clock CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 429 of 2438

AG AND AJ BODIES INDEX

page page

Ambient Temperature Sensor Removal ......... 20

Compass Calibration ...................... 16

Compass Diagnostics ...................... 18

Compass Module Replacement .............. 20

Demagnetizing Procedure .................. 17

Electronic Vehicle Information Center (EVIC) ..... 13

Electronic Vehicle Information Center (EVIC) Removal .............................. 20 Engine Compartment Node (ECN)

............ 15

Engine Compartment Node Compass Calibration . 16

Engine Node Sensor Removal ............... 20

Map Reading Lamps ...................... 13

Overhead Console Replacement ............. 20

Thermometer and Compass ................. 16

Variance Procedure ....................... 17

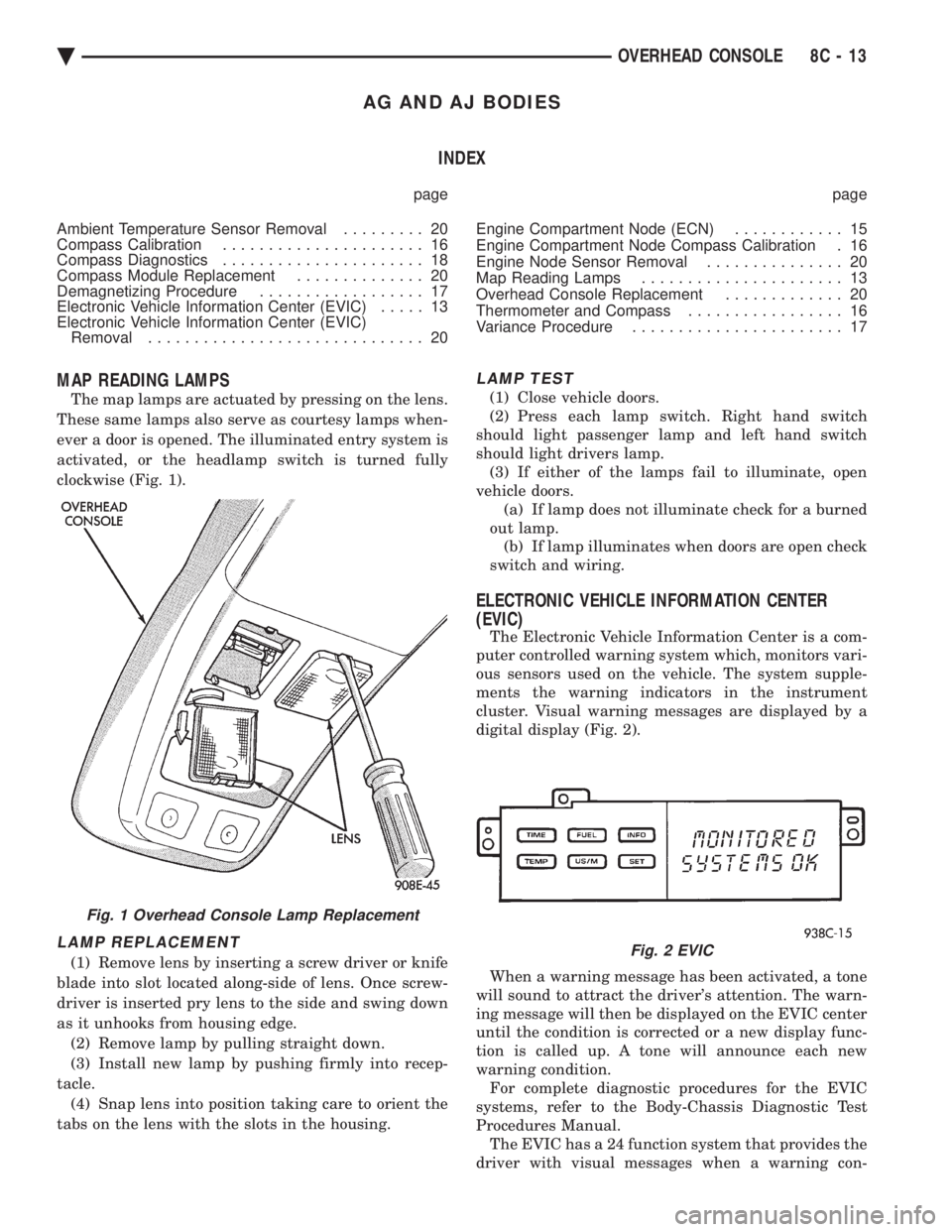

MAP READING LAMPS

The map lamps are actuated by pressing on the lens.

These same lamps also serve as courtesy lamps when-

ever a door is opened. The illuminated entry system is

activated, or the headlamp switch is turned fully

clockwise (Fig. 1).

LAMP REPLACEMENT

(1) Remove lens by inserting a screw driver or knife

blade into slot located along-side of lens. Once screw-

driver is inserted pry lens to the side and swing down

as it unhooks from housing edge. (2) Remove lamp by pulling straight down.

(3) Install new lamp by pushing firmly into recep-

tacle. (4) Snap lens into position taking care to orient the

tabs on the lens with the slots in the housing.

LAMP TEST

(1) Close vehicle doors.

(2) Press each lamp switch. Right hand switch

should light passenger lamp and left hand switch

should light drivers lamp. (3) If either of the lamps fail to illuminate, open

vehicle doors. (a) If lamp does not illuminate check for a burned

out lamp. (b) If lamp illuminates when doors are open check

switch and wiring.

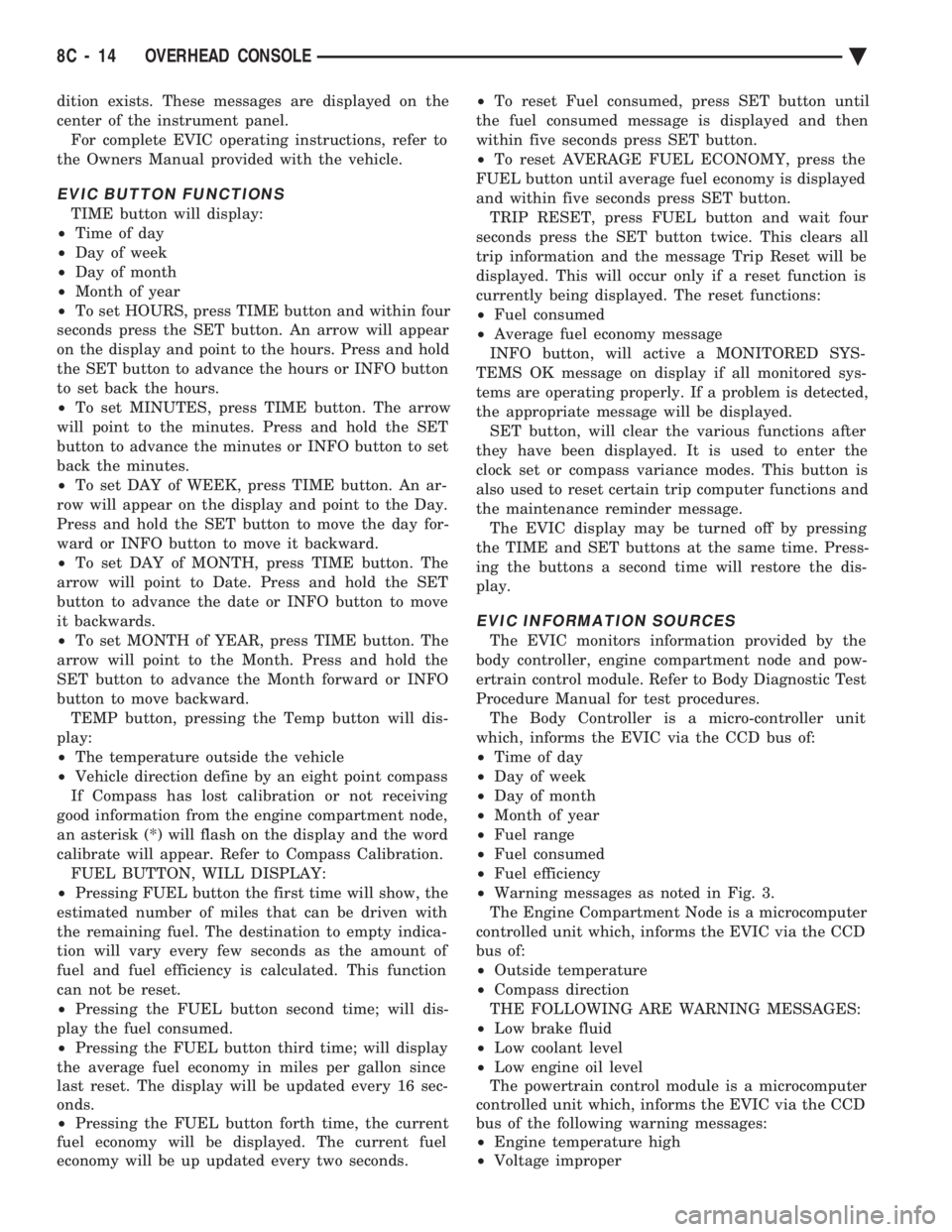

ELECTRONIC VEHICLE INFORMATION CENTER

(EVIC)

The Electronic Vehicle Information Center is a com-

puter controlled warning system which, monitors vari-

ous sensors used on the vehicle. The system supple-

ments the warning indicators in the instrument

cluster. Visual warning messages are displayed by a

digital display (Fig. 2).

When a warning message has been activated, a tone

will sound to attract the driver's attention. The warn-

ing message will then be displayed on the EVIC center

until the condition is corrected or a new display func-

tion is called up. A tone will announce each new

warning condition. For complete diagnostic procedures for the EVIC

systems, refer to the Body-Chassis Diagnostic Test

Procedures Manual. The EVIC has a 24 function system that provides the

driver with visual messages when a warning con-

Fig. 1 Overhead Console Lamp Replacement

Fig. 2 EVIC

Ä OVERHEAD CONSOLE 8C - 13

Page 430 of 2438

dition exists. These messages are displayed on the

center of the instrument panel.For complete EVIC operating instructions, refer to

the Owners Manual provided with the vehicle.

EVIC BUTTON FUNCTIONS

TIME button will display:

² Time of day

² Day of week

² Day of month

² Month of year

² To set HOURS, press TIME button and within four

seconds press the SET button. An arrow will appear

on the display and point to the hours. Press and hold

the SET button to advance the hours or INFO button

to set back the hours.

² To set MINUTES, press TIME button. The arrow

will point to the minutes. Press and hold the SET

button to advance the minutes or INFO button to set

back the minutes.

² To set DAY of WEEK, press TIME button. An ar-

row will appear on the display and point to the Day.

Press and hold the SET button to move the day for-

ward or INFO button to move it backward.

² To set DAY of MONTH, press TIME button. The

arrow will point to Date. Press and hold the SET

button to advance the date or INFO button to move

it backwards.

² To set MONTH of YEAR, press TIME button. The

arrow will point to the Month. Press and hold the

SET button to advance the Month forward or INFO

button to move backward. TEMP button, pressing the Temp button will dis-

play:

² The temperature outside the vehicle

² Vehicle direction define by an eight point compass

If Compass has lost calibration or not receiving

good information from the engine compartment node,

an asterisk (*) will flash on the display and the word

calibrate will appear. Refer to Compass Calibration. FUEL BUTTON, WILL DISPLAY:

² Pressing FUEL button the first time will show, the

estimated number of miles that can be driven with

the remaining fuel. The destination to empty indica-

tion will vary every few seconds as the amount of

fuel and fuel efficiency is calculated. This function

can not be reset.

² Pressing the FUEL button second time; will dis-

play the fuel consumed.

² Pressing the FUEL button third time; will display

the average fuel economy in miles per gallon since

last reset. The display will be updated every 16 sec-

onds.

² Pressing the FUEL button forth time, the current

fuel economy will be displayed. The current fuel

economy will be up updated every two seconds. ²

To reset Fuel consumed, press SET button until

the fuel consumed message is displayed and then

within five seconds press SET button.

² To reset AVERAGE FUEL ECONOMY, press the

FUEL button until average fuel economy is displayed

and within five seconds press SET button. TRIP RESET, press FUEL button and wait four

seconds press the SET button twice. This clears all

trip information and the message Trip Reset will be

displayed. This will occur only if a reset function is

currently being displayed. The reset functions:

² Fuel consumed

² Average fuel economy message

INFO button, will active a MONITORED SYS-

TEMS OK message on display if all monitored sys-

tems are operating properly. If a problem is detected,

the appropriate message will be displayed. SET button, will clear the various functions after

they have been displayed. It is used to enter the

clock set or compass variance modes. This button is

also used to reset certain trip computer functions and

the maintenance reminder message. The EVIC display may be turned off by pressing

the TIME and SET buttons at the same time. Press-

ing the buttons a second time will restore the dis-

play.

EVIC INFORMATION SOURCES

The EVIC monitors information provided by the

body controller, engine compartment node and pow-

ertrain control module. Refer to Body Diagnostic Test

Procedure Manual for test procedures. The Body Controller is a micro-controller unit

which, informs the EVIC via the CCD bus of:

² Time of day

² Day of week

² Day of month

² Month of year

² Fuel range

² Fuel consumed

² Fuel efficiency

² Warning messages as noted in Fig. 3.

The Engine Compartment Node is a microcomputer

controlled unit which, informs the EVIC via the CCD

bus of:

² Outside temperature

² Compass direction

THE FOLLOWING ARE WARNING MESSAGES:

² Low brake fluid

² Low coolant level

² Low engine oil level

The powertrain control module is a microcomputer

controlled unit which, informs the EVIC via the CCD

bus of the following warning messages:

² Engine temperature high

² Voltage improper

8C - 14 OVERHEAD CONSOLE Ä

Page 487 of 2438

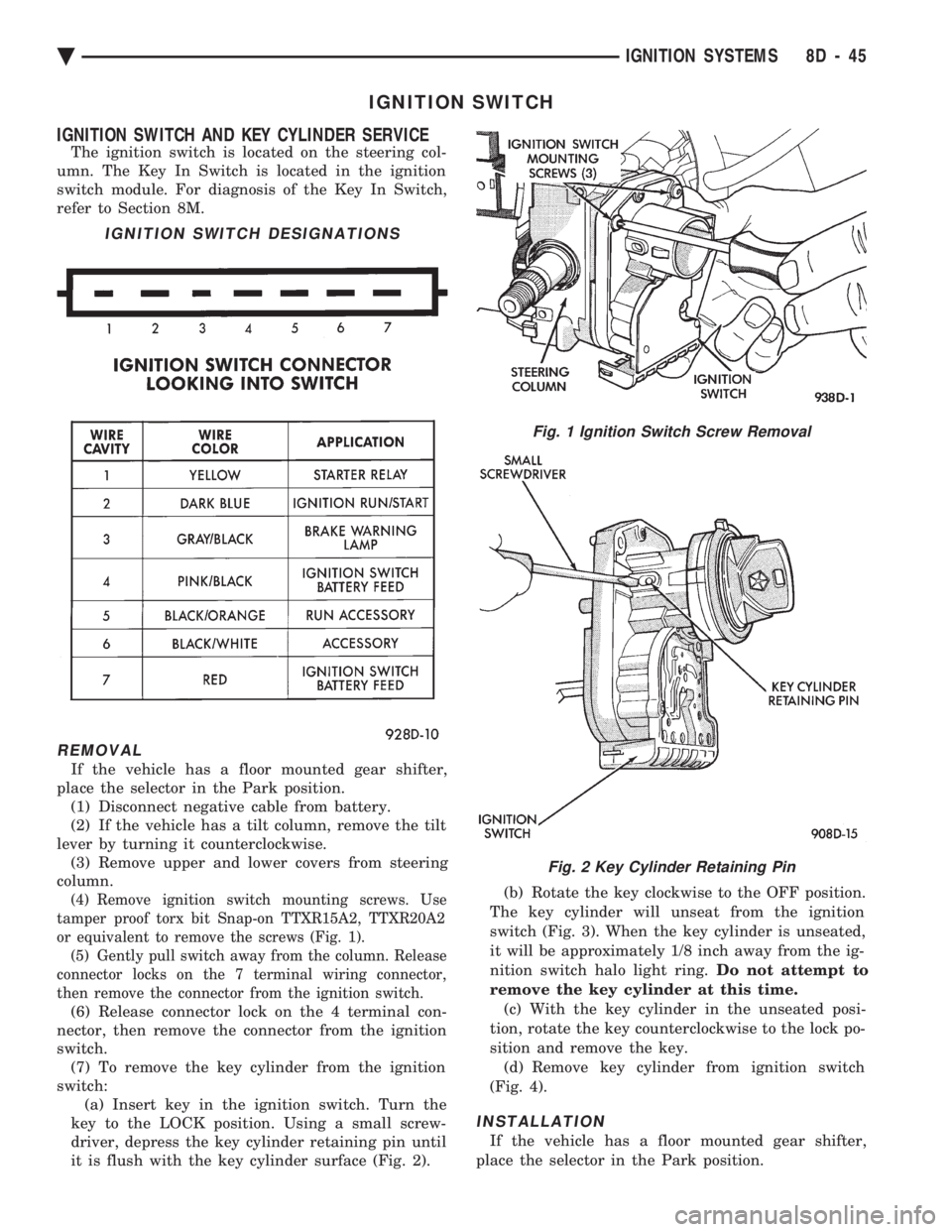

IGNITION SWITCH

IGNITION SWITCH AND KEY CYLINDER SERVICE

The ignition switch is located on the steering col-

umn. The Key In Switch is located in the ignition

switch module. For diagnosis of the Key In Switch,

refer to Section 8M.

REMOVAL

If the vehicle has a floor mounted gear shifter,

place the selector in the Park position. (1) Disconnect negative cable from battery.

(2) If the vehicle has a tilt column, remove the tilt

lever by turning it counterclockwise. (3) Remove upper and lower covers from steering

column.

(4) Remove ignition switch mounting screws. Use

tamper proof torx bit Snap-on TTXR15A2, TTXR20A2

or equivalent to remove the screws (Fig. 1). (5) Gently pull switch away from the column. Release

connector locks on the 7 terminal wiring connector,

then remove the connector from the ignition switch.

(6) Release connector lock on the 4 terminal con-

nector, then remove the connector from the ignition

switch. (7) To remove the key cylinder from the ignition

switch: (a) Insert key in the ignition switch. Turn the

key to the LOCK position. Using a small screw-

driver, depress the key cylinder retaining pin until

it is flush with the key cylinder surface (Fig. 2). (b) Rotate the key clockwise to the OFF position.

The key cylinder will unseat from the ignition

switch (Fig. 3). When the key cylinder is unseated,

it will be approximately 1/8 inch away from the ig-

nition switch halo light ring. Do not attempt to

remove the key cylinder at this time. (c) With the key cylinder in the unseated posi-

tion, rotate the key counterclockwise to the lock po-

sition and remove the key. (d) Remove key cylinder from ignition switch

(Fig. 4).

INSTALLATION

If the vehicle has a floor mounted gear shifter,

place the selector in the Park position.

IGNITION SWITCH DESIGNATIONS

Fig. 1 Ignition Switch Screw Removal

Fig. 2 Key Cylinder Retaining Pin

Ä IGNITION SYSTEMS 8D - 45

Page 493 of 2438

INSTRUMENT PANEL AND GAUGES

CONTENTS

page page

AA BODY .............................. 1

AC AND AY BODIES .................... 23 AG AND AJ BODIES

.................... 42

AP BODY ............................. 58

AA BODY INDEX

page page

Cluster and Gauge Service and Testing ........ 2

Electronic Cluster ........................ 13

Fuel GaugeÐFlexible Fuel .................. 2

Gauges ................................. 7

General Information ........................ 1 Instrument Panel

......................... 21

Interior Lamp Replacement ................. 21

Mechanical/Electronic Cluster Removal ......... 5

Switch and Panel Component Service ......... 15

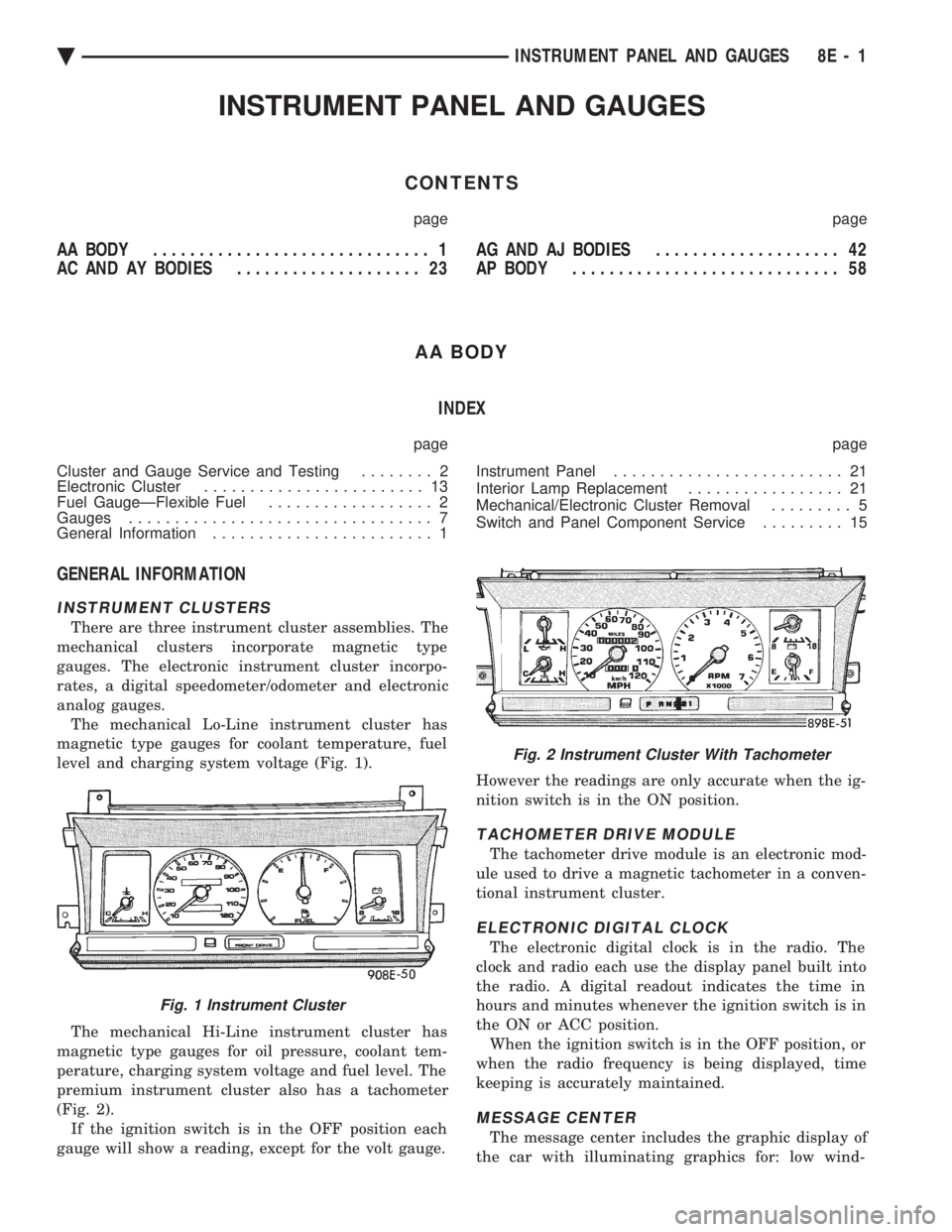

GENERAL INFORMATION

INSTRUMENT CLUSTERS

There are three instrument cluster assemblies. The

mechanical clusters incorporate magnetic type

gauges. The electronic instrument cluster incorpo-

rates, a digital speedometer/odometer and electronic

analog gauges. The mechanical Lo-Line instrument cluster has

magnetic type gauges for coolant temperature, fuel

level and charging system voltage (Fig. 1).

The mechanical Hi-Line instrument cluster has

magnetic type gauges for oil pressure, coolant tem-

perature, charging system voltage and fuel level. The

premium instrument cluster also has a tachometer

(Fig. 2). If the ignition switch is in the OFF position each

gauge will show a reading, except for the volt gauge. However the readings are only accurate when the ig-

nition switch is in the ON position.

TACHOMETER DRIVE MODULE

The tachometer drive module is an electronic mod-

ule used to drive a magnetic tachometer in a conven-

tional instrument cluster.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position. When the ignition switch is in the OFF position, or

when the radio frequency is being displayed, time

keeping is accurately maintained.

MESSAGE CENTER

The message center includes the graphic display of

the car with illuminating graphics for: low wind-

Fig. 1 Instrument Cluster

Fig. 2 Instrument Cluster With Tachometer

Ä INSTRUMENT PANEL AND GAUGES 8E - 1

Page 505 of 2438

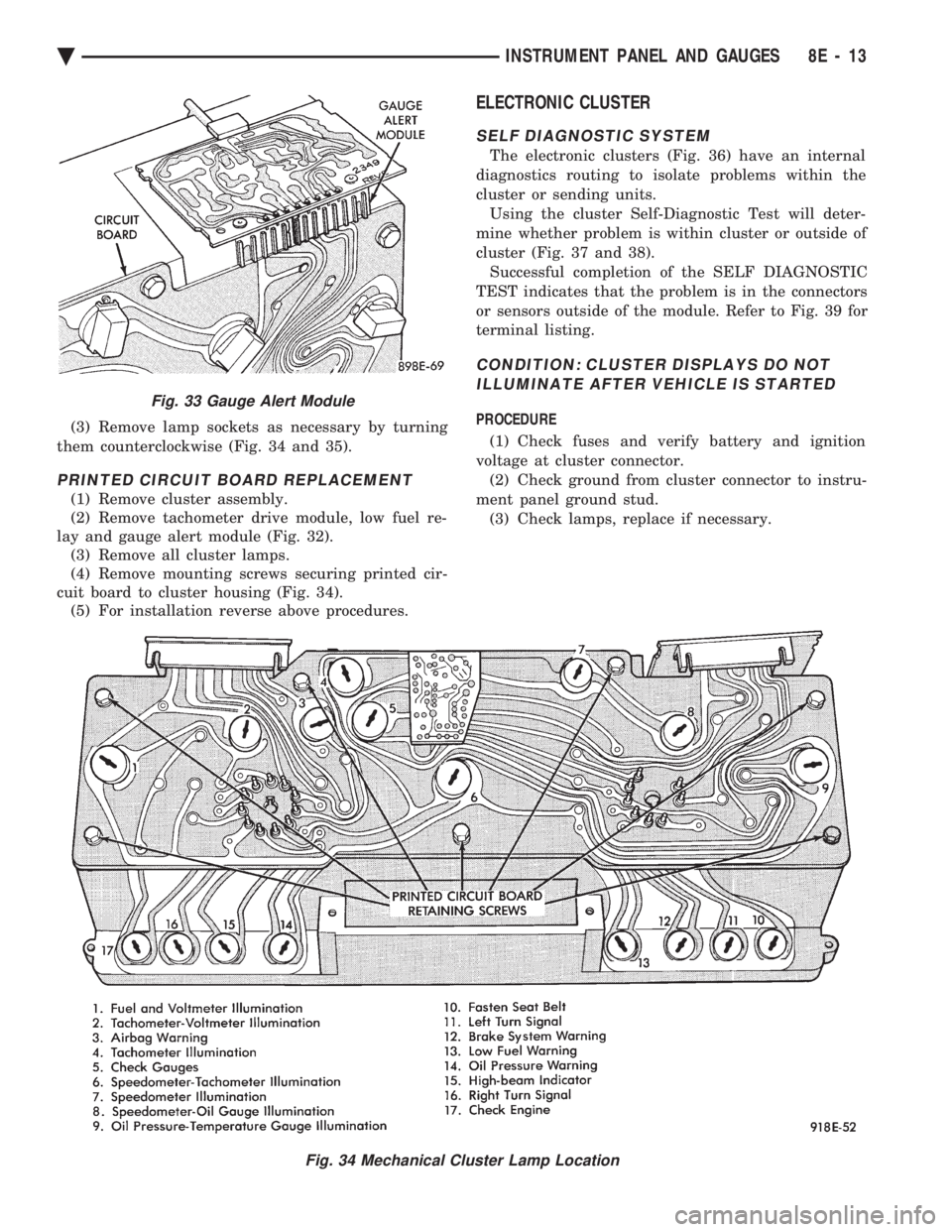

(3) Remove lamp sockets as necessary by turning

them counterclockwise (Fig. 34 and 35).

PRINTED CIRCUIT BOARD REPLACEMENT

(1) Remove cluster assembly.

(2) Remove tachometer drive module, low fuel re-

lay and gauge alert module (Fig. 32). (3) Remove all cluster lamps.

(4) Remove mounting screws securing printed cir-

cuit board to cluster housing (Fig. 34). (5) For installation reverse above procedures.

ELECTRONIC CLUSTER

SELF DIAGNOSTIC SYSTEM

The electronic clusters (Fig. 36) have an internal

diagnostics routing to isolate problems within the

cluster or sending units. Using the cluster Self-Diagnostic Test will deter-

mine whether problem is within cluster or outside of

cluster (Fig. 37 and 38). Successful completion of the SELF DIAGNOSTIC

TEST indicates that the problem is in the connectors

or sensors outside of the module. Refer to Fig. 39 for

terminal listing.

CONDITION: CLUSTER DISPLAYS DO NOT ILLUMINATE AFTER VEHICLE IS STARTED

PROCEDURE

(1) Check fuses and verify battery and ignition

voltage at cluster connector. (2) Check ground from cluster connector to instru-

ment panel ground stud. (3) Check lamps, replace if necessary.

Fig. 34 Mechanical Cluster Lamp Location

Fig. 33 Gauge Alert Module

Ä INSTRUMENT PANEL AND GAUGES 8E - 13

Page 516 of 2438

MESSAGE CENTER

The message center is a car graphic warning lamp

module. This conventional warning system and lo-

cated above the headlamp switch.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position. When the ignition switch is in the OFF position, or

when the radio frequency is being displayed, time

keeping is accurately maintained. The procedure for setting the clock varies slightly

with each radio. The correct procedure is described

under the individual radio operating instructions re-

ferred to in the Owner's Manual supplied with the

vehicle.

AIR BAG WARNING SYSTEM

For testing of this system refer to Group 8M, Re-

straint Systems.

MECHANICAL CLUSTER AND GAUGE SERVICE

CAUTION: Disconnect negative battery cable, in en-

gine compartment, before servicing instrument

panel. When power is required for test purposes,

reconnect battery cable for the test only.

Disconnect negative battery cable after test and be-

fore continuing service procedures.

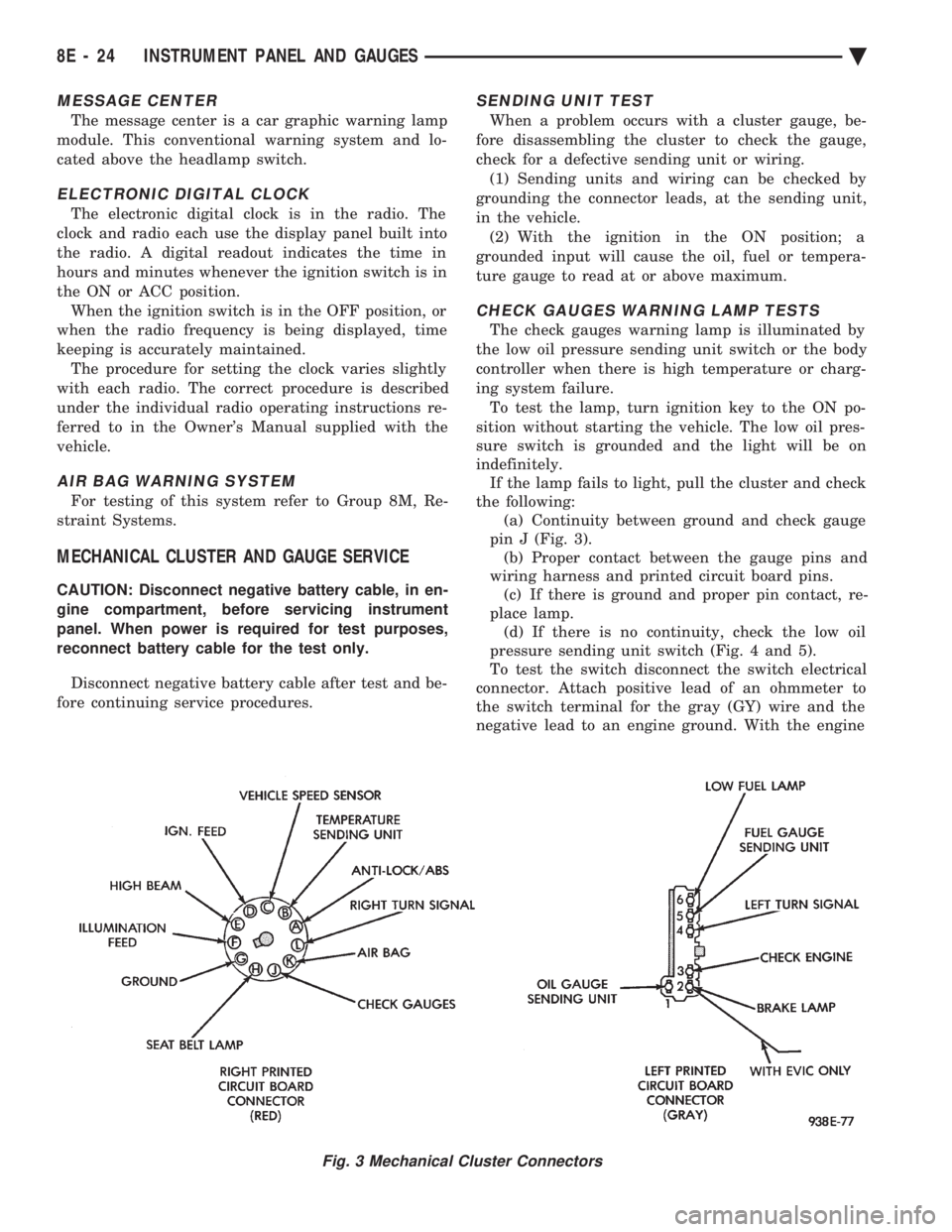

SENDING UNIT TEST

When a problem occurs with a cluster gauge, be-

fore disassembling the cluster to check the gauge,

check for a defective sending unit or wiring. (1) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (2) With the ignition in the ON position; a

grounded input will cause the oil, fuel or tempera-

ture gauge to read at or above maximum.

CHECK GAUGES WARNING LAMP TESTS

The check gauges warning lamp is illuminated by

the low oil pressure sending unit switch or the body

controller when there is high temperature or charg-

ing system failure. To test the lamp, turn ignition key to the ON po-

sition without starting the vehicle. The low oil pres-

sure switch is grounded and the light will be on

indefinitely. If the lamp fails to light, pull the cluster and check

the following: (a) Continuity between ground and check gauge

pin J (Fig. 3). (b) Proper contact between the gauge pins and

wiring harness and printed circuit board pins. (c) If there is ground and proper pin contact, re-

place lamp. (d) If there is no continuity, check the low oil

pressure sending unit switch (Fig. 4 and 5).

To test the switch disconnect the switch electrical

connector. Attach positive lead of an ohmmeter to

the switch terminal for the gray (GY) wire and the

negative lead to an engine ground. With the engine

Fig. 3 Mechanical Cluster Connectors

8E - 24 INSTRUMENT PANEL AND GAUGES Ä

Page 530 of 2438

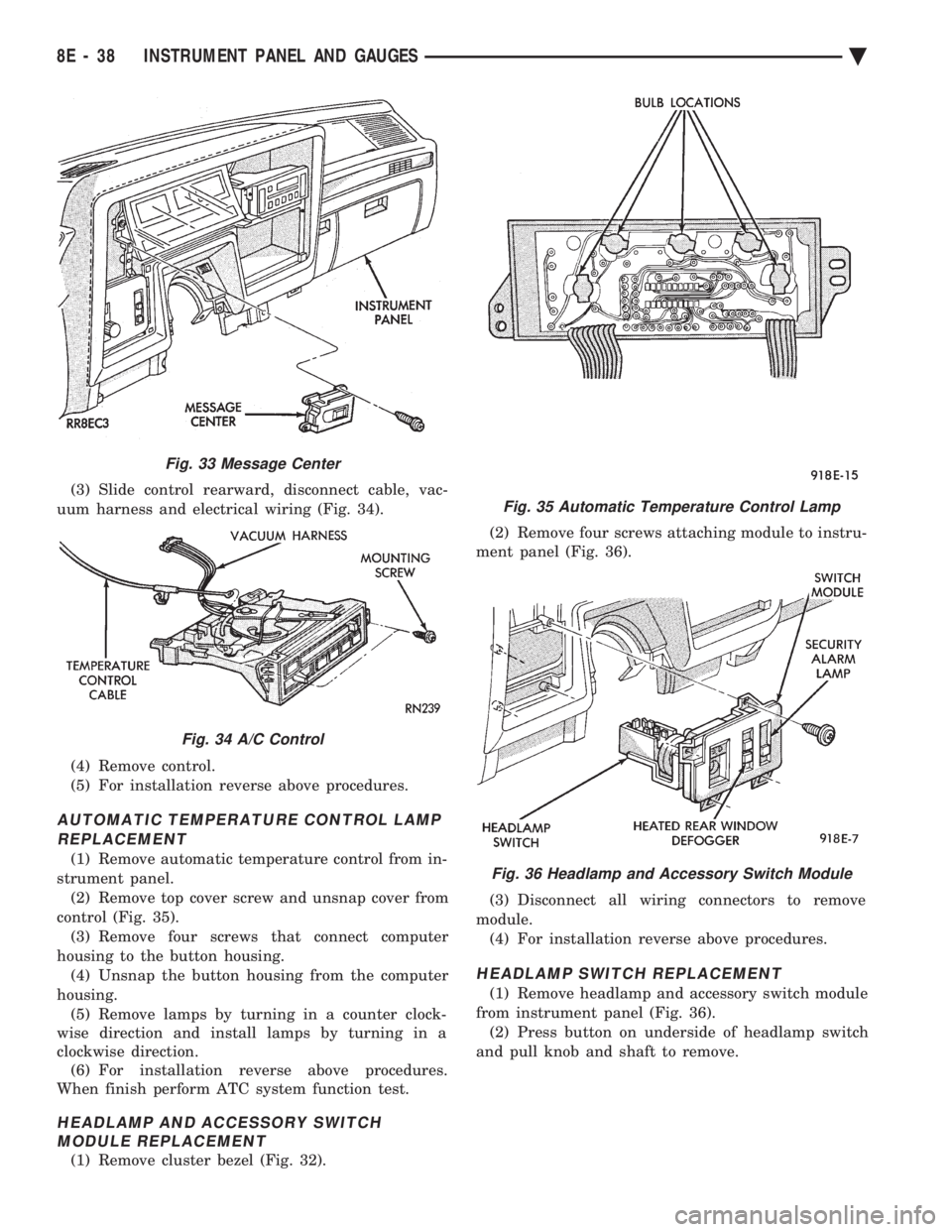

(3) Slide control rearward, disconnect cable, vac-

uum harness and electrical wiring (Fig. 34).

(4) Remove control.

(5) For installation reverse above procedures.

AUTOMATIC TEMPERATURE CONTROL LAMP REPLACEMENT

(1) Remove automatic temperature control from in-

strument panel. (2) Remove top cover screw and unsnap cover from

control (Fig. 35). (3) Remove four screws that connect computer

housing to the button housing. (4) Unsnap the button housing from the computer

housing. (5) Remove lamps by turning in a counter clock-

wise direction and install lamps by turning in a

clockwise direction. (6) For installation reverse above procedures.

When finish perform ATC system function test.

HEADLAMP AND ACCESSORY SWITCH MODULE REPLACEMENT

(1) Remove cluster bezel (Fig. 32). (2) Remove four screws attaching module to instru-

ment panel (Fig. 36).

(3) Disconnect all wiring connectors to remove

module. (4) For installation reverse above procedures.

HEADLAMP SWITCH REPLACEMENT

(1) Remove headlamp and accessory switch module

from instrument panel (Fig. 36). (2) Press button on underside of headlamp switch

and pull knob and shaft to remove.

Fig. 33 Message Center

Fig. 34 A/C Control

Fig. 35 Automatic Temperature Control Lamp

Fig. 36 Headlamp and Accessory Switch Module

8E - 38 INSTRUMENT PANEL AND GAUGES Ä

Page 535 of 2438

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position. When the ignition switch is in the ON or OFF po-

sition, or when the radio frequency is being dis-

played, time keeping is accurately maintained. The procedure for setting the clock varies slightly

with each radio. The correct procedure is described

under the individual radio operating instructions re-

ferred to in the Owner's manual supplied with the

vehicle.

WARNING LAMPS

The AG & AJ Body instrument clusters have warn-

ing lamps or indicators with the electronic cluster for

six different systems. These include low oil pressure,

check gauges, brake system, air bag, seat belt, mal-

function indicator (check engine) lamp.

CLUSTER AND GAUGE SERVICE AND TESTING

CAUTION: Disconnect negative battery cable, in en-

gine compartment, before servicing instrument

panel. When power is required for test purposes,

reconnect battery cable for test only. Disconnect negative battery cable after test and be-

fore continuing service procedures. It is not necessary to remove instrument cluster

from vehicle for gauge replacement. Gauges must be pulled straight out, when remov-

ing or pins may be damaged.

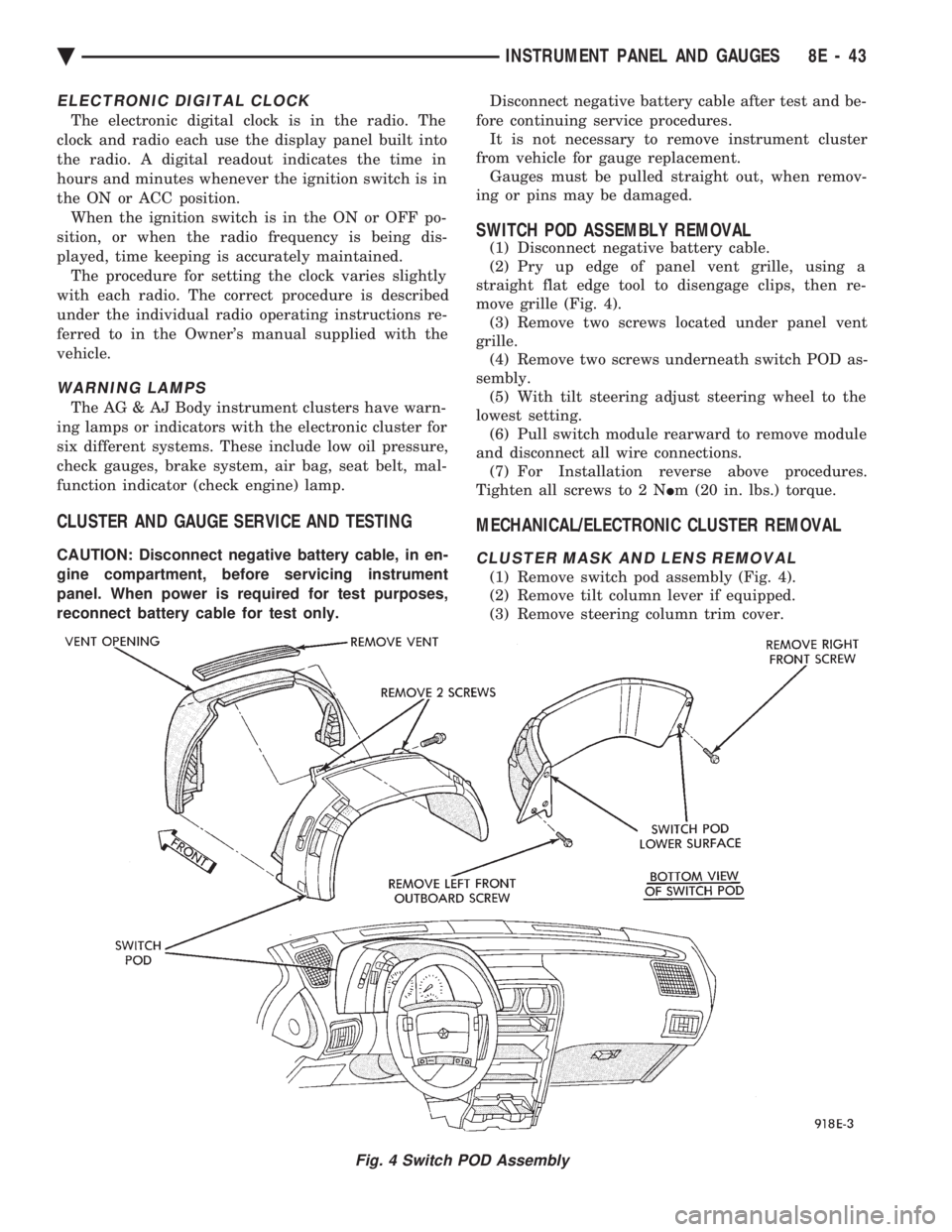

SWITCH POD ASSEMBLY REMOVAL

(1) Disconnect negative battery cable.

(2) Pry up edge of panel vent grille, using a

straight flat edge tool to disengage clips, then re-

move grille (Fig. 4). (3) Remove two screws located under panel vent

grille. (4) Remove two screws underneath switch POD as-

sembly. (5) With tilt steering adjust steering wheel to the

lowest setting. (6) Pull switch module rearward to remove module

and disconnect all wire connections. (7) For Installation reverse above procedures.

Tighten all screws to 2 N Im (20 in. lbs.) torque.

MECHANICAL/ELECTRONIC CLUSTER REMOVAL

CLUSTER MASK AND LENS REMOVAL

(1) Remove switch pod assembly (Fig. 4).

(2) Remove tilt column lever if equipped.

(3) Remove steering column trim cover.

Fig. 4 Switch POD Assembly

Ä INSTRUMENT PANEL AND GAUGES 8E - 43

Page 547 of 2438

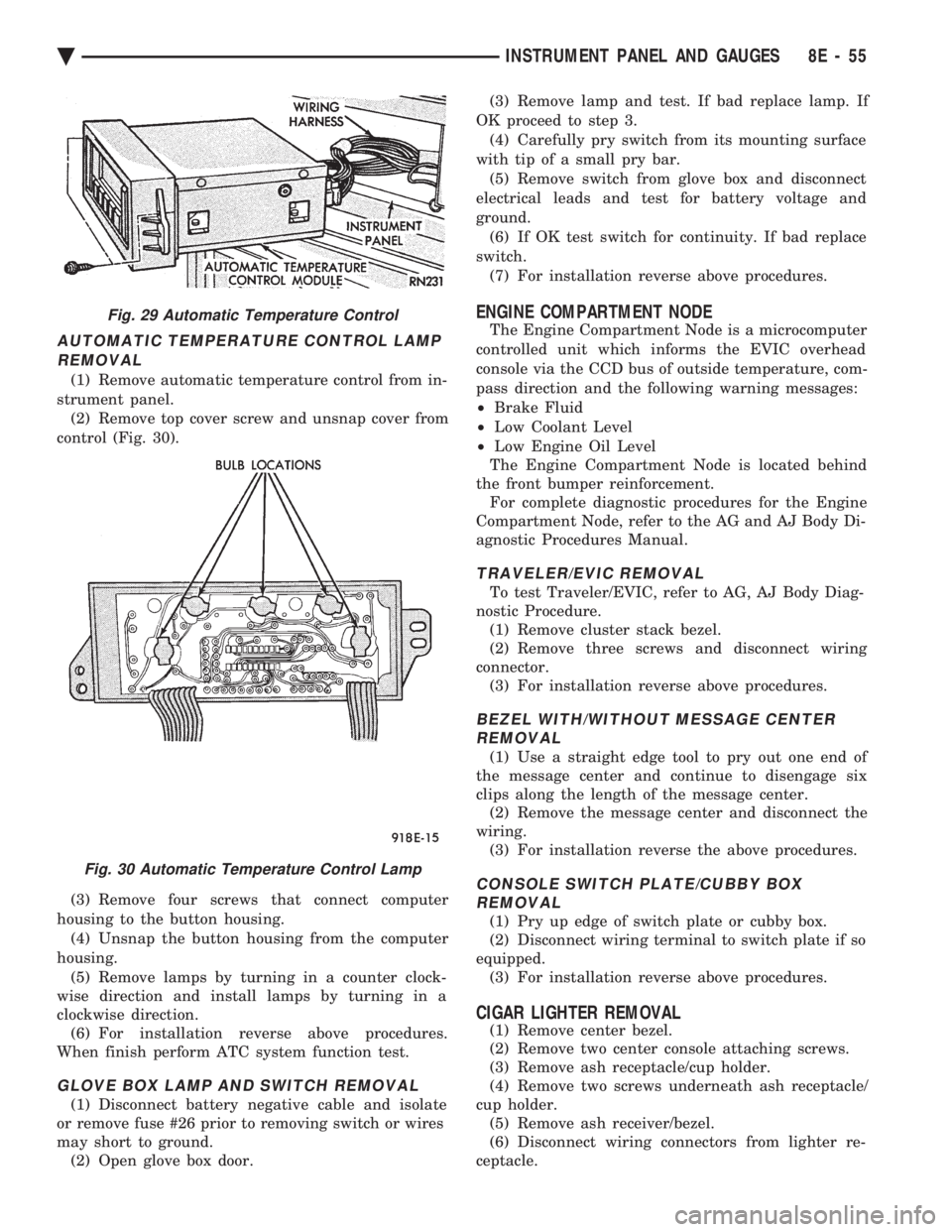

AUTOMATIC TEMPERATURE CONTROL LAMP REMOVAL

(1) Remove automatic temperature control from in-

strument panel. (2) Remove top cover screw and unsnap cover from

control (Fig. 30).

(3) Remove four screws that connect computer

housing to the button housing. (4) Unsnap the button housing from the computer

housing. (5) Remove lamps by turning in a counter clock-

wise direction and install lamps by turning in a

clockwise direction. (6) For installation reverse above procedures.

When finish perform ATC system function test.

GLOVE BOX LAMP AND SWITCH REMOVAL

(1) Disconnect battery negative cable and isolate

or remove fuse #26 prior to removing switch or wires

may short to ground. (2) Open glove box door. (3) Remove lamp and test. If bad replace lamp. If

OK proceed to step 3. (4) Carefully pry switch from its mounting surface

with tip of a small pry bar. (5) Remove switch from glove box and disconnect

electrical leads and test for battery voltage and

ground. (6) If OK test switch for continuity. If bad replace

switch. (7) For installation reverse above procedures.

ENGINE COMPARTMENT NODE

The Engine Compartment Node is a microcomputer

controlled unit which informs the EVIC overhead

console via the CCD bus of outside temperature, com-

pass direction and the following warning messages:

² Brake Fluid

² Low Coolant Level

² Low Engine Oil Level

The Engine Compartment Node is located behind

the front bumper reinforcement. For complete diagnostic procedures for the Engine

Compartment Node, refer to the AG and AJ Body Di-

agnostic Procedures Manual.

TRAVELER/EVIC REMOVAL

To test Traveler/EVIC, refer to AG, AJ Body Diag-

nostic Procedure. (1) Remove cluster stack bezel.

(2) Remove three screws and disconnect wiring

connector. (3) For installation reverse above procedures.

BEZEL WITH/WITHOUT MESSAGE CENTERREMOVAL

(1) Use a straight edge tool to pry out one end of

the message center and continue to disengage six

clips along the length of the message center. (2) Remove the message center and disconnect the

wiring. (3) For installation reverse the above procedures.

CONSOLE SWITCH PLATE/CUBBY BOXREMOVAL

(1) Pry up edge of switch plate or cubby box.

(2) Disconnect wiring terminal to switch plate if so

equipped. (3) For installation reverse above procedures.

CIGAR LIGHTER REMOVAL

(1) Remove center bezel.

(2) Remove two center console attaching screws.

(3) Remove ash receptacle/cup holder.

(4) Remove two screws underneath ash receptacle/

cup holder. (5) Remove ash receiver/bezel.

(6) Disconnect wiring connectors from lighter re-

ceptacle.

Fig. 29 Automatic Temperature Control

Fig. 30 Automatic Temperature Control Lamp

Ä INSTRUMENT PANEL AND GAUGES 8E - 55

Page 550 of 2438

AP BODY INDEX

page page

Cluster and Gauge Service and Testing ....... 58

Gauges ................................ 61

General Information ....................... 58 Instrument Panel Replacement

.............. 72

Interior Lamp Replacement ................. 73

Switch and Panel Component Service ......... 67

GENERAL INFORMATION

INSTRUMENT CLUSTER

There are two conventional instrument cluster as-

semblies available. The clusters incorporates mag-

netic type gauges and an electronically driven

speedometer and odometer assembly (Fig. 1 and 2).

MAGNETIC GAUGES

All gauges on the AP Body clusters are the mag-

netic type gauges. When the ignition switch is in the

OFF position each gauge, except for the voltmeter

and tachometer will show a reading. However, the

readings are only accurate when the ignition switch

is in the ON position.

TACHOMETER DRIVE MODULE

The tachometer drive module is an electronic mod-

ule used to drive the magnetic tachometer in the

high line cluster. This module is located on top of the instrument

cluster.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position. When the ignition switch is in the OFF position, or

when the radio frequency is being displayed, time

keeping is accurately maintained. The procedure for setting the clock varies slightly

with each radio. The correct procedure is described

under the individual radio operating instructions re-

fer to the Sound Systems Manual supplied with the

vehicle.

WARNING LAMPS AND INDICATOR LIGHTS

The instrument cluster has warning and indicators

lamps for eight different systems:

² Low oil pressure

² Brake warning

² Seat belt warning

² Malfunction indicator (check engine) lamp

² Air Bag

² High beam indicator

² Right and left turn signals.

² Anti-lock (ABS)

CLUSTER AND GAUGE SERVICE AND TESTING

CAUTION: Disconnect the negative battery cable

before servicing the instrument panel. When power

is required for test purposes, reconnect battery ca-

ble for test only. Disconnect the negative battery

cable after test and before continuing service pro-

cedures.

SENDING UNIT TEST

Check for a defective sending unit or wiring, when

a problem occurs with a cluster gauge. Do this before

disassembling the cluster. (1) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (2) With the ignition in the ON position, a

grounded input will cause the fuel or temperature

gauge to read at or above maximum.

Fig. 1 Instrument Cluster With Tachometer

Fig. 2 Instrument Cluster Without Tachometer

8E - 58 INSTRUMENT PANEL AND GAUGES Ä