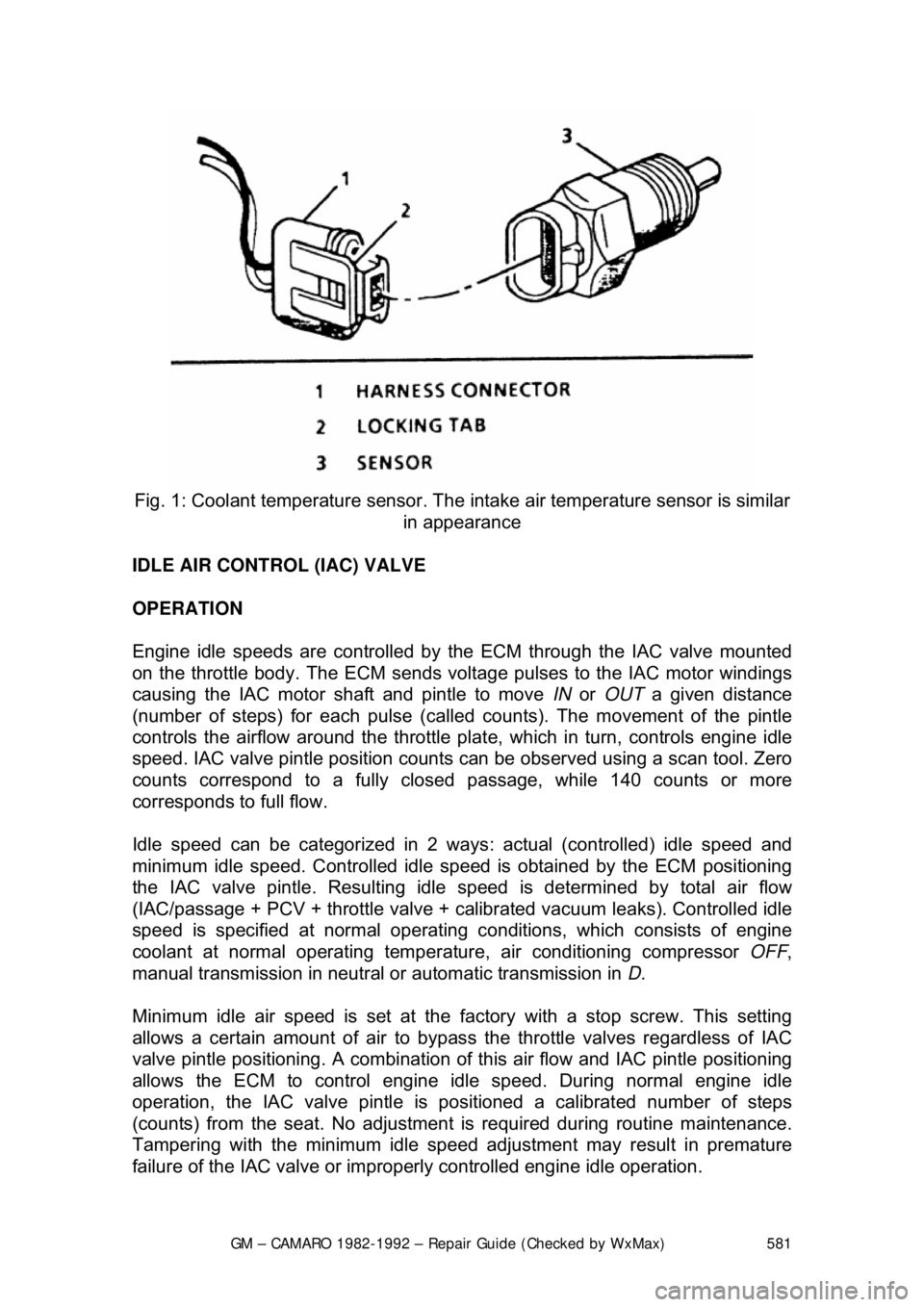

Fig. 1: Coolant temperature sensor. The in take air temperature sensor is similar

in appearance

IDLE AIR CONTROL (IAC) VALVE

OPERATION

Engine idle speeds are controlled by the ECM through the IAC valve mounted

on the throttle body. The ECM sends volt age pulses to the IAC motor windings

causing the IAC motor shaft and pintle to move IN or OUT a given distance

(number of steps) for each pulse (called counts). The movement of the pintle

controls the airflow around the throttle plat e, which in turn, controls engine idle

speed. IAC valve pintle position counts ca n be observed using a scan tool. Zero

counts correspond to a fully closed passage, while 140 counts or more

corresponds to full flow.

Idle speed can be categorized in 2 ways : actual (controlled) idle speed and

minimum idle speed. Contro lled idle speed is obtained by the ECM positioning

the IAC valve pintle. Resulting idle speed is determined by total air fl\

ow

(IAC/passage + PCV + throttle valve + ca librated vacuum leaks). Controlled idle

speed is specified at normal operating c onditions, which consists of engine

coolant at normal operating temper ature, air conditioning compressor OFF,

manual transmission in neutral or automatic transmission in D.

Minimum idle air speed is set at t he factory with a stop screw. This setting

allows a certain amount of air to bypas s the throttle valves regardless of IAC

valve pintle positioning. A co mbination of this air flow and IAC pintle positioning

allows the ECM to control engine idle speed. During normal engine idle

operation, the IAC valve pintle is positioned a calibrated number of steps

(counts) from the seat. No adjustment is required during routine maintenance.

Tampering with the minimum idle speed adjustment may result in premature

failure of the IAC valve or imprope rly controlled engine idle operation.

Page 651 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 651

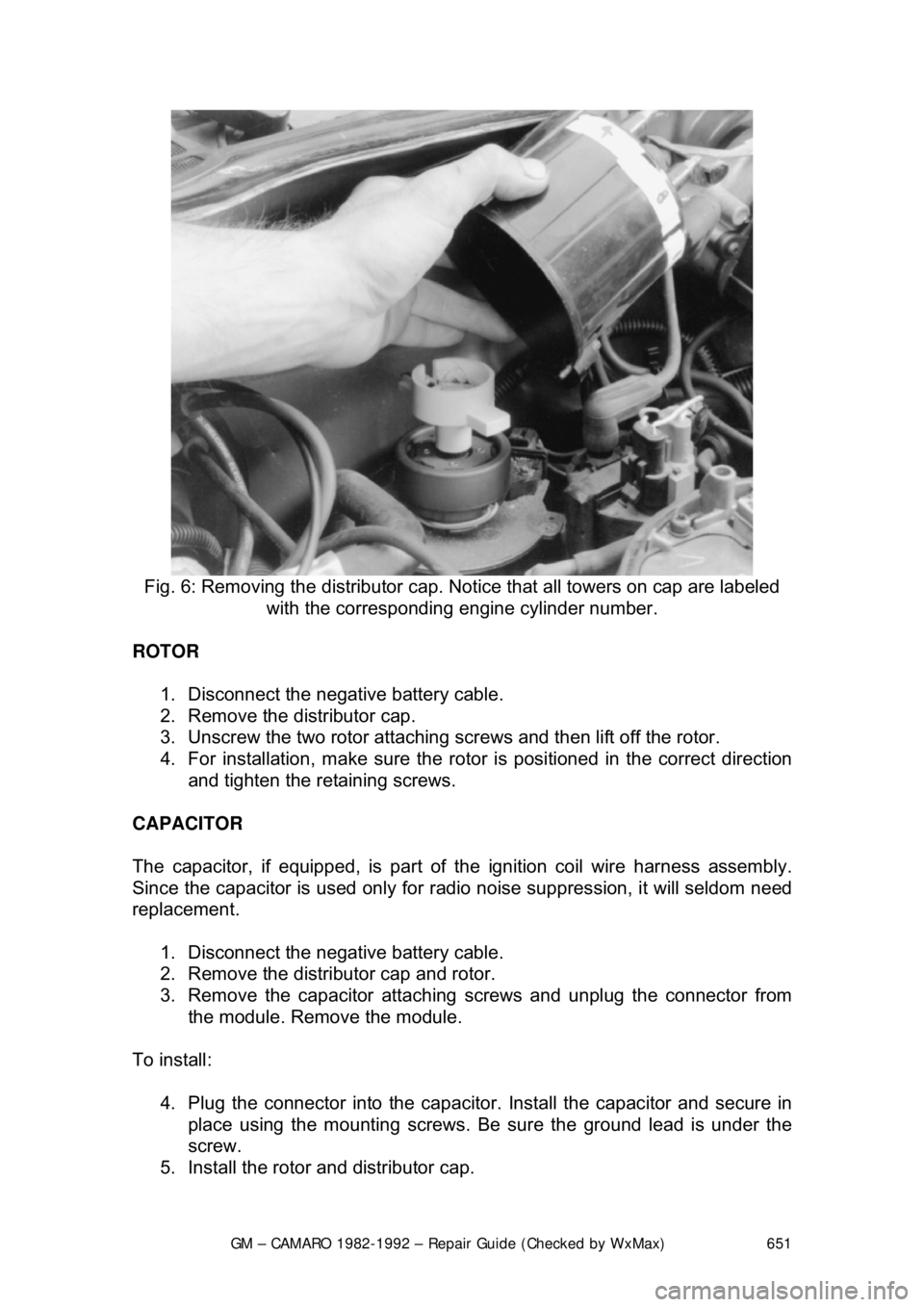

Fig. 6: Removing the distri butor cap. Notice that all towers on cap are labeled

with the corresponding engine cylinder number.

ROTOR 1. Disconnect the negative battery cable.

2. Remove the distributor cap.

3. Unscrew the two rotor attaching screws and then lift off the rotor.

4. For installation, make sure the roto r is positioned in the correct direction

and tighten the retaining screws.

CAPACITOR

The capacitor, if equipped, is part of the ignition coil wire harness assembly.

Since the capacitor is used only for radio noise suppres sion, it will seldom need

replacement.

1. Disconnect the negative battery cable.

2. Remove the distributor cap and rotor.

3. Remove the capacitor attaching screws and unplug the connector from

the module. Remove the module.

To install: 4. Plug the connector into the capacitor. Install the capacitor and secure in

place using the mounting screws. Be sure the ground lead is under the

screw.

5. Install the rotor and distributor cap.

Page 708 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 708

rapidly. Failure to replace all parts s

upplied with the kit (especially gaskets) can

result in poor performance later.

Some carburetor manufacturers supply overhaul kits for three basic types:

minor repair; major repair; and gasket kits. Certain parts may be expected in

most kits based on the desired degree of overhaul.

MINOR REPAIR KITS

• All gaskets

• Float needle valve

• All diaphragms

• Spring for the pump diaphragm

MAJOR REPAIR KITS

• All jets and gaskets

• All diaphragms

• Float needle valve

• Pump ball valve

• Float

• Complete intermediate rod

• Intermediate pump lever

• Some cover hold-down screws and washers

GASKET KITS

• All gaskets

Efficient carburetion depends greatly on careful cleaning and inspection during

overhaul, since dirt, gum, water, or varnis h in or on the carburetor parts are

often responsible for poor performance.

Overhaul your carburetor in a clean, dust-free area. Carefully disassemble the

carburetor, referring often to the explod ed views and directions packaged with

the rebuilding kit. Keep all similar and look-alike parts separated during

disassembly and cleaning to avoid accidental interchange during assembly\

.

Make a note of all jet sizes.

When the carburetor is disassembled, wash all parts (except diaphragms,

electric components, pump pl unger, and any other plastic, leather, fiber, or

rubber parts) in clean carbur etor solvent. Do not leave parts in the solvent any

longer than is necessary to sufficiently loosen the deposits. Excessive cleaning

may remove the special finish from the float bowl and choke valve bodies,

leaving these parts unfit for service. Rinse all parts in clean solvent and blow

them dry with compressed air or allow them to air dry. Wipe clean all cork,

plastic, leather, and fiber parts with a clean, lint-free cloth.

Blow out all passages and jets with comp ressed air and be sure that there are

no restrictions or blockages. Never use wi re or similar tools to clean jets, fuel

Page 709 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 709

passages, or air bleeds. Clean all jets and va

lves separately to avoid accidental

interchange.

Check all parts for wear or damage. If we ar or damage is found, replace the

defective parts. Especially check the following:

1. Check the float needle and seat for wear.

2. Check the float hinge pin for wear and the float(s) for dents or distortion.

Replace the float if fuel has leaked into it.

3. Check the throttle and choke sha ft bores for wear or an out-of-round

condition. Damage or wear to the thro ttle arm, shaft, or shaft bore will

often require replacement of the throttle body. These parts require a

close tolerance of fit; wear may allow air leakage, which could affect

starting and idling.

Throttle shafts and bushings are not included in overhaul kits. They can be

purchased separately or repaired by a qualified carburetor overhaul shop.

4. Inspect the idle mixt ure adjusting needles for bu rrs or grooves. Any such

condition requires replacement of t he needle, since you will not be able

to obtain a satisfactory idle.

5. Test the accelerator pump check va lves. They should pass air one way

but not the other. Test for proper s eating by blowing and sucking on the

valve. Replace the valve check ball and spring as necessary. If the valve

is satisfactory, wash the valve part s again to remove breath moisture.

6. Check the bowl cover for war ped surfaces with a straightedge.

7. Closely inspect the accelerato r pump plunger for wear and damage,

replacing as necessary.

8. After the carburetor is assembled, check the choke valve for freedom of

operation.

9. Check, repair or replace parts, if the following problems are encountered:

FLOODING

• Inspect the float valve and seat for dirt, deep wear grooves, scores and

improper sealing

• Inspect the float valve pull clip for proper installation; be careful no\

t to

bend the pull clip

• Inspect the float, the float arms and the hinge pin for distortion, binds,

and burrs. Check the density of the mate rial in the float; if heavier than

normal, replace the float

• Clean or replace the fuel inlet f ilter and check the valve assembly

HESITATION

• Inspect the pump plunger for cracks, scores or cup excessive wear. A

used pump cup will shrink w hen dry. If dried out, soak in fuel for 8 hours

before testing

• Inspect the pump duration and return springs for weakness or distortion \

Page 761 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 761

MAINTENANCE OR REPAIR?

Maintenance includes routine inspecti

ons, adjustments, and replacement of

parts which show signs of normal wear . Maintenance compensates for wear or

deterioration. Repair implies that someth ing has broken or is not working. A

need for a repair is often caused by lack of maintenance. for example: draining

and refilling automatic transmission fl uid is maintenance recommended at

specific intervals. Failure to do this can shorten the life of the

transmission/transaxle, requiring very expen sive repairs. While no maintenance

program can prevent items from eventually breaking or wearing out, a general

rule is true: MAINTENANCE IS CHEAPER THAN REPAIR.

Two basic mechanic's rules should be mentioned here. First, whenever the left

side of the vehicle or engine is refe rred to, it means the driver's side.

Conversely, the right side of the vehi cle means the passenger's side. Second,

screws and bolts are removed by turn ing counterclockwise, and tightened by

turning clockwise unless specifically noted.

Safety is always the most important rule. Constantly be aware of the dangers

involved in working on an automobile and take the proper precautions. Please

refer to the information in this se ction regarding SERVICING YOUR VEHICLE

SAFELY and the SAFETY NOTICE on the acknowledgment page.

AVOIDING THE MOST COMMON MISTAKES

Pay attention to the instructions prov ided. There are 3 common mistakes in

mechanical work:

1. Incorrect order of assembly, di sassembly or adjustment. When taking

something apart or putting it toget her, performing steps in the wrong

order usually just costs you ex tra time; however, it CAN break

something. Read the entire proc edure before beginning. Perform

everything in the order in which the instructions say you should, even if

you can't see a reason for it. When you' re taking apart something that is

very intricate, you might want to draw a picture of how it looks when

assembled in order to make sure you get everything back in its proper

position. When making adjustments, per form them in the proper order.

One adjustment possibly will affect another.

2. Overtorquing (or undertorquing). While it is more common for overtorquing to cause damage, undertorquing may allow a fastener to

vibrate loose causing serious dam age. Especially when dealing with

aluminum parts, pay attention to tor que specifications and utilize a torque

wrench in assembly. If a torque figure is not available, remember that if

you are using the right tool to perfo rm the job, you will probably not have

to strain yourself to get a fast ener tight enough. The pitch of most

threads is so slight that the te nsion you put on the wrench will be

multiplied many times in actual fo rce on what you are tightening.

There are many commercial products avai lable for ensuring that fasteners won't

come loose, even if they are not torqued just right (a very common brand is