check engine CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 749 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 749

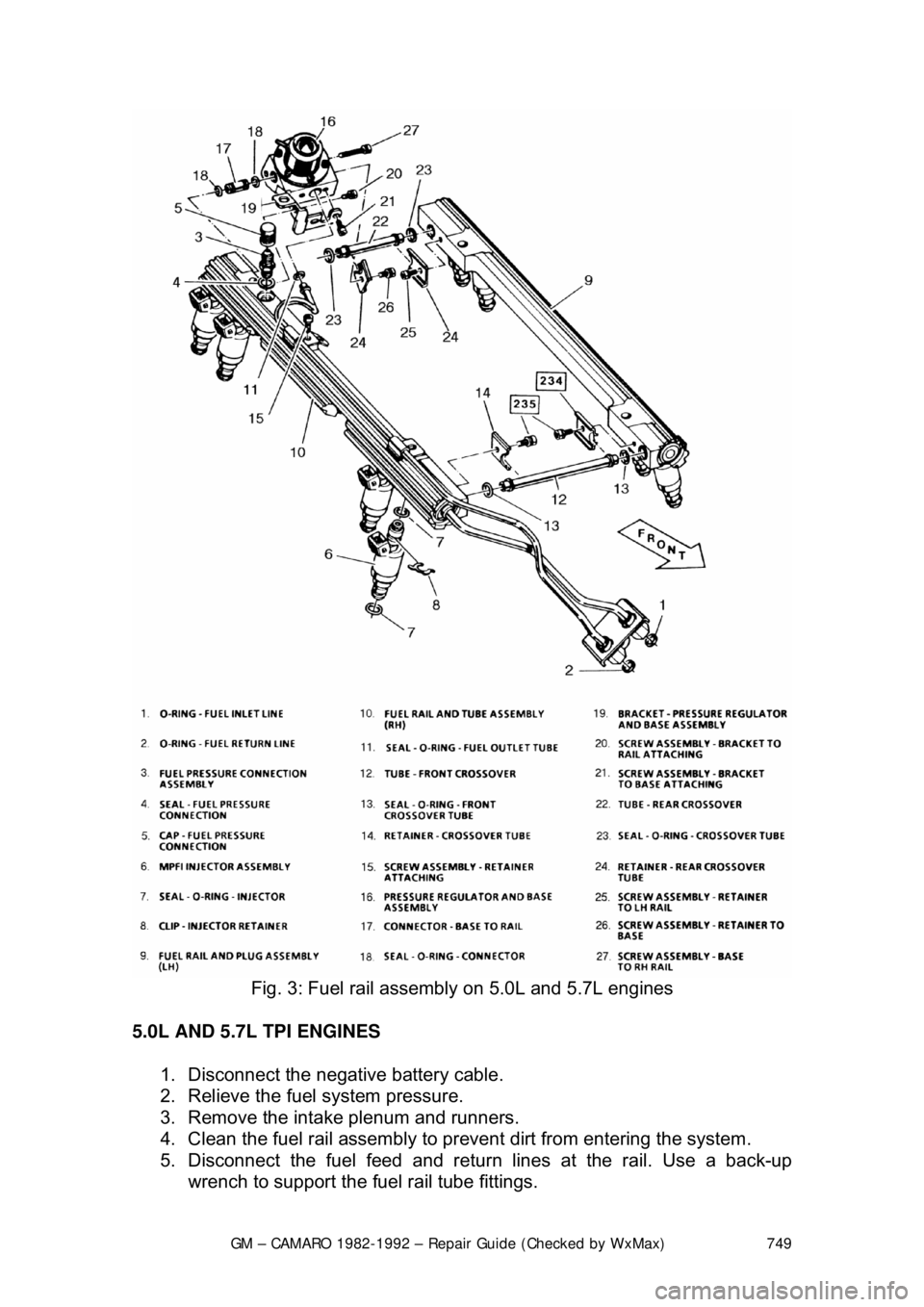

Fig. 3: Fuel rail assembly on 5.0L and 5.7L engines

5.0L AND 5.7L TPI ENGINES 1. Disconnect the negative battery cable.

2. Relieve the fuel system pressure.

3. Remove the intake plenum and runners.

4. Clean the fuel rail assembly to pr event dirt from entering the system.

5. Disconnect the fuel feed and return lines at the rail. Use a back-up

wrench to support the fuel rail tube fittings.

Page 750 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 750

6. Disconnect the vacuum hose

at the pressure regulator.

7. Unplug the electrical connectors.

8. Loosen and remove the fuel rail attaching bolts.

9. Remove the fuel rail assembly from the intake manifold.

10. Discard all of the O-ring seals t hat are exposed during this procedure.

To install: 11. Lubricate with clean engine oil, then install the injector nozzle O-rings.

12. Install the fuel rail assembly in the intake manifold.

13. Tighten the fuel rail attachi ng bolts to specification.

14. Engage the injector electrical connectors. Rotate each injector as

required to avoid stretching the harness.

15. Connect the vacuum hose to the pressure regulator.

16. Connect the fuel feed and return lines. New O-rings must be used.

17. Temporarily connect the negative battery terminal. a. With the engine OF F and the ignition ON, check for fuel leaks.

Repair as necessary.

b. Disconnect the negative battery cable.

18. Install the intake plenum and runners. Use new gaskets.

19. Connect the negative battery cable.

FUEL PRESSURE REGULATOR

REMOVAL & INSTALLATION

2.8L AND 3.1L ENGINES

The pressure regulator and the fuel rail are serviced as a complete assembly

only. DO NOT attempt to remove the regulator cove r from the fuel rail.

5.0L AND 5.7L TPI ENGINES 1. Disconnect the negative battery cable.

2. Relieve the fuel system pressure.

3. Remove the intake plenum and runners.

4. Remove the fuel rail assembly.

5. Remove the rear crossover re tainer and base attaching screw.

6. Remove the rear crossover tube and O-ring from the regulator base.

Discard the O-ring.

7. Remove the pressure regulator bracket.

8. Remove the pressure r egulator base-to-rail screw.

9. Separate the regulator base from the fuel rail, then disconnect from the

fuel outlet tube.

10. Remove the fuel outle t tube O-ring and discard.

11. Remove the regulator bas e-to-fuel rail connector.

To install: 12. Lubricate and install new regul ator base-to-fuel rail O-rings.

Page 751 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 751

13. Lubricate a new outlet tube 0-ring and in

stall it on the end of the tube.

14. Connect the regulator base to the fuel outlet tube, then to the fuel rail.

15. Finger-tighten the base-to-rail screw.

16. Install the pressure regulator br acket. Finger-tighten the screws only.

17. Lubricate a new rear crossover tube O-ring and install it on the end of the

tube.

18. Install the rear crossover tube to the regulator base.

19. Install the crossover tube reta iner and finger-tighten the screw.

20. Tighten all attaching screws to 44 inch lbs. (5 Nm).

21. Install the fuel rail assembly.

22. Temporarily connect the negative battery cable. a. With the engine OFF and the igniti on ON, check for fuel leaks.

b. Disconnect the negative battery cable.

23. Install the intake plenum and runners.

24. Connect the negative battery cable.

IDLE AIR CONTROL VALVE

REMOVAL & INSTALLATION 1. Unplug the electrical connector from idle air control valve.

2. Remove the idle air control valve.

To install: 3. Before installing the idle air contro l valve, measure the distance that the

valve is extended. Measurement s hould be made from the motor housing

to the end of the cone. It should not exceed 28.5mm (1

1/8 in.), or damage

to the valve may occur when installed.

4. On 1985-1992 models, identify the replacement IAC valve as being

either Type 1 (with collar at electric terminal end) or Type 2 (without

collar). If measuring distance is great er than specified above, proceed as

follows:

• Type 1: Use finger pressure to slowly retract the pintle.

• Type 2: Compress retaining spring from valve while turning valve

in with a clockwise motion. Return spring to original position with

straight portion of spring end aligned with flat surface of valve.

On IAC valves that have already been in service, do not push or pull on the

valve pintle. The force required to move the pintle may damage the threads on

the worm drive.

5. Use a new gasket or O-ring and install the IAC valve into the throttle body.

6. Allow the ECM to reset the idle air control valve using the procedure

described earlier in this section.

Page 753 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 753

THROTTLE POSITION SENSOR (TPS)

REMOVAL & INSTALLATION

1. Disconnect the negative battery cable.

2. Detach the electrical connector from the sensor.

3. Remove the attaching screws, lockw ashers and retainers. Some models

use a seal between the throttle body and the sensor, do not lose this! \

4. Remove the throttle position sensor.

To install: 5. Install the throttle position sensor seal, if applicable.

6. With the throttle valve in the norma l closed idle position, install the

sensor on the throttle body assembly. Make sure the sensor pickup lever

is properly located on the th rottle actuator lever.

7. Install the retainers, screws and lockwashers using a thread locking

compound. On models up to 1989, DO NOT tighten the screws until the

sensor is adjusted. Follow the procedures outlined earli er in this section.

COLD START VALVE

REMOVAL & INSTALLATION 1. Disconnect the negative battery cable.

2. Relieve the fuel system pressure.

3. Remove the intake manifold plenum.

4. Unplug the electrical connection.

5. Clean the fuel rail around the cold start valve tube fitting.

6. Remove the tube fitting from t he fuel rail. Use a backup wrench to

prevent it from turning.

7. Remove the cold start valve retain ing bolt and remove the valve from the

intake manifold.

To install: 8. Use new O-rings and install the valve and bolt.

9. Connect the wiring harness.

10. Connect the cold start tube at the f uel rail. Use a wrench to prevent it

from turning.

11. Install the intake manifold plenum.

12. Connect the negative battery cable. With the engine OFF and the ignition

ON, check for fuel leaks.

Page 755 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 755

16. With the aid of an assistant, posit

ion and support the fuel tank with the

straps. Loosely install the front fuel tank attaching bolts.

17. Engage the electrical connection.

18. Connect the fuel hoses and li nes separated during removal.

19. Install the muffler heat sh ield and the exhaust system.

20. Install the rear axle and the fuel filler neck shield.

21. Lower the vehicle.

22. Add fuel and install the filler cap.

23. Connect the negative battery cable.

24. With the engine OFF, turn the igni tion switch to the ON position for 2

seconds, then turn it to the OFF positi on for 10 seconds. Again turn it to

the ON position and check for fuel leaks.

SENDING UNIT REPLACEMENT 1. Remove the fuel tank.

2. Clean the area surrounding t he sender assembly to prevent

contamination of the fuel system.

3. Using tool J-24187 or equivalent, re move the sending unit retaining cam.

Remove the fuel sender and O-rings fr om the tank. Discard the O-rings.

4. If necessary, separate the fuel pum p from the sending unit assembly.

To install: 5. If removed, install the fuel pump to the sending unit. If the strainer was

removed, it must be re placed with a new one.

6. Inspect and clean the O-ring mating surfaces.

7. Install a new O-ring in the groove around the tank opening. If applicable,

install a new O-ring on t he fuel sender feed tube.

8. Install the fuel sender assembly as follows: a. The fuel pump strainer must be in a horizontal position, and when

installed, must not block the travel of the float arm. Gently fold the

strainer over itself an d slowly position the sending assembly in the

tank so the strainer is not dam aged or trapped by the sump walls.

9. Install the retaining cam us ing tool J-24187 or equivalent.

10. Install the fuel tank assembly.

Page 760 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 760

GENERAL INFORMATION & MAINTENANCE

HOW TO USE THIS INFORMATION

The introductory part of this repair gui de is intended to help you learn more

about the inner workings of your Camaro while saving you money on its upkeep

and operation.

The beginning of the repair guide will likely be referred to the most, since that is

where you will find information for maintenance and tune-up. The other

information deals with the more complex systems of your vehicle. Systems

(from engine through brakes) are covered to the extent that the average do-it-

yourselfer can attempt. This repair guide will not explain such things as

rebuilding a differential because the ex pertise required and the special tools

necessary make this uneconomical. It will, however, give you detailed

instructions to help you change your own brake pads and shoes, replace spark

plugs, and perform many more jobs that can save you money and help avoid

expensive problems.

A secondary purpose of this repair guide is a reference for owners who want to

understand their vehicle and/or their mechanics better.

WHERE TO BEGIN

Before removing any bolts, read through t he entire procedure. This will give you

the overall view of what tools and supplies will be required. So read ahead and

plan ahead. Each operation should be approached logically and all procedures

thoroughly understood before attempting any work.

If repair of a component is not considered practical, we tell you how to remove

the part and then how to insta ll the new or rebuilt replacement. In this way, you

at least save labor costs.

AVOIDING TROUBLE

Many procedures in this repair guide r equire you to "label and disconnect ..." a

group of lines, hoses or wires. Don't be think you can remember where

everything goes - you won't. If you hook up va cuum or fuel lines incorrectly, the

vehicle may run poorly, if at all. If you hook up electrical wiring incorrectly, you

may instantly learn a very expensive lesson.

You don't need to know the proper name for each hose or line. A piece of

masking tape on the hose and a piece on its fitting will allow you to assign your

own label. As long as you remember your own code, the lines can be

reconnected by matching your tags. Re member that tape will dissolve in

gasoline or solvents; if a part is to be washed or cleaned, use another method

of identification. A permanent felt-tipped marker or a metal scribe can be very

handy for marking metal parts. Remove any tape or paper labels after

assembly.

Page 761 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 761

MAINTENANCE OR REPAIR?

Maintenance includes routine inspecti

ons, adjustments, and replacement of

parts which show signs of normal wear . Maintenance compensates for wear or

deterioration. Repair implies that someth ing has broken or is not working. A

need for a repair is often caused by lack of maintenance. for example: draining

and refilling automatic transmission fl uid is maintenance recommended at

specific intervals. Failure to do this can shorten the life of the

transmission/transaxle, requiring very expen sive repairs. While no maintenance

program can prevent items from eventually breaking or wearing out, a general

rule is true: MAINTENANCE IS CHEAPER THAN REPAIR.

Two basic mechanic's rules should be mentioned here. First, whenever the left

side of the vehicle or engine is refe rred to, it means the driver's side.

Conversely, the right side of the vehi cle means the passenger's side. Second,

screws and bolts are removed by turn ing counterclockwise, and tightened by

turning clockwise unless specifically noted.

Safety is always the most important rule. Constantly be aware of the dangers

involved in working on an automobile and take the proper precautions. Please

refer to the information in this se ction regarding SERVICING YOUR VEHICLE

SAFELY and the SAFETY NOTICE on the acknowledgment page.

AVOIDING THE MOST COMMON MISTAKES

Pay attention to the instructions prov ided. There are 3 common mistakes in

mechanical work:

1. Incorrect order of assembly, di sassembly or adjustment. When taking

something apart or putting it toget her, performing steps in the wrong

order usually just costs you ex tra time; however, it CAN break

something. Read the entire proc edure before beginning. Perform

everything in the order in which the instructions say you should, even if

you can't see a reason for it. When you' re taking apart something that is

very intricate, you might want to draw a picture of how it looks when

assembled in order to make sure you get everything back in its proper

position. When making adjustments, per form them in the proper order.

One adjustment possibly will affect another.

2. Overtorquing (or undertorquing). While it is more common for overtorquing to cause damage, undertorquing may allow a fastener to

vibrate loose causing serious dam age. Especially when dealing with

aluminum parts, pay attention to tor que specifications and utilize a torque

wrench in assembly. If a torque figure is not available, remember that if

you are using the right tool to perfo rm the job, you will probably not have

to strain yourself to get a fast ener tight enough. The pitch of most

threads is so slight that the te nsion you put on the wrench will be

multiplied many times in actual fo rce on what you are tightening.

There are many commercial products avai lable for ensuring that fasteners won't

come loose, even if they are not torqued just right (a very common brand is

Page 771 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 771

A more advanced set of tools, suit

able for tune-up work, can be drawn up

easily. While the tools are slightly more sophisticated, they need not be

outrageously expensive. There are severa l inexpensive tach/dwell meters on

the market that are every bit as good for the average mechanic as a

professional model. Just be sure that it goes to a least 1200-1500 rpm on the

tach scale and that it works on 4, 6 and 8-cylinder engines. The key to these

purchases is to make them with an eye towards adaptability and wide range. A

basic list of tune-up tools could include:

• Tach/dwell meter.

• Spark plug wrench and gapping tool.

• Feeler gauges for valve adjustment.

• Timing light.

The choice of a timing light should be made carefully. A light which works on the

DC current supplied by the vehicle's battery is the best choice; it should have a

xenon tube for brightness. On any vehi cle with an electronic ignition system, a

timing light with an inductive pickup that clamps around the No. 1 spark plug

cable is preferred.

In addition to these basic tools, ther e are several other tools and gauges you

may find useful. These include:

• Compression gauge. The screw-in type is slower to use, but eliminates

the possibility of a faulty r eading due to escaping pressure.

• Manifold vacuum gauge.

• 12V test light.

• A combination volt/ohmmeter

• Induction Ammeter. This is used for determining whether or not there is

current in a wire. These are handy fo r use if a wire is broken somewhere

in a wiring harness.

As a final note, you will probably find a torque wrench necessary for all but the

most basic work. The beam type models are perfectly adequate, although the

newer click types (breakaway) are eas ier to use. The click type torque

wrenches tend to be more expensive. Also keep in mind that all types of torque

wrenches should be periodically checked a nd/or recalibrated. You will have to

decide for yourself which better fits your pocketbook, and purpose.

SPECIAL TOOLS

Normally, the use of special factory tool s is avoided for repair procedures, since

these are not readily available for the do-it-yourself mechanic. When it is

possible to perform the job with more co mmonly available tools, it will be

pointed out, but occasionally, a special t ool was designed to perform a specific

function and should be used. Before s ubstituting another tool, you should be

convinced that neither your safety nor the performance of the vehicle will be

compromised.

Page 774 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 774

FLUIDS AND LUBRICANTS

FLUID DISPOSAL

Used fluids such as engine

oil, transmission fluid, antifreeze and brake fluid are

hazardous wastes and must be disposed of properly. Befo re draining any fluids,

consult with your local authorities; in many areas waste oil, etc. is being

accepted as a part of recycling programs. A number of service stations and auto

parts stores are also accepti ng waste fluids for recycling.

Be sure of the recycling cent er's policies before draining any fluids, as many will

not accept different fluids that have been mixed together.

FUEL RECOMMENDATIONS

The engine is designed to operate on unleaded gasoline ONLY and is essential

for the proper operation of the emissi on control system. The use of unleaded

fuel will reduce spark plug fouling, exhaust system corrosion and engine oil

deterioration.

In most parts of the United States, f uel with an octane rating of 87 should be

used; in high altitude areas, fuel wit h an octane rating as low as 85 may be

used.

In some areas, fuel consisting of a blen d of alcohol may be used; this blend of

gasoline and alcohol is known as gaso hol. When using gasohol, never use

blends exceeding 10% ethanol (e thyl or grain alcohol) or 5% methanol (methyl

or wood alcohol).

The use of fuel with excessive amounts of alcohol may jeopardize the new car

and emission control system warranties.

Page 775 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 775

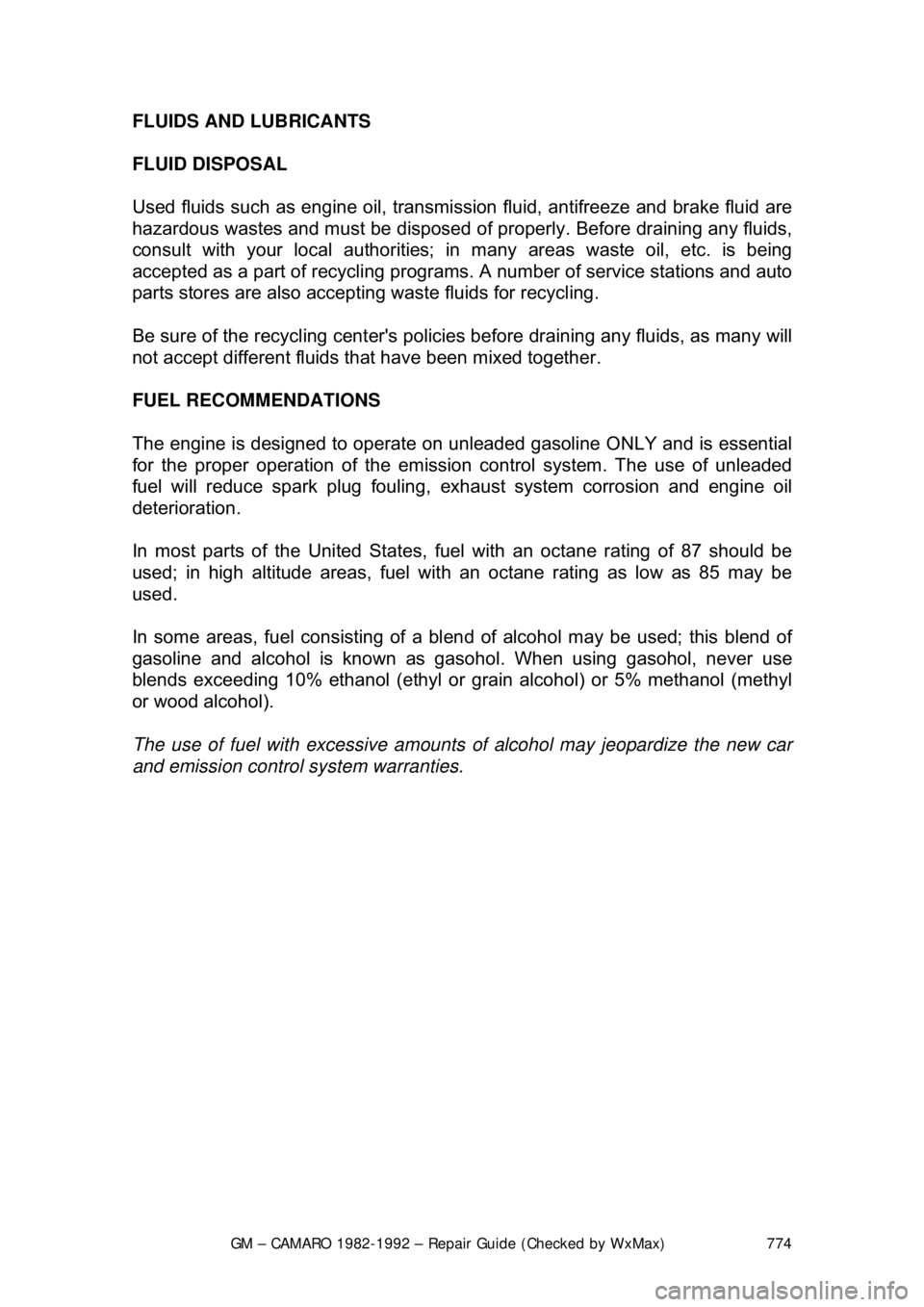

ENGINE OIL RECOMMENDATIONS

Fig. 1: Recommended SAE viscosity grade engine oil

Fig. 2: Look for the API oil identific ation label when choosing your engine oil