parking brake CHEVROLET CORVAIR 1986 2.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1986, Model line: CORVAIR, Model: CHEVROLET CORVAIR 1986 2.GPages: 56, PDF Size: 22.23 MB

Page 7 of 56

Downloaded from www.Manualslib.com manuals search engine A WORD ABOUT ... VEHICLE SAFETY AND THE INI

TIAL FEDERA~ MOTOR VEHICLE SAFETY STANDARDS

Chevrolet has for many years been a leader in the field

of automotive safety. Almost every advance in design and engineering since the jnception of the industry has contributed

to the safety, reliability and durability of our cars. Continua

tion of this important and vital trend is exemplified in your

1968 Chevrolet. Important safety advances are designed to

aid in avoiding accidents, and in reducing injuries during the accident and as a result of the accident.

But remember-it takes more than a safe car to avoid

accidents. Observe all traffic laws, make safe driving a habit and maintain your car in top condition.

Your

n!,)w 1968 Chevrolet conformed to all federal motor

vehicle safety standards applicable at time of manufacture.

Effectiveness of these safety features ~an best be continued

through periodic vehicle inspection and regular maintenance .

Th~ initial Federal Motor Vehicle Safety Standards encompass a number of systems on all passenger cars. To promote better understanding of these standards, listed are those

standards applicable to passenger cars, and the purpose and

scope of each.

Initial

Federal Motor Vehicle Safety Standards (Effective January 1, 1968*)

Amendment to certain of these

Standards and additional Standards that would apply to 1968 Model passenger cars

manufactured after January 1, 1968 , were under cons ideration by the National Highway Safety Bureau at the time this Owner's Manual was prepared. '

STANDARD NO. 101

Control Location and Identification

Purpose and Scope. This standard specifies the requirements

for location and identification of certain controls to facilitate

their selection and ensure their accessibility.

4

STANDARD NO. 102 Transmission Shift Lever Sequence, Starter Interlock, and Transmission Braking Effect Purpose and Scope. This standard specifies the requirements

for the transmission shift lever sequence, a starter interlock, and for a braking effect of automatic transmissions, to requce the likelihood of shifting errors, starter engagement with vehicle in drive position, and to provide supplemental braking at speeds below 25 miles per hour.

STANDARD NO. 103 Windshield Defrosting and Defogging Purpose lind Scope. This standard specifies requirements

for providing vision through the windshield during frosting and fogging conditions.

STANDARD NO. 104 Windshield Wiping and Washing Systems

Purpose and Scope. This standard specifies requirements

for windshi eld wiping and washing systems.

ST ANDARD NO. 105 Hydraulic Service Brake, Emergency Brake, and Parking Brake Systems

Purpose and Scope. This standard specifies requirements

for hydraulic service brake, emergency brake, and parking

brake systems intended to ensure adequate braking performance under normal and emergency conditions.

STANDARD NO. 106 Hydraulic Brake Hoses Purpose and Scope. This standard specifies requirements

for hydraulic brake hoses that will reduce brake failures due to fluid leakage.

STANDARD NO. 107 Reflecting Surfaces

Purpose and Scope. This standard specifies reflecting surface requir ements for certain vehicle components in the driver's field of view.

..

Page 13 of 56

Downloaded from www.Manualslib.com manuals search engine fully synchronized, may be downshifted into first

gear at any speed below 20 mph.

TO STOP-Release the accelerator and depress the

brake pedal. As car slows down, depress the clutch

pedal and move the gearshift lever into neutral.

NEUTRAL-For use when starting or idling engine.

REVERSE-Operate as for 1 st gear but always at a

slow speed.

CAUTION: When parking or leaving the car unattended,

even for a few minutes, remove the ignition key, place

the selector lever in first gear or reverse if manual trans

mission, and fully apply the parking brake.

DRIVING WITH THE POWERGLIDE TRANSMISSION

The optional Powerglide transmission is a completely

automatic transmission which replaces the standard clutch

and transmission. After starting the engine with the se

lector lever

in N (neutral) position, merely select the

range desired and depress the accelerator. The Power

glide

transmission will do the rest.

Automatic transmission shift

quadrants of all GM

cars continue the uniform sequence of selector positions.

This particularly benefits multicar families and those who

occasionally drive other cars. Shift indicators are ar

ranged as follows: "Reverse", "Neutral" and the forward

driving

ranges. All automatic transmissions are equipped

with a starter interlock system designed to permit start

ing the engine only when the transmission selector is in

the "Neutral" position. For additional engine braking

effect,

as sometimes needed in mountainous driving,

place the transmission in an intermediate or low range.

10

The dash-mounted driving range selector is equipped

with mechanical stops to prevent unintentional shifting

into reverse

and low ranges. Move lever to the left, to

override stop,

and continue shift for selection of reverse

or low ranges.

With

lever in 0 position the transmission starts in

automatic low gear and will shift to cruising gear at

some point between approximately 12 and 50 mph,

depending on the accelerator position. Thus, a slow start

with a steady, gradual increase of pressure on the accel

erator pedal will enable the transmission to shift into the

more economical cruising gear in the shortest possible

time. Hard acceleration for fast starts will cause the trans

mission to remain in low gear for a considerably longer

period.

When driving at speeds below 45 mph, the transmis-

Page 14 of 56

Downloaded from www.Manualslib.com manuals search engine sion may be shifted into low range for extra acceleration

for passing by depressing the

accelerator pedal fully. The

transmission

will automatically shift back into cruising

gear when the accelerator pedal is momentarily released.

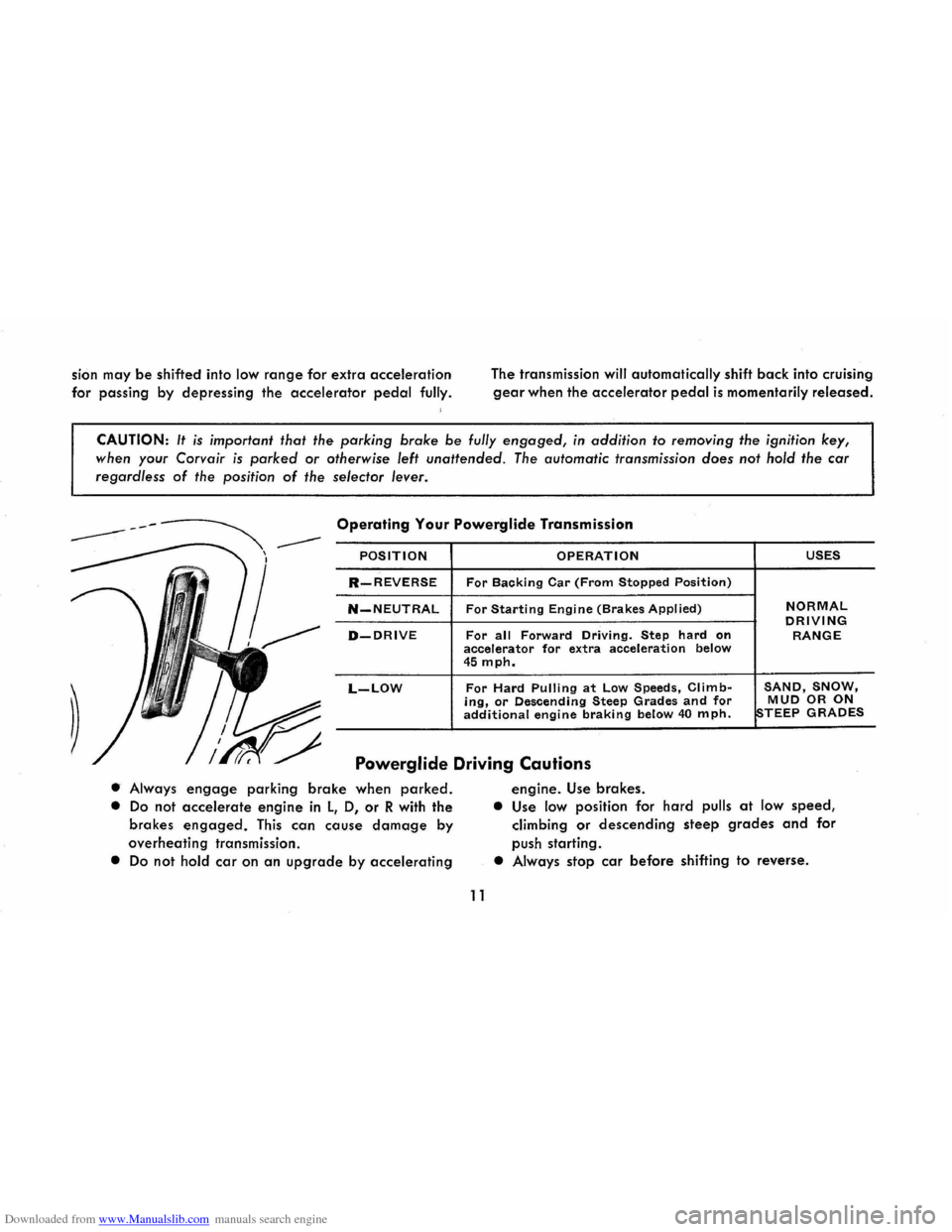

CAUTION: It is important that the parking brake be fully engaged, in addition to removing the ignition key,

when your Corvair is parked or otherwise left unattended. The automatic transmission does not hold the car

regardless

of the position of the selector lever.

Operating Your Powerglide Transmission

POSITION OPERATION USES

R-REVERSE For Backing Car (From Stopped Position)

N-NEUTRAL For Starting Engine (Brakes Applied) NORMAL DRIVING D-DRIVE For all Forward Driving. Step hard on RANGE accelerator for extra acceleration below 45 mph.

L-LOW For Hard Pulling at Low Speeds, Climb-SAND, SNOW, ing, or Descending Steep Grades and for MUD OR ON additional engine braking below 40 mph. STEEP GRADES

Powerglide Driving Cautions

• Always engage parking brake when parked.

• Do not accelerate engine in l, 0, or R with the

brakes

engaged. This can cause damage by

overheating transmission.

• Do not hold car on an upgrade by accelerating

11

engine. Use brakes.

• Use low position for hard pulls at low speed,

climbing or descending steep grades and for

push starting.

• Always stop car before shifting to reverse.

Page 17 of 56

Downloaded from www.Manualslib.com manuals search engine operating, except the GEN-FAN indicator rna)' flicker

when

engine is idling.

CAUTION: If either of these indicators light

while .

car is being. -driYen, immediately follow the

procedure outlined .vnder "EMERGENCY OPER

ATING INSTRUCTIONS," so car may be driyen

to the nearest service facility.

BRAKE SYSTEM WARNING LIGHT

This dual purpose indicator light operates as

follows:

With parking brake applied the red light will light

when

the ignition switch is turned on.

As a dual service brake system warning, the red

light will come on when the brake pedal is depressed

if low pressure has developed in either the front or

rear brake system. Have your authorized Chevrolet

dealer locate and correct the trouble immediately.

EMERGENCY OPERATING INSTRUCTIONS

(To be followed if either

TEMP-PRESS or GEN-FAN indi

cators

light while car is being

driven.)

1. Set heoter FAN and HEAT

controls to full "ON" positions.

14

(If equipped with air conditioning, turn air condi

tioning

COOL switch to OFF.)

NOTE: After setting the heater controls, leave

them in that position until cause of trouble is

corrected.

2.

Stop the car a -s , soon as driving conditions permit.

furn ignition

key to OFF to stop engine but turn

key

back to·-PNso heoter blower will continue

to

cool engine.

3. Check for broken fan belt or belt off pulleys or

engine low oil level. If only GEN-FAN indicator

is lighted, belt is not broken or off pulleys and en

gine oil level is satisfactory, car can be driven at

slow speeds; however, generator must be checked

and serviced as soon as possible.

4. If trouble is found to be a broken fan belt or belt

off pulleys, wait approximately five minutes, start

engine and drive car at no more than 25 miles per

hour until TEMP-PRESS indicator comes on, then

repeat Step 2.

NOTE: The GEN-FAN indicator will stay on until

fan

belt is installed.

5. Repeat Step 4 as necessary until facility is reached

where fan belt can be installed.

Page 18 of 56

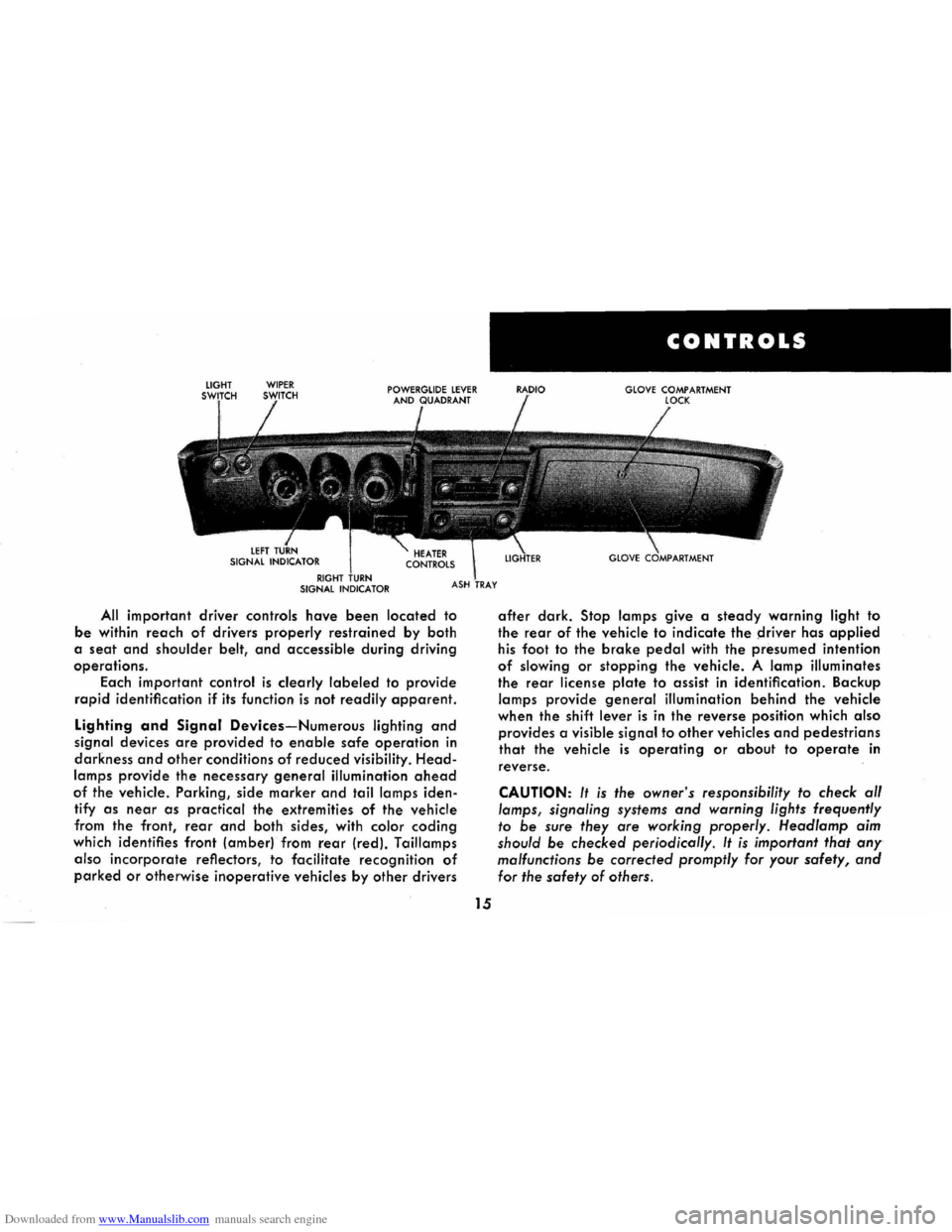

Downloaded from www.Manualslib.com manuals search engine All important driver controls have been located to

be within reach of drivers properly restrained by both

a

seat and shoulder belt, and accessible during driving

operations.

Each important

control is clearly labeled to provide

rapid identification if its function is not readily apparent.

Lighting and Signal Devices-Numerous lighting and

signal devices are provided to enable safe operation in

darkness and other conditions of reduced visibility. Head

lamps provide the necessary general illumination ahead

of the vehicle. Parking, side marker and tail lamps iden

tify

as near as practical the extremities of the vehicle

from the front,

rear and both sides, with color coding

which identifies front (amber) from rear (red). Taillamps

also

incorporate reflectors, to facilitate recognition of

parked or otherwise inoperative vehicles by other drivers

15

CONTROLS

GLOVE COMPARTMENT

after dark. Stop lamps give a steady warning light to

the rear of the vehicle to indicate the ~river has applied

his foot to the brake pedal with the presumed intention

of slowing or stopping the vehicle. A lamp illuminates

the rear license plate to assist in identification. Backup

lamps provide general illumination behind the vehicle

when the shift

lever is in the reverse position which also

provides a visible signal to other vehicles and pedestrians

that the vehicle is operating or about to operate in

reverse.

CAUTION: It is the owner's responsibility to check al/

lamps, signaling systems and warning lights frequently

to be sure they are working properly. Head/amp aim

should

be checked periodicol/y. It is important that any

malfunctions be corrected promptly for your safety, and

for the safety of others.

Page 20 of 56

Downloaded from www.Manualslib.com manuals search engine If the system is not functioning properly, a legal hand

signal should be given, since failure to indicate a turn

is considered a moving traffic violation in many states.

Always signal for a turn

at a reasonable distance before actu 'ally making it.

HAZARD WARNING FLASHER

In the event your car is

disabled or you stop for

any reason on the highway,

the

hazard warning system

which flashes all four turn

signals should

be used to

warn

other drivers that your

vehicle

is a traffic hazard.

The system is activated by

pushing

in on the button

located just

below the steer

ing wheel on the right side

of the steering column. Use this system only when your

vehicle

is a traffic hazard.

FOOT CONTROLS Foot controls consist of the dimmer switch (the op

eration of which is covered on page 16), the clutch

pedal (manual transmissions only), the brake pedal and

the accelerator pedal.

CLUTCH PEDAL The operation of the clutch pedal has been fully

covered under

"Driving with the Manual Transmissions"

on

page 9. Its operation is the same whether your car

is equipped with the 3-speed or the 4-speed transmission. Excessive

clutch

wear can be caused by letting up the

clutch abruptly

rather than smoothly, and by "riding" the

clutch-that is, letting your foot rest on the clutch pedal

while driving .

CLUTCH ADJUSTMENT

Clutch adjustment should be checked and adjusted

periodically as necessary to compensate for clutch facing

wear. To check, depress pedal.by hand until resistance

is felt. Free travel of pedal should be approximately

one-inch;

if very little or no free play is evident, clutch

adjustment

is required.

BRAKES

The service brake system is designed for braking per

formance under a wide range of driving conditions

even when the vehicle

is loaded to its full rated vehicle

load. Driving through deep water may affect brake per

formance. To assure normal operation after being wet

ted, service brakes must be dried. To dry them quickly,

lightly

apply the brakes while maintaining a slow for"

ward speed with an assured clear distance ahead until

brake performance re'turns to normal.

Brake System Warning Light

The service brake system is designed so that in the

event of a hydraulic fluid leak,

in one-half of the sys

tem, the other half still provides some braking action.

A dual purpose brake system warning light is

located at the extreme left side of the instrument panel.

When the parking brake is applied and the ignition

17 .

Page 21 of 56

Downloaded from www.Manualslib.com manuals search engine switch is turned to the "ON" position, the warning light

glows red to indicate to the operator that the parking

brake has not been fully released. This also indicates

that the brake warning light is operational. If the light does not come on, have your Corvair Dealer correct

the trouble as soon as possible. The other function of

this light is to indicate a malfunction in the regular braking system. In the event of broken brake lines,

major brake fluid loss, air in the brake lines or a pres

sure deviation between the front · and the rear wheel

brake lines, the light will come on and stay on while

braking .

In this event, the vehicle should not be driven

until

the cause has been determined and, if necessary,

corrected.

Automatic Brake Adjusters

All Corvair models are equipped with self-adjusting

brakes which eliminates periodic brake adjustments. The

self-adjusting mechanism

is actuated, as needed, when

ever the car is moved in reverse and the brakes applied.

It is possible, however, for excessive brake pedal travel

to

develop if the required reverse movement with a

brake application does not take place during a pro

longed

period of stop and go forward driving. Should

this occur,

the car should be driven backward and for

ward with the brakes applied at the end of each direc

tional movement, until the brake pedal travel is back to

normal. If this procedure fails to restore normal pedal

travel, or if any abnormally rapid increase in pedal

travel is experienced, immediate inspection should be

made by your Authorized Chevrolet Dealer. Care should

18

be exercised to assure that full brake pedal travel can

not be obstructed by improper floor mats or other inter

fering material under the pedal.

PARKING BRAKE

The parking brake operates by cables on the rear

wheel brakes independent of the regular foot brake hydraulic system. The brake system warning light will

be "ON" whenever the parking brake is not fully re

leased and the ignition switch is "ON". Never drive the car with the parking brake engaged. .

Pull the parking brake lever as far as possible to

engage the brake. The lever will remain in the applied

position until released. To release, pull the handle to

ward the steering wheel, depress the "trigger" and

allow the handle to return to the released position. CAUTION: When leaving the car unattended, always

fully apply the parking brake.

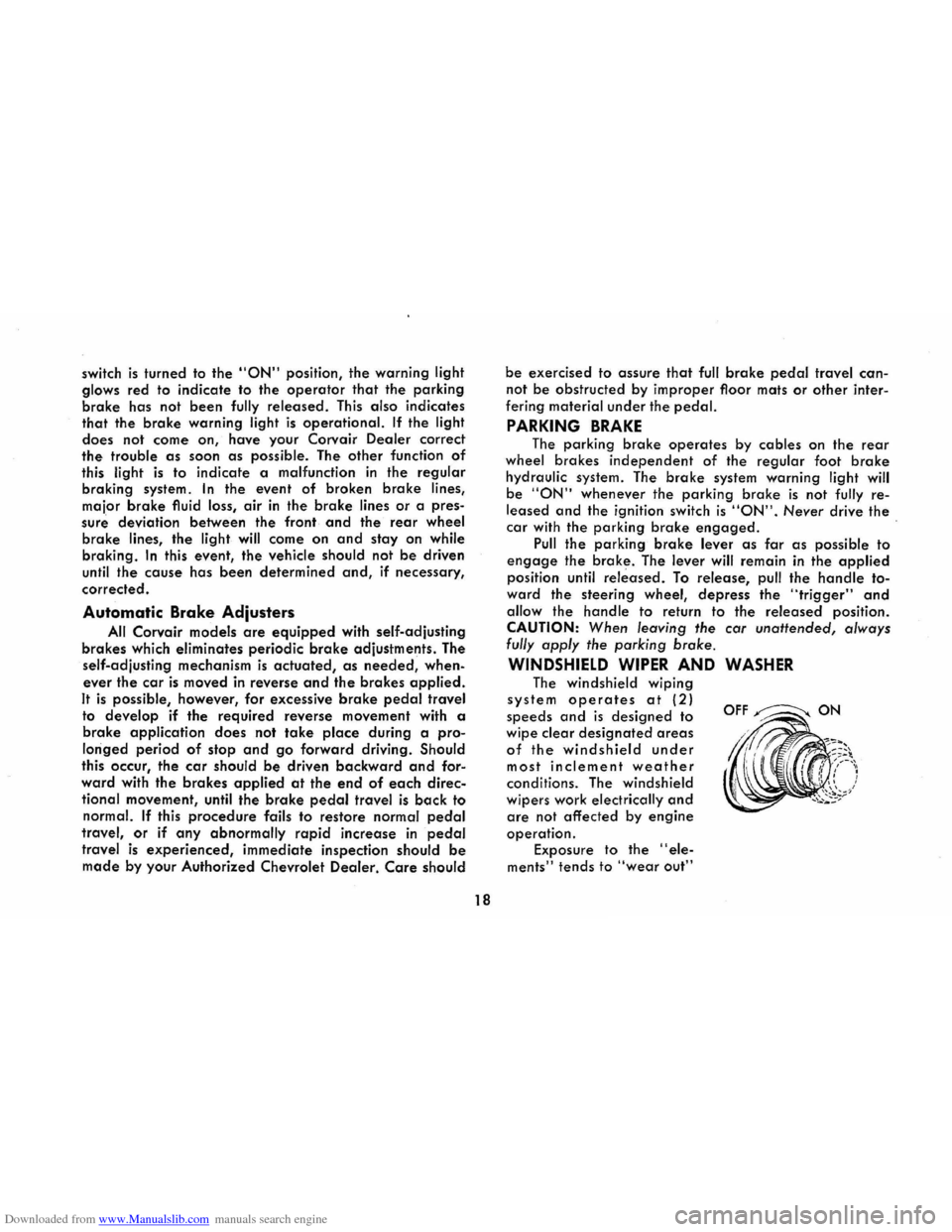

WINDSHIELD WIPER AND WASHER

The windshield wiping

system operates at (2)

speeds and is designed to

wipe clear

designated areas

of the windshield under

most inclement weather

conditions. The windshield

wipers work

electrically and

are not affected by engine

operation.

Exposure to the "ele

ments" tends to "wear out"

OFF~ON

Page 43 of 56

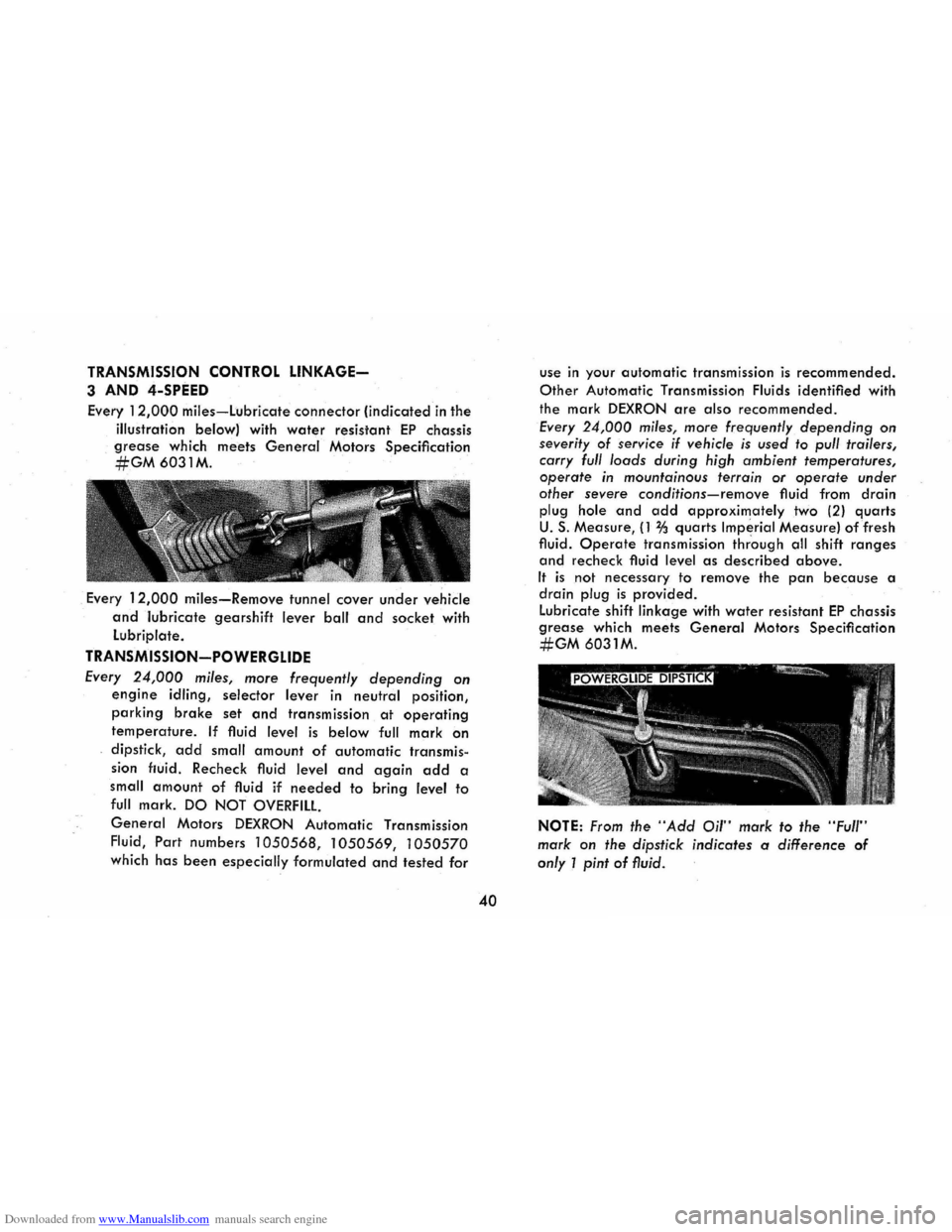

Downloaded from www.Manualslib.com manuals search engine TRANSMISSION CONTROL LlNKAGE-

3 AND 4-SPEED

Every 12,000 miles-Lubricate connector (indicated in the

illustration below) with

water resistant EP chassis

grease which meets General Motors Specification

#GM6031M.

. Every 12,000 miles-Remove tunnel cover under vehicle

and lubricate gearshift lever ball and socket with

Lubriplate.

TRANSMISSION-POWERGLIDE

Every 24,000 miles, more frequently depending on

engine idling, selector lever in neutral position,

parking brake set and transmission at operating

temperature. If fluid level is below full mark on

dipstick, add small amount of automatic transmis

sion fluid. Recheck fluid level and again add a

small

amount of fluid if needed to bring level to

full mark. DO NOT OVERFILL

General Motors DEXRON Automatic Transmission

Fluid,

Part numbers 1050568, 1050569, 1050570

which has been especially formulated and tested for

40

use in your automatic transmission is recommended.

Other Automatic Transmission Fluids identified with

the mark

DEXRON are also recommended.

Every 24,000 miles, more frequently depending on

severity of service if vehicle is used to pull trailers,

carry full loads during high ambient temperatures,

operate in mountainous terrain or operate under

other severe

conditions-remove fluid from drain

plug hole and add approximately two (2) quarts

U. S. Measure, (1 % quarts Imperial Measure) of fresh

fluid.

Operate transmission thr'ough all shift ranges

and recheck fluid level as described above.

It is not necessary to remove the pan because a

drain plug is provided .

Lubricate shift linkage with

water resistant EP chassis

grease which meets General Motors Specification

#GM 6031M.

NOTE: From the "Add Oil" mark to the "Full"

mark on the dipstick indicates a difference of

only 1 pint of fluid.

Page 46 of 56

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Have your Chevrolet Dealer check your air conditioning

system

at some time during the winter months to be

sure there has been no loss in cooling output. Dur

ing

the summer, see your Chevrolet Dealer immedi

ately if you suspect the system is not performing as

it should.

BRAKE LININGS

Brake linings should be periodically inspected for wear.

The frequency of this inspection depends upon driv

ing conditions such

as traffic or terrain, and also

the driving techniques of individual owners. Your

Chevrolet Dealer is best qualified to advise you as

to how often this inspection should be performed.

When brakes require relining use genuine General

Motors Parts or equivalent.

BRAKE MASTER CYLINDER

Every 6,000 miles-Check fluid level in each reservoir

and maintain % II below lowest edge of each open

ing with G.M. Hydraulic Brake Fluid Supreme No. 11

PARKING BRAKE AND CLUTCH PULLEYS

AND CABLES

Every 12,000 miles-lubricate pulleys under dash. Re

move. the tunnel cover under vehicle and lubricate

pulleys

and cable bearing points with a water resist

ant EP chassis grease which meets General Motors

43

Specification #GM 6031 M. Lubricate gearshift lever

ball and socket (see page 38) at the same time.

FRONT WHEEL BEARINGS

Clean, repack with high melting point wheel bearing

lubricant, and adjust whenever the wheels and hub

are removed. Replace grease seals at the same time.

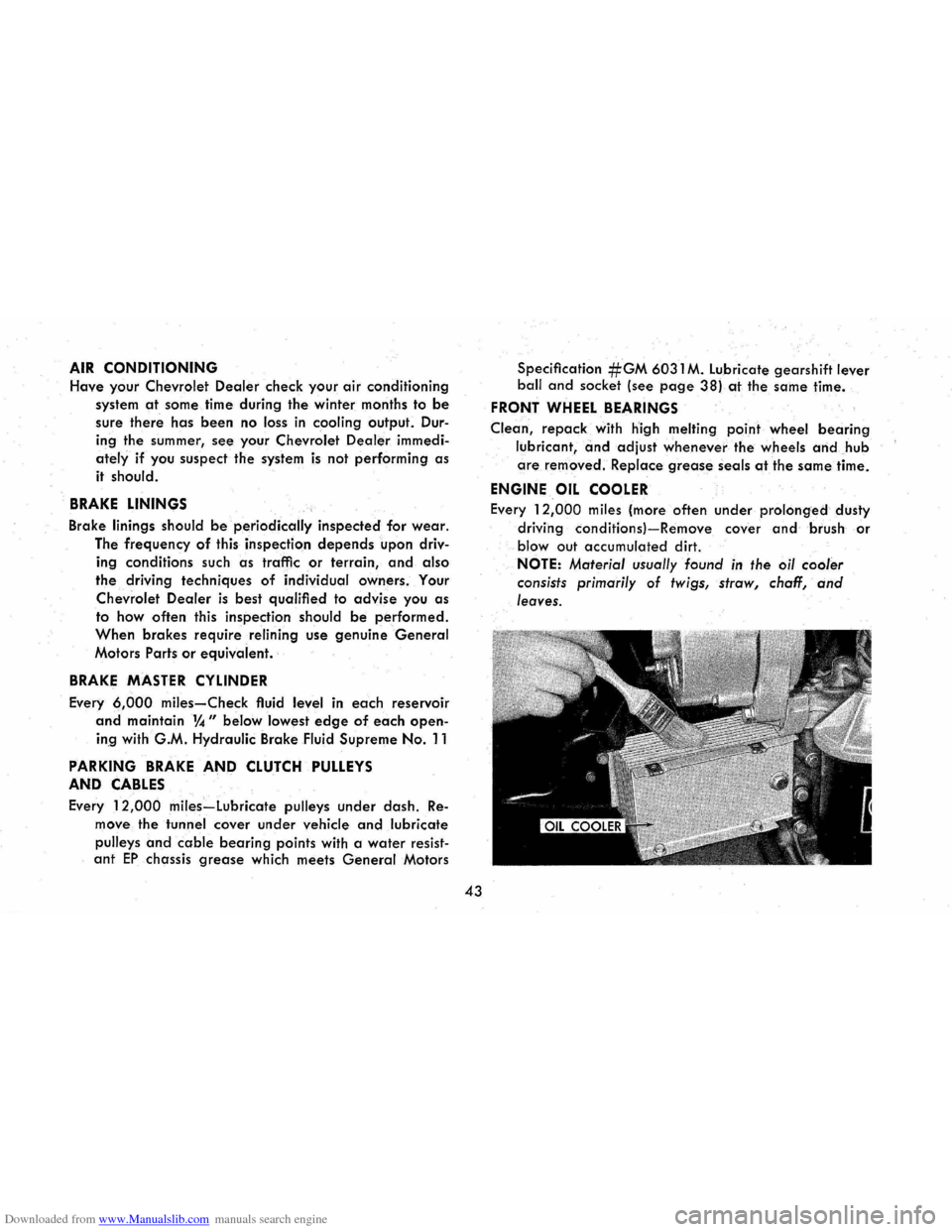

ENGINE OIL COOLER

Every 12,000 miles (more often under prolonged dusty

driving

conditionsl-Remove cover and brush or

blowout accumulated dirt.

NOTE: Material usually found in the oil cooler

consists primarily

of twigs, straw, chaff, and

leaves.

Page 55 of 56

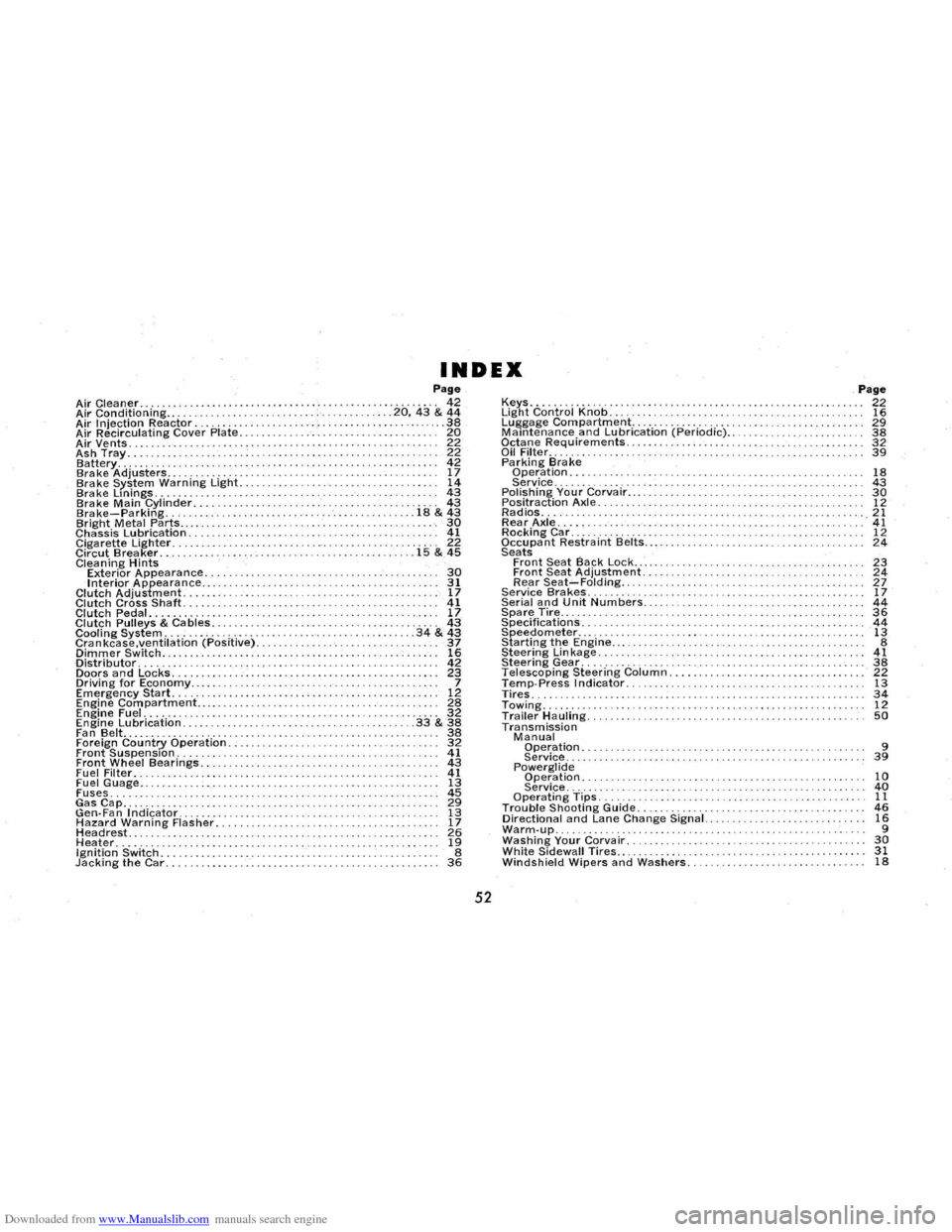

Downloaded from www.Manualslib.com manuals search engine INDEX Page Air Cleaner. . . . . . . . . .. , .. . . . . . . .. . . . . . . . . . . .......... 42 Air Conditioning.. ............ ... .... .• . . .20,43 & 44 Air Injection Reactor......... ........... . ... ... 38 Air Recirculating Cover Plate. . . . . . . . . . . .• . . . . .. . . . .. . . 20 Air Vents. . . . . . . . . . . . . . . . . . . . . . . 22 Ash Tray. ........ .. ... 22 Battery........... ............ ....•...•................. 42 Brake Adjusters...................... .. .. ... ............. 17 Brake System Warning Light. . ................. 14 Brake Lmings. . ....... ....... ........ ............... 43 Brake Main Cylinder.. ........... . ...... 43 Brake-Parking. . ............ .......... . .. 18 & 43 Bright Metal Parts..... .. ..................... '. 30 Chassis Lubrication. . . . . . . . . . . . . . 41 Cigarette Lighter. . . .. .... ... .. . . . .. .. " 22 Circut Brea ker. . . . . . ................. .. .............. 15 & 45 Cleaning Hints Exterior Appearance........ .... .... . ............ . 30 Interior Appearance.. ............... . ............. ........ 31 Clutch Adjustment......... 17 Clutch Cross Shaft. . . .. . . . . . . . ... .. . . 41 Clutch Pedal.. .. . .. .. .. .. . . .. .. . .. .. . 17 Clutch Pulleys & Cables..................... . 43 Cooling System. . . . . . . . . . . . . . . . . . ........ ....... 34 & 43 Crankcase.ventilation (Positive). 37 Dimmer Switch... .......... ..... 16 Distributor. . . . . . . 42 Doors and Locks. .. ..... .................. .• ................. 23 Driving for Economy..... ...... ...... 7 Emergency Start. . . . . . . . . . . . . . . . . . 12 Engine Compartment.... . . . . . . . . . . . . . . . . . . . .. .. . . 28 Engine Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 32 Engine Lubrication. . . . . . . . . .. . . . .• . . . . . . . • . . . . . . .33& 38 Fan Belt........ .... ..................... ..... 38 Foreign Country Operation. .................. 32 Front Suspension. . . . . . . . . . . . . . ... . . . . . . . . . . . . . . . . . . . . . 41 Front Wheel Bearings.. . ............. .......... . 43 Fuel Filter. . . . . . . . . . . . . . . •. . . . . . . . . .. . . . . 41 Fuel Guage.. ............ 13 Fuses.. .. .. ... ...................... ..... 45 ~s~p.......... ~ Gen·Fan .Indicator........ 13 Hazard Warning Flasher. . 17 Headrest...... . . ....... ... .. ........ 26 Heater............................... ..... .. .......... 19 Ignition Switch. . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . 8 Jacking the Car. . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 36

52

Keys............... . ......... .............. . Light Control Knob ...................... . . Luggage Compartment ................... . Maintenance and Lubrication (Periodic) .. Octane Requirements. . . . . ......... . Oil Filter .... ............ . Pa rking Bra ke Operation . ..................... . Service .......... ...... . Polishing Your Corvair... . . ... . . . . . .. . .........•. .... ........ Positraction Axle. . . ... ............... .. ...... .. .. .... . Radios. . . . .... . ........... . Rear Axle.... . . ...................................... . . Rocking Car .............. . Occupant Restraint Belts .. . . Seats Front Seat Back Lock ....... .•...... Front Seat Adjustment. Rear Seat-Folding ... Service Bra kes. . . . . . . . . .. . ......................... ... . Serial and Unit Numbers .......... .. . Spare Tire..... . .• ......... .................•.•. Specifications. . . . ................... ... .. .• ........ Speedometer ... .. ............... . Starting the Engine .... . Steering Lin kage ...... . Steering Gear ............... . Telescoping Steering Column. Temp·Press Indicator. Tires. Towing ..... Trailer Hauling. Transmission Manual Operation. ................ . ....... .. .... . Service ................... .. .. ...... .. . Powerglide Operation. Service ...... . Operating Tips ....... . Trouble Shooting Guide.......... . .............. ... . Directional and Lane Change Signal. . ....• ...•.... Warm·up... ............ . ....... .. ........... ... . Washing Your Corvair. . . ........ . White Sidewall Tires.. . . . . . . . . . . . . . . ......... .. . Windshield Wipers and Washers. . . .. .. .. .. .

Page 22 16 29 38 32 39

18 43 30 12 21 41 12 24

23 24 27 17 44 36 44 13 8 41 38 22 13 34 12 50

9 39

10 40 11 46 16 9 30 31 18