oil type CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 118 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 118

9. Remove the caliper lever pivot pin s

eal, sprag clip, spring and lever. Discard

the clip.

10. Inspect the caliper lever for worn spots, replace as necessary.

11. Remove the 2 guide pins from the mounting bracket.

12. Clean all parts not included in the r ebuild kit in denatured alcohol. Use only

dry filtered compressed air to dry parts . Replace the caliper housing if badly

scored or corroded.

To install:

13. Lubricate the new piston s eal with clean brake fluid. Place the seal into the

caliper groove, making sure t he seal is not twisted.

14. Install the piston. Lubricate seal s and piston with brake fluid prior to

reinstallation.

15. Assemble the pushrod, 2 new boots and new retainers to the actuating

collar.

16. Lightly coat the actuat ing collar with the lubricant provided in the rebuild kit.

Do not use any other type of lubricant.

17. Install the clamp retainers firmly agains t the actuating collar. Bend the tabs

on the retainer to hold the assembly together.

18. Install the preload spring into the boot retainers.

19. Install the clamp rod to the actuati ng collar and boot. Lubricate the clamp rod

with the lubricant supplied in the kit.

20. Slide the clamp rod th rough the holes in the boot and actuating collar. The

boot must be against the reacti on plate on the clamp rod.

21. Lubricate and install t he new compliance bushing with the lubricant supplied

in the kit.

22. Install the clamp rod with assembled parts into the connecting hole in the

caliper piston.

23. Install a new bleeder valve.

24. Install the pivot pin and new nut into the housing, if removed.

25. Install the caliper pivot pin seal, parking brake lever, new sprag clip and

spring, in that order. The teeth of the sprag clip mu st face away from the

lever.

26. Install the 2 collar return springs to the retainer. The retainer must enter the

return springs at the end of the second coil.

27. Install the adjuster screw into the cali per housing until the actuating collar is

parallel to the piston bore face of the caliper housing.

28. Lubricate and then install the guide pi ns and boots. Install the pads and

caliper assembly.

29. Bleed the brake system.

BRAKE DISC (ROTOR)

REMOVAL & INSTALLATION

CAUTION - Brake pads contain asbestos, which has been determined to be a

cancer causing agent. Never clean the brake surfaces with compressed air!

Avoid inhaling any dust from any brake surface! When cleaning brake surfaces,

use a commercially available brake cleaning fluid.

Page 129 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 129

THE BATTERY

In most modern vehicles, the battery is

a lead/acid electrochemical device

consisting of six 2 volt subs ections (cells) connected in se ries, so that the unit is

capable of producing approximately 12 volt s of electrical pressure. Each

subsection consists of a series of positive and negative plates held a short

distance apart in a solution of sulfuric acid and water.

The two types of plates are of dissim ilar metals. This sets up a chemical

reaction, and it is this r eaction which produces current flow from the battery

when its positive and negative terminals are connected to an electrical \

load .

The power removed from the battery is r eplaced by the alternator, restoring the

battery to its original chemical state.

THE ALTERNATOR

On some vehicles there isn't an alter nator, but a generator. The difference is

that an alternator supplies alternating current which is then changed to direct

current for use on the vehicle, while a generator produces direct current.

Alternators tend to be more efficient and that is why they are used.

Alternators and generators are devices t hat consist of coils of wires wound

together making big electrom agnets. One group of coils spins within another set

and the interaction of the magnetic fields causes a current to flow. This current

is then drawn off the coils and fed into the vehicles electrical system.

GROUND

Two types of grounds are used in automot ive electric circuits. Direct ground

components are grounded to the frame thr ough their mounting points. All other

components use some sort of ground wire which is attached to the frame or

chassis of the vehicle. The electrical current runs through the chassis of the

vehicle and returns to the battery thr ough the ground (—) cable; if you look,

you'll see that the battery ground cabl e connects between the battery and the

frame or chassis of the vehicle.

It should be noted that a good percentage of electrical problems can be traced

to bad grounds.

PROTECTIVE DEVICES

It is possible for large surges of current to pass through the electrical system of

your vehicle. If this surge of current we re to reach the load in the circuit, the

surge could burn it out or severely dam age it. It can also overload the wiring,

causing the harness to get hot and melt t he insulation. To prevent this, fuses,

circuit breakers and/or fusible links are connected into the supply wires of the

electrical system. These items are nothing more than a built-in weak spot in the

system. When an abnormal amount of curr ent flows through the system, these

protective devices work as fo llows to protect the circuit:

Page 137 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 137

voltage) is present; it only means that so

me voltage is present. It is advisable

before using the test light to touch its ground clip and probe across the battery

posts or terminals to make sure the light is operating properly.

WARNING - Do not use a test light to probe electronic ignition, spark plug or

coil wires. Never use a pick-type test light to probe wiring on computer

controlled systems unless spec ifically instructed to do so. Any wire insulation

that is pierced by the test light pr obe should be taped and sealed with silicone

after testing

Like the jumper wire, the 12 volt test li ght is used to isolate opens in circuits.

But, whereas the jumper wire is used to bypass the open to operate the load,

the 12 volt test light is us ed to locate the presence of voltage in a circuit. If the

test light illuminates, there is power up to t hat point in the circuit; if the test light

does not illuminate, there is an open circui t (no power). Move the test light in

successive steps back toward the power source until the light in the handle

illuminates. The open is between the pr obe and a point which was previously

probed.

The self-powered test light is similar in design to the 12 volt test light, but

contains a 1.5 volt penlight battery in the handle. It is most often used in place

of a multimeter to check for open or shor t circuits when power is isolated from

the circuit (continuity test).

The battery in a self-powered test light does not provide much current. A weak

battery may not provide enough power to illuminate the test light even when a

complete circuit is made (especially if there is high resistance in the circuit).

Always make sure that the test battery is strong. To check the battery, briefly

touch the ground clip to the pr obe; if the light glows brightly, the battery is strong

enough for testing.

A self-powered test light should not be used on any co mputer controlled system

or component. The small amount of electr icity transmitted by the test light is

enough to damage many electr onic automotive components.

MULTIMETERS

Multimeters are an extremely useful tool for troubleshooting electrical problems.

They can be purchased in either analog or digital form and have a price range

to suit any budget. A multimeter is a voltmeter, ammeter and ohmmeter (along

with other features) combined into one instrument. It is often used when testing

solid state circuits because of its hi gh input impedance (usually 10 megaohms

or more). A brief description of the mult imeter main test functions follows:

• Voltmeter - the voltmeter is used to measure voltage at any point in a

circuit, or to measure the voltage drop across any part of a circuit.

Voltmeters usually have various scales and a selector switch to allow the

reading of different volt age ranges. The voltmeter has a positive and a

negative lead. To avoid damage to the meter, always connect the

negative lead to the negative (—) side of the circ uit (to ground or nearest

Page 294 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 294

25. Connect the negative battery cable at the battery.

CLUTCH

UNDERSTANDING THE CLUTCH

The purpose of the clutch is to disconnect and connect engine power at the

transmission. A vehicle at rest requires a lot of engine torque to get all that

weight moving. An internal combustion engine does not develop a high starting

torque (unlike steam engines) so it must be allowed to operate without any load

until it builds up enough torque to move the vehicle. To a point, torque

increases with engine rpm. The clutch a llows the engine to build up torque by

physically disconnecting t he engine from the transmission, relieving the engine

of any load or resistance.

The transfer of engine power to the tr ansmission (the load) must be smooth and

gradual; if it weren't, driv e line components would wear out or break quickly.

This gradual power transfer is made possi ble by gradually releasing the clutch

pedal. The clutch disc and pressure plat e are the connecting link between the

engine and transmission. When the clutch pedal is released, the disc and plate

contact each other (the clutch is engag ed) physically joining the engine and

transmission. When the pedal is pushed in, the disc and plate separate (the

clutch is disengaged) disconnecting the engine from the transmission.

Most clutch assemblies consists of t he flywheel, the clutch disc, the clutch

pressure plate, the throw out bearing and fork, the actuating linkage and the

pedal. The flywheel and clutch pressure plate (driving members) are connected

to the engine crankshaft and rotate with it. The clutch disc is located between

the flywheel and pressure plate, and is splined to the transmission shaft. A

driving member is one that is attached to the engine and transfers engine power

to a driven member (clutch disc) on t he transmission shaft. A driving member

(pressure plate) rotates (drives) a driv en member (clutch disc) on contact and,

in so doing, turns the transmission shaft.

There is a circular di aphragm spring within th e pressure plate cover

(transmission side). In a relaxed state (w hen the clutch pedal is fully released)

this spring is convex; that is, it is dished outward toward the transmission.

Pushing in the clutch peda l actuates the attached linkage. Connected to the

other end of this is the throw out fork, which hold the throw out bearing. When

the clutch pedal is depre ssed, the clutch linkage pushes the fork and bearing

forward to contact the diaphragm spring of the pressure plate. The outer edges

of the spring are secured to the pressure plate and are pivoted on rings so that

when the center of the spring is compre ssed by the throw out bearing, the outer

edges bow outward and, by so doing, pu ll the pressure plate in the same

direction - away from the clutch disc. This action se parates the disc from the

plate, disengaging the clutch and allowing the transmission to be shifted into

another gear. A coil type clutch return sp ring attached to the clutch pedal arm

permits full release of the pedal. Releasing the pedal pulls the throw out bearing

away from the diaphragm spring resulting in a reversal of spring position. As

bearing pressure is gradually released from the spring center, the outer edges

Page 340 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 340

10. Install the brake line j

unction block bolt at the ax le housing. Connect any

brake lines that were disconnected.

11. Install and secure the driveshaft a ligning the match marks made earlier.

12. Connect the shock absorbers to the axle and install the wheel

assemblies.

13. Lower the vehicle and replace any lost rear axle fluid.

DIFFERENTIAL ASSEMBLY

REMOVAL & INSTALLATION 1. Raise and safely support the vehicle.

2. Place a suitable contai ner under the differential. Remove the carrier

cover and drain the gear oil.

3. Remove the drive axles.

4. Mark the differential bearing caps L and R to make sure they will be

reassembled in their original location.

5. Using a suitable tool, remove the di fferential carrier. Be careful not to

damage the gasket sealing surface wh en removing the unit. Place the

right and left bearing outer races of the side bearing assemblies and

shims in sets with the marked different ial bearings caps so they can be

reinstalled in their original positions.

To install: 6. Inspect the differential carrier housi ng for foreign material. Check the ring

and pinion for chipped teeth, exce ssive wear and scoring. Check the

carrier bearings visually and by feel . Clean the differential housing and

replace components, as necessary.

7. Install the differential carrier. C heck the carrier bearing preload along

with the ring and pinion backlash, then adjust, as necessary. Tighten the

differential bearing cap bolts to 55 ft. lbs. (75 Nm) except on Borg-

Warner rear axles which are ti ghtened to 40 ft. lbs. (54 Nm).

8. Install the axles.

9. Install the carrier cover using a new gasket. Tighten the carrier cover

bolts to 20 ft. lbs. (27 Nm). Add the proper type and quantity of gear oil to

axle assembly.

Page 365 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 365

31. Connect the bulkhead harness connec

tor, wires and hoses. Reroute the

ECM harness in its original location. Install the hush panel and fenderwell

splash panel.

32. Install the radiator, fan and fan sh roud. Connect the radiator and heater

hoses, along with the transmission cooler lines.

33. Connect the vacuum brake booster li ne, the throttle linkage and cruise

control cable. Install the distributor cap.

34. Fill the cooling system with the proper type and amount of coolant and

the crankcase with the proper type of oil to the correct level.

35. Install the water pump drive bel t, the air cleaner duct and the hood.

36. Connect the negative battery cable, st art the engine and check for leaks.

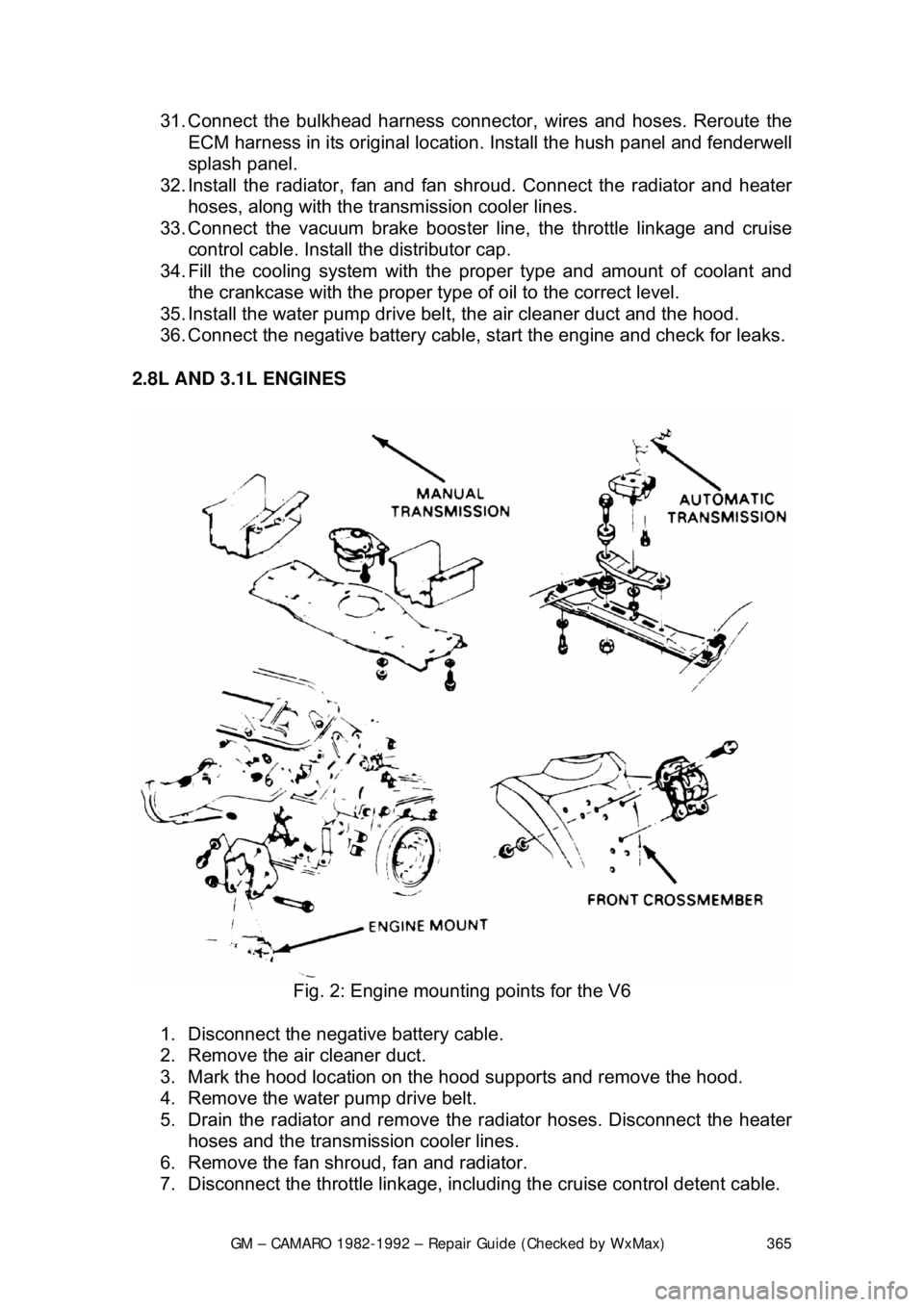

2.8L AND 3.1L ENGINES

Fig. 2: Engine mountin g points for the V6

1. Disconnect the negative battery cable.

2. Remove the air cleaner duct.

3. Mark the hood location on the hood supports and remove the hood.

4. Remove the water pump drive belt.

5. Drain the radiator and remove t he radiator hoses. Disconnect the heater

hoses and the transmission cooler lines.

6. Remove the fan shroud, fan and radiator.

7. Disconnect the throttle linkage, includi ng the cruise control detent cable.

Page 366 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 366

8. Remove the air conditioning co

mpressor and lay aside. Remove the

power steering pump and lay aside.

Do not disconnect the air conditioning or power steering lines.

9. Remove the vacuum brake booster line.

10. Remove the distributor cap and spark plug wires.

11. Disconnect the necessary elec trical connections and hoses.

12. Raise and safely support the vehicle.

13. Disconnect the exhaust pipes at the exhaust manifolds.

14. Remove the flywheel cover and remove the converter bolts.

15. Disconnect the star ter wire connections.

16. Remove the bellhousing and t he motor mount through-bolts.

17. Lower the vehicle.

18. Relieve the fuel system pressu re. Disconnect the fuel lines.

19. Support the transmission with a suit able jack. Attach an engine lifting

device.

20. Remove the engine assembly.

To install: 21. Position the engine assembly in the vehicle.

22. Attach the motor mount to engine br ackets and lower the engine in place.

Remove the engine lifting device and the transmission jack.

23. Raise and support the vehicle safely.

24. Install the motor mount through-bolts and tighten the nuts to 50 ft. lbs. (68 Nm). Install the bellhousing bolts and tighten to 35 ft. lbs. (47 Nm).

25. On vehicles with automatic transmissi on, install the converter to flywheel

attaching bolts to 46 ft. lbs. (63 Nm).

26. Install the flywheel splash shield and tighten to 89 inch lbs. (10 Nm).

27. Connect the starter wires and the fuel lines.

28. Install the exhaust pipe on the exhaust manifold.

29. Lower the vehicle.

30. Install the power steering pump and the air conditioning compressor.

31. Connect the necessary wires and hoses.

32. Install the radiator, fan and fan sh roud. Connect the radiator and heater

hoses and the transmission cooler lines.

33. Connect the vacuum brake booster li ne, the throttle linkage and cruise

control cable. Install the distributor cap.

34. Fill the cooling system with the proper type and amount of coolant and

the crankcase with the proper type of oil to the correct level.

35. Install the water pump drive bel t, the air cleaner duct and the hood.

36. Connect the negative battery cable, st art the engine and check for leaks.

Page 368 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 368

23. Remove the AIR/converter bracket

and ground wires from the rear of the

cylinder head.

24. Attach a suitable lifting devic e and remove the engine assembly.

To install: 25. Position the engine assembly in the vehicle.

26. Attach the motor mount to engine brackets and lower the engine into

place.

27. Remove the engine lifting device and the transmission jack.

28. Raise and safely support the vehicle.

29. Install the motor mount through-bolts and tighten to 50 ft. lbs. (68 (Nm).

30. Install the bellhousing bolts and tighten to 35 ft. lbs. (47 Nm).

31. On vehicles with automatic transmissi on, install the converter to flywheel

bolts. Tighten the bolts to 46 ft. lbs. ( 63 Nm). Install the flywheel cover.

32. Connect the starter wires and the fuel lines.

33. Connect the exhaust pipe at the exhaust manifold.

34. Lower the vehicle.

35. Connect the necessary wires and hoses.

36. Install the power steering pump and air conditioning compressor in their

respective brackets.

37. Install the radiator, fan and fan sh roud, radiator hoses and heater hoses.

38. Connect the transmission cooler lines and cooling fan electrical

connectors.

39. Install the distributor.

40. Install the plenum ex tension, if equipped.

41. Fill the cooling system with the proper type and quantity of coolant and

the crankcase with the proper type of oil to the correct level.

42. Install the air cleaner and the hood.

43. Connect the negative battery cable, start the engine, check for leaks and

check timing.

Page 411 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 411

1. Disconnect the negative battery cable.

2. Relieve the fuel system pressure

and drain the engine coolant from the

radiator into a suitable container.

3. Remove the intake manifold and the spark plugs.

4. Remove the dipstick tube and bra cket. Raise and support the vehicle

safely. Drain the oil and remove the oil filter. Lower the vehicle.

5. Remove the exhaust manifolds.

6. Remove the drive belt(s).

7. Remove the air conditioning compresso r and bracket, reposition it aside.

Do not disconnect the lines.

8. Remove the power steering pump and bracket, reposition it aside.

9. Remove the alternator and br acket, reposition it aside.

10. Remove the ground cable from the rear of the cylinder head and remove

the engine lift bracket.

11. Remove the rocker arm covers.

12. Loosen the rocker arms until the pushrods can be removed.

13. Remove the cylinder head bolts and remove the cylinder heads.

To install: 14. Clean the gasket mating surfaces of all components. Be careful not to

nick or scratch any surfaces as this will allow leak paths. Clean the bolt

threads in the cylinder bl ock and on the head bolts. Dirt will affect bolt

torque.

15. Place the head gaskets in pos ition over the dowel pins.

16. Install the cylinder heads.

17. Coat the cylinder head bolts th reads with GM sealer 1052080 or

equivalent, and install the bolts. Tight en the bolts in the proper sequence

to:

• 1982-1987 engines: 70 ft lbs. (90 Nm)

• 1988-1992 engines: 1st step: 40 ft lbs. (55 Nm); 2nd step: tighten

an additional 1/4 (90 degree) turn

18. Install the pushrods a nd loosely retain them wit h the rocker arms. Make

sure the lower ends of the pushrods ar e in the lifter seats. Refer to the

rocker arm procedures outlined ea rlier in this section.

19. Install the power steering pump br acket and pump. Do the same for the

air conditioning compressor bracket and compressor.

20. Install the ground cable to t he rear of the cylinder head.

21. Install the exhaust manifolds.

22. Install the dipstick tube and bracket.

23. Install the intake manifold.

24. Install the alternator bracket and alternator.

25. Install the drive belt(s).

26. Install the spark plugs.

27. Fill the cooling system with the proper type and quantity of coolant. Install

a new oil filter and fill the crankca se with the proper type and quantity of

oil.

28. Connect the negative battery cable, star t the vehicle and check for leaks.

Page 417 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 417

16. Fill the cooling syst

em with the proper type and amount of coolant.

Connect the negative battery cable.

17. Raise and support the vehicle safely . Install a new oil filter, lower the

vehicle. Fill the crankcase with the proper type and quantity of engine oil.

18. Start the engine, check for lea ks and check the ignition timing.

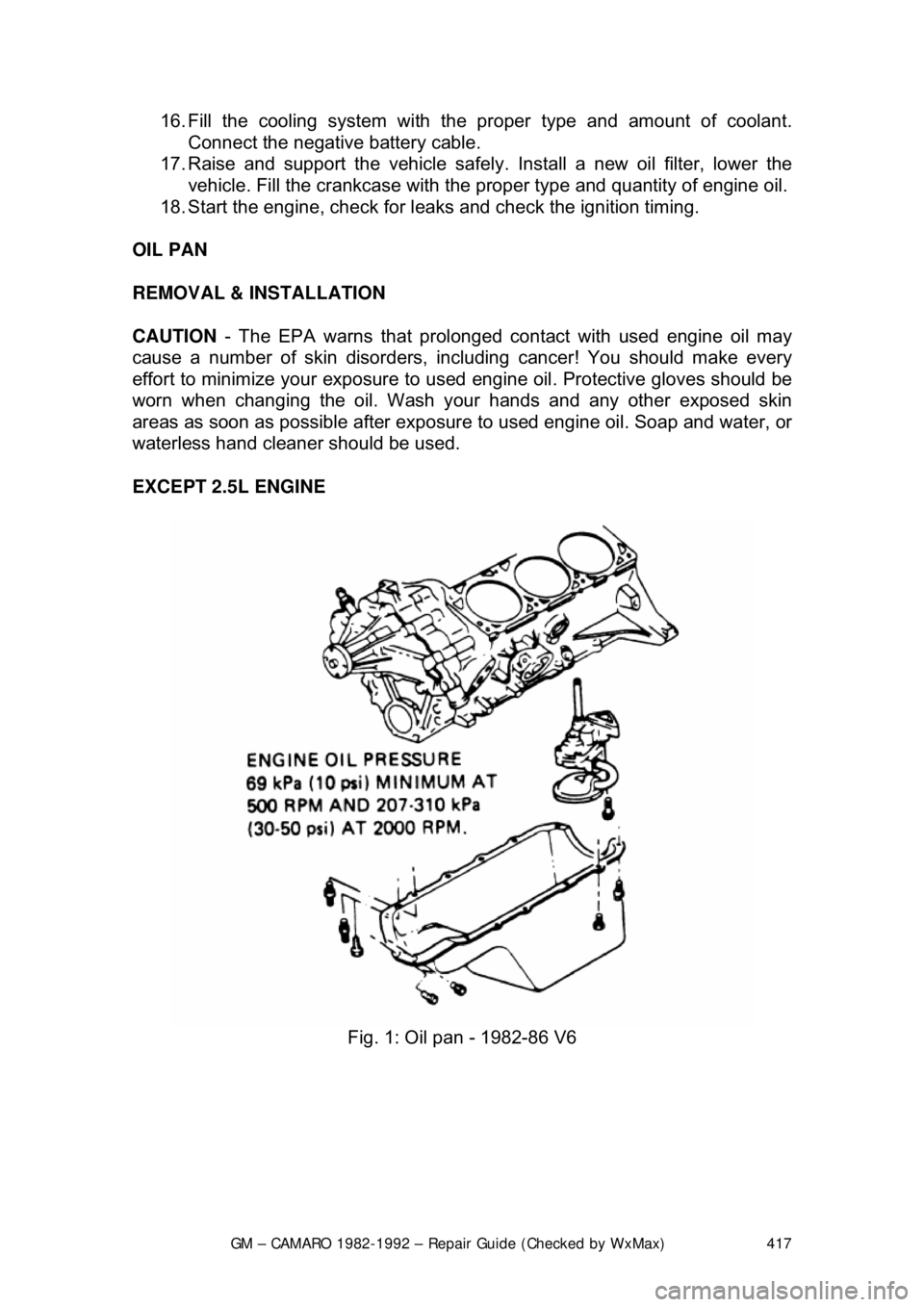

OIL PAN

REMOVAL & INSTALLATION

CAUTION - The EPA warns that prolonged contact with used engine oil may

cause a number of skin disorders, incl uding cancer! You should make every

effort to minimize your exposure to used engine oil. Pr otective gloves should be

worn when changing the oil. Wash y our hands and any other exposed skin

areas as soon as possible after exposure to used engine oil. Soap and water, or

waterless hand cleaner should be used.

EXCEPT 2.5L ENGINE

Fig. 1: Oil pan - 1982-86 V6