CHEVROLET CORVETTE 2003 5.G Owners Manual

CORVETTE 2003 5.G

CHEVROLET

CHEVROLET

https://www.carmanualsonline.info/img/24/8118/w960_8118-0.png

CHEVROLET CORVETTE 2003 5.G Owners Manual

Trending: stop start, wheel alignment, oil filter, air suspension, hood release, clutch, weight

Page 271 of 368

5. Check that the jumper cables don't have loose or

missing insulation. If they do, you could get a

shock. The vehicles could be damaged, too.

Before you connect the cables, here are some

basic things you should know. Positive (+) will go to

positive (+) or to a remote positive (+) terminal if

the vehicle has one. Negative (-) will go to a heavy,

unpainted metal engine part or to a remote

negative (-) terminal if the vehicle has one.

Don't connect positive (+) to negative (-) or you'll

get a short that would damage the battery and

maybe other parts, too. And don't connect

the negative (-) cable to the negative (-) terminal

on the dead battery because this can cause sparks.

6. Connect the red positive (+) cable to the positive (+)

terminal of the dead battery. Use a remote

positive (+) terminal if the vehicle has one.

5-43

Page 272 of 368

7. Don't let the other end

touch metal. Connect it

to the positive (+)

terminal of the good

battery. Use a remote

positive (+) terminal

if the vehicle has one.

8. Now connect the black

negative (-) cable to

the negative (-)

terminal of the good

battery. Use a remote

negative (-) terminal

if the vehicle has one.Don't let the other end touch anything until the next

step. The other end of the negative (-) cabledoesn'tgo to the dead battery. It goes to a heavy, unpainted

metal engine part or to a remote negative (-)

terminal on the vehicle with the dead battery.

9. Connect the other end of the negative (-) cable at

least 18 inches (45 cm) away from the dead battery,

but not near engine parts that move. The electrical

connection is just as good there, and the chance

of sparks getting back to the battery is much less.

10. Now start the vehicle with the good battery and run

the engine for a while.

5-44

Page 273 of 368

11. Try to start the vehicle that had the dead battery. If

it won't start after a few tries, it probably needs

service.

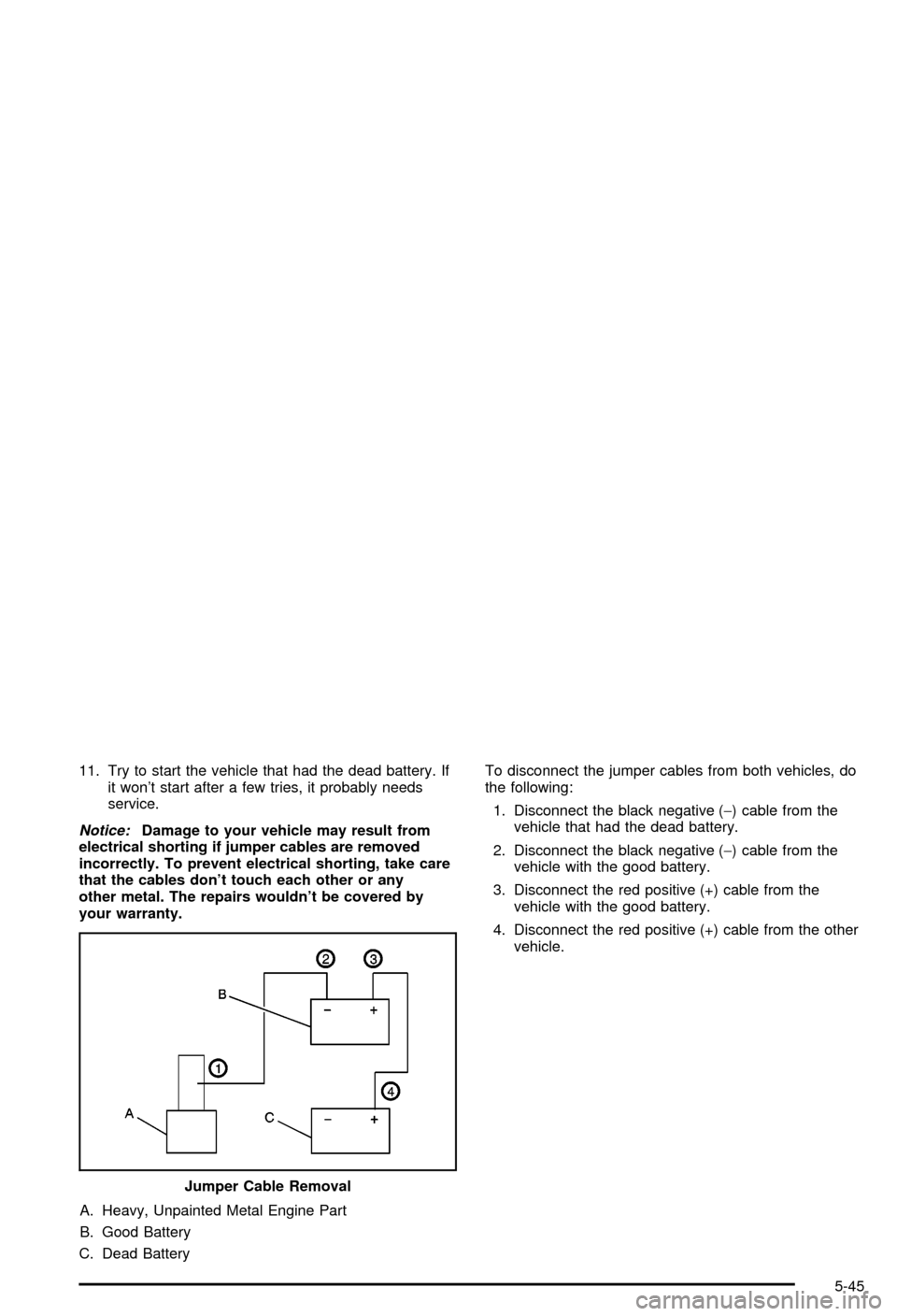

Notice:Damage to your vehicle may result from

electrical shorting if jumper cables are removed

incorrectly. To prevent electrical shorting, take care

that the cables don't touch each other or any

other metal. The repairs wouldn't be covered by

your warranty.

A. Heavy, Unpainted Metal Engine Part

B. Good Battery

C. Dead BatteryTo disconnect the jumper cables from both vehicles, do

the following:

1. Disconnect the black negative (-) cable from the

vehicle that had the dead battery.

2. Disconnect the black negative (-) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other

vehicle.

Jumper Cable Removal

5-45

Page 274 of 368

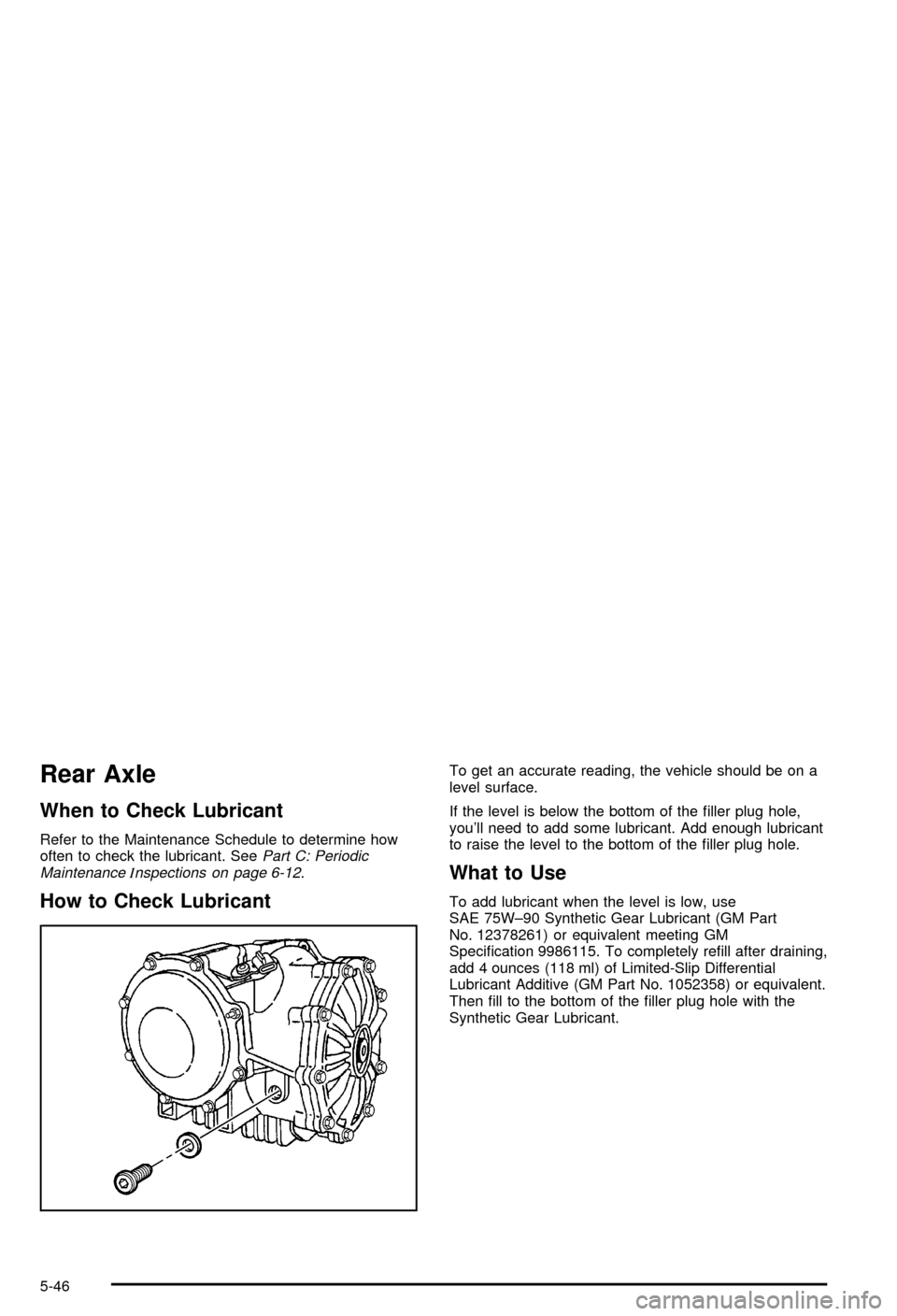

Rear Axle

When to Check Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant. SeePart C: Periodic

MaintenanceInspections on page 6-12.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom of the ®ller plug hole,

you'll need to add some lubricant. Add enough lubricant

to raise the level to the bottom of the ®ller plug hole.

What to Use

To add lubricant when the level is low, use

SAE 75W±90 Synthetic Gear Lubricant (GM Part

No. 12378261) or equivalent meeting GM

Speci®cation 9986115. To completely re®ll after draining,

add 4 ounces (118 ml) of Limited-Slip Differential

Lubricant Additive (GM Part No. 1052358) or equivalent.

Then ®ll to the bottom of the ®ller plug hole with the

Synthetic Gear Lubricant.

5-46

Page 275 of 368

Bulb Replacement

For the proper type of replacement bulb, seeBulb

Replacement on page 5-47.

For any bulb changing procedure not listed in this

section, contact your dealer's service department.

Halogen Bulbs

{CAUTION:

Halogen bulbs have pressurized gas inside

and can burst if you drop or scratch the bulb.

You or others could be injured. Be sure to read

and follow the instructions on the bulb

package.

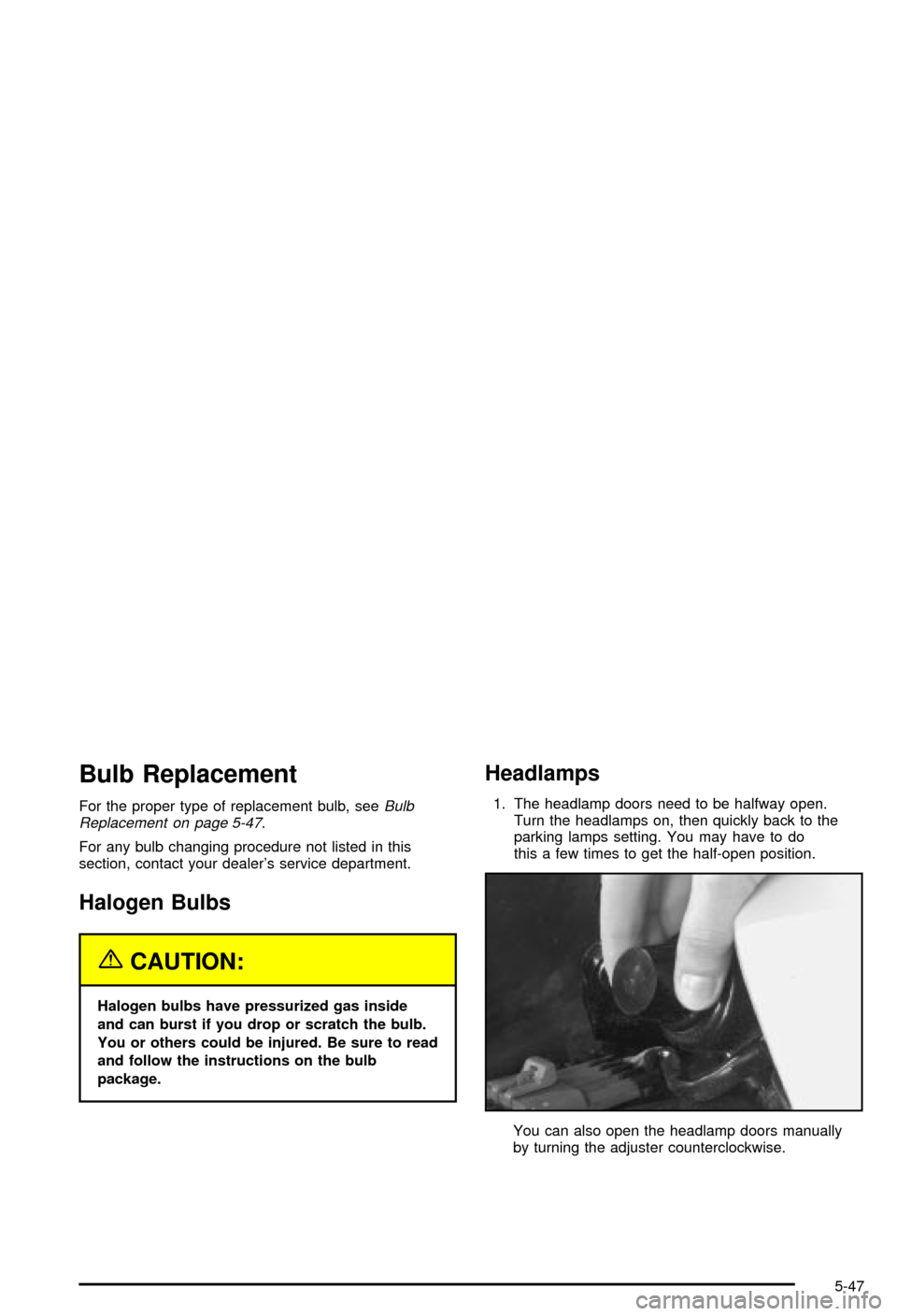

Headlamps

1. The headlamp doors need to be halfway open.

Turn the headlamps on, then quickly back to the

parking lamps setting. You may have to do

this a few times to get the half-open position.

You can also open the headlamp doors manually

by turning the adjuster counterclockwise.

5-47

Page 276 of 368

2. Remove the screws on each side of the

headlamp bezel.

3. Open the hood.

4. To remove the bezel, pull the sides slightly outward

and tilt the bezel forward. Pull the clip centered

above the lens outward. Be careful not to scratch

the paint on the vehicle.5. Reach behind the lamp and turn the bulb

counterclockwise to remove it. Don't touch the

halogen bulbs. The inner bulb is the high beam and

the outer bulb is the low beam.

6. Disconnect the desired bulb from the wiring

harness.

7. Reverse the steps listed previously with a new bulb.

5-48

Page 277 of 368

Taillamps and Turn Signal Lamps

A. Back-Up Lamp

B. Inboard Taillamp

C. Outboard Taillamp1. Remove the screws.

2. Pull the taillamp housing assembly out.

5-49

Page 278 of 368

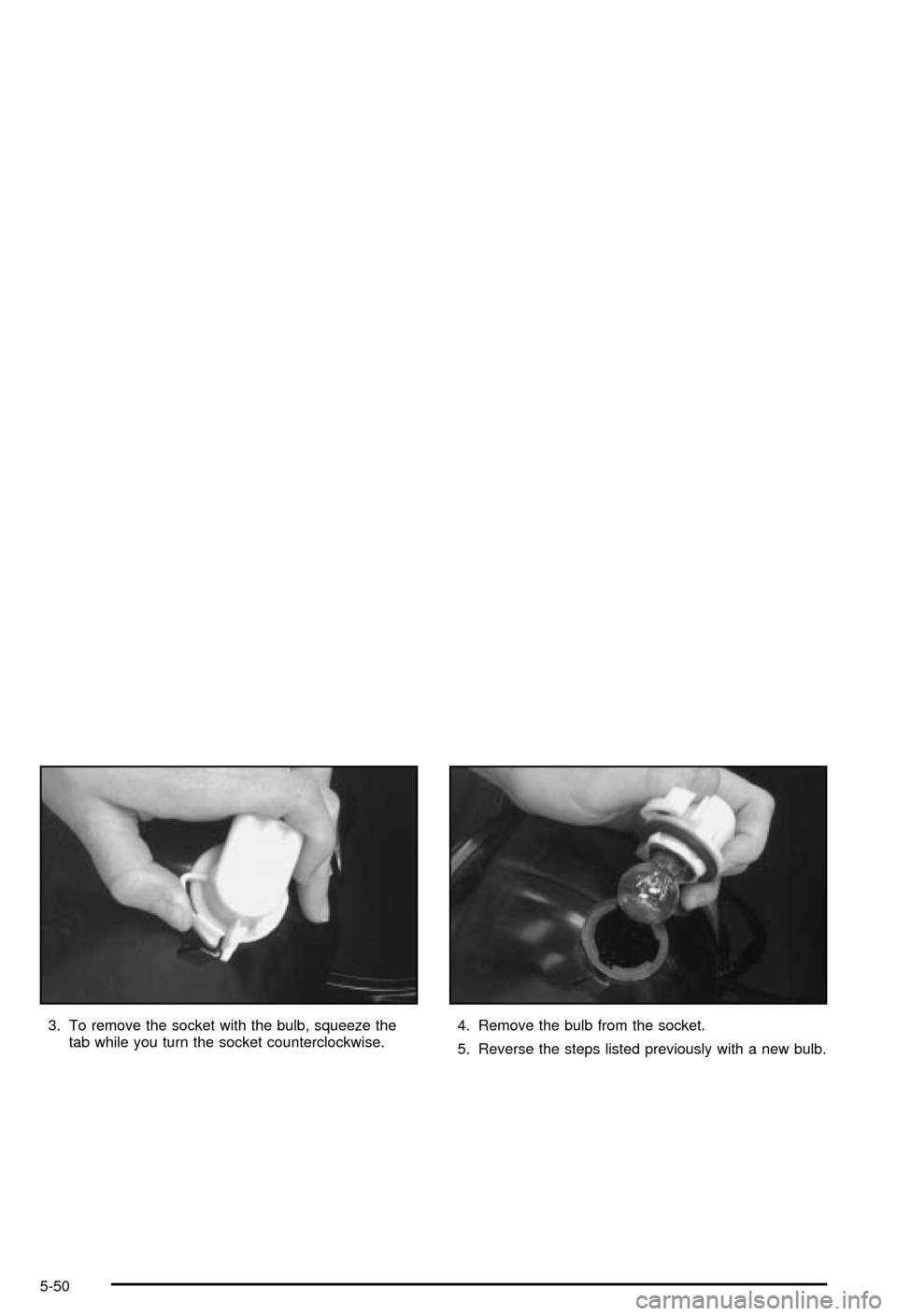

3. To remove the socket with the bulb, squeeze the

tab while you turn the socket counterclockwise.4. Remove the bulb from the socket.

5. Reverse the steps listed previously with a new bulb.

5-50

Page 279 of 368

Back-Up Lamps

You can access the back-up lamps through the inboard

taillamp opening. SeeTaillamps and Turn Signal

Lamps on page 5-49.

1. Squeeze the tab on the socket while turning it

counterclockwise to remove it from the assembly.

2. Remove the bulb from the socket.

3. Reverse the steps listed previously with a new bulb.

Replacement Bulbs

Exterior Lamp Bulb Number

High-Beam Headlamp 9005

Low-Beam Headlamp 9006

Back-Up 2057

Rear Stop/Tail and Turn Signal 3057

For any bulb replacements or procedures not listed

here, please consult your dealer.

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected at least

twice a year for wear or cracking. See ªWiper Blade

Checkº under

Part B: Owner Checks and Services on

page 6-8for more information.

Replacement blades come in different types and are

removed in different ways. For the proper type and

length, see

Normal Maintenance Replacement Parts on

page 5-94.

It's a good idea to clean or replace the wiper blade

assembly every six months.

Notice:Use care when removing or installing a

blade assembly. Accidental bumping can cause the

arm to fall back and strike the windshield.

To remove the wiper blade assembly, do the following:

1. Open the hood to gain access to the windshield

wipers.

2. Lift the wiper arm until it locks into a vertical

position.

5-51

Page 280 of 368

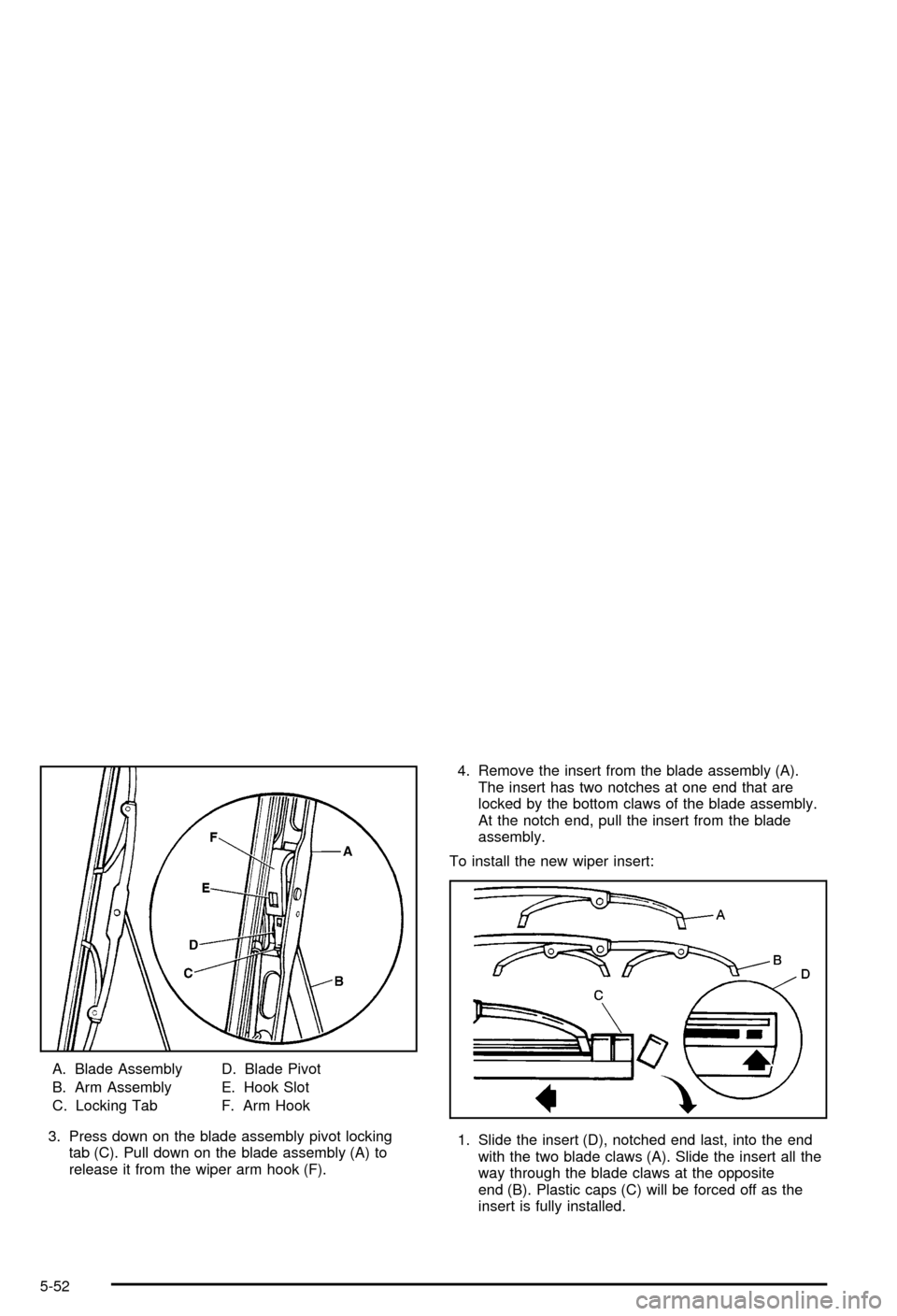

A. Blade Assembly

B. Arm Assembly

C. Locking TabD. Blade Pivot

E. Hook Slot

F. Arm Hook

3. Press down on the blade assembly pivot locking

tab (C). Pull down on the blade assembly (A) to

release it from the wiper arm hook (F).4. Remove the insert from the blade assembly (A).

The insert has two notches at one end that are

locked by the bottom claws of the blade assembly.

At the notch end, pull the insert from the blade

assembly.

To install the new wiper insert:

1. Slide the insert (D), notched end last, into the end

with the two blade claws (A). Slide the insert all the

way through the blade claws at the opposite

end (B). Plastic caps (C) will be forced off as the

insert is fully installed.

5-52

Trending: diagnostic menu, tire pressure reset, MPG, keyless, hood open, seats, clock setting