head CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 200 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 200

9. Lubricate the speedometer cable

with an appropriate lubricant, being

sure to cover the lower thirds of the cable.

10. Insert the cable into the casi ng, then connect the cable and casing

assembly to the speedometer.

11. Install the instrument cluster, then install the cluster attaching screws.

12. Install the instrument cluster trim plate.

13. On models without cruise control, connect the speedometer cable strap

at the power brake booste r. On models with cruise control, connect the

speedometer cable at the cr uise control transducer.

14. Connect the negative battery cable at the battery.

WIPER SWITCH

REMOVAL & INSTALLATION

The wiper switch is part of the multi-function lever, located on the steering

wheel column.

1. Disconnect the electrical connector of the multi-function lever, located

under the instrument panel.

2. Remove the protective cover from the wire.

3. Grasp the lever firmly, twist and pull (the tang on the lever must align

with the socket) the lever straight out.

4. Pull the wire through the steering column.

To install: 5. Slide a music wire tool through the steering column and connect the

lever wire to the tool wire; pull t he wire through the steering column.

6. Push the control lever into the sp ring loaded socket (be sure to align the

tang).

7. Install the protective cover to the wire.

8. Connect the electrical connector of the multi-function lever.

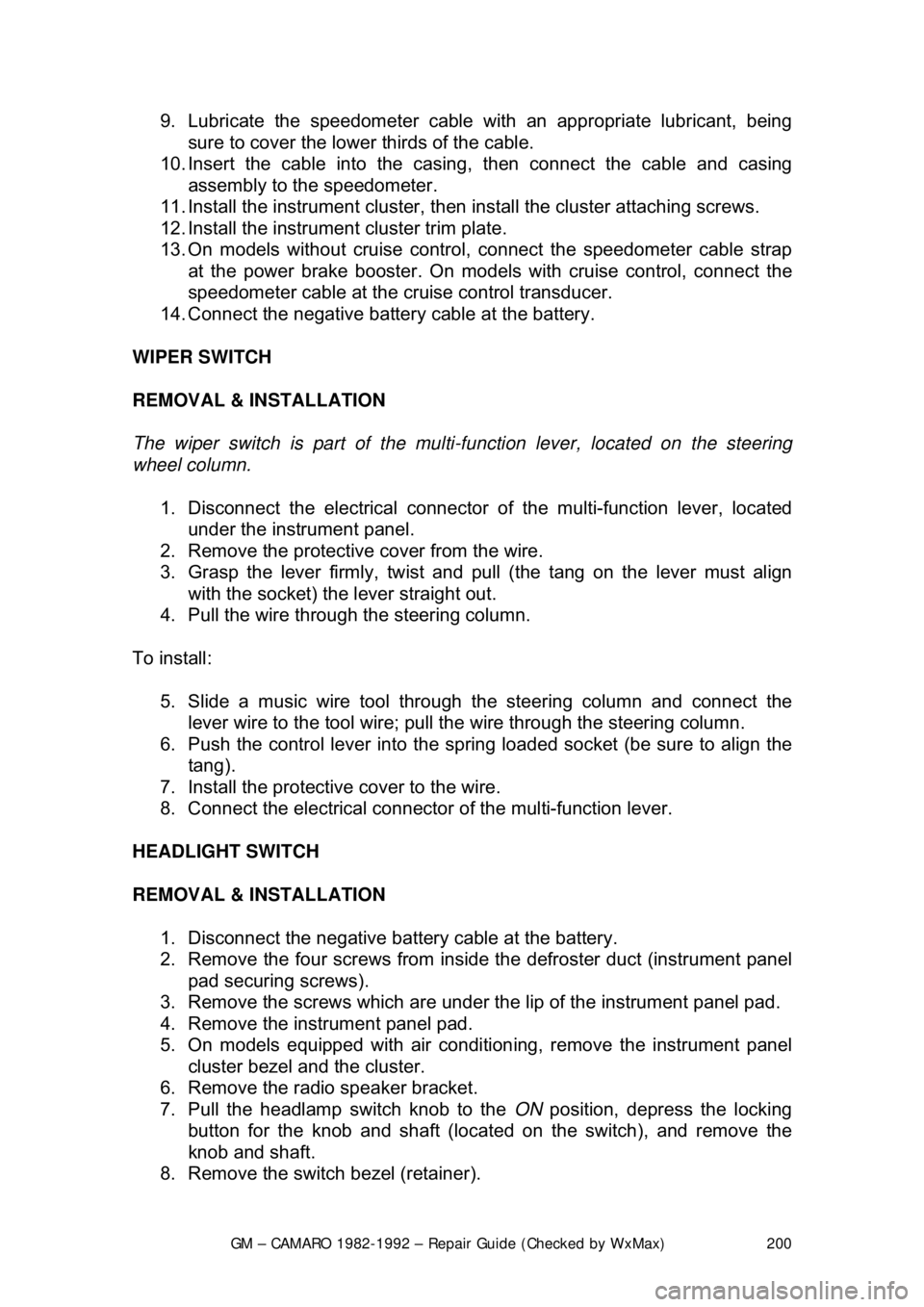

HEADLIGHT SWITCH

REMOVAL & INSTALLATION 1. Disconnect the negative batte ry cable at the battery.

2. Remove the four screws from insi de the defroster duct (instrument panel

pad securing screws).

3. Remove the screws which are under the lip of the instrument panel pad.

4. Remove the instrument panel pad.

5. On models equipped with air condition ing, remove the instrument panel

cluster bezel and the cluster.

6. Remove the radio speaker bracket.

7. Pull the headlamp switch knob to the ON position, depress the locking

button for the knob and shaft (locat ed on the switch), and remove the

knob and shaft.

8. Remove the switch bezel (retainer).

Page 201 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 201

9. Disconnect the wiring from the

switch and remove the switch.

10. To install, position t he switch into place and connect the wiring to the

switch.

11. Install the switch bezel (retainer).

12. Push the headlamp switch knob into the switch. (It may be necessary to

depress the knob release button.

13. Install the radio speaker bracket.

14. On models equipped with air conditioni ng, install the instrument panel

cluster bezel and the cluster.

15. Install the inst rument panel pad.

16. Install the screws which are under t he lip of the instrument panel pad.

17. Install the four screw s from inside the defroster duct (instrument panel

pad securing screws).

18. Connect the negative battery cable at the battery.

Fig. 1: Headlight switch removal

Page 203 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 203

LIGHTING

HEADLIGHTS

REMOVAL & INSTALLATION

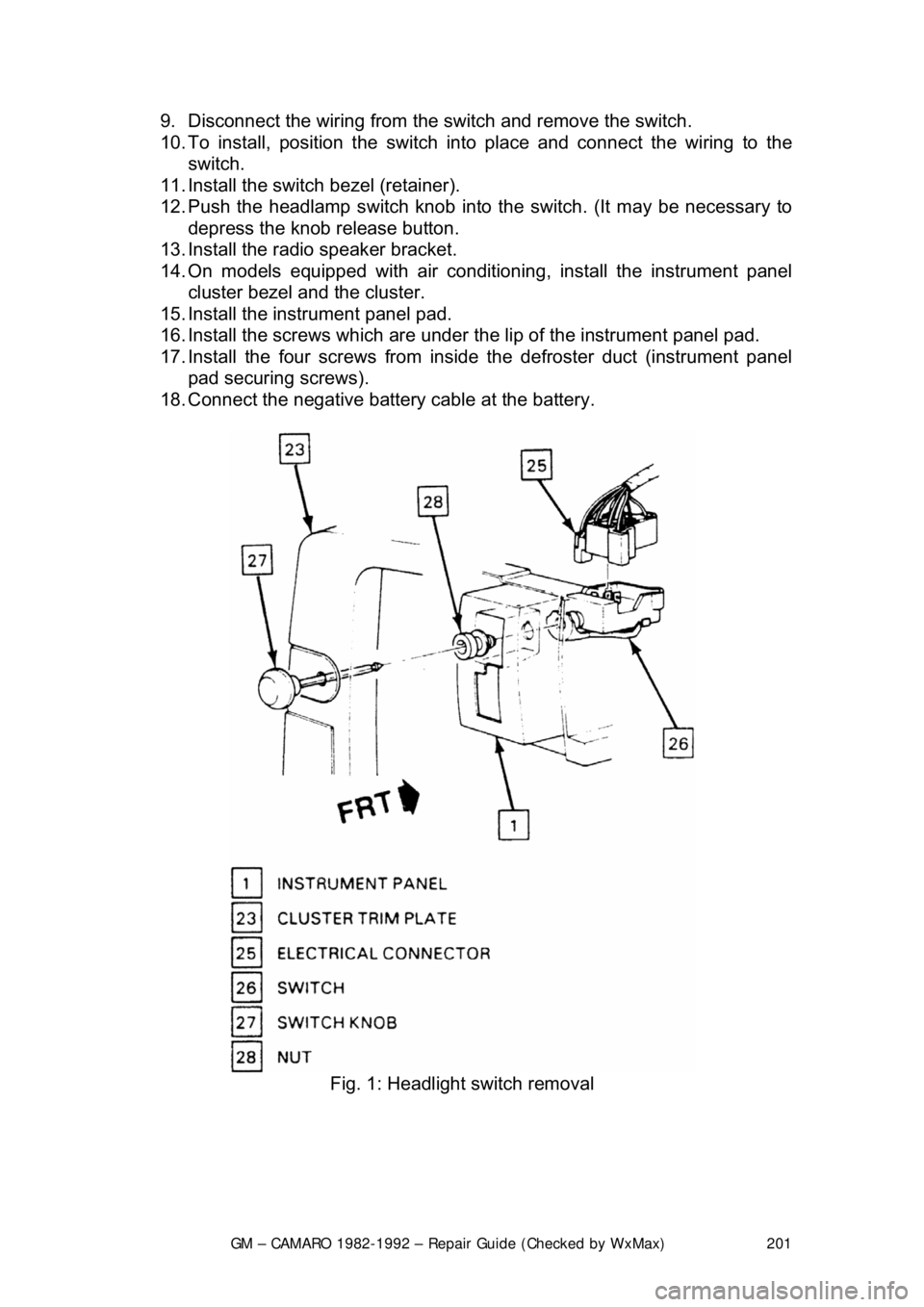

1. Remove headlamp bezel retain ing screws and remove bezel.

2. Disengage spring from the retaini ng ring with a cotter pin removal tool

and remove two attaching screws.

3. Remove retaining ring, disconnect sealed beam unit at wiring connector

and remove the unit.

Fig. 1: Headlight removal - the lowe r bezel mounting screws only need to be

loosened, not removed

Page 204 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 204

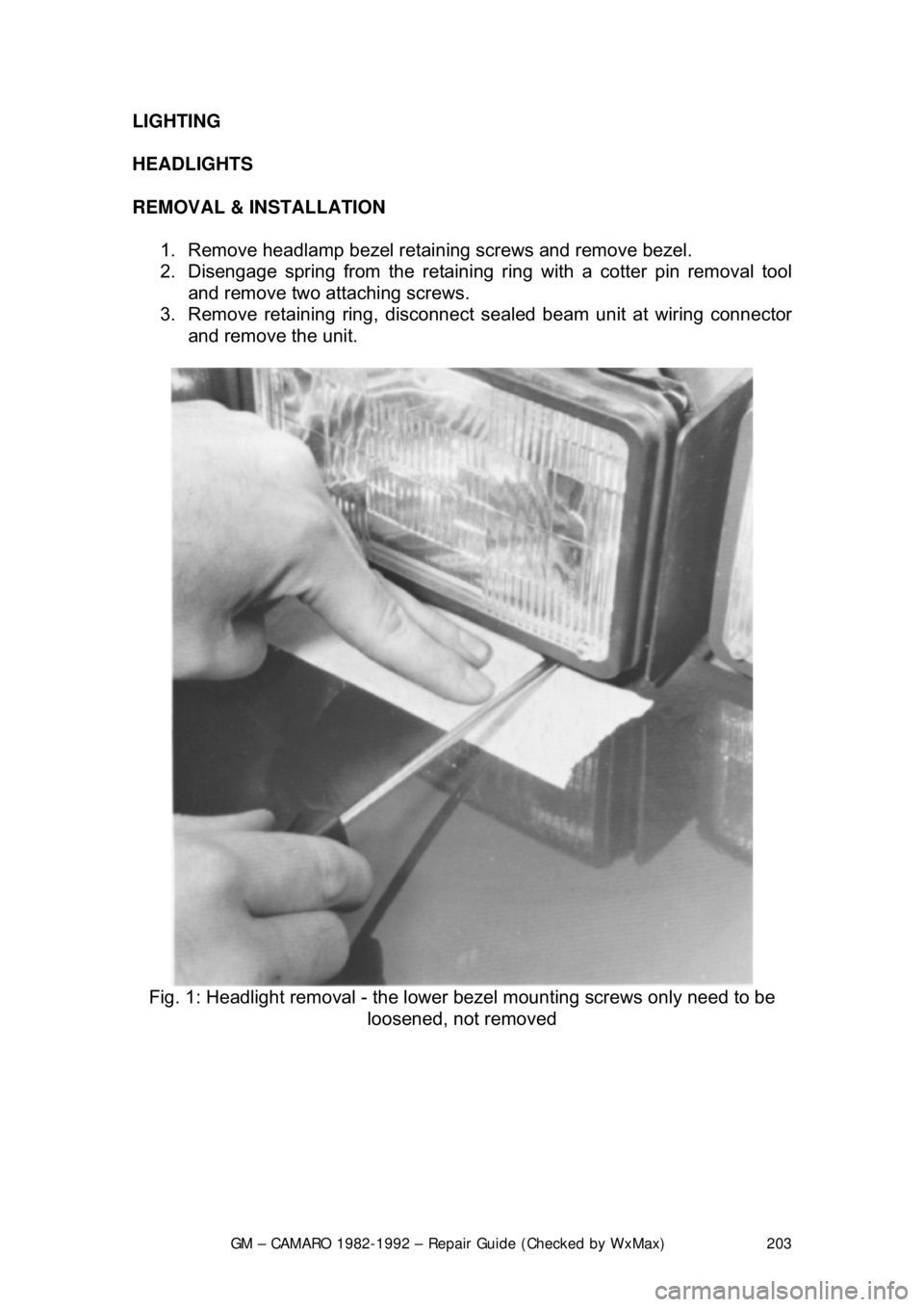

Fig. 2: Remove the upper bezel screws

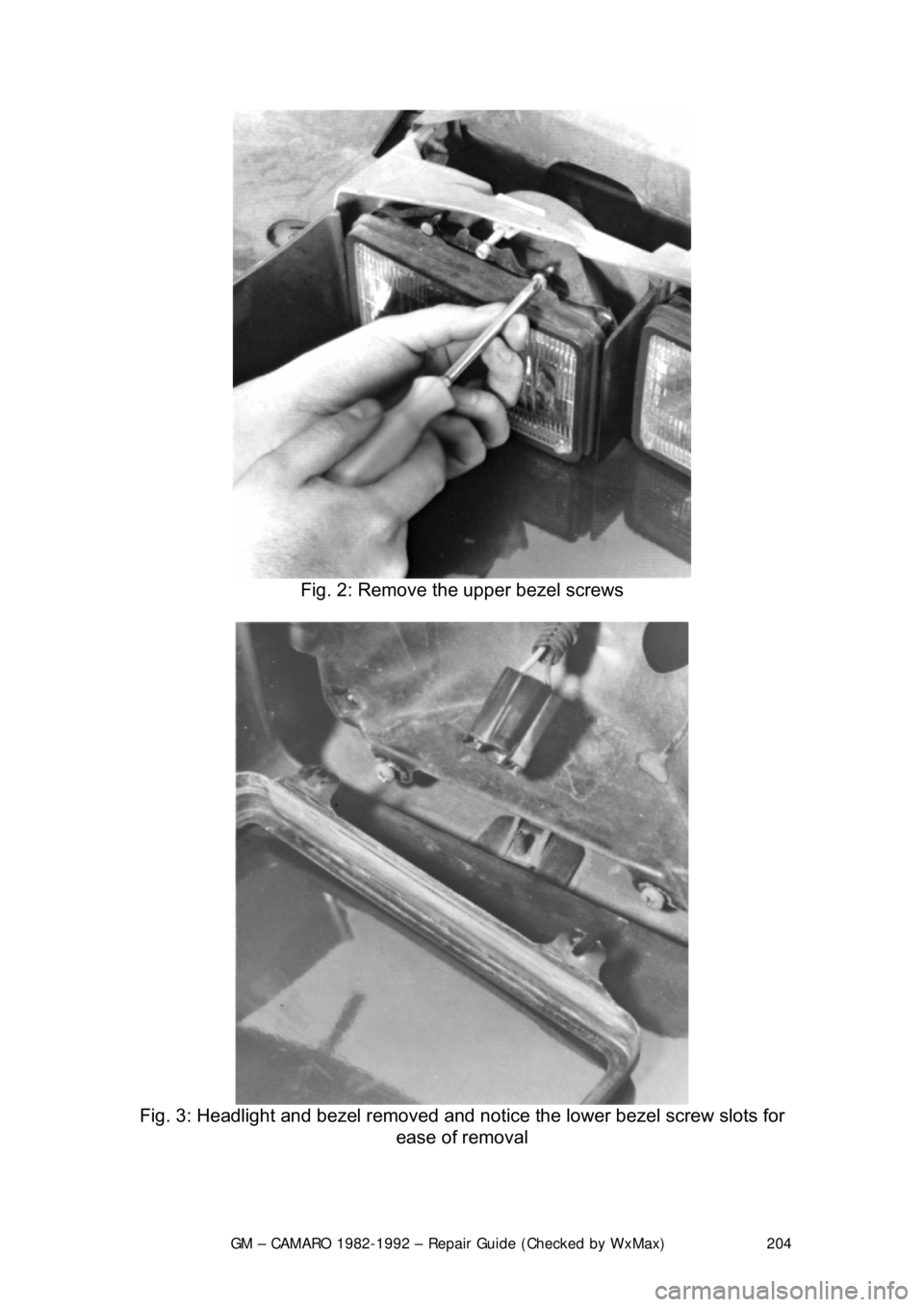

Fig. 3: Headlight and bezel removed and no tice the lower bezel screw slots for

ease of removal

Page 205 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 205

Fig. 4: Plug headlight in and ens ure the headlight is right side up

4. To install, attach the connector to replacement unit and position the unit

in place making sure the number molded in to the lens face is at the top.

In the dual headlamp installation the in board unit (No. 1) takes a double

connector plug, the outboard unit (No. 2) takes a triple connector plug.

5. Position retaining ring into place and install the retaining ring attaching

screws and spring.

6. Check operation of unit and install the headlamp bezel.

AIMING THE HEADLIGHTS

The headlights must be properly aimed to provide the best, safest road

illumination. The lights should be che cked for proper aim and adjusted as

necessary. Certain state and local author ities have requirements for headlight

aiming; these should be check ed before adjustment is made.

CAUTION - About once a year, w hen the headlights are r eplaced or any time

front end work is performed on your vehicl e, the headlight should be accurately

aimed by a reputable repai r shop using the proper equipment. Headlights not

properly aimed can make it virtually impossible to see and may blind other

drivers on the road, possibly causing an accident. Note that the following

procedure is a temporary fix, until you can take your vehicle to a repair shop for

a proper adjustment.

Page 206 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 206

Headlight adjustment may

be temporarily made using a wall, as described

below, or on the rear of another vehicle. When adjust ed, the lights should not

glare in oncoming car or truck windshi elds, nor should they illuminate the

passenger compartment of vehi cles driving in front of you. These adjustments

are rough and should always be fine-t uned by a repair shop which is equipped

with headlight aiming t ools. Improper adjustments may be both dangerous and

illegal.

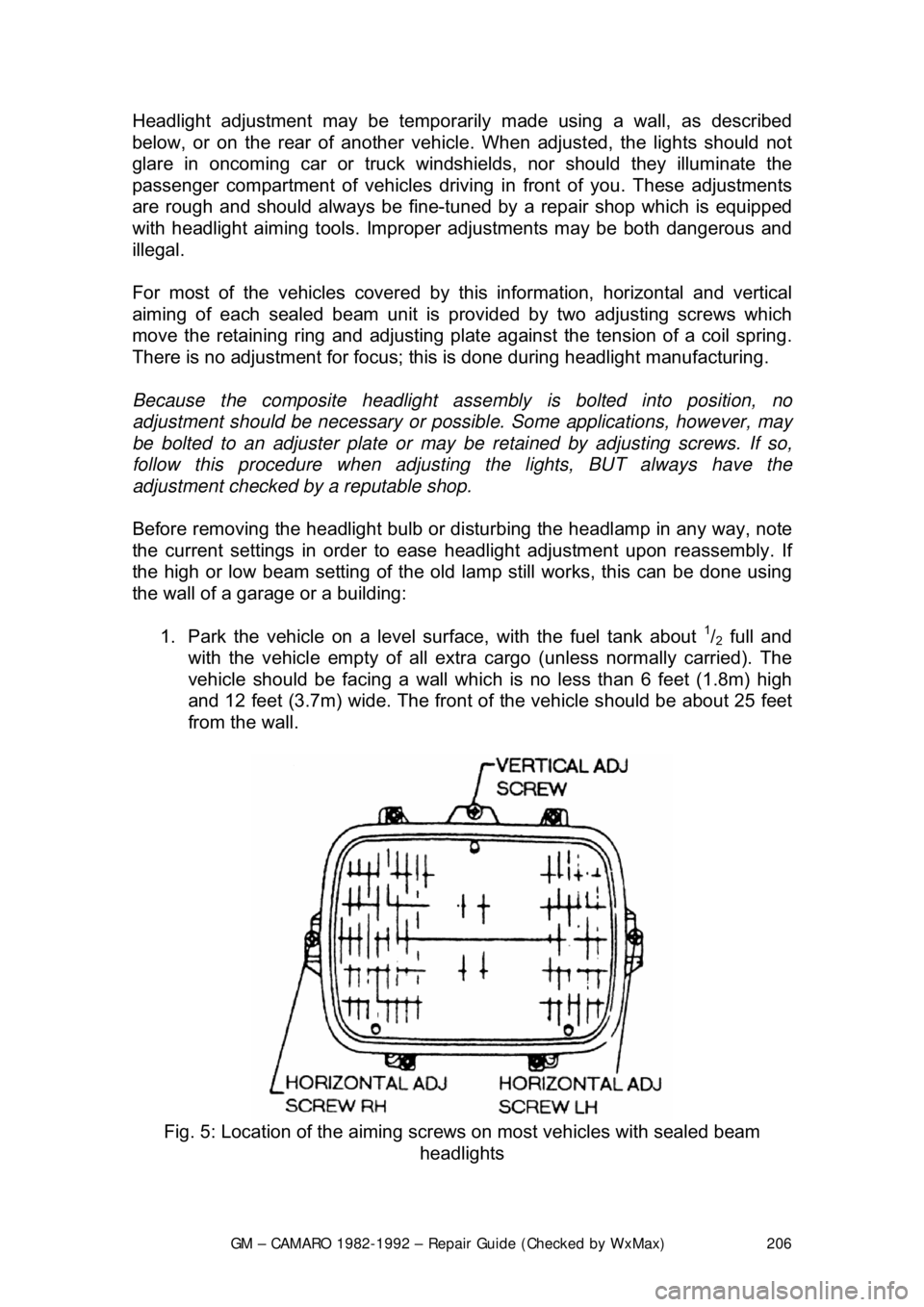

For most of the vehicles covered by th is information, horizontal and vertical

aiming of each sealed beam unit is provided by two adjusting screws which

move the retaining ring and adjusting plat e against the tension of a coil spring.

There is no adjustment for focus; this is done during headlight manufacturing.

Because the composite headlight asse mbly is bolted into position, no

adjustment should be necessary or possibl e. Some applications, however, may

be bolted to an adjuster plate or may be retained by adjusting screws. If so,

follow this procedure when adjusti ng the lights, BUT always have the

adjustment checked by a reputable shop.

Before removing the headlight bulb or di sturbing the headlamp in any way, note

the current settings in order to ease headlight adjustment upon reassembly. If

the high or low beam setting of the old la mp still works, this can be done using

the wall of a garage or a building:

1. Park the vehicle on a level su rface, with the fuel tank about

1/2 full and

with the vehicle empty of all extra cargo (unless normally carried). The

vehicle should be facing a wall whic h is no less than 6 feet (1.8m) high

and 12 feet (3.7m) wide. The front of the vehicle should be about 25 feet

from the wall.

Fig. 5: Location of the aiming screw s on most vehicles with sealed beam

headlights

Page 207 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 207

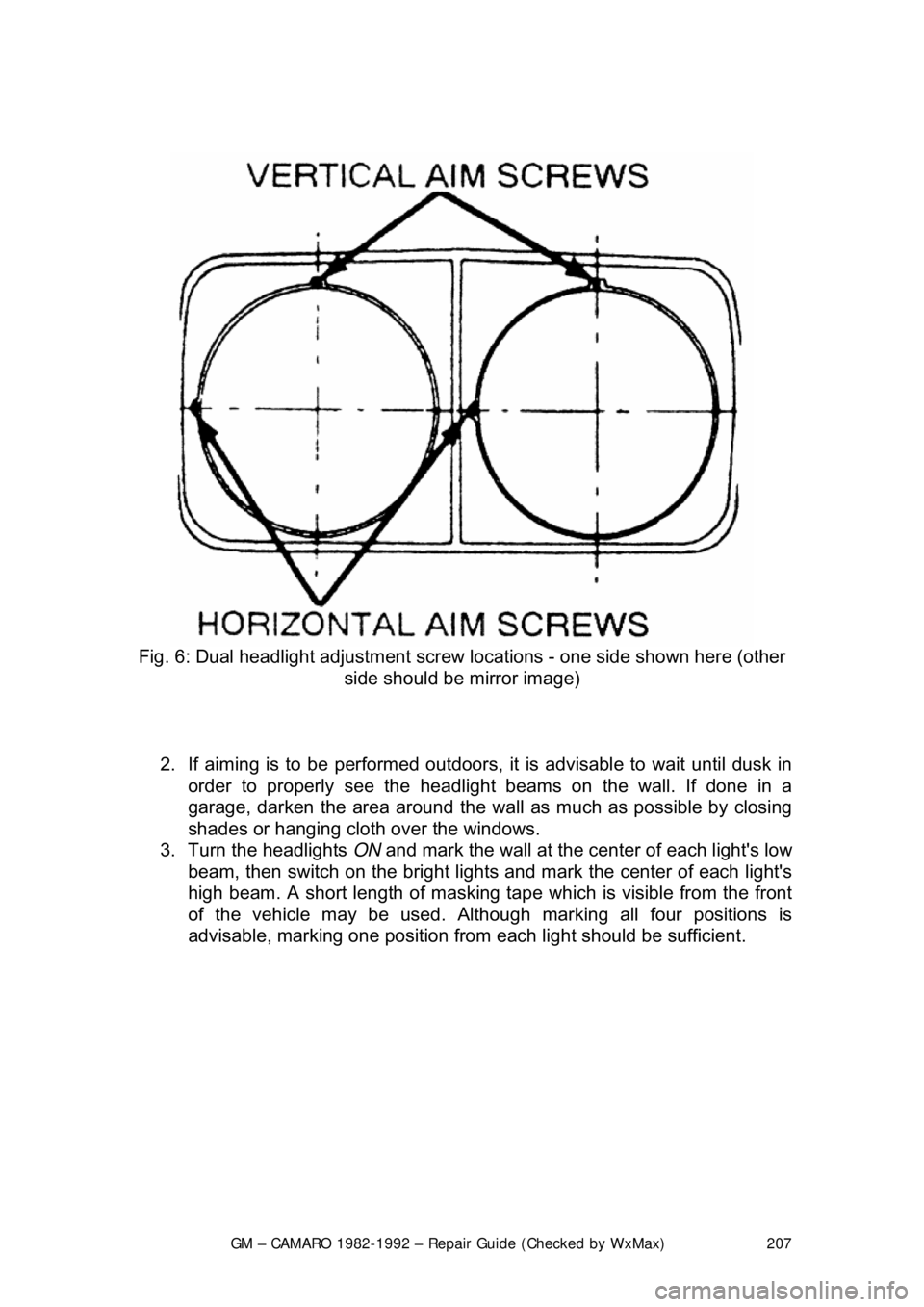

Fig. 6: Dual headlight adjustment screw locations - one side shown here (other

side should be mirror image)

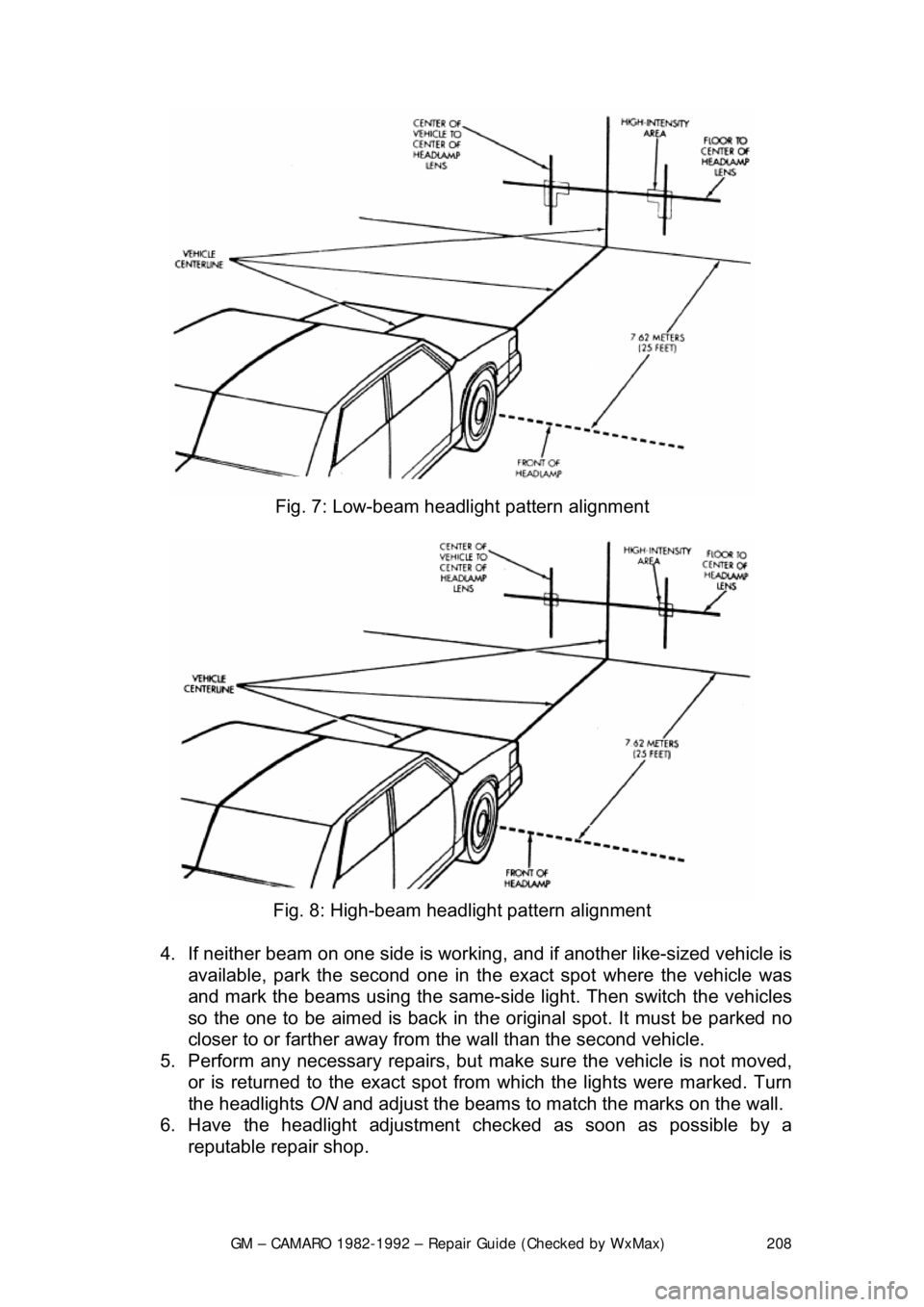

2. If aiming is to be performed outdoors, it is advisable to wait until dusk in

order to properly see t he headlight beams on the wall. If done in a

garage, darken the area around the wall as much as possible by closing

shades or hanging cloth over the windows.

3. Turn the headlights ON and mark the wall at the center of each light's low

beam, then switch on the bright lights and mark the center of each light's

high beam. A short length of masking tape which is visible from the front

of the vehicle may be used. Althoug h marking all four positions is

advisable, marking one position from each light should be sufficient.

Page 208 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 208

Fig. 7: Low-beam headlight pattern alignment

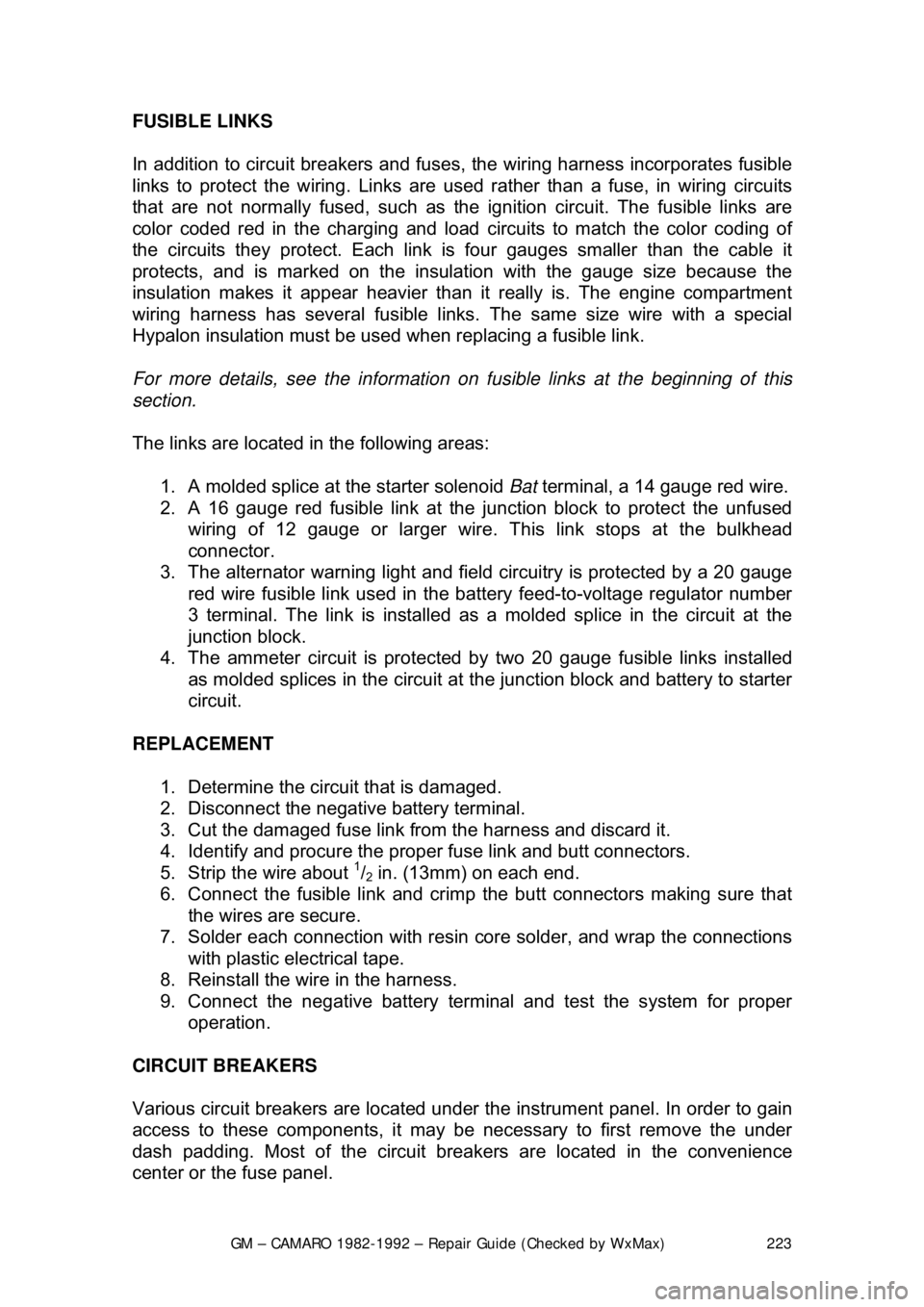

Fig. 8: High-beam headlight pattern alignment

4. If neither beam on one side is working, and if another like-sized vehicle is

available, park the sec ond one in the exact spot where the vehicle was

and mark the beams using the same-si de light. Then switch the vehicles

so the one to be aimed is back in the or iginal spot. It must be parked no

closer to or farther away from the wall than the second vehicle.

5. Perform any necessary repairs, but ma ke sure the vehicle is not moved,

or is returned to the exact spot from which the lights were marked. Turn

the headlights ON and adjust the beams to matc h the marks on the wall.

6. Have the headlight adjustment c hecked as soon as possible by a

reputable repair shop.

Page 223 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 223

FUSIBLE LINKS

In addition to circuit breakers and fuses,

the wiring harness incorporates fusible

links to protect the wiring. Links are used rather than a fuse, in wiring circuits

that are not normally fused, such as th e ignition circuit. The fusible links are

color coded red in the charging and load circuits to match the color coding of

the circuits they protect. Each link is four gauges smaller than the cable it

protects, and is marked on the insulation with the gauge size because the

insulation makes it appear heavier than it really is. The engine compartment

wiring harness has several fusible links. The same size wire with a special

Hypalon insulation must be used w hen replacing a fusible link.

For more details, see the information on fusible links at the beginning of this

section.

The links are located in the following areas:

1. A molded splice at the starter solenoid Bat terminal, a 14 gauge red wire.

2. A 16 gauge red fusible link at the j unction block to protect the unfused

wiring of 12 gauge or larger wire. This link stops at the bulkhead

connector.

3. The alternator warning light and fiel d circuitry is protected by a 20 gauge

red wire fusible link used in the batte ry feed-to-voltage regulator number

3 terminal. The link is installed as a molded splice in the circuit at the

junction block.

4. The ammeter circuit is protected by two 20 gauge fusible links installed

as molded splices in the circuit at t he junction block and battery to starter

circuit.

REPLACEMENT 1. Determine the circuit that is damaged.

2. Disconnect the negative battery terminal.

3. Cut the damaged fuse link from the harness and discard it.

4. Identify and procure the proper fuse link and butt connectors.

5. Strip the wire about

1/2 in. (13mm) on each end.

6. Connect the fusible link and crimp the butt connectors making sure that the wires are secure.

7. Solder each connection with resin core solder, and wrap the connections

with plastic electrical tape.

8. Reinstall the wir e in the harness.

9. Connect the negative battery terminal and test the system for proper

operation.

CIRCUIT BREAKERS

Various circuit breakers are located under the instrument panel. In order to gain

access to these components, it may be ne cessary to first remove the under

dash padding. Most of the circuit breakers are located in the convenience

center or the fuse panel.

Page 287 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 287

DRIVE TRAIN

MANUAL TRANSMISSION

UNDERSTANDING THE MANUAL TRANSMISSION

Because of the way an internal combus tion engine breathes, it can produce

torque (or twisting force) only withi n a narrow speed range. Most overhead

valve pushrod engines must turn at about 2500 rpm to produce their peak

torque. Often by 4500 rpm, they are prod ucing so little torque that continued

increases in engine speed produce no power increases.

The torque peak on overhead camshaft engines is, generally, much higher, but

much narrower.

The manual transmission and clutch are employed to vary the relationship

between engine RPM and the speed of the w heels so that adequate power can

be produced under all circumst ances. The clutch allows engine torque to be

applied to the transmission input shaft gradually, due to mechanical slippage.

The vehicle can, consequently, be star ted smoothly from a full stop.

The transmission changes the ratio between the rotating speeds of the engine

and the wheels by the use of gears. 4-speed or 5-speed transmissions are most

common. The lower gears al low full engine power to be applied to the rear

wheels during acceleration at low speeds.

The clutch driveplate is a thin disc, the center of which is splined to the

transmission input shaft. Both sides of the disc are covered with a layer of

material which is similar to brake li ning and which is capable of allowing

slippage without roughness or excessive noise.

The clutch cover is bolted to the engine flywheel and incorporates a diaphragm

spring which provides the pressure to engage the clutch. The cover also houses

the pressure plate. When the clutch pe dal is released, the driven disc is

sandwiched between the pressu re plate and the smooth surface of the flywheel,

thus forcing the disc to turn at th e same speed as the engine crankshaft.

The transmission contains a mainshaft which passes all the way through the

transmission, from the clutch to the dr iveshaft. This shaft is separated at one

point, so that front and rear portions can turn at different speeds.

Power is transmitted by a countershaft in the lower gears and reverse. The

gears of the countershaft mesh with gear s on the mainshaft, allowing power to

be carried from one to the other. Countershaft gears are often integral with that

shaft, while several of the mainshaft gea rs can either rotate independently of

the shaft or be locked to it. Shifting from one gear to the next causes one of the

gears to be freed from rotating with the shaft and locks another to it. Gears are

locked and unlocked by internal dog clutc hes which slide between the center of

the gear and the shaft. The forward gears us ually employ synchronizers; friction