fuel filter location CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 44 of 2438

ENGINE INDEX

page page

Engine Oil Filter .......................... 9

Battery ................................ 15

Crankcase Ventilation System ............... 13

Drive Belts ............................. 14

Emission Control System ................... 14

Engine Air Cleaner ....................... 11

Engine Cooling System .................... 10 Engine Oil

............................... 8

Frequency of Engine Oil and Filter Changes ..... 8

Fuel Filter .............................. 14

Fuel Recommendations .................... 14

Ignition Cables, Distributor Cap, and Rotor ..... 14

Rubber and Plastic Component Inspection ...... 15

Spark Plugs ............................ 14

FREQUENCY OF ENGINE OIL AND FILTER

CHANGES

ENGINE OIL

Road conditions as well as your kind of driving af-

fect the interval at which your oil should be changed.

Check the following to determine if any apply to you:

² Frequent short trip driving less than 8 kilometers

(5 miles)

² Frequent driving in dusty conditions

² Frequent trailer towing

² Extensive idling (such as vehicle operation in stop

and go traffic)

² More than 50% of your driving is at sustained

high speeds during hot weather, above 32ÉC (90ÉF) If any of these apply to you then change your en-

gine oil every 4 800 kilometers (3,000 miles) or 3

months, whichever comes first. If none of these apply to you then change your oil

every 12 000 kilometers (7,500 miles) or 6 months,

whichever comes first. If none of these apply and the vehicle is in com-

mercial type service such as, Police, Taxi or Limou-

sine and principally used for highway driving of 40

kilometers (25 miles) or more between stations, the

engine oil should be changed every 8 000 kilometers

(5,000 miles) or 6 months, whichever comes first.

FLEXIBLE FUEL VEHICLES

Flexible fuel is corrosive and contributes to engine

oil contamination. When flexible fuel is being used,

the engine oil should be changed every 8 000 kilome-

ters (5,000 miles) or 6 months, whichever comes first.

OIL FILTER

The engine oil filter should be replaced with a new

filter at every second oil change.

ENGINE OIL

WARNING: NEW OR USED ENGINE OIL CAN BE IR-

RITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED

BY INTERNAL COMBUSTION, CAN BE HAZARDOUS TO YOUR HEALTH. THOROUGHLY WASH EX-

POSED SKIN WITH SOAP AND WATER. DO NOT WASH SKIN WITH GASOLINE, DIESEL

FUEL, THINNER, OR SOLVENTS, HEALTH PROB-

LEMS CAN RESULT. DO NOT POLLUTE, DISPOSE OF USED ENGINE

OIL PROPERLY. CONTACT YOUR DEALER OR

GOVERNMENT AGENCY FOR LOCATION OF COL-

LECTION CENTER IN YOUR AREA.

BREAK-IN PERIOD

CAUTION: Wide open throttle operation in low

gears, before engine break-in period is complete,

can damage engine.

On a Chrysler Corporation vehicle an extended

break-in period is not required. Driving speeds of not

over 80-90 km/h (50-55 mph) for the first 100 km (60

miles) is recommended. Hard acceleration and high

engine rpm in lower gears should be avoided.

SELECTING ENGINE OIL

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase lu-

bricant. Engine or Turbocharger failure can result.

The factory fill engine oil is a high quality, energy

conserving, crankcase lubricant. The Recommended

SAE Viscosity Grades chart defines the viscosity

grades that must be used based on temperature in

the region where vehicle is operated and optional

equipment.

NON-FLEXIBLE FUEL VEHICLES Chrysler Corporation recommends that Mopar mo-

tor oil, or equivalent, be used when adding or chang-

ing crankcase lubricant. The API symbol (Fig. 1) on

the container indicates the viscosity grade, quality

and fuel economy ratings of the lubricant it contains.

Use ENERGY CONSERVING II motor oil with API

SERVICE SG or SG/CD classification.

0 - 8 LUBRICATION AND MAINTENANCE Ä

Page 1568 of 2438

The MOPAR Silicone Rubber Adhesive Sealant

gasket material or equivalent should be applied in a

continuous bead approximately 3mm (0.120 inch) in

diameter. All mounting holes must be circled. For

corner sealing, a 3.17 or 6.35 mm (1/8 or 1/4 inch.)

drop is placed in the center of the gasket contact

area. Uncured sealant may be removed with a shop

towels. Components should be torqued in place while

the sealant is still wet to the touch (within 10 min-

utes). The usage of a locating dowel is recommended

during assembly to prevent smearing of material off

location.

CRANKSHAFT SPROCKET BOLT ACCESS PLUG

An Access plug is located in the right inner fender

shield. Remove the plug and insert proper size

socket, extension and rachet, when crankshaft rota-

tion is necessary.

ENGINE PERFORMANCE

If a loss of performance is noticed, ignition timing

should be checked. If ignition timing is retarded by

9, 18 or 27É indicating 1, 2 or 3 (timing belt or chain)

teeth may have skipped, then, camshaft and acces-

sory shaft timing with the crankshaft should be

checked. Refer to Engine Timing Sprockets and Oil

Seals of the Engine Section. To provide best vehicle performance and lowest ve-

hicle emissions, it is most important that the tune-up

be done accurately. Use the specifications listed on

the Vehicle Emission Control Information label

found in the engine compartment. (1) Test cranking amperage draw. See Starting

Motor Cranking Amperage Draw Electrical Section

of this manual. (2) Tighten the intake manifold bolts to specifica-

tions. (3) Perform cylinder compression test.(a) Check engine oil level and add oil if neces-

sary. (b) Drive the vehicle until engine reaches normal

operating temperature. (c) Select a route free from traffic and other

forms of congestion, observe all traffic laws, and ac-

celerate through the gears several times briskly.

CAUTION: Do not overspeed the engine. The higher

engine speed may help clean out valve seat deposits

which can prevent accurate compression readings.

(d) Remove all spark plugs from engine. As

spark plugs are being removed, check electrodes for

abnormal firing indicators fouled, hot, oily, etc.

Record cylinder number of spark plug for future

reference. (e) Disconnect coil wire from distributor and se-

cure to good ground to prevent a spark from start- ing a fire (Conventional Ignition System). For Direct

Ignition System DIS disconnect the coil connector. (f) Be sure throttle blade is fully open during the

compression check. (g) Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure. (h) Repeat Step G for all remaining cylinders.

(i) Compression should not be less than (689kPa)

100 psi and not vary more than 25 percent from

cylinder to cylinder. (j) If one or more cylinders have abnormally low

compression pressures, repeat steps 3b through 3h. (k) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.

The recommended compression pressures are

to be used only as a guide to diagnosing engine

problems. An engine should not be disassembled

to determine the cause of low compression un-

less some malfunction is present. (4) Clean or replace spark plugs as necessary and

adjust gap as specified in Electrical Group 8. Tighten to

specifications. (5) Test resistance of spark plug cables. Refer to

Ignition System Secondary Circuit Inspection Electri-

cal Section Group 8. (6) Inspect the primary wire. Test coil output volt-

age, primary and secondary resistance. Replace parts

as necessary. Refer to Ignition System and make nec-

essary adjustment. (7) Ignition timing should be set to specifications.

(See Specification Label in engine compartment). (8) Test fuel pump for pressure and vacuum. Refer to

Fuel System Group 14, Specifications. (9) The air filter elements should be replaced as

specified in Lubrication and Maintenance, Group 0. (10) Inspect crankcase ventilation system as out

lined in Lubrication and Maintenance, Group 0. For

emission controls see Emission Controls Group 25 for

service procedures. (11) Inspect and adjust accessory belt drives refer-

ring to Accessory Belt Drive in Cooling System, Group

7 for proper adjustments. (12) Road test vehicle as a final test.

HONING CYLINDER BORES

Before honing, stuff plenty of clean shop towels

under the bores, over the crankshaft to keep abrasive

materials from entering crankcase area. (1) Used carefully, the cylinder bore resizing hone

C-823 equipped with 220 grit stones, is the best tool for

this job. In addition to deglazing, it will reduce taper

and out-of-round as well as removing light

9 - 2 ENGINE Ä

Page 1782 of 2438

once the system has entered closed loop. Refer to

Modes of Operation in this section for an explanation

of closed loop operation.

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems and conditions that could have malfunctions

that result in driveability problems. Diagnostic trou-

ble codes may not be displayed for these conditions.

However, problems with these systems may cause di-

agnostic trouble codes to be displayed for other sys-

tems. For example, a fuel pressure problem will not

register a fault directly, but could cause a rich or

lean condition. This could cause an oxygen sensor

fault to be stored in the PCM. Fuel Pressure - Fuel pressure is controlled by the

fuel pressure regulator. The PCM cannot detect a

clogged fuel pump inlet filter, clogged in-line fuel fil-

ter, or a pinched fuel supply or return line. However,

these could result in a rich or lean condition causing

an oxygen sensor fault. Secondary Ignition Circuit - The PCM cannot

detect an inoperative ignition coil, fouled or worn

spark plugs, ignition cross firing, or open spark plug

cables. Engine Timing - The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket and

crankshaft sprocket. The PCM also cannot detect an

incorrectly indexed distributor. However, these could

result in a rich or lean condition causing an oxygen

sensor fault to be stored in the PCM. Cylinder Compression - The PCM cannot detect

uneven, low, or high engine cylinder compression. Exhaust System

- The PCM cannot detect a

plugged, restricted or leaking exhaust system. Fuel Injector Malfunctions - The PCM cannot

determine if the fuel injector is clogged, the pintle is

sticking or the wrong injector is installed. However,

these could result in a rich or lean condition causing

an oxygen sensor fault to be stored in the PCM. Excessive Oil Consumption - Although the PCM

monitors the exhaust stream oxygen content through

the oxygen sensor when the system is in closed loop,

it cannot determine excessive oil consumption. Throttle Body Air Flow - The PCM cannot detect

a clogged or restricted air cleaner inlet or filter ele-

ment. Evaporative System - The PCM will not detect a

restricted, plugged or loaded evaporative purge can-

ister. Vacuum Assist - Leaks or restrictions in the vac-

uum circuits of vacuum assisted engine control sys-

tem devices are not monitored by the PCM. However,

these could result in a MAP sensor fault being stored

in the PCM. PCM System Ground - The PCM cannot deter-

mine a poor system ground. However, a diagnostic

trouble code may be generated as a result of this con-

dition. PCM Connector Engagement - The PCM cannot

determine spread or damaged connector pins. How-

ever, a diagnostic trouble code may be generated as a

result of this condition.

HIGH AND LOW LIMITS

The powertrain control module (PCM) compares in-

put signal voltages from each input device with es-

tablished high and low limits that are programmed

into it for that device. If the input voltage is not

within specifications and other diagnostic trouble

code criteria are met, a diagnostic trouble code will

be stored in memory. Other diagnostic trouble code

criteria might include engine RPM limits or input

voltages from other sensors or switches that must be

present before a fault condition can be verified.

DIAGNOSTIC TROUBLE CODE DESCRIPTION

When a diagnostic trouble code appears, it indi-

cates the powertrain control module (PCM) has rec-

ognized an abnormal condition in the system.

Diagnostic trouble codes can be obtained from the

malfunction indicator lamp (instrument panel Check

Engine lamp) on the Instrument Panel or from the

DRBII scan tool. Diagnostic trouble codes indicate

the results of a failure but do not identify the failed

component directly.

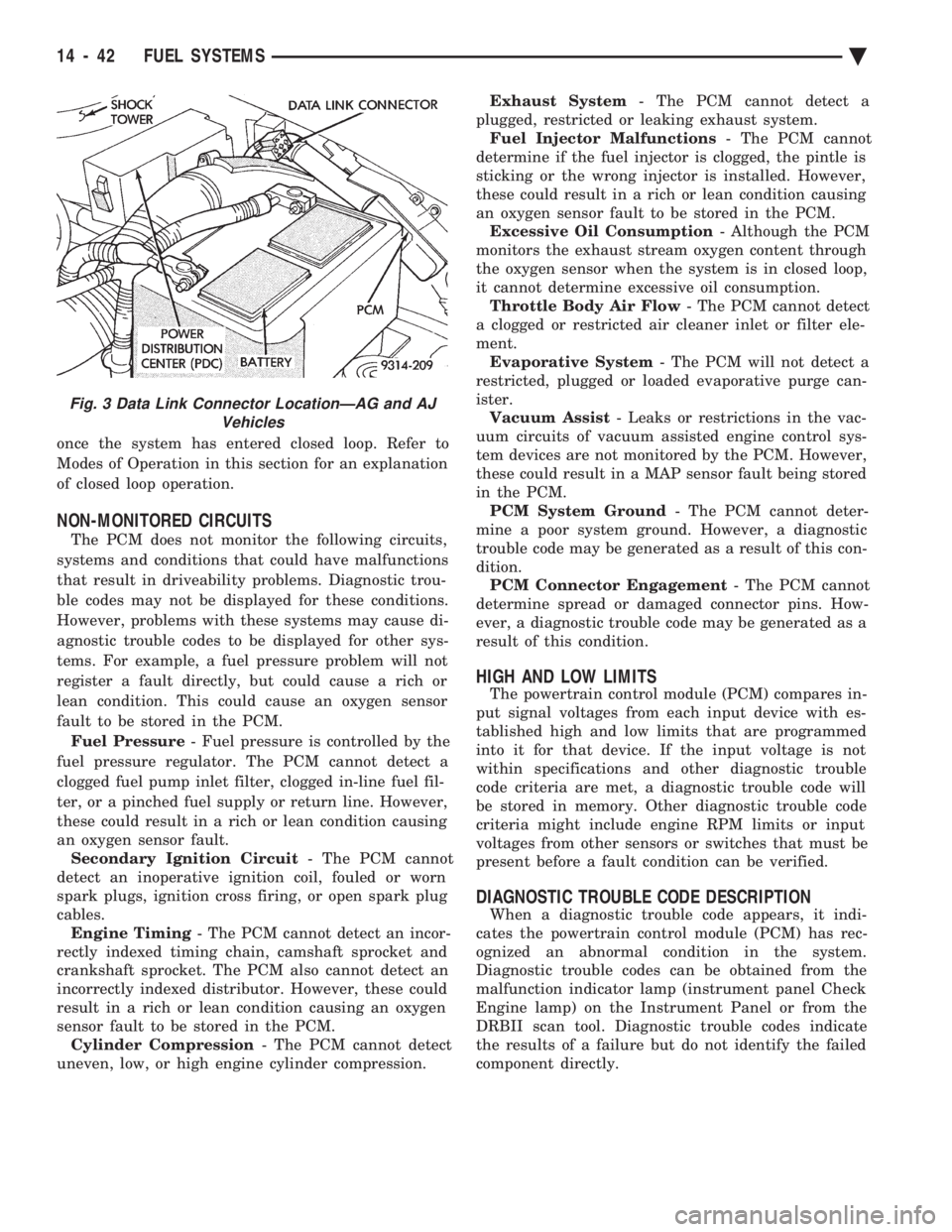

Fig. 3 Data Link Connector LocationÐAG and AJ Vehicles

14 - 42 FUEL SYSTEMS Ä

Page 1840 of 2438

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐON-BOARD DIAGNOSTICS INDEX

page page

60-Way PCM Wiring Connector ............. 105

Circuit Actuation Test Mode ................ 105

Diagnostic Trouble Code Description ......... 101

General Information ...................... 100

High and Low Limits ..................... 101

Ignition Timing Procedure ................. 105 Monitored Circuits

....................... 100

Non-Monitored Circuits ................... 100

State Display Test Mode .................. 104

System Tests .......................... 104

Throttle Body Minimum Air Flow Check Procedure ............................ 105

GENERAL INFORMATION

The powertrain control module (PCM) has been pro-

grammed to monitor many different circuits of the fuel

injection system. If a problem is sensed with a moni-

tored circuit often enough to indicate an actual prob-

lem, the PCM stores a fault. If the problem is repaired

or ceases to exist, the PCM cancels the Diagnostic

trouble code after 51 vehicle key on/off cycles. Certain criteria must be met for a diagnostic trouble

code to be entered into PCM memory. The criteria may

be a specific range of engine RPM, engine temperature,

and/or input voltage to the PCM. It is possible that a diagnostic trouble code for a

monitored circuit may not be entered into memory

even though a malfunction has occurred. This may

happen because one of the diagnostic trouble code

criteria for the circuit has not been met. For example,

assume that one of the diagnostic trouble code criteria

for a certain sensor circuit is that the engine must be

operating between 750 and 2000 RPM. If the sensor

output circuit shorts to ground when engine RPM is

above 2400 RPM (resulting i n a 0 volt input to the

PCM) a diagnostic trouble code will not be entered into

memory. This is because the condition does not occur

within the specified RPM range. There are several operating conditions for which the

PCM does not monitor and set diagnostic trouble codes.

Refer to Monitored Circuits and Non-Monitored Cir-

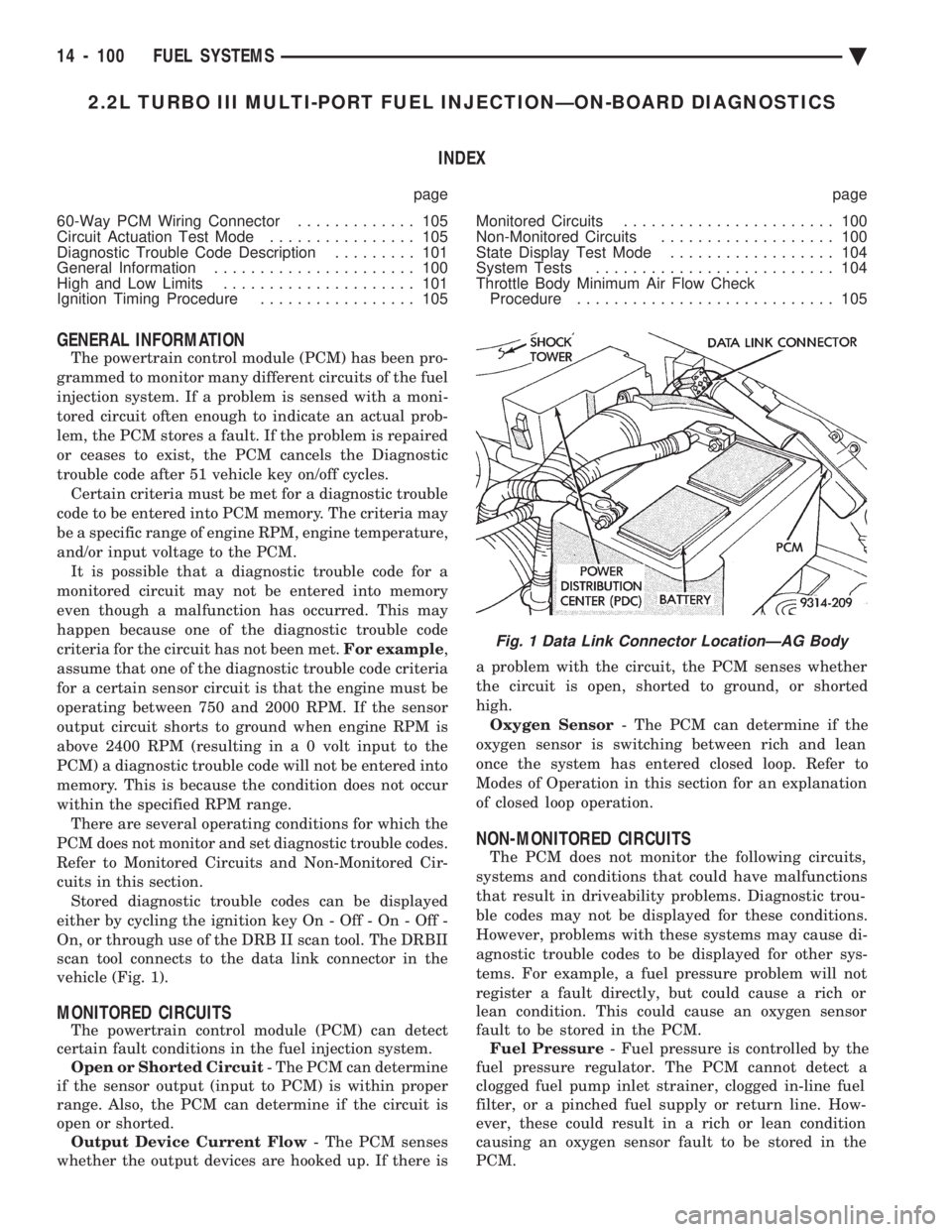

cuits in this section. Stored diagnostic trouble codes can be displayed

either by cycling the ignition key On - Off - On - Off -

On, or through use of the DRB II scan tool. The DRBII

scan tool connects to the data link connector in the

vehicle (Fig. 1).

MONITORED CIRCUITS

The powertrain control module (PCM) can detect

certain fault conditions in the fuel injection system. Open or Shorted Circuit - The PCM can determine

if the sensor output (input to PCM) is within proper

range. Also, the PCM can determine if the circuit is

open or shorted. Output Device Current Flow - The PCM senses

whether the output devices are hooked up. If there is a problem with the circuit, the PCM senses whether

the circuit is open, shorted to ground, or shorted

high. Oxygen Sensor - The PCM can determine if the

oxygen sensor is switching between rich and lean

once the system has entered closed loop. Refer to

Modes of Operation in this section for an explanation

of closed loop operation.

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems and conditions that could have malfunctions

that result in driveability problems. Diagnostic trou-

ble codes may not be displayed for these conditions.

However, problems with these systems may cause di-

agnostic trouble codes to be displayed for other sys-

tems. For example, a fuel pressure problem will not

register a fault directly, but could cause a rich or

lean condition. This could cause an oxygen sensor

fault to be stored in the PCM. Fuel Pressure - Fuel pressure is controlled by the

fuel pressure regulator. The PCM cannot detect a

clogged fuel pump inlet strainer, clogged in-line fuel

filter, or a pinched fuel supply or return line. How-

ever, these could result in a rich or lean condition

causing an oxygen sensor fault to be stored in the

PCM.

Fig. 1 Data Link Connector LocationÐAG Body

14 - 100 FUEL SYSTEMS Ä