fuel CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1862 of 2438

The engine start-up (crank), engine warm-up, and

wide open throttle modes are OPEN LOOP modes. The

acceleration, deceleration, and cruise modes, with the

engine at operating temperature are CLOSED

LOOP modes (under most operating conditions).

IGNITION SWITCH ON (ZERO RPM) MODE

When the multi-port fuel injection system is acti-

vated by the ignition switch, the following actions

occur:

² The PCM determines atmospheric air pressure from

the MAP sensor input to determine basic fuel strategy.

² The PCM monitors the coolant temperature sensor

and throttle position sensor input. The PCM modifies

fuel strategy based on these inputs. When the key is in the ON position and the engine is

not running (zero rpm), the auto shutdown (ASD) relay

and fuel pump relay are not energized. Therefore

battery voltage is not supplied to the fuel pump,

ignition coil, fuel injectors or oxygen sensor heating

element.

ENGINE START-UP MODE

This is an OPEN LOOP mode. The following actions

occur when the starter motor is engaged. If the PCM receives a distributor signal, it energizes

the auto shutdown (ASD) relay and fuel pump relay.

These relays supply battery voltage to the fuel pump,

fuel injectors, ignition coil, and oxygen sensor heating

element. If the PCM does not receive a distributor

input, the ASD relay and fuel pump relay will be

de-energized after approximately one second. The PCM energizes all six injectors until it deter-

mines crankshaft position from the distributor pick-up

signals. The PCM determines crankshaft position

within 2 engine revolutions. After determining crankshaft position, the PCM be-

gins energizing the injectors in sequence. The PCM

adjusts injector pulse width and controls injector syn-

chronization by turning the individual ground paths to

the injectors On and Off. When the engine idles within 664 RPM of its target

RPM, the PCM compares current MAP sensor value

with the atmospheric pressure value received during

the Ignition Switch On (zero RPM) mode. If the PCM

does not detect a minimum difference between the two

values, it sets a MAP fault into memory. Once the ASD and fuel pump relays have been

energized, the PCM:

² determines injector pulse width based on coolant

temperature, manifold absolute pressure (MAP) and

the number of engine revolutions since cranking was

initiated. ²

monitors the coolant temperature sensor, distribu-

tor pick-up, MAP sensor, and throttle position sensor

to determine correct ignition timing.

ENGINE WARM-UP MODE

This is a OPEN LOOP mode. The following inputs

are received by the PCM:

² engine coolant temperature

² crankshaft position (distributor pick-up)

² manifold absolute pressure (MAP)

² engine speed (distributor pick-up)

² throttle position

² A/C switch

² battery voltage

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off. The PCM adjusts engine idle speed by regulating

the idle air control motor and ignition timing.

CRUISE OR IDLE MODE

When the engine is at operating temperature this

is a CLOSED LOOP mode. During cruising speed the

following inputs are received by the PCM:

² engine coolant temperature

² crankshaft position (distributor pick-up)

² manifold absolute pressure

² engine speed (distributor pick-up)

² throttle position

² exhaust gas oxygen content

² A/C control positions

² battery voltage

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off. The PCM adjusts engine idle speed and ignition

timing. The PCM controls the air/fuel ratio according

to the oxygen content in the exhaust gas.

ACCELERATION MODE This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in throttle position or MAP

pressure as a demand for increased engine output

and vehicle acceleration. The PCM increases injector

pulse width in response to increased fuel demand.

DECELERATION MODE This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

² engine coolant temperature

² crankshaft position (distributor pick-up)

² manifold absolute pressure

² engine speed (distributor pick-up)

² throttle position

² exhaust gas oxygen content

² A/C control positions

² battery voltage

14 - 122 FUEL SYSTEMS Ä

Page 1863 of 2438

The PCM may receive a closed throttle input from

the throttle position sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration. The PCM may reduce injector

firing to once per engine revolution. This helps main-

tain better control of the air-fuel mixture. During a deceleration condition, the PCM grounds

the exhaust gas recirculation (EGR) solenoid. When

the PCM grounds the solenoid, preventing EGR.

WIDE OPEN THROTTLE MODE This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

² engine coolant temperature

² crankshaft position (distributor pick-up)

² manifold absolute pressure

² engine speed (distributor pick-up)

² throttle position

When the PCM senses wide open throttle condition

through the throttle position sensor (TPS) it will:

² Provide a ground for the electrical EGR transducer

(EET) solenoid. When the PCM grounds the solenoid,

the EGR system stops operating.

² De-energize the air conditioning relay. This dis-

ables the air conditioning system. The exhaust gas oxygen content input is not ac-

cepted by the PCM during wide open throttle opera- tion. The PCM will adjust injector pulse width to

supply a predetermined amount of additional fuel.

IGNITION SWITCH OFF MODE

When the ignition switch is turned to the OFF po-

sition, the following occurs:

² All outputs are turned off.

² No inputs are monitored.

² The PCM shuts down.

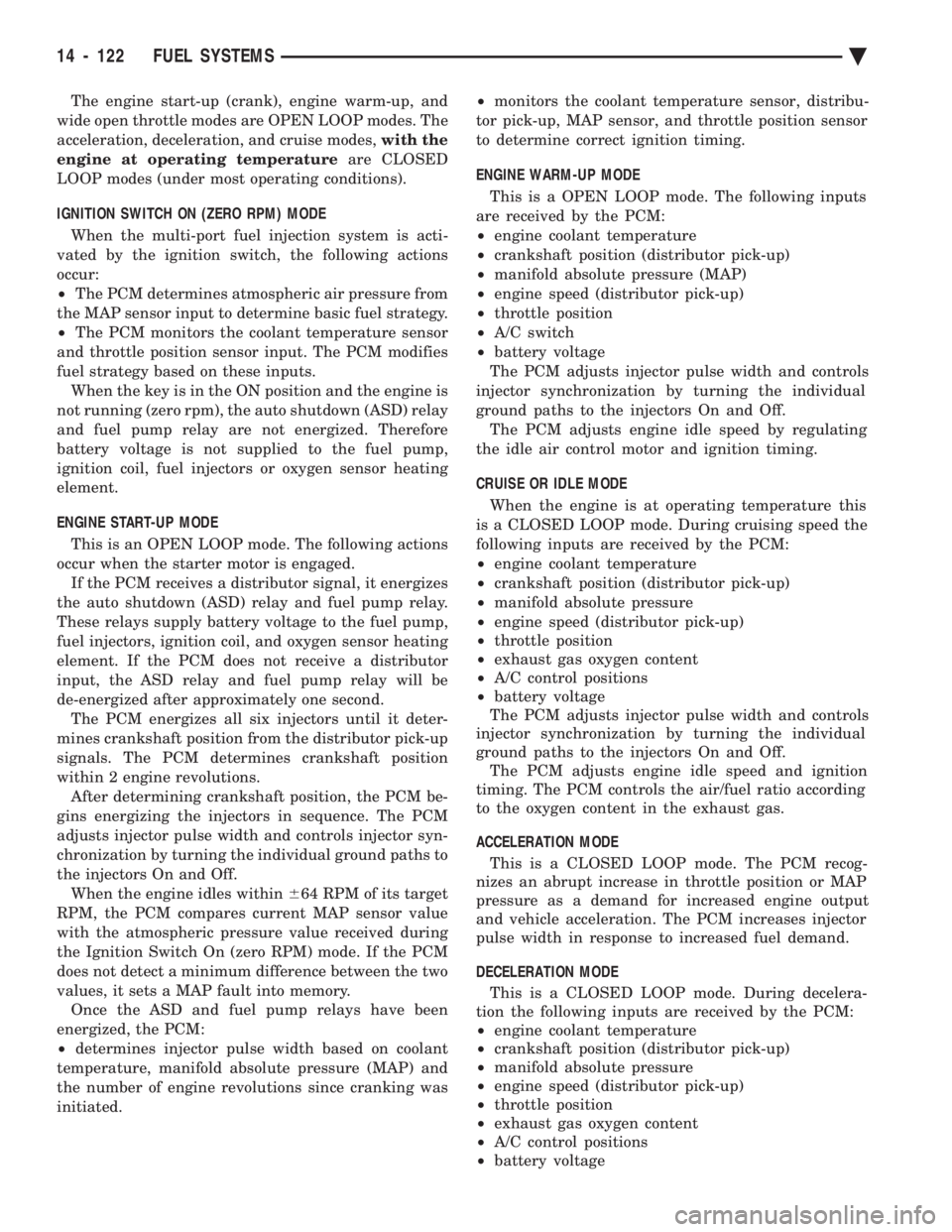

THROTTLE BODY

The throttle body assembly (Fig. 19) is located at

the left end of the air intake plenum. The throttle

body houses the throttle position sensor and the idle

air control motor. Air flow through the throttle body

is controlled by a cable operated throttle blade lo-

cated in the base of the throttle body.

FUEL SUPPLY CIRCUIT

Fuel is supplied to the fuel rail by an electric pump

mounted in the fuel tank. The pump inlet is fitted

with a strainer to prevent water and other contami-

nants from entering the fuel supply circuit. Fuel pressure is controlled to a preset level above

intake manifold pressure by a pressure regulator.

The pressure regulator is mounted on the fuel rail.

The regulator uses intake manifold pressure as a ref-

erence.

Fig. 19 Throttle Body

Ä FUEL SYSTEMS 14 - 123

Page 1864 of 2438

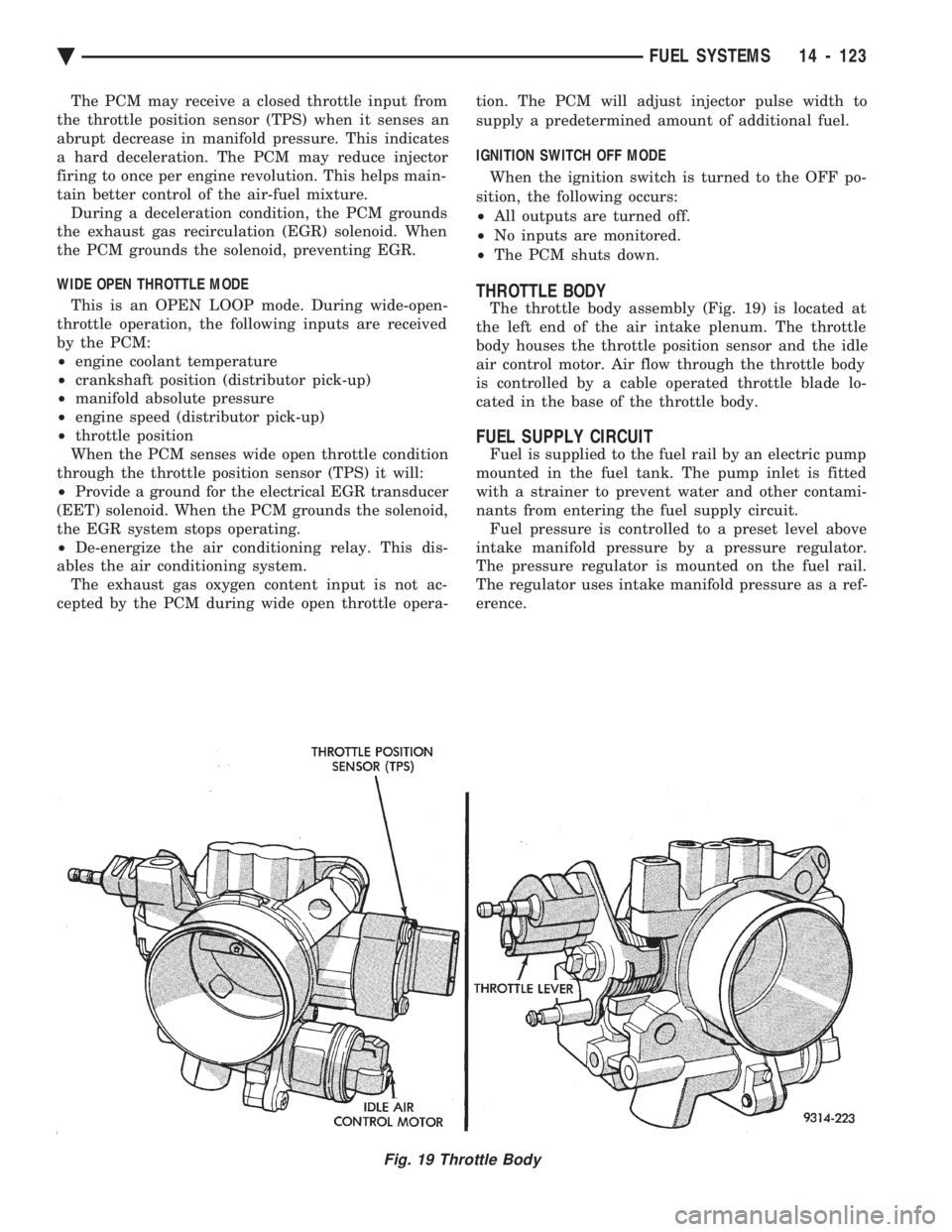

FUEL PRESSURE REGULATOR

The pressure regulator is a mechanical device lo-

cated on the fuel rail, downstream of the fuel injec-

tors (Fig. 20). The regulator maintains a constant

328 kPa (47.6 psi) across the fuel injector tip. The regulator contains a spring loaded rubber dia-

phragm that covers the fuel return port. When the

fuel pump is operating, fuel flows past the injectors

into the regulator. Fuel is restricted from flowing

any further by the blocked return port. When fuel

pressure reaches 328 kPa (47.6 psi) it pushes on the

diaphragm, compresses the spring, and uncovers the

fuel return port. The diaphragm and spring con-

stantly move from an open to closed position to keep

the fuel pressure constant.

Fig. 20 Fuel Pressure Regulator

14 - 124 FUEL SYSTEMS Ä

Page 1865 of 2438

3.0L MULTI-PORT FUEL INJECTIONÐGENERAL DIAGNOSIS INDEX

page page

Fuel System Diagram .................... 125 Visual Inspection........................ 125

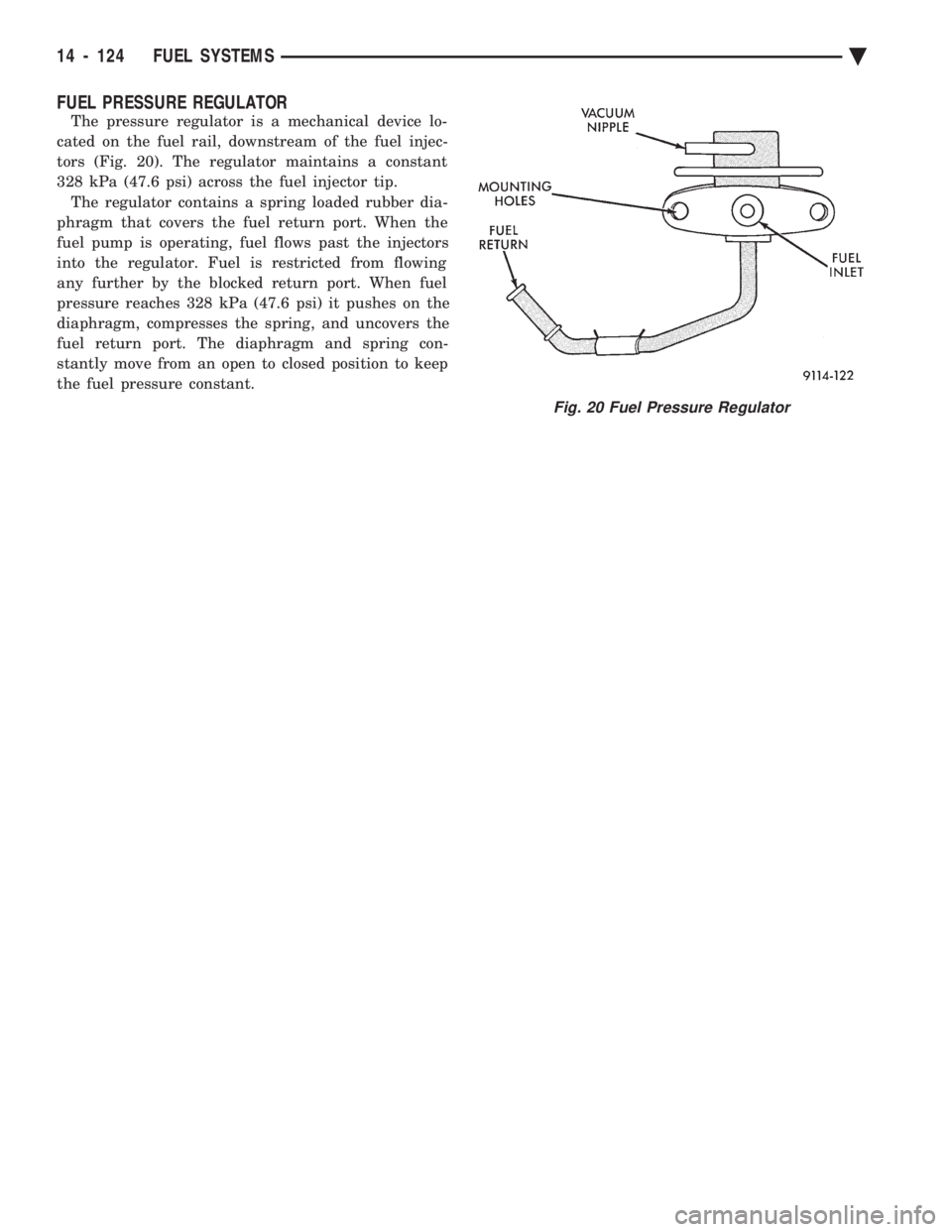

FUEL SYSTEM DIAGRAM

The 3.0L MPI system is managed by the PCM. The

PCM receives inputs from various switches and sen-

sors (Fig. 1). Based on these inputs, the PCM adjusts

ignition timing and idle speed through various out-

put devices. Refer to the Multi-Port Fuel Injec-

tionÐ3.0L Engine section of this group for system

and component descriptions.

VISUAL INSPECTION

Perform a visual inspection for loose, disconnected,

or misrouted wires and hoses before diagnosing or

servicing the fuel injection system. A visual check

saves unnecessary test and diagnostic time. A thor-

ough visual inspection includes the following checks: (1) Check for correct spark plug cable routing. En-

sure the cables are completely connected to the spark

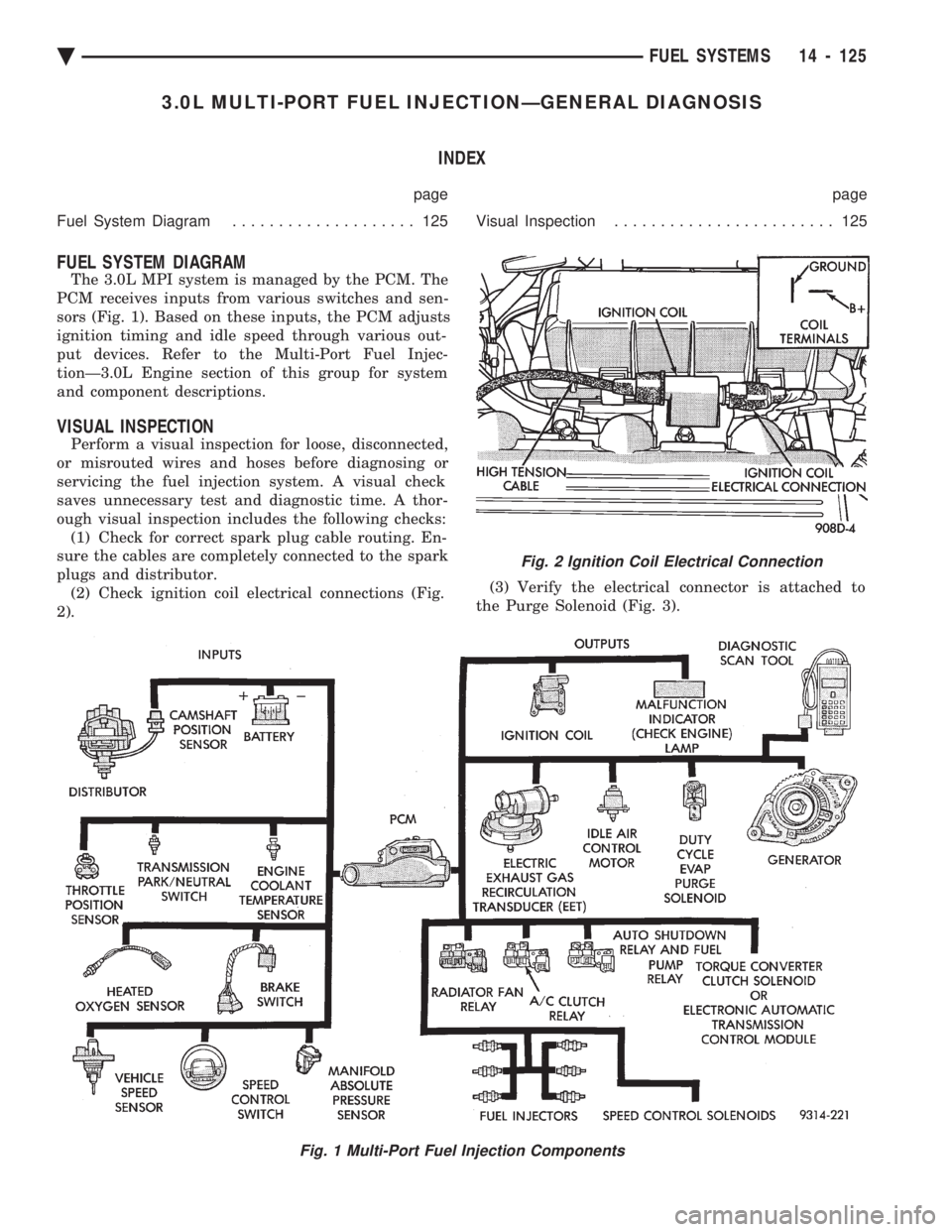

plugs and distributor. (2) Check ignition coil electrical connections (Fig.

2). (3) Verify the electrical connector is attached to

the Purge Solenoid (Fig. 3).

Fig. 1 Multi-Port Fuel Injection Components

Fig. 2 Ignition Coil Electrical Connection

Ä FUEL SYSTEMS 14 - 125

Page 1866 of 2438

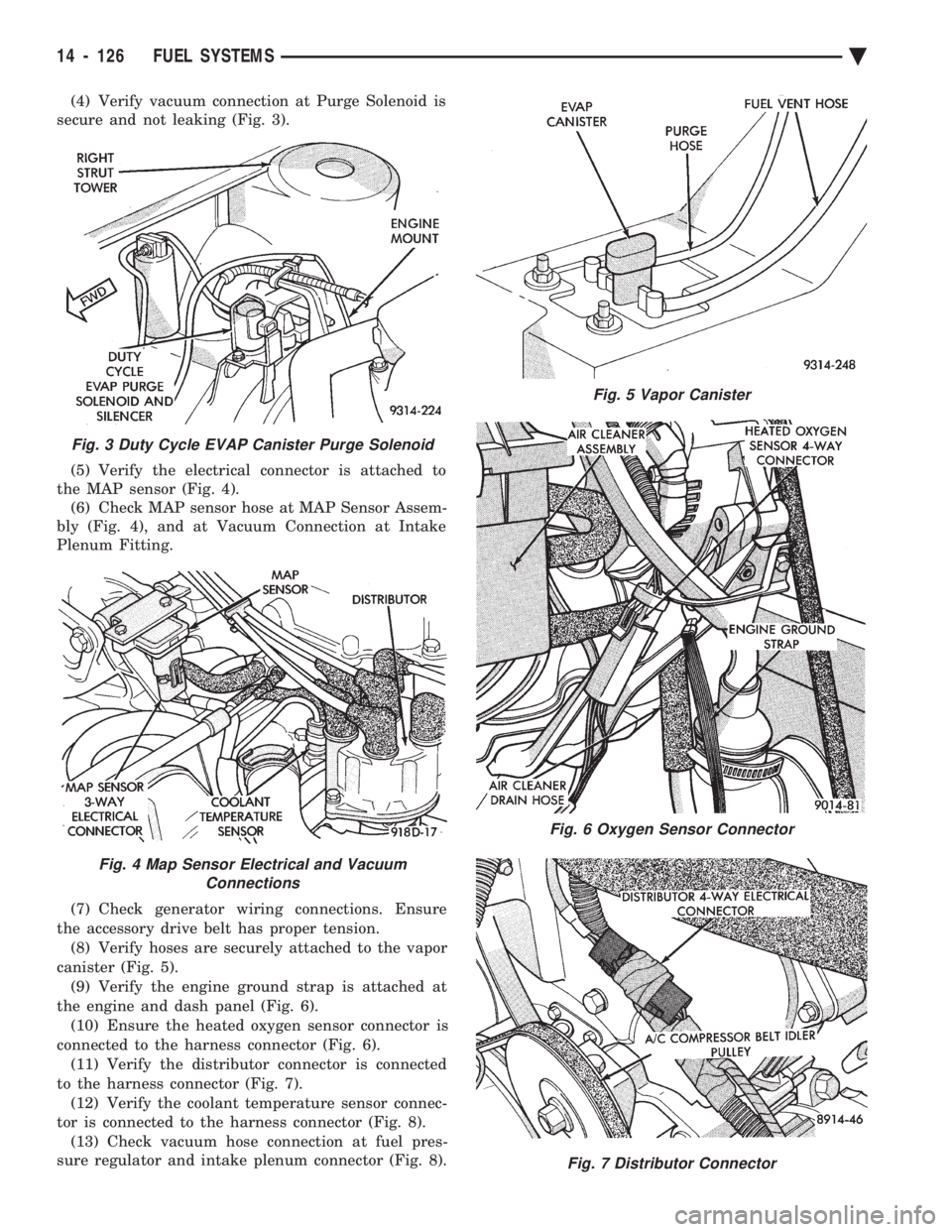

(4) Verify vacuum connection at Purge Solenoid is

secure and not leaking (Fig. 3).

(5) Verify the electrical connector is attached to

the MAP sensor (Fig. 4). (6) Check MAP sensor hose at MAP Sensor Assem-

bly (Fig. 4), and at Vacuum Connection at Intake

Plenum Fitting.

(7) Check generator wiring connections. Ensure

the accessory drive belt has proper tension. (8) Verify hoses are securely attached to the vapor

canister (Fig. 5). (9) Verify the engine ground strap is attached at

the engine and dash panel (Fig. 6). (10) Ensure the heated oxygen sensor connector is

connected to the harness connector (Fig. 6). (11) Verify the distributor connector is connected

to the harness connector (Fig. 7). (12) Verify the coolant temperature sensor connec-

tor is connected to the harness connector (Fig. 8). (13) Check vacuum hose connection at fuel pres-

sure regulator and intake plenum connector (Fig. 8).

Fig. 3 Duty Cycle EVAP Canister Purge Solenoid

Fig. 4 Map Sensor Electrical and Vacuum Connections

Fig. 5 Vapor Canister

Fig. 6 Oxygen Sensor Connector

Fig. 7 Distributor Connector

14 - 126 FUEL SYSTEMS Ä

Page 1867 of 2438

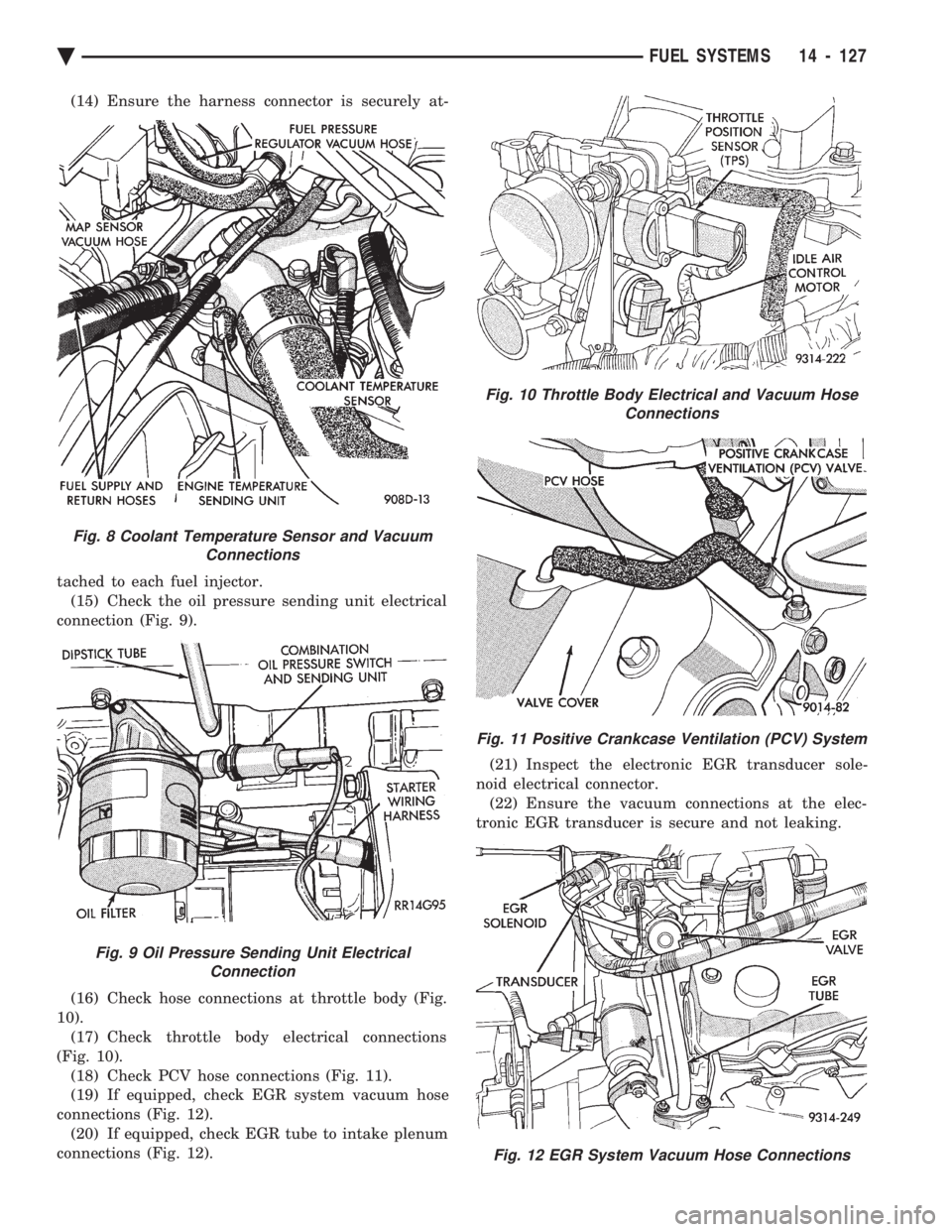

(14) Ensure the harness connector is securely at-

tached to each fuel injector. (15) Check the oil pressure sending unit electrical

connection (Fig. 9).

(16) Check hose connections at throttle body (Fig.

10). (17) Check throttle body electrical connections

(Fig. 10). (18) Check PCV hose connections (Fig. 11).

(19) If equipped, check EGR system vacuum hose

connections (Fig. 12). (20) If equipped, check EGR tube to intake plenum

connections (Fig. 12). (21) Inspect the electronic EGR transducer sole-

noid electrical connector. (22) Ensure the vacuum connections at the elec-

tronic EGR transducer is secure and not leaking.

Fig. 8 Coolant Temperature Sensor and Vacuum Connections

Fig. 9 Oil Pressure Sending Unit ElectricalConnection

Fig. 10 Throttle Body Electrical and Vacuum Hose Connections

Fig. 11 Positive Crankcase Ventilation (PCV) System

Fig. 12 EGR System Vacuum Hose Connections

Ä FUEL SYSTEMS 14 - 127

Page 1868 of 2438

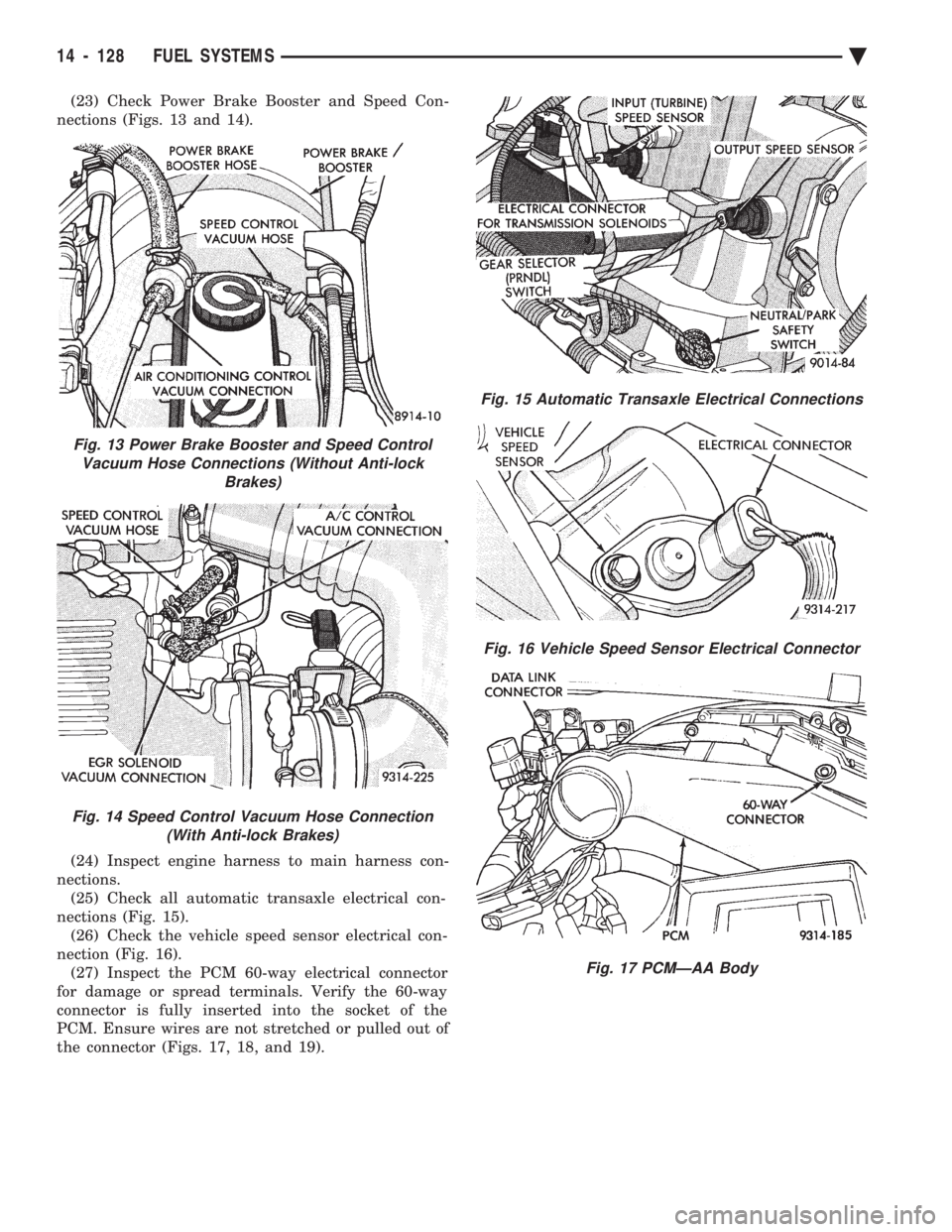

(23) Check Power Brake Booster and Speed Con-

nections (Figs. 13 and 14).

(24) Inspect engine harness to main harness con-

nections. (25) Check all automatic transaxle electrical con-

nections (Fig. 15). (26) Check the vehicle speed sensor electrical con-

nection (Fig. 16). (27) Inspect the PCM 60-way electrical connector

for damage or spread terminals. Verify the 60-way

connector is fully inserted into the socket of the

PCM. Ensure wires are not stretched or pulled out of

the connector (Figs. 17, 18, and 19).

Fig. 13 Power Brake Booster and Speed Control Vacuum Hose Connections (Without Anti-lock Brakes)

Fig. 14 Speed Control Vacuum Hose Connection(With Anti-lock Brakes)

Fig. 15 Automatic Transaxle Electrical Connections

Fig. 16 Vehicle Speed Sensor Electrical Connector

Fig. 17 PCMÐAA Body

14 - 128 FUEL SYSTEMS Ä

Page 1869 of 2438

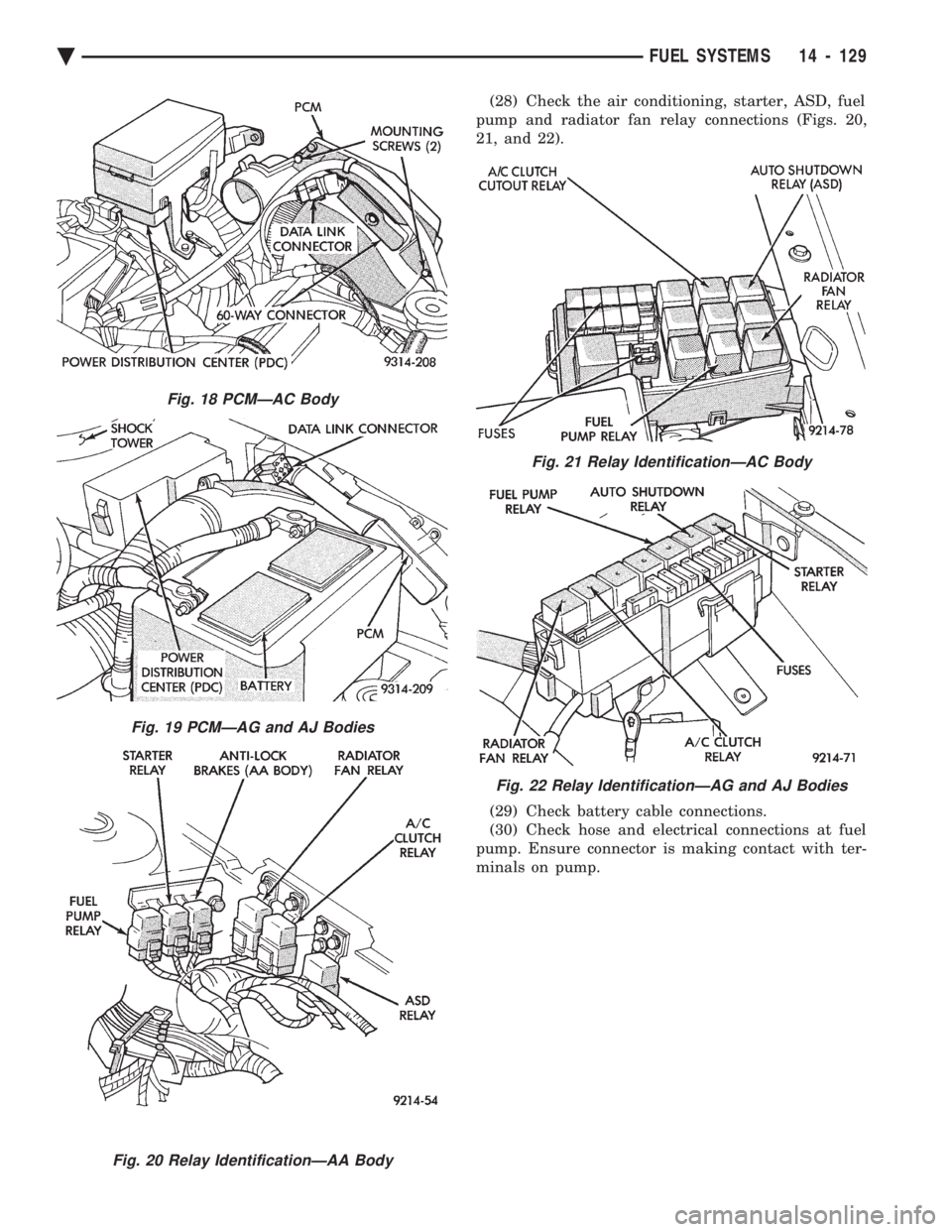

(28) Check the air conditioning, starter, ASD, fuel

pump and radiator fan relay connections (Figs. 20,

21, and 22).

(29) Check battery cable connections.

(30) Check hose and electrical connections at fuel

pump. Ensure connector is making contact with ter-

minals on pump.

Fig. 18 PCMÐAC Body

Fig. 19 PCMÐAG and AJ Bodies

Fig. 20 Relay IdentificationÐAA Body

Fig. 21 Relay IdentificationÐAC Body

Fig. 22 Relay IdentificationÐAG and AJ Bodies

Ä FUEL SYSTEMS 14 - 129

Page 1870 of 2438

3.0L MULTI-PORT FUEL INJECTIONÐON-BOARD DIAGNOSTICS INDEX

page page

60-Way PCM Wiring Connector ............. 136

Circuit Actuation Test Mode ................ 134

Diagnostic Trouble Code Description ......... 131

General Information ...................... 130

High and Low Limits ..................... 131

Ignition Timing Procedure ................. 136 Monitored Circuits

....................... 130

Non-Monitored Circuits ................... 131

State Display Test Mode .................. 134

System Tests .......................... 134

Throttle Body Minimum Air Flow Check Procedure ............................ 135

GENERAL INFORMATION

The PCM has been programmed to monitor many

different circuits of the fuel injection system. If a

problem is sensed with a monitored circuit often

enough to indicate an actual problem, the PCM

stores a fault. If the problem is repaired or ceases to

exist, the PCM cancels the Diagnostic trouble code

after 51 vehicle key on/off cycles. Certain criteria must be met for a diagnostic trou-

ble code to be entered into PCM memory. The crite-

ria may be a specific range of engine RPM, engine

temperature, and/or input voltage to the PCM. It is possible a diagnostic trouble code for a moni-

tored circuit may not be entered into memory even

though a malfunction has occurred. This may happen

because one of the diagnostic trouble code criteria for

the circuit has not been met. For example, assume

one of the diagnostic trouble code criteria for a cer-

tain sensor is the engine must be operating between

750 and 2000 RPM. If the sensor output circuit

shorts to ground when engine RPM is above 2400

RPM (resulting i n a 0 volt input to the PCM) a diag-

nostic trouble code will not be entered into memory.

This is because the condition does not occur within

the specified RPM range. There are several operating conditions that the

PCM does not monitor and set diagnostic trouble

codes for. Refer to Monitored Circuits and Non-Mon-

itored Circuits in this section. Stored diagnostic trouble codes can be displayed ei-

ther by cycling the ignition key On - Off - On - Off -

On, or through use of the DRBII scan tool. The

DRBII scan tool connects to the data link connector

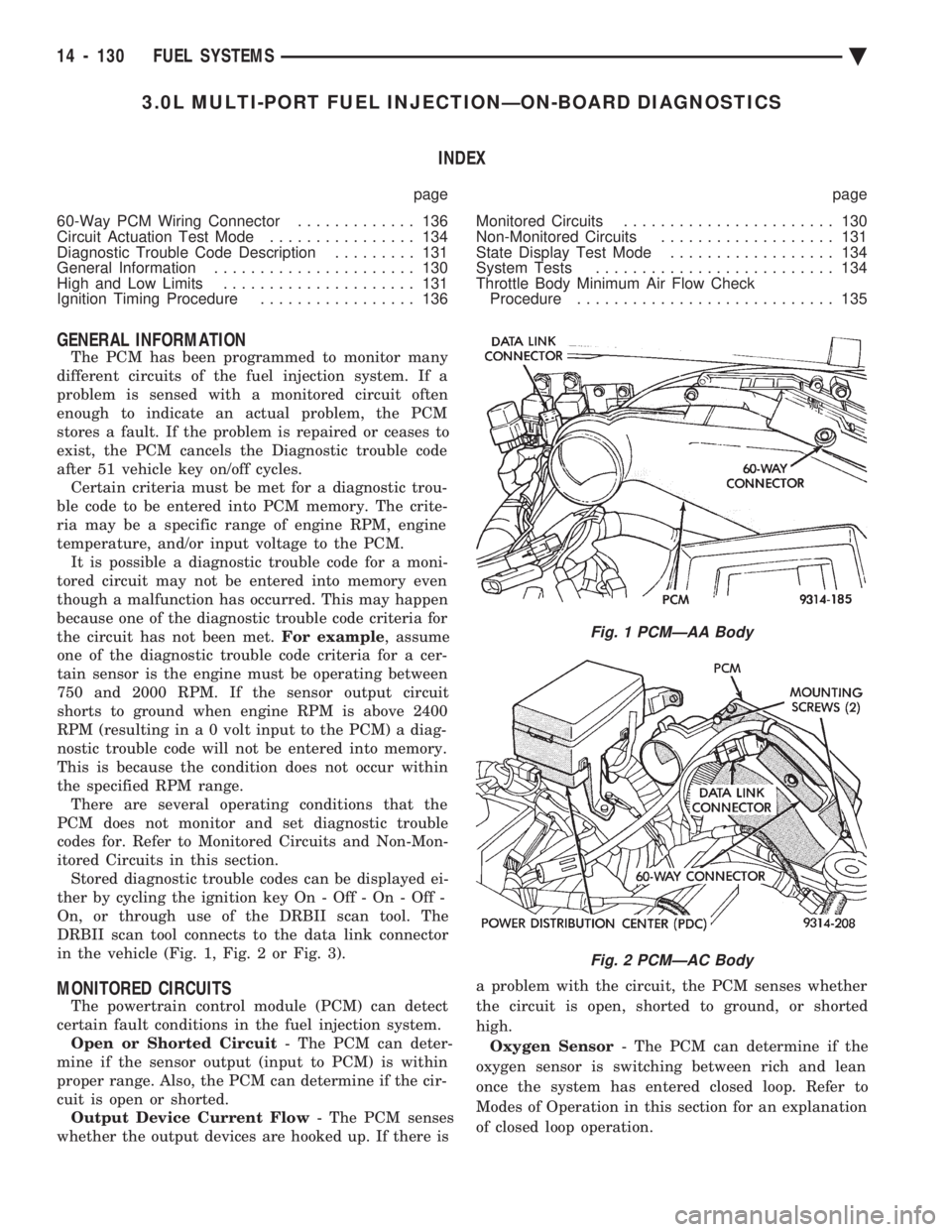

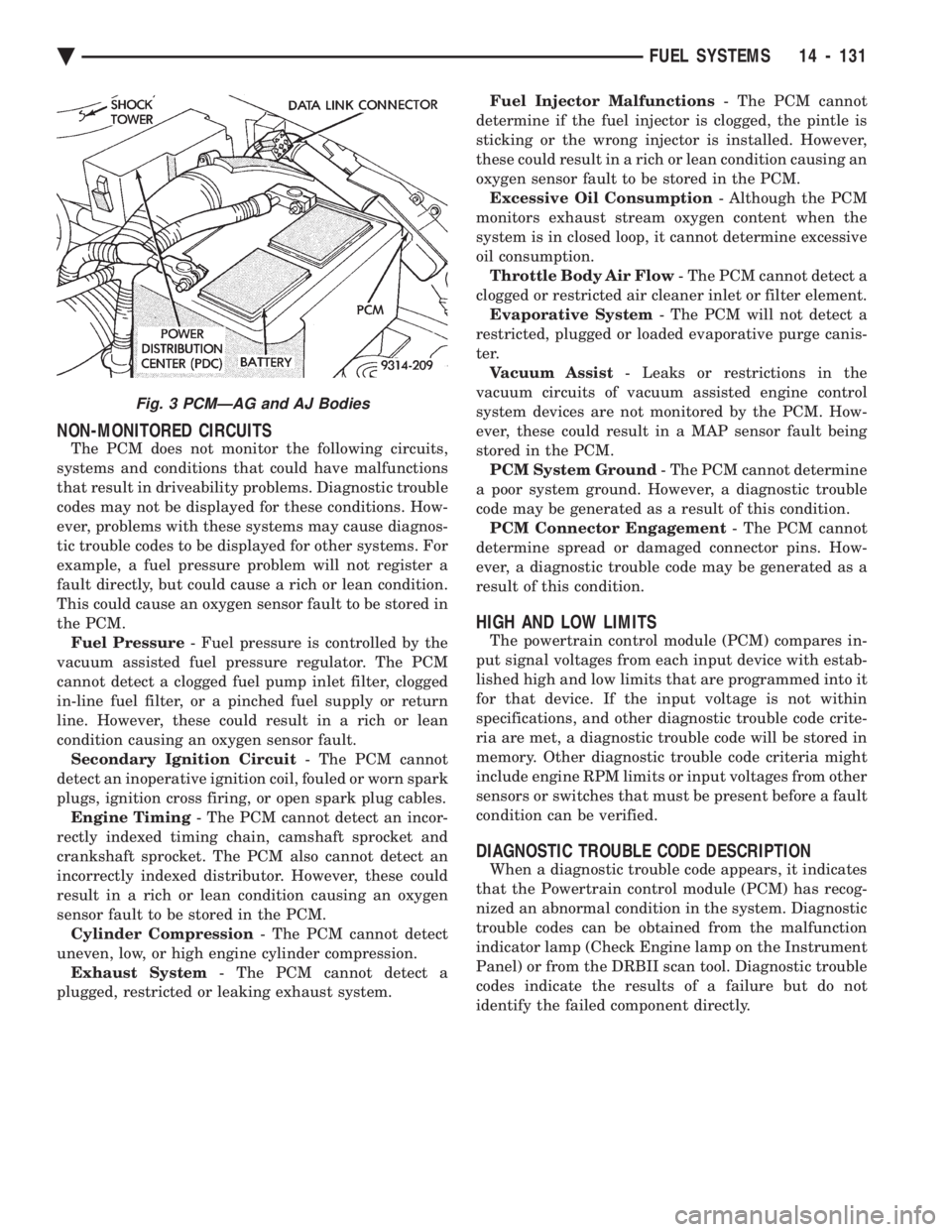

in the vehicle (Fig. 1, Fig. 2 or Fig. 3).

MONITORED CIRCUITS

The powertrain control module (PCM) can detect

certain fault conditions in the fuel injection system. Open or Shorted Circuit - The PCM can deter-

mine if the sensor output (input to PCM) is within

proper range. Also, the PCM can determine if the cir-

cuit is open or shorted. Output Device Current Flow - The PCM senses

whether the output devices are hooked up. If there is a problem with the circuit, the PCM senses whether

the circuit is open, shorted to ground, or shorted

high. Oxygen Sensor - The PCM can determine if the

oxygen sensor is switching between rich and lean

once the system has entered closed loop. Refer to

Modes of Operation in this section for an explanation

of closed loop operation.

Fig. 1 PCMÐAA Body

Fig. 2 PCMÐAC Body

14 - 130 FUEL SYSTEMS Ä

Page 1871 of 2438

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems and conditions that could have malfunctions

that result in driveability problems. Diagnostic trouble

codes may not be displayed for these conditions. How-

ever, problems with these systems may cause diagnos-

tic trouble codes to be displayed for other systems. For

example, a fuel pressure problem will not register a

fault directly, but could cause a rich or lean condition.

This could cause an oxygen sensor fault to be stored in

the PCM. Fuel Pressure - Fuel pressure is controlled by the

vacuum assisted fuel pressure regulator. The PCM

cannot detect a clogged fuel pump inlet filter, clogged

in-line fuel filter, or a pinched fuel supply or return

line. However, these could result in a rich or lean

condition causing an oxygen sensor fault. Secondary Ignition Circuit - The PCM cannot

detect an inoperative ignition coil, fouled or worn spark

plugs, ignition cross firing, or open spark plug cables. Engine Timing - The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket and

crankshaft sprocket. The PCM also cannot detect an

incorrectly indexed distributor. However, these could

result in a rich or lean condition causing an oxygen

sensor fault to be stored in the PCM. Cylinder Compression - The PCM cannot detect

uneven, low, or high engine cylinder compression. Exhaust System - The PCM cannot detect a

plugged, restricted or leaking exhaust system. Fuel Injector Malfunctions

- The PCM cannot

determine if the fuel injector is clogged, the pintle is

sticking or the wrong injector is installed. However,

these could result in a rich or lean condition causing an

oxygen sensor fault to be stored in the PCM. Excessive Oil Consumption - Although the PCM

monitors exhaust stream oxygen content when the

system is in closed loop, it cannot determine excessive

oil consumption. Throttle Body Air Flow - The PCM cannot detect a

clogged or restricted air cleaner inlet or filter element. Evaporative System - The PCM will not detect a

restricted, plugged or loaded evaporative purge canis-

ter. Vacuum Assist - Leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices are not monitored by the PCM. How-

ever, these could result in a MAP sensor fault being

stored in the PCM. PCM System Ground - The PCM cannot determine

a poor system ground. However, a diagnostic trouble

code may be generated as a result of this condition. PCM Connector Engagement - The PCM cannot

determine spread or damaged connector pins. How-

ever, a diagnostic trouble code may be generated as a

result of this condition.

HIGH AND LOW LIMITS

The powertrain control module (PCM) compares in-

put signal voltages from each input device with estab-

lished high and low limits that are programmed into it

for that device. If the input voltage is not within

specifications, and other diagnostic trouble code crite-

ria are met, a diagnostic trouble code will be stored in

memory. Other diagnostic trouble code criteria might

include engine RPM limits or input voltages from other

sensors or switches that must be present before a fault

condition can be verified.

DIAGNOSTIC TROUBLE CODE DESCRIPTION

When a diagnostic trouble code appears, it indicates

that the Powertrain control module (PCM) has recog-

nized an abnormal condition in the system. Diagnostic

trouble codes can be obtained from the malfunction

indicator lamp (Check Engine lamp on the Instrument

Panel) or from the DRBII scan tool. Diagnostic trouble

codes indicate the results of a failure but do not

identify the failed component directly.

Fig. 3 PCMÐAG and AJ Bodies

Ä FUEL SYSTEMS 14 - 131