warning CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 577 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 577

MALFUNCTION INDICATOR LAMP

The primary function of the MIL is to adv

ise the operator and the technician that

a fault is detected, and, in most cases, a code is stored. Under normal

conditions, the malfunction indicator la mp will illuminate when the ignition is

turned ON. Once the engine is started and running, the ECM will perform a

system check and extinguish the lamp if no fault is found.

Additionally, the lamp can be used to retrieve stored codes after the system is

placed in the Diagnostic Mode. Codes ar e transmitted as a series of flashes

with short or long pauses. When the syst em is placed in the Field Service

Mode, the dash lamp will indicate open loop or closed loop function to the

technician.

INTERMITTENTS

If a fault occurs intermittently, such as a loose connector pin breaking contact

as the vehicle hits a bump, the ECM will note the fault as it occurs and energize

the dash warning lamp. If the problem se lf-corrects, as with the terminal pin

again making contact, the dash lamp will extinguish after 10 seconds but\

a code

will remain stored in the ECM memory.

When an unexpected code appe ars during diagnostics, it may have been set

during an intermittent failure that self-c orrected; the codes are still useful in

diagnosis and should not be discounted.

OXYGEN SENSOR

OPERATION

An oxygen sensor is used on all models. The sensor protrudes into the exhaust

stream and monitors the oxygen content of the exhaust gases. The difference

between the oxygen content of the exhaust gases and that of the outside air

generates a voltage si gnal to the ECM. The ECM monitors this voltage and,

depending upon the value of the signal rece ived, issues a command to adjust

for a rich or a lean condition.

No attempt should ever be made to meas ure the voltage output of the sensor.

The current drain of any conventional vo ltmeter would be such that it would

permanently damage the sensor.

Page 594 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 594

REMOVAL & INSTALLATION

1. Disconnect the negative battery cable.

2. Raise and safely support the vehicle.

3. Disconnect the VSS electrical wiring.

4. Remove the retaining bolt.

5. Have a clean container to catch the transmission fluid and remove the

VSS.

6. Remove and discard the O-ring.

To install: 7. Lubricate a new O-ring with a thin f ilm of transmission fluid. Install the O-

ring and VSS.

8. Install the retaining bolt.

9. Connect the electrical wiring.

10. Lower the vehicle.

11. Connect the negative battery cable.

12. Refill transmission to proper level.

TROUBLE CODES

SELF DIAGNOSTICS

READING CODES

The following procedure applies to mode ls with the 12 pin diagnostic connector

only.

1. Turn the ignition switch OFF. Locate the Assembly Line Diagnostic Link

(ALDL), usually under the instrument panel. It may be within a plastic

cover or housing labeled DIAGNOSTIC CONNECTOR. This link is used

to communicate with the ECM.

2. Use a small jumper wire to connect Terminal B of the ALDL to Terminal

A. As the ALDL connector is viewed from the front, Terminal A is on the

extreme right of the upper row; Terminal B is second from the right on

the upper row.

3. After the terminals are connected, turn the ignition switch to the ON

position but do not start the engine. T he dash warning lamp should begin

to flash Code 12. The code will disp lay as one flash, a pause and two

flashes. Code 12 is not a fault code. It is used as a system

acknowledgment or handshake code; its presence indicates that the

ECM can communicate as requested. Code 12 is used to begin every

diagnostic sequence.

4. After Code 12 has been transmitted 3 times, the fault codes, if any, will

each be flashed in the same manner th ree times. The codes are stored

and transmitted in numeric order from lowest to highest.

The order of codes in the memory does not indicate the order of occurrence.

Page 629 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 629

as much voltage to fire the plug at hi

gh speeds than at idle. The improved

air/fuel ratio control of modern fuel injection combin ed with the higher voltage

output of modern ignition systems will often allow an engine to run significantly

longer on a set of standard spark plugs, but keep in mind that efficiency will

drop as the gap widens (along wit h fuel economy and power).

When you're removing spark plugs, work on one at a time. Don't start by

removing the plug wires all at once, because, unless you number them, they

may become mixed up. Take a minute before you begin and number the wires

with tape.

1. Disconnect the negative battery cabl e, and if the vehicle has been run

recently, allow the engine to thoroughly cool.

2. Carefully twist the spark plug wire boot to loosen it, then pull upward and

remove the boot from the plug. Be su re to pull on the boot and not on the

wire, otherwise the connector locat ed inside the boot may become

separated.

3. Using compressed air, blow any water or debris from the spark plug well

to assure that no harmful contam inants are allowed to enter the

combustion chamber when the spark plug is removed. If compressed air

is not available, use a rag or a brush to clean the area.

Remove the spark plugs when the engine is cold, if possible, to prevent damage

to the threads. If removal of the plugs is difficult, apply a few drops of

penetrating oil or silicone spray to t he area around the base of the plug, and

allow it a few minutes to work.

4. Using a spark plug socket that is equipped with a rubber insert to

properly hold the plug, turn the spar k plug counterclockwise to loosen

and remove the spark pl ug from the bore.

WARNING - Be sure not to use a flexible extension on the socket. Use of a

flexible extension may allow a shear fo rce to be applied to the plug. A shear

force could break the plug off in the cylinder head, leading to costly a\

nd

frustrating repairs.

To install:

5. Inspect the spark plug boot for t ears or damage. If a damaged boot is

found, the spark plug wire must be replaced.

6. Using a wire feeler gauge, check and adjust the spark plug gap. When

using a gauge, the proper size shoul d pass between the electrodes with

a slight drag. The next larger size should not be able to pass while the\

next smaller size should pass freely.

7. Carefully thread the plug into the bor e by hand. If resistance is felt before

the plug is almost completely th readed, back the plug out and begin

threading again. In small, hard to r each areas, an old spark plug wire and

boot could be used as a th reading tool. The boot will hold the plug while

you twist the end of the wire and t he wire is supple enough to twist

before it would allow t he plug to crossthread.

Page 630 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 630

WARNING

- Do not use the spark plug socke t to thread the plugs. Always

carefully thread the plug by hand or us ing an old plug wire to prevent the

possibility of crossthreading and damaging the cylinder head bore.

8. Carefully tighten the spark plug. If the plug you are installing is equipped

with a crush washer, seat the plug, then tighten about

1/4 turn to crush

the washer. If you are installing a t apered seat plug, tighten the plug to

specifications provided by the vehicle or plug manufacturer.

9. Apply a small amount of silicone di electric compound to the end of the

spark plug lead or inside the spark pl ug boot to prevent sticking, then

install the boot to the spark plug and pus h until it clicks into place. The

click may be felt or hear d, then gently pull back on the boot to assure

proper contact.

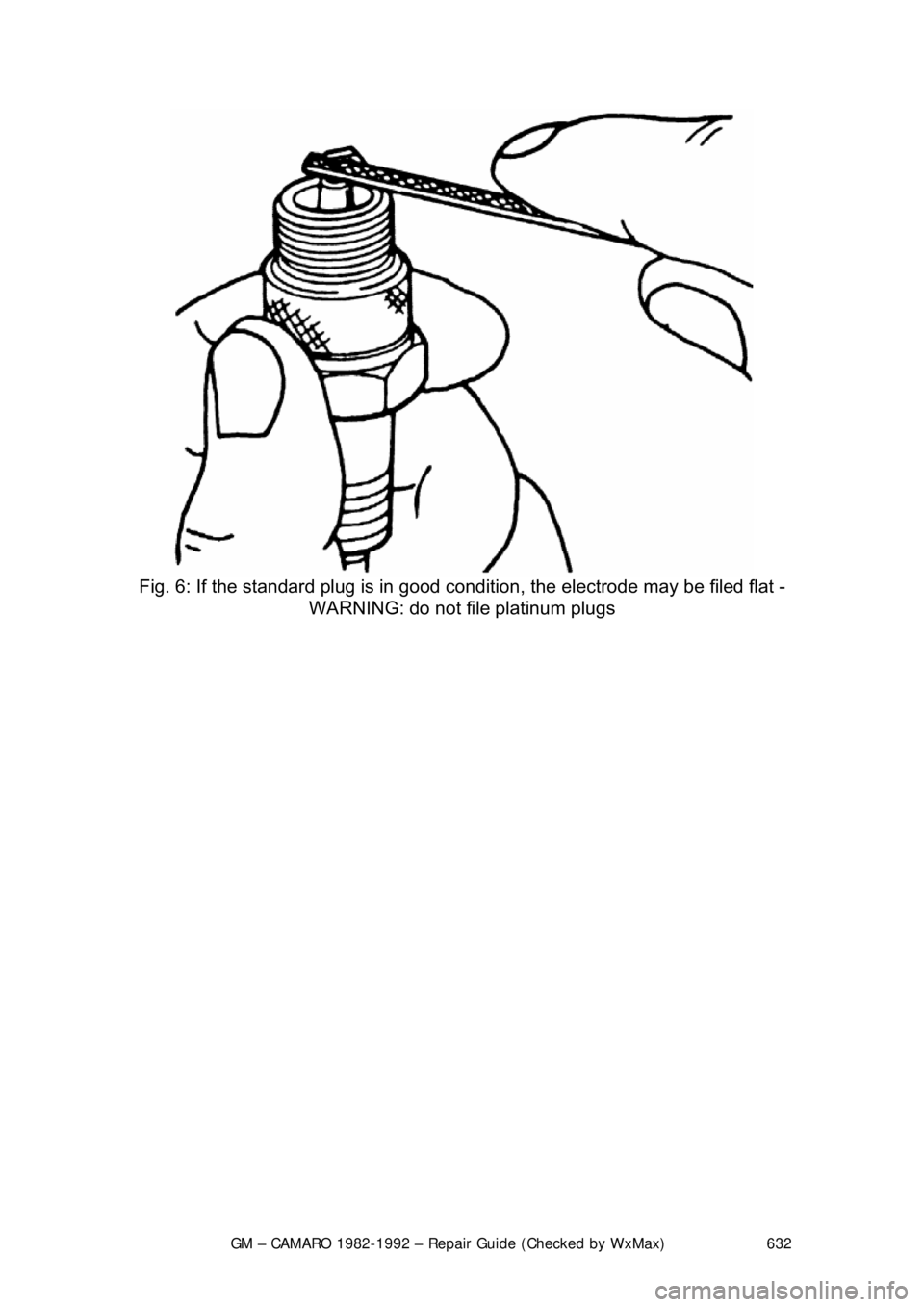

INSPECTION & GAPPING

Check the plugs for deposits and wear. If they are not going to be replaced,

clean the plugs thoroughly. Remember t hat any kind of deposit will decrease

the efficiency of the plug. Plugs can be cleaned on a spark plug cleaning

machine, which can sometimes be found in service stations, or you can do an

acceptable job of cleaning with a stiff br ush. If the plugs are cleaned, the

electrodes must be filed flat. Use an igni tion points file, not an emery board or

the like, which will leave deposits. The electrodes must be filed perfectly flat

with sharp edges; rounded edges reduce the s park plug voltage by as much as

50%.

Check spark plug gap before installati on. The ground electrode (the L-shaped

one connected to the body of the plug) mu st be parallel to the center electrode

and the specified size wire gauge (please refer to the Tune-Up Specifications

chart for details) must pass between t he electrodes with a slight drag.

NEVER adjust the gap on a used platinum type spark plug .

Always check the gap on new plugs as they are not always set correctly a\

t the

factory. Do not use a flat feeler g auge when measuring the gap on a used plug,

because the reading may be inaccurate. A round-wire type gapping tool is the

best way to check the gap. The co rrect gauge should pass through the

electrode gap with a slight drag. If you're in doubt, try one size smaller and one

larger. The smaller gauge should go through easily, while the larger one\

shouldn't go through at all. Wire gapping tools usually have a bending tool

attached. Use that to adjust the side electrode until the proper distance is

obtained. Absolutely never attempt to bend the center electrode. Also, be

careful not to bend the side electrode too fa r or too often as it may weaken and

break off within the engine, requiring remova l of the cylinder head to retrieve it.

Page 632 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 632

Fig. 6: If the standard plug is in good c ondition, the electrode may be filed flat -

WARNING: do not file platinum plugs

Page 655 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 655

2. Clean off the marks and coat them wit

h white paint or chalk, if necessary,

so that they may be seen.

3. Run the engine until it reaches no rmal operating temperature, then shut

off the engine.

4. With the ignition OFF, connect a ta chometer to the distributor, and a

timing light with an inductive pickup lead to the No. 1 spark plug wire.

WARNING - Never pierce a secondary ignition wire in order to connect a timing

light. A pierced wire may lead to engine misfiring and driveability problems.

5. To properly set the ignition timing , the EST must be placed in the bypass

mode. a. On the 2.5L engine, refer to t he emission control label for the

procedure.

If the label is missing or unreadable, c ontact your Chevrolet dealer for a

replacement.

b. On 2.8L and 5.0L ca rbureted engines, disconnect the 4-wire EST

connector at the distributor. (Fault code 42 may be set in ECM memory,

and must be cleared once the procedur e is completed). Proceed to Step

7.

c. On 2.8L, 5.0L and 5.7L fuel inje cted engines, with the engine RUNNING

and all accessories off, use a jumper wire to connect diagnostic terminal

B and ground terminal A of the 12-terminal Assembly Line Diagnostic

Link (ALDL) usually located under t he left side of the instrument panel.

DO NOT disconnect the 4-wir e EST connector at the distributor. Aim the

timing light at the timing mark; the li ne on the balancer or pulley will line

up with the timing mark. Increase engine speed and check for timing

advance. If the timing still advances with engine speed, perform Step 6. If

timing does not advance with engi ne speed, proceed to Step 7.

If timing advances with engine speed, it will be necessary to disconnect the

single-wire Set Timing connector. (Faul t code 42 may be set in ECM memory,

and must be cleared once the procedure is completed).

6. Remove the jumper wire from t he ALDL, and shut off the ignition.

Disconnect the Set Timing connector, usually located under the plastic

cover above the heater unit, in the engi ne compartment. (The wire in this

connector is normally Tan/Black.)

7. With the engine running and all accessories off, aim the light at the timing

mark. The line on the balancer or pulle y will line up with the timing mark.

If a change in timing is necessary, loosen the hold-down clamp bolt at

the base of the distributor . While observing the timing mark, rotate the

distributor slightly unt il the line indicates the correct timing. Use the

timing specification on the emi ssion control label in the engine

compartment. If this label is missi ng or damaged, refer to the Tune-Up

Specifications chart in this Section.

Page 656 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 656

8. Once the timing is set to specific

ation, tighten the distributor hold-down

clamp. Recheck the timing to make su re it did not change while the bolt

was being tightened.

9. Remove the jumper wire from the ALDL connector, if applicable, with the

engine still running. (Usually, if this is performed before the engine is

shut off, no trouble codes will be stored.)

10. Turn the engine OFF, then remove the timing light and tachometer.

Reconnect the number 1 spark plug wire, if disconnected.

11. Attach the 4-wire EST connector at the distributor, or reconnect the Set

Timing connector, if applicable.

12. Check for fault code 42, and clear, if necessary, by disconnecting the

negative battery cable for at least 30 seconds.

To prevent ECM damage, the key must be in the OFF position when

disconnecting or reconnecting battery cables.

1988-90 VEHICLES

When adjusting the timing, refer to the instructions on the emission control

sticker inside the engine compartment. If th e instructions on the label disagree

with the procedure listed below, follo w the instructions on the label.

1. Locate the timing marks on the cran kshaft pulley and the front of the

engine.

2. Clean off the marks and coat them with white paint or chalk, so that they

may be easily seen.

3. Run the engine until it reaches no rmal operating temperature, then shut

off the engine.

4. With the ignition OFF, connect a ta chometer to the distributor, and a

timing light with an inductive pickup lead to the No. 1 spark plug wire.

WARNING - Never pierce a secondary ignition wire in order to connect a timing

light. A pierced wire may lead to engine misfiring and driveability problems.

5. Start the engine. With the engine running and all accessories off, use a

jumper wire to connect diagnostic terminal B and ground terminal A of

the 12-terminal Assembly Line Diagnostic Link (ALDL), located under the

instrument panel.

If jumping the ALDL terminals does not prevent timing advance, the EST

bypass wire will have to be disconnected instead.

6. Aim the timing light at the timing mark. The line on the balancer or pulley

will line up with the timing mark. If a change in timing is necessary,

loosen the hold-down clamp bolt at t he base of the distributor. While

observing the timing mark, rotate the distributor slightly until the line

indicates the correct timing. Use t he timing specification on the emission

control label in the engine compartm ent. If this label is missing or

damaged, refer to the Tune- Up Specifications chart in this Section.

Page 658 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 658

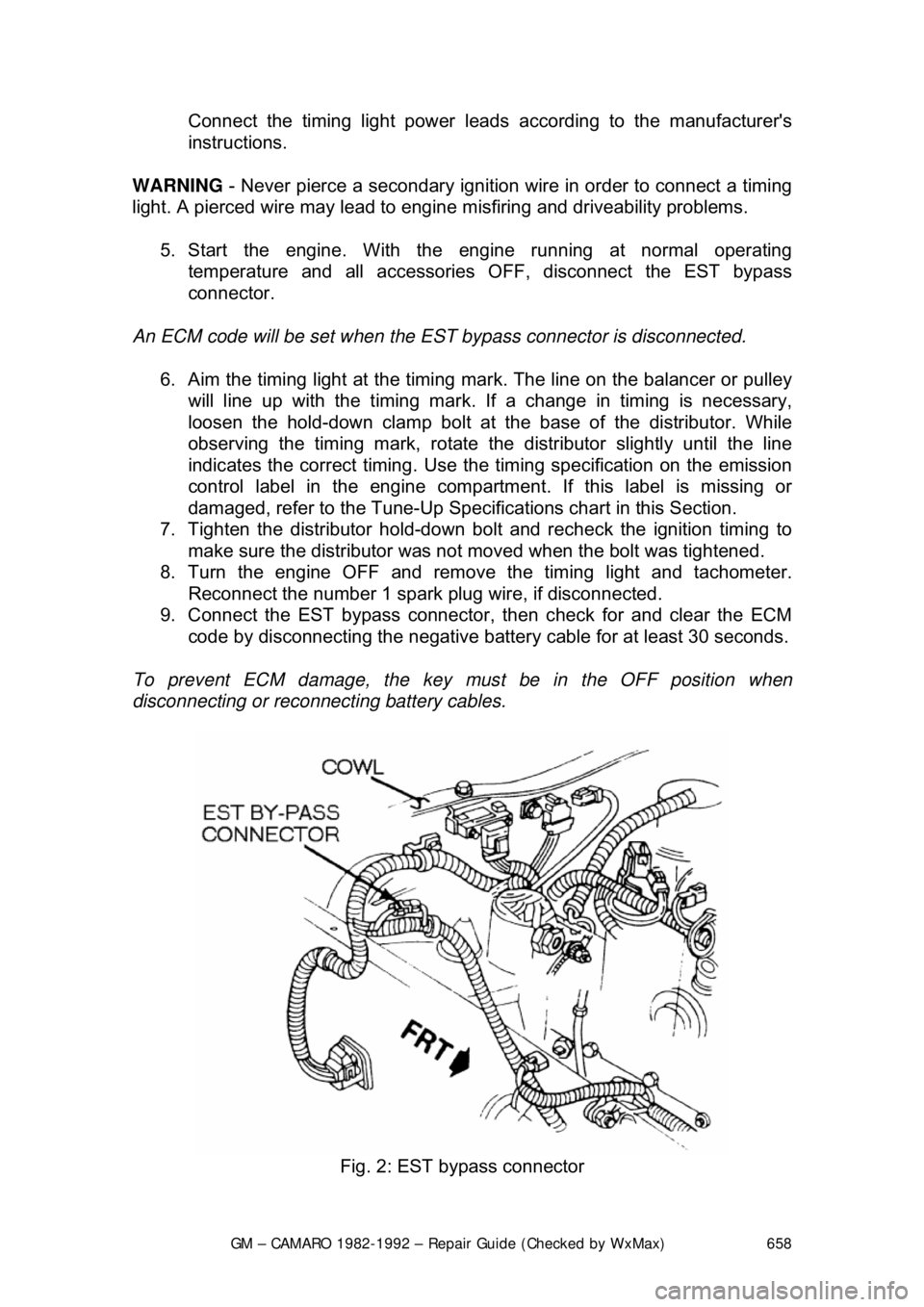

Connect the timing light power leads

according to the manufacturer's

instructions.

WARNING - Never pierce a secondary ignition wire in order to connect a timing

light. A pierced wire may lead to engine misfiring and driveability problems.

5. Start the engine. With the engine running at normal operating

temperature and all accessories OFF, disconnect the EST bypass

connector.

An ECM code will be set when the EST bypass connector is disconnected.

6. Aim the timing light at the timing mark. The line on the balancer or pulley

will line up with the timing mark. If a change in timing is necessary,

loosen the hold-down clamp bolt at t he base of the distributor. While

observing the timing mark, rotate the distributor slightly until the line

indicates the correct timing. Use t he timing specification on the emission

control label in the engine compartm ent. If this label is missing or

damaged, refer to the Tune- Up Specifications chart in this Section.

7. Tighten the distributor hold-down bolt and recheck the ignition timing to

make sure the distributor was not moved when the bolt was tightened.

8. Turn the engine OFF and remove the timing light and tachometer.

Reconnect the number 1 spark plug wire, if disconnected.

9. Connect the EST bypass connector , then check for and clear the ECM

code by disconnecting the negative battery cable for at least 30 seconds.

To prevent ECM damage, the key must be in the OFF position when

disconnecting or reconnecting battery cables.

Fig. 2: EST bypass connector

Page 716 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 716

INJECTOR REPLACEMENT

Use care in removing injectors to prev

ent damage to the electrical connector

pins on top of the injector, the fuel injector fuel filter and nozzle. The fuel injector

is serviced as a complete assembly on ly and should never be immersed in any

type of cleaner.

SINGLE INJECTOR UNITS 1. Relieve the fuel system pressure.

2. Remove the air cleaner.

3. Detach the injector connector by squeezing the two tabs together and

pulling straight up.

4. Remove the screws securing the fuel meter cover. Note the location of

any short screws for correct placement during reassembly.

CAUTION - DO NOT remove the four screws se curing the pressure regulator to

the fuel meter cover. The fuel pressure regulator includes a large spring under

heavy tension which could cause personal injury if released.

5. With the old fuel meter gasket in place to prevent damage to the casting,

use a prytool and fulcrum to pry the inje ctor carefully until it is free from

the fuel meter body.

6. Remove the injector.

7. Remove the large O-ring and steel back-up washer at the top of the

injector cavity in the fuel meter body.

8. Remove the small O-ring located at the bottom of the injector cavity.

To Install: 9. Lubricate the new, small O-ring with automatic transmission fluid; then,

push the new O-ring on the nozzle end of the injector up against the

injector fuel filter.

10. Install the steel backup washer in the recess of the fuel meter body.

Lubricate the new large O-ring with automatic transmission fluid, then

install the O-ring directly above t he backup washer, pressing the O-ring

down into the cavity recess. The O-ri ng is properly installed when it is

flush with the casting surface.

WARNING - Do not attempt to reverse this procedure and install the backup

washer and O-ring after the injector is located in the cavity. To do so will

prevent proper seating of the O-ring in th e cavity recess which could result in a

fuel leak and possible fire.

11. Install the injector by using a pushing/twisting mo tion to center the nozzle

O-ring in the bottom of the injector cavity and aligning the raised lug on

the injector base with the notch cast into the fuel meter body. Push down

on the injector making sure it is fully seated in the cavity. Injector

installation is correct when the lug is seated in the notch and the

electrical terminals are parallel to the throttle shaft.

Page 719 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 719

11. Lubricate the new large O-ring with cl

ean engine oil and install it directly

over the backup washer. Be sure t he O-ring is seated properly and is

flush with the top of the fuel meter body surface.

12. Lubricate the new small O-ring with clean engine oil and install it on the

nozzle end of the injector. Push t he O-ring on far enough to contact the

filter.

WARNING - Do not attempt to reverse this procedure and install the backup

washer and O-ring after the injector is located in the cavity. To do so will

prevent proper seating of the O-ring in th e cavity recess which could result in a

fuel leak and possible fire.

13. Install the injector by aligning the raised lug on the injector base with the

notch cast into the fuel meter body . Push down on the injector making

sure it is fully seated in the cavity. In jector installation is correct when the

lug is seated in the notch and the electrical terminals are parallel to the

throttle shaft.

14. Using new gaskets on the fuel mete r cover and a new dust seal, install

the cover to the fuel meter body. Use an appropriate thread locking

compound on the cover attaching screws.

15. Connect the injector electrical c onnector by pushing straight down until

seated firmly in place.

16. Connect the negative battery cable.

17. With the engine OFF and the igniti on ON, check for fuel leaks.

18. Install the air cleaner.

ADJUSTMENTS

MINIMUM IDLE SPEED

Minimum idle speed should only be adjus ted when installing a replacement

throttle body. The idle stop screw is used to regulate the minimum idle speed of

the engine. The throttle body is adjusted at the factory, then covered with a cap

or plug to discourage unnecessary readjustment.

2.5L ENGINES 1. Remove the air cleaner and pl ug the THERMAC vacuum port.

2. Disconnect the TV cable from the th rottle control bracket to allow access

to the idle adjustment screw.

3. Remove the throttle stop screw plug or cap.

4. Connect a tachometer to the engine.

5. Disconnect the Idle Air Control (IAC) valve connector.

6. Start the engine with the transmi ssion in PARK (auto transmission) or

NEUTRAL (manual transmission) and allow the engine speed to

stabilize. All accessories (A/C, rear defogger, etc.) should be OFF.

7. Install tool J-33047 in t he idle air passage of the throttle body. Be certain

that the tool seats fully in t he passage and no air leaks exist.