fuel type CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 515 of 2438

AC AND AY BODIES INDEX

page page

Electronic Cluster ........................ 34

Gauges ................................ 28

General Information ....................... 23

Interior Lamp Replacement ................. 41 Mechanical Cluster and Gauge Service

........ 24

Mechanical/Electronic Cluster Removal ........ 25

Switch and Panel Component Service ......... 37

GENERAL INFORMATION

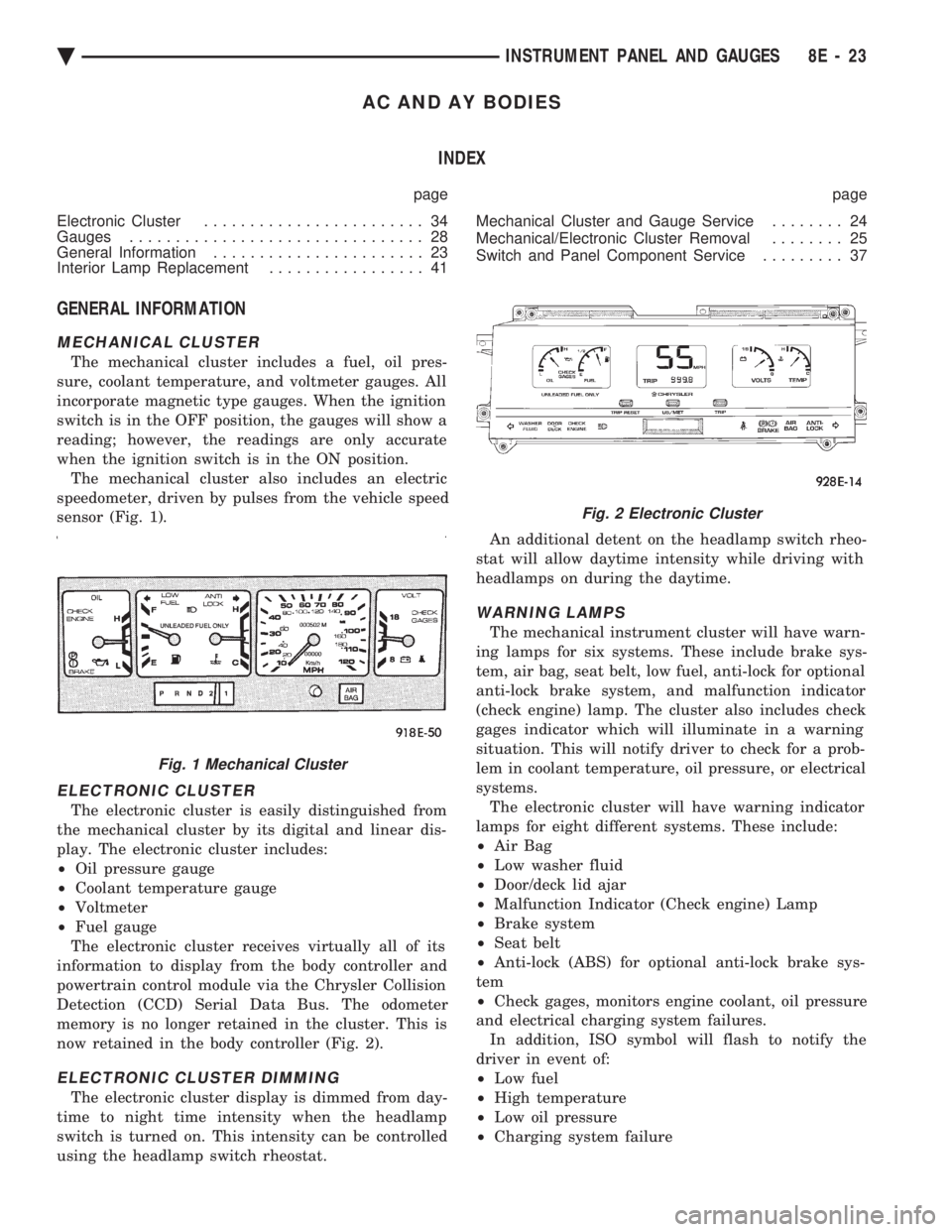

MECHANICAL CLUSTER

The mechanical cluster includes a fuel, oil pres-

sure, coolant temperature, and voltmeter gauges. All

incorporate magnetic type gauges. When the ignition

switch is in the OFF position, the gauges will show a

reading; however, the readings are only accurate

when the ignition switch is in the ON position. The mechanical cluster also includes an electric

speedometer, driven by pulses from the vehicle speed

sensor (Fig. 1).

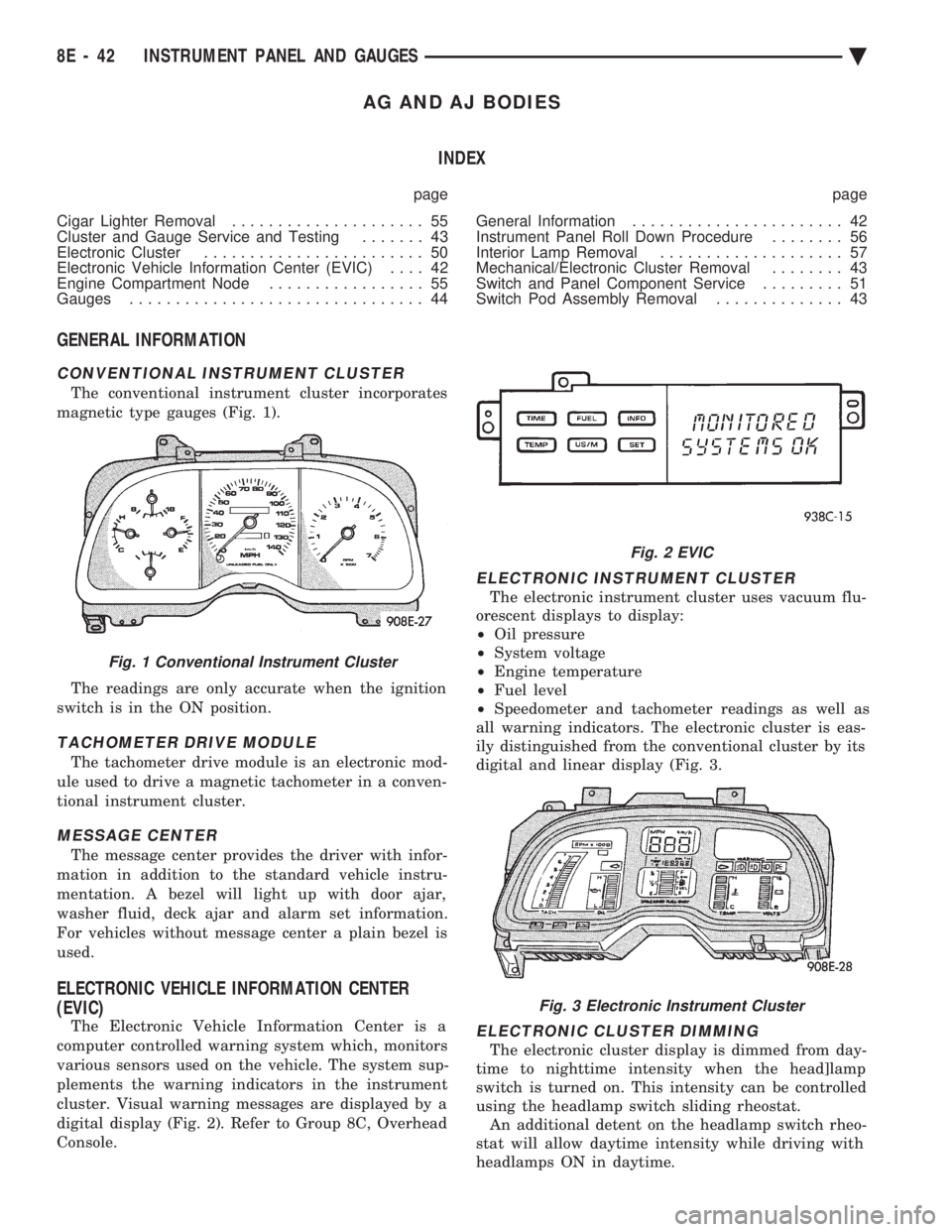

ELECTRONIC CLUSTER

The electronic cluster is easily distinguished from

the mechanical cluster by its digital and linear dis-

play. The electronic cluster includes:

² Oil pressure gauge

² Coolant temperature gauge

² Voltmeter

² Fuel gauge

The electronic cluster receives virtually all of its

information to display from the body controller and

powertrain control module via the Chrysler Collision

Detection (CCD) Serial Data Bus. The odometer

memory is no longer retained in the cluster. This is

now retained in the body controller (Fig. 2).

ELECTRONIC CLUSTER DIMMING

The electronic cluster display is dimmed from day-

time to night time intensity when the headlamp

switch is turned on. This intensity can be controlled

using the headlamp switch rheostat. An additional detent on the headlamp switch rheo-

stat will allow daytime intensity while driving with

headlamps on during the daytime.

WARNING LAMPS

The mechanical instrument cluster will have warn-

ing lamps for six systems. These include brake sys-

tem, air bag, seat belt, low fuel, anti-lock for optional

anti-lock brake system, and malfunction indicator

(check engine) lamp. The cluster also includes check

gages indicator which will illuminate in a warning

situation. This will notify driver to check for a prob-

lem in coolant temperature, oil pressure, or electrical

systems. The electronic cluster will have warning indicator

lamps for eight different systems. These include:

² Air Bag

² Low washer fluid

² Door/deck lid ajar

² Malfunction Indicator (Check engine) Lamp

² Brake system

² Seat belt

² Anti-lock (ABS) for optional anti-lock brake sys-

tem

² Check gages, monitors engine coolant, oil pressure

and electrical charging system failures. In addition, ISO symbol will flash to notify the

driver in event of:

² Low fuel

² High temperature

² Low oil pressure

² Charging system failure

Fig. 1 Mechanical Cluster

Fig. 2 Electronic Cluster

Ä INSTRUMENT PANEL AND GAUGES 8E - 23

Page 534 of 2438

AG AND AJ BODIES INDEX

page page

Cigar Lighter Removal ..................... 55

Cluster and Gauge Service and Testing ....... 43

Electronic Cluster ........................ 50

Electronic Vehicle Information Center (EVIC) .... 42

Engine Compartment Node ................. 55

Gauges ................................ 44 General Information

....................... 42

Instrument Panel Roll Down Procedure ........ 56

Interior Lamp Removal .................... 57

Mechanical/Electronic Cluster Removal ........ 43

Switch and Panel Component Service ......... 51

Switch Pod Assembly Removal .............. 43

GENERAL INFORMATION

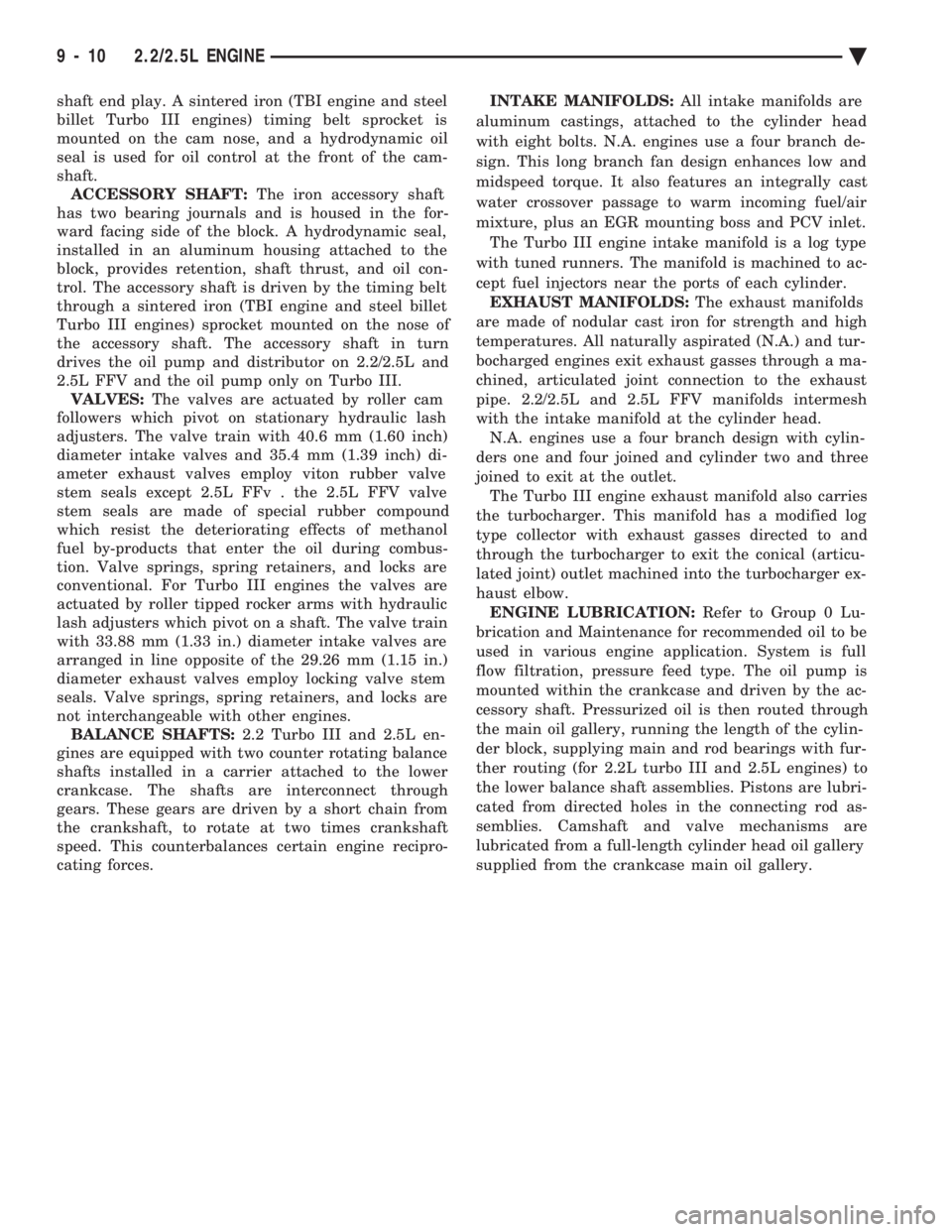

CONVENTIONAL INSTRUMENT CLUSTER

The conventional instrument cluster incorporates

magnetic type gauges (Fig. 1).

The readings are only accurate when the ignition

switch is in the ON position.

TACHOMETER DRIVE MODULE

The tachometer drive module is an electronic mod-

ule used to drive a magnetic tachometer in a conven-

tional instrument cluster.

MESSAGE CENTER

The message center provides the driver with infor-

mation in addition to the standard vehicle instru-

mentation. A bezel will light up with door ajar,

washer fluid, deck ajar and alarm set information.

For vehicles without message center a plain bezel is

used.

ELECTRONIC VEHICLE INFORMATION CENTER

(EVIC)

The Electronic Vehicle Information Center is a

computer controlled warning system which, monitors

various sensors used on the vehicle. The system sup-

plements the warning indicators in the instrument

cluster. Visual warning messages are displayed by a

digital display (Fig. 2). Refer to Group 8C, Overhead

Console.

ELECTRONIC INSTRUMENT CLUSTER

The electronic instrument cluster uses vacuum flu-

orescent displays to display:

² Oil pressure

² System voltage

² Engine temperature

² Fuel level

² Speedometer and tachometer readings as well as

all warning indicators. The electronic cluster is eas-

ily distinguished from the conventional cluster by its

digital and linear display (Fig. 3.

ELECTRONIC CLUSTER DIMMING

The electronic cluster display is dimmed from day-

time to nighttime intensity when the head]lamp

switch is turned on. This intensity can be controlled

using the headlamp switch sliding rheostat. An additional detent on the headlamp switch rheo-

stat will allow daytime intensity while driving with

headlamps ON in daytime.

Fig. 1 Conventional Instrument Cluster

Fig. 2 EVIC

Fig. 3 Electronic Instrument Cluster

8E - 42 INSTRUMENT PANEL AND GAUGES Ä

Page 550 of 2438

AP BODY INDEX

page page

Cluster and Gauge Service and Testing ....... 58

Gauges ................................ 61

General Information ....................... 58 Instrument Panel Replacement

.............. 72

Interior Lamp Replacement ................. 73

Switch and Panel Component Service ......... 67

GENERAL INFORMATION

INSTRUMENT CLUSTER

There are two conventional instrument cluster as-

semblies available. The clusters incorporates mag-

netic type gauges and an electronically driven

speedometer and odometer assembly (Fig. 1 and 2).

MAGNETIC GAUGES

All gauges on the AP Body clusters are the mag-

netic type gauges. When the ignition switch is in the

OFF position each gauge, except for the voltmeter

and tachometer will show a reading. However, the

readings are only accurate when the ignition switch

is in the ON position.

TACHOMETER DRIVE MODULE

The tachometer drive module is an electronic mod-

ule used to drive the magnetic tachometer in the

high line cluster. This module is located on top of the instrument

cluster.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position. When the ignition switch is in the OFF position, or

when the radio frequency is being displayed, time

keeping is accurately maintained. The procedure for setting the clock varies slightly

with each radio. The correct procedure is described

under the individual radio operating instructions re-

fer to the Sound Systems Manual supplied with the

vehicle.

WARNING LAMPS AND INDICATOR LIGHTS

The instrument cluster has warning and indicators

lamps for eight different systems:

² Low oil pressure

² Brake warning

² Seat belt warning

² Malfunction indicator (check engine) lamp

² Air Bag

² High beam indicator

² Right and left turn signals.

² Anti-lock (ABS)

CLUSTER AND GAUGE SERVICE AND TESTING

CAUTION: Disconnect the negative battery cable

before servicing the instrument panel. When power

is required for test purposes, reconnect battery ca-

ble for test only. Disconnect the negative battery

cable after test and before continuing service pro-

cedures.

SENDING UNIT TEST

Check for a defective sending unit or wiring, when

a problem occurs with a cluster gauge. Do this before

disassembling the cluster. (1) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (2) With the ignition in the ON position, a

grounded input will cause the fuel or temperature

gauge to read at or above maximum.

Fig. 1 Instrument Cluster With Tachometer

Fig. 2 Instrument Cluster Without Tachometer

8E - 58 INSTRUMENT PANEL AND GAUGES Ä

Page 1575 of 2438

Flexible fuel vehicles can operate on a mixture of

up to 85 percent methanol, 15 percent unleaded gas-

oline. These vehicles also operate on mixtures con-

taining a lower percentage of methanol or just pure

unleaded gasoline. Engine components which are required for safe op-

eration using fuel containing methanol alcohol are

identified by a standard green color and/or display

the statement methanol compatible imprinted on the

component. To ensure continued safe operation, these

components must be serviced only with genuine MO-

PAR replacement parts. Methanol compatible parts for the 2.5L FFV (Flex-

ible Fuel Vehicle) engine include, but are not limited

to; the valve stem oil seals, all piston rings, the oil

fill cap, the fuel injectors, fuel rail, fuel pressure reg-

ulator, hoses and the vacuum control harness hose. BLOCK: All four cylinder cast iron blocks have

cast-in recesses in the bottom of each cylinder bore to

provide connecting rod clearance; especially needed

for 2.5L engines. The bores are also siamese to min-

imize engine length. A coolant passage is drilled

cross-ways through the siamese section to enhance

between the bore cooling on some engine types. A

partial open deck is used for cooling and weight re-

duction with oil filter, water pump, and distributor

mounting bosses molded into the front (radiator side)

of the block. Nominal wall thickness is 4.5 mm. Five

main bearing bulkheads and a block skirt extending

3 mm below the crankshaft center line add to the

blocks high rigidity with light weight. CRANKSHAFT: A nodular cast iron crankshaft is

used in TBI engines. A forged steel crankshaft is

used in the Turbo III engine. All engines have 5 main bearings, with number 3 flanged to control

thrust. The 60 mm diameter main and 50 mm diam-

eter crank pin journals (all) have undercut radiuses

fillets that are deep rolled for added strength. To op-

timize bearing loading 4 counterweights are used.

Hydrodynamic seals (installed in diecast aluminum

retainers) provide end sealing, where the crankshaft

exits the block. Anaerobic gasket material is used for

retainer-to-block sealing. No vibration damper is

used. A sintered iron (TBI engine and steel billet

Turbo III engines) timing belt sprocket is mounted

on the crankshaft nose. This sprocket provides mo-

tive power; via timing belt to the camshaft and inter-

mediate shaft sprockets (also sintered iron (TBI

engine and steel billet Turbo III engines) providing

timed valve, distributor, and oil pump actuation. PISTONS: Some Chrysler pistons have cast-in

steel struts at the pin bosses for autothermic control.

All 2.2L and 2.5L piston tops have cuts to provide

valve clearance. Some pistons are dished to provide

various compression ratios. Standard 2.2L and 2.5L

engines are designed for 9.5:1 and 8.9:1 compression

ratios respectively. The 2.5L piston is dished and is a

lightweight design to enhance engine smoothness.

The 2.2L turbo III uses dished pistons providing a

8.3:1 compression ratio. All standard 2.2/2.5L and

2.5L FFV engines use pressed-in piston pins to at-

tach forged steel connecting rods, 2.2L turbo III en-

gine uses a full floating piston pin and connecting

rod assembly. PISTONS RINGS: The 2.2/2.5L engines share

common piston rings throughout, including molybde-

num filled top ring for reliable compression sealing

and a tapered faced intermediate ring for additional

cylinder pressure control. The 2.5L FFV engine fea-

ture all chrome rings for enhanced long term dura-

bility under multi-fueled conditions. CYLINDER HEAD: The cylinder head is cast alu-

minum with in-line valves. The 2.2/2.5L and 2.5L

FFV valves are arranged with alternating exhaust

and intake. The intake and exhaust ports are located

in the rearward, facing side of the head. The Turbo

III valves are arranged in two inline banks, with the

ports of the bank of two intake valves per cylinder

facing toward the radiator side of engine and ports of

the bank of two exhaust valve per cylinder facing to-

ward the dash panel. The intake ports feed fast-burn

design combustion chambers (2.2/2.5L and 2.5L FFV

only) with the spark plug located close to the center

line of the combustion chamber for optimum effi-

ciency. An integral oil gallery within the cylinder

head supplies oil to the hydraulic lash adjusters,

camshaft, and valve mechanisms. CAMSHAFT: The nodular iron camshaft has five

bearing journals (2.2/2.5L and 2.5L FFV). The Turbo

III employs dual camshafts that have nine bearing

journals. Flanges at the rear journal control cam-

Fig. 1 Engine Identification

Ä 2.2/2.5L ENGINE 9 - 9

Page 1576 of 2438

shaft end play. A sintered iron (TBI engine and steel

billet Turbo III engines) timing belt sprocket is

mounted on the cam nose, and a hydrodynamic oil

seal is used for oil control at the front of the cam-

shaft. ACCESSORY SHAFT: The iron accessory shaft

has two bearing journals and is housed in the for-

ward facing side of the block. A hydrodynamic seal,

installed in an aluminum housing attached to the

block, provides retention, shaft thrust, and oil con-

trol. The accessory shaft is driven by the timing belt

through a sintered iron (TBI engine and steel billet

Turbo III engines) sprocket mounted on the nose of

the accessory shaft. The accessory shaft in turn

drives the oil pump and distributor on 2.2/2.5L and

2.5L FFV and the oil pump only on Turbo III. VALVES: The valves are actuated by roller cam

followers which pivot on stationary hydraulic lash

adjusters. The valve train with 40.6 mm (1.60 inch)

diameter intake valves and 35.4 mm (1.39 inch) di-

ameter exhaust valves employ viton rubber valve

stem seals except 2.5L FFv . the 2.5L FFV valve

stem seals are made of special rubber compound

which resist the deteriorating effects of methanol

fuel by-products that enter the oil during combus-

tion. Valve springs, spring retainers, and locks are

conventional. For Turbo III engines the valves are

actuated by roller tipped rocker arms with hydraulic

lash adjusters which pivot on a shaft. The valve train

with 33.88 mm (1.33 in.) diameter intake valves are

arranged in line opposite of the 29.26 mm (1.15 in.)

diameter exhaust valves employ locking valve stem

seals. Valve springs, spring retainers, and locks are

not interchangeable with other engines. BALANCE SHAFTS: 2.2 Turbo III and 2.5L en-

gines are equipped with two counter rotating balance

shafts installed in a carrier attached to the lower

crankcase. The shafts are interconnect through

gears. These gears are driven by a short chain from

the crankshaft, to rotate at two times crankshaft

speed. This counterbalances certain engine recipro-

cating forces. INTAKE MANIFOLDS:

All intake manifolds are

aluminum castings, attached to the cylinder head

with eight bolts. N.A. engines use a four branch de-

sign. This long branch fan design enhances low and

midspeed torque. It also features an integrally cast

water crossover passage to warm incoming fuel/air

mixture, plus an EGR mounting boss and PCV inlet. The Turbo III engine intake manifold is a log type

with tuned runners. The manifold is machined to ac-

cept fuel injectors near the ports of each cylinder. EXHAUST MANIFOLDS: The exhaust manifolds

are made of nodular cast iron for strength and high

temperatures. All naturally aspirated (N.A.) and tur-

bocharged engines exit exhaust gasses through a ma-

chined, articulated joint connection to the exhaust

pipe. 2.2/2.5L and 2.5L FFV manifolds intermesh

with the intake manifold at the cylinder head. N.A. engines use a four branch design with cylin-

ders one and four joined and cylinder two and three

joined to exit at the outlet. The Turbo III engine exhaust manifold also carries

the turbocharger. This manifold has a modified log

type collector with exhaust gasses directed to and

through the turbocharger to exit the conical (articu-

lated joint) outlet machined into the turbocharger ex-

haust elbow. ENGINE LUBRICATION: Refer to Group 0 Lu-

brication and Maintenance for recommended oil to be

used in various engine application. System is full

flow filtration, pressure feed type. The oil pump is

mounted within the crankcase and driven by the ac-

cessory shaft. Pressurized oil is then routed through

the main oil gallery, running the length of the cylin-

der block, supplying main and rod bearings with fur-

ther routing (for 2.2L turbo III and 2.5L engines) to

the lower balance shaft assemblies. Pistons are lubri-

cated from directed holes in the connecting rod as-

semblies. Camshaft and valve mechanisms are

lubricated from a full-length cylinder head oil gallery

supplied from the crankcase main oil gallery.

9 - 10 2.2/2.5L ENGINE Ä

Page 1635 of 2438

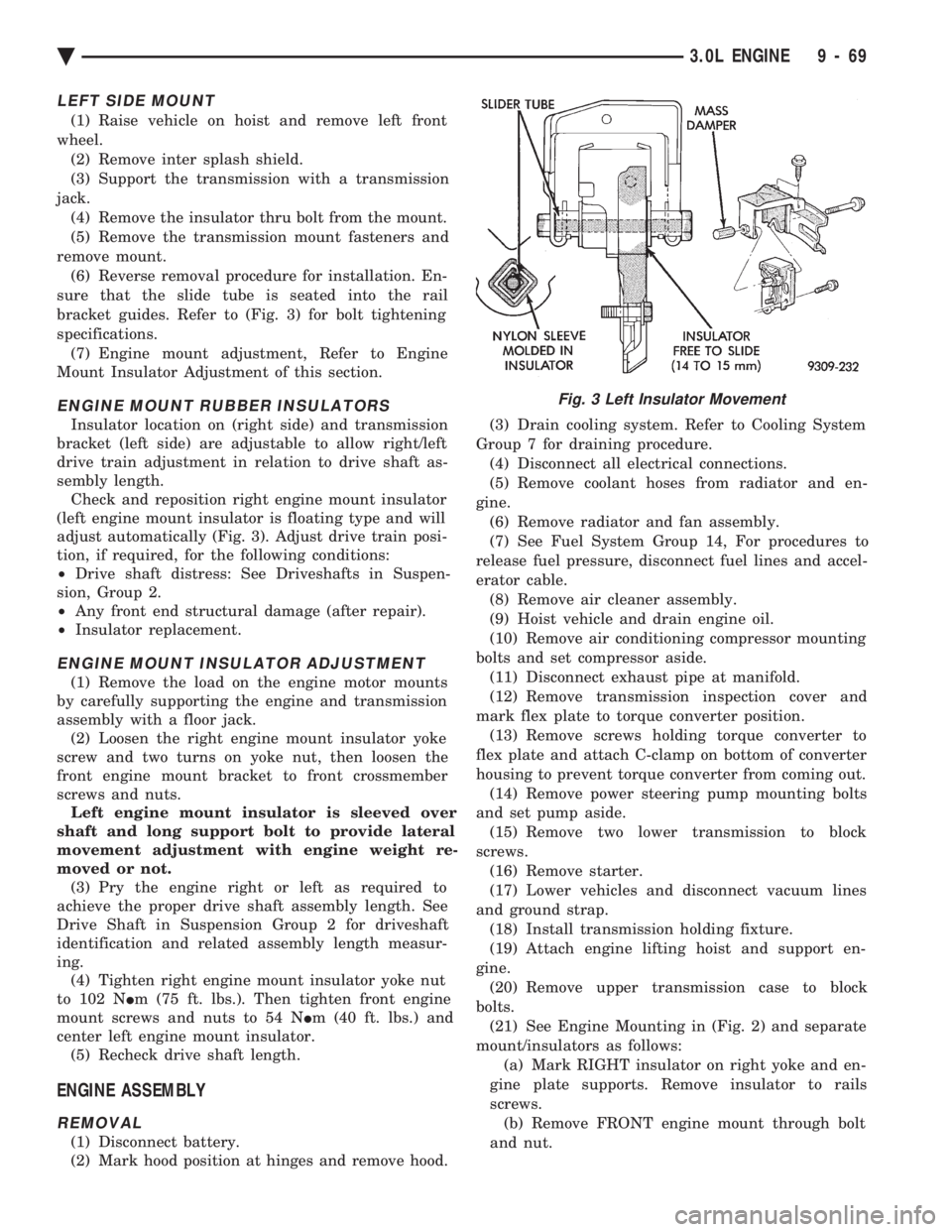

LEFT SIDE MOUNT

(1) Raise vehicle on hoist and remove left front

wheel. (2) Remove inter splash shield.

(3) Support the transmission with a transmission

jack. (4) Remove the insulator thru bolt from the mount.

(5) Remove the transmission mount fasteners and

remove mount. (6) Reverse removal procedure for installation. En-

sure that the slide tube is seated into the rail

bracket guides. Refer to (Fig. 3) for bolt tightening

specifications. (7) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

ENGINE MOUNT RUBBER INSULATORS

Insulator location on (right side) and transmission

bracket (left side) are adjustable to allow right/left

drive train adjustment in relation to drive shaft as-

sembly length. Check and reposition right engine mount insulator

(left engine mount insulator is floating type and will

adjust automatically (Fig. 3). Adjust drive train posi-

tion, if required, for the following conditions:

² Drive shaft distress: See Driveshafts in Suspen-

sion, Group 2.

² Any front end structural damage (after repair).

² Insulator replacement.

ENGINE MOUNT INSULATOR ADJUSTMENT

(1) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack. (2) Loosen the right engine mount insulator yoke

screw and two turns on yoke nut, then loosen the

front engine mount bracket to front crossmember

screws and nuts. Left engine mount insulator is sleeved over

shaft and long support bolt to provide lateral

movement adjustment with engine weight re-

moved or not. (3) Pry the engine right or left as required to

achieve the proper drive shaft assembly length. See

Drive Shaft in Suspension Group 2 for driveshaft

identification and related assembly length measur-

ing. (4) Tighten right engine mount insulator yoke nut

to 102 N Im (75 ft. lbs.). Then tighten front engine

mount screws and nuts to 54 N Im (40 ft. lbs.) and

center left engine mount insulator. (5) Recheck drive shaft length.

ENGINE ASSEMBLY

REMOVAL

(1) Disconnect battery.

(2) Mark hood position at hinges and remove hood. (3) Drain cooling system. Refer to Cooling System

Group 7 for draining procedure. (4) Disconnect all electrical connections.

(5) Remove coolant hoses from radiator and en-

gine. (6) Remove radiator and fan assembly.

(7) See Fuel System Group 14, For procedures to

release fuel pressure, disconnect fuel lines and accel-

erator cable. (8) Remove air cleaner assembly.

(9) Hoist vehicle and drain engine oil.

(10) Remove air conditioning compressor mounting

bolts and set compressor aside. (11) Disconnect exhaust pipe at manifold.

(12) Remove transmission inspection cover and

mark flex plate to torque converter position. (13) Remove screws holding torque converter to

flex plate and attach C-clamp on bottom of converter

housing to prevent torque converter from coming out. (14) Remove power steering pump mounting bolts

and set pump aside. (15) Remove two lower transmission to block

screws. (16) Remove starter.

(17) Lower vehicles and disconnect vacuum lines

and ground strap. (18) Install transmission holding fixture.

(19) Attach engine lifting hoist and support en-

gine. (20) Remove upper transmission case to block

bolts. (21) See Engine Mounting in (Fig. 2) and separate

mount/insulators as follows: (a) Mark RIGHT insulator on right yoke and en-

gine plate supports. Remove insulator to rails

screws. (b) Remove FRONT engine mount through bolt

and nut.

Fig. 3 Left Insulator Movement

Ä 3.0L ENGINE 9 - 69

Page 1742 of 2438

with a minimum octane of 87 may be used. However,

the use of lower octane gasoline will result in re-

duced performance.

FLEXIBLE FUEL AA-BODY VEHICLES

These vehicles will operate on either unleaded gas-

oline with a minimum posted octane of 87 or M85

fuel. M85 fuel is a mixture of 85 percent methanol

and 15 percent unleaded gasoline. The vehicle also

will operate on mixture of M85 and unleaded gaso-

line with a minimum posted octane of 87. Do not

use 100 percent methanol in these vehicles.

THE FOLLOWING IS APPLICABLE TO ALL VEHICLES

Light spark knock at low engine speeds is not

harmful to your engine. However, continued heavy

spark knock at high speeds can cause damage and

should be reported to your dealer immediately. En-

gine damage resulting from operating with a heavy

spark knock may not be covered by the new vehicle

warranty. In addition to using unleaded gasoline with the

proper octane rating, gasolines that contain deter-

gents, corrosion and stability additives are recom-

mended. Using gasolines that have these additives

will help improve fuel economy, reduce emissions,

and maintain vehicle performance. Generally, pre-

mium unleaded gasolines contain more additive than

regular unleaded. Poor quality gasoline can cause problems such as

hard starting, stalling, and stumble. If you experi-

ence these problems, try another brand of gasoline

before considering service for the vehicle.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend gasoline with materials

that contain oxygen such as alcohol, MTBE (Methyl

Tertiary Butyl Ether) and ETBE (Ethyl Tertiary Bu-

tyl Ether). The type and amount of oxygenate used

in the blend is important. The following are generally used in gasoline

blends: Ethanol - (Ethyl or Grain Alcohol) properly blended, is used as a mixture of 10 percent ethanol

and 90 percent gasoline. Gasoline blended with eth-

anol may be used in your vehicle. Methanol - (Methyl or Wood Alcohol) is used in a

variety of concentrations when blended with un-

leaded gasoline. You may find fuels containing 3 per-

cent or more methanol along with other alcohols

called cosolvents. Do not use gasolines containing Methanol.

Use of methanol/gasoline blends may result in

starting and driveability problems and damage criti-

cal fuel system components. Problems that are the result of using methanol/gas-

oline blends are not the responsibility of Chrysler

Motors and may not be covered by the new vehicle

warranty. MTBE/ETBE - Gasoline and MTBE (Methyl Ter-

tiary Butyl Ether) blends are a mixture of unleaded

gasoline blended and up to 15 percent MTBE. Gaso-

line and ETBE (Ethyl Tertiary Butly Ether) are

blends of gasoline and up to 17 percent ETBE. Gas-

oline blended with MTBE or ETBE may be used in

your vehicle. Clean Air Gasoline

Many gasolines are now being blended that con-

tribute to cleaner air, especially in those areas of the

country where pollution levels are high. These new

blends provide a cleaner burning fuel and some are

referred to as reformulated gasoline. In areas of the country where carbon monoxide lev-

els are high, gasolines are being treated with oxy-

genated materials such as ETBE, MTBE and

ethanol. The use of gasoline blended with these ma-

terials also contributes to cleaner air. Chrysler Corporation supports these efforts toward

cleaner air and recommends that you use these gas-

olines as they become available. Materials Added to Fuel

Indiscriminate use of fuel system cleaning agents

should be avoided. Many of these materials intended

for gum and varnish removal may contain active sol-

vents of similar ingredients that can be harmful to

fuel system gasket and diaphragm materials.

14 - 2 FUEL SYSTEMS Ä

Page 1750 of 2438

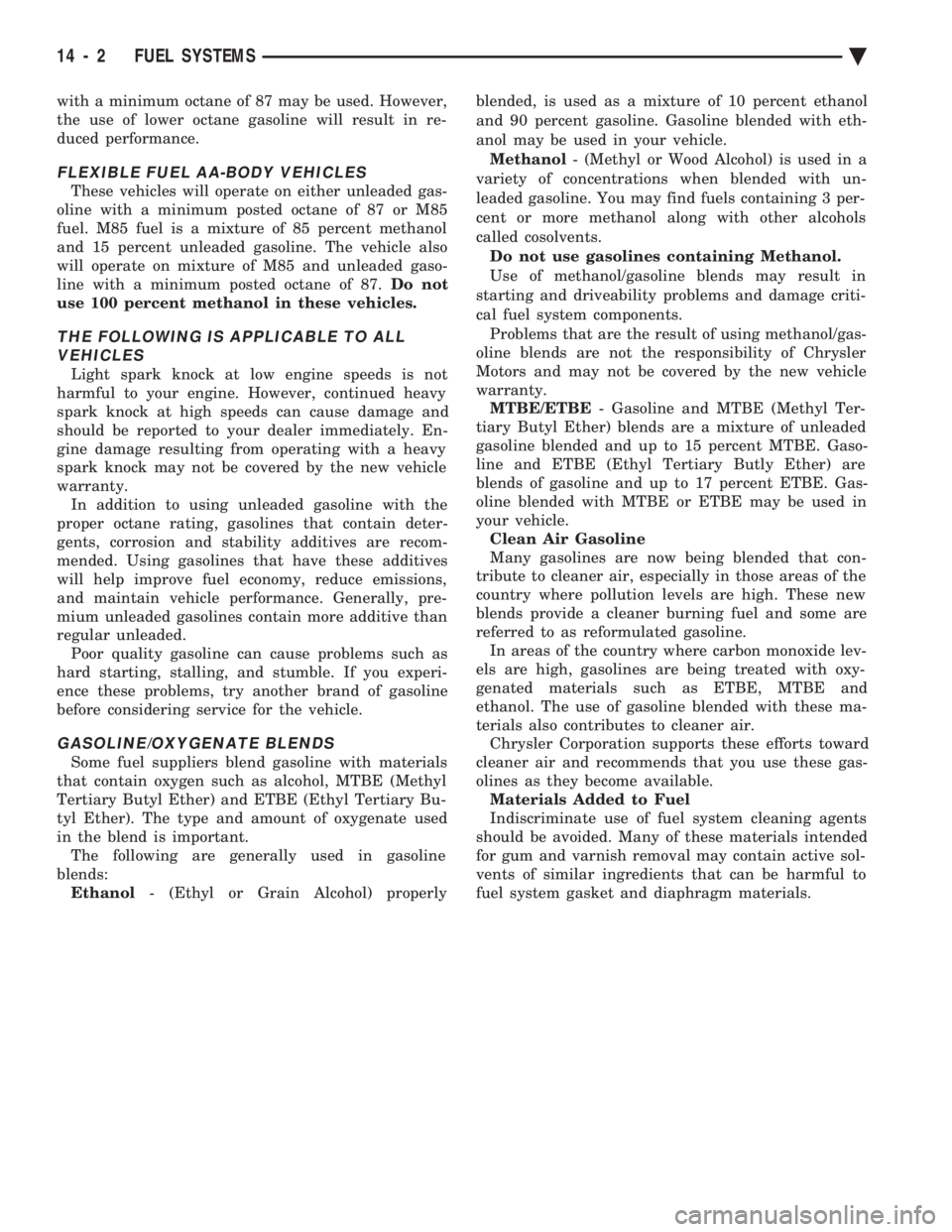

REMOVAL

(1) Perform the Fuel System Pressure Release pro-

cedure. (2) ) Remove the fuel filter retaining screw (Fig.

13). Remove fuel filter from mounting plate.

(3) Wrap a shop towel around hoses to absorb fuel.

Remove quick-connect fittings at filter and fuel supply

tube. Refer to Quick-Connect Fittings in this section.

INSTALLATION

WARNING: FUEL FILTERS DESIGNED FOR GASO-

LINE ONLY VEHICLES CANNOT BE USED ON

FLEXIBLE FUEL AA-BODY VEHICLES. WHEN SER-

VICING THE FUEL SYSTEM OF A FLEXIBLE FUEL

VEHICLE, ONLY USE ORIGINAL EQUIPMENT OR

EQUIVALENT REPLACEMENT COMPONENTS.

(1) Connect quick-connect fuel fittings to the filter

and fuel supply line. Refer to Quick-Connect Fittings

in this section. (2) Position filter assembly on mounting plate and

tighten mounting screw to 8 N Im (75 in. lbs.) torque.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(3) Place the ignition key in the ON position. Us-

ing the DRBII scan tool, access ASD Fuel System

Test. The ASD Fuel System Test will activate the

fuel pump and pressurize the system. Inspect for

leaks.

FUEL HOSES, CLAMPS, AND QUICK CONNECT

FITTINGS

HOSES AND CLAMPS

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS. WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

WARNING: FUEL SYSTEM HOSES AND TUBES DE-

SIGNED FOR GASOLINE ONLY VEHICLES CANNOT

BE USED ON FLEXIBLE FUEL VEHICLES. WHEN

SERVICING THE FUEL SYSTEM OF A FLEXIBLE

FUEL VEHICLE, ONLY USE ORIGINAL EQUIPMENT

OR EQUIVALENT REPLACEMENT COMPONENTS.

Inspect all hose connections (clamps and quick con-

nect fittings) for completeness and make sure they

are not leaking. Hoses that are cracked, scuffed,

swelled, rub against other vehicle components or

show any sign of wear, should be replaced.

When installing hoses, route them away from compo-

nents they could rub against. Avoid contact with clamps

or other components that cause abrasions or scuffing.

Ensure rubber hoses are properly routed and avoid heat

sources. The clamps have rolled edge to prevent the clamp

from cutting into the hose. Only use clamps that are

original equipment or equivalent. Other types of clamps

may cut into the hoses and cause high pressure fuel

leaks. Tighten hose clamps to 1 N Im (10 in. lbs.) torque.

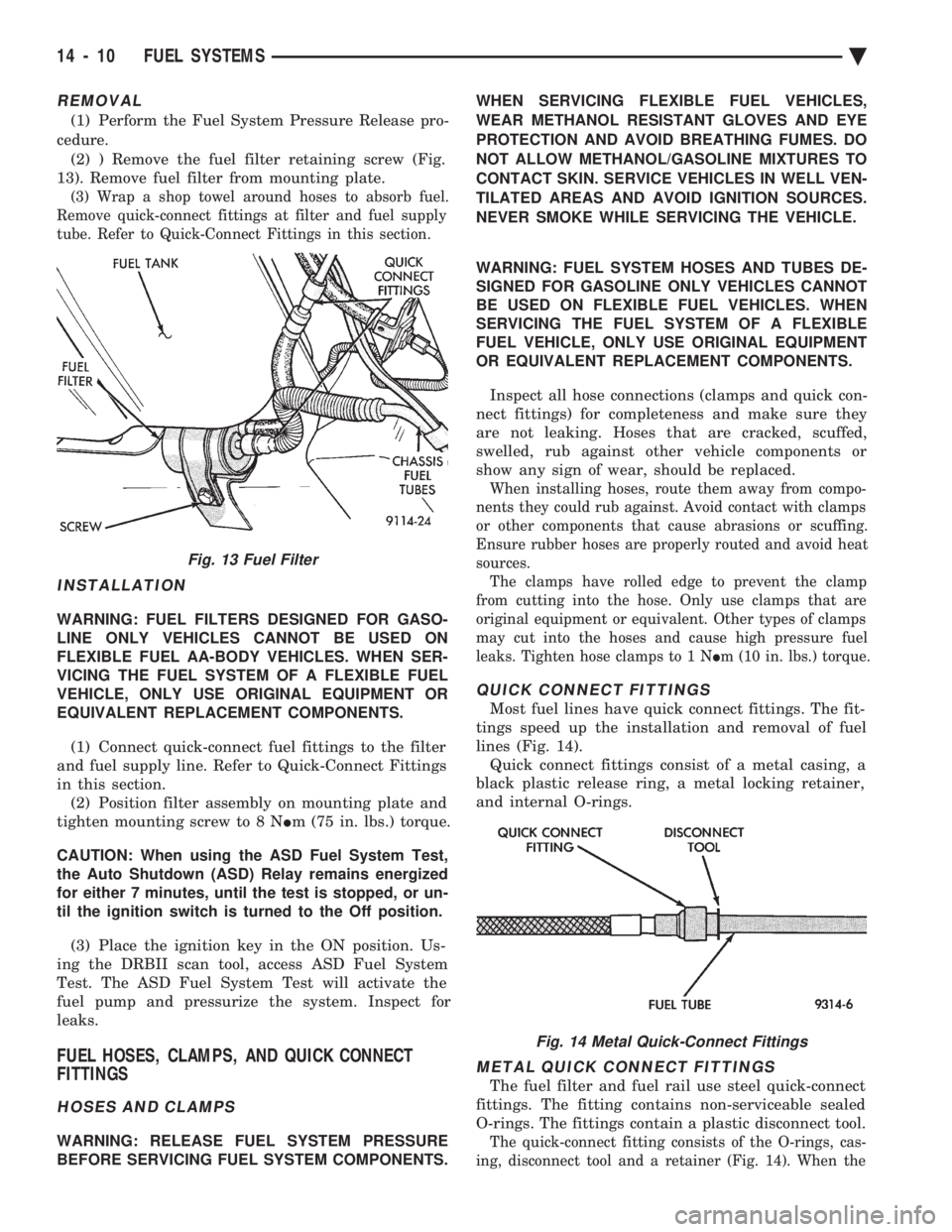

QUICK CONNECT FITTINGS

Most fuel lines have quick connect fittings. The fit-

tings speed up the installation and removal of fuel

lines (Fig. 14). Quick connect fittings consist of a metal casing, a

black plastic release ring, a metal locking retainer,

and internal O-rings.

METAL QUICK CONNECT FITTINGS

The fuel filter and fuel rail use steel quick-connect

fittings. The fitting contains non-serviceable sealed

O-rings. The fittings contain a plastic disconnect tool.

The quick-connect fitting consists of the O-rings, cas-

ing, disconnect tool and a retainer (Fig. 14). When the

Fig. 13 Fuel Filter

Fig. 14 Metal Quick-Connect Fittings

14 - 10 FUEL SYSTEMS Ä

Page 1751 of 2438

fuel tube enters the fitting, the retainer locks the shoul-

der of the nipple in place and the O-rings seal the tube.

CAUTION: Quick-connect fittings are not serviced

separately. Do not attempt to repair damaged quick-

connect fittings or fuel tubes. Replace the complete

fuel tube/quick-connect fitting assembly.

When installing fuel tubes, route them in the holders

along the frame rail, fuel tank and the rear of the en-

gine.

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from the battery.

(2) Perform the Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section. (3) Remove any loose dirt from quick connect fit-

tings.

WARNING: WRAP SHOP TOWELS AROUND HOSES

TO CATCH ANY FUEL SPILLAGE.

(4) Push the quick connect fitting toward the fuel

tube while depressing the built-in release tool. Then

slightly twist the fitting and pull it off the fuel tube

(Fig. 14). (5) Cover the fitting to prevent contamination.

TUBE/FITTING SERVICE

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

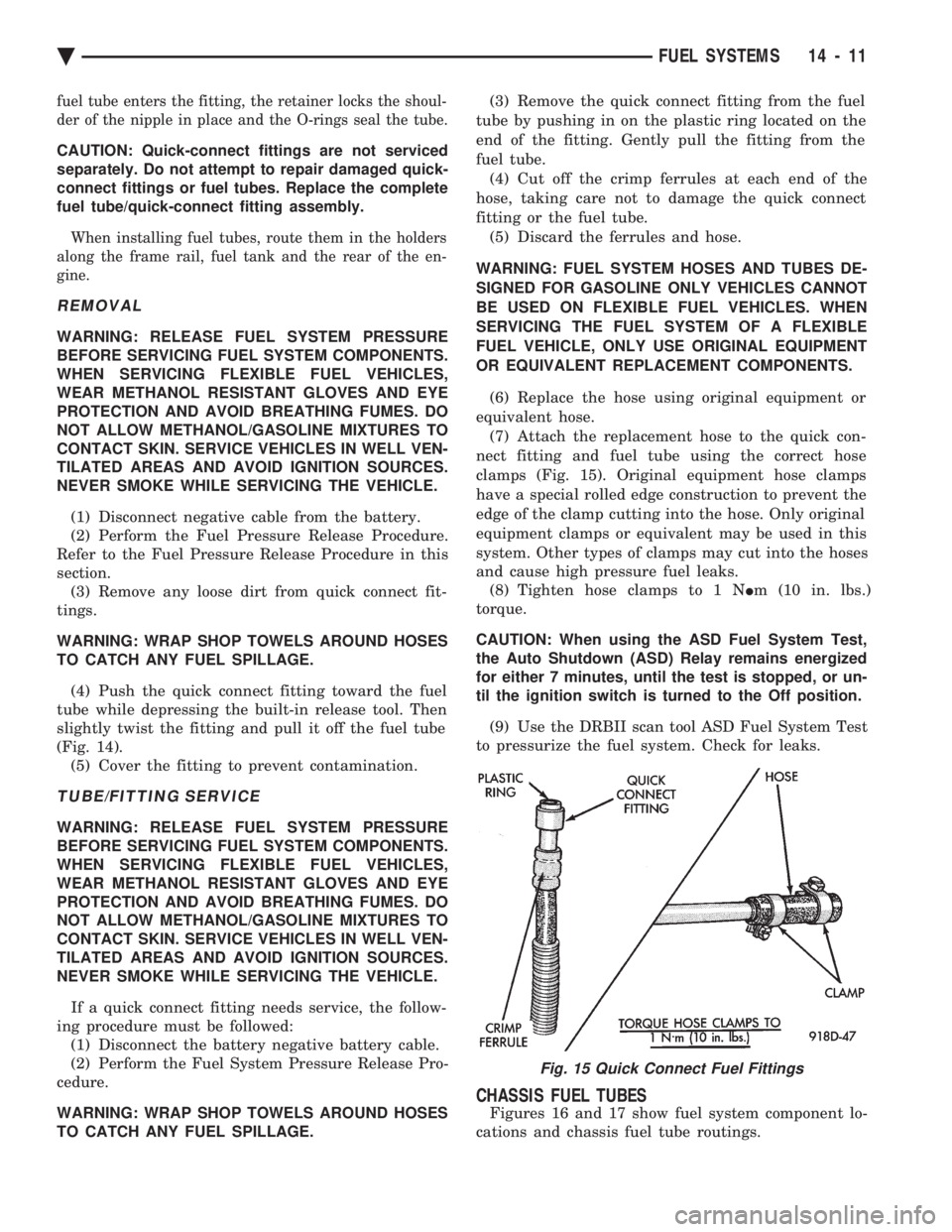

If a quick connect fitting needs service, the follow-

ing procedure must be followed: (1) Disconnect the battery negative battery cable.

(2) Perform the Fuel System Pressure Release Pro-

cedure.

WARNING: WRAP SHOP TOWELS AROUND HOSES

TO CATCH ANY FUEL SPILLAGE. (3) Remove the quick connect fitting from the fuel

tube by pushing in on the plastic ring located on the

end of the fitting. Gently pull the fitting from the

fuel tube. (4) Cut off the crimp ferrules at each end of the

hose, taking care not to damage the quick connect

fitting or the fuel tube. (5) Discard the ferrules and hose.

WARNING: FUEL SYSTEM HOSES AND TUBES DE-

SIGNED FOR GASOLINE ONLY VEHICLES CANNOT

BE USED ON FLEXIBLE FUEL VEHICLES. WHEN

SERVICING THE FUEL SYSTEM OF A FLEXIBLE

FUEL VEHICLE, ONLY USE ORIGINAL EQUIPMENT

OR EQUIVALENT REPLACEMENT COMPONENTS.

(6) Replace the hose using original equipment or

equivalent hose. (7) Attach the replacement hose to the quick con-

nect fitting and fuel tube using the correct hose

clamps (Fig. 15). Original equipment hose clamps

have a special rolled edge construction to prevent the

edge of the clamp cutting into the hose. Only original

equipment clamps or equivalent may be used in this

system. Other types of clamps may cut into the hoses

and cause high pressure fuel leaks. (8) Tighten hose clamps to 1 N Im (10 in. lbs.)

torque.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(9) Use the DRBII scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

CHASSIS FUEL TUBES

Figures 16 and 17 show fuel system component lo-

cations and chassis fuel tube routings.

Fig. 15 Quick Connect Fuel Fittings

Ä FUEL SYSTEMS 14 - 11

Page 1788 of 2438

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐSERVICE PROCEDURES INDEX

page page

Canister Purge Solenoid ................... 53

Electric Exhaust Gas Recirculation Transducer (EET) Service ............................... 53

Fuel Fitting ............................. 50

Fuel Injector ............................ 51

Fuel Lines and Hoses ..................... 48

Fuel Pressure Regulator ................... 51 Fuel System Pressure Release Procedure

...... 48

Heated Oxygen Sensor (O

2Sensor) .......... 54

Idle Air Control Motor ..................... 53

Manifold Absolute Pressure Sensor ........... 53

PCM Service ............................ 54

Throttle Body ............................ 48

Throttle Position Sensor ................... 52

FUEL LINES AND HOSES

Perform the Fuel System Pressure Relief Procedure

before servicing the fuel system. The procedure must

be done to bleed fuel pressure from the system before

removing clamps or hoses. Use care when removing fuel hoses to prevent dam-

age to hose or hose nipple. Always use new hose

clamps, of the correct type, during reassembly. Tighten

hose clamps to 1 N Im (10 in. lbs.) torque. Do not use

aviation style clamps on this system or hose

damage may result.

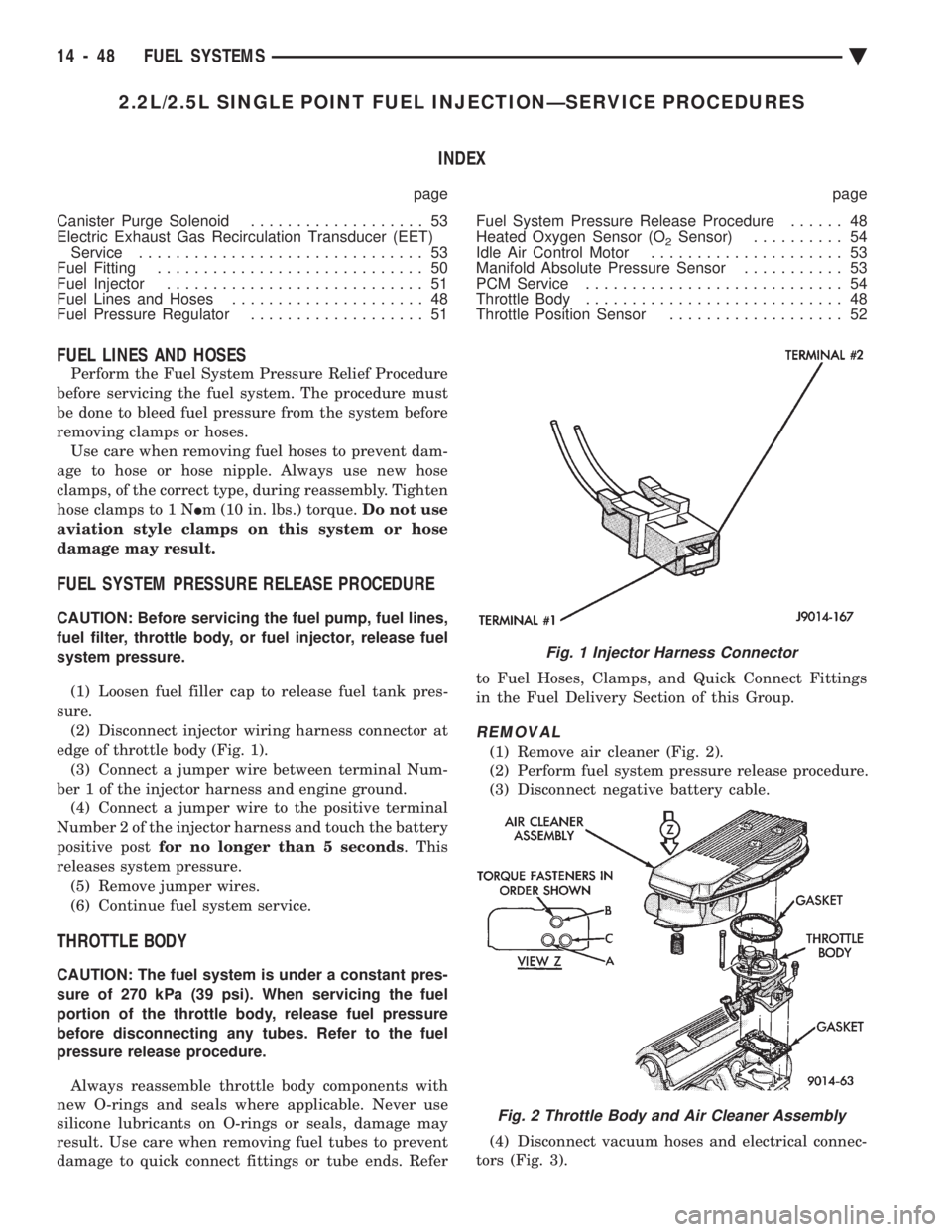

FUEL SYSTEM PRESSURE RELEASE PROCEDURE

CAUTION: Before servicing the fuel pump, fuel lines,

fuel filter, throttle body, or fuel injector, release fuel

system pressure.

(1) Loosen fuel filler cap to release fuel tank pres-

sure. (2) Disconnect injector wiring harness connector at

edge of throttle body (Fig. 1). (3) Connect a jumper wire between terminal Num-

ber 1 of the injector harness and engine ground. (4) Connect a jumper wire to the positive terminal

Number 2 of the injector harness and touch the battery

positive post for no longer than 5 seconds . This

releases system pressure. (5) Remove jumper wires.

(6) Continue fuel system service.

THROTTLE BODY

CAUTION: The fuel system is under a constant pres-

sure of 270 kPa (39 psi). When servicing the fuel

portion of the throttle body, release fuel pressure

before disconnecting any tubes. Refer to the fuel

pressure release procedure.

Always reassemble throttle body components with

new O-rings and seals where applicable. Never use

silicone lubricants on O-rings or seals, damage may

result. Use care when removing fuel tubes to prevent

damage to quick connect fittings or tube ends. Refer to Fuel Hoses, Clamps, and Quick Connect Fittings

in the Fuel Delivery Section of this Group.

REMOVAL

(1) Remove air cleaner (Fig. 2).

(2) Perform fuel system pressure release procedure.

(3) Disconnect negative battery cable.

(4) Disconnect vacuum hoses and electrical connec-

tors (Fig. 3).

Fig. 1 Injector Harness Connector

Fig. 2 Throttle Body and Air Cleaner Assembly

14 - 48 FUEL SYSTEMS Ä