wheel CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 684 of 2438

FRONT IMPACT SENSORS

The driver air bag system is a safety device de-

signed to reduce the risk of fatality or serious injury,

caused by a frontal impact of the vehicle. The impact sensors provide verification of the di-

rection and severity of the impact. Three impact sen-

sors are used. One is called a safing sensor. It is

located inside the diagnostic module which is

mounted on the floor pan, just forward of the center

console. The other two sensors are mounted on the

upper crossmember of the radiator closure panel on

the left and right side of the vehicle under the hood. The impact sensors are threshold sensitive switches

that complete an electrical circuit when an impact

provides a sufficient G force to close the switch. The

sensors are calibrated for the specific vehicle and re-

act to the severity and direction of the impact.

CLOCKSPRING

The clockspring is mounted on the steering column

behind the steering wheel, and is used to maintain a

continuous electrical circuit between the wiring har-

ness and the driver's air bag module. This assembly

consists of a flat ribbon-like electrically conductive

tape which winds and unwinds with the steering

wheel rotation.

DIAGNOSTIC MODULE

The Air Bag System Diagnostic Module (ASDM)

contains the safing sensor and energy reserve capac-

itor. The ASDM monitors the system to determine

the system readiness. The ASDM will store sufficient

energy to deploy the air bag for only two minutes af-

ter the battery is disconnected. If both front impact

sensors are open the air bag could be deployed up to

9.5 minutes after the battery is disconnected. The

ASDM contains on-board diagnostics, and will illumi-

nate the AIR BAG warning lamp in the cluster when

a fault occurs.

STORAGE

The air bag module must be stored in its original

special container until used for service. Additionally,

it must be stored in a clean, dry environment, away

from sources of extreme heat, sparks, and sources of

high electrical energy. Always place or store the

module on a surface with the trim cover facing up to

minimize movement in case of accidental deploy-

ment.

HANDLING LIVE MODULE

At no time should any source of electricity be per-

mitted near the inflator on the back of the module.

When carrying a live module, the trim cover should

be pointed away from the body to minimize injury in

the event of accidental deployment. In addition, if

the module is placed on a bench or other surface, the plastic trim cover should be face up to minimize

movement in case of accidental deployment. When handling a steering column with an air bag

module attached, never place the column on the floor

or other surface with the steering wheel or module

face down.

DEPLOYED MODULE

The vehicle interior may contain a very small

amount of sodium hydroxide powder, a byproduct of

air bag deployment. Since this powder can irritate

the skin, eyes, nose or throat, be sure to wear safety

glasses, rubber gloves and long sleeves during

cleanup (Fig. 2).

If you find that the cleanup is irritating your skin,

run cool water over the affected area. Also, if you ex-

perience nasal or throat irritation, exit the vehicle

for fresh air until the irritation ceases. If irritation

continues, see a physician.

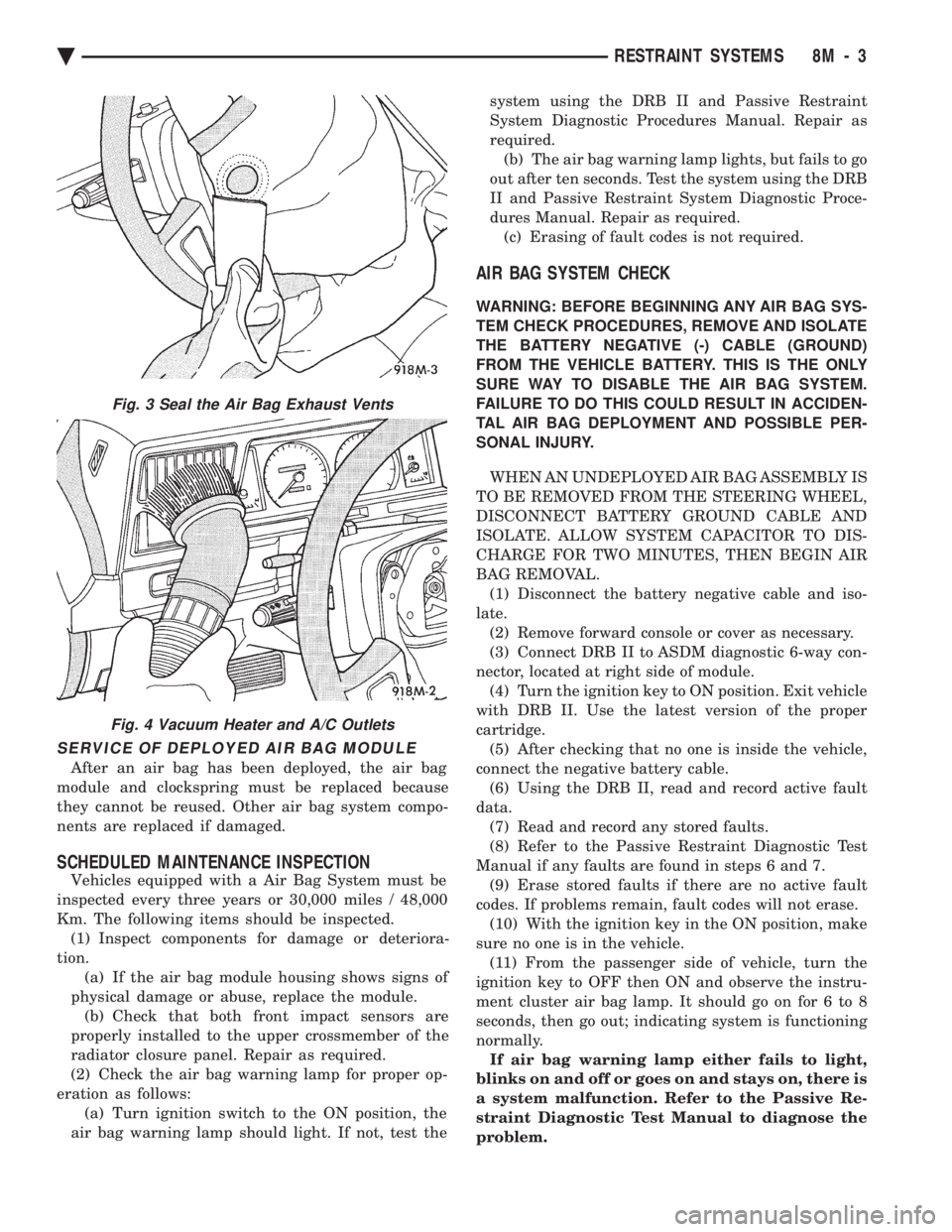

CLEANUP PROCEDURE

Begin the cleanup by putting tape over the two air

bag exhaust vents (Fig. 3) so that no additional pow-

der will find its way into the vehicle interior. Then

remove the air bag and air bag module from the ve-

hicle. Use a vacuum cleaner to remove any residual pow-

der from the vehicle interior. Work from the outside

in so that you avoid kneeling or sitting in a un-

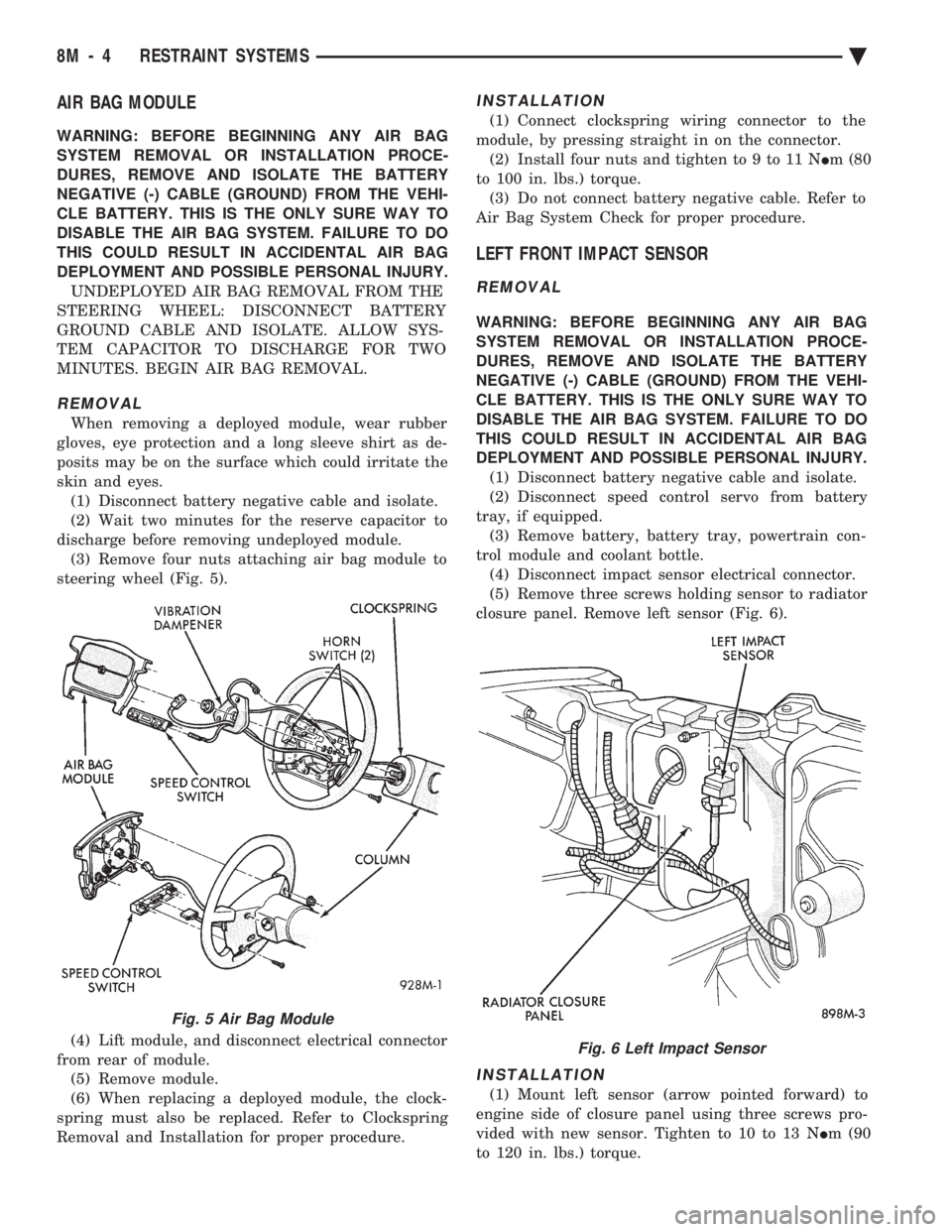

cleaned area. Be sure to vacuum the heater and A/C outlets as

well (Fig. 4). In fact it's a good idea to run the blower

on low and to vacuum up any powder expelled from

the plenum. You may need to vacuum the interior of

the car a second time to recover all of the powder. Place the deployed bag and module in your auto-

motive scrap.

Fig. 2 Wear Safety Glasses and Rubber Gloves

8M - 2 RESTRAINT SYSTEMS Ä

Page 685 of 2438

SERVICE OF DEPLOYED AIR BAG MODULE

After an air bag has been deployed, the air bag

module and clockspring must be replaced because

they cannot be reused. Other air bag system compo-

nents are replaced if damaged.

SCHEDULED MAINTENANCE INSPECTION

Vehicles equipped with a Air Bag System must be

inspected every three years or 30,000 miles / 48,000

Km. The following items should be inspected. (1) Inspect components for damage or deteriora-

tion. (a) If the air bag module housing shows signs of

physical damage or abuse, replace the module. (b) Check that both front impact sensors are

properly installed to the upper crossmember of the

radiator closure panel. Repair as required.

(2) Check the air bag warning lamp for proper op-

eration as follows: (a) Turn ignition switch to the ON position, the

air bag warning lamp should light. If not, test the system using the DRB II and Passive Restraint

System Diagnostic Procedures Manual. Repair as

required.

(b) The air bag warning lamp lights, but fails to go

out after ten seconds. Test the system using the DRB

II and Passive Restraint System Diagnostic Proce-

dures Manual. Repair as required. (c) Erasing of fault codes is not required.

AIR BAG SYSTEM CHECK

WARNING: BEFORE BEGINNING ANY AIR BAG SYS-

TEM CHECK PROCEDURES, REMOVE AND ISOLATE

THE BATTERY NEGATIVE (-) CABLE (GROUND)

FROM THE VEHICLE BATTERY. THIS IS THE ONLY

SURE WAY TO DISABLE THE AIR BAG SYSTEM.

FAILURE TO DO THIS COULD RESULT IN ACCIDEN-

TAL AIR BAG DEPLOYMENT AND POSSIBLE PER-

SONAL INJURY.

WHEN AN UNDEPLOYED AIR BAG ASSEMBLY IS

TO BE REMOVED FROM THE STEERING WHEEL,

DISCONNECT BATTERY GROUND CABLE AND

ISOLATE. ALLOW SYSTEM CAPACITOR TO DIS-

CHARGE FOR TWO MINUTES, THEN BEGIN AIR

BAG REMOVAL. (1) Disconnect the battery negative cable and iso-

late. (2) Remove forward console or cover as necessary.

(3) Connect DRB II to ASDM diagnostic 6-way con-

nector, located at right side of module. (4) Turn the ignition key to ON position. Exit vehicle

with DRB II. Use the latest version of the proper

cartridge. (5) After checking that no one is inside the vehicle,

connect the negative battery cable. (6) Using the DRB II, read and record active fault

data. (7) Read and record any stored faults.

(8) Refer to the Passive Restraint Diagnostic Test

Manual if any faults are found in steps 6 and 7. (9) Erase stored faults if there are no active fault

codes. If problems remain, fault codes will not erase. (10) With the ignition key in the ON position, make

sure no one is in the vehicle. (11) From the passenger side of vehicle, turn the

ignition key to OFF then ON and observe the instru-

ment cluster air bag lamp. It should go on for 6 to 8

seconds, then go out; indicating system is functioning

normally. If air bag warning lamp either fails to light,

blinks on and off or goes on and stays on, there is

a system malfunction. Refer to the Passive Re-

straint Diagnostic Test Manual to diagnose the

problem.

Fig. 3 Seal the Air Bag Exhaust Vents

Fig. 4 Vacuum Heater and A/C Outlets

Ä RESTRAINT SYSTEMS 8M - 3

Page 686 of 2438

AIR BAG MODULE

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY. UNDEPLOYED AIR BAG REMOVAL FROM THE

STEERING WHEEL: DISCONNECT BATTERY

GROUND CABLE AND ISOLATE. ALLOW SYS-

TEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES. BEGIN AIR BAG REMOVAL.

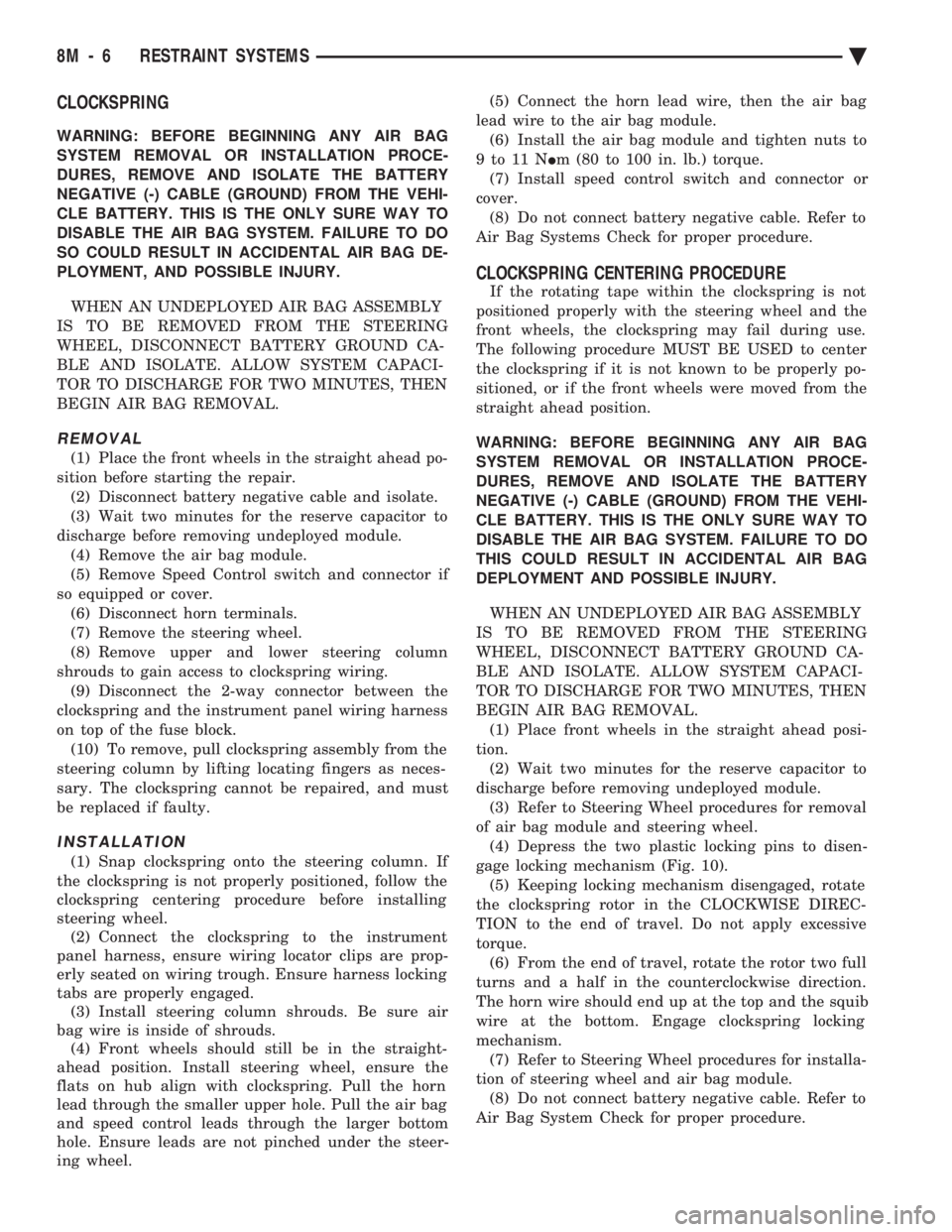

REMOVAL

When removing a deployed module, wear rubber

gloves, eye protection and a long sleeve shirt as de-

posits may be on the surface which could irritate the

skin and eyes. (1) Disconnect battery negative cable and isolate.

(2) Wait two minutes for the reserve capacitor to

discharge before removing undeployed module. (3) Remove four nuts attaching air bag module to

steering wheel (Fig. 5).

(4) Lift module, and disconnect electrical connector

from rear of module. (5) Remove module.

(6) When replacing a deployed module, the clock-

spring must also be replaced. Refer to Clockspring

Removal and Installation for proper procedure.

INSTALLATION

(1) Connect clockspring wiring connector to the

module, by pressing straight in on the connector. (2) Install four nuts and tighten to 9 to 11 N Im (80

to 100 in. lbs.) torque. (3) Do not connect battery negative cable. Refer to

Air Bag System Check for proper procedure.

LEFT FRONT IMPACT SENSOR

REMOVAL

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY. (1) Disconnect battery negative cable and isolate.

(2) Disconnect speed control servo from battery

tray, if equipped. (3) Remove battery, battery tray, powertrain con-

trol module and coolant bottle. (4) Disconnect impact sensor electrical connector.

(5) Remove three screws holding sensor to radiator

closure panel. Remove left sensor (Fig. 6).

INSTALLATION

(1) Mount left sensor (arrow pointed forward) to

engine side of closure panel using three screws pro-

vided with new sensor. Tighten to 10 to 13 N Im (90

to 120 in. lbs.) torque.

Fig. 5 Air Bag Module

Fig. 6 Left Impact Sensor

8M - 4 RESTRAINT SYSTEMS Ä

Page 688 of 2438

CLOCKSPRING

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

SO COULD RESULT IN ACCIDENTAL AIR BAG DE-

PLOYMENT, AND POSSIBLE INJURY.

WHEN AN UNDEPLOYED AIR BAG ASSEMBLY

IS TO BE REMOVED FROM THE STEERING

WHEEL, DISCONNECT BATTERY GROUND CA-

BLE AND ISOLATE. ALLOW SYSTEM CAPACI-

TOR TO DISCHARGE FOR TWO MINUTES, THEN

BEGIN AIR BAG REMOVAL.

REMOVAL

(1) Place the front wheels in the straight ahead po-

sition before starting the repair. (2) Disconnect battery negative cable and isolate.

(3) Wait two minutes for the reserve capacitor to

discharge before removing undeployed module. (4) Remove the air bag module.

(5) Remove Speed Control switch and connector if

so equipped or cover. (6) Disconnect horn terminals.

(7) Remove the steering wheel.

(8) Remove upper and lower steering column

shrouds to gain access to clockspring wiring. (9) Disconnect the 2-way connector between the

clockspring and the instrument panel wiring harness

on top of the fuse block. (10) To remove, pull clockspring assembly from the

steering column by lifting locating fingers as neces-

sary. The clockspring cannot be repaired, and must

be replaced if faulty.

INSTALLATION

(1) Snap clockspring onto the steering column. If

the clockspring is not properly positioned, follow the

clockspring centering procedure before installing

steering wheel. (2) Connect the clockspring to the instrument

panel harness, ensure wiring locator clips are prop-

erly seated on wiring trough. Ensure harness locking

tabs are properly engaged. (3) Install steering column shrouds. Be sure air

bag wire is inside of shrouds. (4) Front wheels should still be in the straight-

ahead position. Install steering wheel, ensure the

flats on hub align with clockspring. Pull the horn

lead through the smaller upper hole. Pull the air bag

and speed control leads through the larger bottom

hole. Ensure leads are not pinched under the steer-

ing wheel. (5) Connect the horn lead wire, then the air bag

lead wire to the air bag module. (6) Install the air bag module and tighten nuts to

9to11N Im (80 to 100 in. lb.) torque.

(7) Install speed control switch and connector or

cover. (8) Do not connect battery negative cable. Refer to

Air Bag Systems Check for proper procedure.

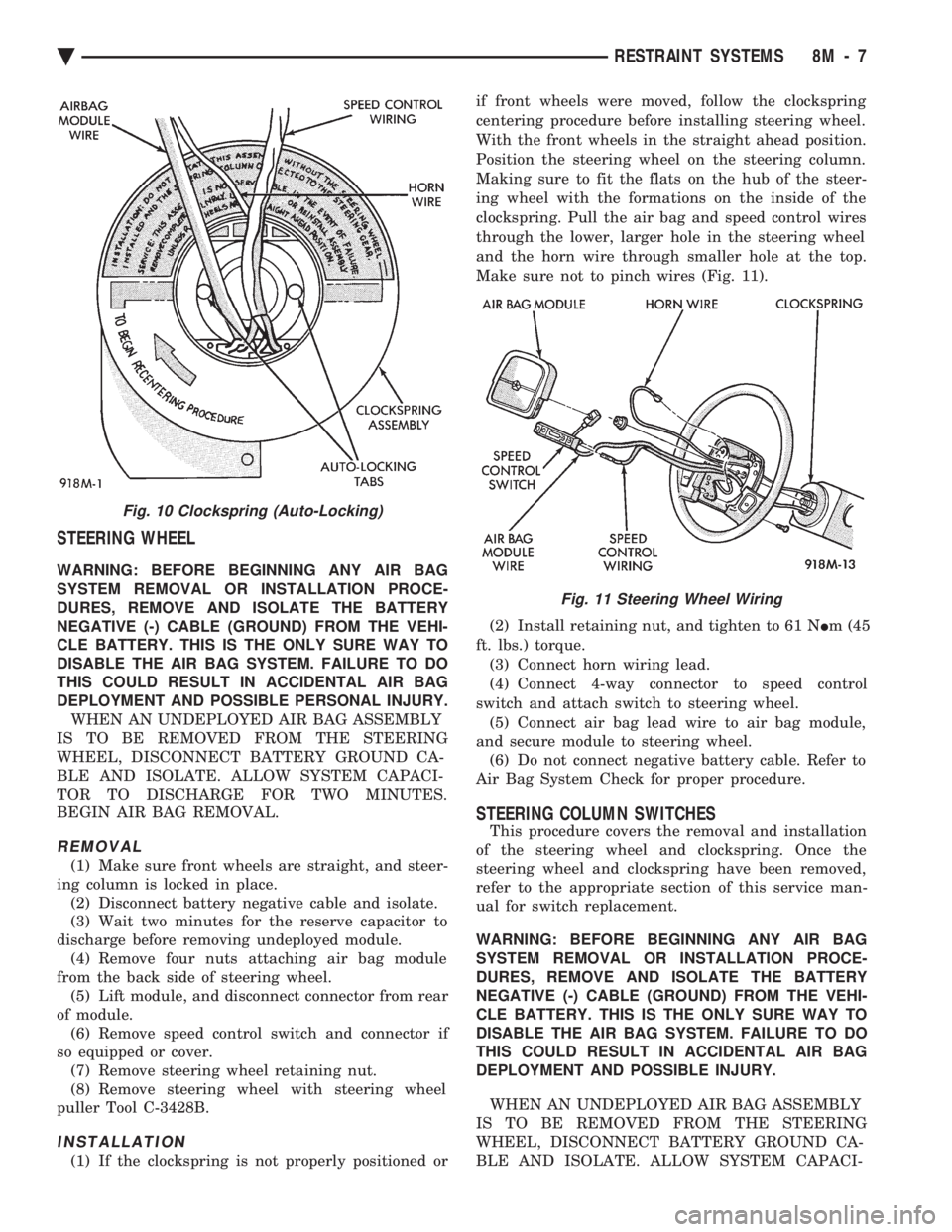

CLOCKSPRING CENTERING PROCEDURE

If the rotating tape within the clockspring is not

positioned properly with the steering wheel and the

front wheels, the clockspring may fail during use.

The following procedure MUST BE USED to center

the clockspring if it is not known to be properly po-

sitioned, or if the front wheels were moved from the

straight ahead position.

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE INJURY.

WHEN AN UNDEPLOYED AIR BAG ASSEMBLY

IS TO BE REMOVED FROM THE STEERING

WHEEL, DISCONNECT BATTERY GROUND CA-

BLE AND ISOLATE. ALLOW SYSTEM CAPACI-

TOR TO DISCHARGE FOR TWO MINUTES, THEN

BEGIN AIR BAG REMOVAL. (1) Place front wheels in the straight ahead posi-

tion. (2) Wait two minutes for the reserve capacitor to

discharge before removing undeployed module. (3) Refer to Steering Wheel procedures for removal

of air bag module and steering wheel. (4) Depress the two plastic locking pins to disen-

gage locking mechanism (Fig. 10). (5) Keeping locking mechanism disengaged, rotate

the clockspring rotor in the CLOCKWISE DIREC-

TION to the end of travel. Do not apply excessive

torque. (6) From the end of travel, rotate the rotor two full

turns and a half in the counterclockwise direction.

The horn wire should end up at the top and the squib

wire at the bottom. Engage clockspring locking

mechanism. (7) Refer to Steering Wheel procedures for installa-

tion of steering wheel and air bag module. (8) Do not connect battery negative cable. Refer to

Air Bag System Check for proper procedure.

8M - 6 RESTRAINT SYSTEMS Ä

Page 689 of 2438

STEERING WHEEL

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY. WHEN AN UNDEPLOYED AIR BAG ASSEMBLY

IS TO BE REMOVED FROM THE STEERING

WHEEL, DISCONNECT BATTERY GROUND CA-

BLE AND ISOLATE. ALLOW SYSTEM CAPACI-

TOR TO DISCHARGE FOR TWO MINUTES.

BEGIN AIR BAG REMOVAL.

REMOVAL

(1) Make sure front wheels are straight, and steer-

ing column is locked in place. (2) Disconnect battery negative cable and isolate.

(3) Wait two minutes for the reserve capacitor to

discharge before removing undeployed module. (4) Remove four nuts attaching air bag module

from the back side of steering wheel. (5) Lift module, and disconnect connector from rear

of module. (6) Remove speed control switch and connector if

so equipped or cover. (7) Remove steering wheel retaining nut.

(8) Remove steering wheel with steering wheel

puller Tool C-3428B.

INSTALLATION

(1) If the clockspring is not properly positioned or if front wheels were moved, follow the clockspring

centering procedure before installing steering wheel.

With the front wheels in the straight ahead position.

Position the steering wheel on the steering column.

Making sure to fit the flats on the hub of the steer-

ing wheel with the formations on the inside of the

clockspring. Pull the air bag and speed control wires

through the lower, larger hole in the steering wheel

and the horn wire through smaller hole at the top.

Make sure not to pinch wires (Fig. 11).

(2) Install retaining nut, and tighten to 61 N Im (45

ft. lbs.) torque. (3) Connect horn wiring lead.

(4) Connect 4-way connector to speed control

switch and attach switch to steering wheel. (5) Connect air bag lead wire to air bag module,

and secure module to steering wheel. (6) Do not connect negative battery cable. Refer to

Air Bag System Check for proper procedure.

STEERING COLUMN SWITCHES

This procedure covers the removal and installation

of the steering wheel and clockspring. Once the

steering wheel and clockspring have been removed,

refer to the appropriate section of this service man-

ual for switch replacement.

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE INJURY.

WHEN AN UNDEPLOYED AIR BAG ASSEMBLY

IS TO BE REMOVED FROM THE STEERING

WHEEL, DISCONNECT BATTERY GROUND CA-

BLE AND ISOLATE. ALLOW SYSTEM CAPACI-

Fig. 10 Clockspring (Auto-Locking)

Fig. 11 Steering Wheel Wiring

Ä RESTRAINT SYSTEMS 8M - 7

Page 690 of 2438

TOR TO DISCHARGE FOR TWO MINUTES.

BEGIN AIR BAG REMOVAL.

REMOVAL

(1) Disconnect battery negative cable, and isolate.

(2) Wait two minutes for the reserve capacitor to

discharge before removing undeployed module. (3) Remove four nuts attaching air bag module

from the back side of steering wheel. (4) Lift module, and disconnect connector from rear

of module. (5) Remove speed control switch and connector if

so equipped or cover. (6) Remove steering wheel.

(7) Unsnap clockspring, and remove it. (8) Refer to the appropriate section for switch re-

placement.

INSTALLATION

(1) Snap clockspring on to steering column. Assure

the 4 way connector is still seated. (2) Install steering wheel.

(3) Install speed control switch and connector or

cover. (4) Connect clockspring wiring connector to the

module. (5) Install four nuts to module, and tighten to 9 to

11 N Im (80 to 100 in. lbs.) torque.

(6) Do not connect negative battery cable. Refer to

Air Bag System Check for proper procedure.

8M - 8 RESTRAINT SYSTEMS Ä

Page 745 of 2438

CHIME WARNING/REMINDER SYSTEM

CONTENTS

page page

BODY CONTROLLER REPLACEMENT ........ 5

CHIME MODULE REPLACEMENT AA and AP BODIES .............................. 5

CHIME SYSTEM DIAGNOSISÐAA AND AP BODIES .............................. 2

CHIME SYSTEM DIAGNOSISÐAC, AG, AJ AND AY BODIES ....................... 3

CHIME WARNING/REMINDER SYSTEM TEST . 1 GENERAL INFORMATION

.................. 1

HEADLAMP SWITCH REPLACEMENT ........ 5

KEY-IN SWITCH REPLACEMENT ............ 5

SEAT BELT BUCKLE REPLACEMENT ........ 5

SEAT BELT BUCKLE SWITCH TEST BUZZER SYSTEM .............................. 1

SERVICE PROCEDURES ................... 5

TIMED BUZZER-RELAY TESTÐAP BODY ..... 1

GENERAL INFORMATION

WARNING: ON VEHICLES EQUIPPED WITH AN AIR

BAG REFER TO THE AIR BAG PORTION OF THIS

SECTION FOR STEERING WHEEL OR SWITCH RE-

MOVAL AND INSTALLATION PROCEDURES.

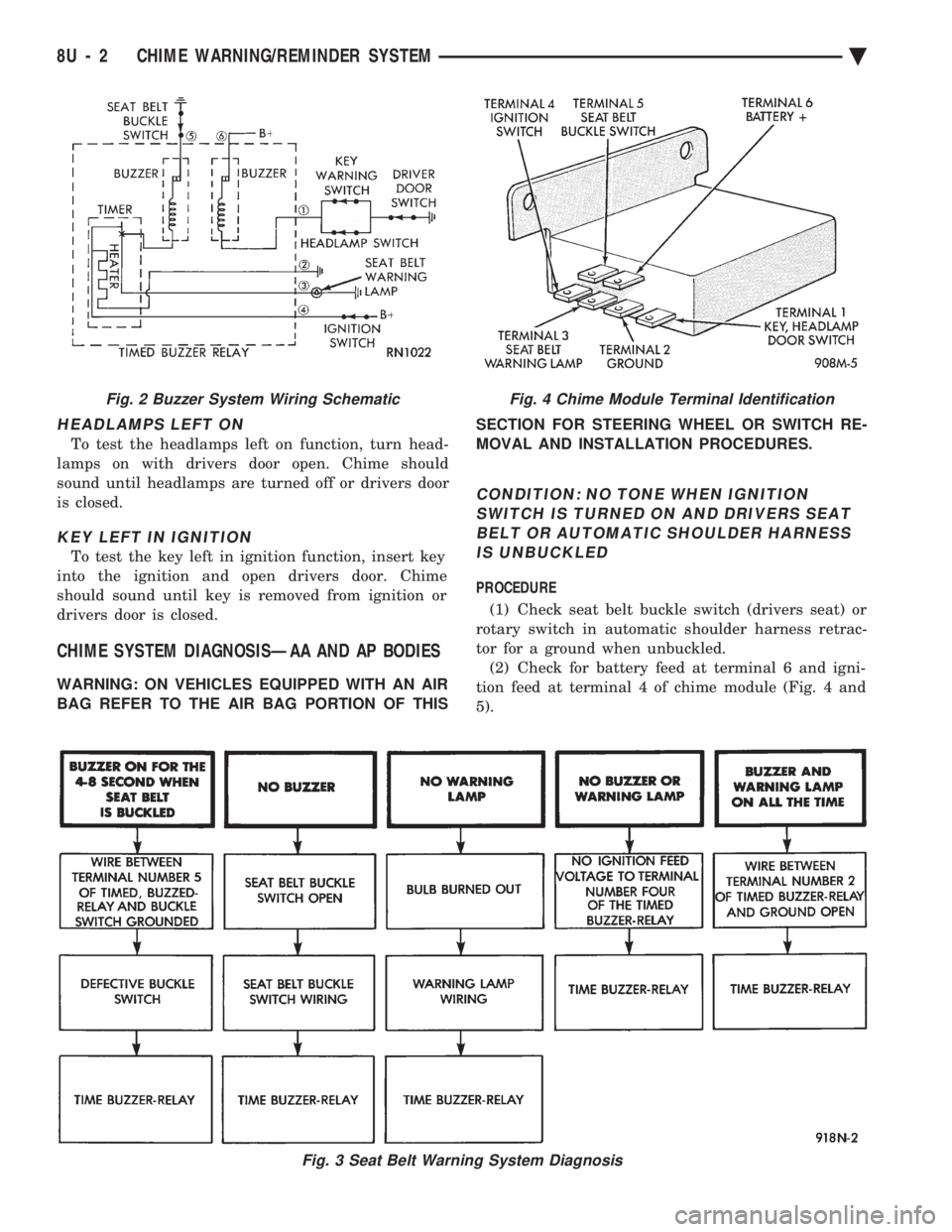

BUZZER SYSTEM

The seat belt warning system uses both visual and

audible signals. A combined seat belt and key warn-

ing buzzer with a red light on the instrument panel. The system will always illuminate the seat belt

warning lamp for four to eight seconds when the ig-

nition switch is turned to the ON position. Also, only

if the driver does not fasten his seat belt, the buzzer

will sound during the same time interval. Passenger

belts are not connected to the system. A timed buzzer-relay is used to operate the system

for the time period. It consists of a time delay mech-

anism and buzzer assembly. Only the driver's seat

belt buckle has a switch that is connected to the sys-

tem.

CHIME WARNING/REMINDER SYSTEM

The chime warning/reminder system is similar in

operation to the buzzer system except for a more

pleasant sounding tone. This chime type tone sounds

for all three warning/reminder conditions; namely

headlamps left on, keys left in ignition and fasten

seat belt.

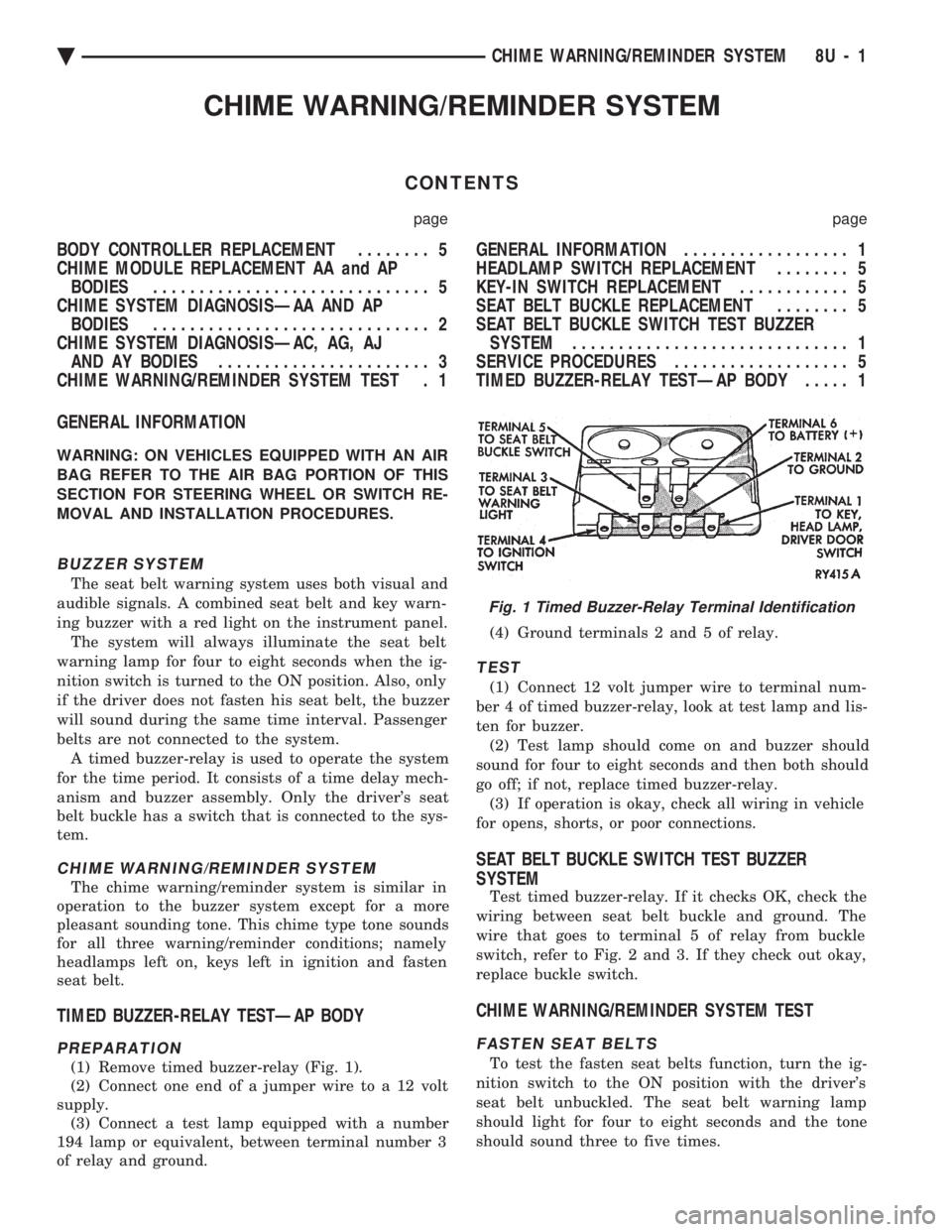

TIMED BUZZER-RELAY TESTÐAP BODY

PREPARATION

(1) Remove timed buzzer-relay (Fig. 1).

(2) Connect one end of a jumper wire to a 12 volt

supply. (3) Connect a test lamp equipped with a number

194 lamp or equivalent, between terminal number 3

of relay and ground. (4) Ground terminals 2 and 5 of relay.

TEST

(1) Connect 12 volt jumper wire to terminal num-

ber 4 of timed buzzer-relay, look at test lamp and lis-

ten for buzzer. (2) Test lamp should come on and buzzer should

sound for four to eight seconds and then both should

go off; if not, replace timed buzzer-relay. (3) If operation is okay, check all wiring in vehicle

for opens, shorts, or poor connections.

SEAT BELT BUCKLE SWITCH TEST BUZZER

SYSTEM

Test timed buzzer-relay. If it checks OK, check the

wiring between seat belt buckle and ground. The

wire that goes to terminal 5 of relay from buckle

switch, refer to Fig. 2 and 3. If they check out okay,

replace buckle switch.

CHIME WARNING/REMINDER SYSTEM TEST

FASTEN SEAT BELTS

To test the fasten seat belts function, turn the ig-

nition switch to the ON position with the driver's

seat belt unbuckled. The seat belt warning lamp

should light for four to eight seconds and the tone

should sound three to five times.

Fig. 1 Timed Buzzer-Relay Terminal Identification

Ä CHIME WARNING/REMINDER SYSTEM 8U - 1

Page 746 of 2438

HEADLAMPS LEFT ON

To test the headlamps left on function, turn head-

lamps on with drivers door open. Chime should

sound until headlamps are turned off or drivers door

is closed.

KEY LEFT IN IGNITION

To test the key left in ignition function, insert key

into the ignition and open drivers door. Chime

should sound until key is removed from ignition or

drivers door is closed.

CHIME SYSTEM DIAGNOSISÐAA AND AP BODIES

WARNING: ON VEHICLES EQUIPPED WITH AN AIR

BAG REFER TO THE AIR BAG PORTION OF THIS SECTION FOR STEERING WHEEL OR SWITCH RE-

MOVAL AND INSTALLATION PROCEDURES.

CONDITION: NO TONE WHEN IGNITION

SWITCH IS TURNED ON AND DRIVERS SEATBELT OR AUTOMATIC SHOULDER HARNESSIS UNBUCKLED

PROCEDURE

(1) Check seat belt buckle switch (drivers seat) or

rotary switch in automatic shoulder harness retrac-

tor for a ground when unbuckled. (2) Check for battery feed at terminal 6 and igni-

tion feed at terminal 4 of chime module (Fig. 4 and

5).

Fig. 3 Seat Belt Warning System Diagnosis

Fig. 4 Chime Module Terminal IdentificationFig. 2 Buzzer System Wiring Schematic

8U - 2 CHIME WARNING/REMINDER SYSTEM Ä

Page 931 of 2438

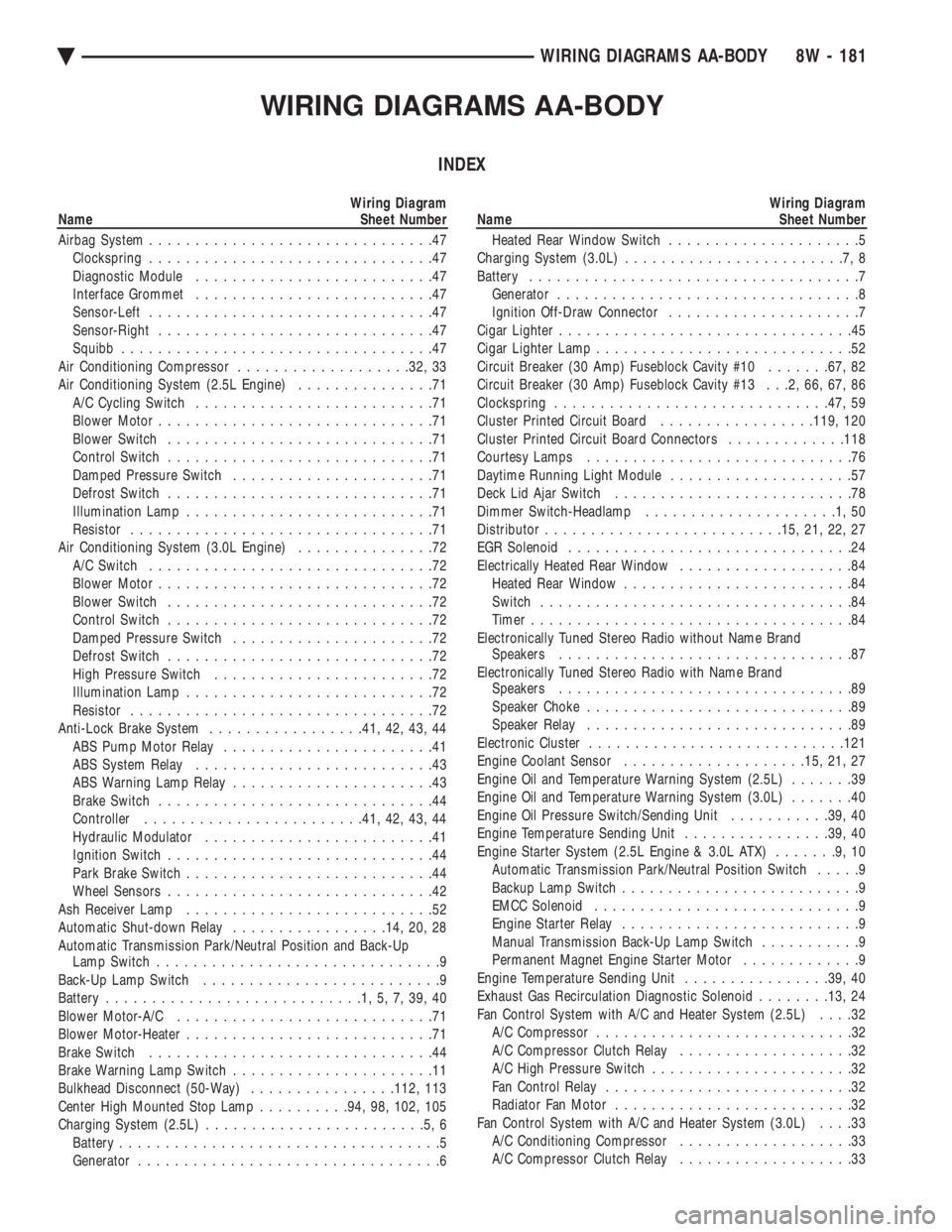

WIRING DIAGRAMS AA-BODY

INDEX

Wiring Diagram

Name Sheet Number

Airbag System ...............................47

Clockspring ...............................47

Diagnostic Module ..........................47

Interface Grommet ..........................47

Sensor-Left ...............................47

Sensor-Right ..............................47

Squibb ..................................47

Air Conditioning Compressor ...................32, 33

Air Conditioning System (2.5L Engine) ...............71

A/C Cycling Switch ..........................71

Blower Motor ..............................71

Blower Switch .............................71

Control Switch .............................71

Damped Pressure Switch ......................71

Defrost Switch .............................71

Illumination Lamp ...........................71

Resistor .................................71

Air Conditioning System (3.0L Engine) ...............72

A/C Switch ...............................72

Blower Motor ..............................72

Blower Switch .............................72

Control Switch .............................72

Damped Pressure Switch ......................72

Defrost Switch .............................72

High Pressure Switch ........................72

Illumination Lamp ...........................72

Resistor .................................72

Anti-Lock Brake System .................41, 42, 43, 44

ABS Pump Motor Relay .......................41

ABS System Relay ..........................43

ABS Warning Lamp Relay ......................43

Brake Switch ..............................44

Controller ....................... .41, 42, 43, 44

Hydraulic Modulator .........................41

Ignition Switch .............................44

Park Brake Switch ...........................44

Wheel Sensors .............................42

Ash Receiver Lamp ...........................52

Automatic Shut-down Relay .................14, 20, 28

Automatic Transmission Park/Neutral Position and Back-Up Lamp Switch ...............................9

Back-Up Lamp Switch ..........................9

Battery ............................1,5,7,39,40

Blower Motor-A/C ............................71

Blower Motor-Heater ...........................71

Brake Switch ...............................44

Brake Warning Lamp Switch ......................11

Bulkhead Disconnect (50-Way) ................112, 113

Center High Mounted Stop Lamp ..........94, 98, 102, 105

Charging System (2.5L) ........................5,6

Battery ...................................5

Generator .................................6Wiring Diagram

Name Sheet Number

Heated Rear Window Switch .....................5

Charging System (3.0L) ........................7,8

Battery ....................................7

Generator .................................8

Ignition Off-Draw Connector .....................7

Cigar Lighter ................................45

Cigar Lighter Lamp ............................52

Circuit Breaker (30 Amp) Fuseblock Cavity #10 .......67, 82

Circuit Breaker (30 Amp) Fuseblock Cavity #13 . . .2, 66, 67, 86

Clockspring ............................. .47, 59

Cluster Printed Circuit Board .................119, 120

Cluster Printed Circuit Board Connectors .............118

Courtesy Lamps .............................76

Daytime Running Light Module ....................57

Deck Lid Ajar Switch ..........................78

Dimmer Switch-Headlamp .....................1,50

Distributor ......................... .15, 21, 22, 27

EGR Solenoid ...............................24

Electrically Heated Rear Window ...................84

Heated Rear Window .........................84

Switch ..................................84

Timer ...................................84

Electronically Tuned Stereo Radio without Name Brand Speakers ................................87

Electronically Tuned Stereo Radio with Name Brand Speakers ................................89

Speaker Choke .............................89

Speaker Relay .............................89

Electronic Cluster ........................... .121

Engine Coolant Sensor ................... .15, 21, 27

Engine Oil and Temperature Warning System (2.5L) .......39

Engine Oil and Temperature Warning System (3.0L) .......40

Engine Oil Pressure Switch/Sending Unit ...........39, 40

Engine Temperature Sending Unit ................39, 40

Engine Starter System (2.5L Engine & 3.0L ATX) .......9,10

Automatic Transmission Park/Neutral Position Switch .....9

Backup Lamp Switch ..........................9

EMCC Solenoid .............................9

Engine Starter Relay ..........................9

Manual Transmission Back-Up Lamp Switch ...........9

Permanent Magnet Engine Starter Motor .............9

Engine Temperature Sending Unit ................39, 40

Exhaust Gas Recirculation Diagnostic Solenoid ........13, 24

Fan Control System with A/C and Heater System (2.5L) ....32

A/C Compressor ............................32

A/C Compressor Clutch Relay ...................32

A/C High Pressure Switch ......................32

Fan Control Relay ...........................32

Radiator Fan Motor ..........................32

Fan Control System with A/C and Heater System (3.0L) ....33

A/C Conditioning Compressor ...................33

A/C Compressor Clutch Relay ...................33

Ä WIRING DIAGRAMS AA-BODY 8W - 181

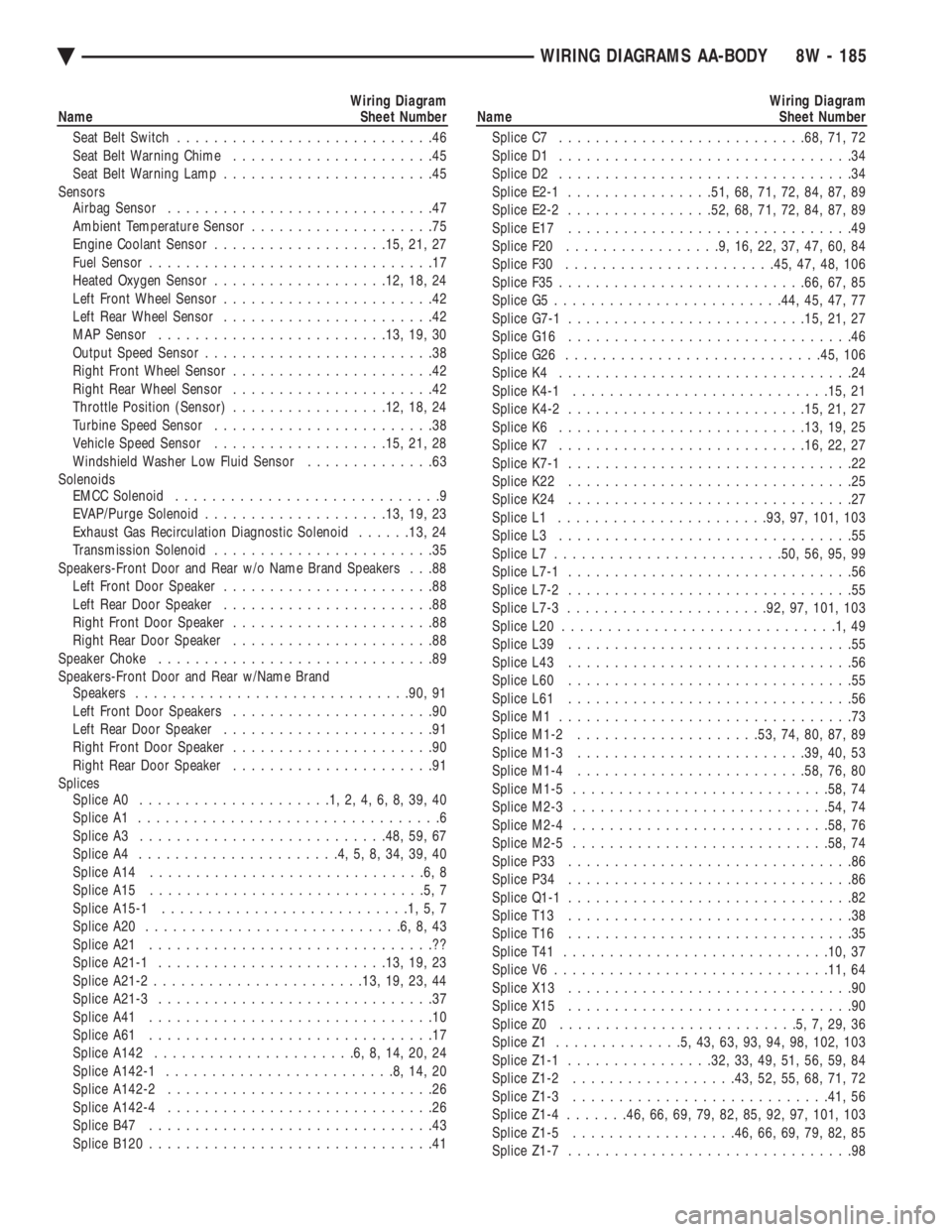

Page 935 of 2438

Wiring Diagram

Name Sheet Number

Seat Belt Switch ............................46

Seat Belt Warning Chime ......................45

Seat Belt Warning Lamp .......................45

Sensors Airbag Sensor .............................47

Ambient Temperature Sensor ....................75

Engine Coolant Sensor .................. .15, 21, 27

Fuel Sensor ...............................17

Heated Oxygen Sensor .................. .12, 18, 24

Left Front Wheel Sensor .......................42

Left Rear Wheel Sensor .......................42

MAP Sensor ........................ .13, 19, 30

Output Speed Sensor .........................38

Right Front Wheel Sensor ......................42

Right Rear Wheel Sensor ......................42

Throttle Position (Sensor) .................12, 18, 24

Turbine Speed Sensor ........................38

Vehicle Speed Sensor .................. .15, 21, 28

Windshield Washer Low Fluid Sensor ..............63

Solenoids EMCC Solenoid .............................9

EVAP/Purge Solenoid ................... .13, 19, 23

Exhaust Gas Recirculation Diagnostic Solenoid ......13, 24

Transmission Solenoid ........................35

Speakers-Front Door and Rear w/o Name Brand Speakers . . .88 Left Front Door Speaker .......................88

Left Rear Door Speaker .......................88

Right Front Door Speaker ......................88

Right Rear Door Speaker ......................88

Speaker Choke ..............................89

Speakers-Front Door and Rear w/Name Brand Speakers ............................. .90, 91

Left Front Door Speakers ......................90

Left Rear Door Speaker .......................91

Right Front Door Speaker ......................90

Right Rear Door Speaker ......................91

Splices Splice A0 .....................1,2,4,6,8,39,40

Splice A1 .................................6

Splice A3 .......................... .48, 59, 67

Splice A4 ......................4,5,8,34,39,40

Splice A14 ..............................6,8

Splice A15 ..............................5,7

Splice A15-1 ...........................1,5,7

Splice A20 ............................6,8,43

Splice A21 ...............................??

Splice A21-1 ........................ .13, 19, 23

Splice A21-2 ...................... .13, 19, 23, 44

Splice A21-3 ..............................37

Splice A41 ...............................10

Splice A61 ...............................17

Splice A142 ......................6,8,14,20,24

Splice A142-1 .........................8,14,20

Splice A142-2 .............................26

Splice A142-4 .............................26

Splice B47 ...............................43

Splice B120 ...............................41Wiring Diagram

Name Sheet Number

Splice C7 .......................... .68, 71, 72

Splice D1 ................................34

Splice D2 ................................34

Splice E2-1 ............... .51, 68, 71, 72, 84, 87, 89

Splice E2-2 ............... .52, 68, 71, 72, 84, 87, 89

Splice E17 ...............................49

Splice F20 .................9,16,22,37,47,60,84

Splice F30 ...................... .45, 47, 48, 106

Splice F35 .......................... .66, 67, 85

Splice G5 ........................ .44, 45, 47, 77

Splice G7-1 ......................... .15, 21, 27

Splice G16 ...............................46

Splice G26 ........................... .45, 106

Splice K4 ................................24

Splice K4-1 ........................... .15, 21

Splice K4-2 ......................... .15, 21, 27

Splice K6 .......................... .13, 19, 25

Splice K7 .......................... .16, 22, 27

Splice K7-1 ...............................22

Splice K22 ...............................25

Splice K24 ...............................27

Splice L1 ...................... .93, 97, 101, 103

Splice L3 ................................55

Splice L7 ........................ .50, 56, 95, 99

Splice L7-1 ...............................56

Splice L7-2 ...............................55

Splice L7-3 ..................... .92, 97, 101, 103

Splice L20 ..............................1,49

Splice L39 ...............................55

Splice L43 ...............................56

Splice L60 ...............................55

Splice L61 ...............................56

Splice M1 ................................73

Splice M1-2 ................... .53, 74, 80, 87, 89

Splice M1-3 ........................ .39, 40, 53

Splice M1-4 ........................ .58, 76, 80

Splice M1-5 ........................... .58, 74

Splice M2-3 ........................... .54, 74

Splice M2-4 ........................... .58, 76

Splice M2-5 ........................... .58, 74

Splice P33 ...............................86

Splice P34 ...............................86

Splice Q1-1 ...............................82

Splice T13 ...............................38

Splice T16 ...............................35

Splice T41 ............................ .10, 37

Splice V6 ............................. .11, 64

Splice X13 ...............................90

Splice X15 ...............................90

Splice Z0 ..........................5,7,29,36

Splice Z1 ..............5,43,63,93,94,98, 102, 103

Splice Z1-1 ............... .32, 33, 49, 51, 56, 59, 84

Splice Z1-2 ................. .43, 52, 55, 68, 71, 72

Splice Z1-3 ........................... .41, 56

Splice Z1-4 .......46, 66, 69, 79, 82, 85, 92, 97, 101, 103

Splice Z1-5 ................. .46, 66, 69, 79, 82, 85

Splice Z1-7 ...............................98

Ä WIRING DIAGRAMS AA-BODY 8W - 185