mileage CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2057 of 2438

first separator plate and watch carefully for the pis-

ton to move forward. The piston should return to its

original position after the air pressure is removed.

UNDERDRIVE CLUTCH

Because this clutch piston cannot be seen, its oper-

ation is checked by function. Air pressure is applied

to the low/reverse and the 2/4 clutches. This locks

the output shaft. Use a piece of rubber hose wrapped

around the input shaft and a pair of clamp-on pliers

to turn the input shaft. Next apply air pressure to

the underdrive clutch. The input shaft should not ro-

tate with hand torque. Release the air pressure and

confirm that the input shaft will rotate.

FLUID LEAKAGE-TORQUE CONVERTER HOUSING

AREA

(1) Check for source of leakage.

Since fluid leakage at or around the torque con-

verter area may originate from an engine oil leak,

the area should be examined closely. Factory fill

fluid is dyed red and, therefore, can be distinguished

from engine oil. (2) Prior to removing the transaxle, perform the

following checks: When leakage is determined to originate from the

transaxle, check fluid level prior to removal of the

transaxle and torque converter. High oil level can result in oil leakage out the vent

in the manual shaft. If the fluid level is high, adjust

to proper level. After performing this operation, inspect for leak-

age. If a leak persists, perform the following opera-

tion on the vehicle to determine if it is the torque

converter or transaxle that is leaking.

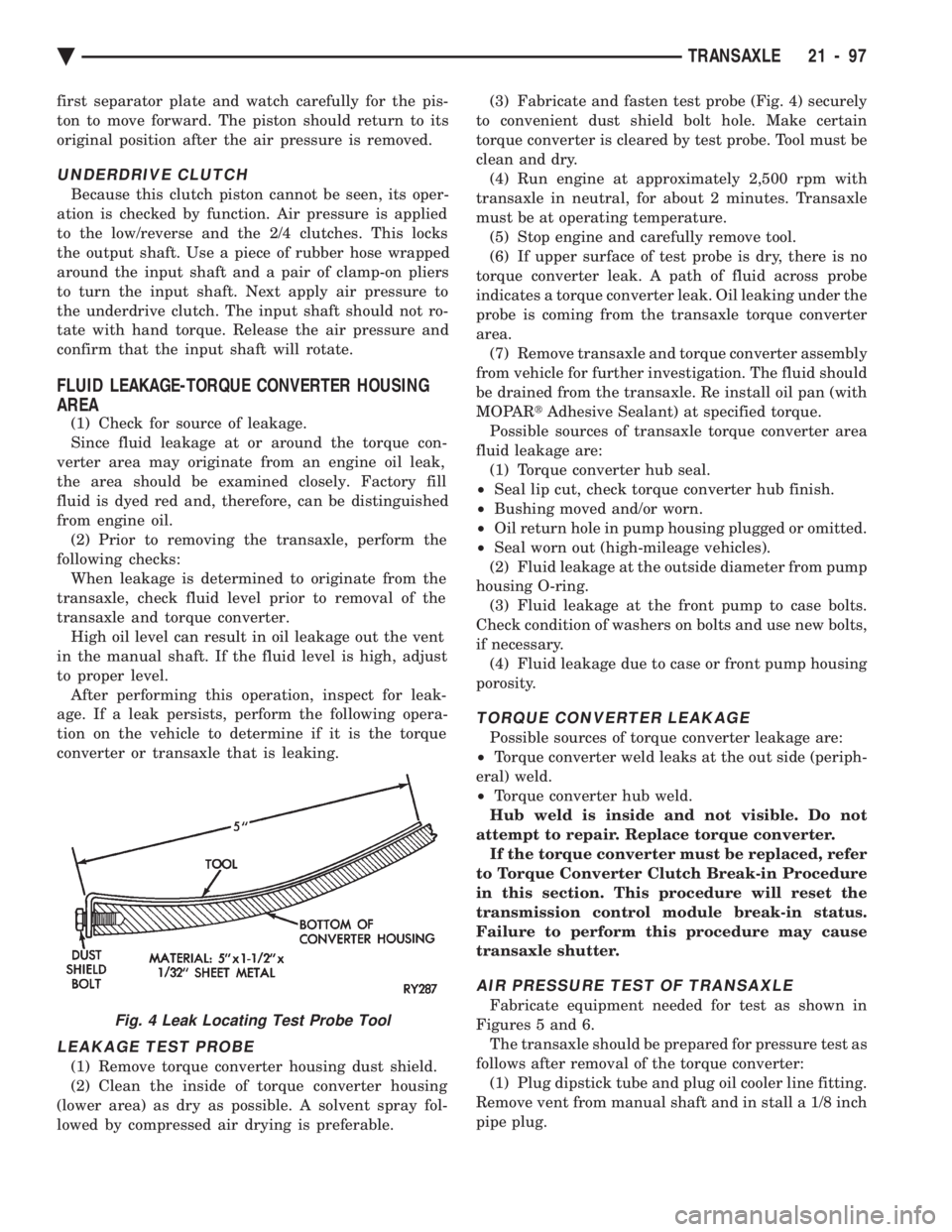

LEAKAGE TEST PROBE

(1) Remove torque converter housing dust shield.

(2) Clean the inside of torque converter housing

(lower area) as dry as possible. A solvent spray fol-

lowed by compressed air drying is preferable. (3) Fabricate and fasten test probe (Fig. 4) securely

to convenient dust shield bolt hole. Make certain

torque converter is cleared by test probe. Tool must be

clean and dry. (4) Run engine at approximately 2,500 rpm with

transaxle in neutral, for about 2 minutes. Transaxle

must be at operating temperature. (5) Stop engine and carefully remove tool.

(6) If upper surface of test probe is dry, there is no

torque converter leak. A path of fluid across probe

indicates a torque converter leak. Oil leaking under the

probe is coming from the transaxle torque converter

area. (7) Remove transaxle and torque converter assembly

from vehicle for further investigation. The fluid should

be drained from the transaxle. Re install oil pan (with

MOPAR tAdhesive Sealant) at specified torque.

Possible sources of transaxle torque converter area

fluid leakage are: (1) Torque converter hub seal.

² Seal lip cut, check torque converter hub finish.

² Bushing moved and/or worn.

² Oil return hole in pump housing plugged or omitted.

² Seal worn out (high-mileage vehicles).

(2) Fluid leakage at the outside diameter from pump

housing O-ring. (3) Fluid leakage at the front pump to case bolts.

Check condition of washers on bolts and use new bolts,

if necessary. (4) Fluid leakage due to case or front pump housing

porosity.

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

² Torque converter weld leaks at the out side (periph-

eral) weld.

² Torque converter hub weld.

Hub weld is inside and not visible. Do not

attempt to repair. Replace torque converter. If the torque converter must be replaced, refer

to Torque Converter Clutch Break-in Procedure

in this section. This procedure will reset the

transmission control module break-in status.

Failure to perform this procedure may cause

transaxle shutter.

AIR PRESSURE TEST OF TRANSAXLE

Fabricate equipment needed for test as shown in

Figures 5 and 6. The transaxle should be prepared for pressure test as

follows after removal of the torque converter: (1) Plug dipstick tube and plug oil cooler line fitting.

Remove vent from manual shaft and in stall a 1/8 inch

pipe plug.Fig. 4 Leak Locating Test Probe Tool

Ä TRANSAXLE 21 - 97

Page 2064 of 2438

(7) Press the number 5 on the DRB II scan tool

key pad (Adjustments). (8) Press the number 3 on the DRB II scan tool

key pad (Quick Learn). Then follow the instructions

on the DRB II scan tool screen.

PINION FACTOR PROCEDURE

The vehicle speed readings for the speedometer are

taken from the output speed sensor. Because of dif-

ferent tire sizes and final drive ratios, the transmis-

sion control module must be calibrated to reflect the

different combinations of equipment. A procedure has

been developed called Pinion Factor. It allows the

technician to set the transmission control module ini-

tial setting so that the speedometer readings will be

correct. Failure to perform this procedure will cause a ``No

Speedometer Operation'' condition. This procedure must be performed if the transmis-

sion control module has been replaced. To properly read or reset the Pinion Factor, it is

necessary to use a DRB II scan tool. Perform the fol-

lowing steps with the DRB II scan tool to read or re-

set the Pinion Factor: (1) Plug the DRB II scan tool into the blue CCD

Bus connector. The connector is located under the in-

strument panel on the drivers side of the vehicle. (2) Insert the 1993 DRB II scan tool cartridge into

the DRB II scan tool. (3) The red and green lights on the DRB II scan

tool will light up and then begin flashing. Wait until

the lights stop flashing before continuing with this

procedure. (4) Press the number 4 key (Select System) on the

DRB II scan tool key pad. Item number 4 will not ap-

pear on the DRB II scan tool screen unless you scroll

down. It is not necessary to scroll down to be able to

choose item 4. (5) Press the number 2 on the DRB II scan tool

key pad (Transmission). (6) Press the number 1 on the DRB II scan tool

key pad. Wait for the DRB II scan tool to perform the

following three tests before continuing (These tests

are done automatically by the DRB II scan tool).

² Bus Test

² Initialize

² Transmission Control Module Part Number

(7) Press the number 5 on the DRB II scan tool

key pad (Adjustments). (8) Press the number 2 on the DRB II scan tool

key pad (Pinion Factor). Then follow the instructions

on the DRB II scan tool screen.

TORQUE CONVERTER CLUTCH BREAK-IN

PROCEDURE

A torque converter clutch break-in program is be-

ing used on all models with a 41TE. This program

will properly condition the torque converter clutch. This will eliminate shudder during partial torque

converter clutch operation on a new torque converter.

If the torque converter is replaced, the new clutch

within the torque converter will require break-in.

The current break-in status stored in the transmis-

sion control module will have to be reset to the start

of break-in with the DRB II scan tool. If a new transmission control module is put on the

vehicle, the status will be at the start of break-in.

This status is acceptable regardless of the mileage on

the torque converter. No modification of the break-in

status is required. To properly service these vehicles, it is necessary to

use a DRB II scan tool to read or reset the break-in

status. Perform the following steps with the DRB II

scan tool to reset the break-in status: (1) Plug the DRB II scan tool into the blue CCD

Bus connector. The connector is located under the in-

strument panel on the drivers side of the vehicle. (2) Insert the 1993 DRB II scan tool cartridge into

the DRB II scan tool. (3) The red and green lights on the DRB II scan

tool will light up and then begin flashing. Wait until

the lights stop flashing before continuing with this

procedure. (4) Press the number 4 key (Select System) on the

DRB II scan tool key pad. Item number 4 will not ap-

pear on the DRB II scan tool screen unless you scroll

down. It is not necessary to scroll down to be able to

choose item 4. (5) Press the number 2 on the DRB II scan tool

key pad (Transmission). (6) Press the number 1 on the DRB II scan tool

key pad. Wait for the DRB II scan tool to perform the

following three tests before continuing (These tests

are done automatically by the DRB II scan tool).

² Bus Test

² Initialize

² Transmission Control Module Part Number

(7) Press the number 5 on the DRB II scan tool

key pad (Adjustments). (8) Press the number 1 on the DRB II scan tool

key pad (Reset LU Clutch). The DRB II scan tool will

display one of three screens. (a) LU Clutch Break-in Status: Start

(b) LU Clutch Break-in Status: In-progress

Press ENTER to Reset Break-in status (c) LU Clutch Break-in Status: CompletePress

ENTER to Reset Break-in status

If screen (a) appears, the transmission control mod-

ule is at the beginning of its break-in program. No

further action is required. If screen (b) appears, the transmission control mod-

ule is in the middle of a its break-in program. Press

the enter key on the DRB II scan tool key pad to re-

turn the status to the start of break-in.

21 - 104 TRANSAXLE Ä

Page 2101 of 2438

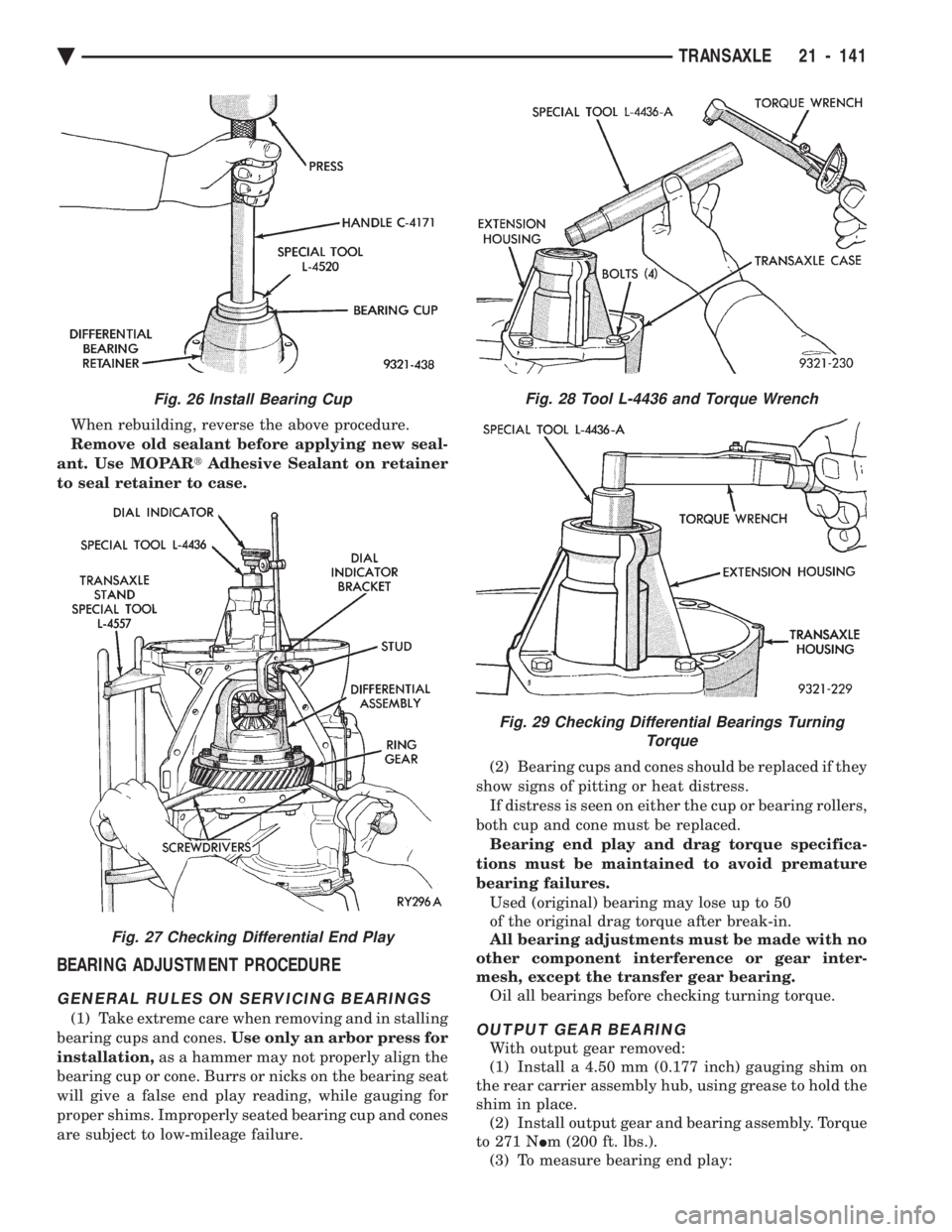

When rebuilding, reverse the above procedure.

Remove old sealant before applying new seal-

ant. Use MOPAR tAdhesive Sealant on retainer

to seal retainer to case.

BEARING ADJUSTMENT PROCEDURE

GENERAL RULES ON SERVICING BEARINGS

(1) Take extreme care when removing and in stalling

bearing cups and cones. Use only an arbor press for

installation, as a hammer may not properly align the

bearing cup or cone. Burrs or nicks on the bearing seat

will give a false end play reading, while gauging for

proper shims. Improperly seated bearing cup and cones

are subject to low-mileage failure. (2) Bearing cups and cones should be replaced if they

show signs of pitting or heat distress. If distress is seen on either the cup or bearing rollers,

both cup and cone must be replaced. Bearing end play and drag torque specifica-

tions must be maintained to avoid premature

bearing failures. Used (original) bearing may lose up to 50

of the original drag torque after break-in.

All bearing adjustments must be made with no

other component interference or gear inter-

mesh, except the transfer gear bearing. Oil all bearings before checking turning torque.OUTPUT GEAR BEARING

With output gear removed:

(1) Install a 4.50 mm (0.177 inch) gauging shim on

the rear carrier assembly hub, using grease to hold the

shim in place. (2) Install output gear and bearing assembly. Torque

to 271 N Im (200 ft. lbs.).

(3) To measure bearing end play:

Fig. 26 Install Bearing Cup

Fig. 27 Checking Differential End Play

Fig. 28 Tool L-4436 and Torque Wrench

Fig. 29 Checking Differential Bearings Turning Torque

Ä TRANSAXLE 21 - 141

Page 2149 of 2438

WHEELSÐTIRES

CONTENTS

page page

SPECIFICATIONS ........................ 8

TIRE SERVICE PROCEDURES .............. 1 WHEELS SERVICE PROCEDURES

........... 6

TIRE SERVICE PROCEDURES INDEX

page page

Cleaning of Tires .......................... 1

General Information ........................ 1

Pressure Gauges ......................... 2

Radial-Ply Tires ........................... 1

Repairing Leaks .......................... 3

Rotation ................................ 3 Spare TireÐCompact

...................... 1

Tire Inflation Pressures ..................... 2

Tire Noise or Vibration ..................... 3

Tire Wear Patterns ........................ 3

Tread Wear Indicators ...................... 3

GENERAL INFORMATION

Throughout this group, references may be made to a

particular vehicle by letter or number designation. A

chart showing the breakdown of these designations is

included in the Introduction Section. Tires are designed for the vehicle and provide the

best overall performance for normal operation. The

ride and handling characteristics match the vehicle's

requirements. With proper care they will give excellent

reliability traction, skid resistance and tread life. They

have load carrying capacity, when properly inflated, to

operate at loads up to the specified Maximum Vehicle

Capacity. Driving habits have more effect on tire life than any

other factor. Careful drivers will obtain, in most cases,

much greater mileage than severe or careless drivers. A

few of the driving habits which will shorten the life of

any tire are:

² Rapid acceleration and deceleration

² Severe application of brakes

² High-speed driving

² Taking turns at excessive speeds

² Striking curbs and other obstacles

Radial ply tires can be more susceptible to irregular

tread wear. It is very important to follow the tire

rotation interval shown in the section on Tire

Rotation to achieve a greater tread life potential.

RADIAL-PLY TIRES

Radial-ply tires improve handling, tread life, and

ride quality and decrease rolling resistance. Radial-ply tires must always be used in sets of four

and under no circumstances should they be used on

the front only. However, they may be mixed with temporary spare tires when necessary,

but reduced speeds are recommended. Radial-ply tires have the same load carrying capac-

ity as other types of tires of the same size. They also

use the same recommended inflation pressures.

SPARE TIREÐCOMPACT

The compact spare tire is designed for emergency

use only. The original tire should be repaired and re-

installed at the first opportunity. Refer to Owner's

Manual for complete details.

TIRE CHAINS

Tire snow chains may be used on certainmodels.

Refer to Owner's Manual for more information.

CLEANING OF TIRES

Remove protective coating on tires before delivery

of vehicle, otherwise it could cause deterioration of

tires. Remove protective coating by applying warm wa-

ter, letting it soak one minute, and then scrubbing

the coating away with a soft bristle brush. Steam cleaning may also be used for cleaning.

DO NOT use gasoline or wire brush for cleaning.

DO NOT use mineral oil or an oil-based solvent.

Ä WHEELSÐTIRES 22 - 1

Page 2154 of 2438

WHEELS SERVICE PROCEDURES INDEX

page page

General Information ........................ 6

Tire and Wheel Balance .................... 6

Tire and Wheel Run Out .................... 7 Wheel Installation

......................... 6

Wheel Replacement ....................... 6

GENERAL INFORMATION

Original equipment wheels are designed for proper

operation at all loads up to the maximum vehicle ca-

pacity. All models use steel or cast aluminum drop center

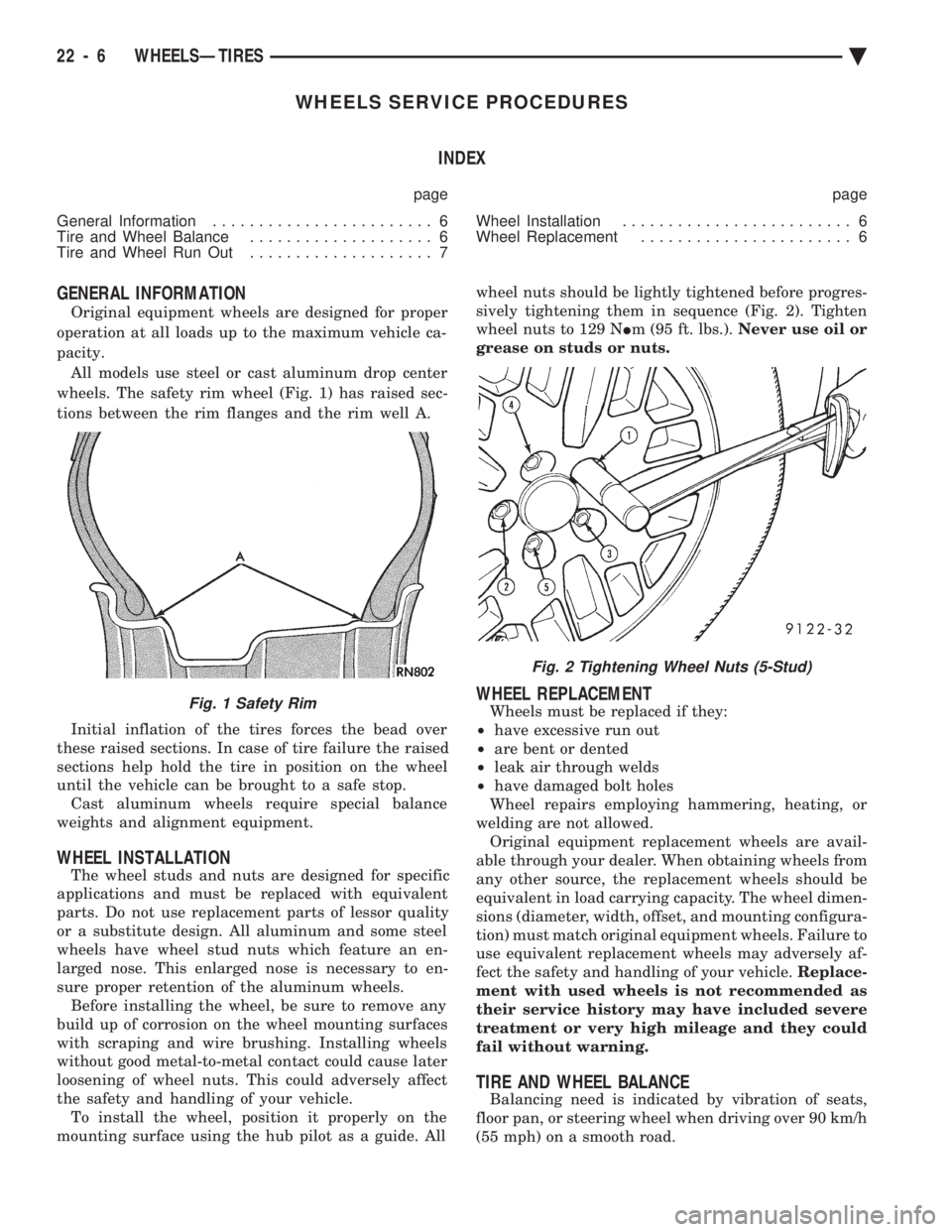

wheels. The safety rim wheel (Fig. 1) has raised sec-

tions between the rim flanges and the rim well A.

Initial inflation of the tires forces the bead over

these raised sections. In case of tire failure the raised

sections help hold the tire in position on the wheel

until the vehicle can be brought to a safe stop. Cast aluminum wheels require special balance

weights and alignment equipment.

WHEEL INSTALLATION

The wheel studs and nuts are designed for specific

applications and must be replaced with equivalent

parts. Do not use replacement parts of lessor quality

or a substitute design. All aluminum and some steel

wheels have wheel stud nuts which feature an en-

larged nose. This enlarged nose is necessary to en-

sure proper retention of the aluminum wheels. Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces

with scraping and wire brushing. Installing wheels

without good metal-to-metal contact could cause later

loosening of wheel nuts. This could adversely affect

the safety and handling of your vehicle. To install the wheel, position it properly on the

mounting surface using the hub pilot as a guide. All wheel nuts should be lightly tightened before progres-

sively tightening them in sequence (Fig. 2). Tighten

wheel nuts to 129 N Im (95 ft. lbs.). Never use oil or

grease on studs or nuts.

WHEEL REPLACEMENT

Wheels must be replaced if they:

² have excessive run out

² are bent or dented

² leak air through welds

² have damaged bolt holes

Wheel repairs employing hammering, heating, or

welding are not allowed. Original equipment replacement wheels are avail-

able through your dealer. When obtaining wheels from

any other source, the replacement wheels should be

equivalent in load carrying capacity. The wheel dimen-

sions (diameter, width, offset, and mounting configura-

tion) must match original equipment wheels. Failure to

use equivalent replacement wheels may adversely af-

fect the safety and handling of your vehicle. Replace-

ment with used wheels is not recommended as

their service history may have included severe

treatment or very high mileage and they could

fail without warning.

TIRE AND WHEEL BALANCE

Balancing need is indicated by vibration of seats,

floor pan, or steering wheel when driving over 90 km/h

(55 mph) on a smooth road.

Fig. 1 Safety Rim

Fig. 2 Tightening Wheel Nuts (5-Stud)

22 - 6 WHEELSÐTIRES Ä

Page 2404 of 2438

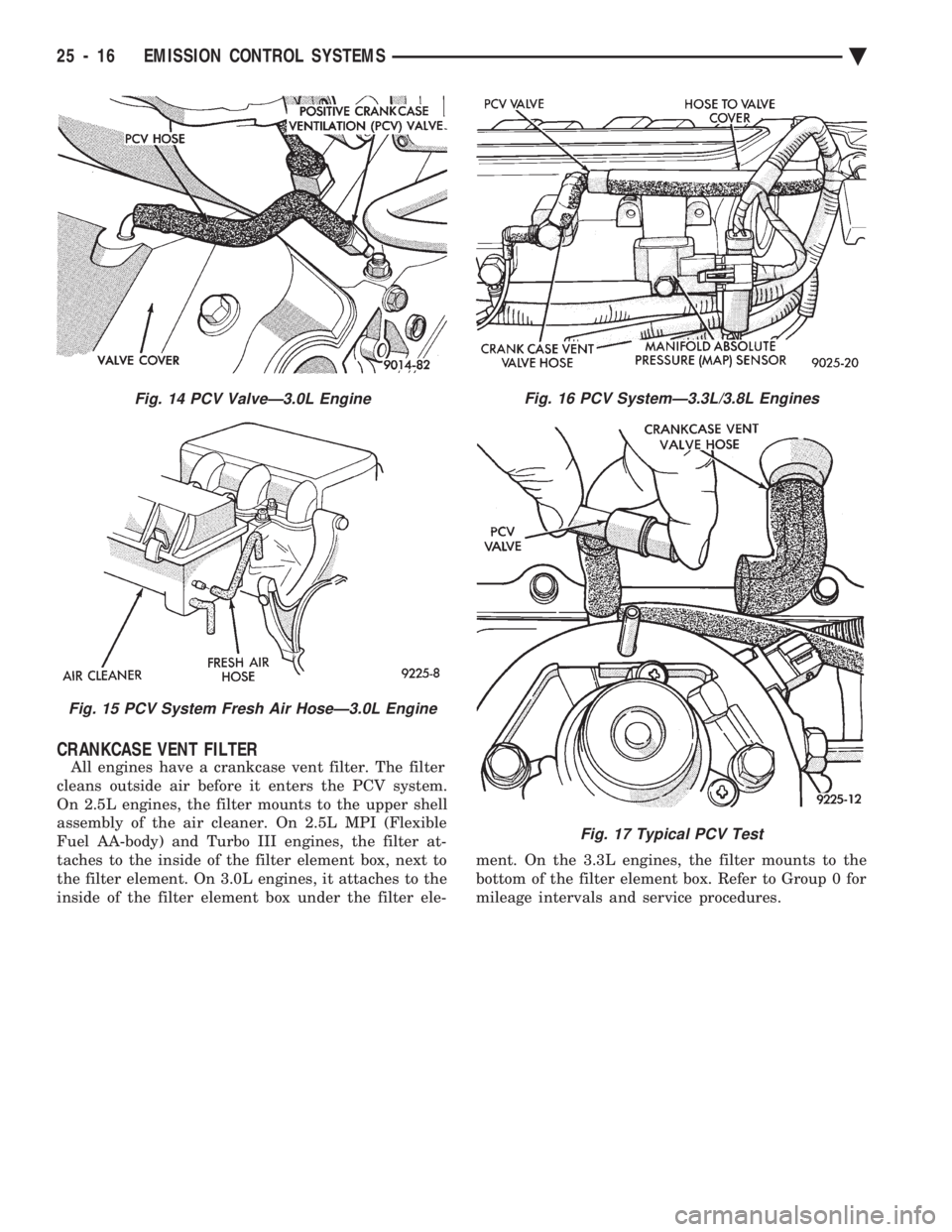

CRANKCASE VENT FILTER

All engines have a crankcase vent filter. The filter

cleans outside air before it enters the PCV system.

On 2.5L engines, the filter mounts to the upper shell

assembly of the air cleaner. On 2.5L MPI (Flexible

Fuel AA-body) and Turbo III engines, the filter at-

taches to the inside of the filter element box, next to

the filter element. On 3.0L engines, it attaches to the

inside of the filter element box under the filter ele- ment. On the 3.3L engines, the filter mounts to the

bottom of the filter element box. Refer to Group 0 for

mileage intervals and service procedures.

Fig. 14 PCV ValveÐ3.0L Engine

Fig. 15 PCV System Fresh Air HoseÐ3.0L Engine

Fig. 16 PCV SystemÐ3.3L/3.8L Engines

Fig. 17 Typical PCV Test

25 - 16 EMISSION CONTROL SYSTEMS Ä