lock CHEVROLET CORVAIR 1986 2.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1986, Model line: CORVAIR, Model: CHEVROLET CORVAIR 1986 2.GPages: 56, PDF Size: 22.23 MB

Page 6 of 56

Downloaded from www.Manualslib.com manuals search engine ..

Don't invite car theft! An unlocked car with the

key still in the ignition offers both opportunity and temptation.

Remember always to lock ignition,

lock all doors ... TAKE THE KEY!

NOTE: Your 1968 Chevrolet features as standard equipment a buzzer device which

will activate when the driver's door is opened and the key left in the switch. Heed

its

warning-let it also serve to remind you to lock all doors.

The identification number

of your vehicle is located on the instrument panel and is

visible from the outside. It is also stamped prominently on the engine and transmission.

These precautions have been taken

for your protection to aid the apprehension of thieves

and the recovery

of stolen vehicles, engines and transmissions and to serve as a deterrent

to

theft itself.

3

Page 7 of 56

Downloaded from www.Manualslib.com manuals search engine A WORD ABOUT ... VEHICLE SAFETY AND THE INI

TIAL FEDERA~ MOTOR VEHICLE SAFETY STANDARDS

Chevrolet has for many years been a leader in the field

of automotive safety. Almost every advance in design and engineering since the jnception of the industry has contributed

to the safety, reliability and durability of our cars. Continua

tion of this important and vital trend is exemplified in your

1968 Chevrolet. Important safety advances are designed to

aid in avoiding accidents, and in reducing injuries during the accident and as a result of the accident.

But remember-it takes more than a safe car to avoid

accidents. Observe all traffic laws, make safe driving a habit and maintain your car in top condition.

Your

n!,)w 1968 Chevrolet conformed to all federal motor

vehicle safety standards applicable at time of manufacture.

Effectiveness of these safety features ~an best be continued

through periodic vehicle inspection and regular maintenance .

Th~ initial Federal Motor Vehicle Safety Standards encompass a number of systems on all passenger cars. To promote better understanding of these standards, listed are those

standards applicable to passenger cars, and the purpose and

scope of each.

Initial

Federal Motor Vehicle Safety Standards (Effective January 1, 1968*)

Amendment to certain of these

Standards and additional Standards that would apply to 1968 Model passenger cars

manufactured after January 1, 1968 , were under cons ideration by the National Highway Safety Bureau at the time this Owner's Manual was prepared. '

STANDARD NO. 101

Control Location and Identification

Purpose and Scope. This standard specifies the requirements

for location and identification of certain controls to facilitate

their selection and ensure their accessibility.

4

STANDARD NO. 102 Transmission Shift Lever Sequence, Starter Interlock, and Transmission Braking Effect Purpose and Scope. This standard specifies the requirements

for the transmission shift lever sequence, a starter interlock, and for a braking effect of automatic transmissions, to requce the likelihood of shifting errors, starter engagement with vehicle in drive position, and to provide supplemental braking at speeds below 25 miles per hour.

STANDARD NO. 103 Windshield Defrosting and Defogging Purpose lind Scope. This standard specifies requirements

for providing vision through the windshield during frosting and fogging conditions.

STANDARD NO. 104 Windshield Wiping and Washing Systems

Purpose and Scope. This standard specifies requirements

for windshi eld wiping and washing systems.

ST ANDARD NO. 105 Hydraulic Service Brake, Emergency Brake, and Parking Brake Systems

Purpose and Scope. This standard specifies requirements

for hydraulic service brake, emergency brake, and parking

brake systems intended to ensure adequate braking performance under normal and emergency conditions.

STANDARD NO. 106 Hydraulic Brake Hoses Purpose and Scope. This standard specifies requirements

for hydraulic brake hoses that will reduce brake failures due to fluid leakage.

STANDARD NO. 107 Reflecting Surfaces

Purpose and Scope. This standard specifies reflecting surface requir ements for certain vehicle components in the driver's field of view.

..

Page 11 of 56

Downloaded from www.Manualslib.com manuals search engine STARTING THE ENGINE

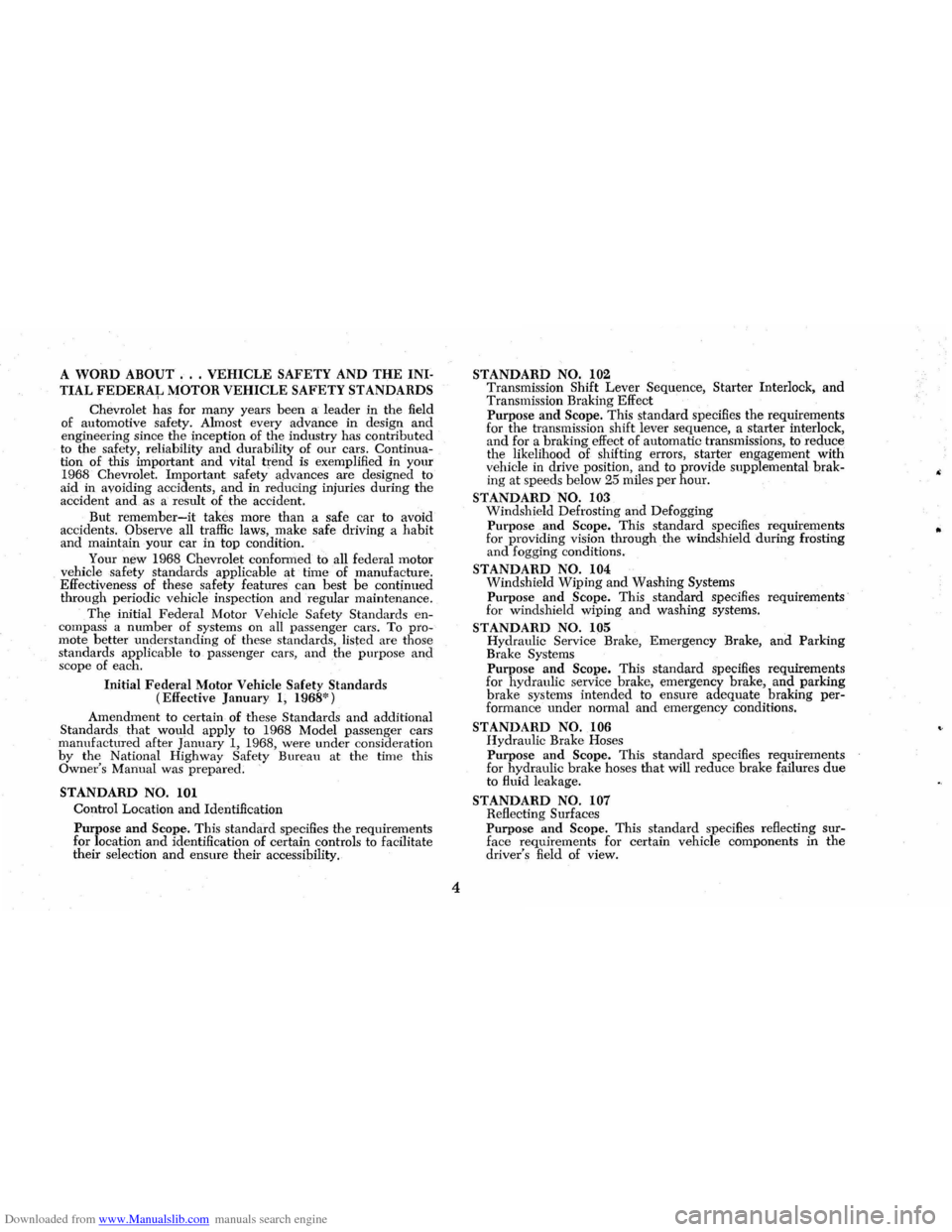

IGNITION SWITCH

OPERA ACCESSORIES ONLY DRIVING STARTING ENGINE

START-Used only when

starting engine. When released,

switch returns to ON.

ON-For normal operation after engine has been started.

OFF-Turns off engine and accessories.

ACC-AII accessories routed through the ignition switch

may

be operated with the switch in this position.

Engine will not

start with switch in ACC position

-ignition system is by-passed, permitting battery

power to flow directly to accessories.

To prevent rapid discharge of battery, do not

operate accessories for prolonged periods with

switch

in ACC position.

KEY WARNING SYSTEM

A high percentage of car thefts occur because car

8

doors are left unlocked or the key is not removed from

the ignition switch. Corvairs

are equipped with an anti

theft key warning system. Failure

to remove the key from

the ignition switch when

in the OFF position will cause a

warning

buzzer to sound when the left door is opened.

STARTING

1. POWERGLIDE-Place control lever in N position.

The

engine will not start with the transmission

in gear.

MANUAL TRANSMISSION-Place gearshift control

lever in neutral, and depress clutch pedal to the

floor.

2. Depress accelerator pedal part way and hold. In

extreme cold weather (O°F. and below), depress

accelerator pedal twice, then hold pedal part

way down during starting .

NOTE: Engine will not start with accelerator ped

al depressed to floor, except when "flooded."

3. Turn ignition switch to START and release as soon

as

engine starts .

4. "FLOODED" ENGINE-Depress accelerator pedal to

floor

and hold while cranking engine. DO NOT

"PUMP"

ACCELERATOR PEDAL WHEN ENGINE

IS "FLOODED."

Page 13 of 56

Downloaded from www.Manualslib.com manuals search engine fully synchronized, may be downshifted into first

gear at any speed below 20 mph.

TO STOP-Release the accelerator and depress the

brake pedal. As car slows down, depress the clutch

pedal and move the gearshift lever into neutral.

NEUTRAL-For use when starting or idling engine.

REVERSE-Operate as for 1 st gear but always at a

slow speed.

CAUTION: When parking or leaving the car unattended,

even for a few minutes, remove the ignition key, place

the selector lever in first gear or reverse if manual trans

mission, and fully apply the parking brake.

DRIVING WITH THE POWERGLIDE TRANSMISSION

The optional Powerglide transmission is a completely

automatic transmission which replaces the standard clutch

and transmission. After starting the engine with the se

lector lever

in N (neutral) position, merely select the

range desired and depress the accelerator. The Power

glide

transmission will do the rest.

Automatic transmission shift

quadrants of all GM

cars continue the uniform sequence of selector positions.

This particularly benefits multicar families and those who

occasionally drive other cars. Shift indicators are ar

ranged as follows: "Reverse", "Neutral" and the forward

driving

ranges. All automatic transmissions are equipped

with a starter interlock system designed to permit start

ing the engine only when the transmission selector is in

the "Neutral" position. For additional engine braking

effect,

as sometimes needed in mountainous driving,

place the transmission in an intermediate or low range.

10

The dash-mounted driving range selector is equipped

with mechanical stops to prevent unintentional shifting

into reverse

and low ranges. Move lever to the left, to

override stop,

and continue shift for selection of reverse

or low ranges.

With

lever in 0 position the transmission starts in

automatic low gear and will shift to cruising gear at

some point between approximately 12 and 50 mph,

depending on the accelerator position. Thus, a slow start

with a steady, gradual increase of pressure on the accel

erator pedal will enable the transmission to shift into the

more economical cruising gear in the shortest possible

time. Hard acceleration for fast starts will cause the trans

mission to remain in low gear for a considerably longer

period.

When driving at speeds below 45 mph, the transmis-

Page 19 of 56

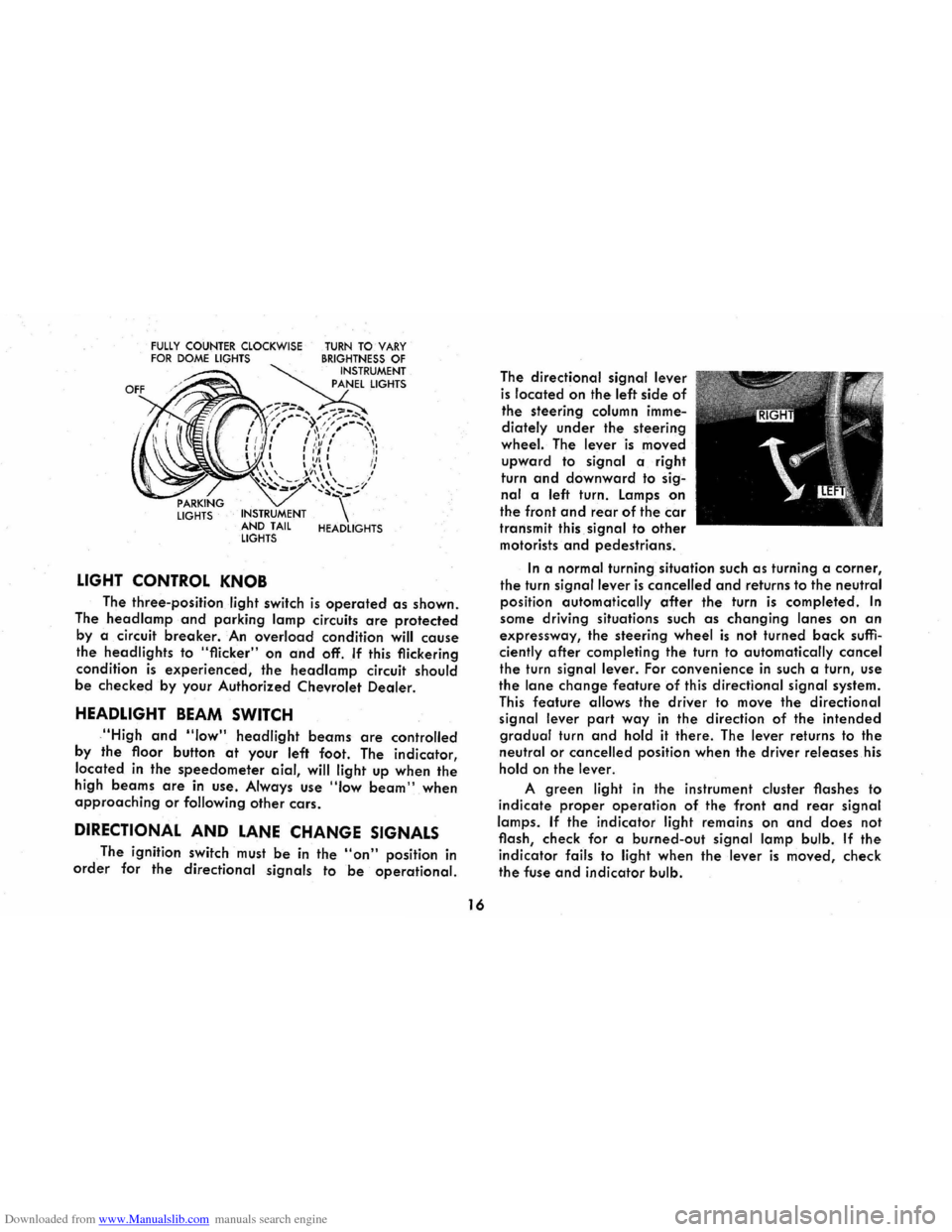

Downloaded from www.Manualslib.com manuals search engine FULLY COUNTER CLOCKWISE FOR DOME LIGHTS

LIGHTS INSTRUMENT

AND TAIL

LIGHTS

LIGHT CONTROL KNOB

TURN TO VARY BRIGHTNESS OF INSTRUMENT

PANEL LIGHTS

HEADLIGHTS

The three-position light switch is operated as shown.

The

head lamp and parking lamp circuits are protected

by a circuit breaker. An overload condition will cause

the headlights to "flicker" on and off. If this flickering

condition

is experienced, the headlamp circuit should

be checked by your Authorized Chevrolet Dealer.

HEADLIGHT BEAM SWITCH

,"High and "low" headlight beams are controlled

by

the floor button at your left foot. The indicator,

located

in the speedometer aial, will light up when the

high beams are in use . Always use "Iow beam" when approaching or following other cars.

DIRECTIONAL AND LANE CHANGE SIGNALS

The ignition switch must be in the "on" position in

order for the directional signals to be operational.

16

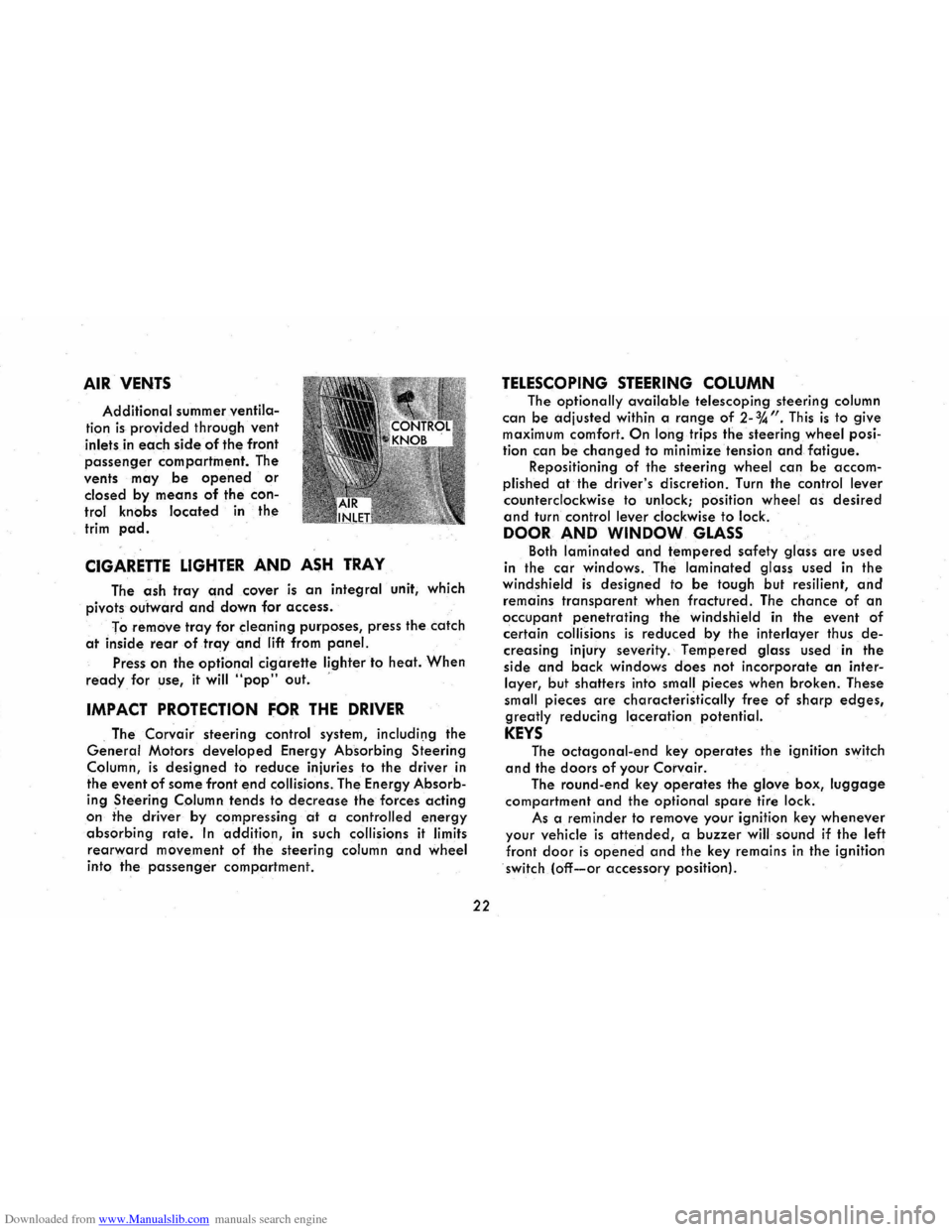

The directional signal lever

is located on the left side of

the steering column imme

diately

under the steering

wheel. The lever is moved

upward to signal a right

turn

and downward to sig

nal a left turn. Lamps on

the front and rear of the car

transmit this signal to other

motorists and pedestrians.

In a normal turning situation such as turning a corner,

the turn signal lever is cancelled and returns to the neutral

position automatically

after the turn is completed. In

some driving situations such as changing lanes on an

expressway, the steering wheel is not turned back suffi

ciently after completing the turn to automatically cancel

the turn signal lever. For convenience in such a turn, use

the lane change feature of this directional signal system.

This feature allows the driver to move the directional

signal lever

part way in the direction of the intended

gradual turn and hold it there. The lever returns to the

neutral or cancelled position when the driver releases his

hold on the lever.

A green light in the instrument cluster flashes to

indicate

proper operation of the front and rear signal

lamps.

If the indicator light remains on and does not

flash, check for a burned-out

signal lamp bulb. If the

indicator fails to light when the lever is moved, check

the fuse and indicator bulb.

Page 25 of 56

Downloaded from www.Manualslib.com manuals search engine AIR VENTS

Additional summer ventila

tion is provided through vent

inlets in each side of the front

passenger compartment. The

vents

may be opened or

closed by means of the con

trol knobs located in the

trim pad.

CIGARETTE LIGHTER AND ASH TRAY

The ash tray and cover is an integral unit, which

pivots

outward and down for access.

To

remove tray for cleaning purposes, press the catch

at inside rear of tray and lift from panel.

Press on the optional cigarette lighter to heat. When

ready for use, it will "pop" out. '

IMPACT PROTECTION FOR THE DRIVER

. The Corvair steering control system, includil)g the

General Motors developed Energy Absorbing Steering

Column,

is designed to reduce injuries to the driver in

the event

of some front end collisions. The Energy Absorb

ing Steering Column tends to decrease the forces acting

on the driver by compressing at a controlled energy

absorbing rate. In addition, in such collisions it limits

rearward movement of the steering column and wheel

into the passenger compartment.

22

TELESCOPING STEERING COLUMN

The optionally available telescoping steering column

can be adjusted

within a range of 2-%". This is to give maximum comfort. On long trips the steering wheel posi

tion can

be changed to minimize tension and fatigue. Repositioning of the steering wheel can be accom

plished

at the driver's discretion. Turn the control lever

counterclockwise to unlock; position wheel as desired

and turn control lever clockwise to lock.

DOOR AND WINDOW GLASS

Both laminated and tempered safety glass are used

in the

car windows. The laminated glass used in the windshield is designed to be tough but resilient, and

remains transparent when fractured. The chance of an

occupant penetrating the windshield in the event of

certain collisions is reduced by the interlayer thus de

creasing injury severity. Tempered glass used in the

side

and back windows does not incorporate an inter

layer, but shatters into small pieces when broken. These

small pieces

are characteristically free of sharp edges,

greatly reducing laceration potential.

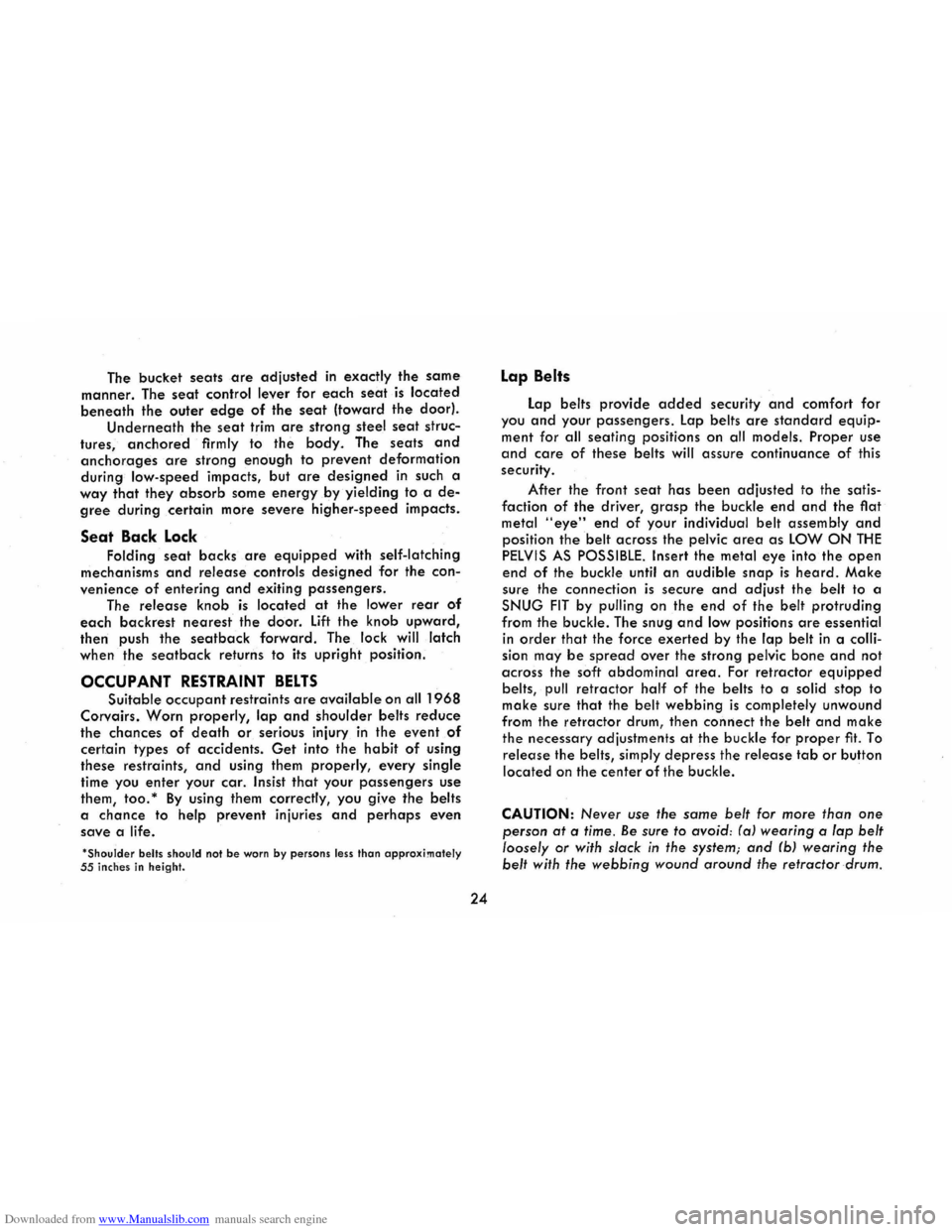

KEYS

The octagonal-end key operates the ignition switch

and the doors of your Corvair.

The round-end key operates the glove box, luggage

compartment and the optional spare tire lock.

As a

reminder to remove your ignition key whenever

your vehicle is attended, a buzzer will sound if the left

front door is opened and the key remains in the ignition

switch (off-or accessory position).

Page 26 of 56

Downloaded from www.Manualslib.com manuals search engine IGNITION, DOOR

LOCK

AND TAIL GATE

ALL OTHER

LOCKS

DOOR LATCHES AND HINGES

The Corvair door lock design contributes to passen

ger safety and to the security of your car and its contents.

For

example: Strong door latches and sturdy hinges

reduce the possibility of the doors being forced open as

23

a result of certain accident situations, thus reducing the

probability

of a person being thrown from the vehicle.

Doors

can be locked from the inside by depressing

the small button located on the upper door panel. Doors

can be locked from the outside by simply depressing the

interior button, holding the outside door handle plunger

and closing the door. Once closed, release the plunger

and the door is locked.

The doors

can also be locked, in the usual manner,

by using

the octagonal shaped key.

All models have as a standard safety feature free

wheeling door locks. When the lock buttons are de

pressed, the door handles become inoperative, prevent

ing

inadvertent opening of the doors.

CAUTION: Do not close the vehicle door by applying

pressure

on the glass. Always lock the doors when driving

as well as when leaving the car unattended.

SEATS

Front Seat Adjustment

The one-piece front seat is easily adjusted forward

or rearward to provide maximum driving comfort.

To adjust the seat, move the control lever on the

driver's end of the seat forward. Then by exerting

slight

body pressure the seat may be moved forward' or

rearward. When the lever is released, the seat is auto

matically locked

in position.

Page 27 of 56

Downloaded from www.Manualslib.com manuals search engine The bucket seats are adjusted in exactly the same

manner. The seat control lever

for each seat is located

beneath the outer edge of the seat (toward the door).

Underneath the seat trim are strong steel seat struc

tures,

anchored firmly to the body. The seats and

anchorages are strong enough to prevent deformation

during low-speed impacts, but are designed in such a way that they absorb some energy by yielding to a de

gree during certain more severe higher-speed impacts.

Seat Back Lock

Folding seat backs are equipped with seH-latching

mechanisms

and release controls designed for the con

venience of entering and exiting passengers.

The release

knob is located at the lower rear of

each backrest nearest the door. lift the knob upward,

then push the seatback forward. The lock will latch

when the

seatback returns to its upright position.

OCCUPANT RESTRAINT BELTS

Suitable occupant restraints are available on all 1968

Corvairs. Worn properly, lap and shoulder belts reduce

the chances

of death or serious injury in the event of cert.ain types of accidents. Get into the habit of using

these restraints,

and using them properly, every single

time you

enter your car. Insist that your passengers use

them,

too. * By using them correctly, you give the belts

a chance

to help prevent injuries and perhaps even

save a

life.

·Shoulder belts should not be worn by persons less thon approximately 55 inches in height.

24

Lap Belts

Lap belts provide added security and comfort for

you and your passengers . Lap belts are standard equip

ment for all seating positions on all models. Proper use

and care of these belts will assure continuance of this

security.

After the front seat has been adjusted to the satis

faction of the driver, grasp the buckle end and the flat

metal "eye" end of your individual belt assembly and

position the belt across the pelvic area as LOW ON THE

PELVIS AS POSSIBLE. Insert the metal eye into the open

end of the buckle until an audible snap is heard. Make

sure the connection is secure and adjust the belt to a

SNUG FIT by pulling on the end of the belt protruding

from the buckle . The snug and low positions are essential

in

order that the force exerted by the lap belt in a colli

sion may be spread over the strong pelvic bone and not

across the soft abdominal area. For retractor equipped

belts, pull retractor half of the belts to a solid stop to

make sure that the belt webbing is completely unwound

from the retractor drum, then connect the belt and make

the necessary adjustments

at the buckle for proper fit. To

release the belts, simply depress the release

tab or button

located on the center of the buckle.

CAUTION: Never use the same belt for more than one

person at a time. Be sure to avoid: (aJ wearing a lap belt

loosely or with slack

in the system; and (bJ wearing the

belt with the

webbing wound around the retractor drum.

Page 30 of 56

Downloaded from www.Manualslib.com manuals search engine deflect or collapse under certain impacts. The soft vinyl

cover over the mirror support base further protects the occupants.

CAUTION: It is important that the driver check the

mirrors

for proper positioning, and that he make frequent

use of the mirrors to be constantly aware of the rearward

aspect

of his total driving situation.

The windshield wiper arms and blades, inside wind

shield moldings,

horn and steering wheel ornamentation,

inside rearview mirror frame and mounting bracket

incorporate low-gloss finishes. This reduces annoying

glare in the driver's forward field of view and provides

a

safer, more comfortable driving environment.

FOLDING REAR SEAT

The folding rear seat-back, standard equipment on

Monza,

optional on all other Corvair models except

convertible, quickly and easily folds forward and down to provide additional

cargo space.

To lower the folding seat

back:

• Pull on each end of the seatback to unlock.

• Swing

the seatback forward and down.

To raise the seatback:

• Lift the seat back and slam firmly into place. FOLDING REAR SEAT

27

CONVERTIBLE

Operating the Folding Top

CAUTION: Prior to raising or lowering the folding

top, the

car must be at a complete stop and the

sunvisors turned down. Also, when lowering the top,

make certain the top is thoroughly dry and that

there are

no items stored in the top well.

When the folding top is to be lowered, the locking

handles located at the front of the side rails near the

windshield header must be rotated inboard. On conver

tibles

equipped with a power operated top, the top

control switch may then be actuated until the top is fully

lowered.

On convertibles that are equipped with a

manually operated top, grasp the under side of the side

rail rearward of the locking handles and lift rail upward

and rotate rearward until top is fully lowered. Also, with

the manual top, downward pressure must then be exerted

to each side rail until catch clip located at top of quar

ter trim panel snaps onto the e.nd of the side rail.

When raising the power operated top, actuate the

control switch until top rests on windshield heater.

In raising the manually operated top, the catch clips

must first

be disehgaged from the right and left side

rails. The raising of the top can be completed by grasp-

Page 31 of 56

Downloaded from www.Manualslib.com manuals search engine ing the front corner of the top and rotating the top for

ward until top rests on windshield header.

The locking handles are then rotated outboard

which engages the lock hooks to the striker assembly

located on the windshield header.

Installing the Top Boot

Remove top boot from its protective case, which is normally stored in the luggage compartment.

Grasping forward

end of the boot, slide the welt on

the

boot into the retainer located on the top of the rear

seat back panel. The boot can then be placed over the

lowered top and the metal snap fasteners on the boot

can be snapped onto the studs on the belt molding and quarter trim. Any wrinkles that may exist may be re

lieved

by sliding the forward portion of the boot to the

right or left in the retainer.

Care of Folding Top and Rear Window

The folding top should never be subiected to vola

tile cleaners or household bleaches. Frequent washing

with

neutral soap suds, lukewarm water and soft bristle

brush

is normally all that is necessary to maintain the

"Factory Fresh" look. In the event heavy soilage or

stubborn stains are encountered, a mild foaming cleanser, lukewarm water, and a soft bristle brush may be

used. If desired, the top may be supported from the

underside during the cleaning

operation. Regardless

which cleaning method is used, a generous amount of

28

rinse water is to be used as any soap that runs down

on the

body finish and allowed to dry, may cause streaks.

After cleaning,

always be sure the top is thoroughly dry before it is lowered.

The pliable plastic window, due to its texture, is sus

ceptible

to scratches and abrasions. As a result, the top

should not be lowered when the rear window is dirty.

When cleaning the

rear window, do not use a dry

cloth or volatile cleaning agents. A soft cloth moistened

with

water should be used to remove superficial dust.

When completely washing the rear window, cold or

luke warm water and a mild neutral soap suds may be

used along with a generous amount of rinse water. In

addition, the rear window can be cleaned with G.M. Plastic Cleaner available at your dealer.

A scraper should never be used for removing snow

or ice from the rear window. In an emergency, warm

water may be cautiously used.

NOTE: DO NOT paste any stickers or masking tape

on rear window as damage will result.

ENGINE COMPARTMENT

• To open: Push up the lid release while lifting the lid.

Lift the lid all the way up, then release.

• To close: Lift up on lid, unlock the support arm catch

lock, then lower the lid. Drop the lid the last six