warning CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 56 of 2438

The power steering pump drive belt should be in-

spected at the time and distance interval described in

the Lubrication and Maintenance Schedules. Refer to

the General Information section of this group.

POWER STEERING FLUID INSPECTION

WARNING: ENGINE MUST NOT BE RUNNING WHEN

INSPECTING POWER STEERING FLUID LEVEL,

PERSONAL INJURY CAN RESULT.

CAUTION: Do not over fill power steering reservoir

when adding fluid, seal damage and leakage can re-

sult.

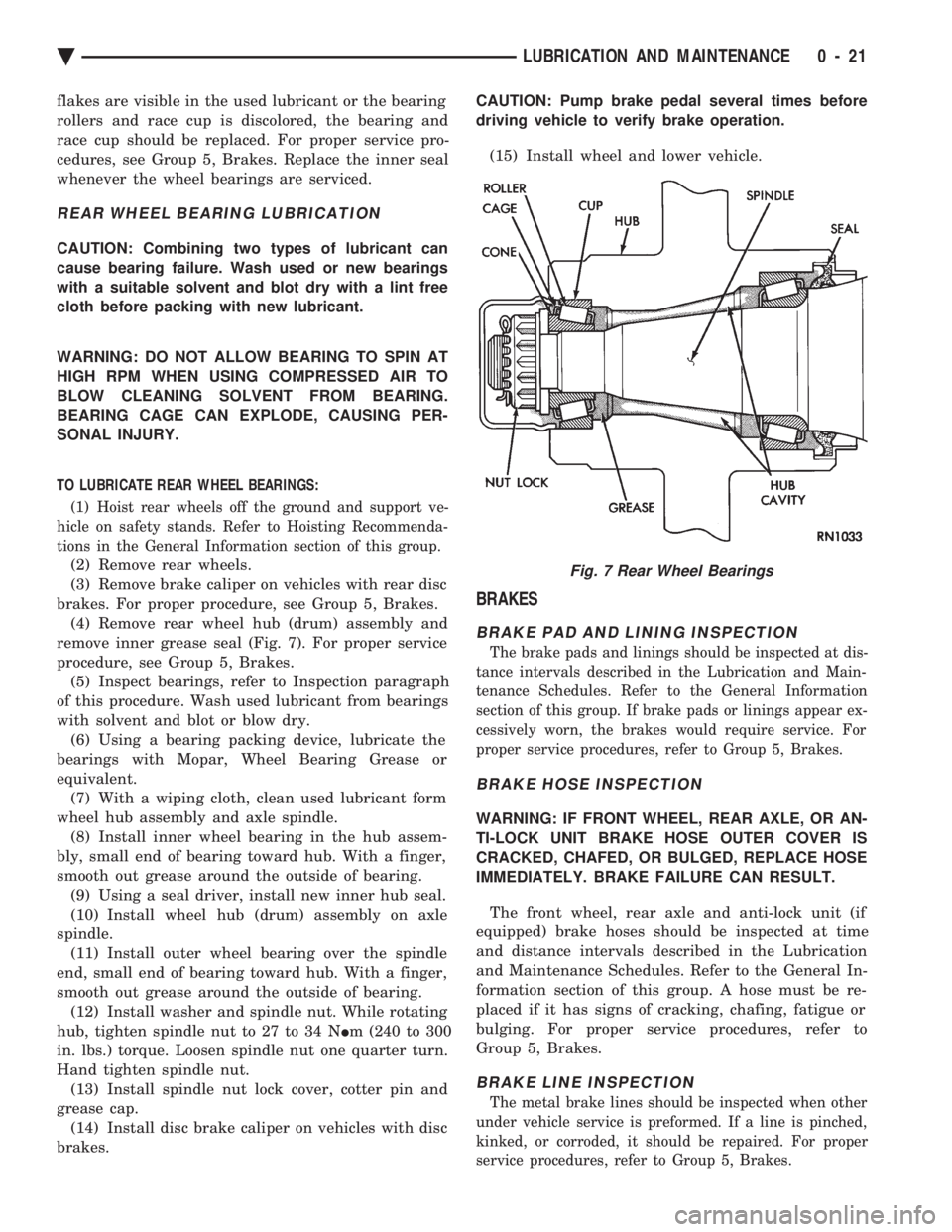

TO INSPECT FLUID LEVEL:

(1) Position vehicle on a level surface with engine

at normal running temperature. (2) Turn OFF engine and remove ignition key.

(3) Using a wiping cloth, clean oil and dirt residue

from around power steering reservoir cap. (4) Remove reservoir cap or dipstick and wipe off

fluid. (5) Install cap or dipstick.

(6) Remove cap or dipstick. Holding handle or cap

above tip of dipstick, read fluid level (Fig. 4, 5, or 6).

Add fluid if reading is below cold level mark on dip-

stick.

REAR WHEEL BEARINGS

INSPECTION

The rear wheel bearings should be packed with

new lubricant at the distance interval described in the Lubrication and Maintenance Schedules. Refer to

the General Information section of this group. The

bearings should be inspected for contamination and

wear before they are cleaned. Slight discoloration of

bearing rollers and race cup is normal. If metal

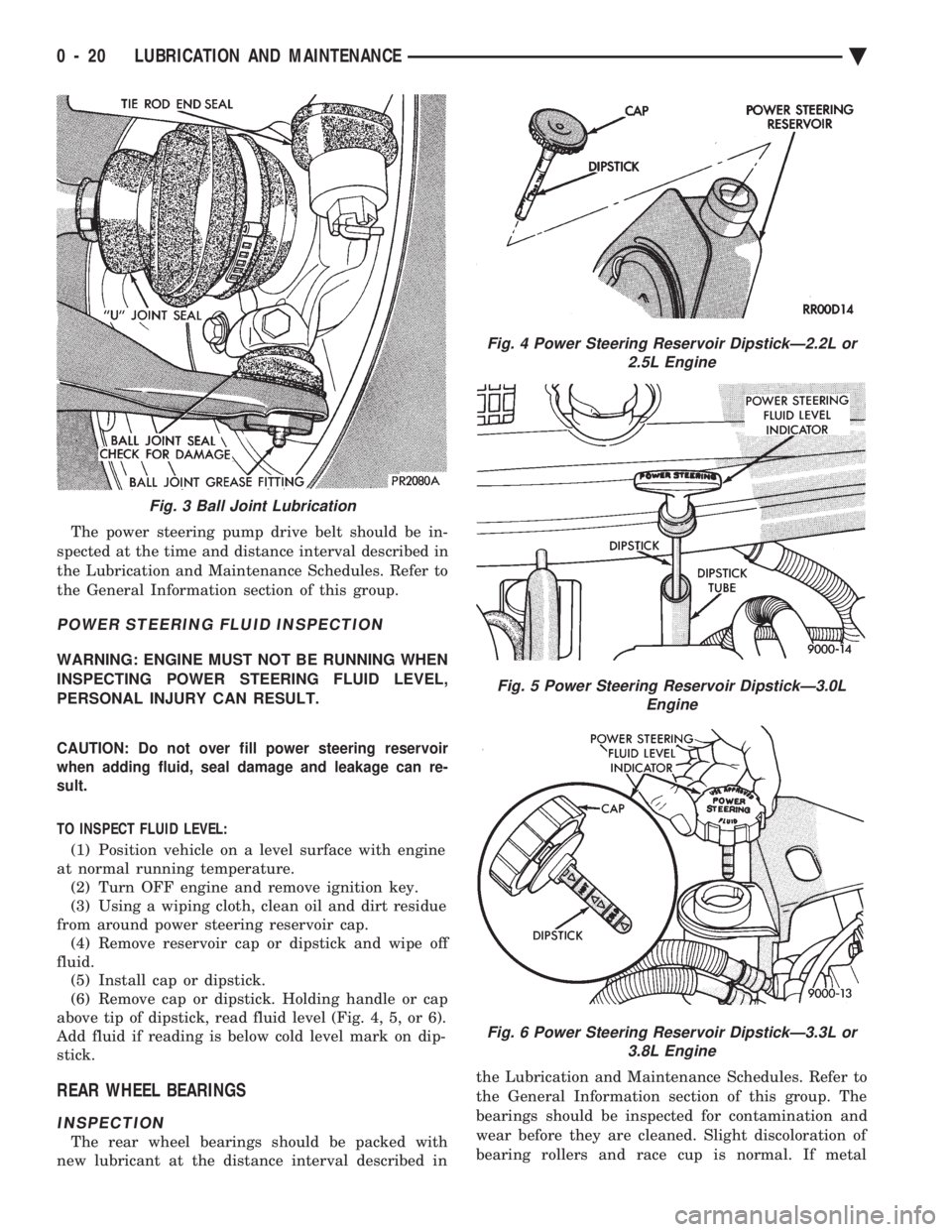

Fig. 3 Ball Joint Lubrication

Fig. 4 Power Steering Reservoir DipstickÐ2.2L or 2.5L Engine

Fig. 5 Power Steering Reservoir DipstickÐ3.0L Engine

Fig. 6 Power Steering Reservoir DipstickÐ3.3L or3.8L Engine

0 - 20 LUBRICATION AND MAINTENANCE Ä

Page 57 of 2438

flakes are visible in the used lubricant or the bearing

rollers and race cup is discolored, the bearing and

race cup should be replaced. For proper service pro-

cedures, see Group 5, Brakes. Replace the inner seal

whenever the wheel bearings are serviced.

REAR WHEEL BEARING LUBRICATION

CAUTION: Combining two types of lubricant can

cause bearing failure. Wash used or new bearings

with a suitable solvent and blot dry with a lint free

cloth before packing with new lubricant.

WARNING: DO NOT ALLOW BEARING TO SPIN AT

HIGH RPM WHEN USING COMPRESSED AIR TO

BLOW CLEANING SOLVENT FROM BEARING.

BEARING CAGE CAN EXPLODE, CAUSING PER-

SONAL INJURY.

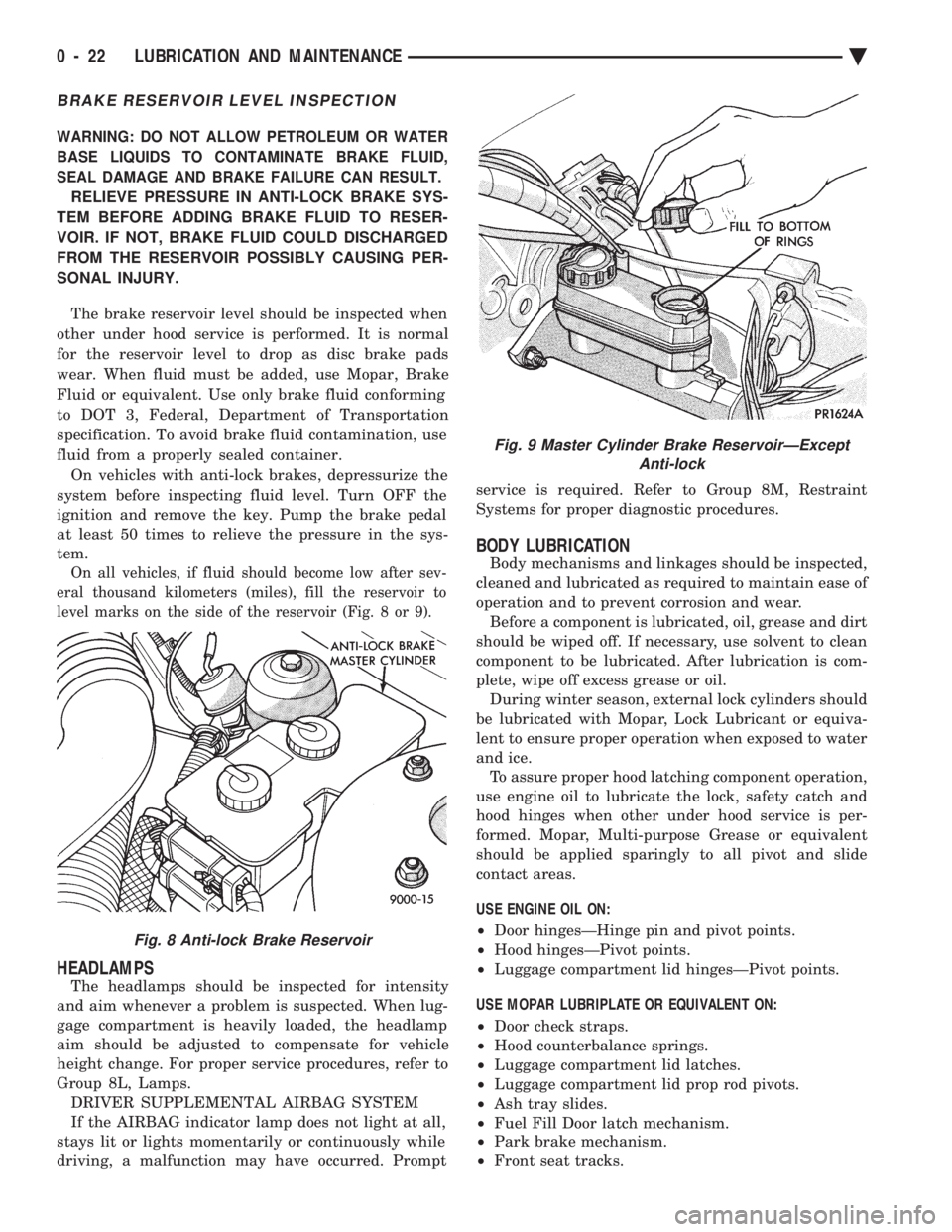

TO LUBRICATE REAR WHEEL BEARINGS:

(1) Hoist rear wheels off the ground and support ve-

hicle on safety stands. Refer to Hoisting Recommenda-

tions in the General Information section of this group.

(2) Remove rear wheels.

(3) Remove brake caliper on vehicles with rear disc

brakes. For proper procedure, see Group 5, Brakes. (4) Remove rear wheel hub (drum) assembly and

remove inner grease seal (Fig. 7). For proper service

procedure, see Group 5, Brakes. (5) Inspect bearings, refer to Inspection paragraph

of this procedure. Wash used lubricant from bearings

with solvent and blot or blow dry. (6) Using a bearing packing device, lubricate the

bearings with Mopar, Wheel Bearing Grease or

equivalent. (7) With a wiping cloth, clean used lubricant form

wheel hub assembly and axle spindle. (8) Install inner wheel bearing in the hub assem-

bly, small end of bearing toward hub. With a finger,

smooth out grease around the outside of bearing. (9) Using a seal driver, install new inner hub seal.

(10) Install wheel hub (drum) assembly on axle

spindle. (11) Install outer wheel bearing over the spindle

end, small end of bearing toward hub. With a finger,

smooth out grease around the outside of bearing. (12) Install washer and spindle nut. While rotating

hub, tighten spindle nut to 27 to 34 N Im (240 to 300

in. lbs.) torque. Loosen spindle nut one quarter turn.

Hand tighten spindle nut. (13) Install spindle nut lock cover, cotter pin and

grease cap. (14) Install disc brake caliper on vehicles with disc

brakes. CAUTION: Pump brake pedal several times before

driving vehicle to verify brake operation.

(15) Install wheel and lower vehicle.

BRAKES

BRAKE PAD AND LINING INSPECTION

The brake pads and linings should be inspected at dis-

tance intervals described in the Lubrication and Main-

tenance Schedules. Refer to the General Information

section of this group. If brake pads or linings appear ex-

cessively worn, the brakes would require service. For

proper service procedures, refer to Group 5, Brakes.

BRAKE HOSE INSPECTION

WARNING: IF FRONT WHEEL, REAR AXLE, OR AN-

TI-LOCK UNIT BRAKE HOSE OUTER COVER IS

CRACKED, CHAFED, OR BULGED, REPLACE HOSE

IMMEDIATELY. BRAKE FAILURE CAN RESULT.

The front wheel, rear axle and anti-lock unit (if

equipped) brake hoses should be inspected at time

and distance intervals described in the Lubrication

and Maintenance Schedules. Refer to the General In-

formation section of this group. A hose must be re-

placed if it has signs of cracking, chafing, fatigue or

bulging. For proper service procedures, refer to

Group 5, Brakes.

BRAKE LINE INSPECTION

The metal brake lines should be inspected when other

under vehicle service is preformed. If a line is pinched,

kinked, or corroded, it should be repaired. For proper

service procedures, refer to Group 5, Brakes.

Fig. 7 Rear Wheel Bearings

Ä LUBRICATION AND MAINTENANCE 0 - 21

Page 58 of 2438

BRAKE RESERVOIR LEVEL INSPECTION

WARNING: DO NOT ALLOW PETROLEUM OR WATER

BASE LIQUIDS TO CONTAMINATE BRAKE FLUID,

SEAL DAMAGE AND BRAKE FAILURE CAN RESULT.

RELIEVE PRESSURE IN ANTI-LOCK BRAKE SYS-

TEM BEFORE ADDING BRAKE FLUID TO RESER-

VOIR. IF NOT, BRAKE FLUID COULD DISCHARGED

FROM THE RESERVOIR POSSIBLY CAUSING PER-

SONAL INJURY.

The brake reservoir level should be inspected when

other under hood service is performed. It is normal

for the reservoir level to drop as disc brake pads

wear. When fluid must be added, use Mopar, Brake

Fluid or equivalent. Use only brake fluid conforming

to DOT 3, Federal, Department of Transportation

specification. To avoid brake fluid contamination, use

fluid from a properly sealed container. On vehicles with anti-lock brakes, depressurize the

system before inspecting fluid level. Turn OFF the

ignition and remove the key. Pump the brake pedal

at least 50 times to relieve the pressure in the sys-

tem.

On all vehicles, if fluid should become low after sev-

eral thousand kilometers (miles), fill the reservoir to

level marks on the side of the reservoir (Fig. 8 or 9).

HEADLAMPS

The headlamps should be inspected for intensity

and aim whenever a problem is suspected. When lug-

gage compartment is heavily loaded, the headlamp

aim should be adjusted to compensate for vehicle

height change. For proper service procedures, refer to

Group 8L, Lamps. DRIVER SUPPLEMENTAL AIRBAG SYSTEM

If the AIRBAG indicator lamp does not light at all,

stays lit or lights momentarily or continuously while

driving, a malfunction may have occurred. Prompt service is required. Refer to Group 8M, Restraint

Systems for proper diagnostic procedures.

BODY LUBRICATION

Body mechanisms and linkages should be inspected,

cleaned and lubricated as required to maintain ease of

operation and to prevent corrosion and wear. Before a component is lubricated, oil, grease and dirt

should be wiped off. If necessary, use solvent to clean

component to be lubricated. After lubrication is com-

plete, wipe off excess grease or oil. During winter season, external lock cylinders should

be lubricated with Mopar, Lock Lubricant or equiva-

lent to ensure proper operation when exposed to water

and ice. To assure proper hood latching component operation,

use engine oil to lubricate the lock, safety catch and

hood hinges when other under hood service is per-

formed. Mopar, Multi-purpose Grease or equivalent

should be applied sparingly to all pivot and slide

contact areas.

USE ENGINE OIL ON:

² Door hingesÐHinge pin and pivot points.

² Hood hingesÐPivot points.

² Luggage compartment lid hingesÐPivot points.

USE MOPAR LUBRIPLATE OR EQUIVALENT ON:

² Door check straps.

² Hood counterbalance springs.

² Luggage compartment lid latches.

² Luggage compartment lid prop rod pivots.

² Ash tray slides.

² Fuel Fill Door latch mechanism.

² Park brake mechanism.

² Front seat tracks.

Fig. 8 Anti-lock Brake Reservoir

Fig. 9 Master Cylinder Brake ReservoirÐExcept

Anti-lock

0 - 22 LUBRICATION AND MAINTENANCE Ä

Page 67 of 2438

(a) Severe deterioration of rubber isolator; re-

tainers for cracks and distortion and bond failure of

retainers and rubber isolators. (b) Bearings for binding.

(c) Shock Absorber for flat spots over full stroke

also see, Shock Absorbers, (strut damper).

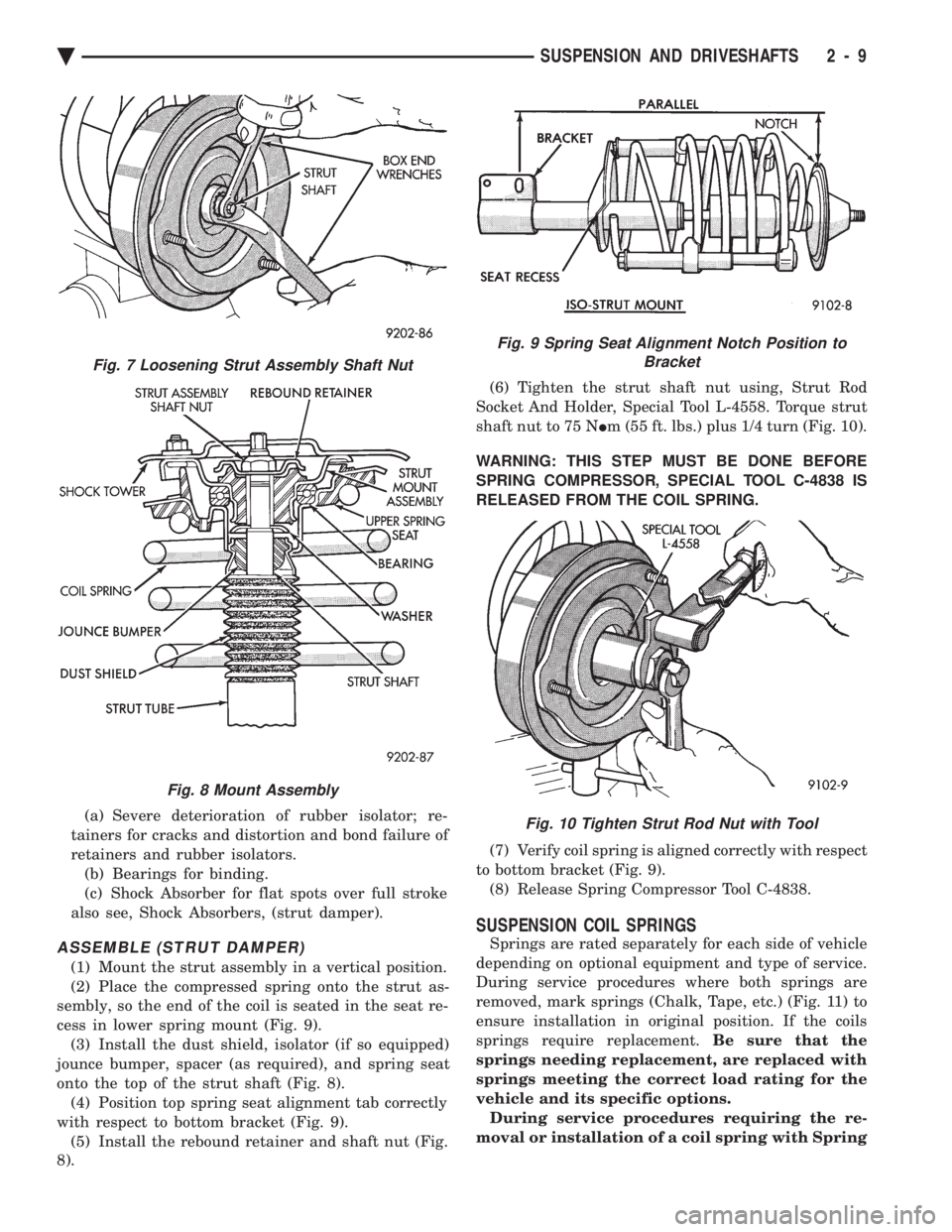

ASSEMBLE (STRUT DAMPER)

(1) Mount the strut assembly in a vertical position.

(2) Place the compressed spring onto the strut as-

sembly, so the end of the coil is seated in the seat re-

cess in lower spring mount (Fig. 9). (3) Install the dust shield, isolator (if so equipped)

jounce bumper, spacer (as required), and spring seat

onto the top of the strut shaft (Fig. 8). (4) Position top spring seat alignment tab correctly

with respect to bottom bracket (Fig. 9). (5) Install the rebound retainer and shaft nut (Fig.

8). (6) Tighten the strut shaft nut using, Strut Rod

Socket And Holder, Special Tool L-4558. Torque strut

shaft nut to 75 N Im (55 ft. lbs.) plus 1/4 turn (Fig. 10).

WARNING: THIS STEP MUST BE DONE BEFORE

SPRING COMPRESSOR, SPECIAL TOOL C-4838 IS

RELEASED FROM THE COIL SPRING.

(7) Verify coil spring is aligned correctly with respect

to bottom bracket (Fig. 9). (8) Release Spring Compressor Tool C-4838.

SUSPENSION COIL SPRINGS

Springs are rated separately for each side of vehicle

depending on optional equipment and type of service.

During service procedures where both springs are

removed, mark springs (Chalk, Tape, etc.) (Fig. 11) to

ensure installation in original position. If the coils

springs require replacement. Be sure that the

springs needing replacement, are replaced with

springs meeting the correct load rating for the

vehicle and its specific options. During service procedures requiring the re-

moval or installation of a coil spring with Spring

Fig. 7 Loosening Strut Assembly Shaft Nut

Fig. 8 Mount Assembly

Fig. 9 Spring Seat Alignment Notch Position to Bracket

Fig. 10 Tighten Strut Rod Nut with Tool

Ä SUSPENSION AND DRIVESHAFTS 2 - 9

Page 111 of 2438

WARNING: WHEN REMOVING THE REAR AXLE

PIVOT BUSHING ON VEHICLES EQUIPPED WITH EI-

THER REAR COIL SPRINGS OR AIR SUSPENSION.

THE REAR AXLE MUST BE SUPPORTED BY THE

AXLE AND TRAILING ARM TO ENSURE ADEQUATE

SUPPORT OF REAR AXLE.

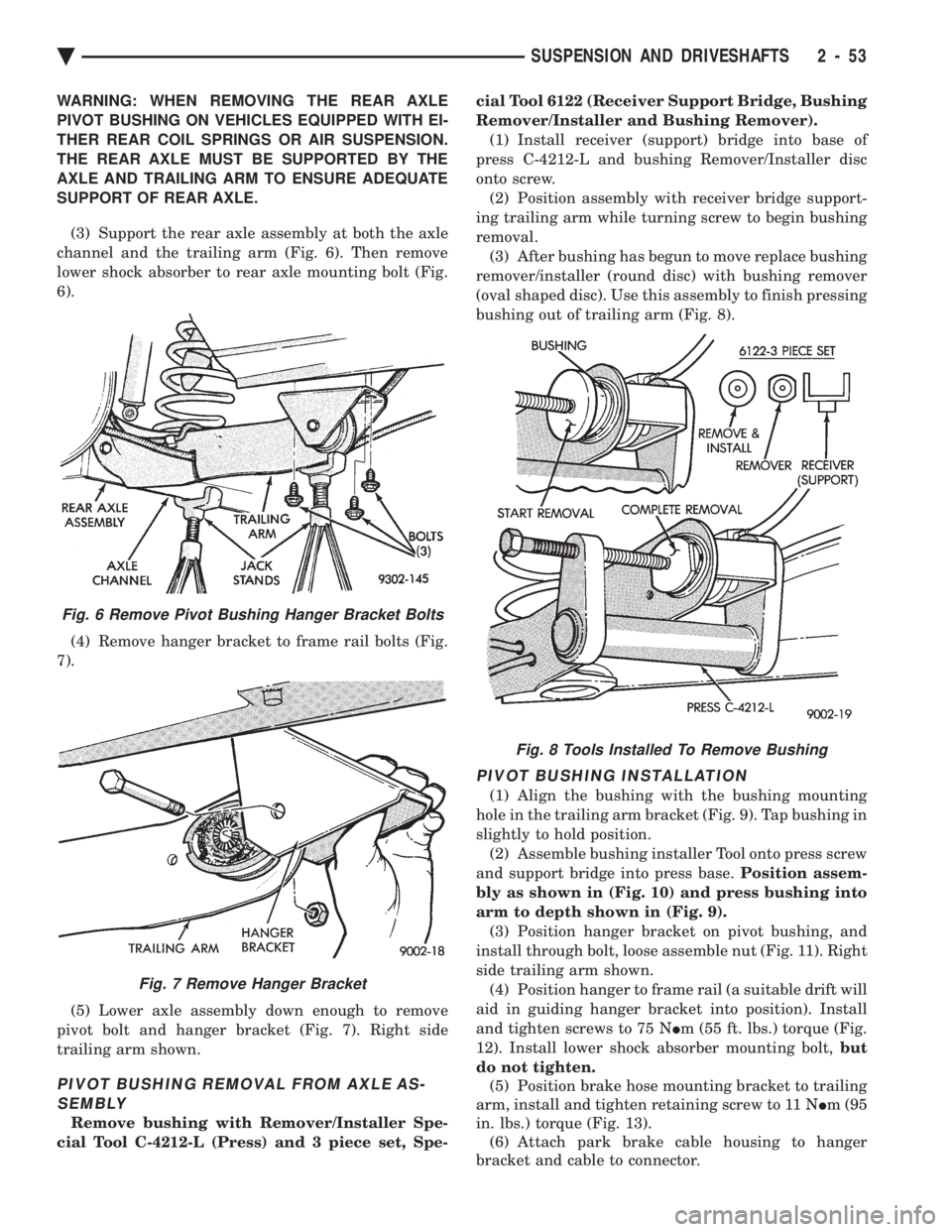

(3) Support the rear axle assembly at both the axle

channel and the trailing arm (Fig. 6). Then remove

lower shock absorber to rear axle mounting bolt (Fig.

6).

(4) Remove hanger bracket to frame rail bolts (Fig.

7).

(5) Lower axle assembly down enough to remove

pivot bolt and hanger bracket (Fig. 7). Right side

trailing arm shown.

PIVOT BUSHING REMOVAL FROM AXLE AS- SEMBLY

Remove bushing with Remover/Installer Spe-

cial Tool C-4212-L (Press) and 3 piece set, Spe- cial Tool 6122 (Receiver Support Bridge, Bushing

Remover/Installer and Bushing Remover). (1) Install receiver (support) bridge into base of

press C-4212-L and bushing Remover/Installer disc

onto screw. (2) Position assembly with receiver bridge support-

ing trailing arm while turning screw to begin bushing

removal. (3) After bushing has begun to move replace bushing

remover/installer (round disc) with bushing remover

(oval shaped disc). Use this assembly to finish pressing

bushing out of trailing arm (Fig. 8).

PIVOT BUSHING INSTALLATION

(1) Align the bushing with the bushing mounting

hole in the trailing arm bracket (Fig. 9). Tap bushing in

slightly to hold position. (2) Assemble bushing installer Tool onto press screw

and support bridge into press base. Position assem-

bly as shown in (Fig. 10) and press bushing into

arm to depth shown in (Fig. 9). (3) Position hanger bracket on pivot bushing, and

install through bolt, loose assemble nut (Fig. 11). Right

side trailing arm shown. (4) Position hanger to frame rail (a suitable drift will

aid in guiding hanger bracket into position). Install

and tighten screws to 75 N Im (55 ft. lbs.) torque (Fig.

12). Install lower shock absorber mounting bolt, but

do not tighten. (5) Position brake hose mounting bracket to trailing

arm, install and tighten retaining screw to 11 N Im (95

in. lbs.) torque (Fig. 13). (6) Attach park brake cable housing to hanger

bracket and cable to connector.

Fig. 8 Tools Installed To Remove Bushing

Fig. 6 Remove Pivot Bushing Hanger Bracket Bolts

Fig. 7 Remove Hanger Bracket

Ä SUSPENSION AND DRIVESHAFTS 2 - 53

Page 113 of 2438

PIVOT BUSHING AC AG AJ AP BODY

REMOVE FROM VEHICLE

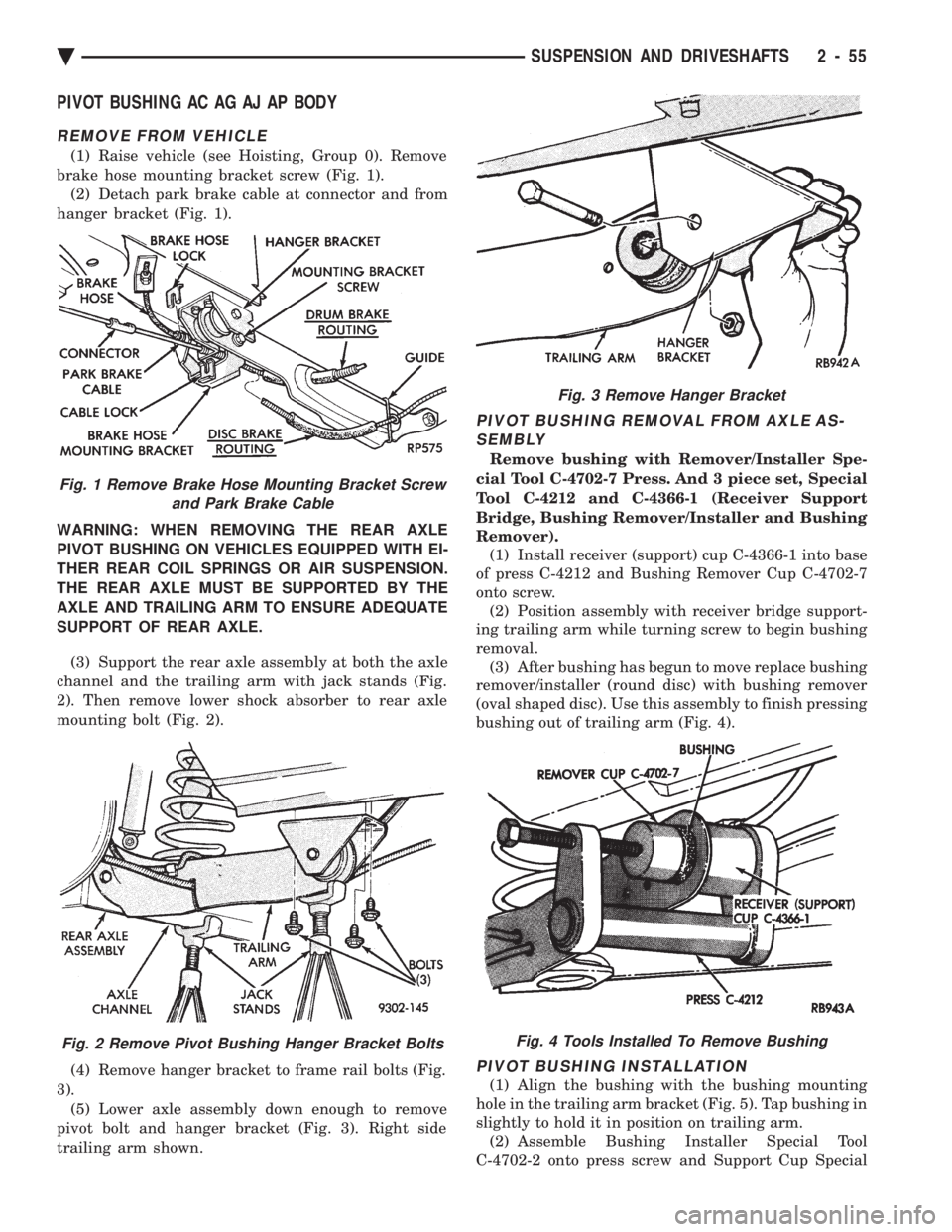

(1) Raise vehicle (see Hoisting, Group 0). Remove

brake hose mounting bracket screw (Fig. 1). (2) Detach park brake cable at connector and from

hanger bracket (Fig. 1).

WARNING: WHEN REMOVING THE REAR AXLE

PIVOT BUSHING ON VEHICLES EQUIPPED WITH EI-

THER REAR COIL SPRINGS OR AIR SUSPENSION.

THE REAR AXLE MUST BE SUPPORTED BY THE

AXLE AND TRAILING ARM TO ENSURE ADEQUATE

SUPPORT OF REAR AXLE. (3) Support the rear axle assembly at both the axle

channel and the trailing arm with jack stands (Fig.

2). Then remove lower shock absorber to rear axle

mounting bolt (Fig. 2).

(4) Remove hanger bracket to frame rail bolts (Fig.

3). (5) Lower axle assembly down enough to remove

pivot bolt and hanger bracket (Fig. 3). Right side

trailing arm shown.

PIVOT BUSHING REMOVAL FROM AXLE AS- SEMBLY

Remove bushing with Remover/Installer Spe-

cial Tool C-4702-7 Press. And 3 piece set, Special

Tool C-4212 and C-4366-1 (Receiver Support

Bridge, Bushing Remover/Installer and Bushing

Remover). (1) Install receiver (support) cup C-4366-1 into base

of press C-4212 and Bushing Remover Cup C-4702-7

onto screw. (2) Position assembly with receiver bridge support-

ing trailing arm while turning screw to begin bushing

removal. (3) After bushing has begun to move replace bushing

remover/installer (round disc) with bushing remover

(oval shaped disc). Use this assembly to finish pressing

bushing out of trailing arm (Fig. 4).

PIVOT BUSHING INSTALLATION

(1) Align the bushing with the bushing mounting

hole in the trailing arm bracket (Fig. 5). Tap bushing in

slightly to hold it in position on trailing arm. (2) Assemble Bushing Installer Special Tool

C-4702-2 onto press screw and Support Cup Special

Fig. 1 Remove Brake Hose Mounting Bracket Screw and Park Brake Cable

Fig. 2 Remove Pivot Bushing Hanger Bracket Bolts

Fig. 3 Remove Hanger Bracket

Fig. 4 Tools Installed To Remove Bushing

Ä SUSPENSION AND DRIVESHAFTS 2 - 55

Page 136 of 2438

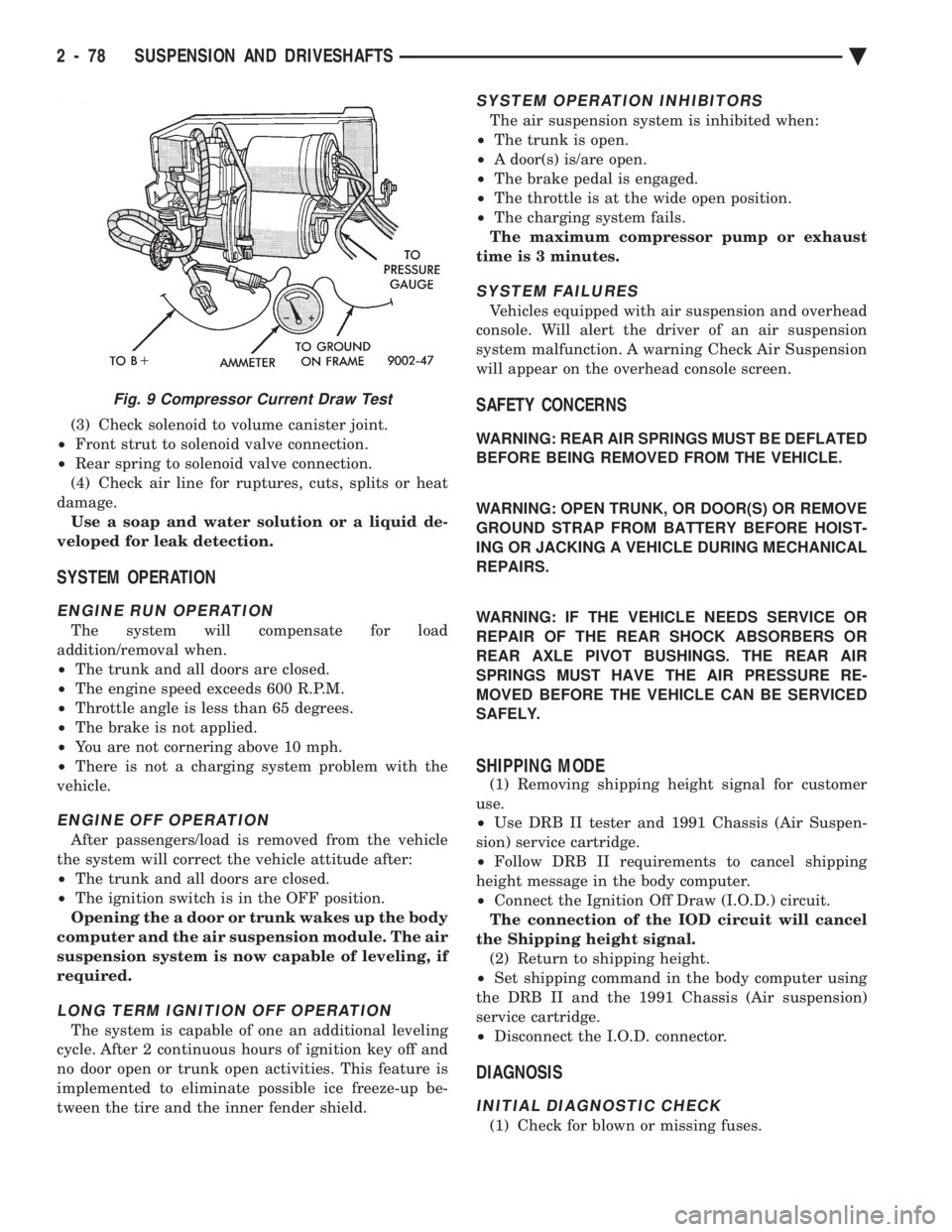

(3) Check solenoid to volume canister joint.

² Front strut to solenoid valve connection.

² Rear spring to solenoid valve connection.

(4) Check air line for ruptures, cuts, splits or heat

damage. Use a soap and water solution or a liquid de-

veloped for leak detection.

SYSTEM OPERATION

ENGINE RUN OPERATION

The system will compensate for load

addition/removal when.

² The trunk and all doors are closed.

² The engine speed exceeds 600 R.P.M.

² Throttle angle is less than 65 degrees.

² The brake is not applied.

² You are not cornering above 10 mph.

² There is not a charging system problem with the

vehicle.

ENGINE OFF OPERATION

After passengers/load is removed from the vehicle

the system will correct the vehicle attitude after:

² The trunk and all doors are closed.

² The ignition switch is in the OFF position.

Opening the a door or trunk wakes up the body

computer and the air suspension module. The air

suspension system is now capable of leveling, if

required.

LONG TERM IGNITION OFF OPERATION

The system is capable of one an additional leveling

cycle. After 2 continuous hours of ignition key off and

no door open or trunk open activities. This feature is

implemented to eliminate possible ice freeze-up be-

tween the tire and the inner fender shield.

SYSTEM OPERATION INHIBITORS

The air suspension system is inhibited when:

² The trunk is open.

² A door(s) is/are open.

² The brake pedal is engaged.

² The throttle is at the wide open position.

² The charging system fails.

The maximum compressor pump or exhaust

time is 3 minutes.

SYSTEM FAILURES

Vehicles equipped with air suspension and overhead

console. Will alert the driver of an air suspension

system malfunction. A warning Check Air Suspension

will appear on the overhead console screen.

SAFETY CONCERNS

WARNING: REAR AIR SPRINGS MUST BE DEFLATED

BEFORE BEING REMOVED FROM THE VEHICLE.

WARNING: OPEN TRUNK, OR DOOR(S) OR REMOVE

GROUND STRAP FROM BATTERY BEFORE HOIST-

ING OR JACKING A VEHICLE DURING MECHANICAL

REPAIRS.

WARNING: IF THE VEHICLE NEEDS SERVICE OR

REPAIR OF THE REAR SHOCK ABSORBERS OR

REAR AXLE PIVOT BUSHINGS. THE REAR AIR

SPRINGS MUST HAVE THE AIR PRESSURE RE-

MOVED BEFORE THE VEHICLE CAN BE SERVICED

SAFELY.

SHIPPING MODE

(1) Removing shipping height signal for customer

use.

² Use DRB II tester and 1991 Chassis (Air Suspen-

sion) service cartridge.

² Follow DRB II requirements to cancel shipping

height message in the body computer.

² Connect the Ignition Off Draw (I.O.D.) circuit.

The connection of the IOD circuit will cancel

the Shipping height signal. (2) Return to shipping height.

² Set shipping command in the body computer using

the DRB II and the 1991 Chassis (Air suspension)

service cartridge.

² Disconnect the I.O.D. connector.

DIAGNOSIS

INITIAL DIAGNOSTIC CHECK

(1) Check for blown or missing fuses.

Fig. 9 Compressor Current Draw Test

2 - 78 SUSPENSION AND DRIVESHAFTS Ä

Page 144 of 2438

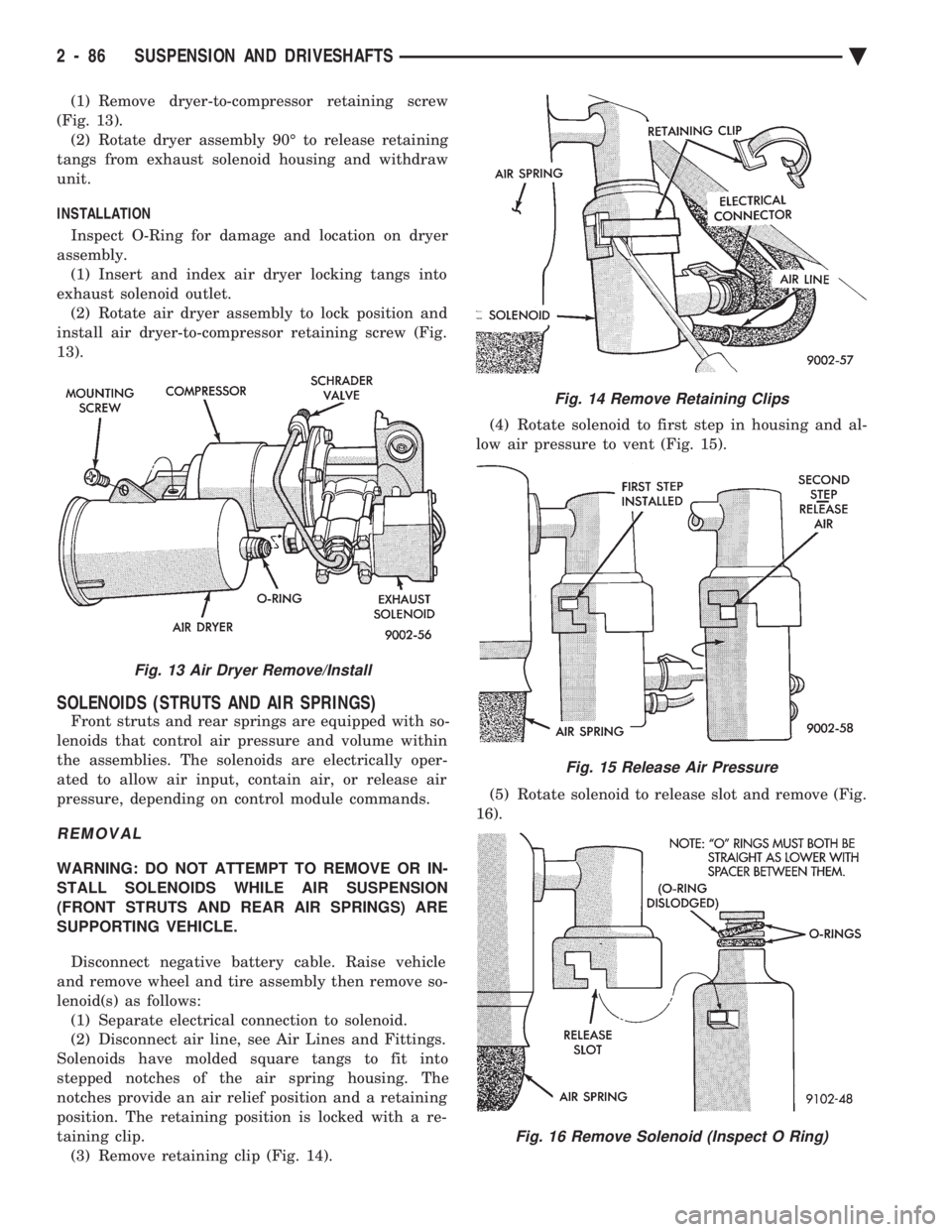

(1) Remove dryer-to-compressor retaining screw

(Fig. 13). (2) Rotate dryer assembly 90É to release retaining

tangs from exhaust solenoid housing and withdraw

unit.

INSTALLATION

Inspect O-Ring for damage and location on dryer

assembly. (1) Insert and index air dryer locking tangs into

exhaust solenoid outlet. (2) Rotate air dryer assembly to lock position and

install air dryer-to-compressor retaining screw (Fig.

13).

SOLENOIDS (STRUTS AND AIR SPRINGS)

Front struts and rear springs are equipped with so-

lenoids that control air pressure and volume within

the assemblies. The solenoids are electrically oper-

ated to allow air input, contain air, or release air

pressure, depending on control module commands.

REMOVAL

WARNING: DO NOT ATTEMPT TO REMOVE OR IN-

STALL SOLENOIDS WHILE AIR SUSPENSION

(FRONT STRUTS AND REAR AIR SPRINGS) ARE

SUPPORTING VEHICLE.

Disconnect negative battery cable. Raise vehicle

and remove wheel and tire assembly then remove so-

lenoid(s) as follows: (1) Separate electrical connection to solenoid.

(2) Disconnect air line, see Air Lines and Fittings.

Solenoids have molded square tangs to fit into

stepped notches of the air spring housing. The

notches provide an air relief position and a retaining

position. The retaining position is locked with a re-

taining clip. (3) Remove retaining clip (Fig. 14). (4) Rotate solenoid to first step in housing and al-

low air pressure to vent (Fig. 15).

(5) Rotate solenoid to release slot and remove (Fig.

16).

Fig. 13 Air Dryer Remove/Install

Fig. 14 Remove Retaining Clips

Fig. 15 Release Air Pressure

Fig. 16 Remove Solenoid (Inspect O Ring)

2 - 86 SUSPENSION AND DRIVESHAFTS Ä

Page 151 of 2438

BRAKES

CONTENTS

page page

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 10 AC/Y BODY ............. 72

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 6 AA,AG,AJ,AP BODY ....... 113

BRAKE DISC (ROTOR) ................... 53

BRAKE SUPPORT ASSEMBLY ............. 25

FRONT DISC BRAKES ................... 31

GENERAL INFORMATION .................. 1

HYDRAULIC SYSTEM CONTROL VALVES . . . 26

KELSEY HAYES DOUBLE PIN FAMILY CALIPER ............................ 35 KELSEY HAYES DOUBLE PIN NON-FAMILY

CALIPER ............................ 38

MASTER CYLINDER ..................... 66

PARKING BRAKES ...................... 57

POWER BRAKES ....................... 68

REAR DISC BRAKES .................... 45

REAR WHEEL DRUM BRAKES ............ 18

SERVICE ADJUSTMENTS .................. 4

WHEEL BEARINGS ...................... 70

WHEEL CYLINDERS ..................... 23

GENERAL INFORMATION

Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the break down of these designa-

tions is included in the Introduction Section at the

front of this service manual. Standard brake equipment consists of:

² Double pin floating caliper disc front brakes.

² Rear automatic adjusting drum brakes.

² Differential valve with a brake warning switch.

² Master cylinder.

² Vacuum power booster.

² Double pin floating caliper rear disc brakes are

available on some models. The Bendix Anti-Lock 10 braking system, uses the

standard power brake system caliper assemblies,

braking discs, pedal assembly, brake lines and hoses.

The unique parts of the Bendix Anti-Lock 10 braking

system consists of the following components. Propor-

tioning valves, wheel speed sensors, tone wheels,

electronic control unit, modulator assembly and hy-

draulic assembly. These components replace the con-

ventional master cylinder and power booster. The

components will be described in detail in the Bendix

Anti-Lock 10 brake section in this group of the ser-

vice manual. The Bendix Anti-Lock 6 braking system, uses the

following standard brake system components. Master

cylinder, power booster, caliper assemblies, braking

discs, pedal assembly, brake lines and hoses. The

unique parts of the Bendix Anti-Lock 6 braking sys-

tem consists of the following components. Modulator

assembly, unique proportioning valves, wheel speed

sensors, tone wheels, and electronic control unit.

These components will be described in detail in the

Bendix Anti-Lock 6 brake section in this group of the

service manual. The front disc brake shoes have semi-metallic lin-

ings. The hydraulic brake system (Fig .123and4)is

diagonally split on both the Non-ABS and ABS brak-

ing system. With the left front and right rear brakes

on one hydraulic system and the right front and left

rear on the other. The Non-ABS and ABS brake system may use dif-

ferent types of brake line fittings and tubing flares.

The Non-ABS brake system uses double wall tubing

flares and fittings at all tubing joint locations. Some

ABS brake systems use both ISO style tubing flares

and double wall tubing flares and corresponding fit-

tings at different joint locations. See (Figs . 2 3 and 4)

for specific joint locations and type of tubing flare. The front disc brakes consist of two different types

of caliper assemblies. A double pin Kelsey-Hayes cal-

iper (family caliper) with a bolt-on adapter attached

to the steering knuckle. Or a double pin Kelsey-

Hayes caliper (non-family caliper) which mounts di-

rectly to rails on the steering knuckle. The non-

family caliper is only used on the AY Body

(Imperials).

CAUTION: Caliper pistons, boots and seals for the

different caliper assemblies used on the front and

rear disc brake assemblies are not interchangeable.

Misusage could result in a complete brake system

failure. Be sure that the parts are replaced with the

correct replacement parts, refer to the parts book

for the type and model year of the vehicle being

worked on.

The master cylinder is anodized, lightweight alu-

minum, with a bore size of 24.0mm, 21.0mm or 7/8

inch.

Ä BRAKES 5 - 1

Page 168 of 2438

REAR WHEEL DRUM BRAKES INDEX

page page

Brake Drum Refacing ..................... 21

Brake Shoe Assemblies ................... 19 Description

............................. 18

Service Procedures ....................... 18

DESCRIPTION

Rear wheel drum brakes (Fig .2&3)aretwoshoe,

internal expanding type with an automatic adjuster

screw assembly that is activated each time the

brakes are applied. The automatic adjuster screw is

located directly below the wheel cylinder as shown in

figure (Fig .2&3).

WARNING: DUST AND DIRT ON BRAKE PARTS

GENERATED DURING THE NORMAL USE AND

WEAR OF MOTOR VEHICLE BRAKE SYSTEMS MAY

CONTAIN ASBESTOS FIBERS. BREATHING EXCES-

SIVE CONCENTRATIONS OF ASBESTOS FIBERS

CAN CAUSE SERIOUS BODILY HARM, SUCH AS

ASBESTOSIS AND CANCER. EXTREME CARE

SHOULD BE EXERCISED WHILE SERVICING

BRAKE ASSEMBLIES OR COMPONENTS. DO NOT CLEAN BRAKE ASSEMBLIES OR COM-

PONENTS WITH COMPRESSED AIR OR BY DRY

BRUSHING; USE A VACUUM CLEANER SPECIFI-

CALLY RECOMMENDED FOR USE WITH ASBES-

TOS FIBERS. IF A SUITABLE VACUUM CLEANER IS

NOT AVAILABLE, CLEANING SHOULD BE DONE

WET USING A WATER DAMPENED CLOTH. DO NOT CREATE DUST BY SANDING, GRINDING,

AND/OR SHAVING BRAKE LININGS OR PADS UN-

LESS SUCH OPERATION IS DONE WHILE USING

PROPERLY EXHAUST VENTILATED EQUIPMENT. DISPOSE OF ALL DUST AND DIRT SUSPECTED

TO CONTAIN ANY ASBESTOS FIBERS IN SEALED

BAGS OR CONTAINERS TO MINIMIZE DUST EXPO-

SURE TO YOURSELF AND OTHERS. FOLLOW ALL RECOMMENDED PRACTICES PRE-

SCRIBED BY THE OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION AND THE ENVIRON-

MENTAL PROTECTION AGENCY. FOR THE HAN-

DLING, PROCESSING, AND DISPOSITION OF DUST

OR DIRT WHICH MAY CONTAIN ASBESTOS FI-

BERS. IT IS RECOMMENDED NOT TO BREATH ANY

TYPE OF BRAKE LINING MATERIAL DUST EVEN

ASBESTOS FREE, DUE TO THE FIBROUS NATURE

OF THE MATERIALS BEING USED.

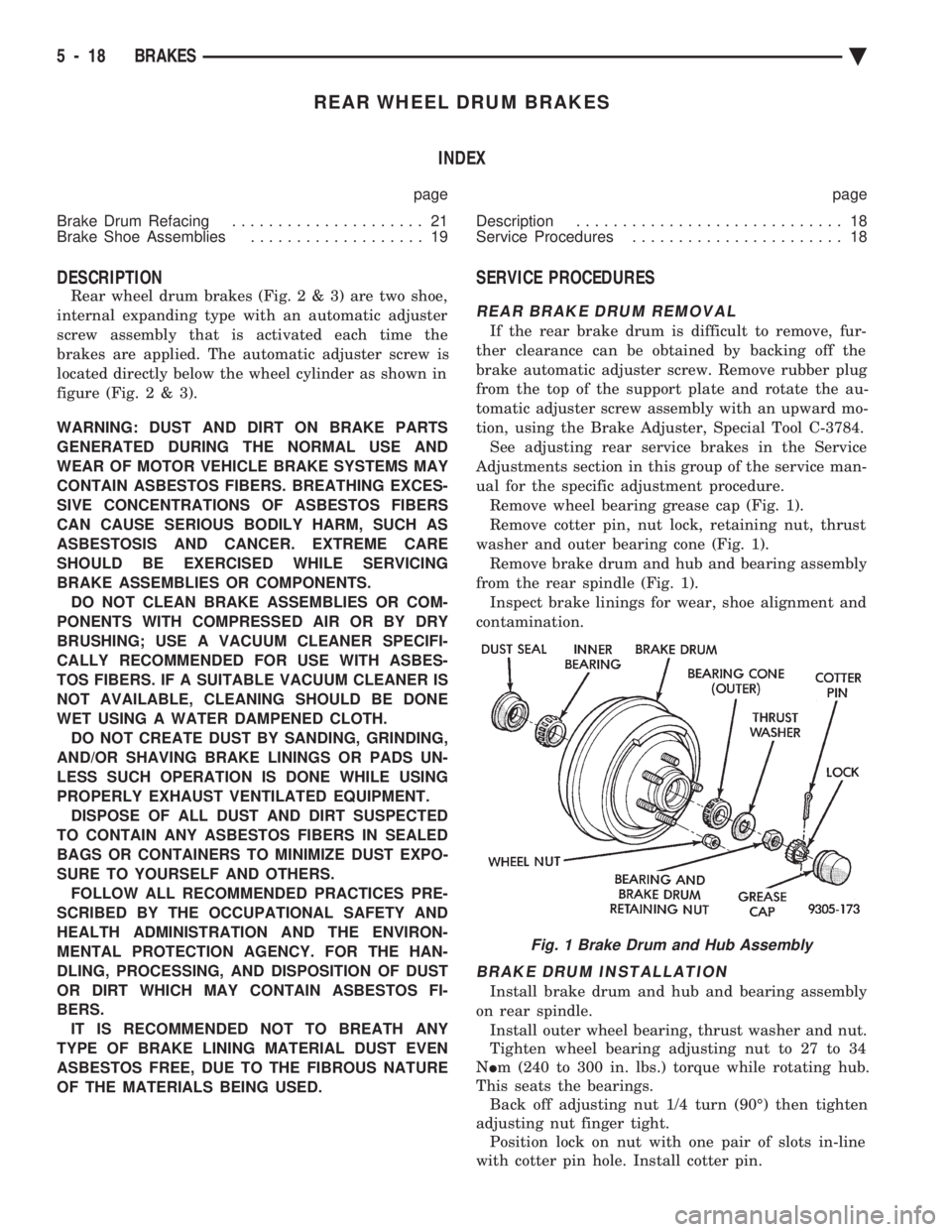

SERVICE PROCEDURES

REAR BRAKE DRUM REMOVAL

If the rear brake drum is difficult to remove, fur-

ther clearance can be obtained by backing off the

brake automatic adjuster screw. Remove rubber plug

from the top of the support plate and rotate the au-

tomatic adjuster screw assembly with an upward mo-

tion, using the Brake Adjuster, Special Tool C-3784. See adjusting rear service brakes in the Service

Adjustments section in this group of the service man-

ual for the specific adjustment procedure. Remove wheel bearing grease cap (Fig. 1).

Remove cotter pin, nut lock, retaining nut, thrust

washer and outer bearing cone (Fig. 1). Remove brake drum and hub and bearing assembly

from the rear spindle (Fig. 1). Inspect brake linings for wear, shoe alignment and

contamination.

BRAKE DRUM INSTALLATION

Install brake drum and hub and bearing assembly

on rear spindle. Install outer wheel bearing, thrust washer and nut.

Tighten wheel bearing adjusting nut to 27 to 34

N Im (240 to 300 in. lbs.) torque while rotating hub.

This seats the bearings. Back off adjusting nut 1/4 turn (90É) then tighten

adjusting nut finger tight. Position lock on nut with one pair of slots in-line

with cotter pin hole. Install cotter pin.

Fig. 1 Brake Drum and Hub Assembly

5 - 18 BRAKES Ä