air conditioning CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 368 of 2438

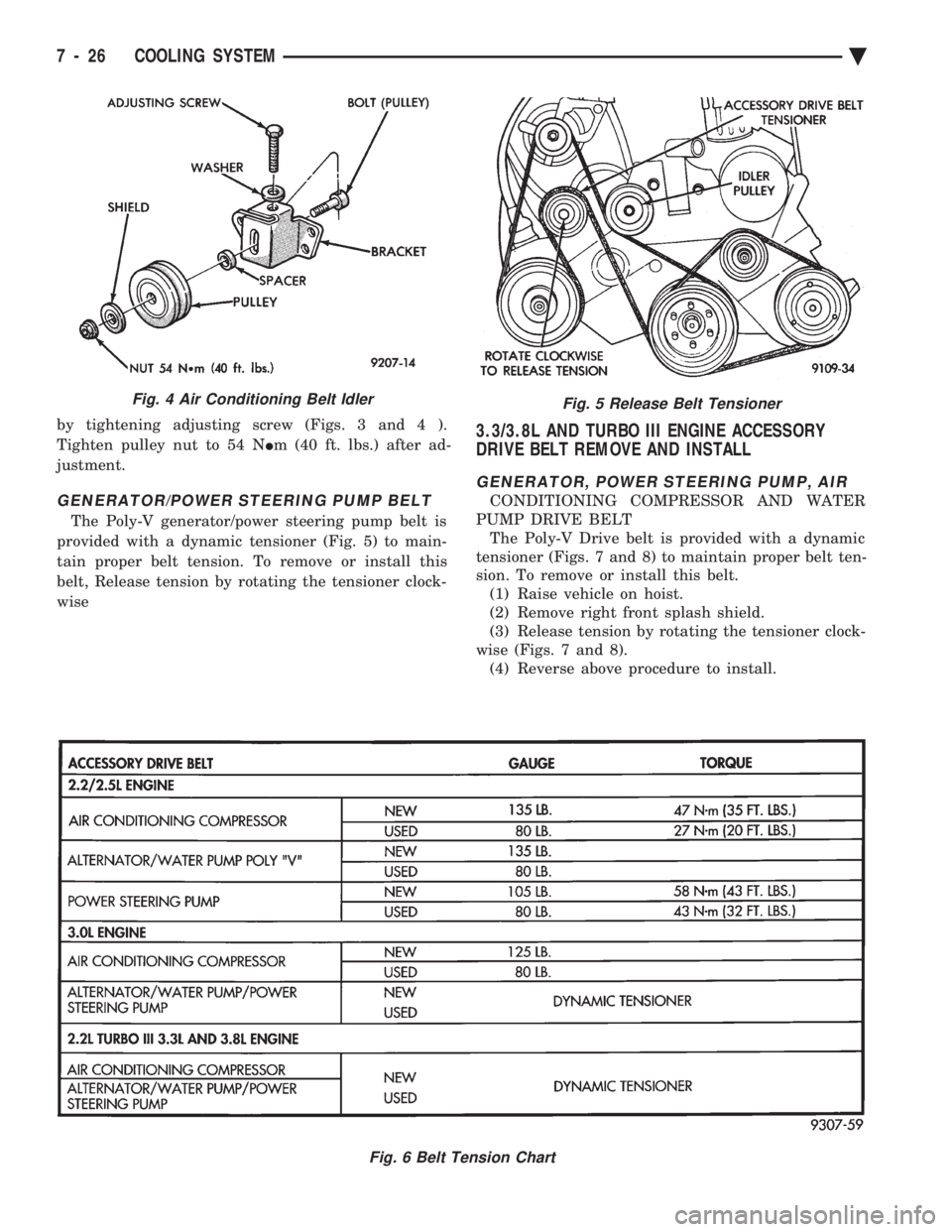

by tightening adjusting screw (Figs. 3 and 4 ).

Tighten pulley nut to 54 N Im (40 ft. lbs.) after ad-

justment.

GENERATOR/POWER STEERING PUMP BELT

The Poly-V generator/power steering pump belt is

provided with a dynamic tensioner (Fig. 5) to main-

tain proper belt tension. To remove or install this

belt, Release tension by rotating the tensioner clock-

wise

3.3/3.8L AND TURBO III ENGINE ACCESSORY

DRIVE BELT REMOVE AND INSTALL

GENERATOR, POWER STEERING PUMP, AIR

CONDITIONING COMPRESSOR AND WATER

PUMP DRIVE BELT The Poly-V Drive belt is provided with a dynamic

tensioner (Figs. 7 and 8) to maintain proper belt ten-

sion. To remove or install this belt. (1) Raise vehicle on hoist.

(2) Remove right front splash shield.

(3) Release tension by rotating the tensioner clock-

wise (Figs. 7 and 8). (4) Reverse above procedure to install.

Fig. 5 Release Belt Tensioner

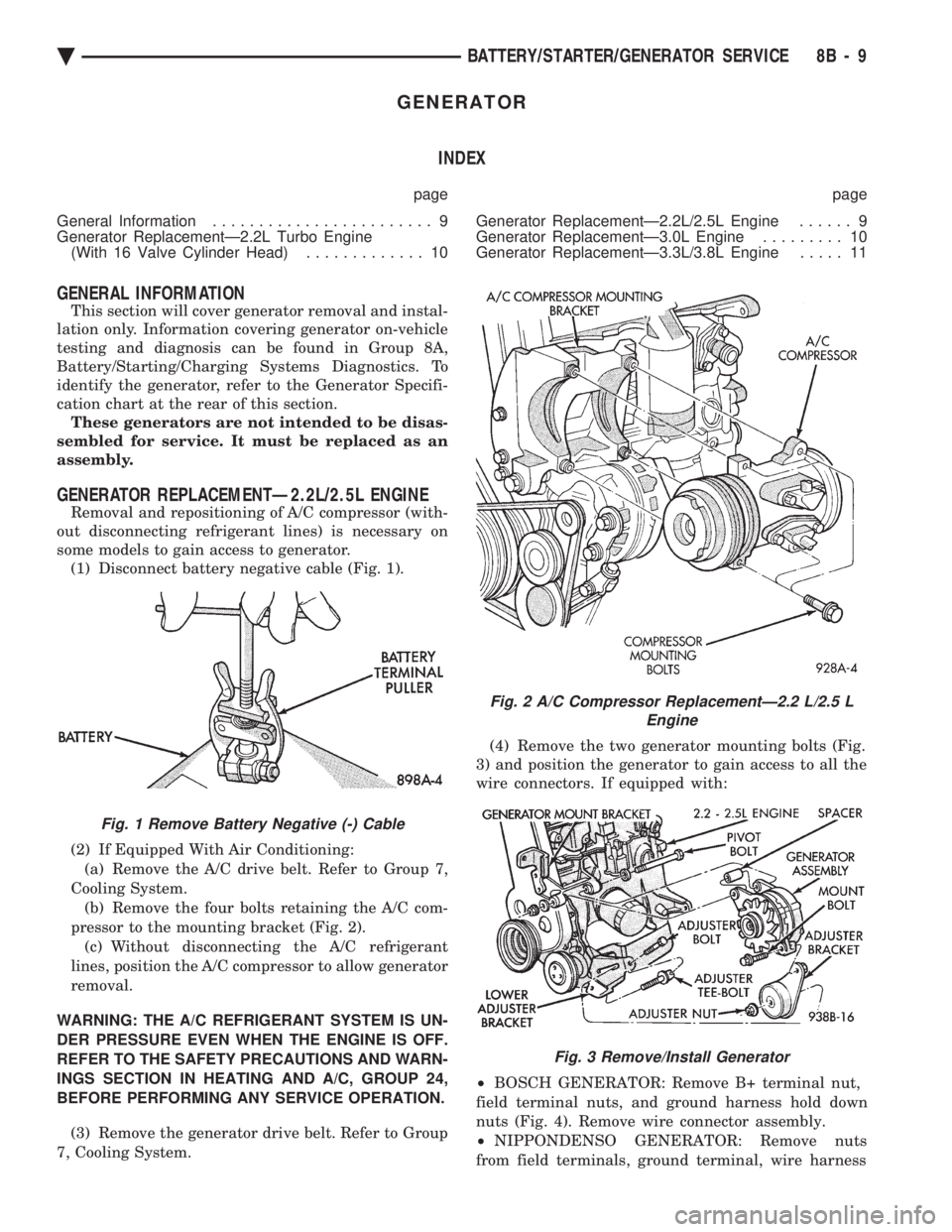

Fig. 6 Belt Tension Chart

Fig. 4 Air Conditioning Belt Idler

7 - 26 COOLING SYSTEM Ä

Page 411 of 2438

GENERATOR INDEX

page page

General Information ........................ 9

Generator ReplacementÐ2.2L Turbo Engine (With 16 Valve Cylinder Head) ............. 10 Generator ReplacementÐ2.2L/2.5L Engine

...... 9

Generator ReplacementÐ3.0L Engine ......... 10

Generator ReplacementÐ3.3L/3.8L Engine ..... 11

GENERAL INFORMATION

This section will cover generator removal and instal-

lation only. Information covering generator on-vehicle

testing and diagnosis can be found in Group 8A,

Battery/Starting/Charging Systems Diagnostics. To

identify the generator, refer to the Generator Specifi-

cation chart at the rear of this section. These generators are not intended to be disas-

sembled for service. It must be replaced as an

assembly.

GENERATOR REPLACEMENTÐ2.2L/2.5L ENGINE

Removal and repositioning of A/C compressor (with-

out disconnecting refrigerant lines) is necessary on

some models to gain access to generator. (1) Disconnect battery negative cable (Fig. 1).

(2) If Equipped With Air Conditioning:

(a) Remove the A/C drive belt. Refer to Group 7,

Cooling System. (b) Remove the four bolts retaining the A/C com-

pressor to the mounting bracket (Fig. 2). (c) Without disconnecting the A/C refrigerant

lines, position the A/C compressor to allow generator

removal.

WARNING: THE A/C REFRIGERANT SYSTEM IS UN-

DER PRESSURE EVEN WHEN THE ENGINE IS OFF.

REFER TO THE SAFETY PRECAUTIONS AND WARN-

INGS SECTION IN HEATING AND A/C, GROUP 24,

BEFORE PERFORMING ANY SERVICE OPERATION. (3) Remove the generator drive belt. Refer to Group

7, Cooling System. (4) Remove the two generator mounting bolts (Fig.

3) and position the generator to gain access to all the

wire connectors. If equipped with:

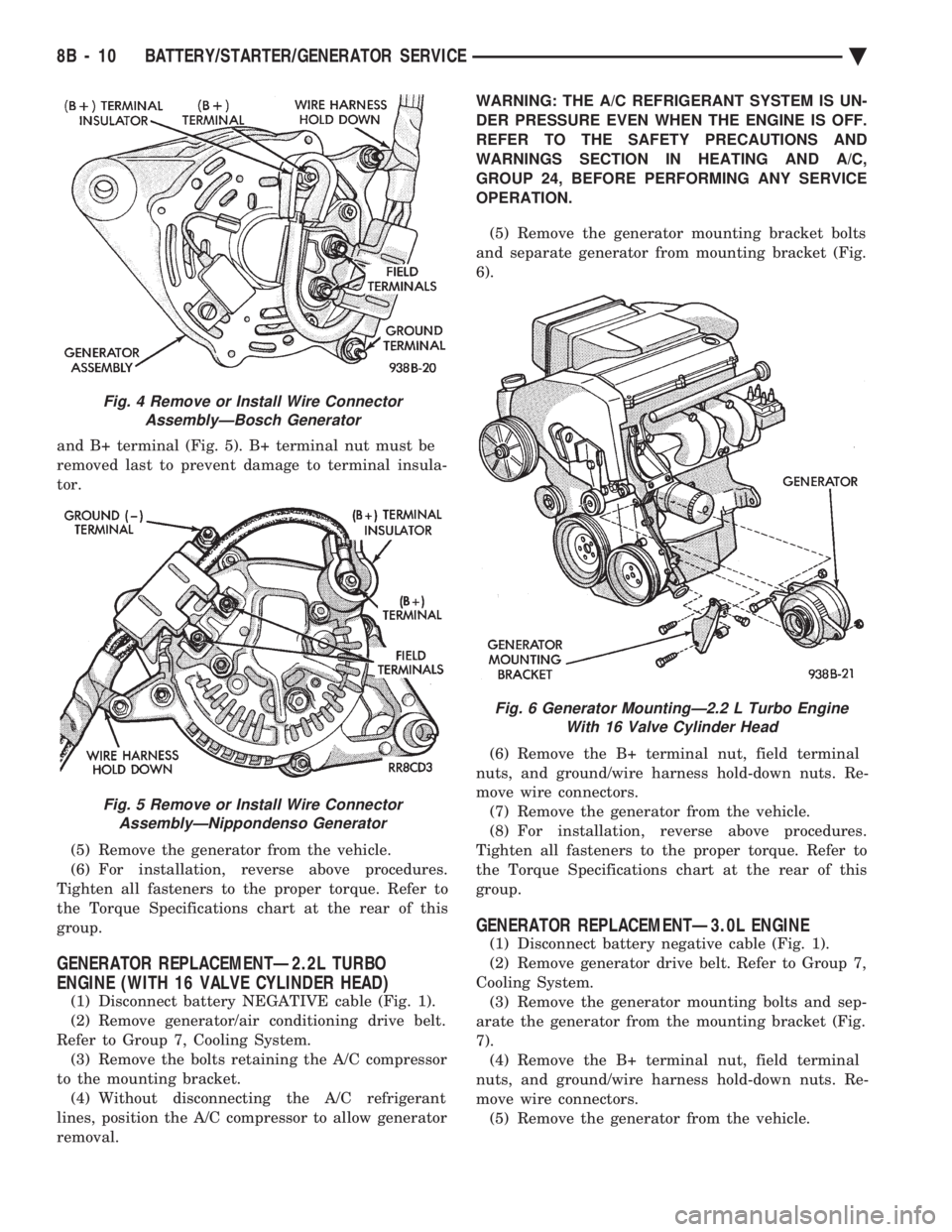

² BOSCH GENERATOR: Remove B+ terminal nut,

field terminal nuts, and ground harness hold down

nuts (Fig. 4). Remove wire connector assembly.

² NIPPONDENSO GENERATOR: Remove nuts

from field terminals, ground terminal, wire harness

Fig. 1 Remove Battery Negative (-) Cable

Fig. 2 A/C Compressor ReplacementÐ2.2 L/2.5 L Engine

Fig. 3 Remove/Install Generator

Ä BATTERY/STARTER/GENERATOR SERVICE 8B - 9

Page 412 of 2438

and B+ terminal (Fig. 5). B+ terminal nut must be

removed last to prevent damage to terminal insula-

tor. (5) Remove the generator from the vehicle.

(6) For installation, reverse above procedures.

Tighten all fasteners to the proper torque. Refer to

the Torque Specifications chart at the rear of this

group.

GENERATOR REPLACEMENTÐ2.2L TURBO

ENGINE (WITH 16 VALVE CYLINDER HEAD)

(1) Disconnect battery NEGATIVE cable (Fig. 1).

(2) Remove generator/air conditioning drive belt.

Refer to Group 7, Cooling System. (3) Remove the bolts retaining the A/C compressor

to the mounting bracket. (4) Without disconnecting the A/C refrigerant

lines, position the A/C compressor to allow generator

removal. WARNING: THE A/C REFRIGERANT SYSTEM IS UN-

DER PRESSURE EVEN WHEN THE ENGINE IS OFF.

REFER TO THE SAFETY PRECAUTIONS AND

WARNINGS SECTION IN HEATING AND A/C,

GROUP 24, BEFORE PERFORMING ANY SERVICE

OPERATION.

(5) Remove the generator mounting bracket bolts

and separate generator from mounting bracket (Fig.

6).

(6) Remove the B+ terminal nut, field terminal

nuts, and ground/wire harness hold-down nuts. Re-

move wire connectors. (7) Remove the generator from the vehicle.

(8) For installation, reverse above procedures.

Tighten all fasteners to the proper torque. Refer to

the Torque Specifications chart at the rear of this

group.

GENERATOR REPLACEMENTÐ3.0L ENGINE

(1) Disconnect battery negative cable (Fig. 1).

(2) Remove generator drive belt. Refer to Group 7,

Cooling System. (3) Remove the generator mounting bolts and sep-

arate the generator from the mounting bracket (Fig.

7). (4) Remove the B+ terminal nut, field terminal

nuts, and ground/wire harness hold-down nuts. Re-

move wire connectors. (5) Remove the generator from the vehicle.

Fig. 4 Remove or Install Wire Connector AssemblyÐBosch Generator

Fig. 5 Remove or Install Wire ConnectorAssemblyÐNippondenso Generator

Fig. 6 Generator MountingÐ2.2 L Turbo Engine With 16 Valve Cylinder Head

8B - 10 BATTERY/STARTER/GENERATOR SERVICE Ä

Page 513 of 2438

(3) Remove four screws from ash receiver/cup

holder housing. (4) For installation reverse above procedures.

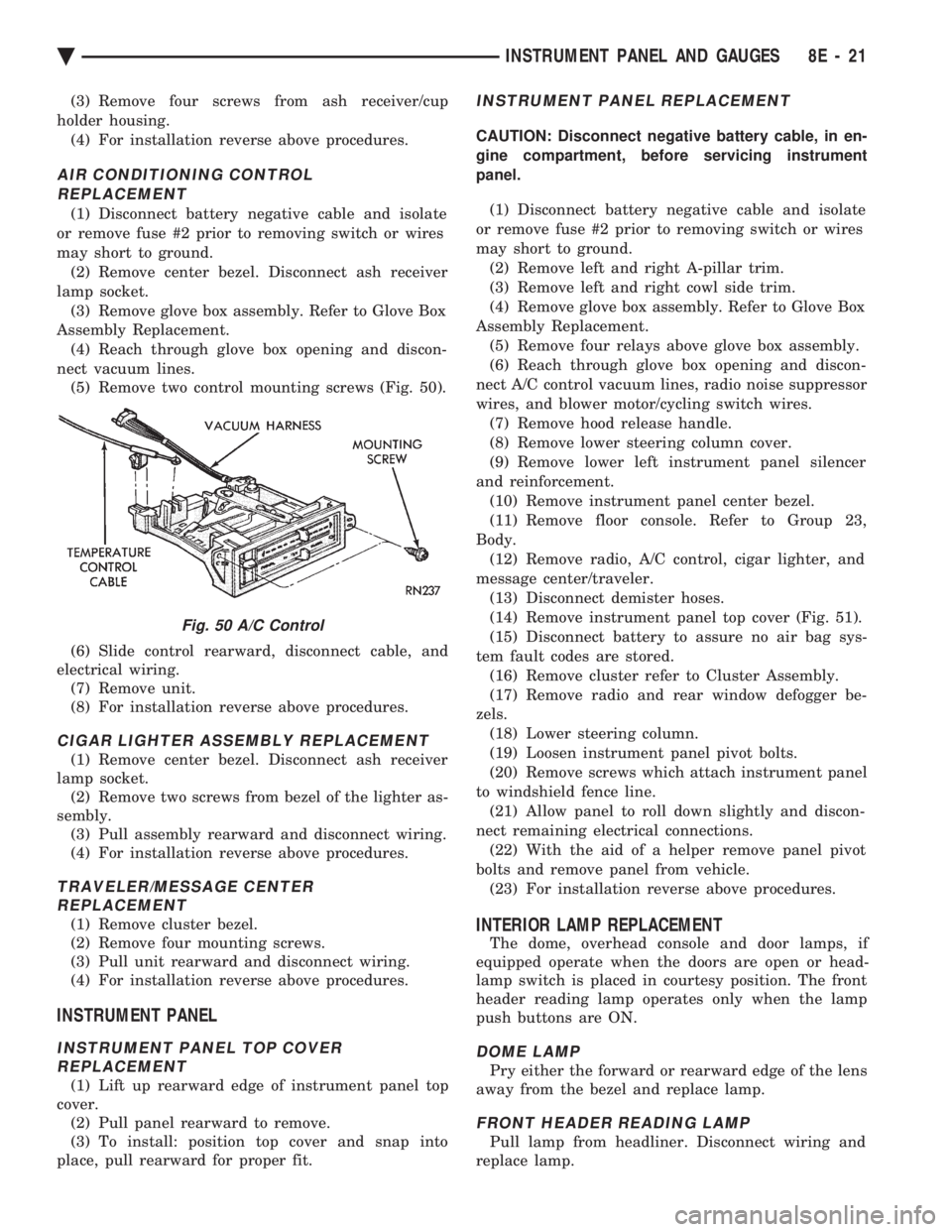

AIR CONDITIONING CONTROLREPLACEMENT

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground. (2) Remove center bezel. Disconnect ash receiver

lamp socket. (3) Remove glove box assembly. Refer to Glove Box

Assembly Replacement. (4) Reach through glove box opening and discon-

nect vacuum lines. (5) Remove two control mounting screws (Fig. 50).

(6) Slide control rearward, disconnect cable, and

electrical wiring. (7) Remove unit.

(8) For installation reverse above procedures.

CIGAR LIGHTER ASSEMBLY REPLACEMENT

(1) Remove center bezel. Disconnect ash receiver

lamp socket. (2) Remove two screws from bezel of the lighter as-

sembly. (3) Pull assembly rearward and disconnect wiring.

(4) For installation reverse above procedures.

TRAVELER/MESSAGE CENTER REPLACEMENT

(1) Remove cluster bezel.

(2) Remove four mounting screws.

(3) Pull unit rearward and disconnect wiring.

(4) For installation reverse above procedures.

INSTRUMENT PANEL

INSTRUMENT PANEL TOP COVER REPLACEMENT

(1) Lift up rearward edge of instrument panel top

cover. (2) Pull panel rearward to remove.

(3) To install: position top cover and snap into

place, pull rearward for proper fit.

INSTRUMENT PANEL REPLACEMENT

CAUTION: Disconnect negative battery cable, in en-

gine compartment, before servicing instrument

panel.

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground. (2) Remove left and right A-pillar trim.

(3) Remove left and right cowl side trim.

(4) Remove glove box assembly. Refer to Glove Box

Assembly Replacement. (5) Remove four relays above glove box assembly.

(6) Reach through glove box opening and discon-

nect A/C control vacuum lines, radio noise suppressor

wires, and blower motor/cycling switch wires. (7) Remove hood release handle.

(8) Remove lower steering column cover.

(9) Remove lower left instrument panel silencer

and reinforcement. (10) Remove instrument panel center bezel.

(11) Remove floor console. Refer to Group 23,

Body. (12) Remove radio, A/C control, cigar lighter, and

message center/traveler. (13) Disconnect demister hoses.

(14) Remove instrument panel top cover (Fig. 51).

(15) Disconnect battery to assure no air bag sys-

tem fault codes are stored. (16) Remove cluster refer to Cluster Assembly.

(17) Remove radio and rear window defogger be-

zels. (18) Lower steering column.

(19) Loosen instrument panel pivot bolts.

(20) Remove screws which attach instrument panel

to windshield fence line. (21) Allow panel to roll down slightly and discon-

nect remaining electrical connections. (22) With the aid of a helper remove panel pivot

bolts and remove panel from vehicle. (23) For installation reverse above procedures.

INTERIOR LAMP REPLACEMENT

The dome, overhead console and door lamps, if

equipped operate when the doors are open or head-

lamp switch is placed in courtesy position. The front

header reading lamp operates only when the lamp

push buttons are ON.

DOME LAMP

Pry either the forward or rearward edge of the lens

away from the bezel and replace lamp.

FRONT HEADER READING LAMP

Pull lamp from headliner. Disconnect wiring and

replace lamp.

Fig. 50 A/C Control

Ä INSTRUMENT PANEL AND GAUGES 8E - 21

Page 529 of 2438

CONDITION: US/METRIC MODES WILL NOT TOGGLE OR TRIP ODOMETER WILL NOTRESET

PROCEDURE

(1) Perform cluster self-diagnostics to determine if

push buttons are operational. (2) Refer to the Body Chassis Diagnostic Manual

to diagnose CCD Bus. The US/Metric toggle and trip

odometer reset are activated over the CCD Bus.

ODOMETER ADJUSTMENT

The odometer memory is no longer retained in the

cluster. This information is stored in the body con-

troller. Therefore, there is no adjustment procedure.

If the cluster is replaced odometer value will not

change. If the body controller is replaced the mileage

may be transferred using the DRB II. Refer to the

Body Chassis Diagnostic Manual for the procedure.

SWITCH AND PANEL COMPONENT SERVICE

MESSAGE CENTER REPLACEMENT

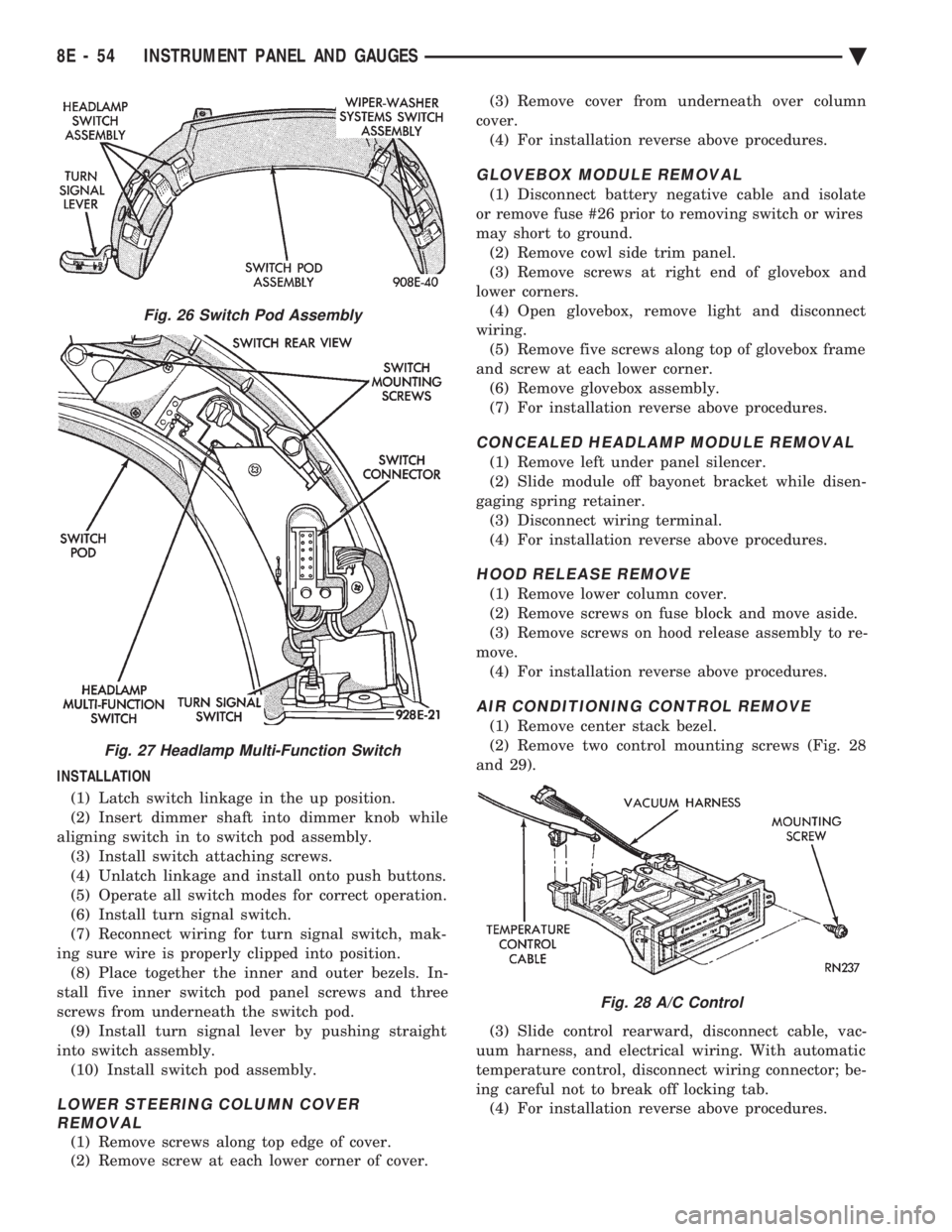

(1) Remove upper cluster bezel (Fig. 32).

(2) Remove two attaching screws (Fig. 33).

(3) Disconnect wiring connector and remove mes-

sage center. (4) For installation reverse above procedures.AIR CONDITIONING CONTROLREPLACEMENT

(1) Remove upper cluster bezel (Fig. 32).

(2) Remove two control mounting screws.

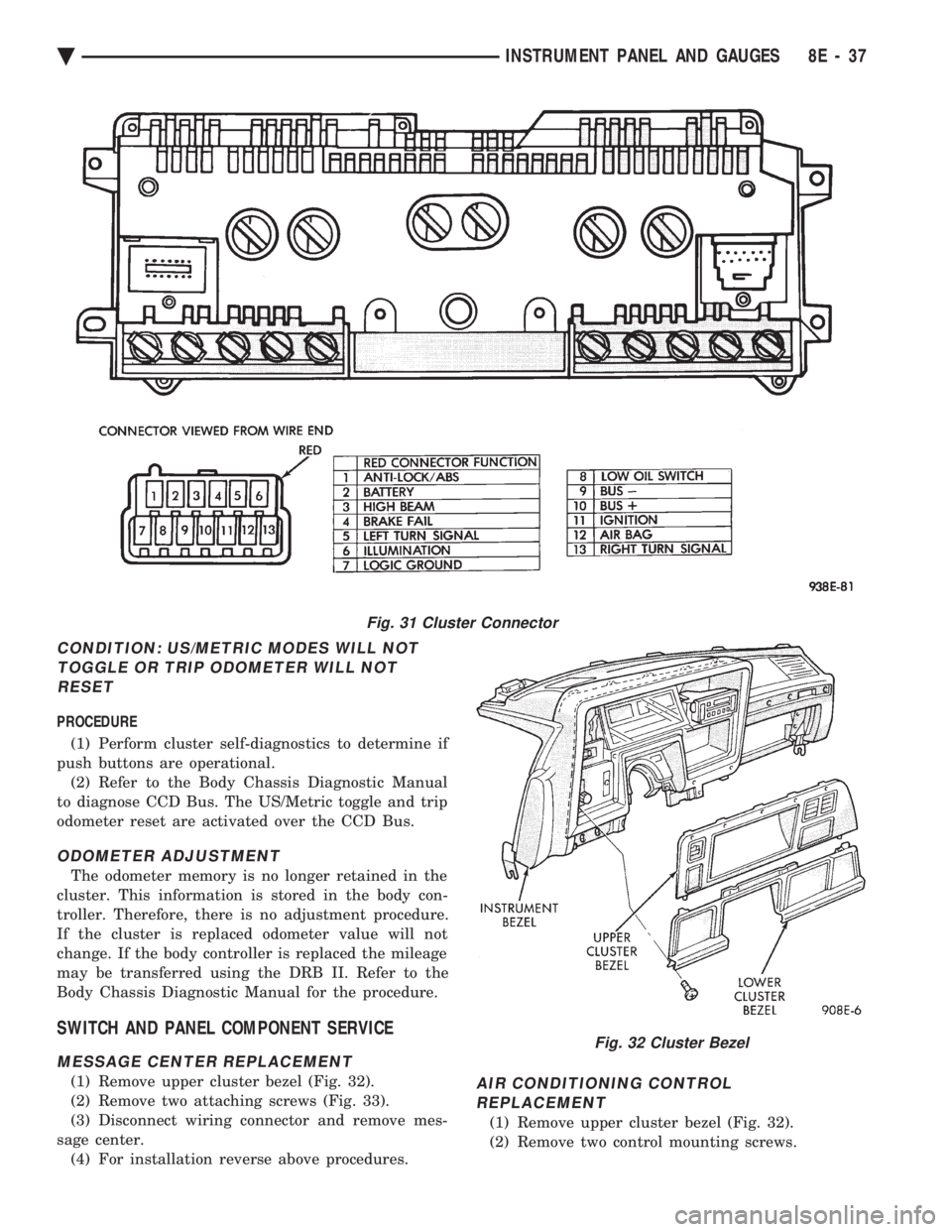

Fig. 31 Cluster Connector

Fig. 32 Cluster Bezel

Ä INSTRUMENT PANEL AND GAUGES 8E - 37

Page 546 of 2438

INSTALLATION (1) Latch switch linkage in the up position.

(2) Insert dimmer shaft into dimmer knob while

aligning switch in to switch pod assembly. (3) Install switch attaching screws.

(4) Unlatch linkage and install onto push buttons.

(5) Operate all switch modes for correct operation.

(6) Install turn signal switch.

(7) Reconnect wiring for turn signal switch, mak-

ing sure wire is properly clipped into position. (8) Place together the inner and outer bezels. In-

stall five inner switch pod panel screws and three

screws from underneath the switch pod. (9) Install turn signal lever by pushing straight

into switch assembly. (10) Install switch pod assembly.

LOWER STEERING COLUMN COVER REMOVAL

(1) Remove screws along top edge of cover.

(2) Remove screw at each lower corner of cover. (3) Remove cover from underneath over column

cover. (4) For installation reverse above procedures.

GLOVEBOX MODULE REMOVAL

(1) Disconnect battery negative cable and isolate

or remove fuse #26 prior to removing switch or wires

may short to ground. (2) Remove cowl side trim panel.

(3) Remove screws at right end of glovebox and

lower corners. (4) Open glovebox, remove light and disconnect

wiring. (5) Remove five screws along top of glovebox frame

and screw at each lower corner. (6) Remove glovebox assembly.

(7) For installation reverse above procedures.

CONCEALED HEADLAMP MODULE REMOVAL

(1) Remove left under panel silencer.

(2) Slide module off bayonet bracket while disen-

gaging spring retainer. (3) Disconnect wiring terminal.

(4) For installation reverse above procedures.

HOOD RELEASE REMOVE

(1) Remove lower column cover.

(2) Remove screws on fuse block and move aside.

(3) Remove screws on hood release assembly to re-

move. (4) For installation reverse above procedures.

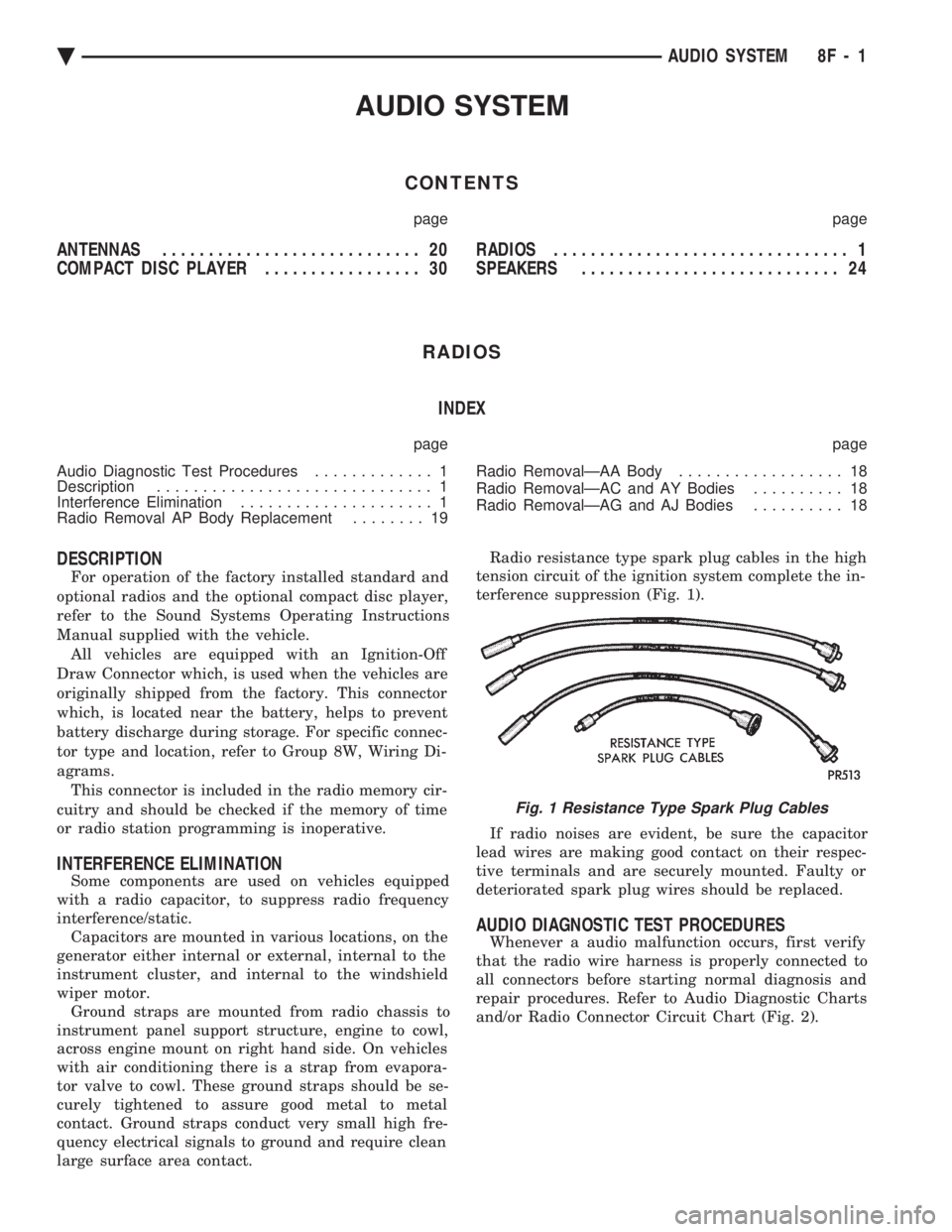

AIR CONDITIONING CONTROL REMOVE

(1) Remove center stack bezel.

(2) Remove two control mounting screws (Fig. 28

and 29).

(3) Slide control rearward, disconnect cable, vac-

uum harness, and electrical wiring. With automatic

temperature control, disconnect wiring connector; be-

ing careful not to break off locking tab. (4) For installation reverse above procedures.

Fig. 26 Switch Pod Assembly

Fig. 27 Headlamp Multi-Function Switch

Fig. 28 A/C Control

8E - 54 INSTRUMENT PANEL AND GAUGES Ä

Page 567 of 2438

AUDIO SYSTEM

CONTENTS

page page

ANTENNAS ............................ 20

COMPACT DISC PLAYER ................. 30 RADIOS

................................ 1

SPEAKERS ............................ 24

RADIOS INDEX

page page

Audio Diagnostic Test Procedures ............. 1

Description .............................. 1

Interference Elimination ..................... 1

Radio Removal AP Body Replacement ........ 19 Radio RemovalÐAA Body

.................. 18

Radio RemovalÐAC and AY Bodies .......... 18

Radio RemovalÐAG and AJ Bodies .......... 18

DESCRIPTION

For operation of the factory installed standard and

optional radios and the optional compact disc player,

refer to the Sound Systems Operating Instructions

Manual supplied with the vehicle. All vehicles are equipped with an Ignition-Off

Draw Connector which, is used when the vehicles are

originally shipped from the factory. This connector

which, is located near the battery, helps to prevent

battery discharge during storage. For specific connec-

tor type and location, refer to Group 8W, Wiring Di-

agrams. This connector is included in the radio memory cir-

cuitry and should be checked if the memory of time

or radio station programming is inoperative.

INTERFERENCE ELIMINATION

Some components are used on vehicles equipped

with a radio capacitor, to suppress radio frequency

interference/static. Capacitors are mounted in various locations, on the

generator either internal or external, internal to the

instrument cluster, and internal to the windshield

wiper motor. Ground straps are mounted from radio chassis to

instrument panel support structure, engine to cowl,

across engine mount on right hand side. On vehicles

with air conditioning there is a strap from evapora-

tor valve to cowl. These ground straps should be se-

curely tightened to assure good metal to metal

contact. Ground straps conduct very small high fre-

quency electrical signals to ground and require clean

large surface area contact. Radio resistance type spark plug cables in the high

tension circuit of the ignition system complete the in-

terference suppression (Fig. 1).

If radio noises are evident, be sure the capacitor

lead wires are making good contact on their respec-

tive terminals and are securely mounted. Faulty or

deteriorated spark plug wires should be replaced.

AUDIO DIAGNOSTIC TEST PROCEDURES

Whenever a audio malfunction occurs, first verify

that the radio wire harness is properly connected to

all connectors before starting normal diagnosis and

repair procedures. Refer to Audio Diagnostic Charts

and/or Radio Connector Circuit Chart (Fig. 2).

Fig. 1 Resistance Type Spark Plug Cables

Ä AUDIO SYSTEM 8F - 1

Page 931 of 2438

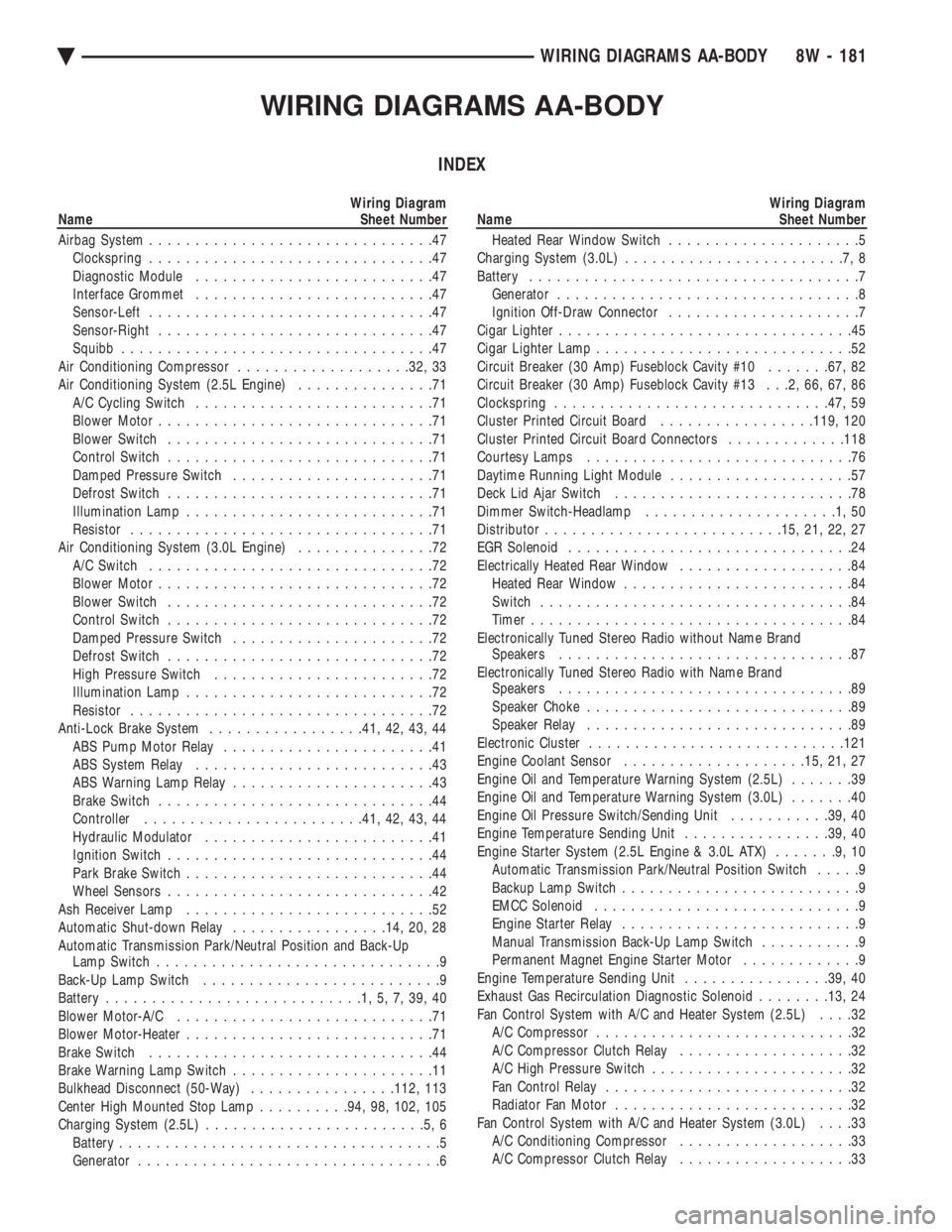

WIRING DIAGRAMS AA-BODY

INDEX

Wiring Diagram

Name Sheet Number

Airbag System ...............................47

Clockspring ...............................47

Diagnostic Module ..........................47

Interface Grommet ..........................47

Sensor-Left ...............................47

Sensor-Right ..............................47

Squibb ..................................47

Air Conditioning Compressor ...................32, 33

Air Conditioning System (2.5L Engine) ...............71

A/C Cycling Switch ..........................71

Blower Motor ..............................71

Blower Switch .............................71

Control Switch .............................71

Damped Pressure Switch ......................71

Defrost Switch .............................71

Illumination Lamp ...........................71

Resistor .................................71

Air Conditioning System (3.0L Engine) ...............72

A/C Switch ...............................72

Blower Motor ..............................72

Blower Switch .............................72

Control Switch .............................72

Damped Pressure Switch ......................72

Defrost Switch .............................72

High Pressure Switch ........................72

Illumination Lamp ...........................72

Resistor .................................72

Anti-Lock Brake System .................41, 42, 43, 44

ABS Pump Motor Relay .......................41

ABS System Relay ..........................43

ABS Warning Lamp Relay ......................43

Brake Switch ..............................44

Controller ....................... .41, 42, 43, 44

Hydraulic Modulator .........................41

Ignition Switch .............................44

Park Brake Switch ...........................44

Wheel Sensors .............................42

Ash Receiver Lamp ...........................52

Automatic Shut-down Relay .................14, 20, 28

Automatic Transmission Park/Neutral Position and Back-Up Lamp Switch ...............................9

Back-Up Lamp Switch ..........................9

Battery ............................1,5,7,39,40

Blower Motor-A/C ............................71

Blower Motor-Heater ...........................71

Brake Switch ...............................44

Brake Warning Lamp Switch ......................11

Bulkhead Disconnect (50-Way) ................112, 113

Center High Mounted Stop Lamp ..........94, 98, 102, 105

Charging System (2.5L) ........................5,6

Battery ...................................5

Generator .................................6Wiring Diagram

Name Sheet Number

Heated Rear Window Switch .....................5

Charging System (3.0L) ........................7,8

Battery ....................................7

Generator .................................8

Ignition Off-Draw Connector .....................7

Cigar Lighter ................................45

Cigar Lighter Lamp ............................52

Circuit Breaker (30 Amp) Fuseblock Cavity #10 .......67, 82

Circuit Breaker (30 Amp) Fuseblock Cavity #13 . . .2, 66, 67, 86

Clockspring ............................. .47, 59

Cluster Printed Circuit Board .................119, 120

Cluster Printed Circuit Board Connectors .............118

Courtesy Lamps .............................76

Daytime Running Light Module ....................57

Deck Lid Ajar Switch ..........................78

Dimmer Switch-Headlamp .....................1,50

Distributor ......................... .15, 21, 22, 27

EGR Solenoid ...............................24

Electrically Heated Rear Window ...................84

Heated Rear Window .........................84

Switch ..................................84

Timer ...................................84

Electronically Tuned Stereo Radio without Name Brand Speakers ................................87

Electronically Tuned Stereo Radio with Name Brand Speakers ................................89

Speaker Choke .............................89

Speaker Relay .............................89

Electronic Cluster ........................... .121

Engine Coolant Sensor ................... .15, 21, 27

Engine Oil and Temperature Warning System (2.5L) .......39

Engine Oil and Temperature Warning System (3.0L) .......40

Engine Oil Pressure Switch/Sending Unit ...........39, 40

Engine Temperature Sending Unit ................39, 40

Engine Starter System (2.5L Engine & 3.0L ATX) .......9,10

Automatic Transmission Park/Neutral Position Switch .....9

Backup Lamp Switch ..........................9

EMCC Solenoid .............................9

Engine Starter Relay ..........................9

Manual Transmission Back-Up Lamp Switch ...........9

Permanent Magnet Engine Starter Motor .............9

Engine Temperature Sending Unit ................39, 40

Exhaust Gas Recirculation Diagnostic Solenoid ........13, 24

Fan Control System with A/C and Heater System (2.5L) ....32

A/C Compressor ............................32

A/C Compressor Clutch Relay ...................32

A/C High Pressure Switch ......................32

Fan Control Relay ...........................32

Radiator Fan Motor ..........................32

Fan Control System with A/C and Heater System (3.0L) ....33

A/C Conditioning Compressor ...................33

A/C Compressor Clutch Relay ...................33

Ä WIRING DIAGRAMS AA-BODY 8W - 181

Page 1063 of 2438

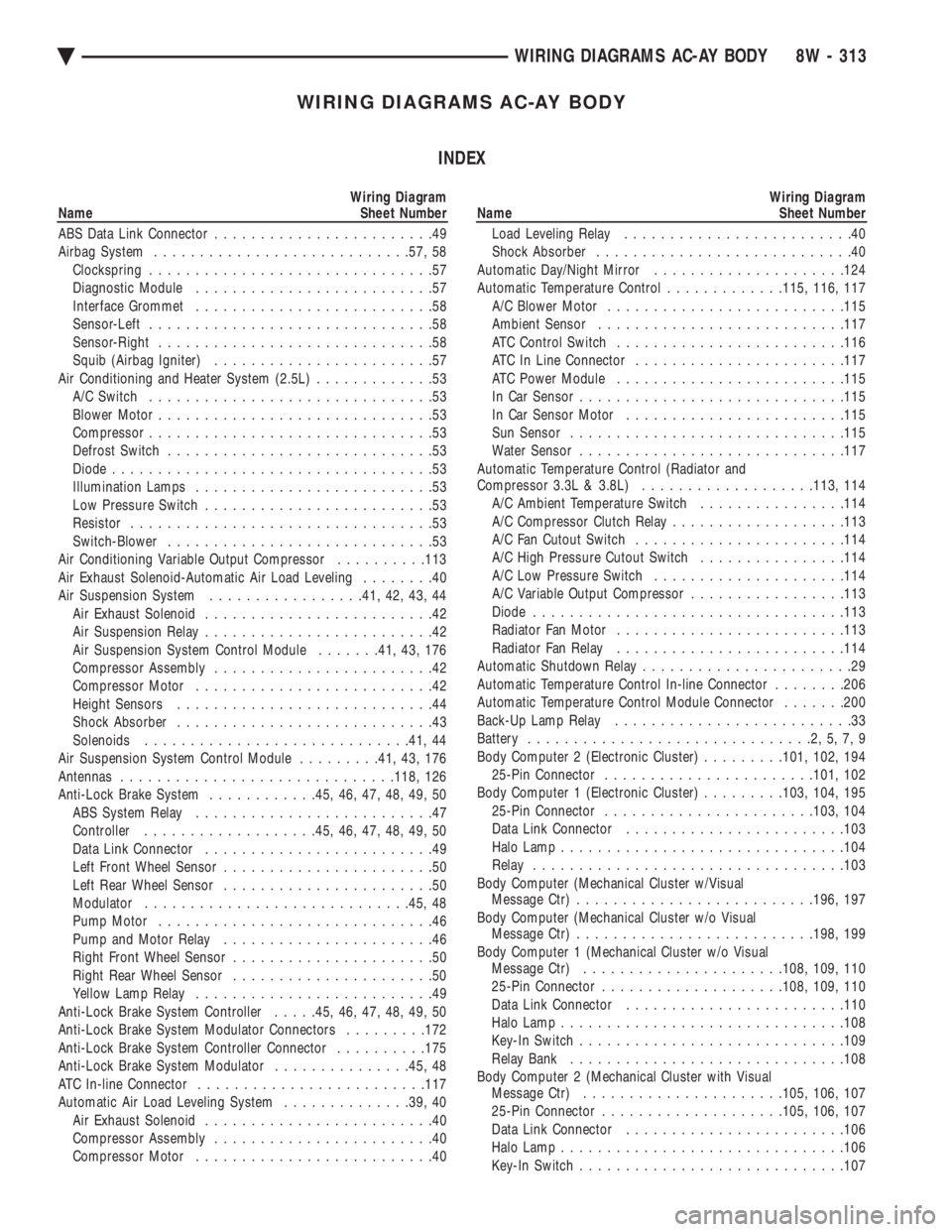

WIRING DIAGRAMS AC-AY BODY INDEX

Wiring Diagram

Name Sheet Number

ABS Data Link Connector ........................49

Airbag System ........................... .57, 58

Clockspring ...............................57

Diagnostic Module ..........................57

Interface Grommet ..........................58

Sensor-Left ...............................58

Sensor-Right ..............................58

Squib (Airbag Igniter) ........................57

Air Conditioning and Heater System (2.5L) .............53

A/C Switch ...............................53

Blower Motor ..............................53

Compressor ...............................53

Defrost Switch .............................53

Diode ...................................53

Illumination Lamps ..........................53

Low Pressure Switch .........................53

Resistor .................................53

Switch-Blower .............................53

Air Conditioning Variable Output Compressor ..........113

Air Exhaust Solenoid-Automatic Air Load Leveling ........40

Air Suspension System .................41, 42, 43, 44

Air Exhaust Solenoid .........................42

Air Suspension Relay .........................42

Air Suspension System Control Module .......41, 43, 176

Compressor Assembly ........................42

Compressor Motor ..........................42

Height Sensors ............................44

Shock Absorber ............................43

Solenoids ............................ .41, 44

Air Suspension System Control Module .........41, 43, 176

Antennas ............................. .118, 126

Anti-Lock Brake System ............45, 46, 47, 48, 49, 50

ABS System Relay ..........................47

Controller .................. .45, 46, 47, 48, 49, 50

Data Link Connector .........................49

Left Front Wheel Sensor .......................50

Left Rear Wheel Sensor .......................50

Modulator ............................ .45, 48

Pump Motor ..............................46

Pump and Motor Relay .......................46

Right Front Wheel Sensor ......................50

Right Rear Wheel Sensor ......................50

Yellow Lamp Relay ..........................49

Anti-Lock Brake System Controller .....45, 46, 47, 48, 49, 50

Anti-Lock Brake System Modulator Connectors .........172

Anti-Lock Brake System Controller Connector ..........175

Anti-Lock Brake System Modulator ...............45, 48

ATC In-line Connector ........................ .117

Automatic Air Load Leveling System ..............39, 40

Air Exhaust Solenoid .........................40

Compressor Assembly ........................40

Compressor Motor ..........................40Wiring Diagram

Name Sheet Number

Load Leveling Relay .........................40

Shock Absorber ............................40

Automatic Day/Night Mirror .................... .124

Automatic Temperature Control .............115, 116, 117

A/C Blower Motor ......................... .115

Ambient Sensor .......................... .117

ATC Control Switch ........................ .116

ATC In Line Connector ...................... .117

ATC Power Module ........................ .115

In Car Senso r............................ .115

In Car Sensor Motor ....................... .115

Sun Sensor ............................. .115

Water Sensor ............................ .117

Automatic Temperature Control (Radiator and

Compressor 3.3L & 3.8L) .................. .113, 114

A/C Ambient Temperature Switch ................114

A/C Compressor Clutch Relay ...................113

A/C Fan Cutout Switch ...................... .114

A/C High Pressure Cutout Switch ................114

A/C Low Pressure Switch .................... .114

A/C Variable Output Compressor .................113

Diode ................................. .113

Radiator Fan Motor ........................ .113

Radiator Fan Relay ........................ .114

Automatic Shutdown Relay .......................29

Automatic Temperature Control In-line Connector ........206

Automatic Temperature Control Module Connector .......200

Back-Up Lamp Relay ..........................33

Battery ...............................2,5,7,9

Body Computer 2 (Electronic Cluster) .........101, 102, 194

25-Pin Connector ...................... .101, 102

Body Computer 1 (Electronic Cluster) .........103, 104, 195

25-Pin Connector ...................... .103, 104

Data Link Connector ....................... .103

Halo Lamp .............................. .104

Relay ................................. .103

Body Computer (Mechanical Cluster w/Visual Message Ctr) ......................... .196, 197

Body Computer (Mechanical Cluster w/o Visual Message Ctr) ......................... .198, 199

Body Computer 1 (Mechanical Cluster w/o Visual Message Ctr) ..................... .108, 109, 110

25-Pin Connector ................... .108, 109, 110

Data Link Connector ....................... .110

Halo Lamp .............................. .108

Key-In Switch ............................ .109

Relay Bank ............................. .108

Body Computer 2 (Mechanical Cluster with Visual Message Ctr) ..................... .105, 106, 107

25-Pin Connector ................... .105, 106, 107

Data Link Connector ....................... .106

Halo Lamp .............................. .106

Key-In Switch ............................ .107

Ä WIRING DIAGRAMS AC-AY BODY 8W - 313

Page 1065 of 2438

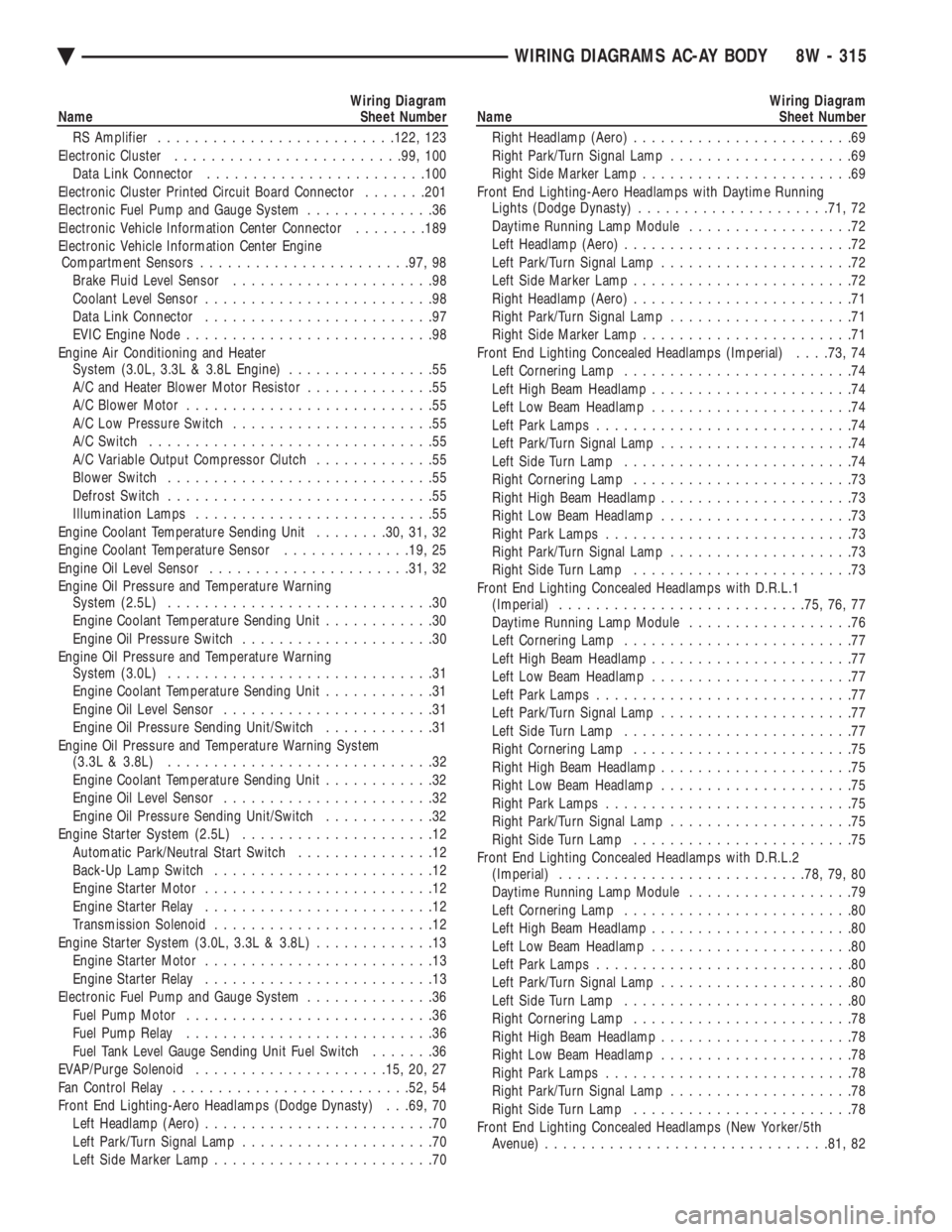

Wiring Diagram

Name Sheet Number

RS Amplifier ......................... .122, 123

Electronic Cluster ........................ .99, 100

Data Link Connector ....................... .100

Electronic Cluster Printed Circuit Board Connector .......201

Electronic Fuel Pump and Gauge System ..............36

Electronic Vehicle Information Center Connector ........189

Electronic Vehicle Information Center Engine Compartment Sensors ...................... .97, 98

Brake Fluid Level Sensor ......................98

Coolant Level Sensor .........................98

Data Link Connector .........................97

EVIC Engine Node ...........................98

Engine Air Conditioning and Heater System (3.0L, 3.3L & 3.8L Engine) ................55

A/C and Heater Blower Motor Resistor ..............55

A/C Blower Motor ...........................55

A/C Low Pressure Switch ......................55

A/C Switch ...............................55

A/C Variable Output Compressor Clutch .............55

Blower Switch .............................55

Defrost Switch .............................55

Illumination Lamps ..........................55

Engine Coolant Temperature Sending Unit ........30, 31, 32

Engine Coolant Temperature Sensor ..............19, 25

Engine Oil Level Sensor ..................... .31, 32

Engine Oil Pressure and Temperature Warning System (2.5L) .............................30

Engine Coolant Temperature Sending Unit ............30

Engine Oil Pressure Switch .....................30

Engine Oil Pressure and Temperature Warning System (3.0L) .............................31

Engine Coolant Temperature Sending Unit ............31

Engine Oil Level Sensor .......................31

Engine Oil Pressure Sending Unit/Switch ............31

Engine Oil Pressure and Temperature Warning System (3.3L & 3.8L) .............................32

Engine Coolant Temperature Sending Unit ............32

Engine Oil Level Sensor .......................32

Engine Oil Pressure Sending Unit/Switch ............32

Engine Starter System (2.5L) .....................12

Automatic Park/Neutral Start Switch ...............12

Back-Up Lamp Switch ........................12

Engine Starter Motor .........................12

Engine Starter Relay .........................12

Transmission Solenoid ........................12

Engine Starter System (3.0L, 3.3L & 3.8L) .............13

Engine Starter Motor .........................13

Engine Starter Relay .........................13

Electronic Fuel Pump and Gauge System ..............36

Fuel Pump Motor ...........................36

Fuel Pump Relay ...........................36

Fuel Tank Level Gauge Sending Unit Fuel Switch .......36

EVAP/Purge Solenoid .................... .15, 20, 27

Fan Control Relay ......................... .52, 54

Front End Lighting-Aero Headlamps (Dodge Dynasty) . . .69, 70 Left Headlamp (Aero) .........................70

Left Park/Turn Signal Lamp .....................70

Left Side Marker Lamp ........................70Wiring Diagram

Name Sheet Number

Right Headlamp (Aero) ........................69

Right Park/Turn Signal Lamp ....................69

Right Side Marker Lamp .......................69

Front End Lighting-Aero Headlamps with Daytime Running Lights (Dodge Dynasty) .................... .71, 72

Daytime Running Lamp Module ..................72

Left Headlamp (Aero) .........................72

Left Park/Turn Signal Lamp .....................72

Left Side Marker Lamp ........................72

Right Headlamp (Aero) ........................71

Right Park/Turn Signal Lamp ....................71

Right Side Marker Lamp .......................71

Front End Lighting Concealed Headlamps (Imperial) . . . .73, 74

Left Cornering Lamp .........................74

Left High Beam Headlamp ......................74

Left Low Beam Headlamp ......................74

Left Park Lamps ............................74

Left Park/Turn Signal Lamp .....................74

Left Side Turn Lamp .........................74

Right Cornering Lamp ........................73

Right High Beam Headlamp .....................73

Right Low Beam Headlamp .....................73

Right Park Lamps ...........................73

Right Park/Turn Signal Lamp ....................73

Right Side Turn Lamp ........................73

Front End Lighting Concealed Headlamps with D.R.L.1 (Imperial) .......................... .75, 76, 77

Daytime Running Lamp Module ..................76

Left Cornering Lamp .........................77

Left High Beam Headlamp ......................77

Left Low Beam Headlamp ......................77

Left Park Lamps ............................77

Left Park/Turn Signal Lamp .....................77

Left Side Turn Lamp .........................77

Right Cornering Lamp ........................75

Right High Beam Headlamp .....................75

Right Low Beam Headlamp .....................75

Right Park Lamps ...........................75

Right Park/Turn Signal Lamp ....................75

Right Side Turn Lamp ........................75

Front End Lighting Concealed Headlamps with D.R.L.2 (Imperial) .......................... .78, 79, 80

Daytime Running Lamp Module ..................79

Left Cornering Lamp .........................80

Left High Beam Headlamp ......................80

Left Low Beam Headlamp ......................80

Left Park Lamps ............................80

Left Park/Turn Signal Lamp .....................80

Left Side Turn Lamp .........................80

Right Cornering Lamp ........................78

Right High Beam Headlamp .....................78

Right Low Beam Headlamp .....................78

Right Park Lamps ...........................78

Right Park/Turn Signal Lamp ....................78

Right Side Turn Lamp ........................78

Front End Lighting Concealed Headlamps (New Yorker/5th Avenue) .............................. .81, 82

Ä WIRING DIAGRAMS AC-AY BODY 8W - 315