warning CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 45 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 45

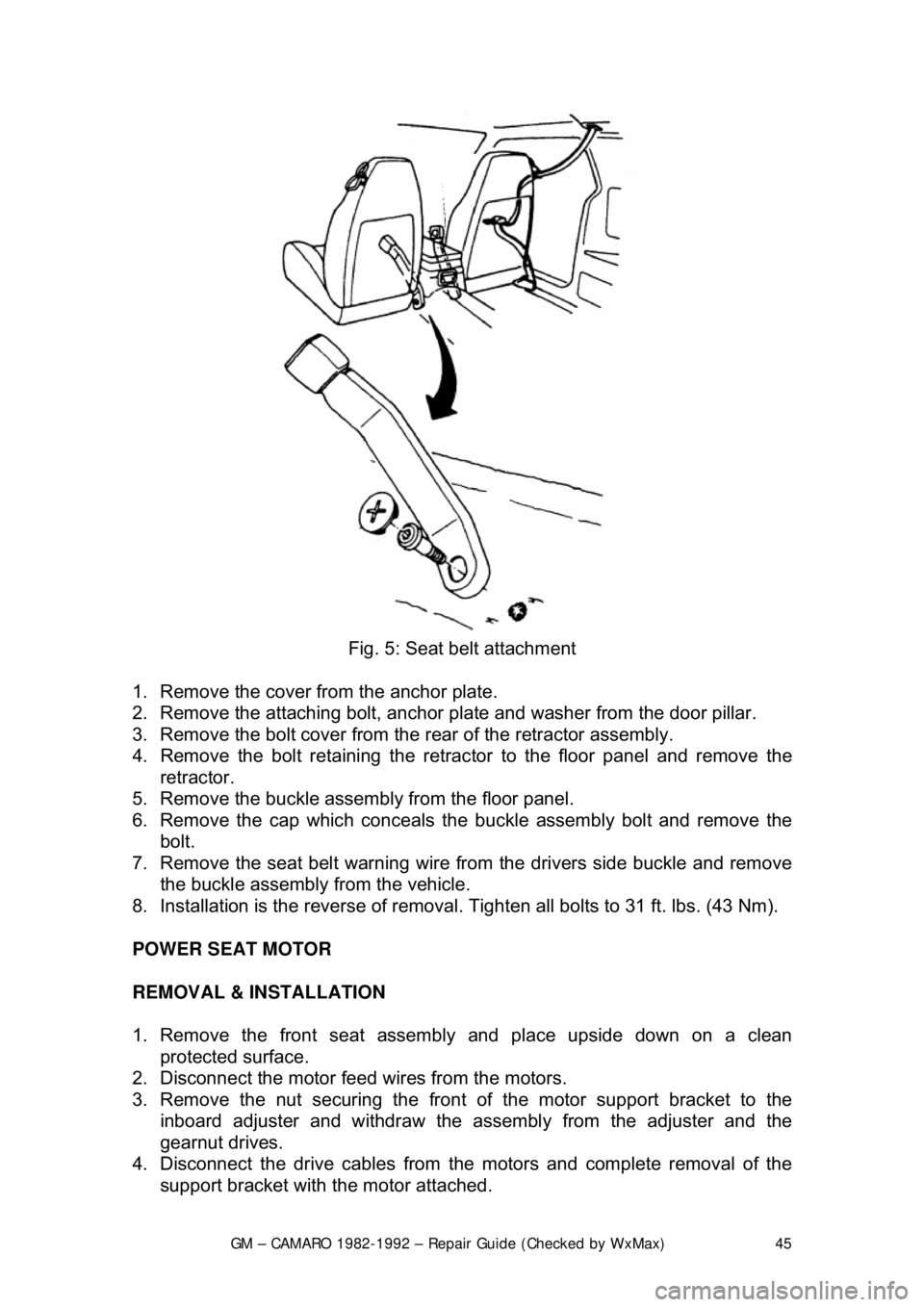

Fig. 5: Seat belt attachment

1. Remove the cover from the anchor plate.

2. Remove the attaching bolt, anchor pl ate and washer from the door pillar.

3. Remove the bolt cover from the rear of the retractor assembly.

4. Remove the bolt retaining the retrac tor to the floor panel and remove the

retractor.

5. Remove the buckle assemb ly from the floor panel.

6. Remove the cap which conceals t he buckle assembly bolt and remove the

bolt.

7. Remove the seat belt warning wire from the drivers side buckle and remove

the buckle assembly from the vehicle.

8. Installation is the reverse of removal. Tighten all bolts to 31 ft. lbs. (43 Nm).

POWER SEAT MOTOR

REMOVAL & INSTALLATION

1. Remove the front seat assemb ly and place upside down on a clean

protected surface.

2. Disconnect the motor feed wires from the motors.

3. Remove the nut securing the front of the motor support bracket to the

inboard adjuster and withdraw the asse mbly from the adjuster and the

gearnut drives.

4. Disconnect the drive cables from t he motors and complete removal of the

support bracket with the motor attached.

Page 49 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 49

Upon release of the brake pedal, a spri

ng located inside the master cylinder

immediately returns the master cylinder pistons to the normal position. The

pistons contain check valv es and the master cylinder has compensating ports

drilled in it. These are uncovered as the pistons reach their normal position. The

piston check valves allow fluid to flow to ward the wheel cylinders or calipers as

the pistons withdraw. Then, as the return springs force the brake pads or shoes

into the released position, the excess fluid reservoir through the compensating

ports. It is during the time the pedal is in the released position that any fluid that

has leaked out of the syst em will be replaced through the compensating ports.

Dual circuit master cylinders employ tw o pistons, located one behind the other,

in the same cylinder. The primary pist on is actuated directly by mechanical

linkage from the brake peda l through the power booster. The secondary piston

is actuated by fluid tra pped between the two pistons. If a leak develops in front

of the secondary piston, it moves forward until it bottoms against the front of the

master cylinder, and the fluid trapped betw een the pistons will operate the rear

brakes. If the rear brakes develop a l eak, the primary piston will move forward

until direct contact with the secondary pi ston takes place, and it will force the

secondary piston to actuate the front brakes. In either case, the brake pedal

moves farther when the brakes are applied, and less braking power is available.

All dual circuit systems use a switch to wa rn the driver when only half of the

brake system is operational. This switch is usually located in a valve body which

is mounted on the firewall or the frame below the master cylinder. A hydraulic

piston receives pressure from both circui ts, each circuit's pressure being applied

to one end of the piston. When the pressures are in balance, the piston remains

stationary. When one circuit has a leak, however, the greater pressure in that

circuit during application of the brakes will push the piston to one side, closing

the switch and activating the brake warning light.

In disc brake systems, this valve body also contains a metering valve and, in

some cases, a proportioning valve. The metering valve keeps pressure fro\

m

traveling to the disc brakes on the front wheels until the brake shoes on the rear

wheels have contacted the drums, ensuri ng that the front brakes will never be

used alone. The proportioning va lve controls the pressure to the rear brakes to

lessen the chance of rear wheel lo ck-up during very hard braking.

Warning lights may be tested by depressi ng the brake pedal and holding it while

opening one of the wheel cyli nder bleeder screws. If this does not cause the

light to go on, substitute a new lamp , make continuity checks, and, finally,

replace the switch as necessary.

The hydraulic system may be checked for leaks by applying pressure to the

pedal gradually and steadily. If the pedal sinks very slowly to the floor, the

system has a leak. This is not to be conf used with a springy or spongy feel due

to the compression of air within the lin es. If the system leaks, there will be a

gradual change in the position of the pedal with a constant pressure.

Check for leaks along all lines and at wheel cylinders. If no external leaks are

apparent, the problem is inside the master cylinder.

Page 73 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 73

To install:

9. Install the new line or hose, starti

ng with the end farthest from the master

cylinder. Connect the other end, then confirm that both fittings are correctly

threaded and turn smoothly using finger pressure. Make sure the new line

will not rub against any ot her part. Brake lines must be at least 1/2 in.

(13mm) from the steering column and other moving parts. Any protective

shielding or insulators must be rein stalled in the original location.

WARNING - Make sure the hose is NO T kinked or touching any part of the

frame or suspension after installation. These conditions may cause the hose to

fail prematurely.

10. Using two wrenches as bef ore, tighten each fitting.

11. Install any retaining clips or brackets on the lines.

12. If removed, install the wheel and tire assemblies, then carefully lower the

vehicle to the ground.

13. Refill the brake master cylinder re servoir with clean, fresh brake fluid,

meeting DOT 3 specifications. Pr operly bleed the brake system.

14. Connect the negative battery cable.

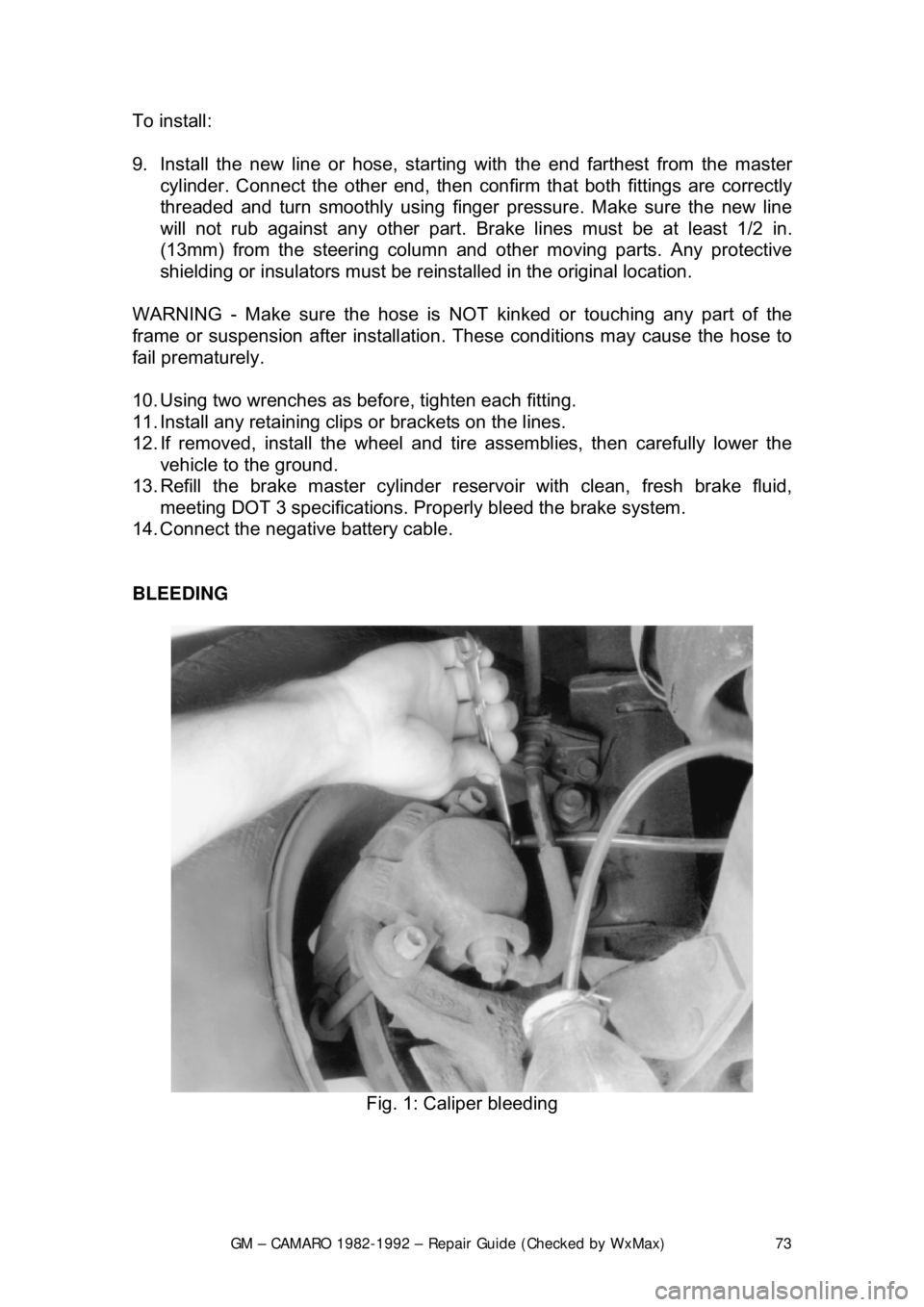

BLEEDING

Fig. 1: Caliper bleeding

Page 75 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 75

5. Have your assistant sl

owly depress the brake pedal. As this is done, open

the bleeder screw 3/4 of a turn and allow the flui d to run through the tube.

Then close the bleeder screw before the pedal reaches the end of its travel.

Have your assistant slo wly release the pedal. Rep eat this process until no

air bubbles appear in the expelled fluid.

6. Repeat the procedure on the other three br akes, checking the level of fluid in

the master cylinder reservoir often.

7. Upon completion, check the brak e pedal for sponginess and the brake

warning light for unbalanced pressure . If necessary, repeat the entire

bleeding procedure.

FRONT DISC BRAKES

CAUTION - Some brake pads contain asbest os, which has been determined to

be a cancer causing agent. Never clean the brake surfaces with compressed

air! Avoid inhaling any dust from any brake surface! When cleaning brake

surfaces, use a commercially available brake cleaning fluid.

BRAKE PADS

CAUTION - Some brake pads contain asbest os, which has been determined to

be a cancer causing agent. Never clean the brake surfaces with compressed

air! Avoid inhaling any dust from any brake surface! When cleaning brake

surfaces, use a commercially available brake cleaning fluid.

INSPECTION

The pad thickness should be inspected ever y time that the tires are removed for

rotation. The outer pad can be checked by looking in each end, which is the

point at which the highest rate of wear occurs. The inner pad can be checked by

looking down through the inspection hole in the top of the caliper. If the

thickness of the pad is worn to within 0.030 in. (0.8mm) of the rivet at either end

of the pad, all the pads should be replaced.

Always replace all pads on both front wheel s at the same time. Failure to do so

will result in uneven braking action and premature wear.

REMOVAL & INSTALLATION

Page 105 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 105

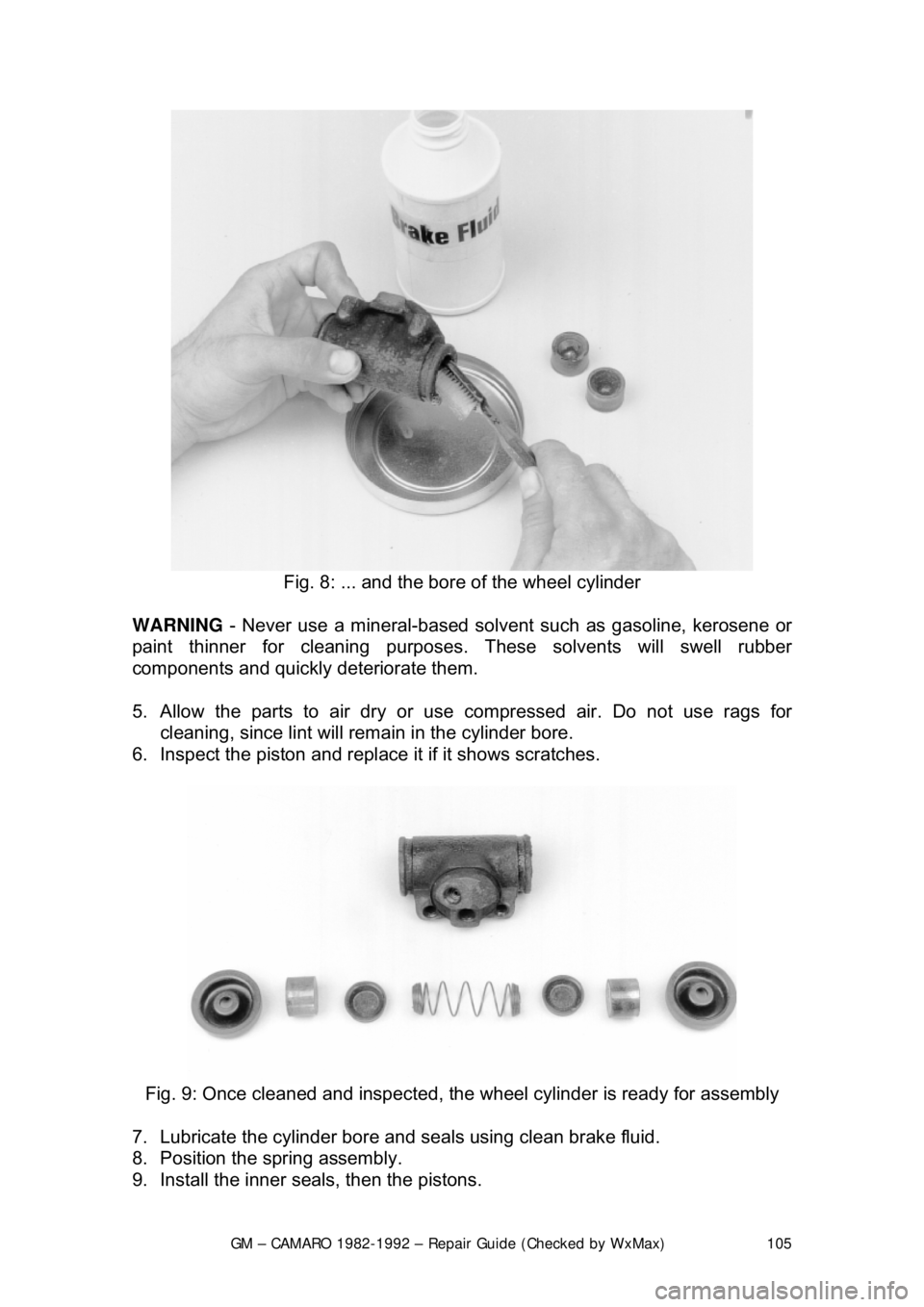

Fig. 8: ... and the bor e of the wheel cylinder

WARNING - Never use a mineral-based solvent such as gasoline, kerosene or

paint thinner for cleaning purposes . These solvents will swell rubber

components and quickly deteriorate them.

5. Allow the parts to air dry or use compressed air. Do not use rags for

cleaning, since lint will rema in in the cylinder bore.

6. Inspect the piston and replace it if it shows scratches.

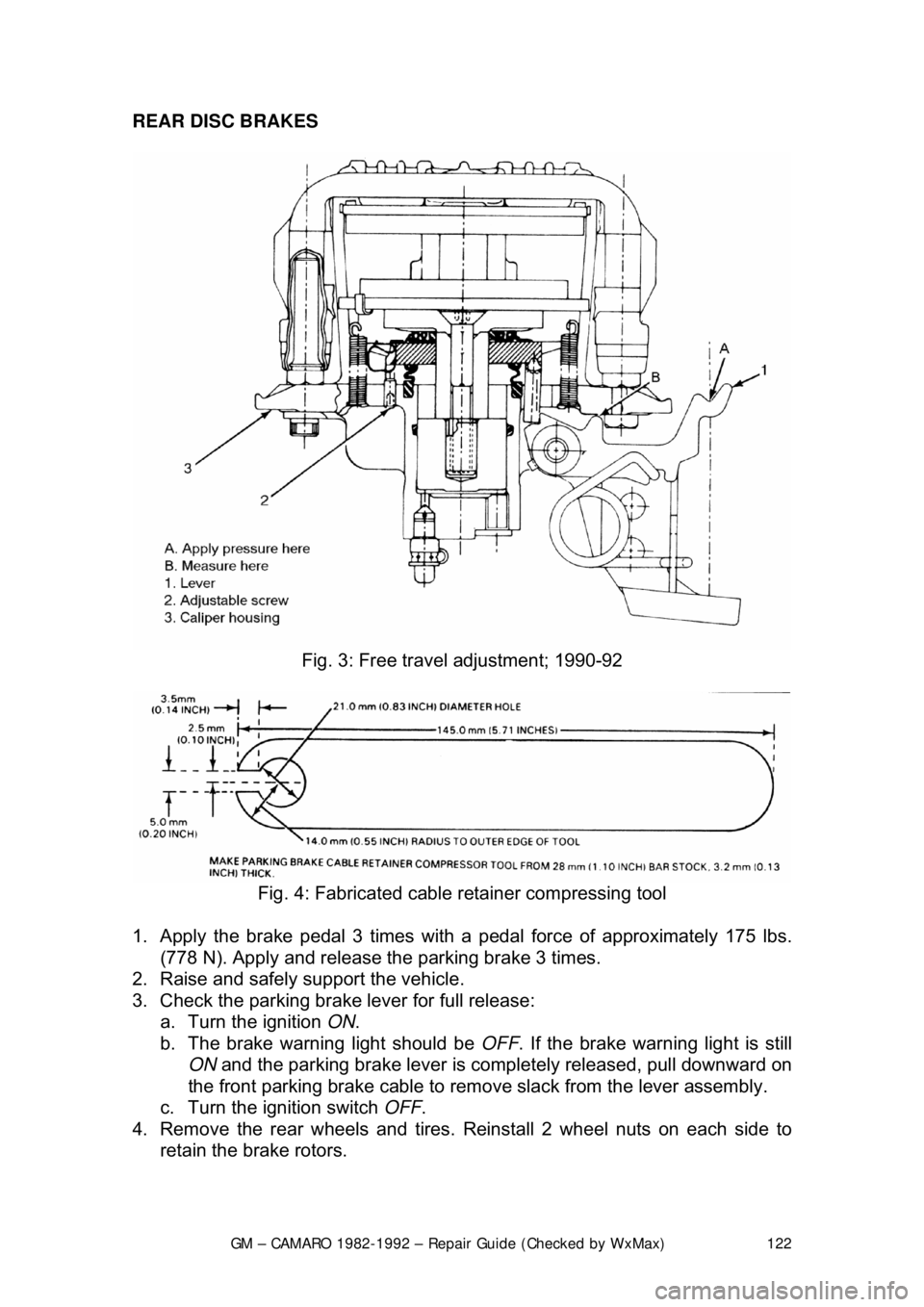

Fig. 9: Once cleaned and inspected, the wheel cylinder is ready for assembly

7. Lubricate the cylinder bore and s eals using clean brake fluid.

8. Position the spring assembly.

9. Install the inner seals, then the pistons.

Page 122 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 122

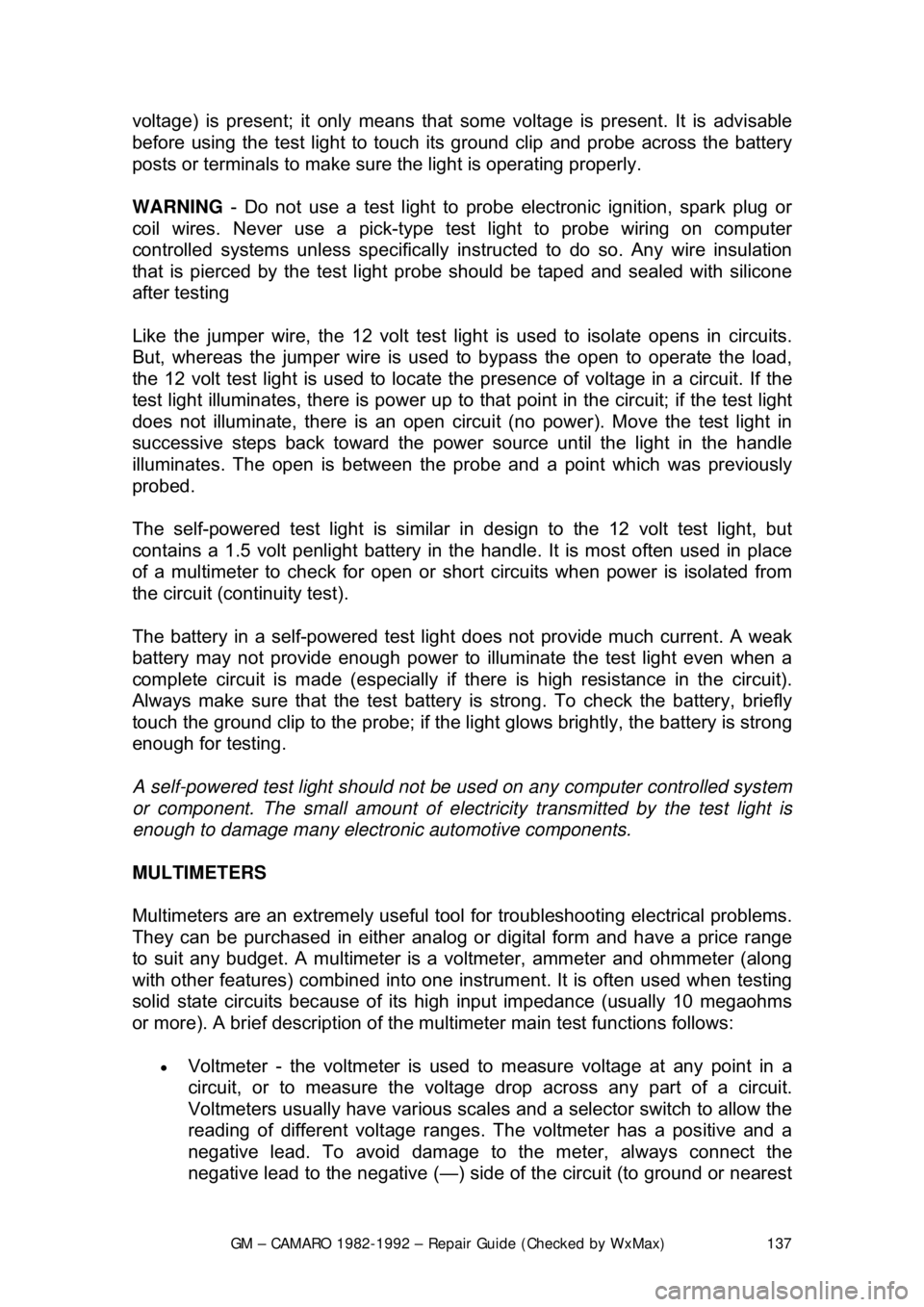

REAR DISC BRAKES

Fig. 3: Free trav el adjustment; 1990-92

Fig. 4: Fabricated cable retainer compressing tool

1. Apply the brake pedal 3 times with a pedal force of approximately 175 lbs.

(778 N). Apply and release t he parking brake 3 times.

2. Raise and safely support the vehicle.

3. Check the parking brake lever for full release: a. Turn the ignition ON.

b. The brake warning light should be OFF. If the brake warning light is still

ON and the parking brake lever is comple tely released, pull downward on

the front parking brake cable to remove slack from the lever assembly.

c. Turn the ignition switch OFF.

4. Remove the rear wheels and tires. Reinstall 2 wheel nuts on each side to

retain the brake rotors.

Page 137 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 137

voltage) is present; it only means that so

me voltage is present. It is advisable

before using the test light to touch its ground clip and probe across the battery

posts or terminals to make sure the light is operating properly.

WARNING - Do not use a test light to probe electronic ignition, spark plug or

coil wires. Never use a pick-type test light to probe wiring on computer

controlled systems unless spec ifically instructed to do so. Any wire insulation

that is pierced by the test light pr obe should be taped and sealed with silicone

after testing

Like the jumper wire, the 12 volt test li ght is used to isolate opens in circuits.

But, whereas the jumper wire is used to bypass the open to operate the load,

the 12 volt test light is us ed to locate the presence of voltage in a circuit. If the

test light illuminates, there is power up to t hat point in the circuit; if the test light

does not illuminate, there is an open circui t (no power). Move the test light in

successive steps back toward the power source until the light in the handle

illuminates. The open is between the pr obe and a point which was previously

probed.

The self-powered test light is similar in design to the 12 volt test light, but

contains a 1.5 volt penlight battery in the handle. It is most often used in place

of a multimeter to check for open or shor t circuits when power is isolated from

the circuit (continuity test).

The battery in a self-powered test light does not provide much current. A weak

battery may not provide enough power to illuminate the test light even when a

complete circuit is made (especially if there is high resistance in the circuit).

Always make sure that the test battery is strong. To check the battery, briefly

touch the ground clip to the pr obe; if the light glows brightly, the battery is strong

enough for testing.

A self-powered test light should not be used on any co mputer controlled system

or component. The small amount of electr icity transmitted by the test light is

enough to damage many electr onic automotive components.

MULTIMETERS

Multimeters are an extremely useful tool for troubleshooting electrical problems.

They can be purchased in either analog or digital form and have a price range

to suit any budget. A multimeter is a voltmeter, ammeter and ohmmeter (along

with other features) combined into one instrument. It is often used when testing

solid state circuits because of its hi gh input impedance (usually 10 megaohms

or more). A brief description of the mult imeter main test functions follows:

• Voltmeter - the voltmeter is used to measure voltage at any point in a

circuit, or to measure the voltage drop across any part of a circuit.

Voltmeters usually have various scales and a selector switch to allow the

reading of different volt age ranges. The voltmeter has a positive and a

negative lead. To avoid damage to the meter, always connect the

negative lead to the negative (—) side of the circ uit (to ground or nearest

Page 138 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 138

the ground side of the circuit) and

connect the positive lead to the

positive (+) side of the circuit (to t he power source or the nearest power

source). Note that the negative voltme ter lead will always be black and

that the positive voltmeter will alwa ys be some color other than black

(usually red).

• Ohmmeter - the ohmmeter is designed to read resistance (measured in

ohms) in a circuit or component. Mo st ohmmeters will have a selector

switch which permits the measurement of different ranges of resistance

(usually the selector swit ch allows the multiplication of the meter reading

by 10, 100, 1,000 and 10,000). Some ohmmeters are "auto-ranging"

which means the meter itself will dete rmine which scale to use. Since the

meters are powered by an internal battery, the ohmmeter can be used

like a self-powered test light. When the ohmmeter is connected, current

from the ohmmeter flows through the ci rcuit or component being tested.

Since the ohmmeter's internal resi stance and voltage are known values,

the amount of current flow throug h the meter depends on the resistance

of the circuit or component being test ed. The ohmmeter can also be used

to perform a continuity test for suspected open circuits. In using the

meter for making continuity checks, do not be concerned with the actual

resistance readings. Zero resistance, or any ohm reading, indicates

continuity in the circui t. Infinite resistance indi cates an opening in the

circuit. A high resistance reading w here there should be none indicates a

problem in the circuit. Checks for s hort circuits are made in the same

manner as checks for open circuits, ex cept that the circuit must be

isolated from both power and normal gr ound. Infinite resistance indicates

no continuity, while zero resi stance indicates a dead short.

WARNING - Never use an ohmmeter to check the resistance of a component or

wire while there is volt age applied to the circuit

• Ammeter - an ammeter measures the am ount of current flowing through

a circuit in units called amperes or amps. At normal operating voltage,

most circuits have a characteristic amount of amperes, called "current

draw" which can be measured usi ng an ammeter. By referring to a

specified current draw rating, then measuring the amperes and

comparing the two values, one can det ermine what is happening within

the circuit to aid in diagnosis. An open circuit, for example, will not allow

any current to flow, so the amme ter reading will be zero. A damaged

component or circuit will have an incr eased current draw, so the reading

will be high. The ammeter is always connected in series with the circuit\

being tested. All of the current that normally flows through the circuit

must also flow through the ammeter; if there is any other path for the

current to follow, the ammeter readi ng will not be accurate. The ammeter

itself has very little resistance to curr ent flow and, therefore, will not affect

the circuit, but it will measure current draw only when the circuit is closed

and electricity is flowing. Excessive current draw can blow fuses and

drain the battery, while a reduced current draw can cause motors to run \

slowly, lights to dim and other components to not operate properly.

Page 143 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 143

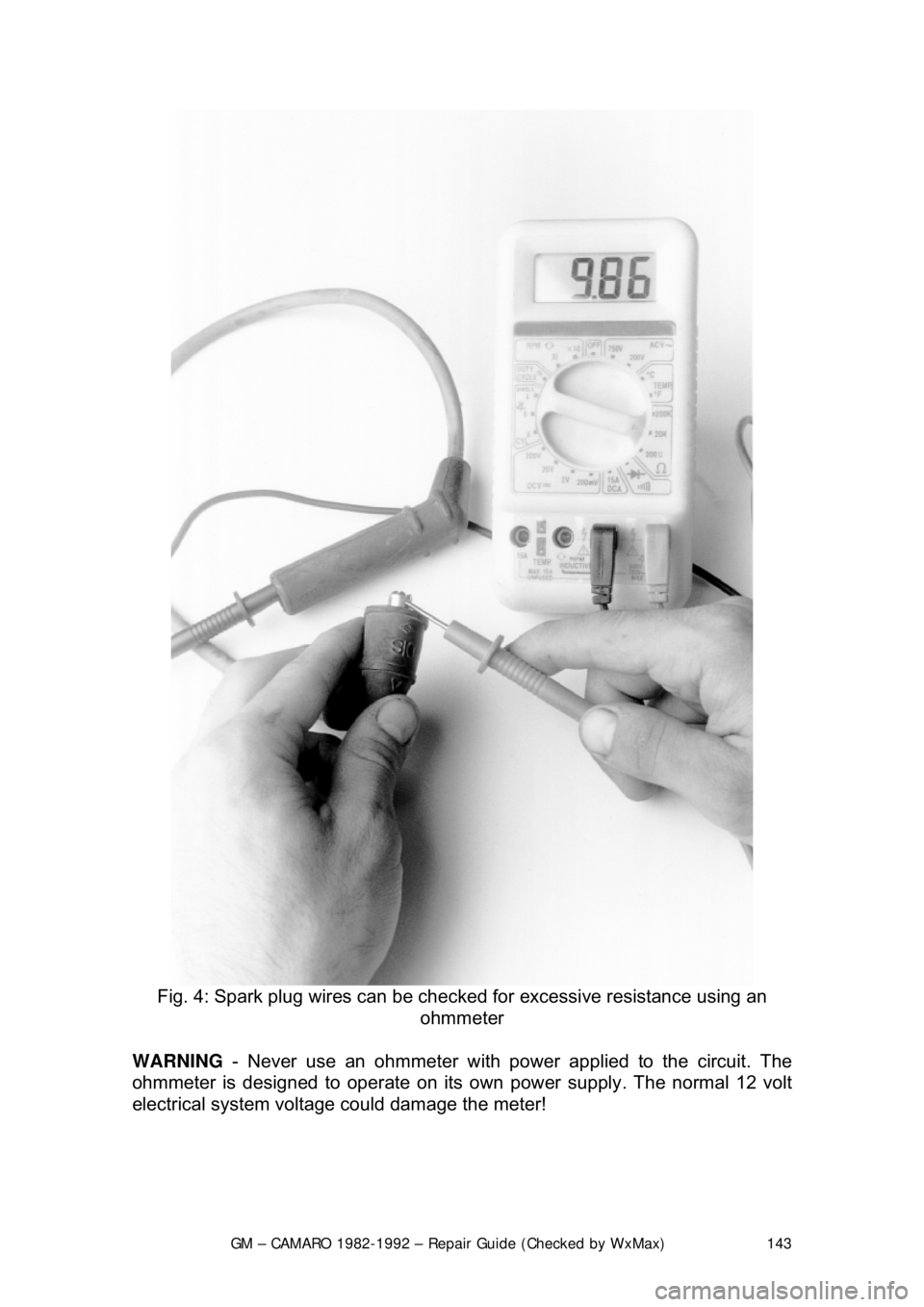

Fig. 4: Spark plug wires can be checked for excessive resistance using an

ohmmeter

WARNING - Never use an ohmmeter with power applied to the circuit. The

ohmmeter is designed to operate on its own power supply. The normal 12 volt

electrical system voltage could damage the meter!

Page 147 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 147

SYSTEM OPERATION

The main portions of the SIR system

are the deployment loops and the

Diagnostic Energy Reserve Module (D ERM). The main function of the

deployment loops is to supply current through the inflator module(s), which will

cause deployment of the air bag(s) in t he event of a frontal crash of sufficient

force. The arming sensor, SIR coil assembly (driver side only), passen\

ger

inflator module jumper (passenger side only), inflator module(s), passenger

compartment discriminating sensor and fo rward discriminating sensor make up

the deployment loops.

The DERM has two functions. One to supply the deployment loops with a 36

volt reserve to ensure sufficient energy is available to deploy the airbag(s) if the

battery voltage feed to the arming sensor is lost during a frontal crash. Another

function is SIR electrical system diagnostics.

The arming sensor switches power to th e inflator module(s) on the high side

(power side) of the deployment loops. Ei ther of the discriminating sensors can

supply ground to the inflator module(s) on the low side (ground side) of the loop.

The inflator module(s) ar e only supplied sufficient cu rrent to deploy when the

arming sensor and at least one of the two discriminating sensors are closed

simultaneously.

SYSTEM COMPONENTS

DIAGNOSTIC ENERGY RESERVE MODULE

The DERM is designed to perform the following functions in the SIR system:

• Energy Reserve - Maintains 36 volt energy reserve(s) to provide

deployment energy when the vehicle volt age is low or lost in a frontal

impact

• Malfunction Detection - Performs diagnostic monitoring of the SIR

system electrical components

• Malfunction Recording - Provides diagnostic trouble code information

• Frontal Crash Recording - Record s the SIR system status during a

frontal crash

WARNING LAMP

The "INFL REST" or "AIR BAG" warning lamp is used to do the following:

• Verify lamp and DERM oper ation by flashing seven to nine times when

the ignition key is first turned ON

• Warn the driver of SIR electrical system faults which could potentially

affect the operation of the SIR system

• Provide diagnostic information by fl ashing the fault codes when the

diagnostic mode is enabled