stop start CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 305 of 2438

(4) Provide communication to the DRB II while in

the Antilock brakes diagnostic mode. The CAB continuously monitors the speed of each

wheel, through the signals generated at the Wheel

Speed Sensors. This is used to determine if any

wheel of the vehicle is beginning to lock-up (skid)

when the brakes are applied. When a wheel locking

tendency is detected during brake apply. The CAB

commands the appropriate Build/Decay valves to

modulate brake fluid pressure in some or all of the

hydraulic circuits. The CAB continues to control

pressure in individual hydraulic circuits until a lock-

ing tendency is no longer present. The ABS system is constantly monitored by the

CAB for proper operation. If the CAB detects a fault,

it will turn on the Amber Antilock Warning Lamp

and disable the ABS brake system. The normal Non

ABS brake system will remain operational. The CAB contains a self-diagnostic program which

will turn on the Amber Antilock Warning Lamp

when a system fault is detected. Faults are stored in

a diagnostic program memory. There are 16 fault

codes which may be stored in the CAB and displayed

through the DRB II. These fault codes will remain in

the CAB memory even after the ignition has been

turned off. The fault codes can be cleared by using

the DRB II diagnostics tester, or they will be auto-

matically cleared from the memory after (50) ignition

switch on/off cycles.

CONTROLLER ANTILOCK BRAKE (INPUTS)

² Four wheel speed sensors.

² Stop lamp switch.

² Ignition switch.

² System relay voltage.

² Ground.

² Pump/Motor Relay Monitor

² Diagnostics Communications

CONTROLLER ANTILOCK BRAKE (OUTPUTS)

²4 Build/Decay valves.

² Antilock warning lamp.

² System relay actuation.

² Diagnostic communication.

² Pump/Motor relay actuation

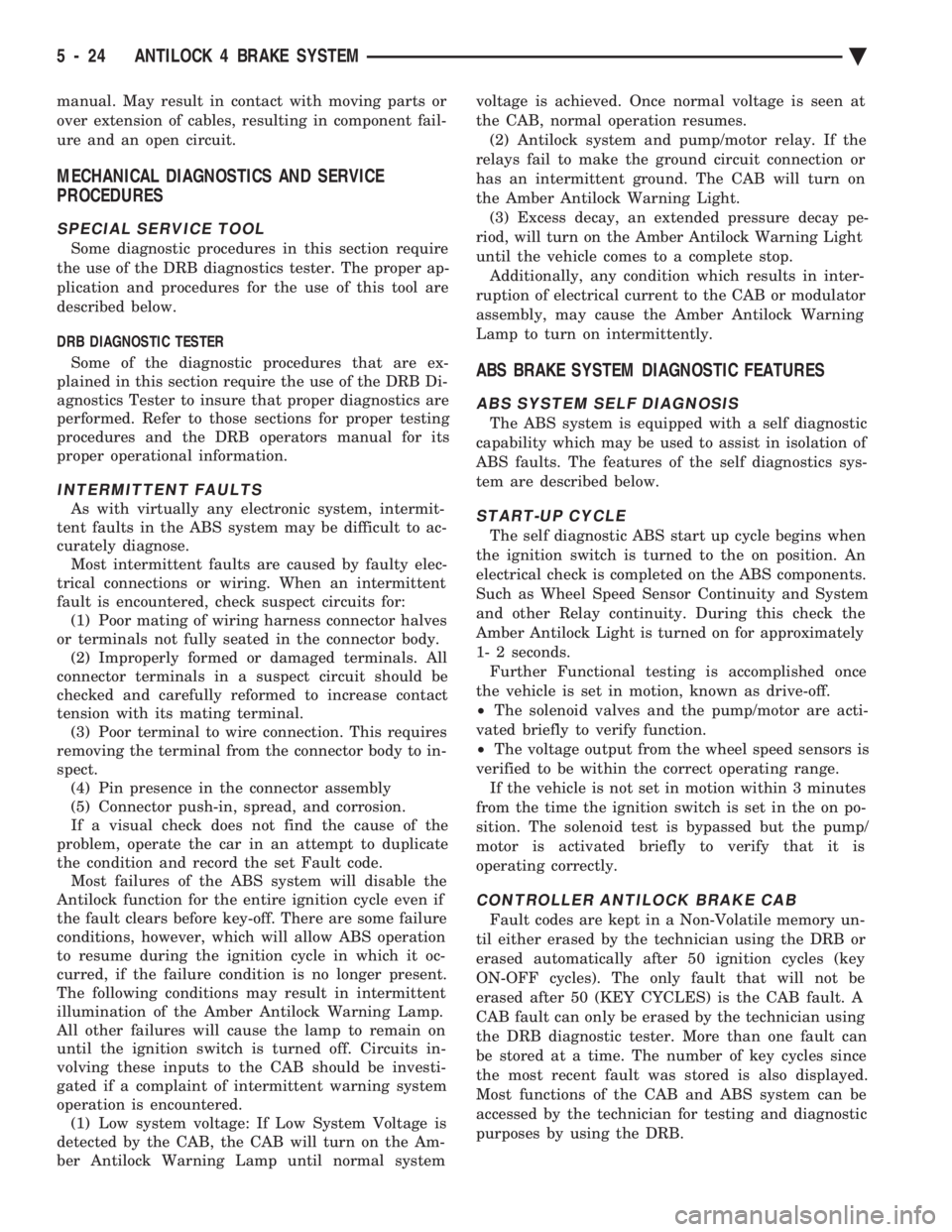

DIAGNOSTIC CONNECTOR

The Bendix Antilock 4 Brake System diagnostic

connector is located under the fuse panel access

cover. The access cover is located on the lower sec-

tion of the instrument panel to the left side of the

steering column. The diagnostics connector is a blue

6 way connector see (Fig. 9).

ANTILOCK SYSTEM RELAYS AND WARNING LAMPS

SYSTEM RELAY

The ABS Modulator Valves are powered through

the System Relay which is located on a bracket

mounted to the CAB (Fig. 10). The System Relay

provides power to the CAB for modulator valve oper-

ation (pins 47 and 41) after the startup cycle when

the ignition is turned on.

Fig. 8 CAB Location

Fig. 9 Antilock Diagnostic Connector Location

Fig. 10 System Relay Location On The CAB

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 19

Page 310 of 2438

manual. May result in contact with moving parts or

over extension of cables, resulting in component fail-

ure and an open circuit.

MECHANICAL DIAGNOSTICS AND SERVICE

PROCEDURES

SPECIAL SERVICE TOOL

Some diagnostic procedures in this section require

the use of the DRB diagnostics tester. The proper ap-

plication and procedures for the use of this tool are

described below.

DRB DIAGNOSTIC TESTER

Some of the diagnostic procedures that are ex-

plained in this section require the use of the DRB Di-

agnostics Tester to insure that proper diagnostics are

performed. Refer to those sections for proper testing

procedures and the DRB operators manual for its

proper operational information.

INTERMITTENT FAULTS

As with virtually any electronic system, intermit-

tent faults in the ABS system may be difficult to ac-

curately diagnose. Most intermittent faults are caused by faulty elec-

trical connections or wiring. When an intermittent

fault is encountered, check suspect circuits for: (1) Poor mating of wiring harness connector halves

or terminals not fully seated in the connector body. (2) Improperly formed or damaged terminals. All

connector terminals in a suspect circuit should be

checked and carefully reformed to increase contact

tension with its mating terminal. (3) Poor terminal to wire connection. This requires

removing the terminal from the connector body to in-

spect. (4) Pin presence in the connector assembly

(5) Connector push-in, spread, and corrosion.

If a visual check does not find the cause of the

problem, operate the car in an attempt to duplicate

the condition and record the set Fault code. Most failures of the ABS system will disable the

Antilock function for the entire ignition cycle even if

the fault clears before key-off. There are some failure

conditions, however, which will allow ABS operation

to resume during the ignition cycle in which it oc-

curred, if the failure condition is no longer present.

The following conditions may result in intermittent

illumination of the Amber Antilock Warning Lamp.

All other failures will cause the lamp to remain on

until the ignition switch is turned off. Circuits in-

volving these inputs to the CAB should be investi-

gated if a complaint of intermittent warning system

operation is encountered. (1) Low system voltage: If Low System Voltage is

detected by the CAB, the CAB will turn on the Am-

ber Antilock Warning Lamp until normal system voltage is achieved. Once normal voltage is seen at

the CAB, normal operation resumes.

(2) Antilock system and pump/motor relay. If the

relays fail to make the ground circuit connection or

has an intermittent ground. The CAB will turn on

the Amber Antilock Warning Light. (3) Excess decay, an extended pressure decay pe-

riod, will turn on the Amber Antilock Warning Light

until the vehicle comes to a complete stop. Additionally, any condition which results in inter-

ruption of electrical current to the CAB or modulator

assembly, may cause the Amber Antilock Warning

Lamp to turn on intermittently.

ABS BRAKE SYSTEM DIAGNOSTIC FEATURES

ABS SYSTEM SELF DIAGNOSIS

The ABS system is equipped with a self diagnostic

capability which may be used to assist in isolation of

ABS faults. The features of the self diagnostics sys-

tem are described below.

START-UP CYCLE

The self diagnostic ABS start up cycle begins when

the ignition switch is turned to the on position. An

electrical check is completed on the ABS components.

Such as Wheel Speed Sensor Continuity and System

and other Relay continuity. During this check the

Amber Antilock Light is turned on for approximately

1- 2 seconds. Further Functional testing is accomplished once

the vehicle is set in motion, known as drive-off.

² The solenoid valves and the pump/motor are acti-

vated briefly to verify function.

² The voltage output from the wheel speed sensors is

verified to be within the correct operating range. If the vehicle is not set in motion within 3 minutes

from the time the ignition switch is set in the on po-

sition. The solenoid test is bypassed but the pump/

motor is activated briefly to verify that it is

operating correctly.

CONTROLLER ANTILOCK BRAKE CAB

Fault codes are kept in a Non-Volatile memory un-

til either erased by the technician using the DRB or

erased automatically after 50 ignition cycles (key

ON-OFF cycles). The only fault that will not be

erased after 50 (KEY CYCLES) is the CAB fault. A

CAB fault can only be erased by the technician using

the DRB diagnostic tester. More than one fault can

be stored at a time. The number of key cycles since

the most recent fault was stored is also displayed.

Most functions of the CAB and ABS system can be

accessed by the technician for testing and diagnostic

purposes by using the DRB.

5 - 24 ANTILOCK 4 BRAKE SYSTEM Ä

Page 382 of 2438

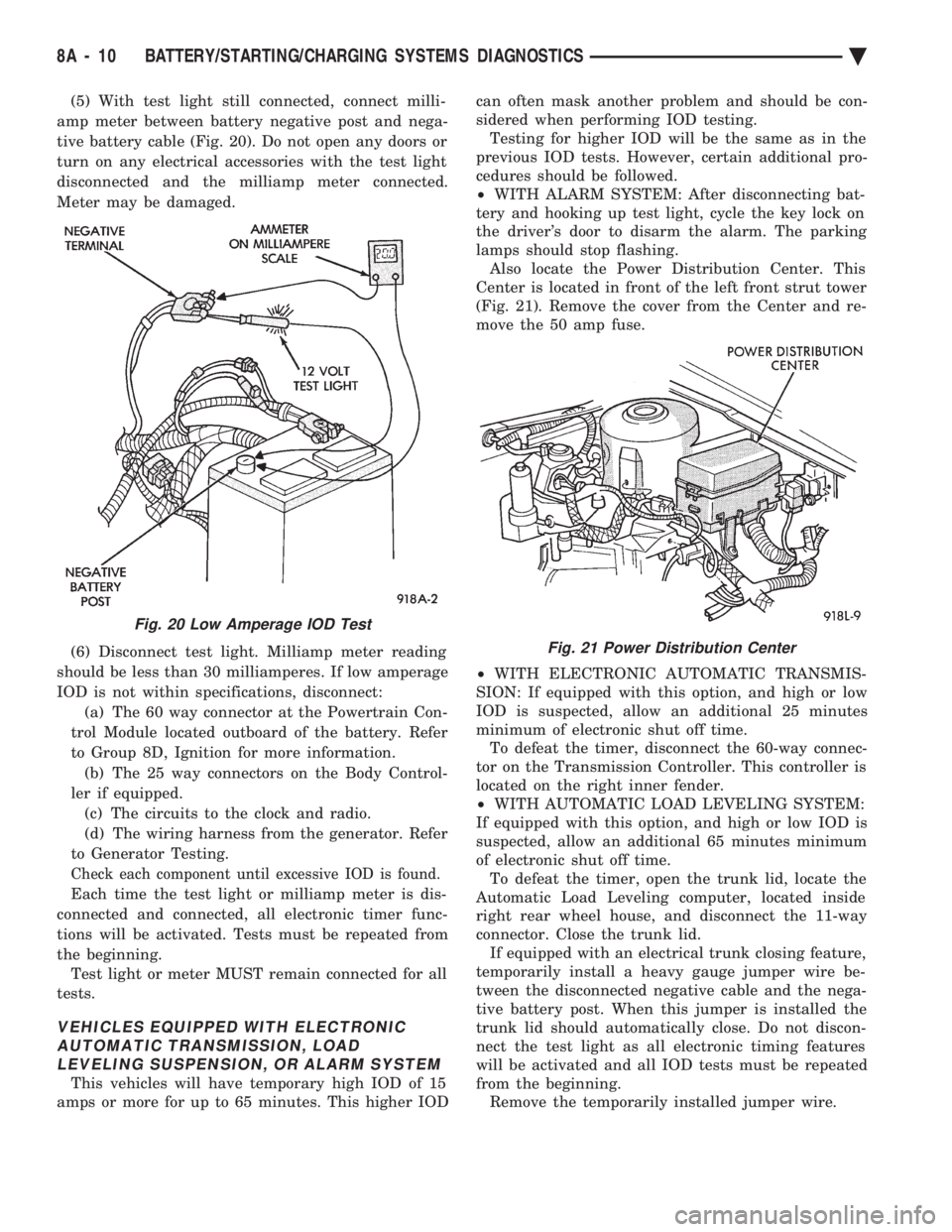

(5) With test light still connected, connect milli-

amp meter between battery negative post and nega-

tive battery cable (Fig. 20). Do not open any doors or

turn on any electrical accessories with the test light

disconnected and the milliamp meter connected.

Meter may be damaged.

(6) Disconnect test light. Milliamp meter reading

should be less than 30 milliamperes. If low amperage

IOD is not within specifications, disconnect: (a) The 60 way connector at the Powertrain Con-

trol Module located outboard of the battery. Refer

to Group 8D, Ignition for more information. (b) The 25 way connectors on the Body Control-

ler if equipped. (c) The circuits to the clock and radio.

(d) The wiring harness from the generator. Refer

to Generator Testing.

Check each component until excessive IOD is found.

Each time the test light or milliamp meter is dis-

connected and connected, all electronic timer func-

tions will be activated. Tests must be repeated from

the beginning. Test light or meter MUST remain connected for all

tests.

VEHICLES EQUIPPED WITH ELECTRONIC AUTOMATIC TRANSMISSION, LOADLEVELING SUSPENSION, OR ALARM SYSTEM

This vehicles will have temporary high IOD of 15

amps or more for up to 65 minutes. This higher IOD can often mask another problem and should be con-

sidered when performing IOD testing. Testing for higher IOD will be the same as in the

previous IOD tests. However, certain additional pro-

cedures should be followed.

² WITH ALARM SYSTEM: After disconnecting bat-

tery and hooking up test light, cycle the key lock on

the driver's door to disarm the alarm. The parking

lamps should stop flashing. Also locate the Power Distribution Center. This

Center is located in front of the left front strut tower

(Fig. 21). Remove the cover from the Center and re-

move the 50 amp fuse.

² WITH ELECTRONIC AUTOMATIC TRANSMIS-

SION: If equipped with this option, and high or low

IOD is suspected, allow an additional 25 minutes

minimum of electronic shut off time. To defeat the timer, disconnect the 60-way connec-

tor on the Transmission Controller. This controller is

located on the right inner fender.

² WITH AUTOMATIC LOAD LEVELING SYSTEM:

If equipped with this option, and high or low IOD is

suspected, allow an additional 65 minutes minimum

of electronic shut off time. To defeat the timer, open the trunk lid, locate the

Automatic Load Leveling computer, located inside

right rear wheel house, and disconnect the 11-way

connector. Close the trunk lid. If equipped with an electrical trunk closing feature,

temporarily install a heavy gauge jumper wire be-

tween the disconnected negative cable and the nega-

tive battery post. When this jumper is installed the

trunk lid should automatically close. Do not discon-

nect the test light as all electronic timing features

will be activated and all IOD tests must be repeated

from the beginning. Remove the temporarily installed jumper wire.

Fig. 20 Low Amperage IOD Test

Fig. 21 Power Distribution Center

8A - 10 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS Ä

Page 610 of 2438

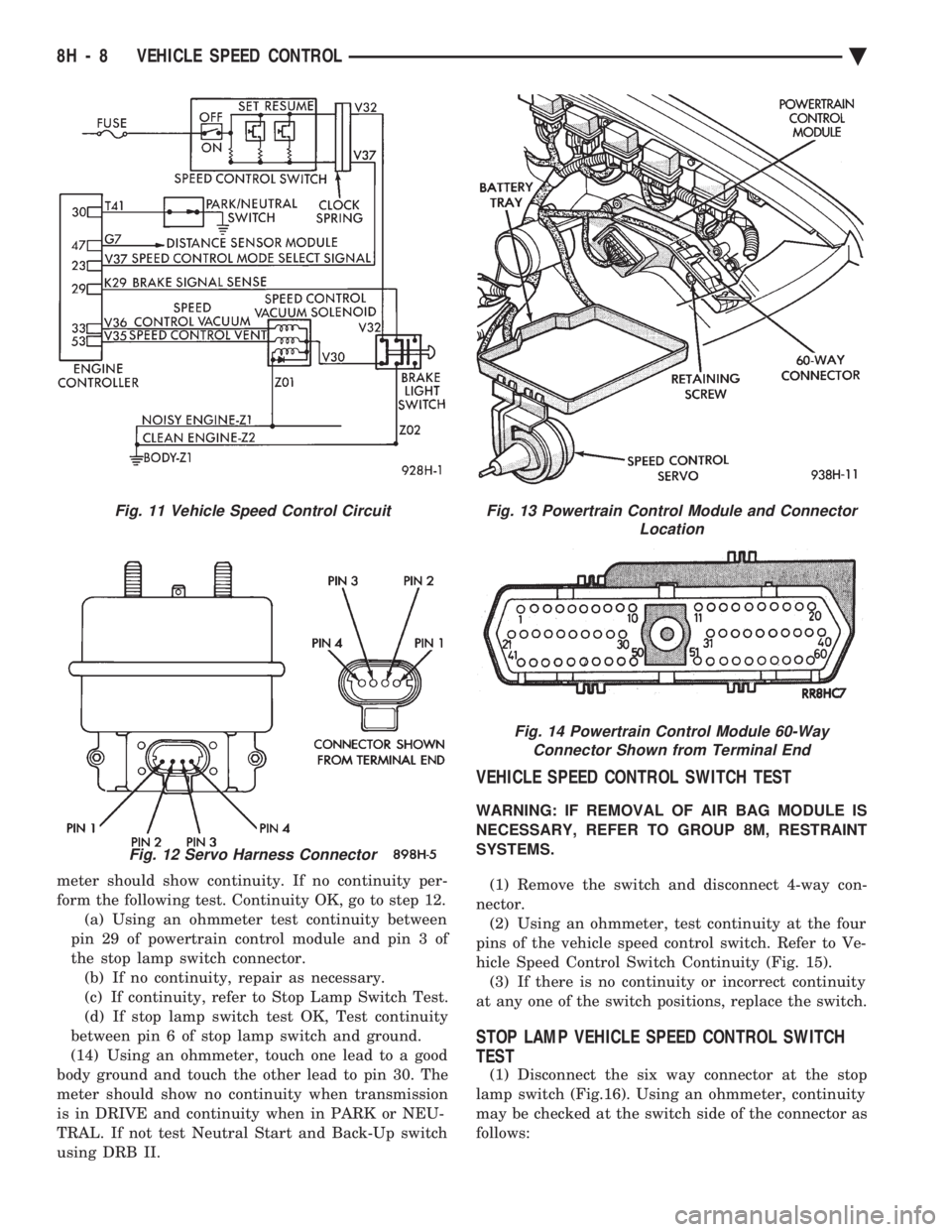

meter should show continuity. If no continuity per-

form the following test. Continuity OK, go to step 12.(a) Using an ohmmeter test continuity between

pin 29 of powertrain control module and pin 3 of

the stop lamp switch connector. (b) If no continuity, repair as necessary.

(c) If continuity, refer to Stop Lamp Switch Test.

(d) If stop lamp switch test OK, Test continuity

between pin 6 of stop lamp switch and ground.

(14) Using an ohmmeter, touch one lead to a good

body ground and touch the other lead to pin 30. The

meter should show no continuity when transmission

is in DRIVE and continuity when in PARK or NEU-

TRAL. If not test Neutral Start and Back-Up switch

using DRB II.

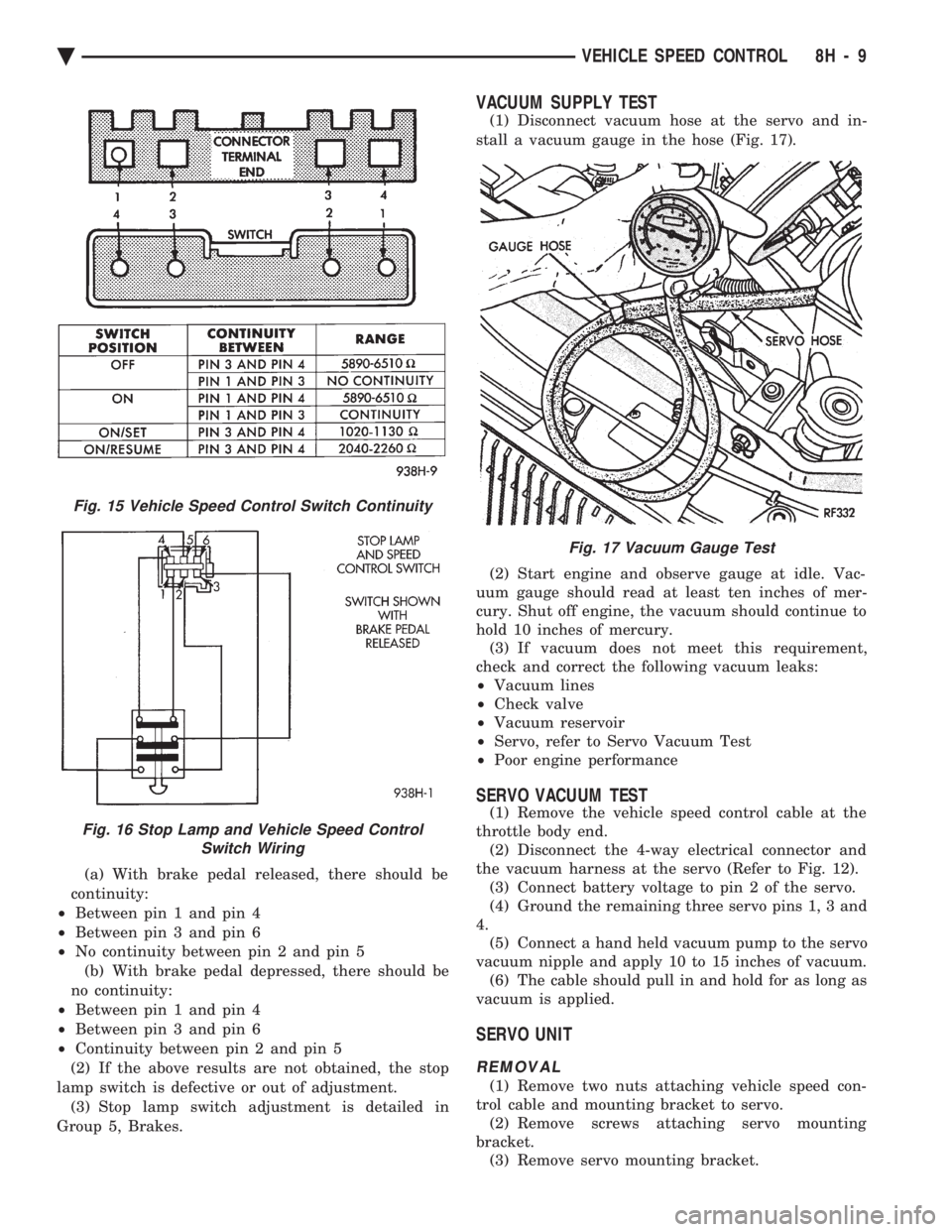

VEHICLE SPEED CONTROL SWITCH TEST

WARNING: IF REMOVAL OF AIR BAG MODULE IS

NECESSARY, REFER TO GROUP 8M, RESTRAINT

SYSTEMS.

(1) Remove the switch and disconnect 4-way con-

nector. (2) Using an ohmmeter, test continuity at the four

pins of the vehicle speed control switch. Refer to Ve-

hicle Speed Control Switch Continuity (Fig. 15). (3) If there is no continuity or incorrect continuity

at any one of the switch positions, replace the switch.

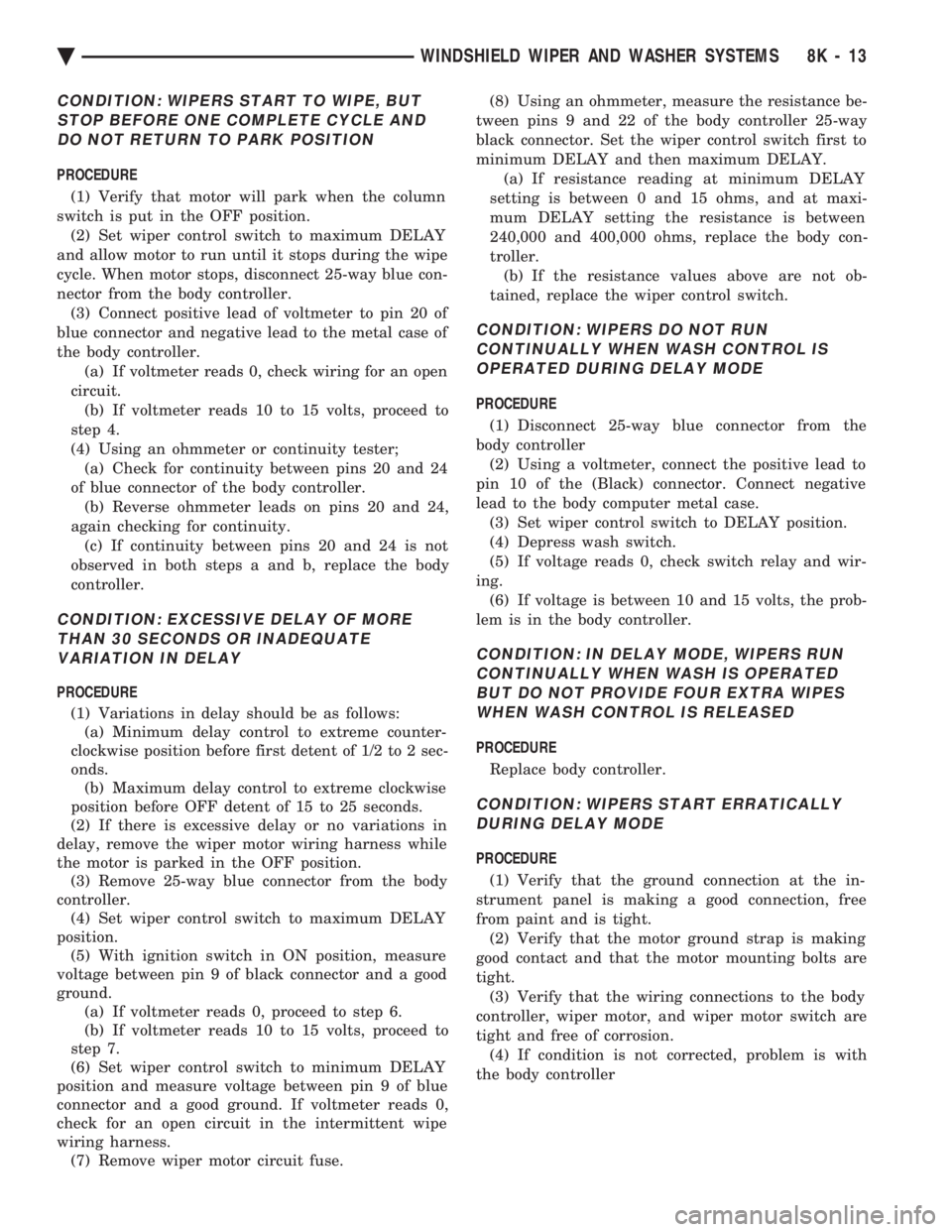

STOP LAMP VEHICLE SPEED CONTROL SWITCH

TEST

(1) Disconnect the six way connector at the stop

lamp switch (Fig.16). Using an ohmmeter, continuity

may be checked at the switch side of the connector as

follows:

Fig. 11 Vehicle Speed Control Circuit

Fig. 12 Servo Harness Connector

Fig. 13 Powertrain Control Module and Connector Location

Fig. 14 Powertrain Control Module 60-WayConnector Shown from Terminal End

8H - 8 VEHICLE SPEED CONTROL Ä

Page 611 of 2438

(a) With brake pedal released, there should be

continuity:

² Between pin 1 and pin 4

² Between pin 3 and pin 6

² No continuity between pin 2 and pin 5

(b) With brake pedal depressed, there should be

no continuity:

² Between pin 1 and pin 4

² Between pin 3 and pin 6

² Continuity between pin 2 and pin 5

(2) If the above results are not obtained, the stop

lamp switch is defective or out of adjustment. (3) Stop lamp switch adjustment is detailed in

Group 5, Brakes.

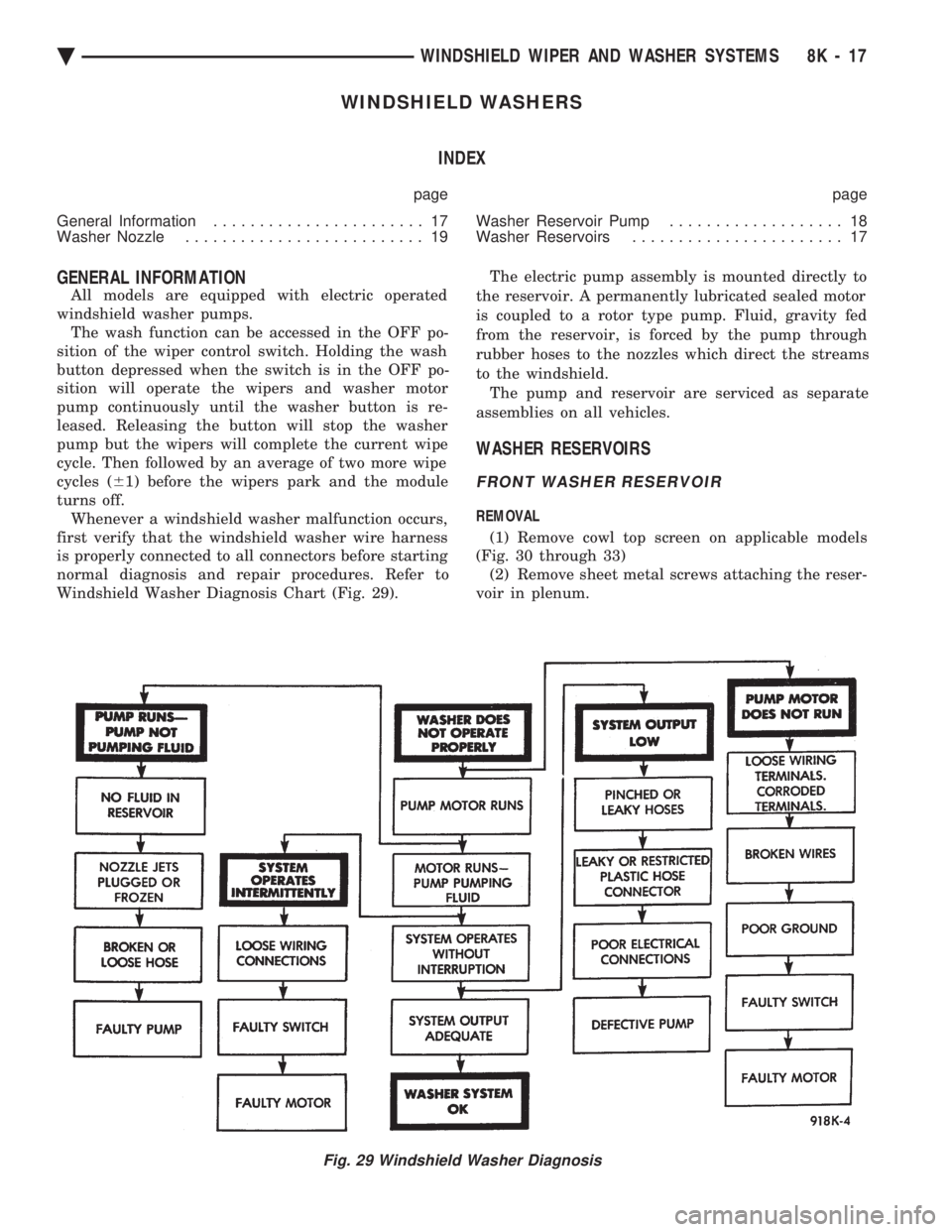

VACUUM SUPPLY TEST

(1) Disconnect vacuum hose at the servo and in-

stall a vacuum gauge in the hose (Fig. 17).

(2) Start engine and observe gauge at idle. Vac-

uum gauge should read at least ten inches of mer-

cury. Shut off engine, the vacuum should continue to

hold 10 inches of mercury. (3) If vacuum does not meet this requirement,

check and correct the following vacuum leaks:

² Vacuum lines

² Check valve

² Vacuum reservoir

² Servo, refer to Servo Vacuum Test

² Poor engine performance

SERVO VACUUM TEST

(1) Remove the vehicle speed control cable at the

throttle body end. (2) Disconnect the 4-way electrical connector and

the vacuum harness at the servo (Refer to Fig. 12). (3) Connect battery voltage to pin 2 of the servo.

(4) Ground the remaining three servo pins 1, 3 and

4. (5) Connect a hand held vacuum pump to the servo

vacuum nipple and apply 10 to 15 inches of vacuum. (6) The cable should pull in and hold for as long as

vacuum is applied.

SERVO UNIT

REMOVAL

(1) Remove two nuts attaching vehicle speed con-

trol cable and mounting bracket to servo. (2) Remove screws attaching servo mounting

bracket. (3) Remove servo mounting bracket.

Fig. 15 Vehicle Speed Control Switch Continuity

Fig. 16 Stop Lamp and Vehicle Speed Control Switch Wiring

Fig. 17 Vacuum Gauge Test

Ä VEHICLE SPEED CONTROL 8H - 9

Page 633 of 2438

CONDITION: WIPERS START TO WIPE, BUT STOP BEFORE ONE COMPLETE CYCLE ANDDO NOT RETURN TO PARK POSITION

PROCEDURE

(1) Verify that motor will park when the column

switch is put in the OFF position. (2) Set wiper control switch to maximum DELAY

and allow motor to run until it stops during the wipe

cycle. When motor stops, disconnect 25-way blue con-

nector from the body controller. (3) Connect positive lead of voltmeter to pin 20 of

blue connector and negative lead to the metal case of

the body controller. (a) If voltmeter reads 0, check wiring for an open

circuit. (b) If voltmeter reads 10 to 15 volts, proceed to

step 4.

(4) Using an ohmmeter or continuity tester; (a) Check for continuity between pins 20 and 24

of blue connector of the body controller. (b) Reverse ohmmeter leads on pins 20 and 24,

again checking for continuity. (c) If continuity between pins 20 and 24 is not

observed in both steps a and b, replace the body

controller.

CONDITION: EXCESSIVE DELAY OF MORE THAN 30 SECONDS OR INADEQUATEVARIATION IN DELAY

PROCEDURE

(1) Variations in delay should be as follows: (a) Minimum delay control to extreme counter-

clockwise position before first detent of 1/2 to 2 sec-

onds. (b) Maximum delay control to extreme clockwise

position before OFF detent of 15 to 25 seconds.

(2) If there is excessive delay or no variations in

delay, remove the wiper motor wiring harness while

the motor is parked in the OFF position. (3) Remove 25-way blue connector from the body

controller. (4) Set wiper control switch to maximum DELAY

position. (5) With ignition switch in ON position, measure

voltage between pin 9 of black connector and a good

ground. (a) If voltmeter reads 0, proceed to step 6.

(b) If voltmeter reads 10 to 15 volts, proceed to

step 7.

(6) Set wiper control switch to minimum DELAY

position and measure voltage between pin 9 of blue

connector and a good ground. If voltmeter reads 0,

check for an open circuit in the intermittent wipe

wiring harness. (7) Remove wiper motor circuit fuse. (8) Using an ohmmeter, measure the resistance be-

tween pins 9 and 22 of the body controller 25-way

black connector. Set the wiper control switch first to

minimum DELAY and then maximum DELAY. (a) If resistance reading at minimum DELAY

setting is between 0 and 15 ohms, and at maxi-

mum DELAY setting the resistance is between

240,000 and 400,000 ohms, replace the body con-

troller. (b) If the resistance values above are not ob-

tained, replace the wiper control switch.

CONDITION: WIPERS DO NOT RUN CONTINUALLY WHEN WASH CONTROL ISOPERATED DURING DELAY MODE

PROCEDURE

(1) Disconnect 25-way blue connector from the

body controller (2) Using a voltmeter, connect the positive lead to

pin 10 of the (Black) connector. Connect negative

lead to the body computer metal case. (3) Set wiper control switch to DELAY position.

(4) Depress wash switch.

(5) If voltage reads 0, check switch relay and wir-

ing. (6) If voltage is between 10 and 15 volts, the prob-

lem is in the body controller.

CONDITION: IN DELAY MODE, WIPERS RUN CONTINUALLY WHEN WASH IS OPERATEDBUT DO NOT PROVIDE FOUR EXTRA WIPESWHEN WASH CONTROL IS RELEASED

PROCEDURE

Replace body controller.

CONDITION: WIPERS START ERRATICALLY DURING DELAY MODE

PROCEDURE

(1) Verify that the ground connection at the in-

strument panel is making a good connection, free

from paint and is tight. (2) Verify that the motor ground strap is making

good contact and that the motor mounting bolts are

tight. (3) Verify that the wiring connections to the body

controller, wiper motor, and wiper motor switch are

tight and free of corrosion. (4) If condition is not corrected, problem is with

the body controller

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 13

Page 637 of 2438

WINDSHIELD WASHERS INDEX

page page

General Information ....................... 17

Washer Nozzle .......................... 19 Washer Reservoir Pump

................... 18

Washer Reservoirs ....................... 17

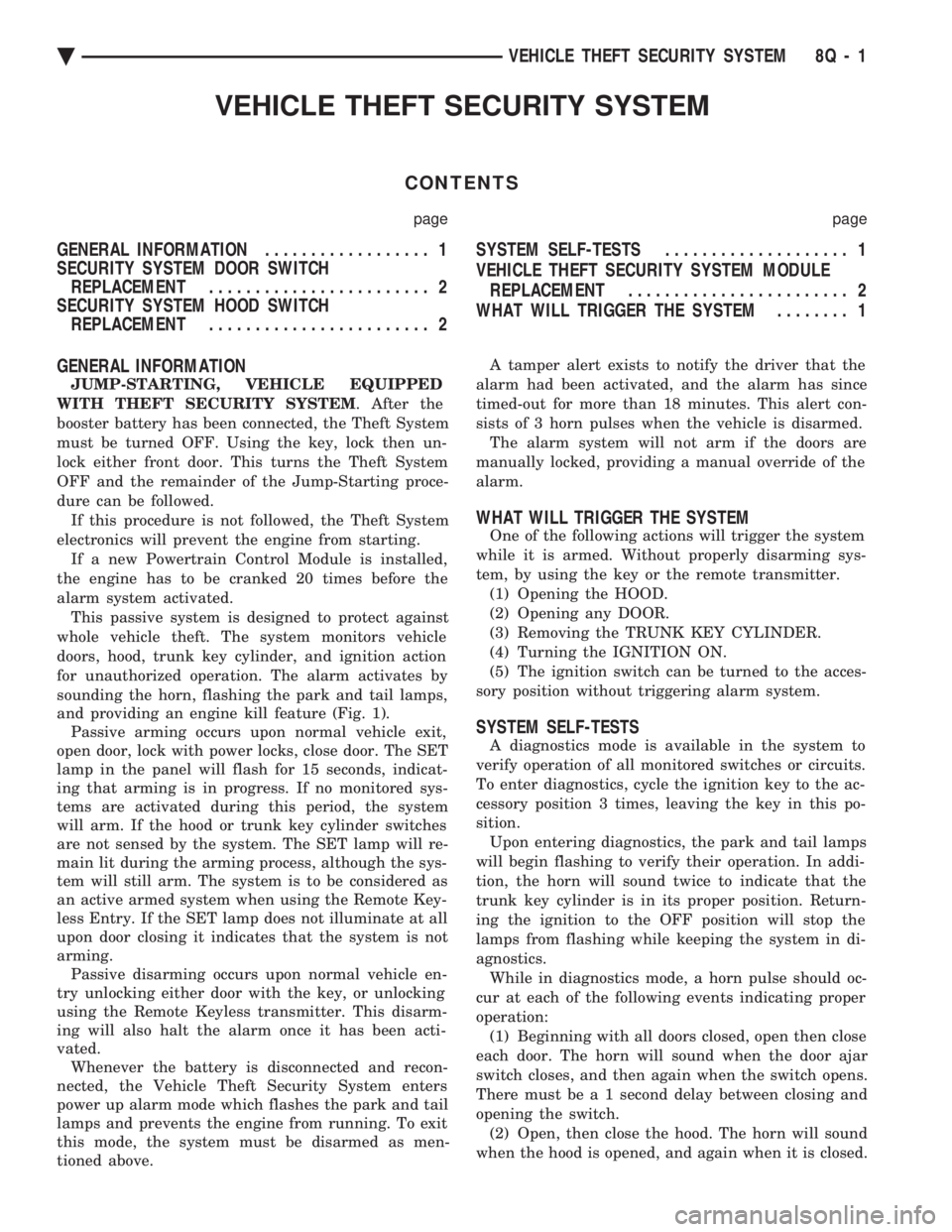

GENERAL INFORMATION

All models are equipped with electric operated

windshield washer pumps. The wash function can be accessed in the OFF po-

sition of the wiper control switch. Holding the wash

button depressed when the switch is in the OFF po-

sition will operate the wipers and washer motor

pump continuously until the washer button is re-

leased. Releasing the button will stop the washer

pump but the wipers will complete the current wipe

cycle. Then followed by an average of two more wipe

cycles ( 61) before the wipers park and the module

turns off. Whenever a windshield washer malfunction occurs,

first verify that the windshield washer wire harness

is properly connected to all connectors before starting

normal diagnosis and repair procedures. Refer to

Windshield Washer Diagnosis Chart (Fig. 29). The electric pump assembly is mounted directly to

the reservoir. A permanently lubricated sealed motor

is coupled to a rotor type pump. Fluid, gravity fed

from the reservoir, is forced by the pump through

rubber hoses to the nozzles which direct the streams

to the windshield. The pump and reservoir are serviced as separate

assemblies on all vehicles.

WASHER RESERVOIRS

FRONT WASHER RESERVOIR

REMOVAL

(1) Remove cowl top screen on applicable models

(Fig. 30 through 33) (2) Remove sheet metal screws attaching the reser-

voir in plenum.

Fig. 29 Windshield Washer Diagnosis

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 17

Page 703 of 2438

VEHICLE THEFT SECURITY SYSTEM

CONTENTS

page page

GENERAL INFORMATION .................. 1

SECURITY SYSTEM DOOR SWITCH REPLACEMENT ........................ 2

SECURITY SYSTEM HOOD SWITCH REPLACEMENT ........................ 2 SYSTEM SELF-TESTS

.................... 1

VEHICLE THEFT SECURITY SYSTEM MODULE REPLACEMENT ........................ 2

WHAT WILL TRIGGER THE SYSTEM ........ 1

GENERAL INFORMATION

JUMP-STARTING, VEHICLE EQUIPPED

WITH THEFT SECURITY SYSTEM . After the

booster battery has been connected, the Theft System

must be turned OFF. Using the key, lock then un-

lock either front door. This turns the Theft System

OFF and the remainder of the Jump-Starting proce-

dure can be followed. If this procedure is not followed, the Theft System

electronics will prevent the engine from starting. If a new Powertrain Control Module is installed,

the engine has to be cranked 20 times before the

alarm system activated. This passive system is designed to protect against

whole vehicle theft. The system monitors vehicle

doors, hood, trunk key cylinder, and ignition action

for unauthorized operation. The alarm activates by

sounding the horn, flashing the park and tail lamps,

and providing an engine kill feature (Fig. 1). Passive arming occurs upon normal vehicle exit,

open door, lock with power locks, close door. The SET

lamp in the panel will flash for 15 seconds, indicat-

ing that arming is in progress. If no monitored sys-

tems are activated during this period, the system

will arm. If the hood or trunk key cylinder switches

are not sensed by the system. The SET lamp will re-

main lit during the arming process, although the sys-

tem will still arm. The system is to be considered as

an active armed system when using the Remote Key-

less Entry. If the SET lamp does not illuminate at all

upon door closing it indicates that the system is not

arming. Passive disarming occurs upon normal vehicle en-

try unlocking either door with the key, or unlocking

using the Remote Keyless transmitter. This disarm-

ing will also halt the alarm once it has been acti-

vated. Whenever the battery is disconnected and recon-

nected, the Vehicle Theft Security System enters

power up alarm mode which flashes the park and tail

lamps and prevents the engine from running. To exit

this mode, the system must be disarmed as men-

tioned above. A tamper alert exists to notify the driver that the

alarm had been activated, and the alarm has since

timed-out for more than 18 minutes. This alert con-

sists of 3 horn pulses when the vehicle is disarmed. The alarm system will not arm if the doors are

manually locked, providing a manual override of the

alarm.

WHAT WILL TRIGGER THE SYSTEM

One of the following actions will trigger the system

while it is armed. Without properly disarming sys-

tem, by using the key or the remote transmitter. (1) Opening the HOOD.

(2) Opening any DOOR.

(3) Removing the TRUNK KEY CYLINDER.

(4) Turning the IGNITION ON.

(5) The ignition switch can be turned to the acces-

sory position without triggering alarm system.

SYSTEM SELF-TESTS

A diagnostics mode is available in the system to

verify operation of all monitored switches or circuits.

To enter diagnostics, cycle the ignition key to the ac-

cessory position 3 times, leaving the key in this po-

sition. Upon entering diagnostics, the park and tail lamps

will begin flashing to verify their operation. In addi-

tion, the horn will sound twice to indicate that the

trunk key cylinder is in its proper position. Return-

ing the ignition to the OFF position will stop the

lamps from flashing while keeping the system in di-

agnostics. While in diagnostics mode, a horn pulse should oc-

cur at each of the following events indicating proper

operation: (1) Beginning with all doors closed, open then close

each door. The horn will sound when the door ajar

switch closes, and then again when the switch opens.

There must b e a 1 second delay between closing and

opening the switch. (2) Open, then close the hood. The horn will sound

when the hood is opened, and again when it is closed.

Ä VEHICLE THEFT SECURITY SYSTEM 8Q - 1

Page 931 of 2438

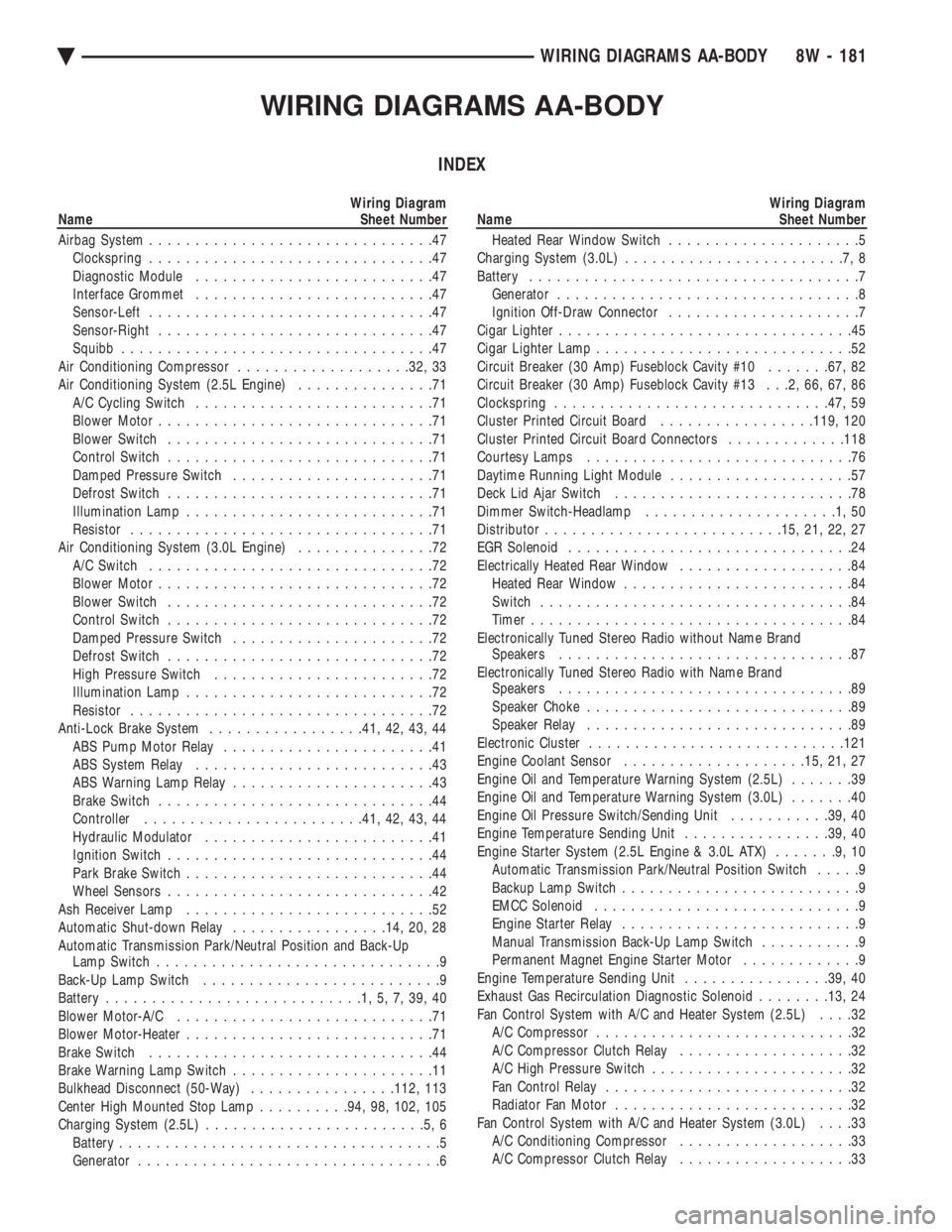

WIRING DIAGRAMS AA-BODY

INDEX

Wiring Diagram

Name Sheet Number

Airbag System ...............................47

Clockspring ...............................47

Diagnostic Module ..........................47

Interface Grommet ..........................47

Sensor-Left ...............................47

Sensor-Right ..............................47

Squibb ..................................47

Air Conditioning Compressor ...................32, 33

Air Conditioning System (2.5L Engine) ...............71

A/C Cycling Switch ..........................71

Blower Motor ..............................71

Blower Switch .............................71

Control Switch .............................71

Damped Pressure Switch ......................71

Defrost Switch .............................71

Illumination Lamp ...........................71

Resistor .................................71

Air Conditioning System (3.0L Engine) ...............72

A/C Switch ...............................72

Blower Motor ..............................72

Blower Switch .............................72

Control Switch .............................72

Damped Pressure Switch ......................72

Defrost Switch .............................72

High Pressure Switch ........................72

Illumination Lamp ...........................72

Resistor .................................72

Anti-Lock Brake System .................41, 42, 43, 44

ABS Pump Motor Relay .......................41

ABS System Relay ..........................43

ABS Warning Lamp Relay ......................43

Brake Switch ..............................44

Controller ....................... .41, 42, 43, 44

Hydraulic Modulator .........................41

Ignition Switch .............................44

Park Brake Switch ...........................44

Wheel Sensors .............................42

Ash Receiver Lamp ...........................52

Automatic Shut-down Relay .................14, 20, 28

Automatic Transmission Park/Neutral Position and Back-Up Lamp Switch ...............................9

Back-Up Lamp Switch ..........................9

Battery ............................1,5,7,39,40

Blower Motor-A/C ............................71

Blower Motor-Heater ...........................71

Brake Switch ...............................44

Brake Warning Lamp Switch ......................11

Bulkhead Disconnect (50-Way) ................112, 113

Center High Mounted Stop Lamp ..........94, 98, 102, 105

Charging System (2.5L) ........................5,6

Battery ...................................5

Generator .................................6Wiring Diagram

Name Sheet Number

Heated Rear Window Switch .....................5

Charging System (3.0L) ........................7,8

Battery ....................................7

Generator .................................8

Ignition Off-Draw Connector .....................7

Cigar Lighter ................................45

Cigar Lighter Lamp ............................52

Circuit Breaker (30 Amp) Fuseblock Cavity #10 .......67, 82

Circuit Breaker (30 Amp) Fuseblock Cavity #13 . . .2, 66, 67, 86

Clockspring ............................. .47, 59

Cluster Printed Circuit Board .................119, 120

Cluster Printed Circuit Board Connectors .............118

Courtesy Lamps .............................76

Daytime Running Light Module ....................57

Deck Lid Ajar Switch ..........................78

Dimmer Switch-Headlamp .....................1,50

Distributor ......................... .15, 21, 22, 27

EGR Solenoid ...............................24

Electrically Heated Rear Window ...................84

Heated Rear Window .........................84

Switch ..................................84

Timer ...................................84

Electronically Tuned Stereo Radio without Name Brand Speakers ................................87

Electronically Tuned Stereo Radio with Name Brand Speakers ................................89

Speaker Choke .............................89

Speaker Relay .............................89

Electronic Cluster ........................... .121

Engine Coolant Sensor ................... .15, 21, 27

Engine Oil and Temperature Warning System (2.5L) .......39

Engine Oil and Temperature Warning System (3.0L) .......40

Engine Oil Pressure Switch/Sending Unit ...........39, 40

Engine Temperature Sending Unit ................39, 40

Engine Starter System (2.5L Engine & 3.0L ATX) .......9,10

Automatic Transmission Park/Neutral Position Switch .....9

Backup Lamp Switch ..........................9

EMCC Solenoid .............................9

Engine Starter Relay ..........................9

Manual Transmission Back-Up Lamp Switch ...........9

Permanent Magnet Engine Starter Motor .............9

Engine Temperature Sending Unit ................39, 40

Exhaust Gas Recirculation Diagnostic Solenoid ........13, 24

Fan Control System with A/C and Heater System (2.5L) ....32

A/C Compressor ............................32

A/C Compressor Clutch Relay ...................32

A/C High Pressure Switch ......................32

Fan Control Relay ...........................32

Radiator Fan Motor ..........................32

Fan Control System with A/C and Heater System (3.0L) ....33

A/C Conditioning Compressor ...................33

A/C Compressor Clutch Relay ...................33

Ä WIRING DIAGRAMS AA-BODY 8W - 181

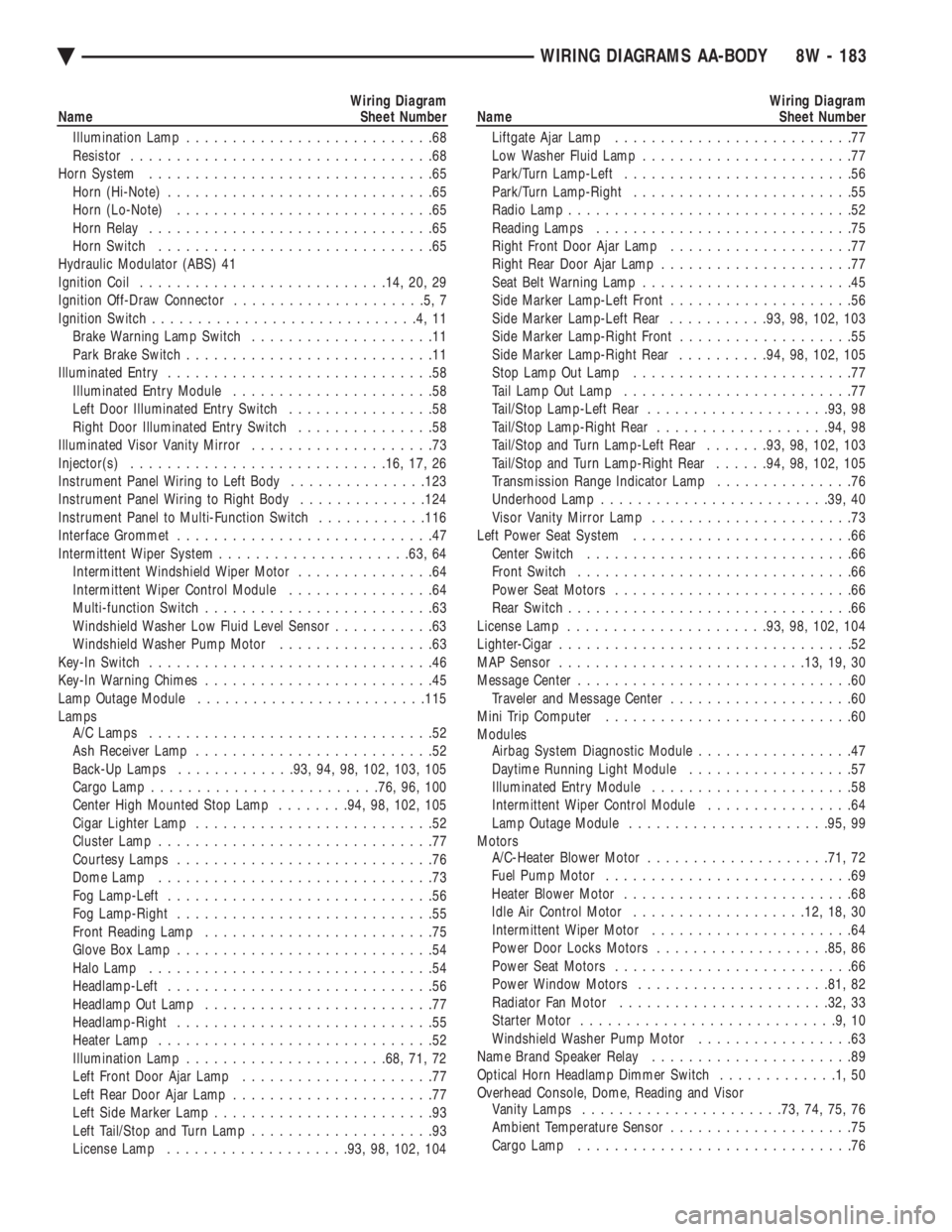

Page 933 of 2438

Wiring Diagram

Name Sheet Number

Illumination Lamp ...........................68

Resistor .................................68

Horn System ...............................65

Horn (Hi-Note) .............................65

Horn (Lo-Note) ............................65

Horn Relay ...............................65

Horn Switch ..............................65

Hydraulic Modulator (ABS) 41

Ignition Coil .......................... .14, 20, 29

Ignition Off-Draw Connector .....................5,7

Ignition Switch .............................4,11

Brake Warning Lamp Switch ....................11

Park Brake Switch ...........................11

Illuminated Entry .............................58

Illuminated Entry Module ......................58

Left Door Illuminated Entry Switch ................58

Right Door Illuminated Entry Switch ...............58

Illuminated Visor Vanity Mirror ....................73

Injector(s) ........................... .16, 17, 26

Instrument Panel Wiring to Left Body ...............123

Instrument Panel Wiring to Right Body ..............124

Instrument Panel to Multi-Function Switch ............116

Interface Grommet ............................47

Intermittent Wiper System .................... .63, 64

Intermittent Windshield Wiper Motor ...............64

Intermittent Wiper Control Module ................64

Multi-function Switch .........................63

Windshield Washer Low Fluid Level Sensor ...........63

Windshield Washer Pump Motor .................63

Key-In Switch ...............................46

Key-In Warning Chimes .........................45

Lamp Outage Module ........................ .115

Lamps A/C Lamps ...............................52

Ash Receiver Lamp ..........................52

Back-Up Lamps ............ .93, 94, 98, 102, 103, 105

Cargo Lamp ........................ .76, 96, 100

Center High Mounted Stop Lamp ........94, 98, 102, 105

Cigar Lighter Lamp ..........................52

Cluster Lamp ..............................77

Courtesy Lamps ............................76

Dome Lamp ..............................73

Fog Lamp-Left .............................56

Fog Lamp-Right ............................55

Front Reading Lamp .........................75

Glove Box Lamp ............................54

Halo Lamp ...............................54

Headlamp-Left .............................56

Headlamp Out Lamp .........................77

Headlamp-Right ............................55

Heater Lamp ..............................52

Illumination Lamp ..................... .68, 71, 72

Left Front Door Ajar Lamp .....................77

Left Rear Door Ajar Lamp ......................77

Left Side Marker Lamp ........................93

Left Tail/Stop and Turn Lamp ....................93

License Lamp ................... .93, 98, 102, 104Wiring Diagram

Name Sheet Number

Liftgate Ajar Lamp ..........................77

Low Washer Fluid Lamp .......................77

Park/Turn Lamp-Left .........................56

Park/Turn Lamp-Right ........................55

Radio Lamp ...............................52

Reading Lamps ............................75

Right Front Door Ajar Lamp ....................77

Right Rear Door Ajar Lamp .....................77

Seat Belt Warning Lamp .......................45

Side Marker Lamp-Left Front ....................56

Side Marker Lamp-Left Rear ...........93, 98, 102, 103

Side Marker Lamp-Right Front ...................55

Side Marker Lamp-Right Rear ..........94, 98, 102, 105

Stop Lamp Out Lamp ........................77

Tail Lamp Out Lamp .........................77

Tail/Stop Lamp-Left Rear ................... .93, 98

Tail/Stop Lamp-Right Rear .................. .94, 98

Tail/Stop and Turn Lamp-Left Rear .......93, 98, 102, 103

Tail/Stop and Turn Lamp-Right Rear ......94, 98, 102, 105

Transmission Range Indicator Lamp ...............76

Underhood Lamp ........................ .39, 40

Visor Vanity Mirror Lamp ......................73

Left Power Seat System ........................66

Center Switch .............................66

Front Switch ..............................66

Power Seat Motors ..........................66

Rear Switch ...............................66

License Lamp ..................... .93, 98, 102, 104

Lighter-Cigar ................................52

MAP Sensor .......................... .13, 19, 30

Message Center ..............................60

Traveler and Message Center ....................60

Mini Trip Computer ...........................60

Modules Airbag System Diagnostic Module .................47

Daytime Running Light Module ..................57

Illuminated Entry Module ......................58

Intermittent Wiper Control Module ................64

Lamp Outage Module ..................... .95, 99

Motors A/C-Heater Blower Motor ................... .71, 72

Fuel Pump Motor ...........................69

Heater Blower Motor .........................68

Idle Air Control Motor .................. .12, 18, 30

Intermittent Wiper Motor ......................64

Power Door Locks Motors .................. .85, 86

Power Seat Motors ..........................66

Power Window Motors .................... .81, 82

Radiator Fan Motor ...................... .32, 33

Starter Motor ............................9,10

Windshield Washer Pump Motor .................63

Name Brand Speaker Relay ......................89

Optical Horn Headlamp Dimmer Switch .............1,50

Overhead Console, Dome, Reading and Visor Vanity Lamps ..................... .73, 74, 75, 76

Ambient Temperature Sensor ....................75

Cargo Lamp ..............................76

Ä WIRING DIAGRAMS AA-BODY 8W - 183