warning CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2365 of 2438

HEATER-A/C UNIT ASSEMBLYÐREMOVAL AND

INSTALLATION

AP, AC, AY BODY PROCEDURE

WARNING: IF EQUIPPED WITH A/C, THE REFRIG-

ERATION SYSTEM MUST BE COMPLETELY EMPTY

BEFORE PROCEEDING WITH THIS OPERATION.

(1) Disconnect battery NEGATIVE cable.

(2) Drain radiator and disconnect heater hoses at

unit. Tape heater tubes to keep from leaking during

removal. Refer to Group 7, Cooling System. (3) Remove A/C condensate drain and disconnect

vacuum lines. (4) Inside passenger compartment, perform as fol-

lows, according to body designation. (a) AC-body, remove right upper and lower un-

der-panel silencers. (b) AP & AC-bodies, remove steering column

cover. (c) AC-body, remove left under-panel silencer.

(5) Position front seat or right front seat full rear. (a) AP-body, remove right A-pillar trim.

(b) Remove right cowl side trim.

(6) Remove glove box. (a) AC-body, remove right instrument panel re-

inforcement.

(7) AP-body only: (a) Remove right instrument panel lower mount-

ing screw. (b) Remove center bezel.

(c) Remove lower center module cover.

(d) Remove floor console.

(e) Remove instrument panel support brace (from

steering column opening to right cowl side at bot-

tom of instrument panel). (f) Remove instrument panel to support bracket

(below glove box opening). (g) Remove ash receiver.

(h) Remove radio.

(i) Remove panel top cover.

(j) Remove three right side panel to fence (below

windshield) attaching screws.

(8) AC-body, remove ash receiver.

(9) AP body, pull right lower side of instrument

panel rearward. (10) Remove center distribution and defroster

adapter ducts. (11) AP and AC-bodies, disconnect relay module.

(12) AP-body, remove instrument panel to unit

bracket. (13) AP-body, remove lower air distribution duct.

(14) Disconnect blower motor wire connector.

(15) Disconnect demister hoses from top of unit.

(16) For Non-ATC equipped vehicles, disconnect

the temperature control cable flag from the bottom of

the heater-A/C unit. Then un-clip the cable from the

left side of the heat distribution duct. Swing the ca-

ble out of the way to the left. Disconnect the vacuum

lines at the unit. (17) For ATC equipped vehicles, disconnect the in-

strument panel wiring from the rear face of the ATC

control unit. (18) AC body, disconnect right 25-way connector

bracket and fuse block from panel. (19) Fold floor right side carpet back (except AC

body). (20) From engine compartment, remove four unit

attaching nuts. (21) Remove unit hanger strap lower screw, and

rotate strap. (22) Move heater-A/C unit rearward to clear

mounting studs, and lower unit. (23) AP-body, remove demister adapter from top of

unit. (24) While pulling the lower right of instrument

panel rearward: (a) Slide unit upright from under instrument

panel for AP-body. (b) Except for AP-body, rotate unit while pulling

from under instrument panel.

To install, reverse the preceding operation.

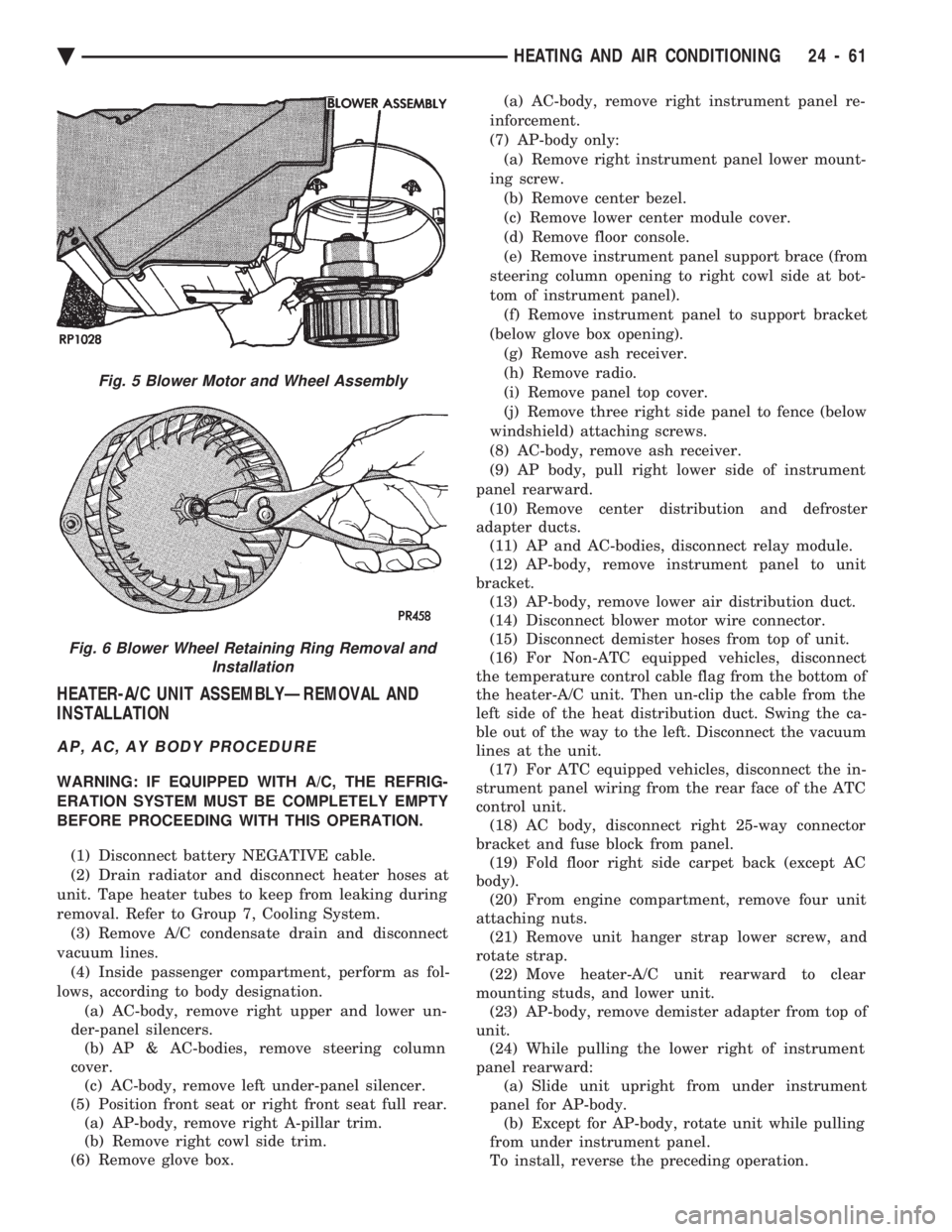

Fig. 5 Blower Motor and Wheel Assembly

Fig. 6 Blower Wheel Retaining Ring Removal and Installation

Ä HEATING AND AIR CONDITIONING 24 - 61

Page 2366 of 2438

AA BODY PROCEDURE

WARNING: IF EQUIPPED WITH A/C, THE REFRIG-

ERATION SYSTEM MUST BE COMPLETELY EMPTY

BEFORE PROCEEDING WITH THIS OPERATION. Refer to Group 8E and Group 23 for component re-

moval and installation when performing this opera-

tion. (1) Perform steps 1 through 7 of Blower Motor re-

moval and installation. (2) Remove relay panel above glove compartment

opening. (3) Disconnect the A/C vacuum line connector and

radio noise capacitor connectors. (4) Remove left windshield pillar trim cover.

(5) Remove left lower side cowl trim cover.

(6) Remove hood release handle mechanism attach-

ing screws. (7) Remove steering column trim covers.

(8) Disconnect parking brake release mechanism

connecting rod. Gain access through fuse panel open-

ing. (9) Remove lower left instrument panel silencer.

(10) Remove lower left instrument panel reinforce-

ment. (11) Remove instrument panel center (radio) bezel.

(12) Remove forward floor console.

(13) Remove the radio.

(14) Remove the heater-A/C control.

(15) Remove cigar lighter.

(16) Remove message center/trip computer, if

equipped. (17) Disconnect side window demister tubes from

top of heat A/C unit. (18) Remove steering column upper attaching bolts

and allow the steering wheel to rest on the driver

seat cushion. (19) Remove upper instrument panel (defroster

outlet) cover. (20) Remove upper instrument panel attaching

screws from below the windshield opening. (21) Loosen (do not remove) the left lower cowl in-

strument panel attaching screw. (22) Remove the right lower cowl instrument panel

attaching screw.

CAUTION: Protect the passenger seat cover from

soiling or damage using a suitable cover.

(23) Carefully pull the right side of the instrument

panel away from the vehicle. Allow the instrument

panel to rest on the passenger seat cushion.

CAUTION: Before proceeding with the next opera-

tion, review the Safety Precautions and Warnings at

the front of this Group. (24) From the engine compartment, drain the cool-

ing system and disconnect the heater hoses from the

heater core nipples. Plug the nipples to avoid spilling

coolant inside the vehicle. (25) Disconnect the refrigerant lines from the ex-

pansion-valve at the dash panel on the right side of

the vehicle. Seal the refrigerant lines to prevent con-

tamination. (26) Remove the expansion valve from the evapo-

rator plate. Seal the valve to avoid contamination. (27) Remove the condensate drain tube.

(28) Remove heater-A/C unit to dash panel attach-

ing nuts. (29) From inside the vehicle, pull rearward on the

heater-A/C unit to clear the dash panel silencer and

remove the unit from the vehicle. To install, reverse the preceding operation. Refill

cooling system and test for leaks. Evacuate and

charge the refrigerant system and test overall perfor-

mance.

AG, AJ BODY PROCEDURE

WARNING: IF EQUIPPED WITH A/C, THE REFRIG-

ERATION SYSTEM MUST BE COMPLETELY EMPTY

BEFORE PROCEEDING WITH THIS OPERATION.

(1) Disconnect the battery negative cable.

(2) Drain the coolant from cooling system. Refer to

Group 7, Cooling System. (3) Remove the air conditioner expansion valve (if

equipped). (4) Disconnect the heater hoses from heater core.

Then plug or cap the tubes on heater core. This will

prevent spilling coolant into the interior of vehicle

during unit removal. (5) Remove the condensate drain tube.

(6) Disconnect the A/C-heater vacuum supply line

from vacuum supply nipple (in the engine compart-

ment). (7) Remove the four A/C-heater assembly-to-dash

panel attaching nuts. (8) Remove the passenger side front seat. Refer to

Group 23, Body. (9) Remove the kick panel/sill cover at right door

opening. (10) Remove the body computer (Fig. 6) located at

the lower right section of the right front door pillar. (11) Remove the glove box assembly. Refer to

Group 8E, Instrument Panel. (12) Remove the carpeted panels from both sides of

the console. (13) Un-clip the radio antenna cable from the

metal support (Fig. 6) located behind and below the

glove box opening. (14) Instrument panel removal is not necessary to

remove the A/C-heater assembly from the vehicle.

24 - 62 HEATING AND AIR CONDITIONING Ä

Page 2403 of 2438

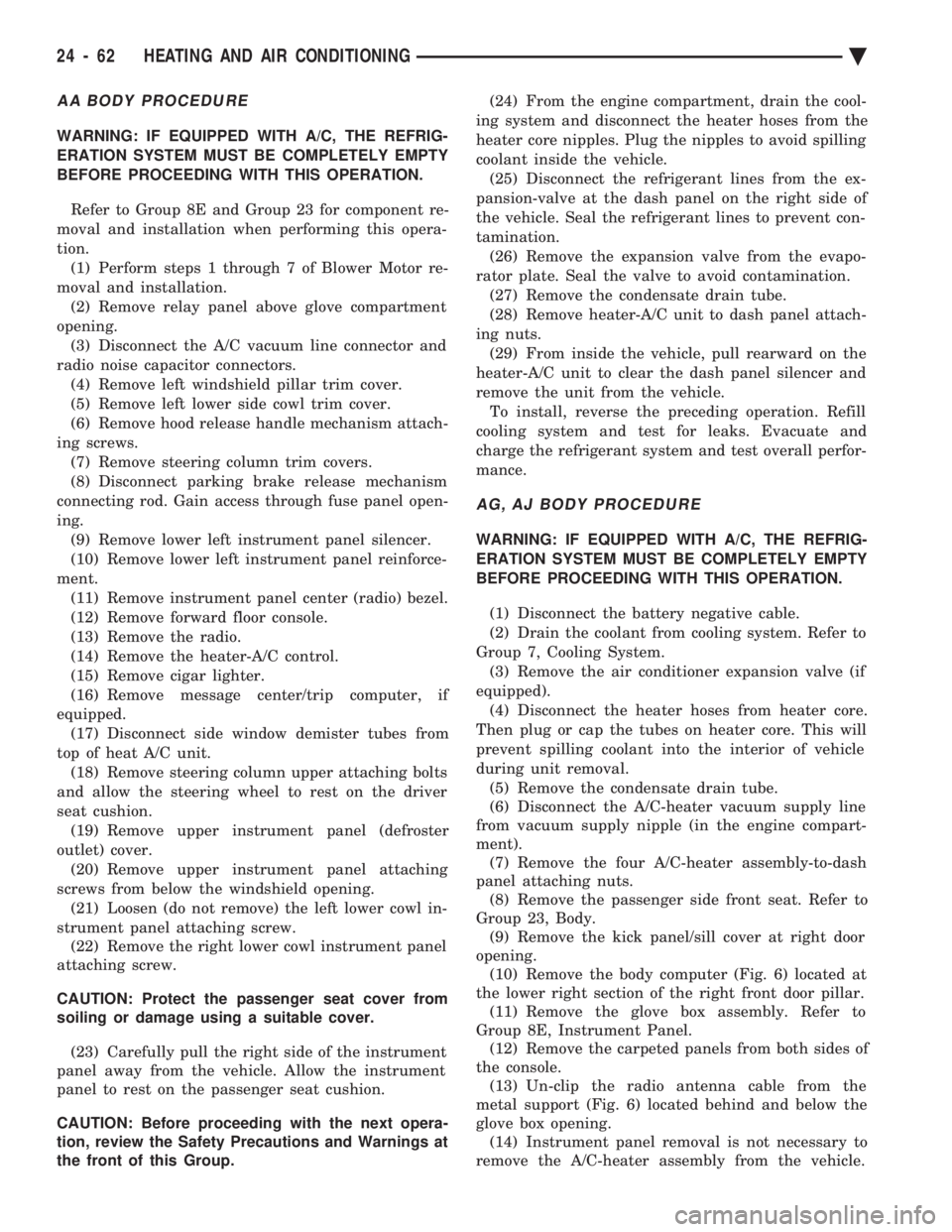

POSITIVE CRANKCASE VENTILATION (PCV)

SYSTEMS

Intake manifold vacuum removes crankcase vapors

and piston blow-by from the engine. The emissions pass

through the PCV valve into the intake manifold where

they become part of the calibrated air-fuel mixture.

They are burned and expelled with the exhaust gases.

The air cleaner supplies make up air when the engine

does not have enough vapor or blow-by gases. In this

system, fresh air does not enter the crankcase (Figs. 10,

11, 12, 13, 14, 15, and 16).

PCV VALVE TEST

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK WHEELS BEFORE PERFORMING ANY TEST

OR ADJUSTMENT WITH THE ENGINE OPERATING. With the engine idling, remove the PCV valve

from its attaching point. If the valve is operating

properly, a hissing noise will be heard and a strong

vacuum felt when placing a finger over the valve in-

let (Fig. 17). With the engine off, the shake the

valve. The valve should rattle when shaken. Replace

the valve if it does not operate properly. Do not at-

tempt to clean the PCV valve.

Fig. 10 PCV ValveÐ2.5L TBI Engine

Fig. 11 PCV SystemÐ2.5L MPI (Flexible Fuel)

Fig. 12 PCV SystemÐTurbo III Engine

Fig. 13 PCV SystemÐ3.0L Engine

Ä EMISSION CONTROL SYSTEMS 25 - 15

Page 2407 of 2438

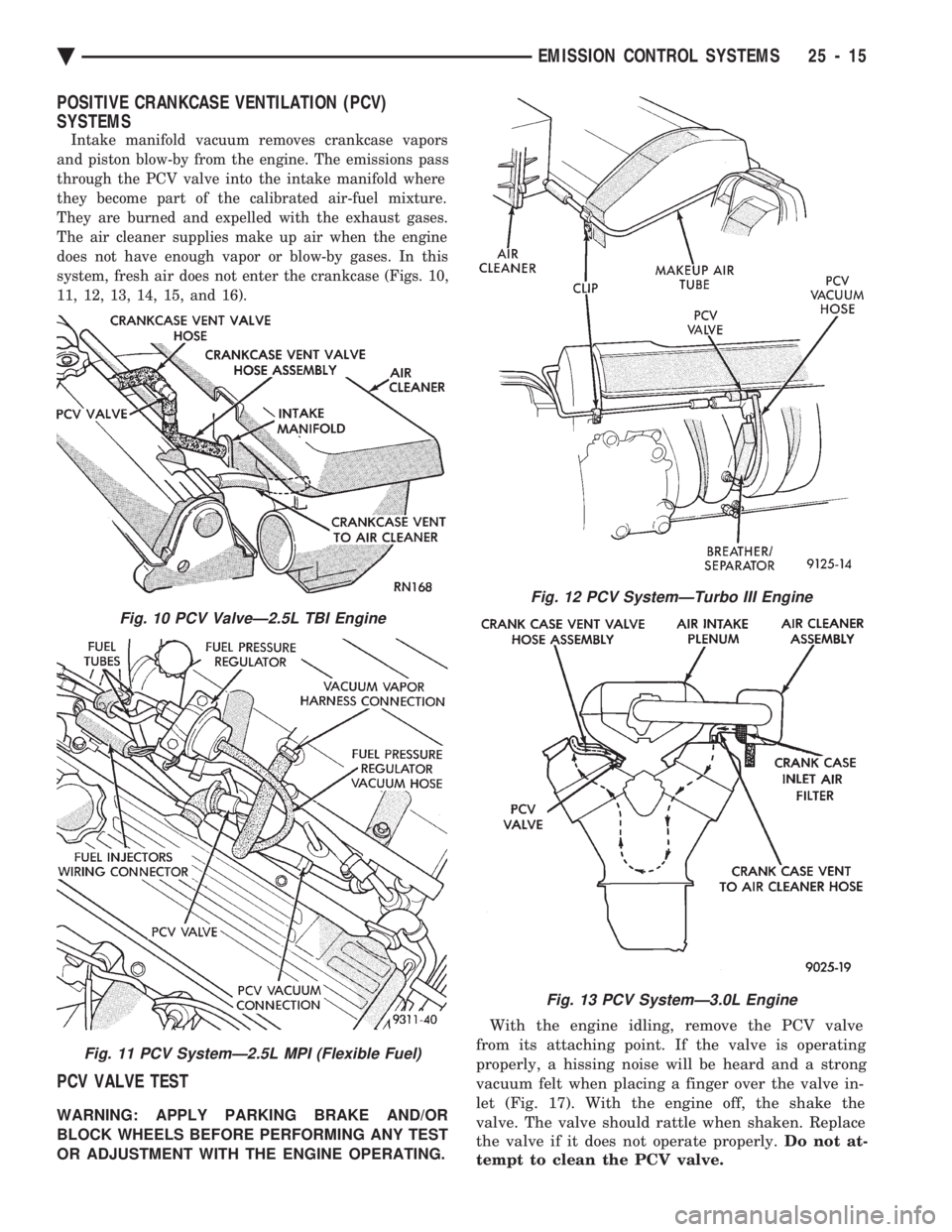

The oxygen sensor contains a heating element that

keeps it at proper temperature during all operating

modes. Maintaining correct sensor temperature at all times allows the system to enter into closed loop op-

eration sooner and remain in closed loop during pe-

riods of extended idle.

In Closed Loop operation the powertrain control

module (PCM) monitors the O

2sensor input (along

with other inputs) and adjusts the injector pulse

width accordingly. During Open Loop operation the

PCM ignores the O

2sensor input. The PCM adjusts

injector pulse width based on preprogrammed (fixed)

oxygen sensor input values and the current inputs

from other sensors.

REMOVAL

CAUTION: Do not pull on the oxygen sensor wire

when disconnecting the electrical connector.

WARNING: THE EXHAUST MANIFOLD MAY BE EX-

TREMELY HOT. USE CARE WHEN SERVICING THE

OXYGEN SENSOR.

Fig. 6 Heated Oxygen SensorÐ2.5L Engine

Fig. 7 Heated Oxygen SensorÐ2.5L MPI Engine (Flexible Fuel AA-body)

Fig. 8 Heated Oxygen SensorÐTurbo III Engine

Fig. 9 Heated Oxygen SensorÐ3.0L Engine

Fig. 10 Heated Oxygen SensorÐ3.3L/3.8L Engine

Ä EMISSION CONTROL SYSTEMS 25 - 19

Page 2409 of 2438

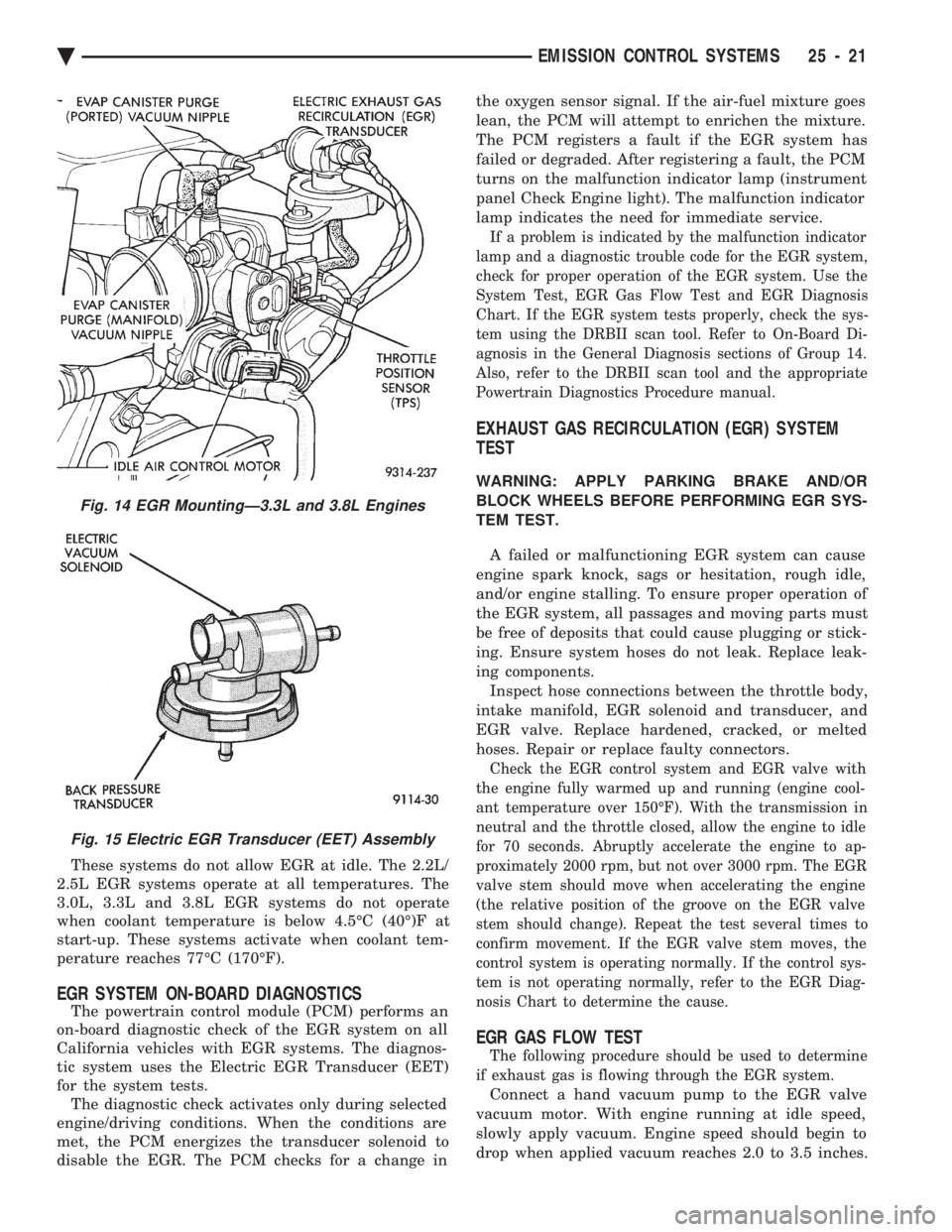

These systems do not allow EGR at idle. The 2.2L/

2.5L EGR systems operate at all temperatures. The

3.0L, 3.3L and 3.8L EGR systems do not operate

when coolant temperature is below 4.5ÉC (40É)F at

start-up. These systems activate when coolant tem-

perature reaches 77ÉC (170ÉF).

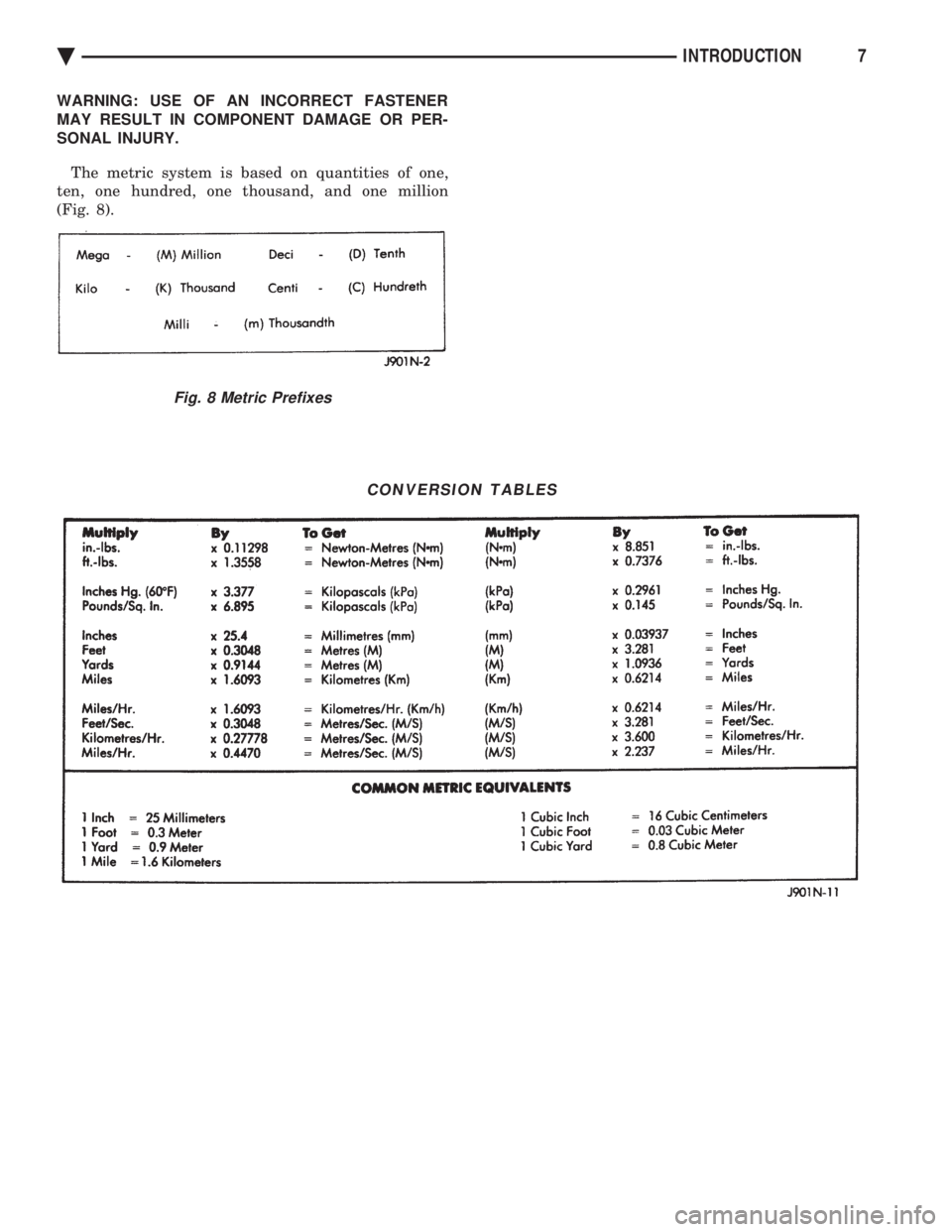

EGR SYSTEM ON-BOARD DIAGNOSTICS

The powertrain control module (PCM) performs an

on-board diagnostic check of the EGR system on all

California vehicles with EGR systems. The diagnos-

tic system uses the Electric EGR Transducer (EET)

for the system tests. The diagnostic check activates only during selected

engine/driving conditions. When the conditions are

met, the PCM energizes the transducer solenoid to

disable the EGR. The PCM checks for a change in the oxygen sensor signal. If the air-fuel mixture goes

lean, the PCM will attempt to enrichen the mixture.

The PCM registers a fault if the EGR system has

failed or degraded. After registering a fault, the PCM

turns on the malfunction indicator lamp (instrument

panel Check Engine light). The malfunction indicator

lamp indicates the need for immediate service.

If a problem is indicated by the malfunction indicator

lamp and a diagnostic trouble code for the EGR system,

check for proper operation of the EGR system. Use the

System Test, EGR Gas Flow Test and EGR Diagnosis

Chart. If the EGR system tests properly, check the sys-

tem using the DRBII scan tool. Refer to On-Board Di-

agnosis in the General Diagnosis sections of Group 14.

Also, refer to the DRBII scan tool and the appropriate

Powertrain Diagnostics Procedure manual.

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

TEST

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK WHEELS BEFORE PERFORMING EGR SYS-

TEM TEST.

A failed or malfunctioning EGR system can cause

engine spark knock, sags or hesitation, rough idle,

and/or engine stalling. To ensure proper operation of

the EGR system, all passages and moving parts must

be free of deposits that could cause plugging or stick-

ing. Ensure system hoses do not leak. Replace leak-

ing components. Inspect hose connections between the throttle body,

intake manifold, EGR solenoid and transducer, and

EGR valve. Replace hardened, cracked, or melted

hoses. Repair or replace faulty connectors.

Check the EGR control system and EGR valve with

the engine fully warmed up and running (engine cool-

ant temperature over 150ÉF). With the transmission in

neutral and the throttle closed, allow the engine to idle

for 70 seconds. Abruptly accelerate the engine to ap-

proximately 2000 rpm, but not over 3000 rpm. The EGR

valve stem should move when accelerating the engine

(the relative position of the groove on the EGR valve

stem should change). Repeat the test several times to

confirm movement. If the EGR valve stem moves, the

control system is operating normally. If the control sys-

tem is not operating normally, refer to the EGR Diag-

nosis Chart to determine the cause.

EGR GAS FLOW TEST

The following procedure should be used to determine

if exhaust gas is flowing through the EGR system.

Connect a hand vacuum pump to the EGR valve

vacuum motor. With engine running at idle speed,

slowly apply vacuum. Engine speed should begin to

drop when applied vacuum reaches 2.0 to 3.5 inches.

Fig. 14 EGR MountingÐ3.3L and 3.8L Engines

Fig. 15 Electric EGR Transducer (EET) Assembly

Ä EMISSION CONTROL SYSTEMS 25 - 21

Page 2422 of 2438

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

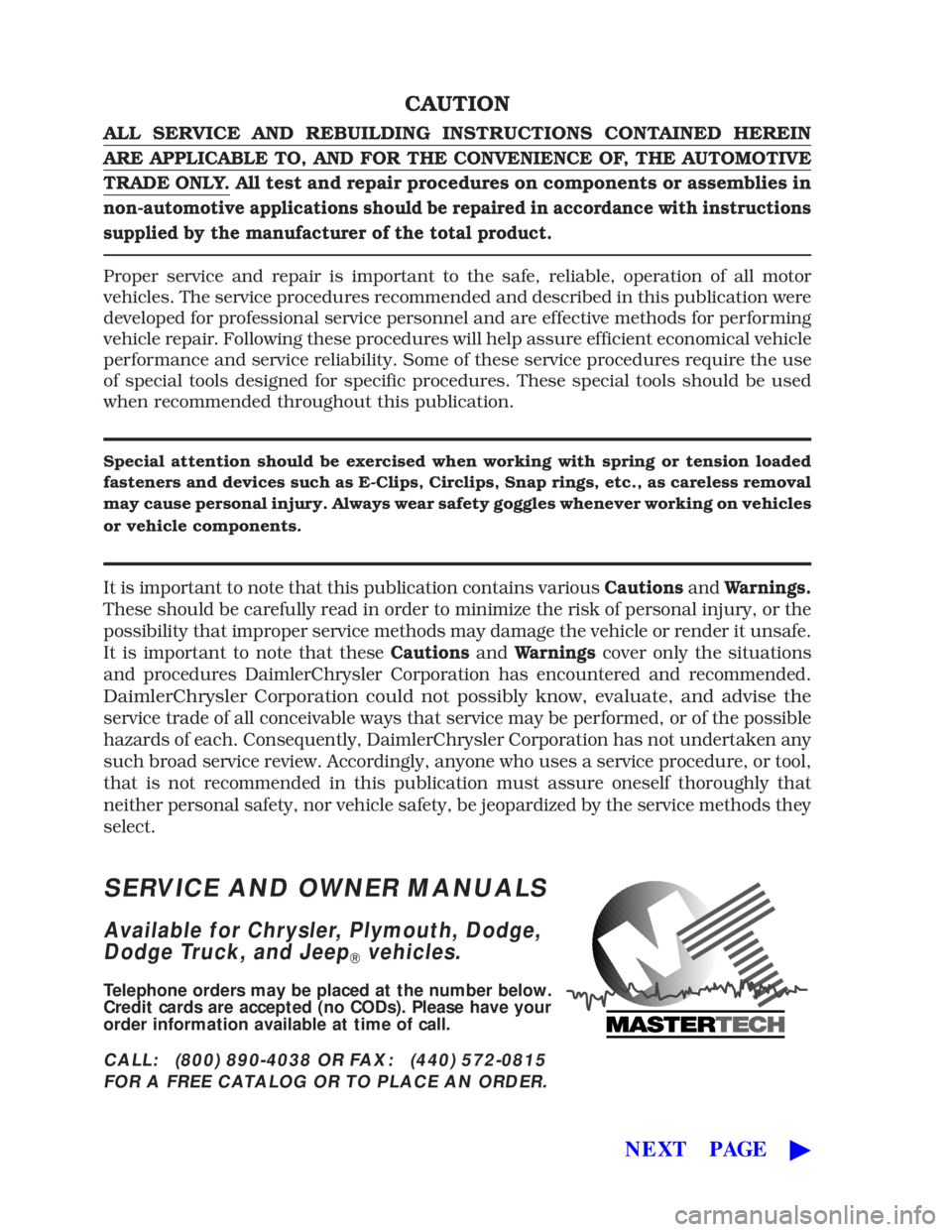

The metric system is based on quantities of one,

ten, one hundred, one thousand, and one million

(Fig. 8).

Fig. 8 Metric Prefixes

CONVERSION TABLES

Ä INTRODUCTION7

Page 2427 of 2438

CAUTION

ALL SERVICE AND REBUILDING INSTRUCTIONS CONTAINED HEREIN

ARE APPLICABLE TO, AND FOR THE CONVENIENCE OF, THE AUTOMOTIVE

TRADE ONLY. All test and repair procedures on components or assemblies in

non-automotive applications should be repaired in accordance with instructions

supplied by the manufacturer of the total product.

Proper service and repair is important to the safe, reliable, operation of all motor

vehicles. The service procedures recommended and described in this publication were

developed for professional service personnel and are effective methods for performing

vehicle repair. Following these procedures will help assure efficient economical vehicle

performance and service reliability. Some of these service procedures require the use

of special tools designed for specific procedures. These special tools should be used

when recommended throughout this publication.

Special attention should be exercised when working with spring or tension loaded

fasteners and devices such as E-Clips, Circlips, Snap rings, etc., as careless removal

may cause personal injury. Always wear safety goggles whenever working on vehicles

or vehicle components.

It is important to note that this publication contains various CautionsandWarnings.

These should be carefully read in order to minimize the risk of personal injury, or the

possibility that improper service methods may damage the vehicle or render it unsafe.

It is important to note that these CautionsandWarnings cover only the situations

and procedures DaimlerChrysler Corporation has encountered and recommended.

DaimlerChrysler Corporation could not possibly know, evaluate, and advise the

service trade of all conceivable ways that service may be performed, or of the possible

hazards of each. Consequently, DaimlerChrysler Corporation has not undertaken any

such broad service review. Accordingly, anyone who uses a service procedure, or tool,

that is not recommended in this publication must assure oneself thoroughly that

neither personal safety, nor vehicle safety, be jeopardized by the service methods they

select.

SERVICE AND OWNER MANUALS

Available for Chrysler, Plymouth, Dodge, Dodge Truck, and Jeep

Tvehicles.

Telephone orders may be placed at the number below.

Credit cards are accepted (no CODs). Please have your

order information available at time of call.

CALL: (800) 890-4038 OR FAX: (440) 572-0815

FOR A FREE CATALOG OR TO PLACE AN ORDER.

NEXT PAGE ©

llllllllllll