turn signal CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 11 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 11

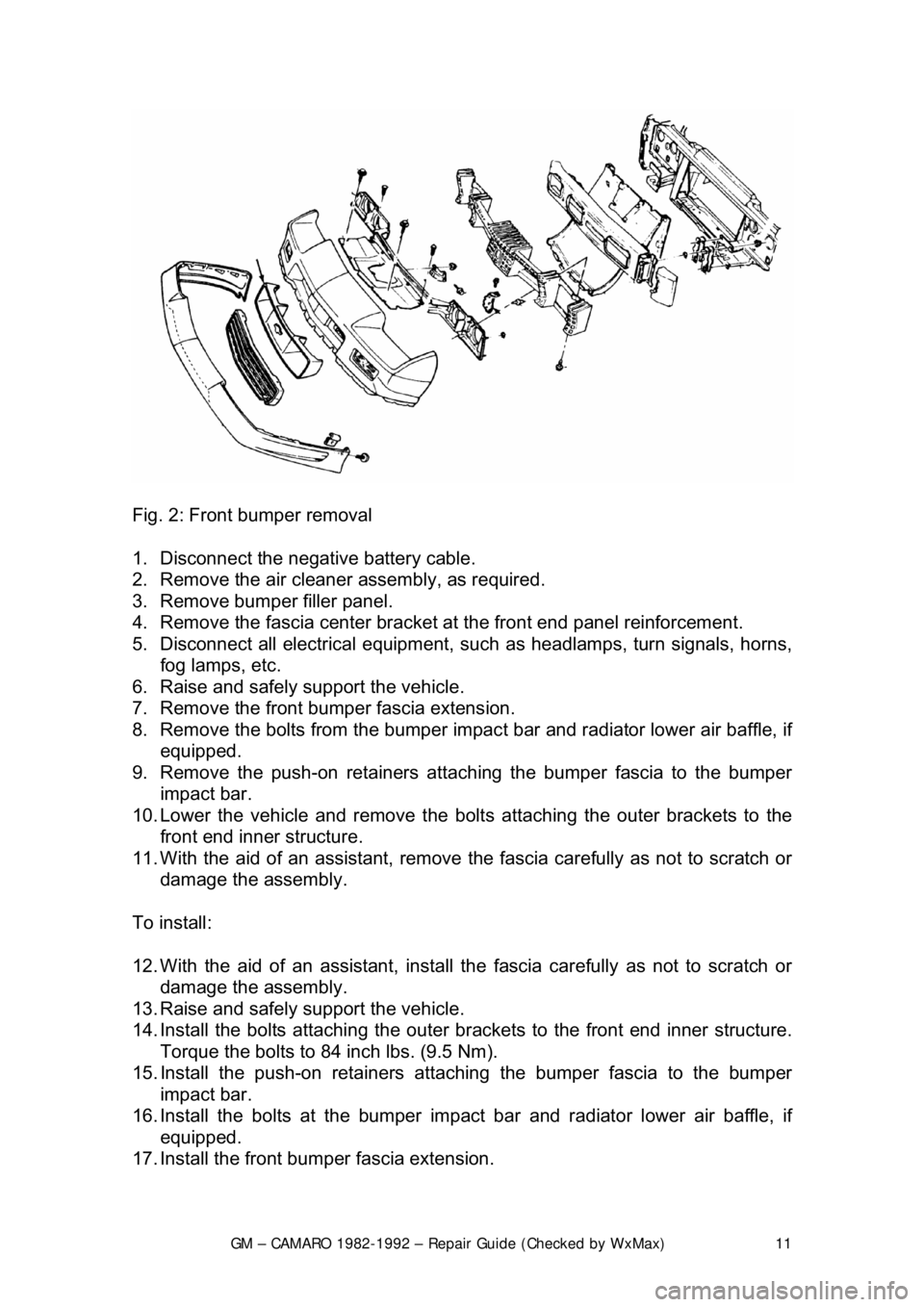

Fig. 2: Front bumper removal

1. Disconnect the negative battery cable.

2. Remove the air cleaner assembly, as required.

3. Remove bumper filler panel.

4. Remove the fascia center bracket at the front end panel reinforcement.

5. Disconnect all electrical equipment, su ch as headlamps, turn signals, horns,

fog lamps, etc.

6. Raise and safely support the vehicle.

7. Remove the front bumper fascia extension.

8. Remove the bolts from the bumper impac t bar and radiator lower air baffle, if

equipped.

9. Remove the push-on retainers attach ing the bumper fascia to the bumper

impact bar.

10. Lower the vehicle and remove the bolt s attaching the outer brackets to the

front end inner structure.

11. With the aid of an assistant, remove t he fascia carefully as not to scratch or

damage the assembly.

To install:

12. With the aid of an assistant, install t he fascia carefully as not to scratch or

damage the assembly.

13. Raise and safely support the vehicle.

14. Install the bolts attachi ng the outer brackets to the front end inner structure.

Torque the bolts to 84 inch lbs. (9.5 Nm).

15. Install the push-on retainers atta ching the bumper fascia to the bumper

impact bar.

16. Install the bolts at t he bumper impact bar and radiat or lower air baffle, if

equipped.

17. Install the front bum per fascia extension.

Page 12 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 12

18. Connect all electrical equipment, such

as headlamps, turn signals, horns,

fog lamps, etc.

19. Install the fascia center bracket at the front end panel reinforcement.

20. Install bumper filler panel.

21. Install the air cleaner assembly, as required.

22. Connect the negative battery cable.

REAR

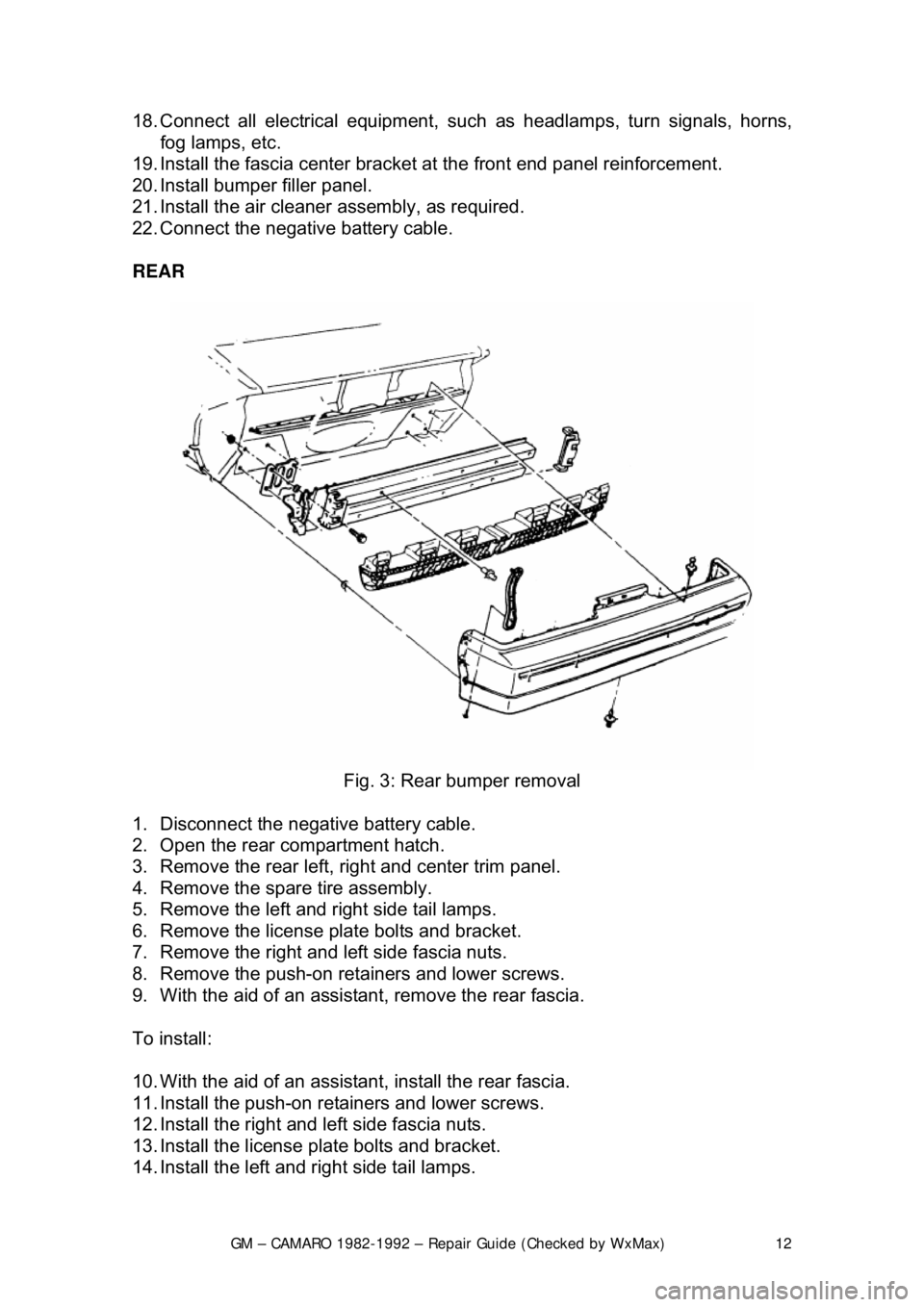

Fig. 3: Rear bumper removal

1. Disconnect the negative battery cable.

2. Open the rear compartment hatch.

3. Remove the rear left, ri ght and center trim panel.

4. Remove the spare tire assembly.

5. Remove the left and right side tail lamps.

6. Remove the license plate bolts and bracket.

7. Remove the right and left side fascia nuts.

8. Remove the push-on retainers and lower screws.

9. With the aid of an assistan t, remove the rear fascia.

To install:

10. With the aid of an assistan t, install the rear fascia.

11. Install the push-on retainers and lower screws.

12. Install the right and left side fascia nuts.

13. Install the license plate bolts and bracket.

14. Install the left and right side tail lamps.

Page 16 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 16

8. Remove the front end bumper fa

scia-to-fender nuts and screws.

9. Remove the hood hinge-to-fender bolts.

10. Disconnect all electrical connections from horn, turn signal lamps, etc.

11. Remove the fender by sliding rearward and outward, at rear, with the aid of

an assistant. Place an old blanket over the fender as to avoid scratches or

dents.

To install:

12. Install the fender with the aid of an assistant. Plac e an old blanket over the

fender as to avoid scratches or dents.

13. Connect all electrical connections to the horn, turn signal lamps, etc.

14. Install the hood hinge-to-fender bolts.

15. Install the front end bumper fascia-to-fender nuts and screws.

16. Install the bolt at the support brace.

17. Install the lower front end panel deflector-to-fender bolts.

18. Install the rocker panel molding.

19. Install the lower fender bol ts and inner wheel house panel.

20. Install the hood.

21. Disconnect the negative battery cable. Align the fender and hood as

necessary, placing existing shims in original positions.

Page 169 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 169

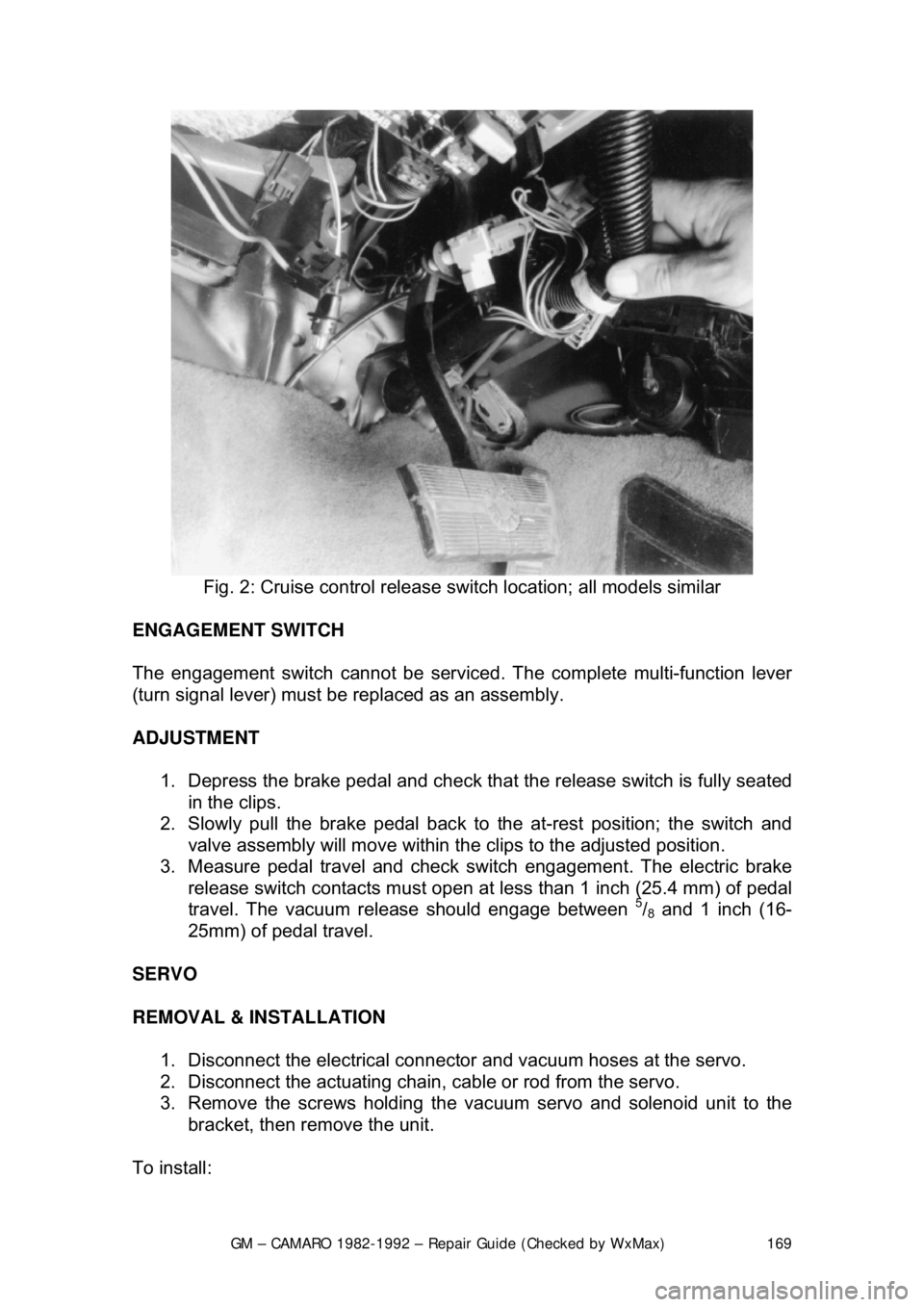

Fig. 2: Cruise control release sw itch location; all models similar

ENGAGEMENT SWITCH

The engagement switch cannot be serviced . The complete multi-function lever

(turn signal lever) must be replaced as an assembly.

ADJUSTMENT

1. Depress the brake pedal and check that the release switch is fully seated

in the clips.

2. Slowly pull the brake pedal back to the at-rest position; the switch and

valve assembly will move within the clips to the adjusted position.

3. Measure pedal travel and check s witch engagement. The electric brake

release switch contacts must open at less than 1 inch (25.4 mm) of pedal

travel. The vacuum release should engage between

5/8 and 1 inch (16-

25mm) of pedal travel.

SERVO

REMOVAL & INSTALLATION 1. Disconnect the electrical connecto r and vacuum hoses at the servo.

2. Disconnect the actuating chain, cable or rod from the servo.

3. Remove the screws holding the vac uum servo and solenoid unit to the

bracket, then remove the unit.

To install:

Page 209 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 209

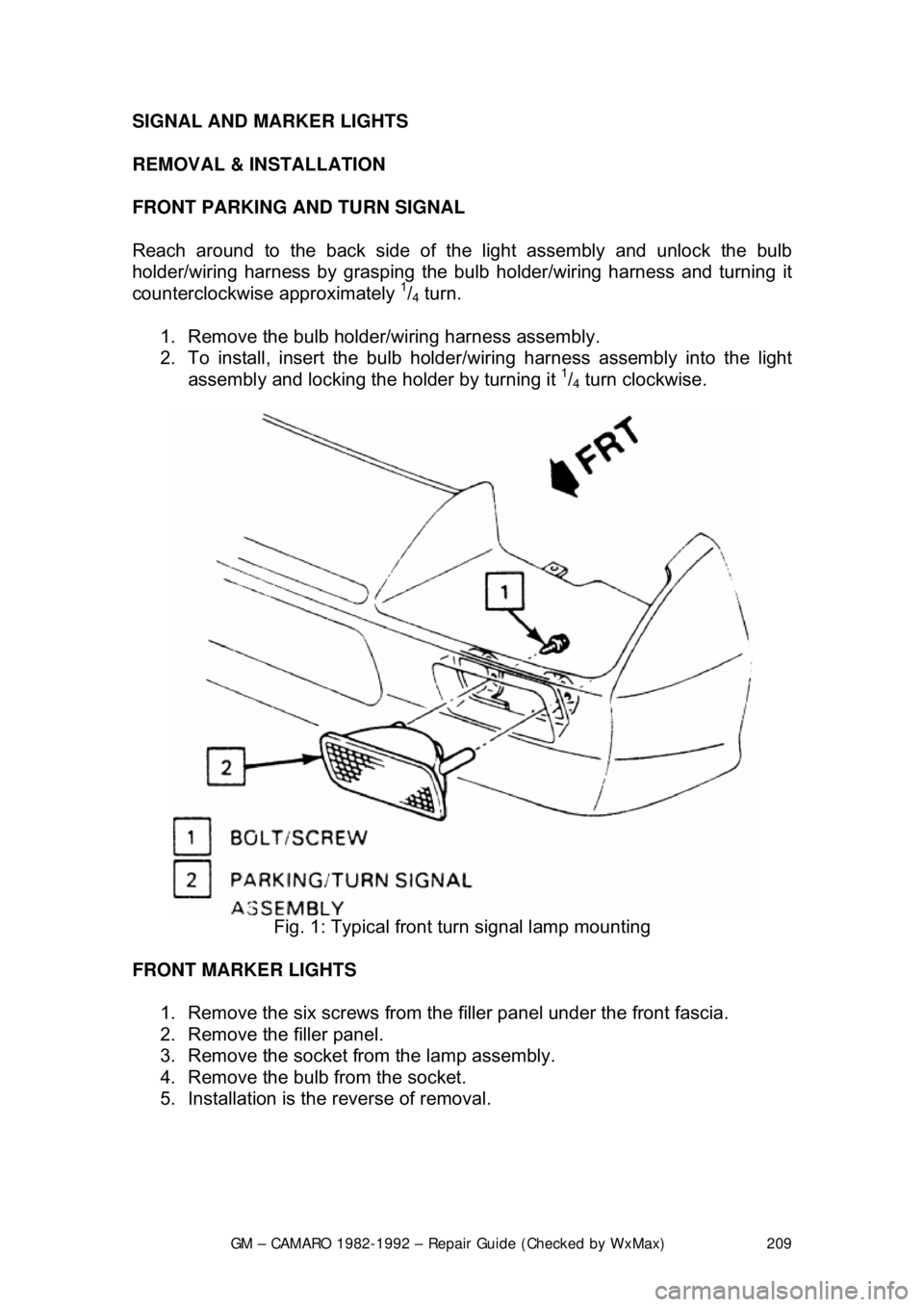

SIGNAL AND MARKER LIGHTS

REMOVAL & INSTALLATION

FRONT PARKING AND TURN SIGNAL

Reach around to the back side of t

he light assembly and unlock the bulb

holder/wiring harness by grasping the bul b holder/wiring harness and turning it

counterclockwise approximately

1/4 turn.

1. Remove the bulb holder/wiring harness assembly.

2. To install, insert the bulb holder /wiring harness assembly into the light

assembly and locking the holder by turning it

1/4 turn clockwise.

Fig. 1: Typical front turn signal lamp mounting

FRONT MARKER LIGHTS 1. Remove the six screws from the filler panel under the front fascia.

2. Remove the filler panel.

3. Remove the socket from the lamp assembly.

4. Remove the bulb from the socket.

5. Installation is the reverse of removal.

Page 211 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 211

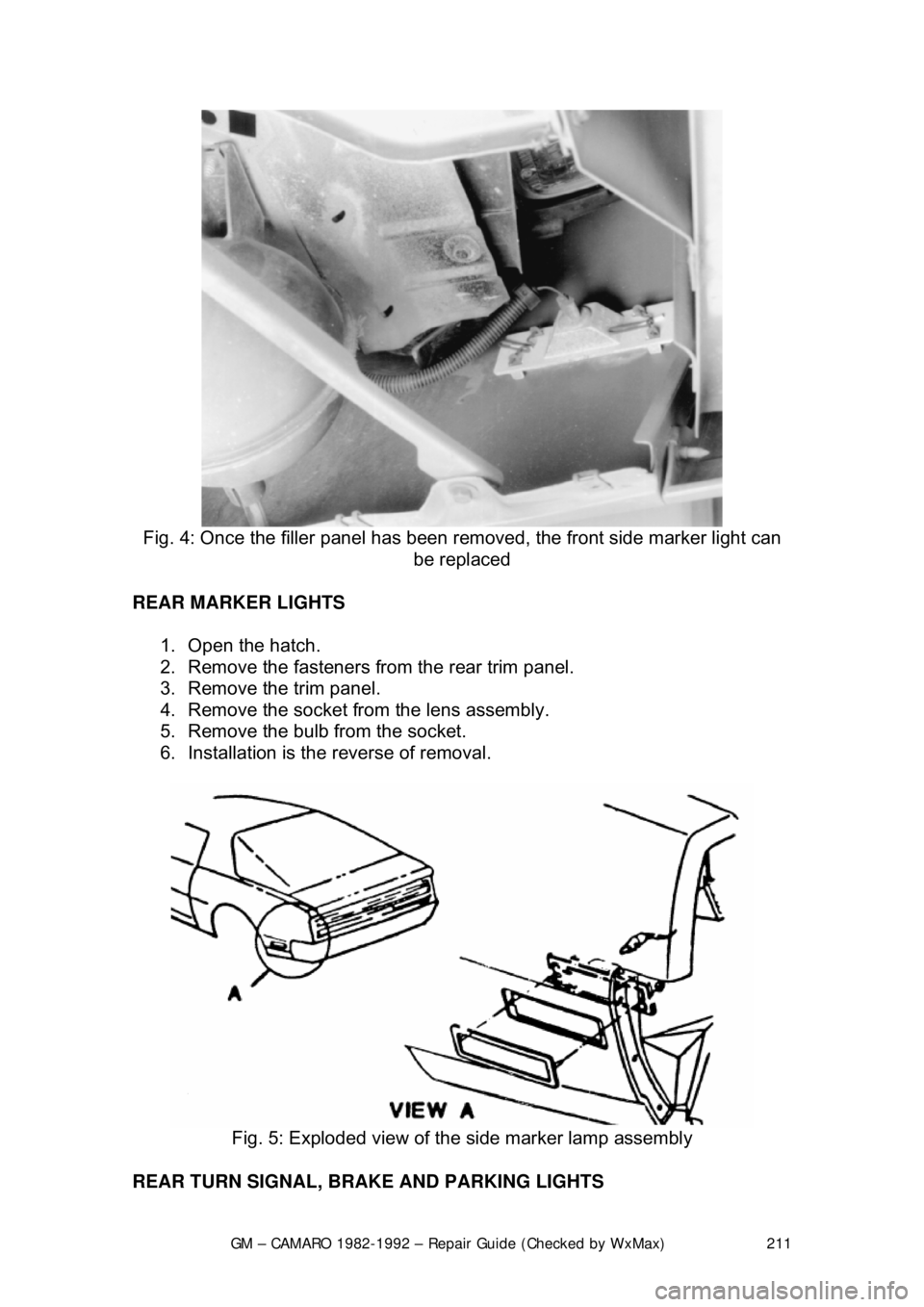

Fig. 4: Once the filler panel has been remo ved, the front side marker light can

be replaced

REAR MARKER LIGHTS 1. Open the hatch.

2. Remove the fasteners from the rear trim panel.

3. Remove the trim panel.

4. Remove the socket from the lens assembly.

5. Remove the bulb from the socket.

6. Installation is the reverse of removal.

Fig. 5: Exploded view of the side marker lamp assembly

REAR TURN SIGNAL, BRAKE AND PARKING LIGHTS

Page 224 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 224

BUZZERS, RELAYS, AND FLASHERS

The electrical protection dev

ices are located in the convenience center, which is

a swing down unit located under the inst rument panel. All units are serviced by

plug-in replacements.

TURN SIGNAL FLASHER

The turn signal flasher is located inside th e convenience center. In order to gain

access to the turn signal flasher, it ma y be necessary to first remove the under

dash padding.

HAZARD FLASHER

The hazard flasher is located inside the convenience center. In order to gain

access to the turn signal flasher, it ma y be necessary to first remove the under

dash padding.

Page 298 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 298

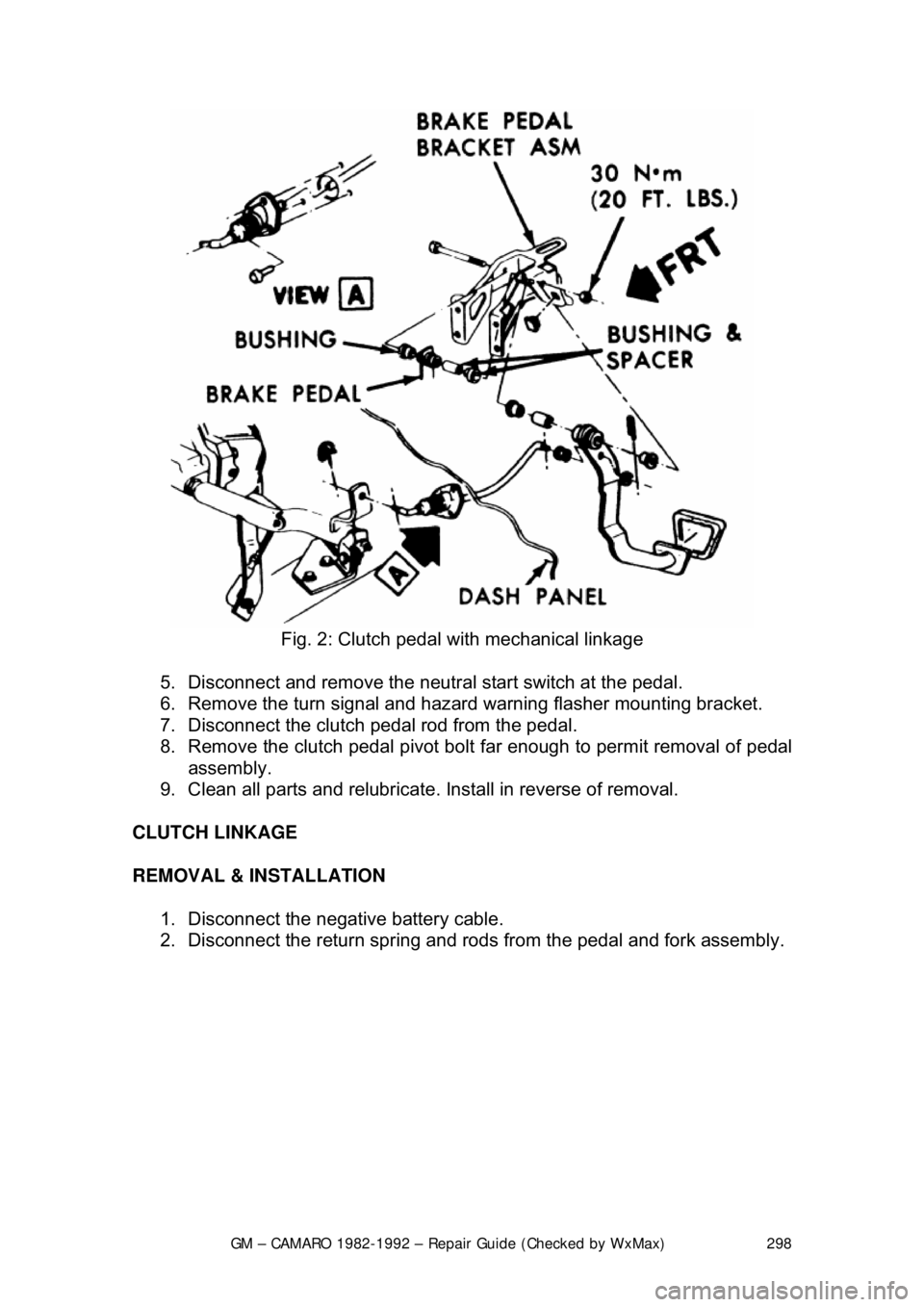

Fig. 2: Clutch pedal with mechanical linkage

5. Disconnect and remove the neutra l start switch at the pedal.

6. Remove the turn signal and hazard warning flasher mounting bracket.

7. Disconnect the clutch pedal rod from the pedal.

8. Remove the clutch pedal pivot bolt far enough to permit removal of pedal\

assembly.

9. Clean all parts and relubricate. Install in reverse of removal.

CLUTCH LINKAGE

REMOVAL & INSTALLATION 1. Disconnect the negative battery cable.

2. Disconnect the return spring and rods from the pedal and fork assembly.

Page 547 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 547

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

OPERATION

All models are equipped with

this system, which consists of a metering valve, a

vacuum line to the carburet or or intake manifold, and cast-in exhaust passages

in the intake manifold. The EGR valve is controlled by vacuum, which opens

and closes in response to the vacuum signals to admit exhaust gases into the

air/fuel mixture. The exhaust gases lower peak combustion temperatures,

reducing the formation of NOx. The valve is closed at idle and wide open

throttle, but is open between the two extreme positions.

There are actually four types of EGR systems: Ported, Positive Back-Pressure,

Negative Backpressure and Digital. The pr inciple of all the systems are the

same; the only difference is in the me thod used to control how the EGR valve

opens.

Too much EGR flow at idle, cruise or during cold operation may result in the

engine stalling after cold start, the engine stalling at idle after deceleration,

vehicle surge during cruise and rough idle . If the EGR valve is always open, the

vehicle may not idle. Too little or no EGR flow allows combustion temperatures

to rise, which could result in spar k knock (detonation), engine overheating

and/or emission test failure.

A Thermal Vacuum Switch (TVS) or vacuum control solenoid may sometimes\

be used in combination with the EGR va lve. The TVS will close off vacuum

during cold operation. A va cuum control solenoid uses Pulse Width Modulation

(PWM) to turn the solenoid ON and OFF numerous times a second and varies

the amount of ON time (pulse width) to vary the amount of ported vacuum

supplied the EGR valve.

PORTED VALVE

In the ported system, the amount of ex haust gas admitted into the intake

manifold depends on a ported vacuum signal. A ported vacuum signal is one

taken from the carburetor above the th rottle plates; thus, the vacuum signal

(amount of vacuum) is dependent on how far the throttle plates are opened.

When the throttle is closed (idle or dec eleration) there is no vacuum signal.

Thus, the EGR valve is closed, and no exhaust gas enters the intake mani\

fold.

As the throttle is opened, a vacuum is produced, which opens the EGR valve,

admitting exhaust gas into the intake manifold.

POSITIVE BACKPRE SSURE VALVE

This valve operates the same as the ported, except, it has an internal air bleed

that acts as a vacuum regulator. T he bleed valve controls the amount of

vacuum inside the vacuum chamber duri ng operation. When the valve receives

sufficient exhaust backpressure through the hollow shaft, it closes the bleed; at

this point the EGR valve opens.

Page 577 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 577

MALFUNCTION INDICATOR LAMP

The primary function of the MIL is to adv

ise the operator and the technician that

a fault is detected, and, in most cases, a code is stored. Under normal

conditions, the malfunction indicator la mp will illuminate when the ignition is

turned ON. Once the engine is started and running, the ECM will perform a

system check and extinguish the lamp if no fault is found.

Additionally, the lamp can be used to retrieve stored codes after the system is

placed in the Diagnostic Mode. Codes ar e transmitted as a series of flashes

with short or long pauses. When the syst em is placed in the Field Service

Mode, the dash lamp will indicate open loop or closed loop function to the

technician.

INTERMITTENTS

If a fault occurs intermittently, such as a loose connector pin breaking contact

as the vehicle hits a bump, the ECM will note the fault as it occurs and energize

the dash warning lamp. If the problem se lf-corrects, as with the terminal pin

again making contact, the dash lamp will extinguish after 10 seconds but\

a code

will remain stored in the ECM memory.

When an unexpected code appe ars during diagnostics, it may have been set

during an intermittent failure that self-c orrected; the codes are still useful in

diagnosis and should not be discounted.

OXYGEN SENSOR

OPERATION

An oxygen sensor is used on all models. The sensor protrudes into the exhaust

stream and monitors the oxygen content of the exhaust gases. The difference

between the oxygen content of the exhaust gases and that of the outside air

generates a voltage si gnal to the ECM. The ECM monitors this voltage and,

depending upon the value of the signal rece ived, issues a command to adjust

for a rich or a lean condition.

No attempt should ever be made to meas ure the voltage output of the sensor.

The current drain of any conventional vo ltmeter would be such that it would

permanently damage the sensor.