ignition CHEVROLET CORVAIR 1986 2.G User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1986, Model line: CORVAIR, Model: CHEVROLET CORVAIR 1986 2.GPages: 56, PDF Size: 22.23 MB

Page 24 of 56

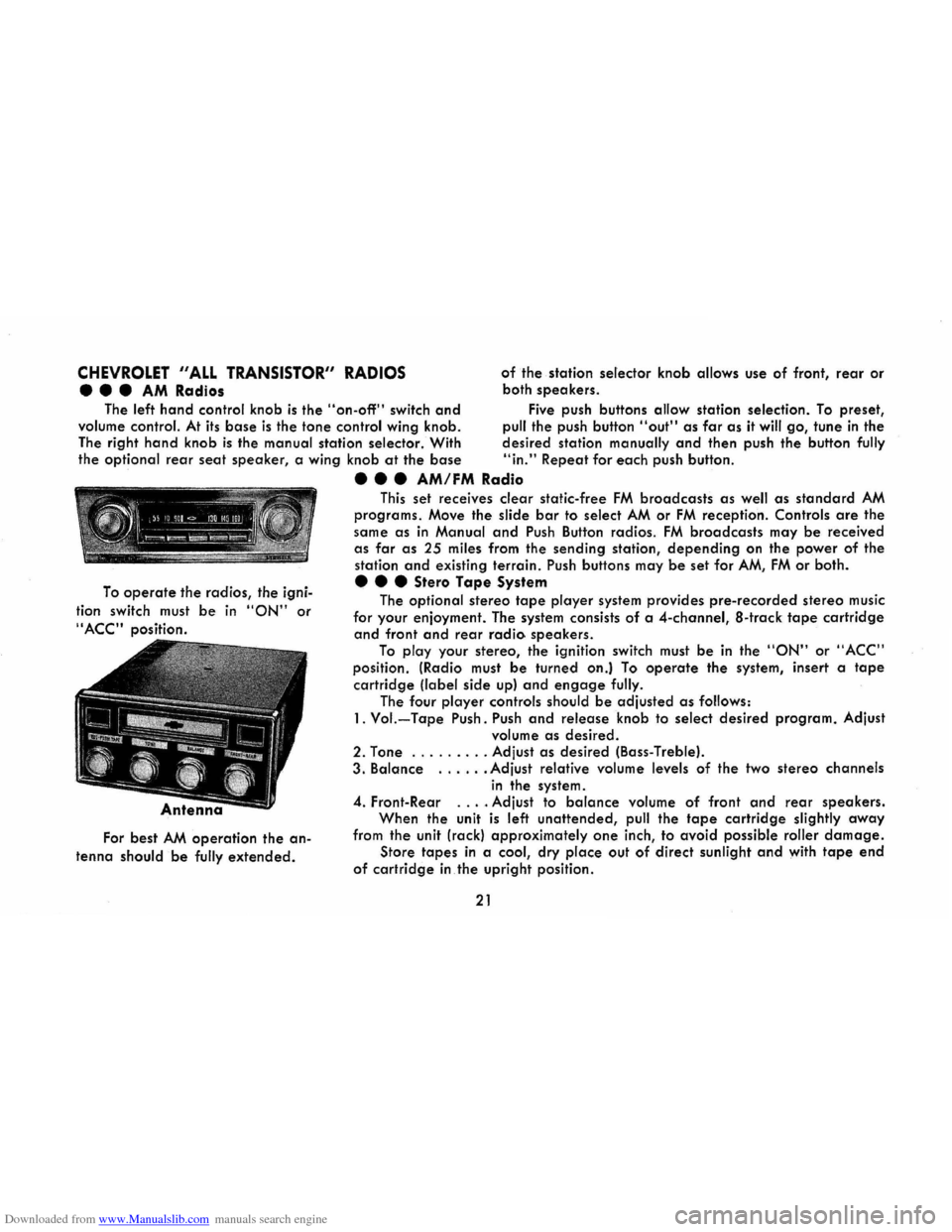

Downloaded from www.Manualslib.com manuals search engine CHEVROLET "ALL TRANSISTOR" RADIOS

••• AM Radios

of the station selector knob allows use of front, rear or

both

speakers .

The

left hand control knob is the "on-off" switch and Five push buttons allow station selection. To preset,

volume

control. At its base is the tone control wing knob. pull the push button "out" as far as it will go, tune in the

The right

hand knob is the manual station selector. With desired station manually and then push the button fully

the optional rear seat speaker, a wing knob at the base "in." Repeat for each push button .

To operate the radios, the igni

tion switch must

be in "ON" or

"ACC" position.

For best AM operation the an

tenna should be fully extended.

• • • AM/FM Radio

This set receives clear static-free FM broadcasts as well as standard AM

programs. Move the slide bar to select AM or FM reception. Controls are the

same

as in Manual and Push Button radios. FM broadcasts may be received

as far as 25 miles from the sending station, depending on the power of the

station

and existing terrain. Push buttons may be set for AM, FM or both .

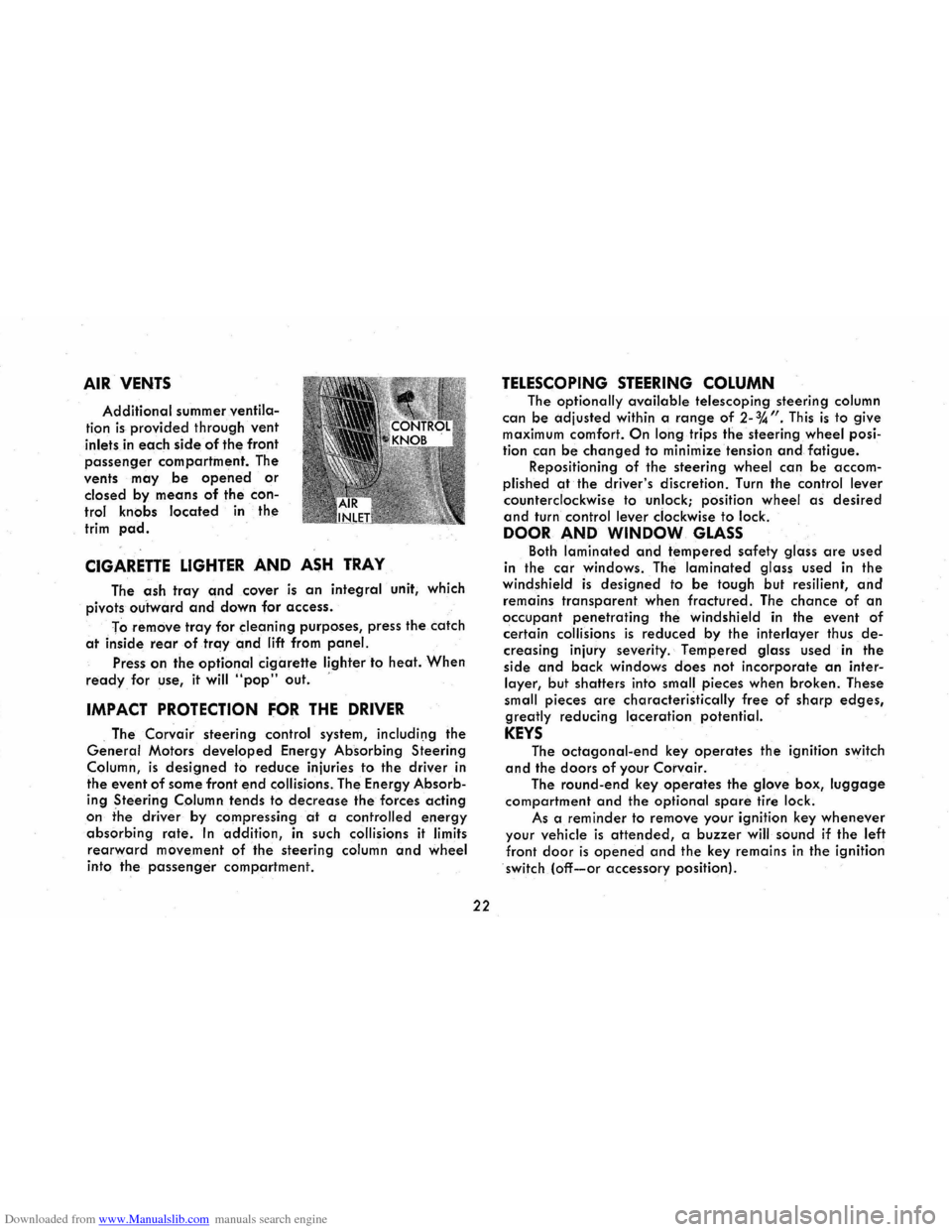

• • • Stero Tape System

The optional stereo tape player system provides pre-recorded stereo music

for your enjoyment. The system consists

of a 4-channel, a-track tape cartridge

and front and rear radio speakers.

To play your stereo, the ignition switch must be in the "ON" or "ACC"

position. (Radio must be turned on.) To operate the system, insert a tape

cartridge (label side up) and engage fully.

The four player controls should be adjusted as follows:

1. Vol.-Tape Push. Push and release knob to select desired program. Adjust

volume

as desired.

2. Tone ... .

..... Adjust as desired (Bass-Treble).

3. Balance ...... Adjust relative volume levels of the two stereo channels

in the system.

4. Front-Rear .... Adjust to balance volume of front and rear speakers.

When the unit

is left unattended, pull the tape cartridge slightly away

from the unit (rack) approximately one inch, to avoid possible roller damage.

Store tapes in a cool, dry place out of direct sunlight and with tape end

of cartridge in the upright position.

21

Page 25 of 56

Downloaded from www.Manualslib.com manuals search engine AIR VENTS

Additional summer ventila

tion is provided through vent

inlets in each side of the front

passenger compartment. The

vents

may be opened or

closed by means of the con

trol knobs located in the

trim pad.

CIGARETTE LIGHTER AND ASH TRAY

The ash tray and cover is an integral unit, which

pivots

outward and down for access.

To

remove tray for cleaning purposes, press the catch

at inside rear of tray and lift from panel.

Press on the optional cigarette lighter to heat. When

ready for use, it will "pop" out. '

IMPACT PROTECTION FOR THE DRIVER

. The Corvair steering control system, includil)g the

General Motors developed Energy Absorbing Steering

Column,

is designed to reduce injuries to the driver in

the event

of some front end collisions. The Energy Absorb

ing Steering Column tends to decrease the forces acting

on the driver by compressing at a controlled energy

absorbing rate. In addition, in such collisions it limits

rearward movement of the steering column and wheel

into the passenger compartment.

22

TELESCOPING STEERING COLUMN

The optionally available telescoping steering column

can be adjusted

within a range of 2-%". This is to give maximum comfort. On long trips the steering wheel posi

tion can

be changed to minimize tension and fatigue. Repositioning of the steering wheel can be accom

plished

at the driver's discretion. Turn the control lever

counterclockwise to unlock; position wheel as desired

and turn control lever clockwise to lock.

DOOR AND WINDOW GLASS

Both laminated and tempered safety glass are used

in the

car windows. The laminated glass used in the windshield is designed to be tough but resilient, and

remains transparent when fractured. The chance of an

occupant penetrating the windshield in the event of

certain collisions is reduced by the interlayer thus de

creasing injury severity. Tempered glass used in the

side

and back windows does not incorporate an inter

layer, but shatters into small pieces when broken. These

small pieces

are characteristically free of sharp edges,

greatly reducing laceration potential.

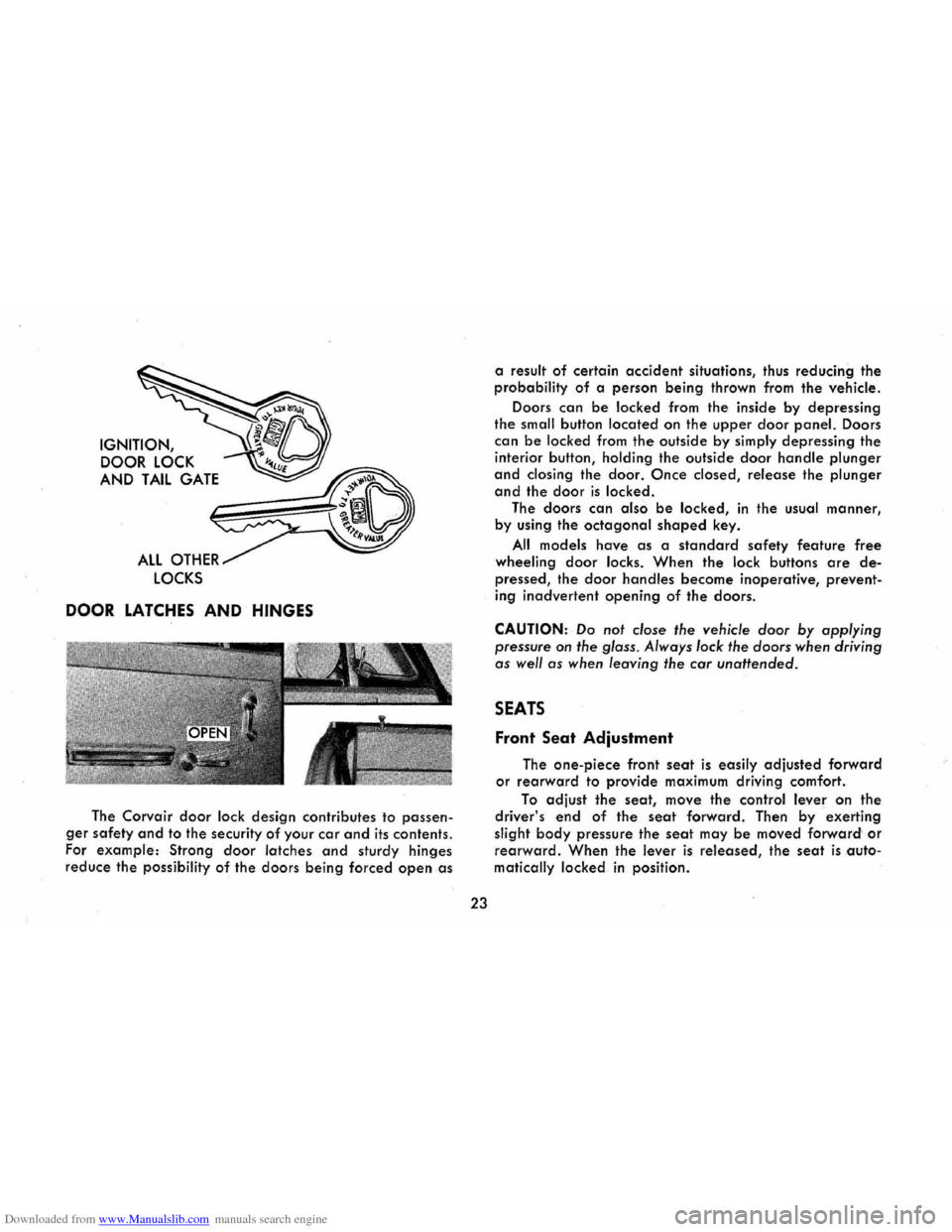

KEYS

The octagonal-end key operates the ignition switch

and the doors of your Corvair.

The round-end key operates the glove box, luggage

compartment and the optional spare tire lock.

As a

reminder to remove your ignition key whenever

your vehicle is attended, a buzzer will sound if the left

front door is opened and the key remains in the ignition

switch (off-or accessory position).

Page 26 of 56

Downloaded from www.Manualslib.com manuals search engine IGNITION, DOOR

LOCK

AND TAIL GATE

ALL OTHER

LOCKS

DOOR LATCHES AND HINGES

The Corvair door lock design contributes to passen

ger safety and to the security of your car and its contents.

For

example: Strong door latches and sturdy hinges

reduce the possibility of the doors being forced open as

23

a result of certain accident situations, thus reducing the

probability

of a person being thrown from the vehicle.

Doors

can be locked from the inside by depressing

the small button located on the upper door panel. Doors

can be locked from the outside by simply depressing the

interior button, holding the outside door handle plunger

and closing the door. Once closed, release the plunger

and the door is locked.

The doors

can also be locked, in the usual manner,

by using

the octagonal shaped key.

All models have as a standard safety feature free

wheeling door locks. When the lock buttons are de

pressed, the door handles become inoperative, prevent

ing

inadvertent opening of the doors.

CAUTION: Do not close the vehicle door by applying

pressure

on the glass. Always lock the doors when driving

as well as when leaving the car unattended.

SEATS

Front Seat Adjustment

The one-piece front seat is easily adjusted forward

or rearward to provide maximum driving comfort.

To adjust the seat, move the control lever on the

driver's end of the seat forward. Then by exerting

slight

body pressure the seat may be moved forward' or

rearward. When the lever is released, the seat is auto

matically locked

in position.

Page 40 of 56

Downloaded from www.Manualslib.com manuals search engine PERIODIC MAINTENANCE AND LUBRICATION

The time or mileage intervals on the following pages

are intended as a general guide for establishing regular

maintenance and lubrication periods for your Corvair.

Sustained heavy duty or high speed operations or oper-

A WORD ABOUT VEHICLE EMISSIONS

All new 1968 Corvairs are certified by the United States Department of Health, Education and Welfare as

conforming to the requirements of the regulations for

the Control of Air Pollution from New Motor Vehicles

and New Motor Vehicle Engines.

General Motors has developed control systems which

are highly effective in reducing undesirable crankcase

and exhaust emissions. It is very important that the owner make certain that the engine is serviced regularly

in order to maintain its efficiency and to keep emissions

below maximum allowable limits.

The emission control system on

your 1968 Corvair is

relatively easy to maintain, requiring only specific serv

ices as recommended by Chevrolet. To function properly,

this system must be inspected periodically and engine

tune-up performed at specified intervals by qualified

repairmen. For ready reference, pertinent information regarding ignition timing and idle speed and fuel mix

ture specifications is shown on a sticker affixed under

the hood of your vehicle. Following the prescribed main-

37

ation under adverse conditions may necessitate more

frequent servicing. For specific recommendations for con

ditions under which you use your vehicle, consult your

authorized Chevrolet Dealer.

tenance services

will help assure cleaner air and will

provide better running, longer lasting engines for greater

all-around satisfaction, economy and performance.

POSITIVE CRANKCASE VENTILATION (P.C.V')

The Positive Crankcase Ventilation system, which is

standard equipment on your vehicle, prevents emission

of gases from the crankcase. The P .C.V. system connects

the crankcase and intake manifold of the engine and

crankcase gases are returned through this system to the

combustion

chamber where they are burned. Periodic

inspection

and required servicing of your P.C.V. system

assures a cleaner, better-performing, longer-lasting

engine. A plugged P.C.V. system results in a loss of

crankcase ventilation which can cause condensation of

blow-by gases in the crankcase, resulting in the forma

tion of acids, sludge build-up and oil dilution. This also

results in

an increase in exhaust emissions due to car

buretor enrichment. Every 12,000 miles or 12 months,

whichever occurs first, the PCV valve should be replaced.

Page 41 of 56

Downloaded from www.Manualslib.com manuals search engine Also, all hoses, fittings and the inlet air filter should be

inspected, cleaned and replciced if necessary.

NOTE: If the positive crankcase ventilator valve should

become

dogged, the engine idle will be adversely

affect~d. Therefore, if the engine idle becomes too slow

or rough, the ventilator valve should be checked before

any carburetor ad;ustments are made to compensate for

the trouble.

AIR INJECTION REACTOR (A.I.R.l

The Air

Injection Reactor system is designed to re

duce .air pollution caused by exhaust emissions. It is entirely separate from the Positive Crankcase Ventilating

system. The Air

Injection Reactor system operates by

oxidizing (or burning) the

hydrocarbons and carbon

monoxide as they are expelled from the combustion

chamber into the exhaust. A positive displacement air

pump, driven by the engine, compresses clean frltered

air, which

is distributed and injected at the exhaust part

of each cylinder. This fresh air mixes with the hot exhaust

gases and promotes further oxidation (or burning) of

both hydrocarbons and carbon monoxide by converting

some

of them to carbon dioxide and water. This does not

reduce the danger of inhaling carbon monoxide in con

frned areas. See page 7 for carbon monoxide warning.

Supplementing

the air pump a special carburetor and

distributor plus related components are required.

The Air

Injection Reactor system should have the A.I.R. pump filter serviced and the drive belt inspected

for

wear and tension every 12 months or 12,000 miles,

38

whichever occurs frrst. In addition, complete effectiveness

of the system, as well as full power and performance,

depends upon idle speed, ignition timing, and idle fuel

mixture being

set according to specifrcation. A quality

tune-up which includes

these adjustments should be per

formed periodically to assure normal engine efficiency,

operation and performance.

STEERING GEAR

Every 36,000 miles -Re

move frller plug and

check lubricant level. If

necessary, add water

resistant EP chassis lu

bricant which meets

General Motors Specifr

cation GM 6031 M to

bring to level

of frller

plug hole.

FAN BELT

Every 6000 miles-check condition of belt. Check belt

guide to belt clearance. Belt guide ciearance should

be approximately 1/16" after belt is tensioned.

(See page 49). Retensioning a belt unnecessarily

may result

in premature belt fciilure.

ENGINE OIL CHANGE INTERVAL

Change engine oil each 4 months. If more than

6000 miles are driven in a 4-month period, change oil

Page 45 of 56

Downloaded from www.Manualslib.com manuals search engine AIR CLEANER

CAUTION: In addition to its function of filtering air

drawn into

the engine through the carburetor, the air

cleaner also acts as

a flame arrester in the event the

engine backfires. Because backfiring

may cause fire in

the engine compartment, the air cleaner should be in

stalled at all times unless its removal is necessary for

repair or maintenance services.

Paper Element Type

The oil-wetted paper element is a long-life efficient air

cleaner and should not require replacement before

24,000 miles except under extreme adverse condi

tions .

Inspect air cleaner at 12,000 miles for dust leaks,

holes

or other damage, replace if necessary . If

condition is satisfactory, rotate element 1800 from

originally installed position. Replace

at 24,000 miles.

Under extreme

adverse conditions inspect every 6,000 miles.

Oil Bath Type

Every 12,000 miles-Inspect and clean if necessary.

Refill with SAE 50 engine oil when lowest anticipated

temperature is above freezing; use SAE 20 if below

freezing.

BATTERY (ENERGIZER)

Every 6,000 miles-Clean and oil battery terminals and

oil felt washer. Check fluid level frequently. Keep

filled with distilled water to level of split ring in

42

vent tube. The electrolyte level indicator in the cap

of one cell will glow if the fluid level is low. In this

case each cell should be checked.

CAUTION: Since normal battery or Energizer

chemical action generates hydrogen gas which

is highly explosive when mixed with air, never

expose the battery to an open flame or electric

spark. Also, avoid getting battery fluid, which

is a sulfuric acid solution, on skin, on clothing

or other fabrics, or on painted surfaces . Eye

protection should

be worn while working on the

battery for

any reason.

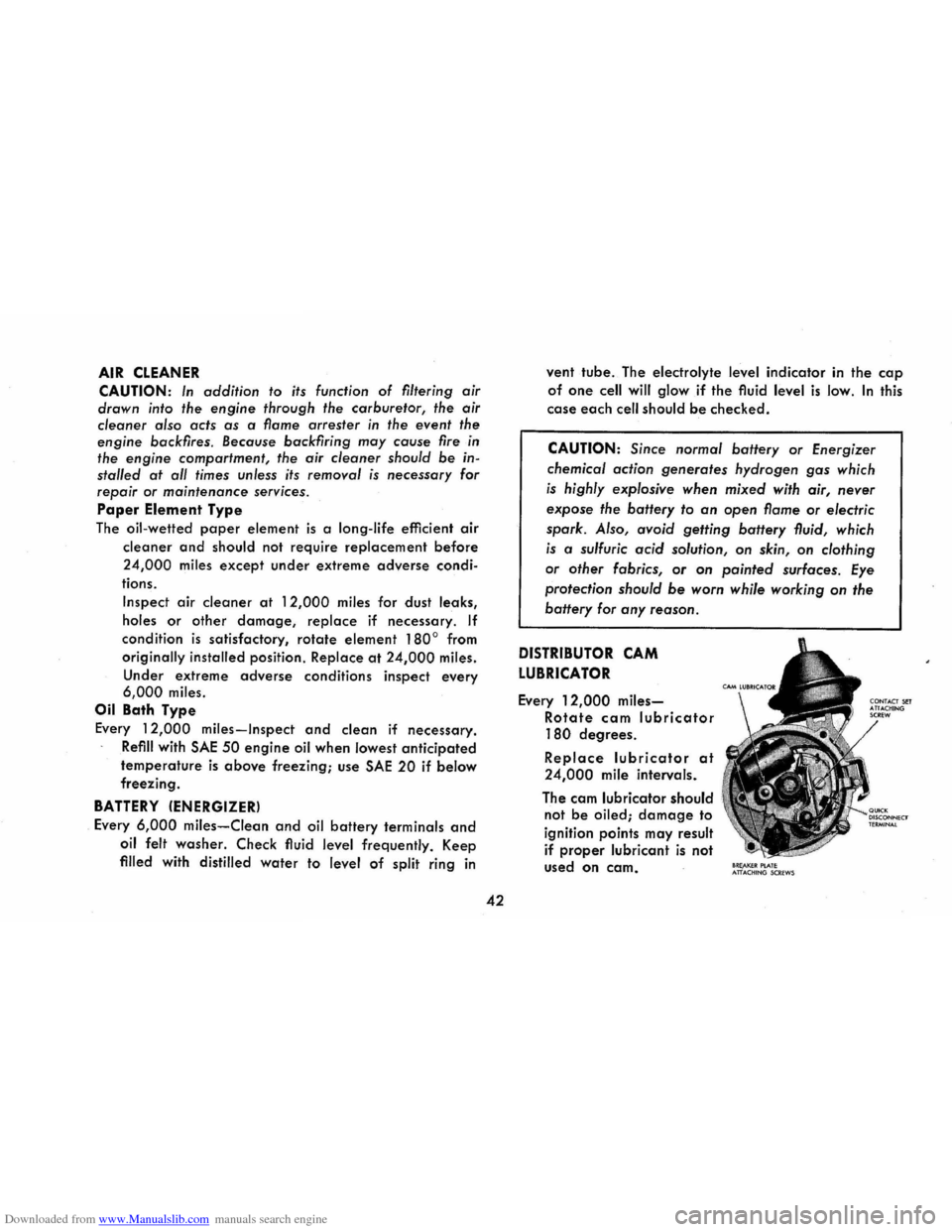

DISTRIBUTOR CAM

LUBRICATOR

Every 12,000 miles

Rotate cam lubricator

180 degrees.

Replace lubricator at

24,000 mile intervals.

The cam lubricator should

not

be oiled; damage to

ignition points may result

if

proper lubricant is not

used

on cam. 8RE,AKEIt PlATE ATTACHtNG SCREWS

Page 47 of 56

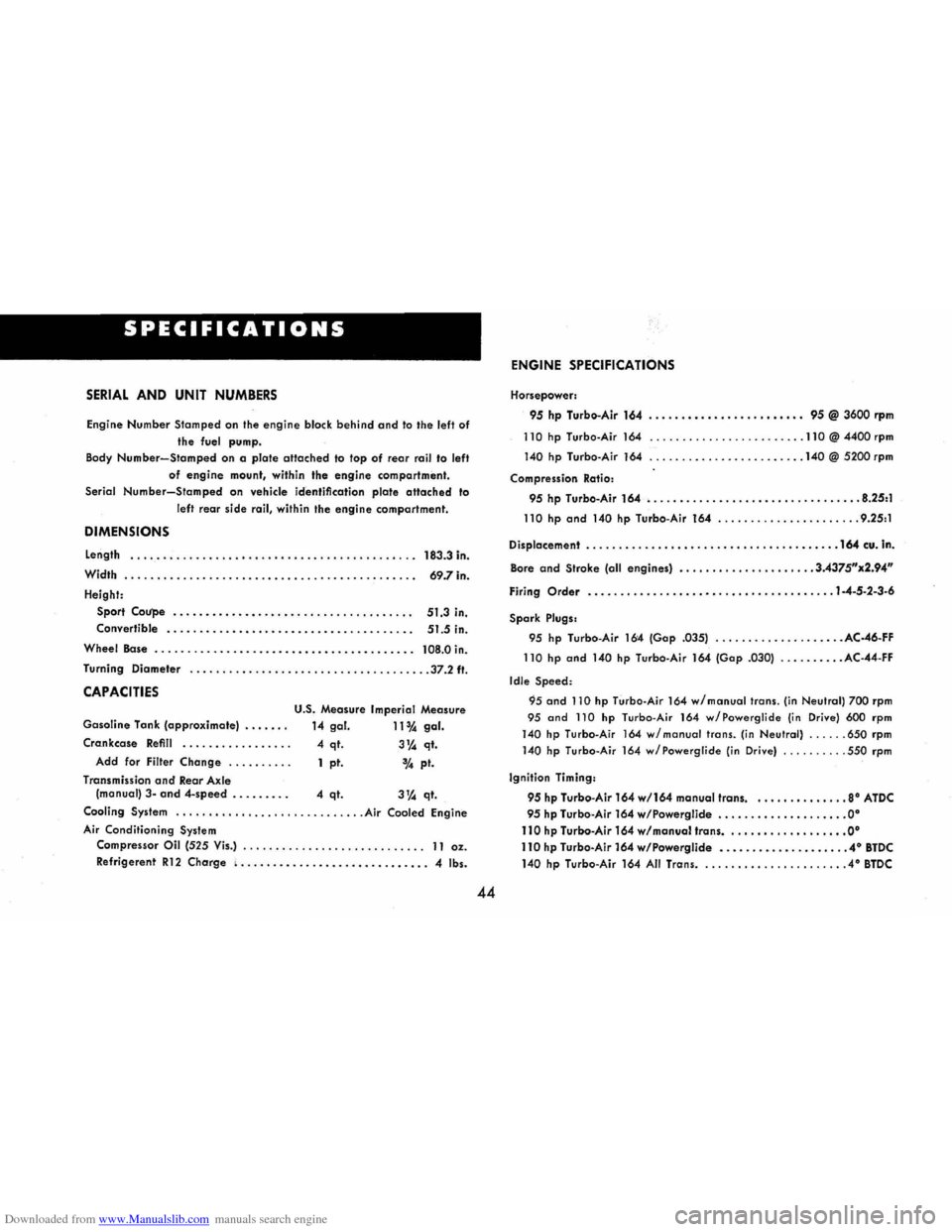

Downloaded from www.Manualslib.com manuals search engine SPECIFICATIONS

SERIAL AND UNIT NUMBERS

Engine Number Stamped on the engine block behind and to the left of

the fuel pump.

Body

Number-Stamped on a plate attached to top of rear rail to left

of engine mount, within the engine compartment .

Serial

Number-Stamped on vehicle identification plate attached to

left

rear side rail, within the engine compartment.

DIMENSIONS

Length .•...............•.•.•..................•... 183.3 in.

Width

.......•....•. . ....•..••......•.............• 69.7 in.

Height: Sport

Coupe ......•...••• ..•..••............•..•• 51.3 in.

Convertible

..........•.....••..•...•............. 51.5 in.

Wheel Base

...................•..•...•.... , ........ 108.0 in.

Turning Diameter .

.•..........•............... ........ 37.2 ft.

CAPACITIES

U.S. Measure Imperial Measure

Gasoline Tank (approximate) ...... .

14 gal. 11 % gal.

Crankcase Refill •....•..... ...... 4 qt. 3~ qt.

Add for Filter Change ......... . 1 pt. 3,4 pt.

Transmission

and Rear Axle

(manual) 3-and 4-speed ........ . 4 qt. 3~ qt.

Cooling System .....••...................... Air Cooled Engine

Air Conditioning System

Compressor Oil (525 Vis.) ...•............. ......... " 11 oz.

Refrigerent

R12 Charge ( •......•................•.... 4 Ibs.

44

ENGINE SPECIFICATIONS

Horsepower:

95 hp Turbo-Air 164 ......••.•.•........•.•• 95 @ 3600 rpm

110 hp Turbo-Air 164 ........................ 110 @ 4400 rpm

140 hp Turbo -Air 164 ........................ 140 @ 5200 rpm

Compression Ratio:

95 hp Turbo-Air 164 •...•........•.•.••••.•...••.•••. 8.25:1

110 hp and 140 hp Turbo-Air 164 ...................... 9.25:1

Displacement

......•....••••••..••••••...•..•.••\

•.•• 164 cu. In.

Bore and Stroke (all engines) ................. .... 3.4375"x2.94"

Firing Order •.........•..•••••••..•.•.••.•\

..••..•. 1-4-5-2-3·6

Spark Plugs.

95 hp Turbo-Air 164 (Gop .035)

.................... AC-46-FF

110

hp and 140 hp Turbo-Air 164 (Gop .030) .......... AC- 44-FF

Idle

Speed:

95 and 110 hp Turbo-Air 164 wi manual trans. (in Neutral) 700 rpm

95

and 110 hp Turbo-Air 164 w/Powerglide (in Drive) 600 rpm

140 hp Turbo-Air 164 wi manual trans. (in Neutral) ...... 650 rpm

140 hp Turbo-Air 164 w/Powerglide (in Drive) .......... 550 rpm

Ignition Timing:

95 hp Turbo-Air 164 wl164 manual trans •..•...•.•••.•. 8· ATDC

95 hp Turbo-Air 164 w/Powerglide ••.•..•••.••••..•••• 0·

110 hp Turbo-Air 164 wi manual Irons •....•..•..••....•. 0·

110 hp Turbo-Air 164 w/Powerglide •.••..•••.•..•••••.. 4· BTDC

140 hp Turbo-Air 164 All Trans ....................... 4° BTDC

Page 50 of 56

Downloaded from www.Manualslib.com manuals search engine MINOR TROUBLE SHOOTING PROCEDURES

The chart on the previous page, and the information on the pages

which follow, contains information designed to aid the average

driver to discover, and possibly correct, conditions resulting in minor

mechanical

difficulties in his car. The chart, designed to point out

possible solutions to

several of the most common automotive mal

functions

and point out a logical checking sequence, will lead step

by step to the most likely causes and corrective procedures. If, after

making the checks and adjustments suggested, the source of the

trouble

has not been found and corrected, it is strongly recom

mended

that an Authorized Chevrolet Dealer inspect the vehicle and

make whatever repairs or adjustments are necessary.

FUEL SYSTEM AND ENGINE

If the ignition switch will cause the engine to "turn over" or

"crank" but the car will not start, check Steps A through D below.

NOTE:

If continual "flooding" of the carburetor is evidenced by a

carburetor wet with fuel or black exhaust smoke, perform the

operation

suggested in paragraph 0 only .

(A) The first and most obvious,

and one of the most frequently

overlooked, items to check when

you

have- difficulty in starting your

car is the amount of fuel in the

tank.

Make it a habit to check the

FUEL GAUGE regularly and most

especially

at a time when the en

gine will "turn over" but will not

start.

(8)

If the fuel tank is not empty, Checking Fuel Flow

47

you may check further to see whether the fuel is reaching the

engine. Disconnect the fuel lines

at the carburetor. Place a jar or cup

under open line and briefly "crank" the engine by means of the

starter. If fuel spurts from the line, you may assume that the FUEL

LINES are clear and the FUEL PUMP is operating properly. If no fuel

leaves the line, either the fuel lines

or fuel pump are at fault. See

your Authorized Chevrolet Dealer.

(C) Before reconnecting the fuel lines to the carburetor, remove

the

FUel FilTER from carburetor inlet and check its condition.

If it appears to be clean, replace it and reconnect the fuel lines. If

the filter appears to be plugged, clean it as well as possible by

scraping out the foreign material and cleaning in a solvent. Then

reinstall the filter

and repeat the procedure with the second carbu

retor. Replace the filters with new ones as soon as possible .

(0) If the fuel seems to be reaching the carburetors properly, the

problem may

be: an EMPTY CARBURETOR BOWL caused by a

"stuck shut" float valve or a flOODED CARBURETOR caused by a

"stuck open" condition and evidenced by gasoline flowing down

the outside

of the carburetor; or a stuck CHOKE valve. Remove the

air cleaners from the carburetors. Check that the choke valves move

freely and are not stuck. Tap the side of the carburetors sharply

several times with a light tool such as a screwdriver handle or pliers.

Replace the

air deaners and attempt to start the engine in the

normal manner.

(E) If the car will start but stalls when hot or has a rough idle,

you

can suspect a faulty IDLE ADJUSTMENT, or extremely dirty

Page 51 of 56

Downloaded from www.Manualslib.com manuals search engine and blocked AIR CLEANER ELEMENTS. Replace the air cleaner ele

ments

if necessary. Idle adjustment should be performed by your

Chevrolet Dealer.

If the above Fuel System checks and the checks suggested under

the Electrical System following do not correct the malfunction, it is

recommended that you turn to your Authorized Chevrolet Dealer

for further checks, adjustments

or repairs.

ELECTRICAL SYSTEM

If, when the ignition key is turned to START, the engine will not

turn over, you have

good reason to suspect electrical trouble.

(F) When there is no response at all to attempts to start the car,

check the obvious-your AUTOMATIC TRANSMISSION SELECTOR

LEVER must be in neutral position before the engine can be started.

Turning the IGNITION SWITCH rapidly back and forth several

times

will sometimes correct a poor internal switch contact.

(G) The BATTERY may be discharged. If so, lights will be dim and

the horn will have a poor tone if it will blow at all.

Usually

a garage recharge will be necessary to return the battery

to operotion. Occasionally, however, a long drive will recharge

the battery.

NOTE:

If the battery is determined to be dead, and for no apparent

reason, have

your Authorized Chevrolet Dealer check the

battery, the GENERATOR and the

VOLTAGE REGULATOR.

GENERATOR trouble should already have been indicated

by

the indicator on the instrument panel. Never remove generator

"BAT" lead without first disconnecting battery ground cable.

48

POOR BATTERY CONNECTIONS may be suspected if the car has operated properly a short time before and now not even the horn

will operate. Check both ends of both battery cables. If the con

nections are corroded, a car may sometimes be restored to operation by removing all cable ends, scraping all contacting surfaces

clean with a pen knife, and reassembling. If the cables are broken,

they must be replaced. The power supply should now be restored

unless the battery is dead.

(H) If, however, the lights and horn work properly but the starter will still not turn over, check the STARTER connections. A "click" from the starter solenoid indicates that the wiring to the starter is properly installed. If the wiring seems to be clean and tightly installed, the trouble is probably in the starter itself and should be referred to your Authorized Chevrolet Dealer.

When the engine will "turn over" but will not start, the following

items may be checked along with Fuel System Checks listed previously.

(I) With a clean dry cloth wipe the ceramic portions of the spark plugs dry. In particularly damp or rainy weather dampness may be the cause of not sta rting, especially when the engine is cold.

(J) Check the cables at the top of the distributor and coil as well as each spark plug cable for

tightness.

(K) If the car will still not start, check for spark at the spark plugs in the following manner:

Pull one of the spark plug

wires off its spark plug. Insert a

short piece of bare wire (such as a bobby pin) between the rubber Distributor and Coil Leads

Page 52 of 56

Downloaded from www.Manualslib.com manuals search engine cup at the end of the spark plug

wire

and the tubular metal con

nector inside of it. If the spark

plug wire is wet or oily, wipe it

dry.

Wrap a dry handkerchief or

facial tissue, folded several thick

nesss, around the wire at least

three inches back from the end

and grasp wire at this point.

Hold the

bare wire about V4 inch

from the bare tip of the spark

plug from which you removed the

wire. When the engine is "turned Checking for Spork

over" a spark should jump across the V4 inch space, indicating

ample current supply.

If no spark jumps, the difflcultyis probably

caused by a defective ignition part and should be corrected by

your Authorized

Chevrolet Dealer.

COOLING SYSTEM

When the car will run but evidences serious overheating on the

temperature

gauge in the instrument panel, there are several items

which may

be checkd.

(L) Engine overheating will occur when the OIL LEVEL falls

dangerously low.

Check the oil level as a matter of course.

CAUTION: Never drive the car when the TEMP-PRESS indicator in

the instrument panel is lighted.

49

1M) Check the air intake louvers. Clean them if they are plugged

with leaves

or other foreign material.

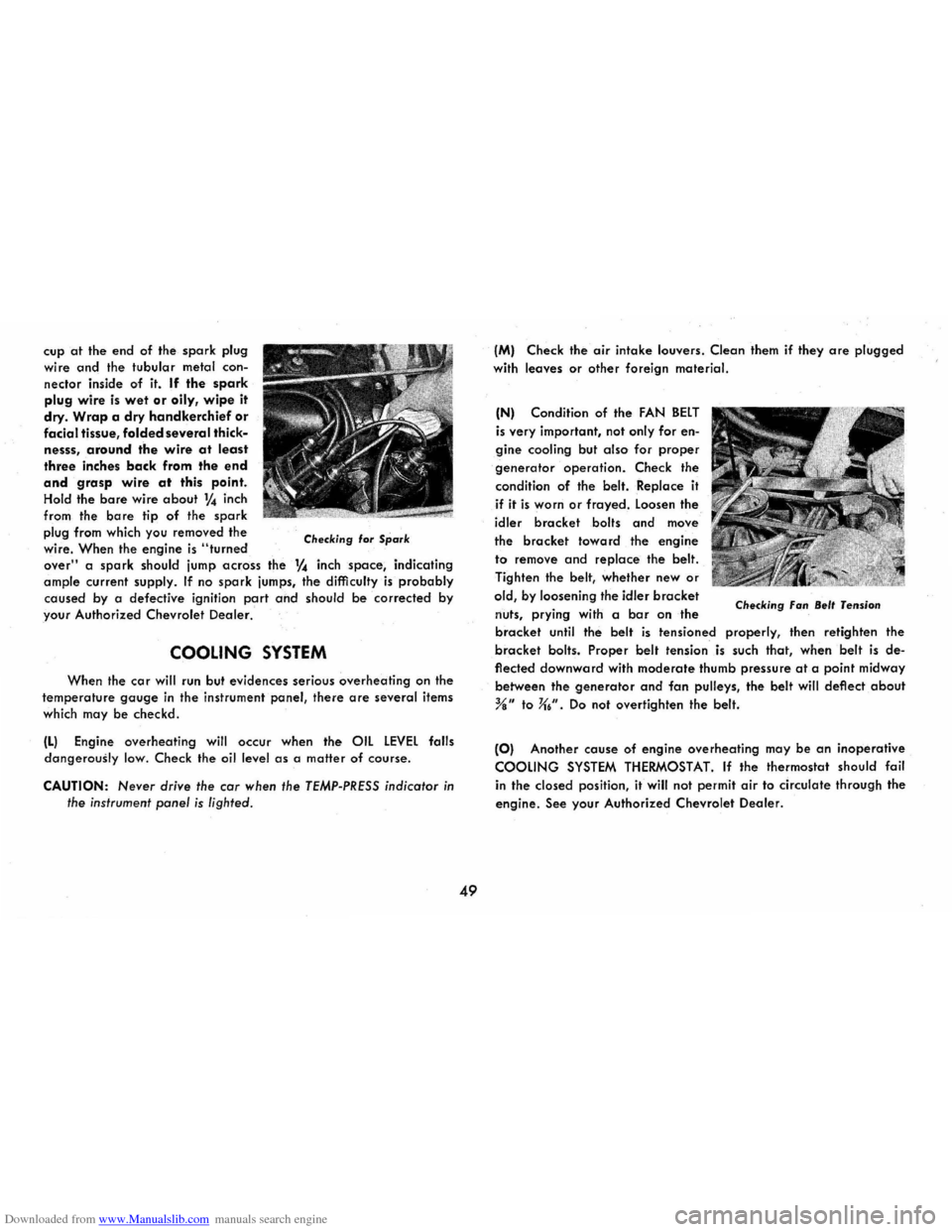

IN) Condition of the FAN BELT

is very important, not only for en

gine cooling but also for proper

generator operation. Check the

condition of the belt. Replace

it

if it is worn or frayed. Loosen the

idler

bracket bolts and move

the

bracket toward the engine

to remove and replace the belt.

Tighten the belt, whether new

or

old, by loosening the idler bracket

nuts, prying with a bar on the Checking Fan Be" Tension

bracket until the belt is tensioned properly, then retighten the

bracket bolts. Proper belt tension is such that, when belt is de

flected downward with moderate thumb pressure at a point midway

between the

generator and fan pulleys, the belt will deflect about

:Va" to K6". Do not overtighten the belt.

(0) Another cause of engine overheating may be an inoperative

COOLING SYSTEM THERMOSTAT. If the thermostat should fail

in the closed position, it will not permit air to circulate through the

engine.

See your Authorized Chevrolet Dealer.