ESP CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 801 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 801

Fig. 3: Note location of power steering fluid on indicator. Do not overfill power

steering pump when adding fluid.

Power steering fluid level s hould be checked at least twice a year. To prevent

possible overfilling, check the fluid le vel only when the fluid has warmed to

operating temperatures and the wheels are turned straight ahead. If the level is

low, fill the pump reservoir until the flui d level measures between the COLD and

HOT marks on the reservoir dipstick. Low fluid level usually produces a

moaning sound as the wheels are turned (especially when standing still or

parking) and increases st eering wheel effort.

STEERING GEAR

FLUID RECOMMENDATIONS

The 1982-92 vehicles are equipped with a pow er steering gear. All vehicles use

GM power steering fluid, or equivalent.

CHASSIS GREASING

Chassis lubrication can be performed with a pressurized grease gun or by using

a hand-operated grease gun. Wipe the grease fittings clean before greasing in

order to prevent the possibility of fo rcing any dirt into the component.

Page 810 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 810

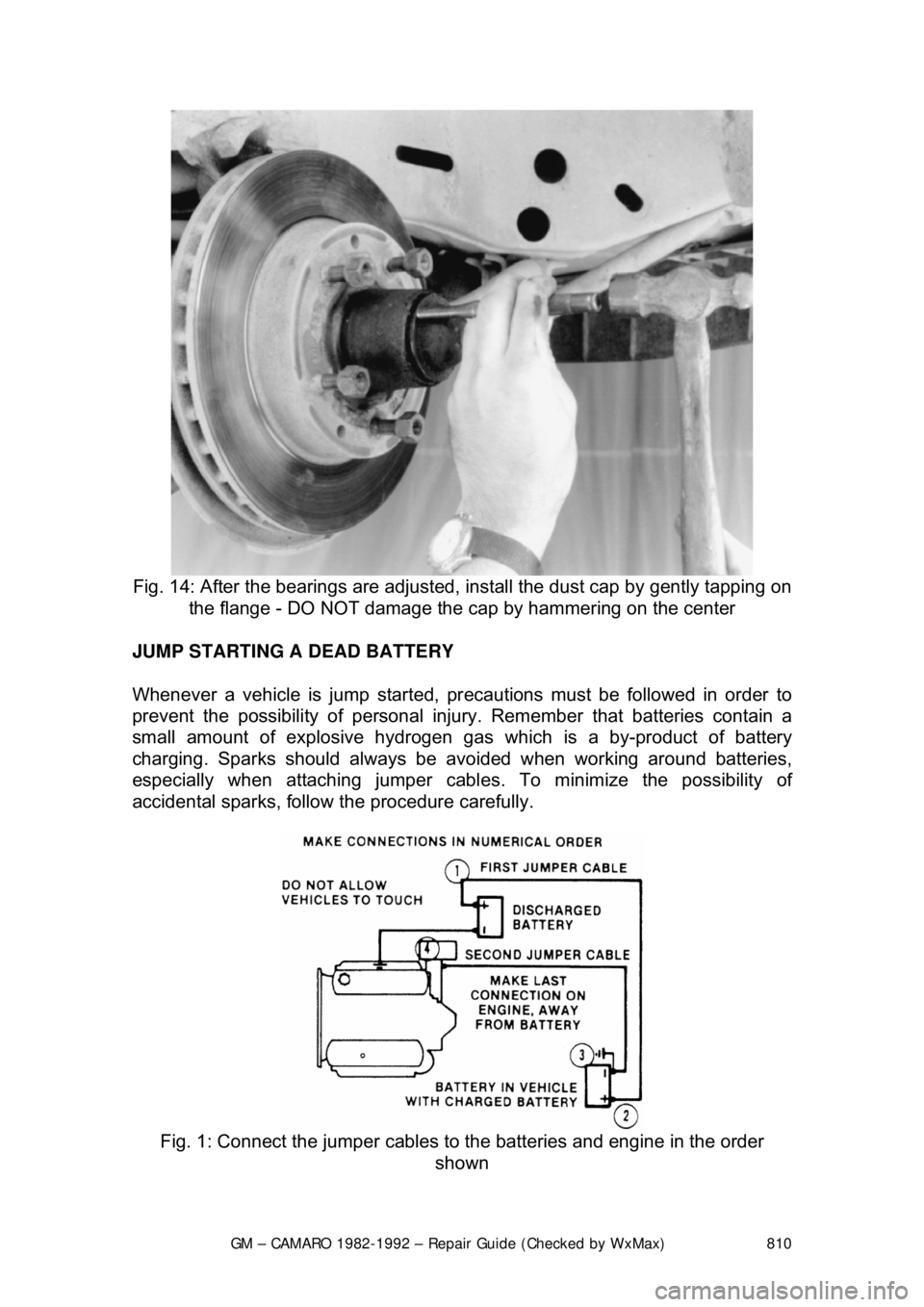

Fig. 14: After the bearings are adjusted, install the dust cap by gently tapping on

the flange - DO NOT damage the c ap by hammering on the center

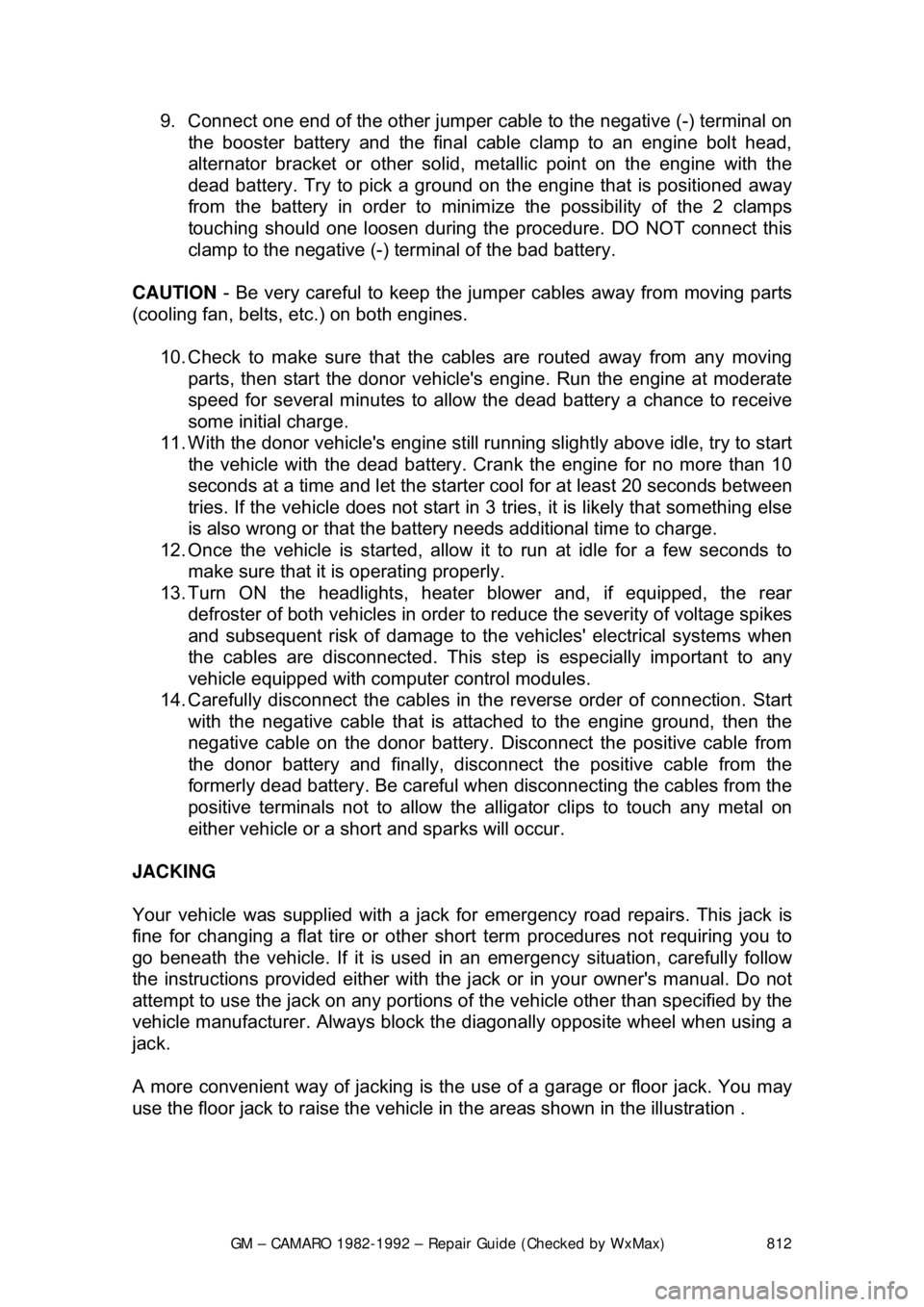

JUMP STARTING A DEAD BATTERY

Whenever a vehicle is jump started, pr ecautions must be followed in order to

prevent the possibility of personal inju ry. Remember that batteries contain a

small amount of explosive hydrogen gas which is a by-product of battery

charging. Sparks should always be av oided when working around batteries,

especially when attaching jumper cabl es. To minimize the possibility of

accidental sparks, follow the procedure carefully.

Fig. 1: Connect the jumper cables to the batteries and engine in the order

shown

Page 812 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 812

9. Connect one end of the other jumper

cable to the negative (-) terminal on

the booster battery and the final cable clamp to an engine bolt head,

alternator bracket or ot her solid, metallic point on the engine with the

dead battery. Try to pick a ground on the engine that is positioned away

from the battery in order to minimi ze the possibility of the 2 clamps

touching should one l oosen during the procedure. DO NOT connect this

clamp to the negative (-) term inal of the bad battery.

CAUTION - Be very careful to keep the jum per cables away from moving parts

(cooling fan, belts, etc.) on both engines.

10. Check to make sure that the c ables are routed away from any moving

parts, then start the d onor vehicle's engine. Run the engine at moderate

speed for several minutes to allow the dead battery a chance to receive

some initial charge.

11. With the donor vehicle's engine still r unning slightly above idle, try to start

the vehicle with the dead battery. Crank the engine for no more than 10 \

seconds at a time and let the starter cool for at least 20 seconds between

tries. If the vehicl e does not start in 3 tries, it is likely that something else

is also wrong or that the battery needs additional time to charge.

12. Once the vehicle is star ted, allow it to run at idle for a few seconds to

make sure that it is operating properly.

13. Turn ON the headlight s, heater blower and, if equipped, the rear

defroster of both vehicles in order to reduce the severity of voltage spikes

and subsequent risk of dam age to the vehicles' electrical systems when

the cables are disconnected. This st ep is especially important to any

vehicle equipped with computer control modules.

14. Carefully disconnect the cables in the reverse order of connection. Star\

t with the negative cable that is attached to the engine ground, then the

negative cable on the donor battery. Di sconnect the positive cable from

the donor battery and finally, disconnect the positive cable from the

formerly dead battery. Be careful when disconnecting the cables from the

positive terminals not to allow the alli gator clips to touch any metal on

either vehicle or a short and sparks will occur.

JACKING

Your vehicle was supplied with a jack for emergency road repairs. This jack is

fine for changing a flat tire or other s hort term procedures not requiring you to

go beneath the vehicle. If it is used in an emergency situation, carefully follow

the instructions provided eit her with the jack or in your owner's manual. Do not

attempt to use the jack on any portions of the vehicle other than specified by the

vehicle manufacturer. Always block the diagonally opposite wheel when using a

jack.

A more convenient way of jacking is the use of a garage or floor jack. You may

use the floor jack to raise the vehicle in the areas shown in the illustration .

Page 849 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 849

2. Loosen the screws and lo

cknuts from the back of the steering wheel

using a suitable Torx® driver or equi valent, until the inflator module can

be released from the steering wheel. Remove the inflator module from

the steering wheel.

CAUTION - When carrying a live inflator modul e, ensure the bag and trim cover

are pointed away from the body. In ca se of an accidental deployment, the bag

will then deploy with minima l chance of injury. When placing a live inflator

module on a bench or other surface, a lways place the bag and trim cover up,

away from the surface. This is necessa ry so a free space is provided to allow

the air bag to expand in the unlikely event of accidental deployment. Otherwise,

personal injury may result. Also, never carry the inflator module by the wires or

connector on the underside of the module.

4. Disconnect the coil assembly connec tor and CPA clip from the inflator

module terminal.

5. Remove the steering wheel locking nut.

6. Using a suitable pulle r, remove the steering wheel and disconnect the

horn contact. When attaching the steer ing wheel puller, use care to

prevent threading the side screws into the coil assembly and damaging

the coil assembly.

To install: 7. Route the coil assembly connec tor through the steering wheel.

8. Connect the horn contact and install the steering wheel. When installing

the steering wheel, ali gn the block tooth on the steering wheel with the

block tooth on the steering shaft within 1 female serration.

9. Install the steering wheel locking nu t. Tighten the nut to 31 ft. lbs. (42

Nm).

10. Connect the coil assembly connector and CPA clip to the inflator module

terminal.

11. Install the inflator module. Ensu re the wiring is not exposed or trapped

between the inflator modul e and the steering wheel. Tighten the inflator

module screws to 25 inch lbs. (2.8 Nm).

12. Connect the negative battery cable.

13. Enable the SIR system as follows: a. Connect the yellow 2-way SIR harness connector to base of the steering column and CPA.

b. Install the left sound insulator.

c. Install the SIR fuse in the fuse block.

d. Turn the ignition switch to the RUN position and verify that the

inflatable restraint indicator fl ashes 7-9 times and then turns OFF.

If the indicator does not respond as stated, a problem within the

SIR system is indicated.

Page 857 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 857

6. Remove the bolts attaching the toe plate to the cowl.

7. Disconnect the electrical connectors.

8. Remove the capsule nuts attachi

ng the steering column support bracket

to the instrument panel.

9. Disconnect the park lock cable from the ignition switch inhibitor, if

equipped with automatic transmission.

10. Remove the steering column from the vehicle.

To install:

If a replacement steering column is bein g installed, do not remove the anti-

rotation pin until after the steering co lumn has been connected to the steering

gear. Removing the anti-rotation pin before the steering column is connected to

the steering gear may dam age the SIR coil assembly.

11. Position the steering column in the vehicle.

12. Connect the park lock cable to the ig nition switch inhibitor on vehicles

with automatic transmission.

13. Install the capsule nuts attaching the steering column support bracket to

the instrument panel and tighten to 20 ft. lbs. (27 Nm).

14. Install the nut and bolt to the upper intermediate shaft coupling attaching

the upper intermediate shaft to the steer ing column. Tighten the nut to 44

ft. lbs. (60 Nm).

15. Install the bolts attaching the toe pl ate to the cowl and tighten to 58 inch

lbs. (6.5 Nm).

16. Connect the electrical connectors.

17. Remove the anti-rotation pin if a se rvice replacement steering column is

being installed.

18. Install the knee bolster and bracket, if equipped.

19. Install the sound insulator panel.

If SIR coil has become uncentered by turni ng of the steering wheel without the

column connected to the st eering gear, follow the proper adjustment procedure

for the SIR coil assembly before proceeding.

20. Install the steering wheel.

21. Connect the negative battery cable.

22. Enable the SIR system as follows: a. Connect the yellow 2-way SIR harness connector to the base of

the steering column and CPA clip and install the SIR fuse.

b. Install the left sound insulator.

c. Turn the ignition switch to the RUN position and verify that the

inflatable restraint indicator fl ashes 7-9 times and then turns OFF.

If the indicator does not respond as stated, a problem within the

SIR system is indicated.