transmission fluid CHEVROLET CORVAIR 1986 2.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1986, Model line: CORVAIR, Model: CHEVROLET CORVAIR 1986 2.GPages: 56, PDF Size: 22.23 MB

Page 7 of 56

Downloaded from www.Manualslib.com manuals search engine A WORD ABOUT ... VEHICLE SAFETY AND THE INI

TIAL FEDERA~ MOTOR VEHICLE SAFETY STANDARDS

Chevrolet has for many years been a leader in the field

of automotive safety. Almost every advance in design and engineering since the jnception of the industry has contributed

to the safety, reliability and durability of our cars. Continua

tion of this important and vital trend is exemplified in your

1968 Chevrolet. Important safety advances are designed to

aid in avoiding accidents, and in reducing injuries during the accident and as a result of the accident.

But remember-it takes more than a safe car to avoid

accidents. Observe all traffic laws, make safe driving a habit and maintain your car in top condition.

Your

n!,)w 1968 Chevrolet conformed to all federal motor

vehicle safety standards applicable at time of manufacture.

Effectiveness of these safety features ~an best be continued

through periodic vehicle inspection and regular maintenance .

Th~ initial Federal Motor Vehicle Safety Standards encompass a number of systems on all passenger cars. To promote better understanding of these standards, listed are those

standards applicable to passenger cars, and the purpose and

scope of each.

Initial

Federal Motor Vehicle Safety Standards (Effective January 1, 1968*)

Amendment to certain of these

Standards and additional Standards that would apply to 1968 Model passenger cars

manufactured after January 1, 1968 , were under cons ideration by the National Highway Safety Bureau at the time this Owner's Manual was prepared. '

STANDARD NO. 101

Control Location and Identification

Purpose and Scope. This standard specifies the requirements

for location and identification of certain controls to facilitate

their selection and ensure their accessibility.

4

STANDARD NO. 102 Transmission Shift Lever Sequence, Starter Interlock, and Transmission Braking Effect Purpose and Scope. This standard specifies the requirements

for the transmission shift lever sequence, a starter interlock, and for a braking effect of automatic transmissions, to requce the likelihood of shifting errors, starter engagement with vehicle in drive position, and to provide supplemental braking at speeds below 25 miles per hour.

STANDARD NO. 103 Windshield Defrosting and Defogging Purpose lind Scope. This standard specifies requirements

for providing vision through the windshield during frosting and fogging conditions.

STANDARD NO. 104 Windshield Wiping and Washing Systems

Purpose and Scope. This standard specifies requirements

for windshi eld wiping and washing systems.

ST ANDARD NO. 105 Hydraulic Service Brake, Emergency Brake, and Parking Brake Systems

Purpose and Scope. This standard specifies requirements

for hydraulic service brake, emergency brake, and parking

brake systems intended to ensure adequate braking performance under normal and emergency conditions.

STANDARD NO. 106 Hydraulic Brake Hoses Purpose and Scope. This standard specifies requirements

for hydraulic brake hoses that will reduce brake failures due to fluid leakage.

STANDARD NO. 107 Reflecting Surfaces

Purpose and Scope. This standard specifies reflecting surface requir ements for certain vehicle components in the driver's field of view.

..

Page 20 of 56

Downloaded from www.Manualslib.com manuals search engine If the system is not functioning properly, a legal hand

signal should be given, since failure to indicate a turn

is considered a moving traffic violation in many states.

Always signal for a turn

at a reasonable distance before actu 'ally making it.

HAZARD WARNING FLASHER

In the event your car is

disabled or you stop for

any reason on the highway,

the

hazard warning system

which flashes all four turn

signals should

be used to

warn

other drivers that your

vehicle

is a traffic hazard.

The system is activated by

pushing

in on the button

located just

below the steer

ing wheel on the right side

of the steering column. Use this system only when your

vehicle

is a traffic hazard.

FOOT CONTROLS Foot controls consist of the dimmer switch (the op

eration of which is covered on page 16), the clutch

pedal (manual transmissions only), the brake pedal and

the accelerator pedal.

CLUTCH PEDAL The operation of the clutch pedal has been fully

covered under

"Driving with the Manual Transmissions"

on

page 9. Its operation is the same whether your car

is equipped with the 3-speed or the 4-speed transmission. Excessive

clutch

wear can be caused by letting up the

clutch abruptly

rather than smoothly, and by "riding" the

clutch-that is, letting your foot rest on the clutch pedal

while driving .

CLUTCH ADJUSTMENT

Clutch adjustment should be checked and adjusted

periodically as necessary to compensate for clutch facing

wear. To check, depress pedal.by hand until resistance

is felt. Free travel of pedal should be approximately

one-inch;

if very little or no free play is evident, clutch

adjustment

is required.

BRAKES

The service brake system is designed for braking per

formance under a wide range of driving conditions

even when the vehicle

is loaded to its full rated vehicle

load. Driving through deep water may affect brake per

formance. To assure normal operation after being wet

ted, service brakes must be dried. To dry them quickly,

lightly

apply the brakes while maintaining a slow for"

ward speed with an assured clear distance ahead until

brake performance re'turns to normal.

Brake System Warning Light

The service brake system is designed so that in the

event of a hydraulic fluid leak,

in one-half of the sys

tem, the other half still provides some braking action.

A dual purpose brake system warning light is

located at the extreme left side of the instrument panel.

When the parking brake is applied and the ignition

17 .

Page 43 of 56

Downloaded from www.Manualslib.com manuals search engine TRANSMISSION CONTROL LlNKAGE-

3 AND 4-SPEED

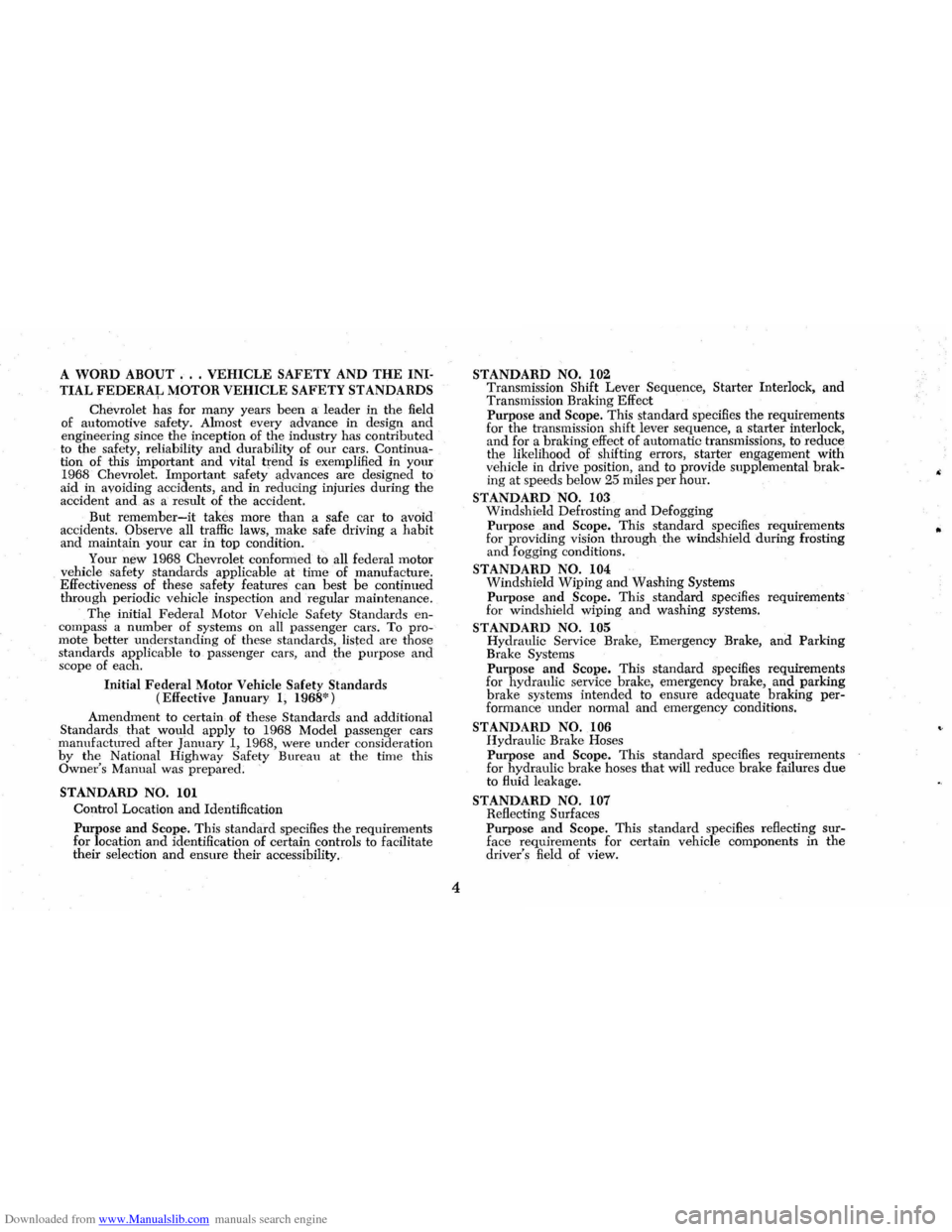

Every 12,000 miles-Lubricate connector (indicated in the

illustration below) with

water resistant EP chassis

grease which meets General Motors Specification

#GM6031M.

. Every 12,000 miles-Remove tunnel cover under vehicle

and lubricate gearshift lever ball and socket with

Lubriplate.

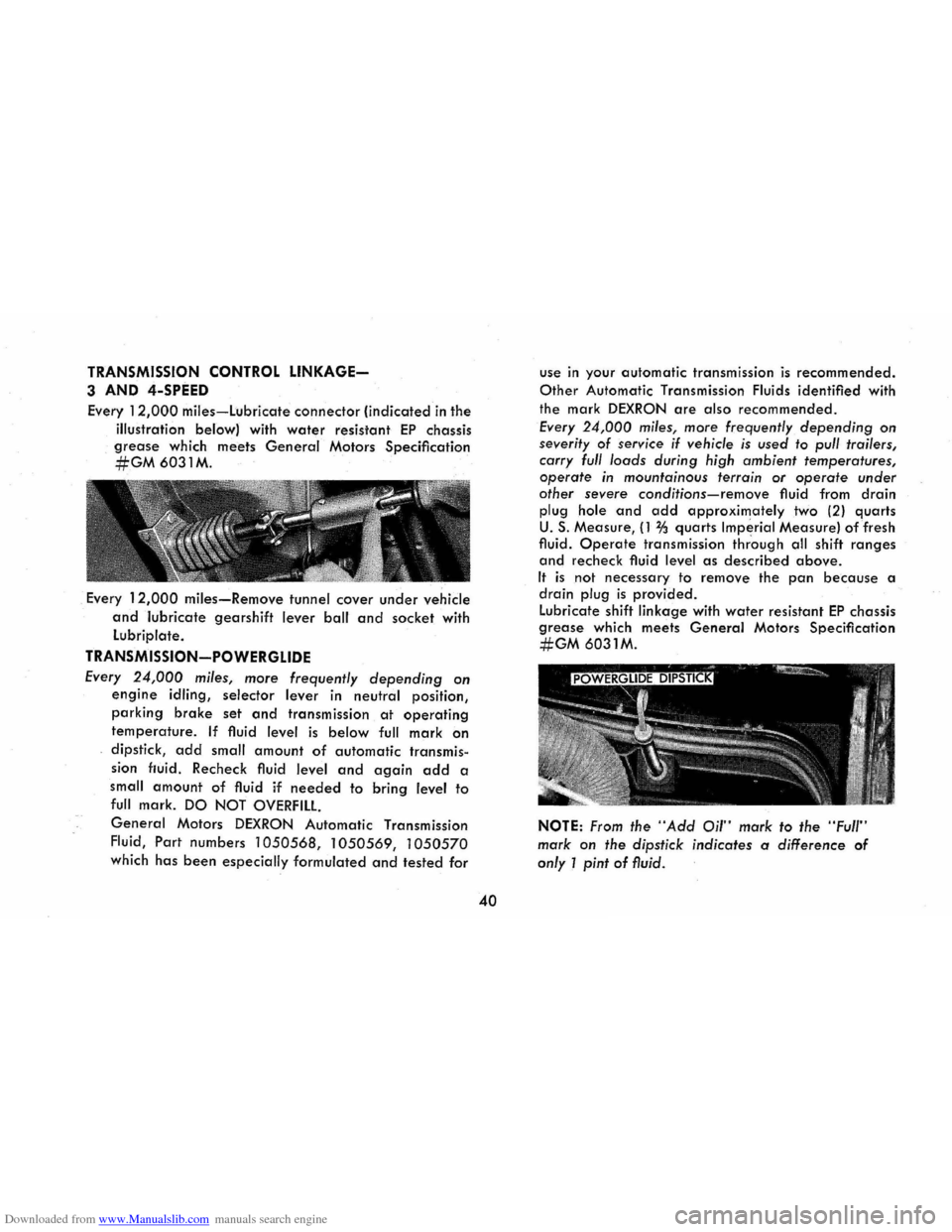

TRANSMISSION-POWERGLIDE

Every 24,000 miles, more frequently depending on

engine idling, selector lever in neutral position,

parking brake set and transmission at operating

temperature. If fluid level is below full mark on

dipstick, add small amount of automatic transmis

sion fluid. Recheck fluid level and again add a

small

amount of fluid if needed to bring level to

full mark. DO NOT OVERFILL

General Motors DEXRON Automatic Transmission

Fluid,

Part numbers 1050568, 1050569, 1050570

which has been especially formulated and tested for

40

use in your automatic transmission is recommended.

Other Automatic Transmission Fluids identified with

the mark

DEXRON are also recommended.

Every 24,000 miles, more frequently depending on

severity of service if vehicle is used to pull trailers,

carry full loads during high ambient temperatures,

operate in mountainous terrain or operate under

other severe

conditions-remove fluid from drain

plug hole and add approximately two (2) quarts

U. S. Measure, (1 % quarts Imperial Measure) of fresh

fluid.

Operate transmission thr'ough all shift ranges

and recheck fluid level as described above.

It is not necessary to remove the pan because a

drain plug is provided .

Lubricate shift linkage with

water resistant EP chassis

grease which meets General Motors Specification

#GM 6031M.

NOTE: From the "Add Oil" mark to the "Full"

mark on the dipstick indicates a difference of

only 1 pint of fluid.