gas mileage CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 45 of 2438

² SG service engine oil is a high quality crankcase

lubricant designed for use in all naturally aspirated

engines. If SG service engine oil is used in turbo-

charged engine, change engine oil at every 4 800

km (3,000 miles) or three months.

² SG/CD service engine oil is a high quality crank-

case lubricant designed for use in most naturally as-

pirated and turbocharged gasoline or diesel engines.

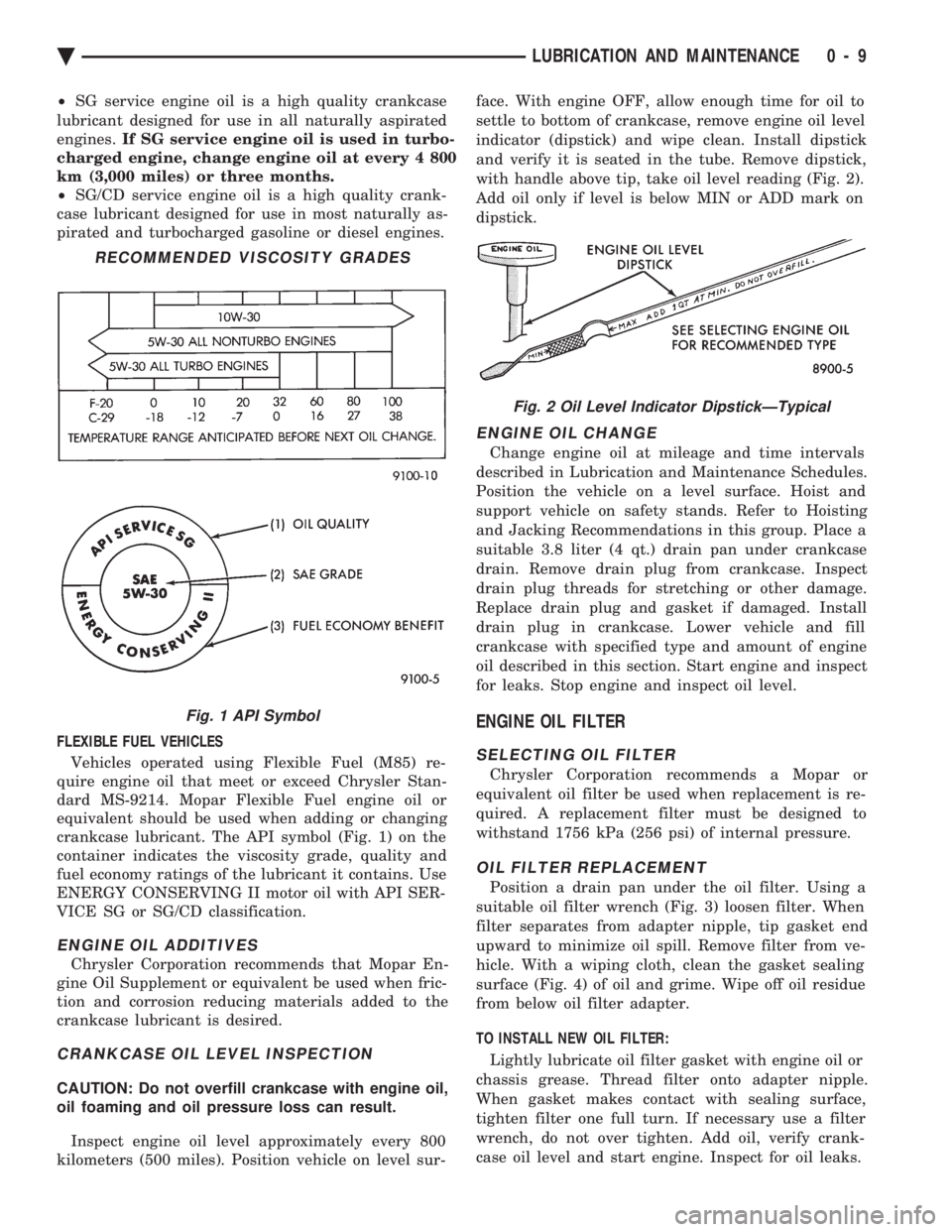

FLEXIBLE FUEL VEHICLES

Vehicles operated using Flexible Fuel (M85) re-

quire engine oil that meet or exceed Chrysler Stan-

dard MS-9214. Mopar Flexible Fuel engine oil or

equivalent should be used when adding or changing

crankcase lubricant. The API symbol (Fig. 1) on the

container indicates the viscosity grade, quality and

fuel economy ratings of the lubricant it contains. Use

ENERGY CONSERVING II motor oil with API SER-

VICE SG or SG/CD classification.

ENGINE OIL ADDITIVES

Chrysler Corporation recommends that Mopar En-

gine Oil Supplement or equivalent be used when fric-

tion and corrosion reducing materials added to the

crankcase lubricant is desired.

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

oil foaming and oil pressure loss can result.

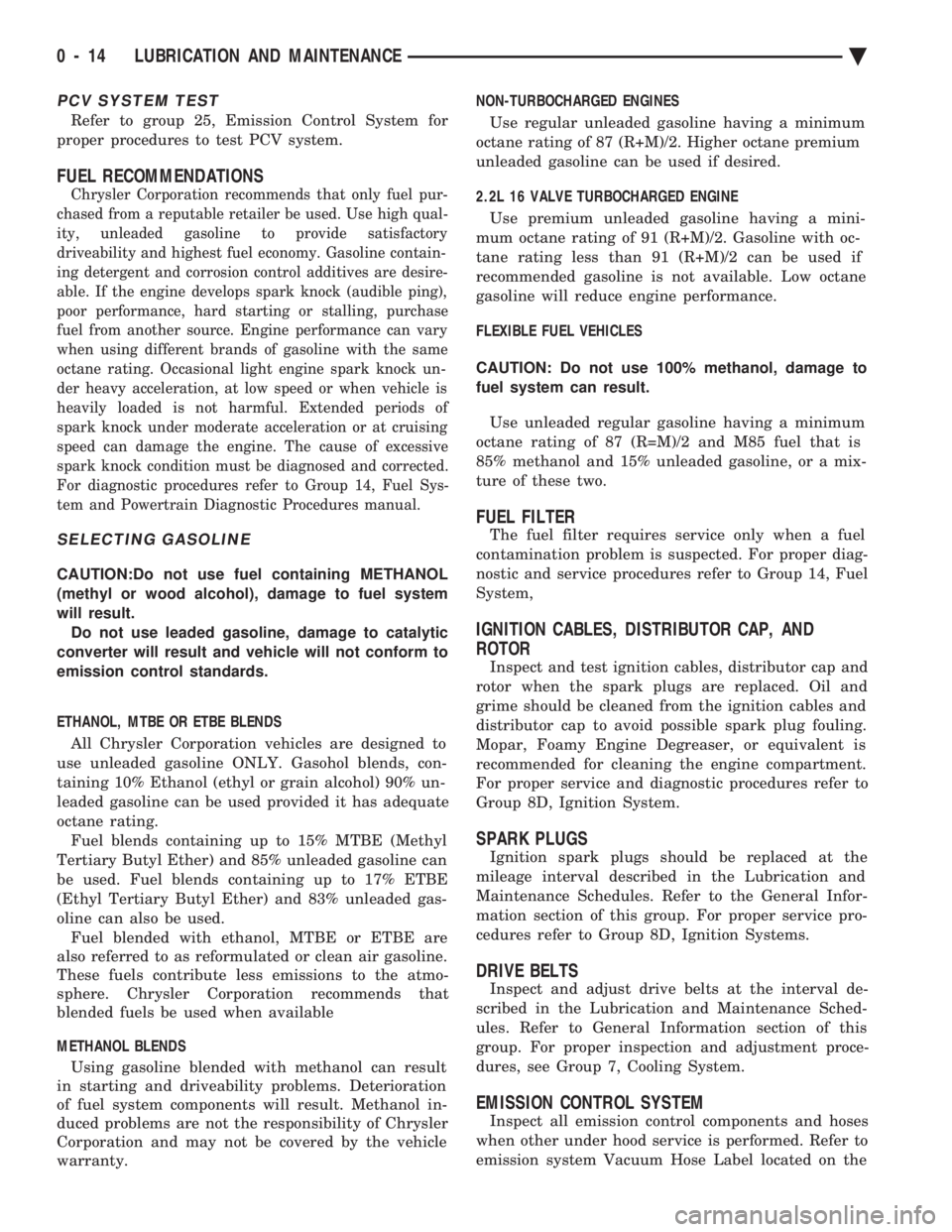

Inspect engine oil level approximately every 800

kilometers (500 miles). Position vehicle on level sur- face. With engine OFF, allow enough time for oil to

settle to bottom of crankcase, remove engine oil level

indicator (dipstick) and wipe clean. Install dipstick

and verify it is seated in the tube. Remove dipstick,

with handle above tip, take oil level reading (Fig. 2).

Add oil only if level is below MIN or ADD mark on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in Lubrication and Maintenance Schedules.

Position the vehicle on a level surface. Hoist and

support vehicle on safety stands. Refer to Hoisting

and Jacking Recommendations in this group. Place a

suitable 3.8 liter (4 qt.) drain pan under crankcase

drain. Remove drain plug from crankcase. Inspect

drain plug threads for stretching or other damage.

Replace drain plug and gasket if damaged. Install

drain plug in crankcase. Lower vehicle and fill

crankcase with specified type and amount of engine

oil described in this section. Start engine and inspect

for leaks. Stop engine and inspect oil level.

ENGINE OIL FILTER

SELECTING OIL FILTER

Chrysler Corporation recommends a Mopar or

equivalent oil filter be used when replacement is re-

quired. A replacement filter must be designed to

withstand 1756 kPa (256 psi) of internal pressure.

OIL FILTER REPLACEMENT

Position a drain pan under the oil filter. Using a

suitable oil filter wrench (Fig. 3) loosen filter. When

filter separates from adapter nipple, tip gasket end

upward to minimize oil spill. Remove filter from ve-

hicle. With a wiping cloth, clean the gasket sealing

surface (Fig. 4) of oil and grime. Wipe off oil residue

from below oil filter adapter.

TO INSTALL NEW OIL FILTER: Lightly lubricate oil filter gasket with engine oil or

chassis grease. Thread filter onto adapter nipple.

When gasket makes contact with sealing surface,

tighten filter one full turn. If necessary use a filter

wrench, do not over tighten. Add oil, verify crank-

case oil level and start engine. Inspect for oil leaks.

RECOMMENDED VISCOSITY GRADES

Fig. 1 API Symbol

Fig. 2 Oil Level Indicator DipstickÐTypical

Ä LUBRICATION AND MAINTENANCE 0 - 9

Page 50 of 2438

PCV SYSTEM TEST

Refer to group 25, Emission Control System for

proper procedures to test PCV system.

FUEL RECOMMENDATIONS

Chrysler Corporation recommends that only fuel pur-

chased from a reputable retailer be used. Use high qual-

ity, unleaded gasoline to provide satisfactory

driveability and highest fuel economy. Gasoline contain-

ing detergent and corrosion control additives are desire-

able. If the engine develops spark knock (audible ping),

poor performance, hard starting or stalling, purchase

fuel from another source. Engine performance can vary

when using different brands of gasoline with the same

octane rating. Occasional light engine spark knock un-

der heavy acceleration, at low speed or when vehicle is

heavily loaded is not harmful. Extended periods of

spark knock under moderate acceleration or at cruising

speed can damage the engine. The cause of excessive

spark knock condition must be diagnosed and corrected.

For diagnostic procedures refer to Group 14, Fuel Sys-

tem and Powertrain Diagnostic Procedures manual.

SELECTING GASOLINE

CAUTION:Do not use fuel containing METHANOL

(methyl or wood alcohol), damage to fuel system

will result. Do not use leaded gasoline, damage to catalytic

converter will result and vehicle will not conform to

emission control standards.

ETHANOL, MTBE OR ETBE BLENDS

All Chrysler Corporation vehicles are designed to

use unleaded gasoline ONLY. Gasohol blends, con-

taining 10% Ethanol (ethyl or grain alcohol) 90% un-

leaded gasoline can be used provided it has adequate

octane rating. Fuel blends containing up to 15% MTBE (Methyl

Tertiary Butyl Ether) and 85% unleaded gasoline can

be used. Fuel blends containing up to 17% ETBE

(Ethyl Tertiary Butyl Ether) and 83% unleaded gas-

oline can also be used. Fuel blended with ethanol, MTBE or ETBE are

also referred to as reformulated or clean air gasoline.

These fuels contribute less emissions to the atmo-

sphere. Chrysler Corporation recommends that

blended fuels be used when available

METHANOL BLENDS Using gasoline blended with methanol can result

in starting and driveability problems. Deterioration

of fuel system components will result. Methanol in-

duced problems are not the responsibility of Chrysler

Corporation and may not be covered by the vehicle

warranty. NON-TURBOCHARGED ENGINES

Use regular unleaded gasoline having a minimum

octane rating of 87 (R+M)/2. Higher octane premium

unleaded gasoline can be used if desired.

2.2L 16 VALVE TURBOCHARGED ENGINE

Use premium unleaded gasoline having a mini-

mum octane rating of 91 (R+M)/2. Gasoline with oc-

tane rating less than 91 (R+M)/2 can be used if

recommended gasoline is not available. Low octane

gasoline will reduce engine performance.

FLEXIBLE FUEL VEHICLES

CAUTION: Do not use 100% methanol, damage to

fuel system can result. Use unleaded regular gasoline having a minimum

octane rating of 87 (R=M)/2 and M85 fuel that is

85% methanol and 15% unleaded gasoline, or a mix-

ture of these two.

FUEL FILTER

The fuel filter requires service only when a fuel

contamination problem is suspected. For proper diag-

nostic and service procedures refer to Group 14, Fuel

System,

IGNITION CABLES, DISTRIBUTOR CAP, AND

ROTOR

Inspect and test ignition cables, distributor cap and

rotor when the spark plugs are replaced. Oil and

grime should be cleaned from the ignition cables and

distributor cap to avoid possible spark plug fouling.

Mopar, Foamy Engine Degreaser, or equivalent is

recommended for cleaning the engine compartment.

For proper service and diagnostic procedures refer to

Group 8D, Ignition System.

SPARK PLUGS

Ignition spark plugs should be replaced at the

mileage interval described in the Lubrication and

Maintenance Schedules. Refer to the General Infor-

mation section of this group. For proper service pro-

cedures refer to Group 8D, Ignition Systems.

DRIVE BELTS

Inspect and adjust drive belts at the interval de-

scribed in the Lubrication and Maintenance Sched-

ules. Refer to General Information section of this

group. For proper inspection and adjustment proce-

dures, see Group 7, Cooling System.

EMISSION CONTROL SYSTEM

Inspect all emission control components and hoses

when other under hood service is performed. Refer to

emission system Vacuum Hose Label located on the

0 - 14 LUBRICATION AND MAINTENANCE Ä

Page 355 of 2438

(5) Install drive belt. See Accessory Drive Belts

this group. (6) Install right front lower fender shield.

(7) Refill Cooling System. See Refilling Cooling

System in this section.

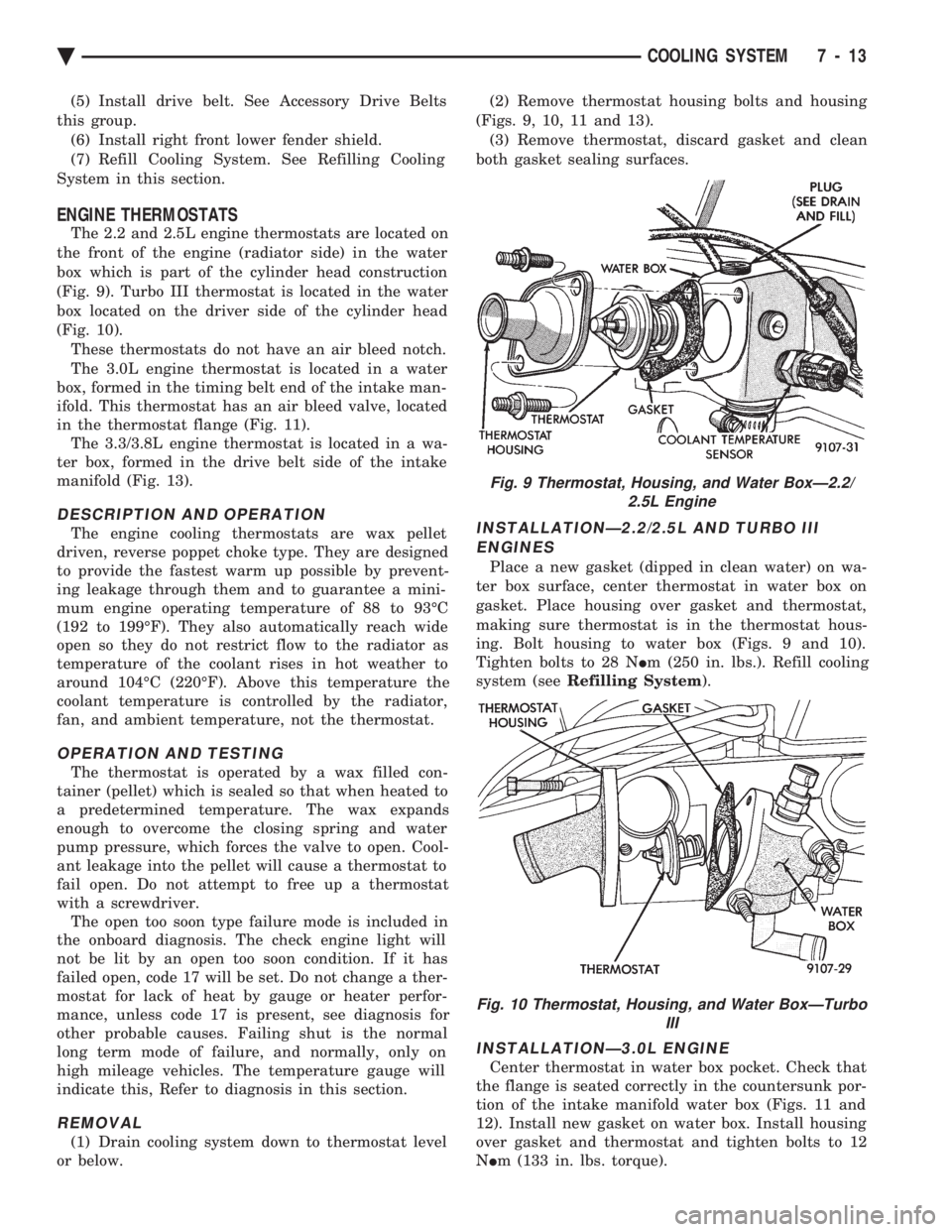

ENGINE THERMOSTATS

The 2.2 and 2.5L engine thermostats are located on

the front of the engine (radiator side) in the water

box which is part of the cylinder head construction

(Fig. 9). Turbo III thermostat is located in the water

box located on the driver side of the cylinder head

(Fig. 10). These thermostats do not have an air bleed notch.

The 3.0L engine thermostat is located in a water

box, formed in the timing belt end of the intake man-

ifold. This thermostat has an air bleed valve, located

in the thermostat flange (Fig. 11). The 3.3/3.8L engine thermostat is located in a wa-

ter box, formed in the drive belt side of the intake

manifold (Fig. 13).

DESCRIPTION AND OPERATION

The engine cooling thermostats are wax pellet

driven, reverse poppet choke type. They are designed

to provide the fastest warm up possible by prevent-

ing leakage through them and to guarantee a mini-

mum engine operating temperature of 88 to 93ÉC

(192 to 199ÉF). They also automatically reach wide

open so they do not restrict flow to the radiator as

temperature of the coolant rises in hot weather to

around 104ÉC (220ÉF). Above this temperature the

coolant temperature is controlled by the radiator,

fan, and ambient temperature, not the thermostat.

OPERATION AND TESTING

The thermostat is operated by a wax filled con-

tainer (pellet) which is sealed so that when heated to

a predetermined temperature. The wax expands

enough to overcome the closing spring and water

pump pressure, which forces the valve to open. Cool-

ant leakage into the pellet will cause a thermostat to

fail open. Do not attempt to free up a thermostat

with a screwdriver. The open too soon type failure mode is included in

the onboard diagnosis. The check engine light will

not be lit by an open too soon condition. If it has

failed open, code 17 will be set. Do not change a ther-

mostat for lack of heat by gauge or heater perfor-

mance, unless code 17 is present, see diagnosis for

other probable causes. Failing shut is the normal

long term mode of failure, and normally, only on

high mileage vehicles. The temperature gauge will

indicate this, Refer to diagnosis in this section.

REMOVAL

(1) Drain cooling system down to thermostat level

or below. (2) Remove thermostat housing bolts and housing

(Figs. 9, 10, 11 and 13). (3) Remove thermostat, discard gasket and clean

both gasket sealing surfaces.

INSTALLATIONÐ2.2/2.5L AND TURBO III ENGINES

Place a new gasket (dipped in clean water) on wa-

ter box surface, center thermostat in water box on

gasket. Place housing over gasket and thermostat,

making sure thermostat is in the thermostat hous-

ing. Bolt housing to water box (Figs. 9 and 10).

Tighten bolts to 28 N Im (250 in. lbs.). Refill cooling

system (see Refilling System ).

INSTALLATIONÐ3.0L ENGINE

Center thermostat in water box pocket. Check that

the flange is seated correctly in the countersunk por-

tion of the intake manifold water box (Figs. 11 and

12). Install new gasket on water box. Install housing

over gasket and thermostat and tighten bolts to 12

N Im (133 in. lbs. torque).

Fig. 9 Thermostat, Housing, and Water BoxÐ2.2/

2.5L Engine

Fig. 10 Thermostat, Housing, and Water BoxÐTurbo III

Ä COOLING SYSTEM 7 - 13

Page 357 of 2438

-37ÉC (-35ÉF) to -59ÉC (-50ÉF). If it looses color or

becomes contaminated, drain, flush, and replace with

fresh properly mixed solution.

SERVICE

Coolant should be changed at 52,500 miles or three

years, whichever occurs first, then every two years or

30,000 miles.

ROUTINE LEVEL CHECK

Do not remove radiator cap for routine coolant

level inspections. The coolant reserve system provides a quick visual

method for determining the coolant level without re-

moving the radiator cap. Simply observe, with the

engine idling and warmed up to normal operating

temperature, that the level of the coolant in the reserve

tank (Figs. 5 and 6) is between the minimum and

maximum marks.

ADDING ADDITIONAL COOLANT

The radiator cap should not be removed. When

additional coolant is needed to maintain this level, it

should be added to the coolant reserve tank. Use only

50/50 concentration of ethylene glycol type antifreeze

and water.

SERVICE COOLANT LEVEL

The cooling system is closed and designed to main-

tain coolant level to the top of the radiator. When servicing requires a coolant level check in the

radiator, the engine must be offand notunder pres-

sure. Drain several ounces of coolant from the radiator

drain cock while observing the Coolant Recovery Sys-

tem (CRS) Tank. Coolant level in the CRS tank should

drop slightly. Then remove the radiator cap. The radia-

tor should be full to the top. If not, and the coolant level

in the CRS tank is at the MIN mark there is a air leak

in the CRS system. Check hose or hose connections to

the CRS tank, radiator filler neck or the pressure cap

seal to the radiator filler neck for leaks.

LOW COOLANT LEVEL AERATION

Low coolant level in a cross flow radiator will equal-

ize in both tanks with engine off. With engine at

running operating temperature the high pressure inlet

tank runs full and the low pressure outlet tank drops.

If this level drops below the top of the transmission oil

cooler, air will be sucked into the water pump:

² Transmission oil will become hotter.

² High reading shown on the temperature gauge.

² Air in the coolant will also cause loss of flow through

the heater.

² Exhaust gas leaks into the coolant can also cause the

same problems.

DEAERATION

Air can only be removed from the system by gather-

ing under the pressure cap. On the next heat up it will

be pushed past the pressure cap into the CRS tank by

thermal expansion of the coolant. It then escapes to the

atmosphere in the CRS tank and is replaced with solid

coolant on cool down.

COOLING SYSTEM DRAIN, CLEAN, FLUSH AND

REFILL

Drain, flush, and fill the cooling system at the

mileage or time intervals specified in the Maintenance

Schedule in this Group. If the solution is dirty or rusty

or contains a considerable amount of sediment, clean

and flush with a reliable cooling system cleaner. Care

should be taken in disposing of the used engine coolant

from your vehicle. Check governmental regulations for

disposal of used engine coolant.

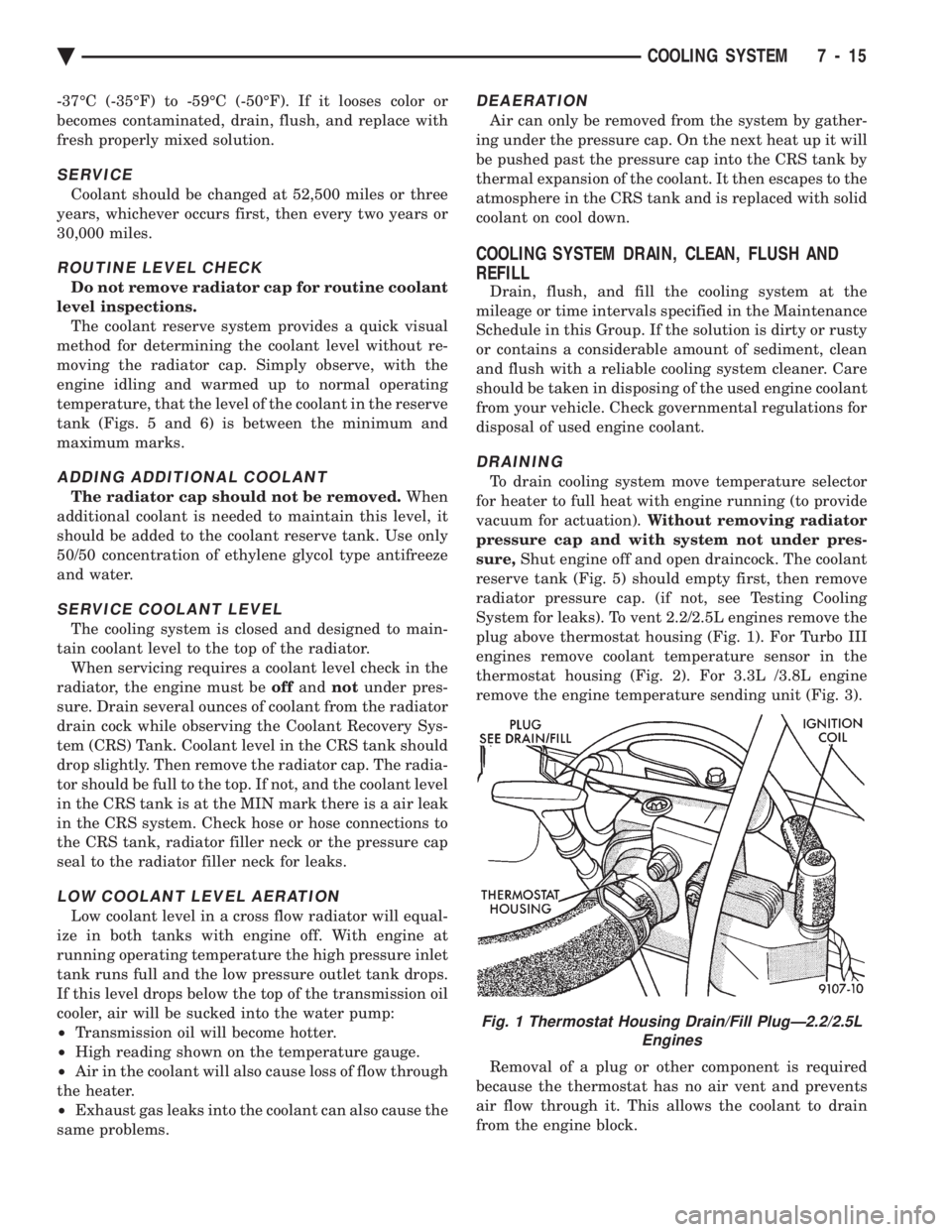

DRAINING

To drain cooling system move temperature selector

for heater to full heat with engine running (to provide

vacuum for actuation). Without removing radiator

pressure cap and with system not under pres-

sure, Shut engine off and open draincock. The coolant

reserve tank (Fig. 5) should empty first, then remove

radiator pressure cap. (if not, see Testing Cooling

System for leaks). To vent 2.2/2.5L engines remove the

plug above thermostat housing (Fig. 1). For Turbo III

engines remove coolant temperature sensor in the

thermostat housing (Fig. 2). For 3.3L /3.8L engine

remove the engine temperature sending unit (Fig. 3).

Removal of a plug or other component is required

because the thermostat has no air vent and prevents

air flow through it. This allows the coolant to drain

from the engine block.

Fig. 1 Thermostat Housing Drain/Fill PlugÐ2.2/2.5L Engines

Ä COOLING SYSTEM 7 - 15

Page 1992 of 2438

ing seat will give a false end play reading while

gauging for proper shims. Improperly seated bearing

cups and cones are subject to low mileage failure.(2) Bearing cups and cones should be replaced if they

show signs of pitting or heat distress. If distress is seen

on either the cup or bearing rollers, both cup and cone

must be replaced. (3) Bearing preload and drag torque specifications

must be maintained to avoid premature bearing

failures. Used (original) bearing may lose up to 50% of

the original drag torque after break in. All bearing

adjustments must be made with no other compo-

nent interference or gear intermesh. (4) Replace bearings as a pair. For example, if one

differential bearing is defective, replace both differen-

tial bearings. If one input shaft bearing is defective,

replace both input shaft bearings. (5) Bearing cones must notbe reused if removed.

(6) Turning torque readings should be obtained

while smoothly rotating in either direction (break-

away reading is not indicative of the true turning

torque). (7) Replace oil baffle, if damaged.

INPUT SHAFT BEARING END PLAY ADJUST-MENT

(1) Using Tool C-4656 with Handle C-4171, press

input shaft front bearing cup slightly forward in case.

Then, using Tool C-4655 with Handle C-4171, press

bearing cup back into case from the front. Properly

position bearing cup, before checking input shaft end

play (see input shaft front bearing cup replace in

Subassembly Recondition section).This step is

not necessary if Tool C-4655 was previously used

to install input shaft front bearing cup in the

case. Also no input shaft shim has been installed

since pressing cup into case. (2) Select a gauging shim which will give 0.025 to

0.254mm (.001 to .010 inch) end play. SUGGESTION:

Measure original shim from input shaft seal retainer and select a shim 0.254mm (.010

inch) thinner than original for the gauging shim.

(3) Install gauging shim on bearing cup and install

input shaft seal retainer.

CAUTION: The input shaft seal retainer is used to

draw the input shaft front bearing cup the proper

distance into the case bore during this step. Alter-

nately tighten input shaft seal retainer bolts until

input shaft seal retainer is bottomed against case.

Tighten bolts to 28 N Im (21 ft. lbs.).

(4) Oil input shaft bearings with SAE 5W-30 engine

oil and install input shaft in case. Install bearing

retainer plate with input shaft rear bearing cup

pressed in and bearing support plate installed. Tighten

all bolts and nuts to 28 N Im (21 ft. lbs.).

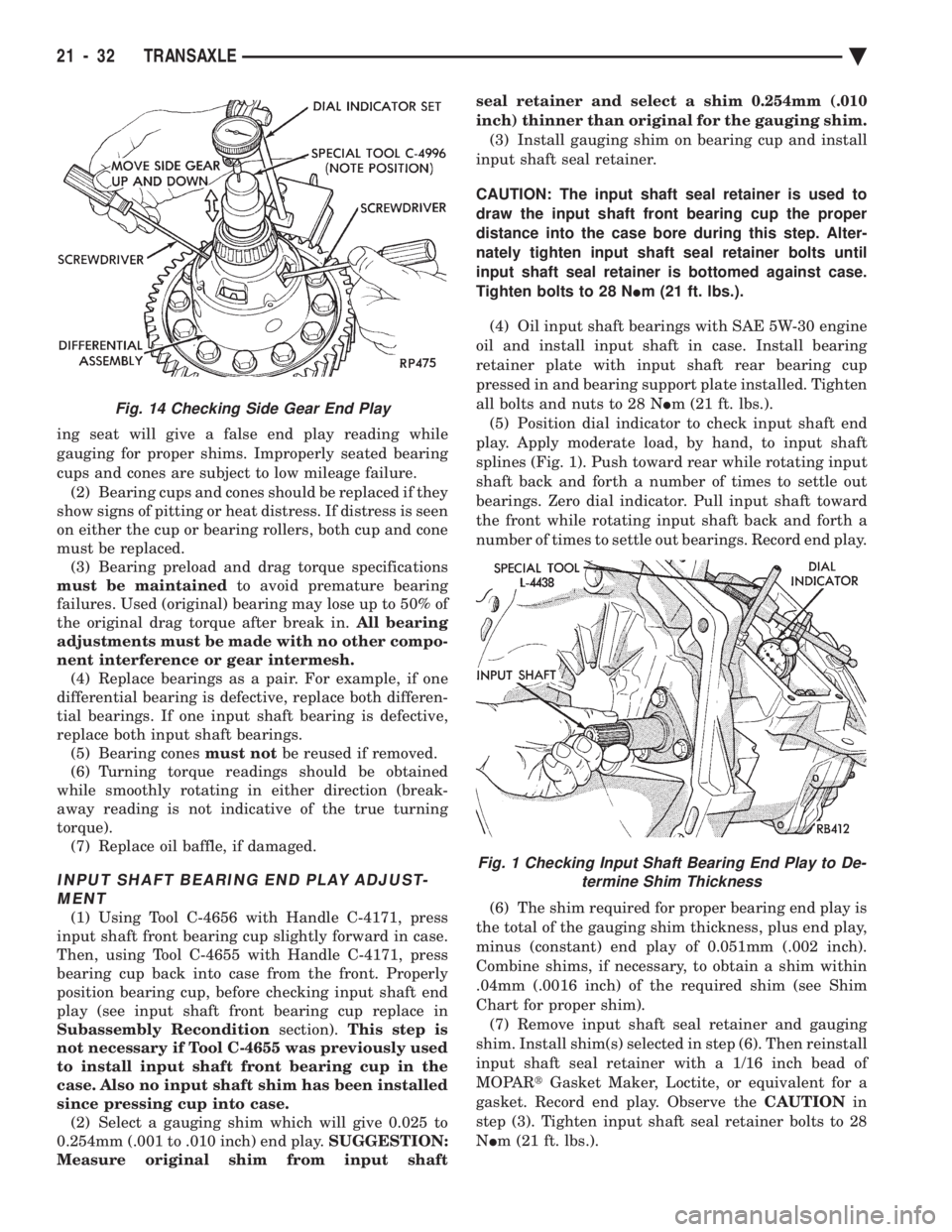

(5) Position dial indicator to check input shaft end

play. Apply moderate load, by hand, to input shaft

splines (Fig. 1). Push toward rear while rotating input

shaft back and forth a number of times to settle out

bearings. Zero dial indicator. Pull input shaft toward

the front while rotating input shaft back and forth a

number of times to settle out bearings. Record end play.

(6) The shim required for proper bearing end play is

the total of the gauging shim thickness, plus end play,

minus (constant) end play of 0.051mm (.002 inch).

Combine shims, if necessary, to obtain a shim within

.04mm (.0016 inch) of the required shim (see Shim

Chart for proper shim). (7) Remove input shaft seal retainer and gauging

shim. Install shim(s) selected in step (6). Then reinstall

input shaft seal retainer with a 1/16 inch bead of

MOPAR tGasket Maker, Loctite, or equivalent for a

gasket. Record end play. Observe the CAUTIONin

step (3). Tighten input shaft seal retainer bolts to 28

N Im (21 ft. lbs.).

Fig. 14 Checking Side Gear End Play

Fig. 1 Checking Input Shaft Bearing End Play to De-

termine Shim Thickness

21 - 32 TRANSAXLE Ä

Page 2149 of 2438

WHEELSÐTIRES

CONTENTS

page page

SPECIFICATIONS ........................ 8

TIRE SERVICE PROCEDURES .............. 1 WHEELS SERVICE PROCEDURES

........... 6

TIRE SERVICE PROCEDURES INDEX

page page

Cleaning of Tires .......................... 1

General Information ........................ 1

Pressure Gauges ......................... 2

Radial-Ply Tires ........................... 1

Repairing Leaks .......................... 3

Rotation ................................ 3 Spare TireÐCompact

...................... 1

Tire Inflation Pressures ..................... 2

Tire Noise or Vibration ..................... 3

Tire Wear Patterns ........................ 3

Tread Wear Indicators ...................... 3

GENERAL INFORMATION

Throughout this group, references may be made to a

particular vehicle by letter or number designation. A

chart showing the breakdown of these designations is

included in the Introduction Section. Tires are designed for the vehicle and provide the

best overall performance for normal operation. The

ride and handling characteristics match the vehicle's

requirements. With proper care they will give excellent

reliability traction, skid resistance and tread life. They

have load carrying capacity, when properly inflated, to

operate at loads up to the specified Maximum Vehicle

Capacity. Driving habits have more effect on tire life than any

other factor. Careful drivers will obtain, in most cases,

much greater mileage than severe or careless drivers. A

few of the driving habits which will shorten the life of

any tire are:

² Rapid acceleration and deceleration

² Severe application of brakes

² High-speed driving

² Taking turns at excessive speeds

² Striking curbs and other obstacles

Radial ply tires can be more susceptible to irregular

tread wear. It is very important to follow the tire

rotation interval shown in the section on Tire

Rotation to achieve a greater tread life potential.

RADIAL-PLY TIRES

Radial-ply tires improve handling, tread life, and

ride quality and decrease rolling resistance. Radial-ply tires must always be used in sets of four

and under no circumstances should they be used on

the front only. However, they may be mixed with temporary spare tires when necessary,

but reduced speeds are recommended. Radial-ply tires have the same load carrying capac-

ity as other types of tires of the same size. They also

use the same recommended inflation pressures.

SPARE TIREÐCOMPACT

The compact spare tire is designed for emergency

use only. The original tire should be repaired and re-

installed at the first opportunity. Refer to Owner's

Manual for complete details.

TIRE CHAINS

Tire snow chains may be used on certainmodels.

Refer to Owner's Manual for more information.

CLEANING OF TIRES

Remove protective coating on tires before delivery

of vehicle, otherwise it could cause deterioration of

tires. Remove protective coating by applying warm wa-

ter, letting it soak one minute, and then scrubbing

the coating away with a soft bristle brush. Steam cleaning may also be used for cleaning.

DO NOT use gasoline or wire brush for cleaning.

DO NOT use mineral oil or an oil-based solvent.

Ä WHEELSÐTIRES 22 - 1