belt CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2317 of 2438

VARIABLE DISPLACEMENT COMPRESSORÐMODEL 6C17 INDEX

page page

Clutch Coil Tests ......................... 17

Compressor ............................. 17

Compressor Clutch Inoperative .............. 13

Compressor Clutch/Coil Assembly ............ 19

Compressor Diagnosis ..................... 13

Compressor Front Shaft Seal ............... 20 Compressor High Pressure Cut-Out Switch

..... 21

Compressor High Pressure Relief Valve (HPR) . . 22

Compressor Identification ................... 13

Compressor Main or Sub Control Valves ....... 22

Compressor Noise ........................ 13

General Information ....................... 13

GENERAL INFORMATION

The Variable Displacement Compressor (VDC) pro-

vides maximum A/C performance under most condi-

tions. It is designed to operate continuously without

any cycling of the compressor clutch. The compressor

has a variable angle wobble plate with six axially

oriented cylinders. During vehicle A/C system operation, the compres-

sor will change its displacement to match the vehi-

cles A/C cooling demands. When the A/C system

needs more cooling capacity, the compressor will in-

crease its pumping capacity. This is done by increas-

ing the wobble plate angle to increase the piston

stroke. When the A/C system cooling demand is low,

the compressor will decrease its pumping capacity by

reducing the piston pumping stroke. The low cooling

capacity will prevent evaporator from freezing.

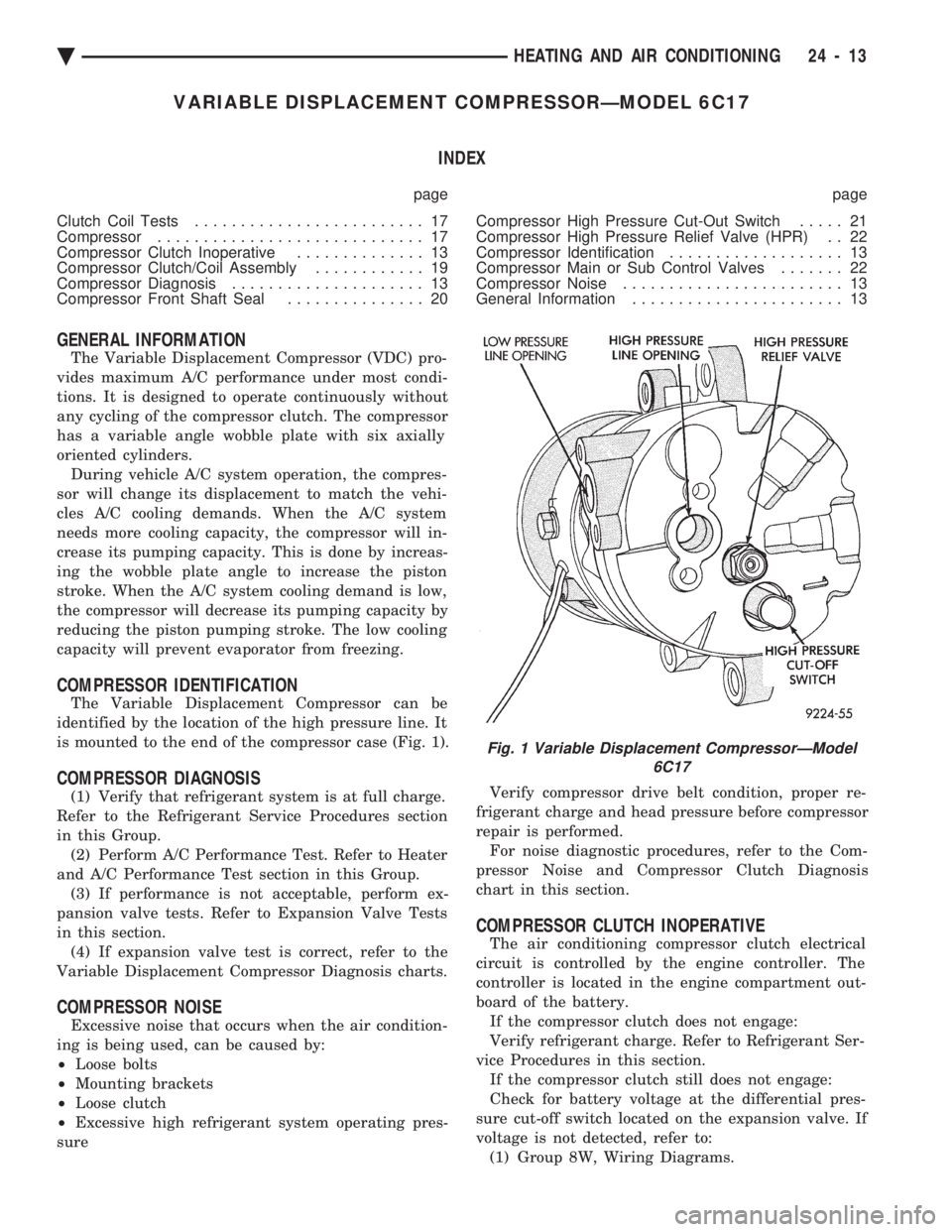

COMPRESSOR IDENTIFICATION

The Variable Displacement Compressor can be

identified by the location of the high pressure line. It

is mounted to the end of the compressor case (Fig. 1).

COMPRESSOR DIAGNOSIS

(1) Verify that refrigerant system is at full charge.

Refer to the Refrigerant Service Procedures section

in this Group. (2) Perform A/C Performance Test. Refer to Heater

and A/C Performance Test section in this Group. (3) If performance is not acceptable, perform ex-

pansion valve tests. Refer to Expansion Valve Tests

in this section. (4) If expansion valve test is correct, refer to the

Variable Displacement Compressor Diagnosis charts.

COMPRESSOR NOISE

Excessive noise that occurs when the air condition-

ing is being used, can be caused by:

² Loose bolts

² Mounting brackets

² Loose clutch

² Excessive high refrigerant system operating pres-

sure Verify compressor drive belt condition, proper re-

frigerant charge and head pressure before compressor

repair is performed. For noise diagnostic procedures, refer to the Com-

pressor Noise and Compressor Clutch Diagnosis

chart in this section.

COMPRESSOR CLUTCH INOPERATIVE

The air conditioning compressor clutch electrical

circuit is controlled by the engine controller. The

controller is located in the engine compartment out-

board of the battery. If the compressor clutch does not engage:

Verify refrigerant charge. Refer to Refrigerant Ser-

vice Procedures in this section. If the compressor clutch still does not engage:

Check for battery voltage at the differential pres-

sure cut-off switch located on the expansion valve. If

voltage is not detected, refer to: (1) Group 8W, Wiring Diagrams.

Fig. 1 Variable Displacement CompressorÐModel 6C17

Ä HEATING AND AIR CONDITIONING 24 - 13

Page 2321 of 2438

(2) The appropriate Powertrain Diagnostic Proce-

dures Manual for diagnostic information. (3) The Compressor Clutch DiagnosisÐVariable

Displacement Compressor chart in this section. (4) On 2.2 L Turbo III engines, check for battery

voltage at the Thermal Limiter Switch located on the

compressor. If voltage is found at the cut-off and/or thermal

limiter switch, reconnect switch. Then check for bat-

tery voltage between the compressor clutch connector

terminals. If voltage is detected, perform A/C Clutch Coil

Tests. Refer to Clutch Coil Tests in this section.

CLUTCH COIL TESTS

(1) Verify battery state of charge. (Test indicator

in battery should be green). (2) Connect an ammeter (0-10 ampere scale) in se-

ries with the clutch coil terminal. Use a volt meter

(0-20 volt scale) with clip leads measuring voltage

across the battery and A/C clutch. (3) With A/C control in A/C mode and blower at

low speed, start the engine and run at normal idle. (4) The A/C clutch should engage immediately and

the clutch voltage should be within two volts of the

battery voltage. If the A/C clutch does not engage,

test the fusible link. (5) The A/C clutch coil is acceptable if the current

draw is 2.0 to 3.7 amperes at 11.5-12.5 volts at clutch

coil. This is with the work area temperature at 21ÉC

(70ÉF). If voltage is more than 12.5 volts, add electri-

cal loads by turning on electrical accessories until

voltage reads below 12.5 volts. If coil current reads zero, the coil is open and

should be replaced. If the ammeter reading is 4 am-

peres or more, the coil is shorted and should be re-

placed. If the coil voltage is not within two volts of

the battery voltage, test clutch coil feed circuit for

excessive voltage drop.

COMPRESSOR

The A/C compressor may be removed and posi-

tioned without discharging the refrigerant system.

Discharging is not necessary if removing the A/C

compressor clutch/coil assembly, engine, cylinder

head, or generator.

WARNING: REFRIGERANT PRESSURES REMAIN HIGH

EVEN THOUGH THE ENGINE MAY BE TURNED OFF.

BEFORE REMOVING A FULLY CHARGED COMPRES-

SOR, REVIEW THE SAFETY PRECAUTIONS AND

WARNINGS SECTION IN THIS GROUP. DO NOT TWIST

OR KINK THE REFRIGERANT LINES WHEN REMOV-

ING A FULLY CHARGED COMPRESSOR. SAFETY

GLASSES MUST BE WORN.

REMOVAL AND INSTALLATION

(1) Disconnect NEGATIVE battery cable.

(2) Loosen and remove drive belts (Refer to Group

7, Cooling System) and disconnect compressor clutch

wire lead. (3) Remove refrigerant lines from compressor (if

necessary). (4) Remove compressor attaching nuts and bolts

(Fig. 2 or 3).

(5) Remove compressor. If refrigerant lines were

not removed, lift compressor/clutch assembly and tie

it to a suitable component. To install, reverse the preceding operation.

Fig. 2 A/C Compressor Removal and InstallationÐ3.3L Engines

Fig. 3 A/C Compressor Removal and InstallationÐ3.0 L Engine

Ä HEATING AND AIR CONDITIONING 24 - 17

Page 2328 of 2438

FIXED DISPLACEMENT COMPRESSORÐMODEL 10PA17 INDEX

page page

Compressor ............................. 24

Compressor Clutch/Coil Assembly ............ 24

Compressor Front Shaft Seal ............... 27 Compressor High-Pressure Relief Valve

....... 30

Refrigerant System Diagnosis ............... 30

COMPRESSOR

COMPRESSOR NOISE

Excessive noise that occurs when the air condition-

ing is being used, can be caused by:

² Loose bolts

² Mounting brackets

² Loose clutch

² Excessive high refrigerant system operating pres-

sure Verify compressor drive belt condition, proper re-

frigerant charge and head pressure before compressor

repair is performed. For noise diagnostic procedures, refer to the Com-

pressor Noise and Compressor Clutch Diagnosis

chart in this section.

REMOVAL AND INSTALLATION

The A/C compressor may be removed and posi-

tioned without discharging the refrigerant system.

Discharging is not necessary if removing the A/C

compressor clutch/coil assembly, engine, cylinder

head, or generator.

WARNING: REFRIGERANT PRESSURES REMAIN

HIGH EVEN THOUGH THE ENGINE MAY BE

TURNED OFF. BEFORE REMOVING A FULLY

CHARGED COMPRESSOR, REVIEW THE SAFETY

PRECAUTIONS AND WARNINGS SECTION IN THIS

GROUP. DO NOT TWIST OR KINK THE REFRIGER-

ANT LINES WHEN REMOVING A FULLY CHARGED

COMPRESSOR. SAFETY GLASSES MUST BE

WORN.

(1) Disconnect Negative battery cable.

(2) Loosen and remove drive belts (refer to Group

7, Cooling System) and disconnect compressor clutch

wire lead. (3) Remove refrigerant lines from compressor (if

necessary). (4) Remove compressor attaching nuts and bolts.

(5) Remove compressor. If refrigerant lines were

not removed, lift compressor/clutch assembly and tie

it to a suitable component. To install, reverse the preceding operation. If nec-

essary, refer to Charging Refrigerant System in the

Refrigerant Service Procedures section.

COMPRESSOR CLUTCH/COIL ASSEMBLY

CLUTCH INOPERATIVE

The air conditioning compressor clutch electrical

circuit is controlled by the engine controller. The

controller is located in the engine compartment out-

board of the battery. If the compressor clutch does not engage:

Verify refrigerant charge.

If the compressor clutch still does not engage check

for battery voltage at the low pressure or differential

pressure cut-off switch located on the expansion

valve. If voltage is not detected, refer to:

² Group 8W, Wiring Diagrams.

² The appropriate Powertrain Diagnostic Procedures

Manual for diagnostic information. If voltage is detected at the cut-off switch, recon-

nect switch. Then check for battery voltage between

the compressor clutch connector terminals. If voltage is detected, perform A/C Clutch Coil

Tests.

CLUTCH COIL TESTS

(1) Verify battery state of charge. (Test indicator

in battery should be green). (2) Connect an ammeter (0-10 ampere scale) in se-

ries with the clutch coil terminal. Use a volt meter

(0-20 volt scale) with clip leads measuring voltage

across the battery and A/C clutch. (3) With A/C control in A/C mode and blower at

low speed, start the engine and run at normal idle. (4) The A/C clutch should engage immediately and

the clutch voltage should be within two volts of the

battery voltage. If the A/C clutch does not engage,

test the fusible link. (5) The A/C clutch coil is acceptable if the current

draw is 2.0 to 3.7 amperes at 11.5-12.5 volts at clutch

coil. This is with the work area temperature at 21ÉC

(70ÉF). If voltage is more than 12.5 volts, add electri-

cal loads by turning on electrical accessories until

voltage reads below 12.5 volts. If coil current reads zero, the coil is open and

should be replaced. If the ammeter reading is 4 am-

peres or more, the coil is shorted and should be re-

placed. If the coil voltage is not within two volts of

the battery voltage, test clutch coil feed circuit for

excessive voltage drop.

24 - 24 HEATING AND AIR CONDITIONING Ä

Page 2336 of 2438

FIXED DISPLACEMENT COMPRESSORÐMODEL TR105 INDEX

page page

Compressor ............................. 32

Compressor Clutch/Coil Assembly ............ 32

Compressor Shaft Bearing/Seal .............. 35 Refrigerant System Diagnosis

............... 36

Thermal Limiter Switch .................... 34

COMPRESSOR

Cleanliness is extremely important when disassem-

bly of the compressor is necessary. The surfaces

around the suction and discharge ports of the com-

pressor should be cleaned thoroughly before opening

the system at these points. If compressor is removed

from vehicle, apply tape to the opened ports to pre-

vent any contamination.

REMOVAL

(1) Disconnect battery negative cable.

(2) Loosen and remove drive belts (refer to Group

7, Cooling System). (3) Disconnect compressor clutch wire lead.

(4) Using a refrigerant recovery machine, remove

refrigerant from the A/C system. (5) Remove refrigerant lines from compressor.

(6) Remove compressor attaching bolts.

(7) Remove compressor.

INSTALLATION

(1) Position the compressor on the mount and fit

drive belt. (2) Tighten the compressor attaching bolts to 41

N Im (30 ft. lbs.) torque.

(3) Adjust drive belt (see Group 7, Cooling Sys-

tem). (4) Install refrigerant hoses.

(5) Connect the clutch wire.

(6) Evacuate and charge the system.

(7) Connect the battery negative cable.

COMPRESSOR CLUTCH/COIL ASSEMBLY

CLUTCH INOPERATIVE

The air conditioning compressor clutch electrical

circuit is controlled by the engine controller. The

controller is located in the engine compartment out-

board of the battery. If the compressor clutch does not engage:

Verify refrigerant charge.

If the compressor clutch still does not engage check

for battery voltage at the low pressure or differential

pressure cut-off switch located on the expansion

valve. If voltage is not detected, refer to:

² Group 8W, Wiring Diagrams.

² The appropriate Powertrain Diagnostic Procedures

Manual for diagnostic information. If voltage is detected at the cut-off switch, recon-

nect switch. Then check for battery voltage between

the compressor clutch connector terminals. If voltage is detected, perform A/C Clutch Coil

Tests.

CLUTCH COIL TESTS

(1) Verify battery state of charge. (Test indicator

in battery should be green). (2) Connect an ammeter (0-10 ampere scale) in se-

ries with the clutch coil terminal. Use a volt meter

(0-20 volt scale) with clip leads measuring voltage

across the battery and A/C clutch. (3) With A/C control in A/C mode and blower at

low speed, start the engine and run at normal idle. (4) The A/C clutch should engage immediately and

the clutch voltage should be within two volts of the

battery voltage. If the A/C clutch does not engage,

test the fusible link. (5) The A/C clutch coil is acceptable if the current

draw is 2.0 to 3.7 amperes at 11.5-12.5 volts at clutch

coil. This is with the work area temperature at 21ÉC

(70ÉF). If voltage is more than 12.5 volts, add electri-

cal loads by turning on electrical accessories until

voltage reads below 12.5 volts. If coil current reads zero, the coil is open and

should be replaced. If the ammeter reading is 4 am-

peres or more, the coil is shorted and should be re-

placed. If the coil voltage is not within two volts of

the battery voltage, test clutch coil feed circuit for

excessive voltage drop.

REMOVAL

(1) Remove the compressor from the mount.

(2) To prevent compressor shaft rotation, install 2

(6 mm) bolts, along with 2 wrenches, to the threaded

holes in the armature plate (Fig. 1). Remove com-

pressor shaft nut. (3) Tap the armature plate with a plastic and re-

move plate and shim(s).

CAUTION: Do not use screwdrivers between the ar-

mature plate assembly and rotor-pulley to remove

the armature plate. This may damage the armature

plate assembly.

24 - 32 HEATING AND AIR CONDITIONING Ä

Page 2342 of 2438

FIXED DISPLACEMENT COMPRESSORÐMODEL SD709P INDEX

page page

Compressor ............................. 38

Compressor Clutch/Coil Assembly ............ 38

Compressor Shaft Seal .................... 41 Cylinder Head/Valve Plate

.................. 44

Description ............................. 38

Refrigerant System Diagnosis ............... 45

DESCRIPTION

The Sanden compressor is a 7 piston design. Sys-

tem lubrication is provided by 135 ml 615 ml (4.6 oz.

6 0.5 oz.) of 500 viscosity refrigerant oil.

The clutch used on the compressor consists of 3 ba-

sic components:

² The pulley

² Front plate

² Field coil

The pulley and field coil are attached to the front

head of the compressor with tapered snap rings. The

hub is keyed to the compressor shaft and is retained

on the shaft with a self-locking nut. Special service

tools are required to remove and install the clutch

plate on the compressor shaft.

COMPRESSOR

The A/C compressor may be removed and posi-

tioned without discharging the refrigerant system.

Discharging is not necessary if removing the A/C

compressor clutch/coil assembly, engine, cylinder

head, or generator.

WARNING: REFRIGERANT PRESSURES REMAIN

HIGH EVEN THOUGH THE ENGINE MAY BE

TURNED OFF. BEFORE REMOVING A FULLY

CHARGED COMPRESSOR, REVIEW THE SAFETY

PRECAUTIONS AND WARNINGS SECTION IN THIS

GROUP. DO NOT TWIST OR KINK THE REFRIGER-

ANT LINES WHEN REMOVING A FULLY CHARGED

COMPRESSOR. SAFETY GLASSES MUST BE

WORN.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Loosen and remove drive belts (refer to group

7, Cooling System) and disconnect compressor clutch

wire lead. (3) Remove refrigerant lines from compressor (if

necessary). (4) Remove compressor attaching nuts and bolts.

(5) Remove compressor. If refrigerant lines were

not removed, lift compressor/clutch assembly and tie

it to a suitable component. To install, reverse the removal procedure.

COMPRESSOR CLUTCH/COIL ASSEMBLY

The magnetic clutch consists of a stationary elec-

tro-magnetic coil and a rotating pulley and plate as-

sembly. The electromagnetic coil is retained on the com-

pressor with a snap ring and is dimpled to maintain

its position. The pulley and plate assembly are mounted on the

compressor shaft. When the compressor is not in operation, the pul-

ley free wheels on the clutch hub bearing. When the

coil is energized the plate is magnetically engaged

with the pulley and turns the compressor shaft.

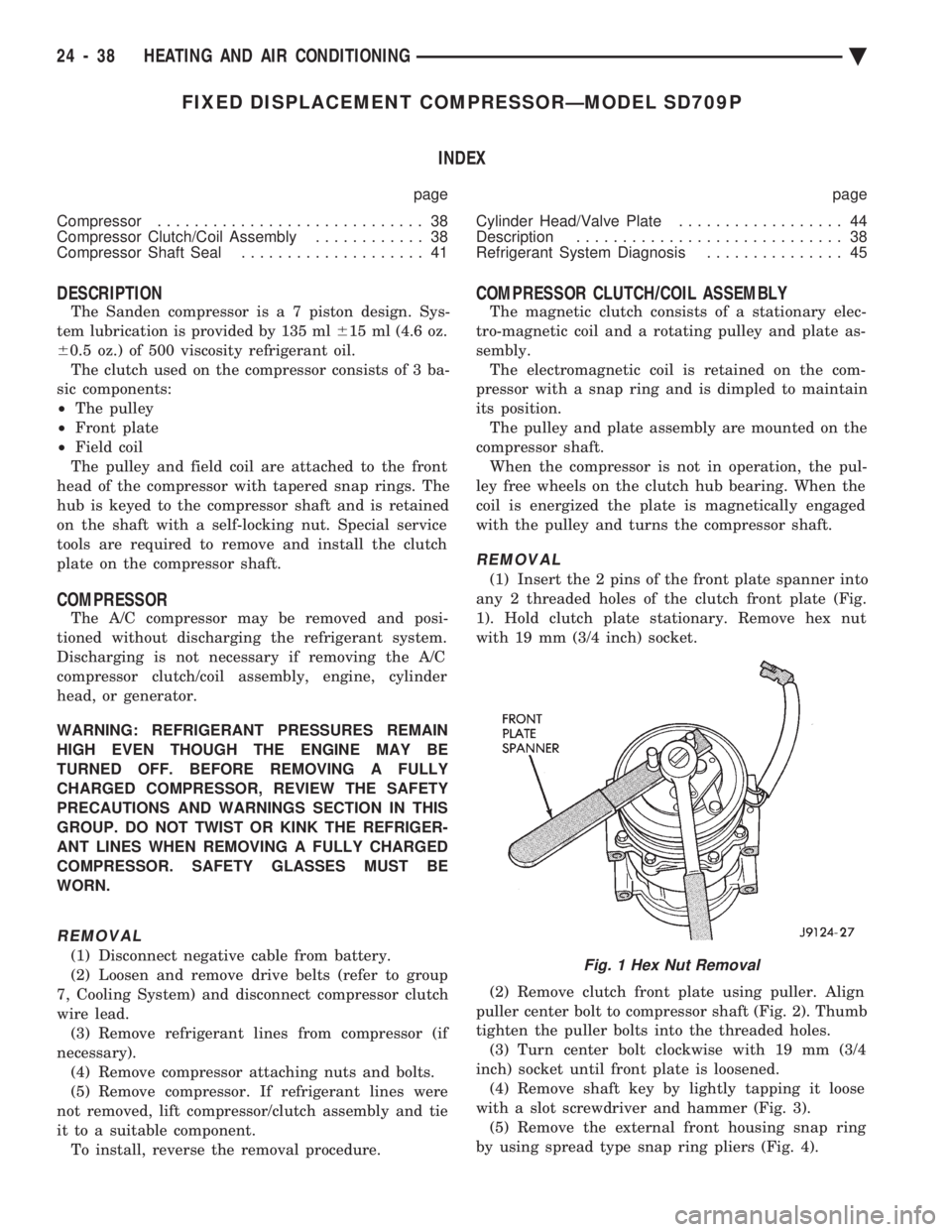

REMOVAL

(1) Insert the 2 pins of the front plate spanner into

any 2 threaded holes of the clutch front plate (Fig.

1). Hold clutch plate stationary. Remove hex nut

with 19 mm (3/4 inch) socket.

(2) Remove clutch front plate using puller. Align

puller center bolt to compressor shaft (Fig. 2). Thumb

tighten the puller bolts into the threaded holes. (3) Turn center bolt clockwise with 19 mm (3/4

inch) socket until front plate is loosened. (4) Remove shaft key by lightly tapping it loose

with a slot screwdriver and hammer (Fig. 3). (5) Remove the external front housing snap ring

by using spread type snap ring pliers (Fig. 4).

Fig. 1 Hex Nut Removal

24 - 38 HEATING AND AIR CONDITIONING Ä

Page 2376 of 2438

NONÐCOMPUTER AIDED DIAGNOSTIC TESTS

Determine whether the operator complaint is due

to a system failure or improper operation of the ATC

system. The system will to go into a maximum heat

or cooling mode if the operator changes the tempera-

ture setting four or more degrees. Check the following:

² Coolant level

² Refrigerant charge

² Drive belt tension

² Radiator air flow

² Radiator fan operation

² Air suction of In-car Temperature Sensor/Aspirator

To check air suction of the Aspirator, place a small

piece of tissue paper over the Aspirator opening on

the instrument panel. This opening is located to the

right of the steering column. The tissue paper should

cling to the opening if system is functioning properly. Bring the engine to normal operating temperature

and proceed with Computer Aided Diagnostic Proce-

dures. Always test the entire system after each re-

pair has been performed.

COMPUTER AIDED DIAGNOSTIC TESTS

The ATC control has a computer capable of trou-

bleshooting the entire ATC system in approximately

60 seconds. The engine must be running and at nor-

mal operating temperature during the test to provide

hot coolant for the heater. During the ATC Diagnostic Test, the computer will

calibrate the Mode and Blend Door actuators.

CAUTION: Do not remove the actuators from the

heater-A/C unit assembly with power applied. Re-

moval should only be done with the Ignition OFF.

The actuators have no mechanical stops to limit the

travel. If the actuator rotates and is not connected

to the unit assembly, it will become un-calibrated.

The Diagnostic Test is capable of checking all elec-

trical signals between the ATC Control Module, ac-

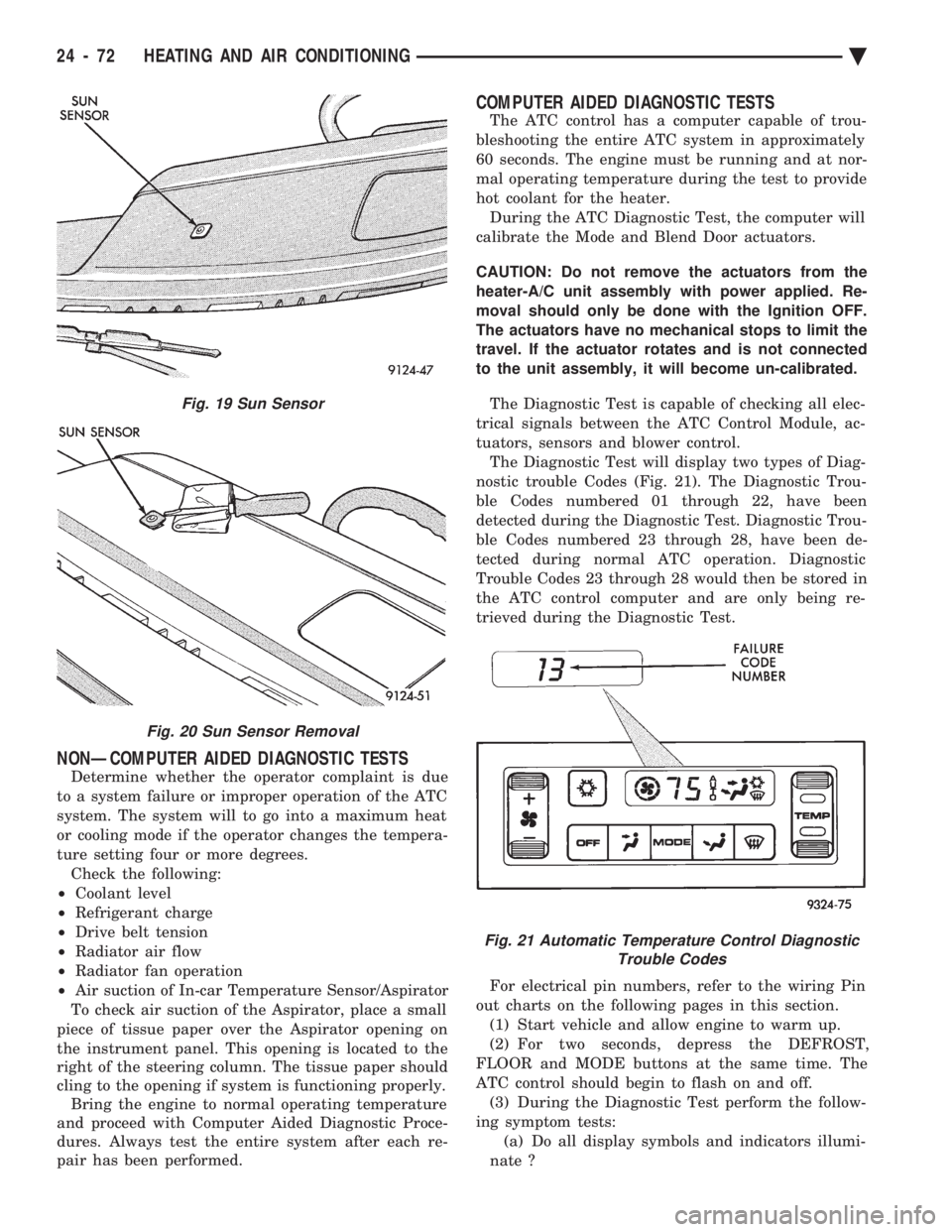

tuators, sensors and blower control. The Diagnostic Test will display two types of Diag-

nostic trouble Codes (Fig. 21). The Diagnostic Trou-

ble Codes numbered 01 through 22, have been

detected during the Diagnostic Test. Diagnostic Trou-

ble Codes numbered 23 through 28, have been de-

tected during normal ATC operation. Diagnostic

Trouble Codes 23 through 28 would then be stored in

the ATC control computer and are only being re-

trieved during the Diagnostic Test.

For electrical pin numbers, refer to the wiring Pin

out charts on the following pages in this section. (1) Start vehicle and allow engine to warm up.

(2) For two seconds, depress the DEFROST,

FLOOR and MODE buttons at the same time. The

ATC control should begin to flash on and off. (3) During the Diagnostic Test perform the follow-

ing symptom tests: (a) Do all display symbols and indicators illumi-

nate ?

Fig. 19 Sun Sensor

Fig. 20 Sun Sensor Removal

Fig. 21 Automatic Temperature Control Diagnostic Trouble Codes

24 - 72 HEATING AND AIR CONDITIONING Ä