change time CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 621 of 2438

WINDSHIELD WIPER AND WASHER SYSTEMS

CONTENTS

page page

GENERAL WIPER INFORMATION ........... 1

INTERMITTENT WINDSHIELD WIPER MOTOR AND SWITCH SERVICE PROCEDURES .... 12

WINDSHIELD WASHERS ................. 17 WINDSHIELD WIPER BLADE AND ARM SERVICE

PROCEDURES ......................... 1

WINDSHIELD WIPER MOTOR AND LINKAGE ASSEMBLY SERVICE PROCEDURES ....... 3

GENERAL WIPER INFORMATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

The windshield wipers can be operated with the

windshield wiper switch only when the ignition

switch is in the ACCESSORY or IGNITION position.

A fuse, located in the fuse block, protects the cir-

cuitry of the wiper system and the vehicle. The wiper motor has permanent magnet fields. The speeds are determined by current flow to the appro-

priate set of brushes. The intermittent wipe system, in addition to low

and high speed, has a delay mode. The delay mode

has a range of 2 to 15 seconds. This is accomplished

by a variable resistor in the wiper switch and is con-

trolled electrically by a relay. The wiper system completes the wipe cycle when

the switch is turned OFF. The blades park in the

lowest portion of the wipe pattern.

WINDSHIELD WIPER BLADE AND ARM SERVICE PROCEDURES

WIPER BLADES

Wiper blades, exposed to the weather for a long pe-

riod of time, tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is suggested to

remove the accumulation of salt and road film. The

wiper blades, arms, and windshield should be cleaned

with a sponge or cloth and a mild detergent or nona-

brasive cleaner. If the blades continue to streak or

smear, they should be replaced.

WIPER BLADE ELEMENT CHANGE

(1) Turn wiper switch ON, position blades to a con-

venient place by turning the ignition switch ON and

OFF. (2) Lift wiper arm to raise blade off glass.

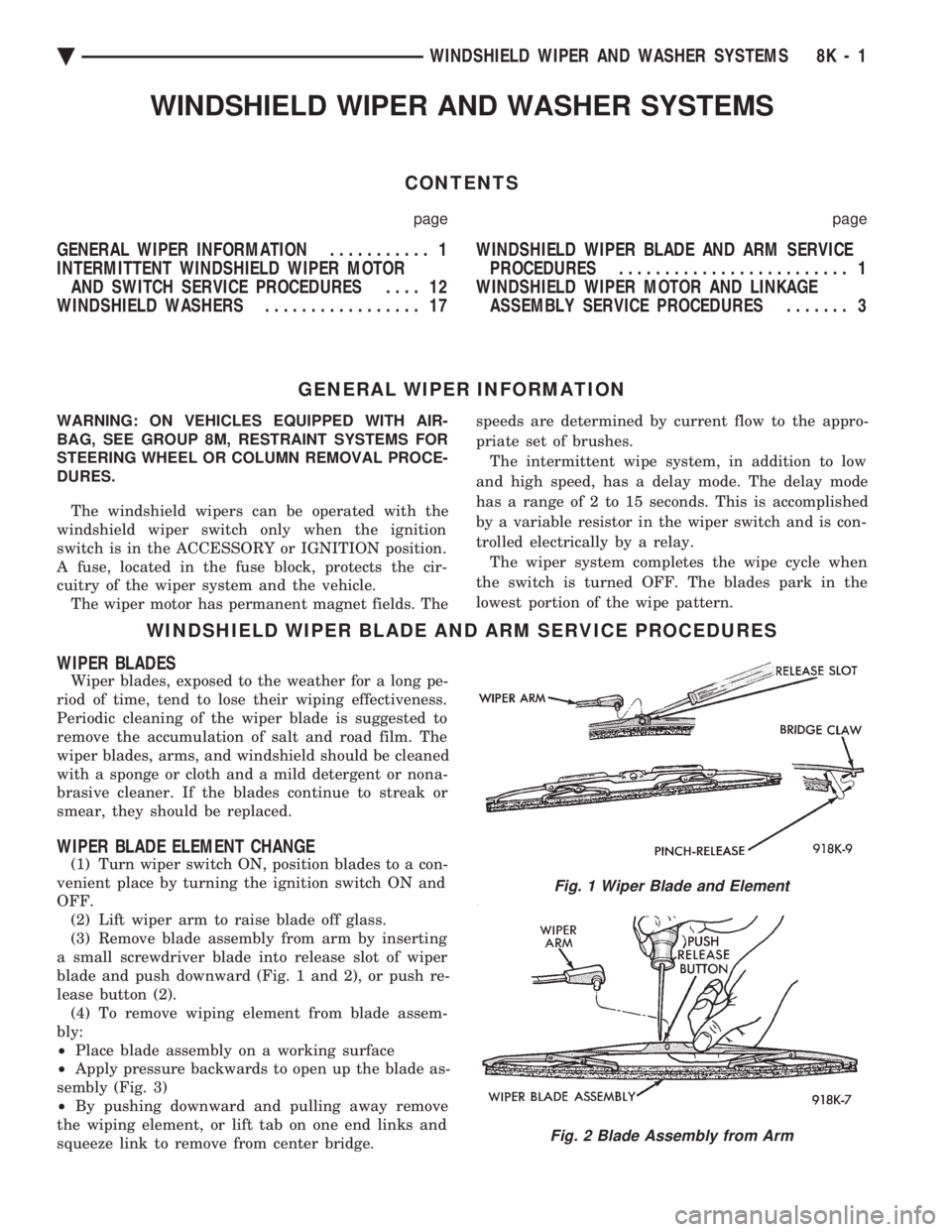

(3) Remove blade assembly from arm by inserting

a small screwdriver blade into release slot of wiper

blade and push downward (Fig. 1 and 2), or push re-

lease button (2). (4) To remove wiping element from blade assem-

bly:

² Place blade assembly on a working surface

² Apply pressure backwards to open up the blade as-

sembly (Fig. 3)

² By pushing downward and pulling away remove

the wiping element, or lift tab on one end links and

squeeze link to remove from center bridge.

Fig. 1 Wiper Blade and Element

Fig. 2 Blade Assembly from Arm

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 1

Page 683 of 2438

RESTRAINT SYSTEMS

CONTENTS

page page

AIR BAG MODULE ....................... 4

AIR BAG SERVICE AND TEST PROCEDURES . 1

AIR BAG SYSTEM CHECK ................. 3

AIR BAG SYSTEM DIAGNOSTIC MODULE (ASDM) .............................. 5

CLOCKSPRING .......................... 6

CLOCKSPRING CENTERING PROCEDURE .... 6 GENERAL INFORMATION

.................. 1

LEFT FRONT IMPACT SENSOR ............. 4

RIGHT FRONT IMPACT SENSOR ........... 5

SCHEDULED MAINTENANCE INSPECTION .... 3

STEERING COLUMN SWITCHES ............ 7

STEERING WHEEL ....................... 7

AIR BAG SERVICE AND TEST PROCEDURES

WARNING: THIS SYSTEM IS A SENSITIVE, COM-

PLEX ELECTRO-MECHANICAL UNIT. BEFORE AT-

TEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIR BAG SYSTEM COMPONENTS, YOU MUST

FIRST DISCONNECT AND ISOLATE THE NEGATIVE

(GROUND) BATTERY CABLE. FAILURE TO DO SO

COULD RESULT IN ACCIDENTAL DEPLOYMENT

AND POSSIBLE PERSONAL INJURY. WHEN AN UNDEPLOYED AIR BAG ASSEMBLY

IS TO BE REMOVED FROM THE STEERING

WHEEL, DISCONNECT BATTERY GROUND CA-

BLE AND ISOLATE. ALLOW SYSTEM CAPACI-

TOR TO DISCHARGE FOR TWO MINUTES THEN

BEGIN AIR BAG SYSTEM COMPONENT RE-

MOVAL. Vehicles equipped with a Air Bag System must be

inspected every three years or 30,000 miles / 48,000

Km. To inspect system use Passive Restraint System

Diagnostic Procedures Manual. If the Air Bag Module Assembly is defective and

non-deployed, refer to Chrysler Motors current re-

turn list for proper handling procedures.

WARNING: REPLACE AIR BAG SYSTEM COMPO-

NENTS WITH CHRYSLER MOPAR TSPECIFIED RE-

PLACEMENT PARTS. SUBSTITUTE PARTS MAY

VISUALLY APPEAR INTERCHANGEABLE, BUT IN-

TERNAL DIFFERENCES MAY RESULT IN INFERIOR

OCCUPANT PROTECTION.

THE FASTENERS, SCREWS, AND BOLTS, ORIG-

INALLY USED FOR THE AIR BAG COMPO-

NENTS, HAVE SPECIAL COATINGS AND ARE

SPECIFICALLY DESIGNED FOR THE AIR BAG

SYSTEM. THEY MUST NEVER BE REPLACED

WITH ANY SUBSTITUTES. ANYTIME A NEW

FASTENER IS NEEDED, REPLACE WITH THE CORRECT FASTENERS PROVIDED IN THE SER-

VICE PACKAGE OR FASTENERS LISTED IN THE

PARTS BOOKS.

GENERAL INFORMATION

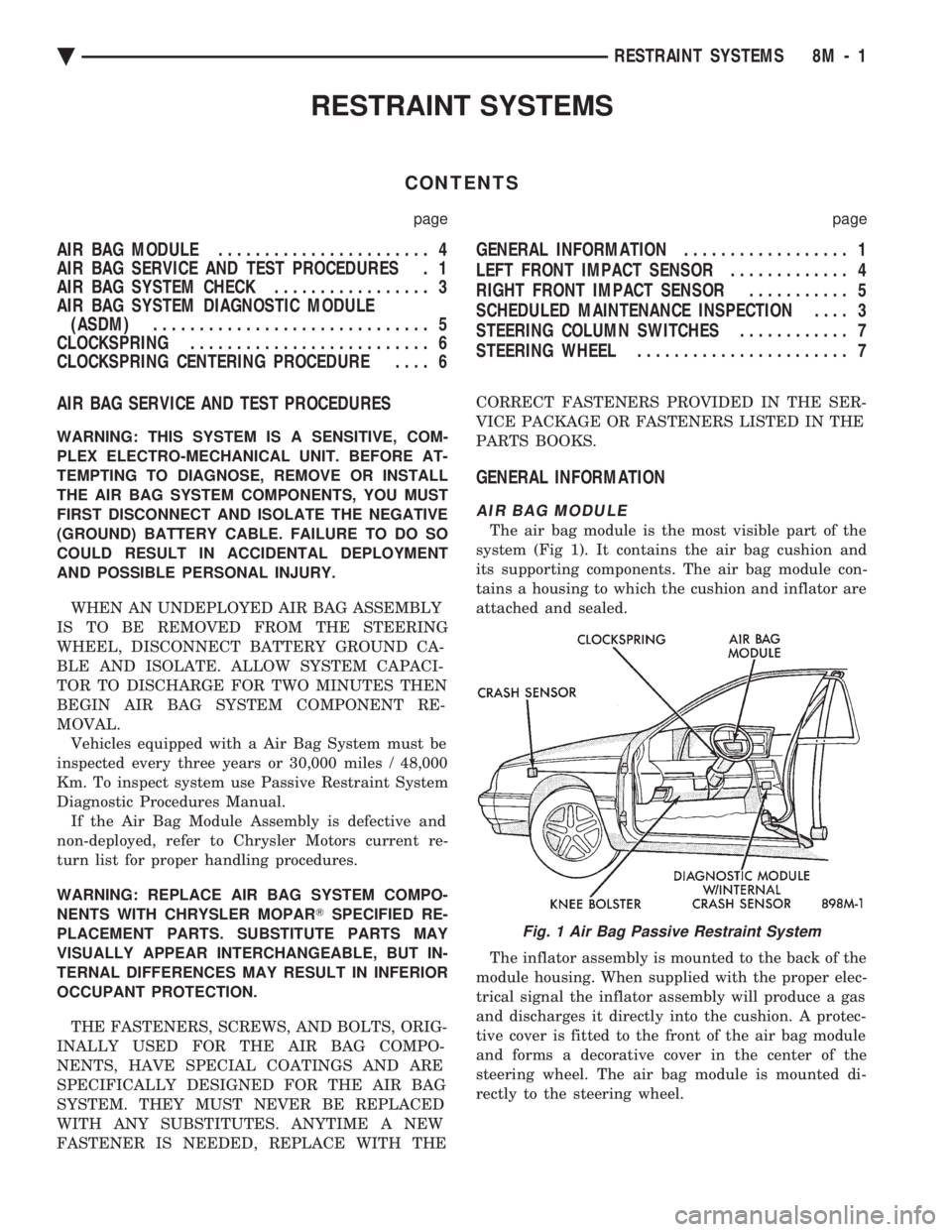

AIR BAG MODULE

The air bag module is the most visible part of the

system (Fig 1). It contains the air bag cushion and

its supporting components. The air bag module con-

tains a housing to which the cushion and inflator are

attached and sealed.

The inflator assembly is mounted to the back of the

module housing. When supplied with the proper elec-

trical signal the inflator assembly will produce a gas

and discharges it directly into the cushion. A protec-

tive cover is fitted to the front of the air bag module

and forms a decorative cover in the center of the

steering wheel. The air bag module is mounted di-

rectly to the steering wheel.

Fig. 1 Air Bag Passive Restraint System

Ä RESTRAINT SYSTEMS 8M - 1

Page 692 of 2438

(6) Steps (3, 4 or 5) above will confirm system op-

eration. Indicator light illumination means that

there is power available at the output of the relay

only, and does not necessarily verify system opera-

tion. (7) If turning the switch ON produced no distinct

current draw on the ammeter the problem should be

isolated in the following manner: (a) Confirm the ignition switch is ON.

(b) Ensure that the heated rear glass feed wire is

connected to the terminal or pigtail and that the

ground wire is in fact grounded. (c) Ensure that the fusible link and control cir-

cuit fuse is operational and all electrical connec-

tions are secure.

(8) When the above steps have been completed and

the system is still inoperative, one or more of the fol-

lowing is defective: (a) Control switch/timer relay module.

(b) All rear window grid lines would have to be

broken or one of the feed wires are not connected

for the system to be inoperative.

(9) If turning the switch ON produces severe volt-

meter deflection, the circuit should be closely

checked for a shorting condition. (10) If the system operation has been verified but

indicator lamp does not light, replace the switch. (11) For detailed wiring information, refer to group

8W, Wiring Diagrams.

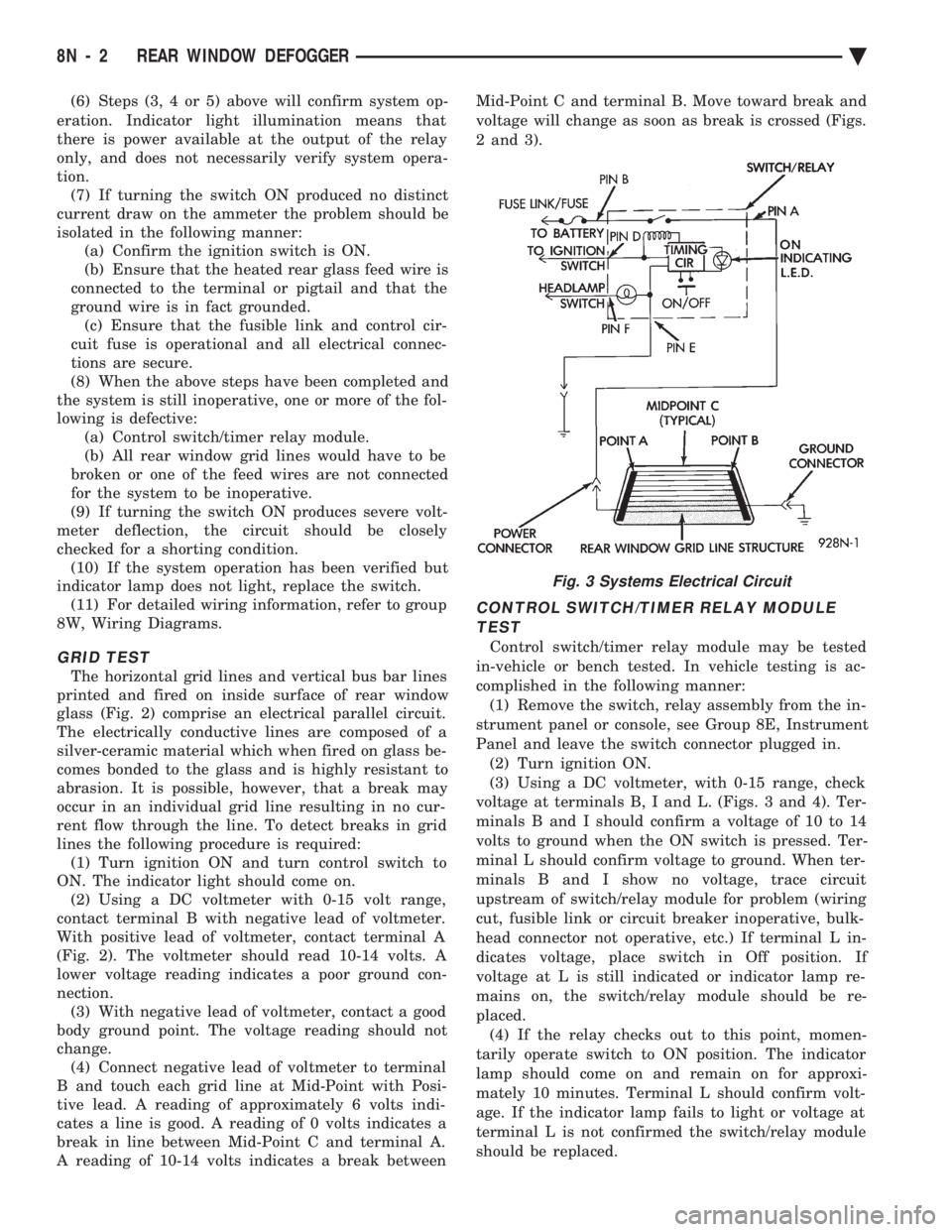

GRID TEST

The horizontal grid lines and vertical bus bar lines

printed and fired on inside surface of rear window

glass (Fig. 2) comprise an electrical parallel circuit.

The electrically conductive lines are composed of a

silver-ceramic material which when fired on glass be-

comes bonded to the glass and is highly resistant to

abrasion. It is possible, however, that a break may

occur in an individual grid line resulting in no cur-

rent flow through the line. To detect breaks in grid

lines the following procedure is required: (1) Turn ignition ON and turn control switch to

ON. The indicator light should come on. (2) Using a DC voltmeter with 0-15 volt range,

contact terminal B with negative lead of voltmeter.

With positive lead of voltmeter, contact terminal A

(Fig. 2). The voltmeter should read 10-14 volts. A

lower voltage reading indicates a poor ground con-

nection. (3) With negative lead of voltmeter, contact a good

body ground point. The voltage reading should not

change. (4) Connect negative lead of voltmeter to terminal

B and touch each grid line at Mid-Point with Posi-

tive lead. A reading of approximately 6 volts indi-

cates a line is good. A reading of 0 volts indicates a

break in line between Mid-Point C and terminal A.

A reading of 10-14 volts indicates a break between Mid-Point C and terminal B. Move toward break and

voltage will change as soon as break is crossed (Figs.

2 and 3).

CONTROL SWITCH/TIMER RELAY MODULE TEST

Control switch/timer relay module may be tested

in-vehicle or bench tested. In vehicle testing is ac-

complished in the following manner: (1) Remove the switch, relay assembly from the in-

strument panel or console, see Group 8E, Instrument

Panel and leave the switch connector plugged in. (2) Turn ignition ON.

(3) Using a DC voltmeter, with 0-15 range, check

voltage at terminals B, I and L. (Figs. 3 and 4). Ter-

minals B and I should confirm a voltage of 10 to 14

volts to ground when the ON switch is pressed. Ter-

minal L should confirm voltage to ground. When ter-

minals B and I show no voltage, trace circuit

upstream of switch/relay module for problem (wiring

cut, fusible link or circuit breaker inoperative, bulk-

head connector not operative, etc.) If terminal L in-

dicates voltage, place switch in Off position. If

voltage at L is still indicated or indicator lamp re-

mains on, the switch/relay module should be re-

placed. (4) If the relay checks out to this point, momen-

tarily operate switch to ON position. The indicator

lamp should come on and remain on for approxi-

mately 10 minutes. Terminal L should confirm volt-

age. If the indicator lamp fails to light or voltage at

terminal L is not confirmed the switch/relay module

should be replaced.

Fig. 3 Systems Electrical Circuit

8N - 2 REAR WINDOW DEFOGGER Ä

Page 744 of 2438

(2) The headlamps and parking lamps should turn

ON for about five seconds.

² AUTO MIRROR LED

² DARK LED

² AUTO LAMP LED

² The LED indicators blink for about 5 seconds.

² If the three indicators continue to blink consider-

ably longer than 5 seconds, then the mirror assembly

is defective. (3) The mirror should change to dim state.(a) Place shift selector in reverse (R), with igni-

tion switch ON:

² AUTO MIRROR LED indicator ON

² DARK LED indicator flashing

² Lasting about 15 seconds

(b) The mirror should slowly change to bright

state. (c) If the ignition is not turned OFF within the

15 second time period, the mirror will reset to its

previous setting.

The previous conditions are OK, the mirror is op-

erating properly. If not OK, continue with voltage tests below.

VOLTAGE TEST

To test for voltage insert voltmeter probe into wire

end of connector to contact terminal. Pin 1 ignition voltage (a) Ignition switch OFF, zero volts.

(b) Ignition switch ON, battery voltage.

Pin 2 battery voltage (a) Battery voltage at all times.

(b) No voltage, check 15 amp. fuse.

Pin 3 Ground (a) Continuity to ground.

(b) No voltage

Pin 4 Reverse over-ride (a) Ignition OFF, zero voltage.

(b) Ignition ON shift selector in Reverse (R), bat-

tery voltage. (c) Ignition ON shift selector in any position

other than Reverse (R), zero voltage.

Pin 5 Headlamp relay (a) Battery voltage at all times from headlamp

relay. (b) No battery voltage, test headlamp relay.

Pin 6 Park lamp relay (a) Ignition switch ON, battery voltage feed from

park lamp relay. (b) Ignition switch OFF, zero voltage.

(c) Ignition ON, No battery voltage test park

lamp relay.

If Voltage Test are OK, replace mirror assembly.

If not OK, refer to Wiring Diagrams manual.

8T - 8 POWER MIRRORS Ä

Page 1570 of 2438

REMOVE ALL SHIMS BEFORE REASSEM-

BLING ENGINE ALTERNATIVE METHOD Ð With the weight of

the crankshaft being supported by a jack under the

counterweight adjacent to the bearing being checked. (3) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 inch) off center and away from the oil

holes (Fig. 2). (In addition, suspect areas can be

checked by placing the Plastigage in the suspect area).

Torque the bearing cap bolts of the bearing being

checked to the proper specifications. (4) Remove the bearing cap and compare the width

of the flattened Plastigage (Fig. 3) with the metric scale

provided on the package. Locate the band closest to the

same width. This band shows the amount of clearance

in thousandths of a millimeter. Differences in readings

between the ends indicate the amount of taper present.

Record all readings taken. Refer to Engine Specifica-

tions. Plastic-Gage generally is accompanied by

two scales. One scale is in inches, the other is a

metric scale. (5) Plastigage is available in a variety of clearance

ranges. The 0.025-0.076mm (.001-.003 inch) is usually

the most appropriate for checking engine bearing

proper specifications.

CONNECTING ROD BEARING CLEARANCE

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or equivalent. The following

is the recommended procedure for the use of Plasti-

gage: (1) Rotate the crankshaft until the connecting rod to

be checked is at the bottom of its stroke. (2) Remove oil film from surface to be checked.

Plastigage is soluble in oil. (3) Place a piece of Plastigage across the entire

width of the bearing shell in the bearing cap approxi-

mately 6.35 mm (1/4 inch.) off center and away from

the oil hole (Fig. 2). In addition, suspect areas can be

checked by placing plastigage in the suspect area. (4) Before assembling the rod cap with Plastigage in

place, the crankshaft must be rotated until the con-

necting being checked starts moving toward the top of

the engine. Only then should the cap be assembled and

torqued to specifications. Do not rotate the crank-

shaft while assembling the cap or the Plastigage

may be smeared, giving inaccurate results. (5) Remove the bearing cap and compare the width

of the flattened Plastigage (Fig. 3) with the metric

scale provided on the package. Locate the band closest

to the same width. This band shows the amount

of clearance in thousandths of a millimeter. Differences

in readings between the ends indicate the amount

of taper present. Record all readings taken.

Refer to Engine Specifications. Plastigage generally is accompanied by two scales. One scale is in

inches, the other is a metric scale. (6) Plastigage is available in a variety of clearance

ranges. The 0.025-0.076mm (.001-.003 inch) is usually

the most appropriate for checking engine bearing

proper specifications.

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items. (1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause them

to be spongy. (2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required. During this time, turn engine off and let set for a few

minutes before restarting. Repeat this several times

after engine has reached normal operating tempera-

ture. (3) Low oil pressure.

(4) The oil restrictor pressed into the vertical oil

passage to the cylinder head of Balance Shaft Engines

Only is plugged with debris. (5) Air ingested into oil due to broken or cracked oil

pump pick up. (6) Worn valve guides.

(7) Rocker arm ears contacting valve spring retainer

(2.2/2.5L engines). (8) Rocker arm loose, adjuster or tappet stuck or at

maximum extension and still leaves lash in the system. (9) Faulty lash adjuster or tappet.(a) Check for sponginess while still installed in

engine. Depress part of rocker arm just over adjuster

or pushrod . Normal adjusters should feel very firm.

Spongy adjusters can be depressed to the bottomed

position easily. (b) Remove suspected lash adjuster or tappet, pry

off retainer cap or snap ring and disassemble. Do

not reuse retainer caps . Do not interchange parts

and make sure that care and cleanliness is exercised

in the handling of parts. (c) Clean out dirt and varnish with solvent.

(d) Reassemble with engine oil.

(e) Check for sponginess.

(f) If still spongy, replace with new adjuster.

REPAIR OF DAMAGED OR WORN THREADS

Damaged or worn threads (including aluminum head

spark plug threads) can be repaired. Essentially, this

repair consists of drilling out worn or damaged

threads, tapping the hole with a special Heli-Coil (or

equivalent) Tap, and installing an insert into the

tapped hole. This brings the hole back to its original

thread size.

9 - 4 ENGINE Ä

Page 1576 of 2438

shaft end play. A sintered iron (TBI engine and steel

billet Turbo III engines) timing belt sprocket is

mounted on the cam nose, and a hydrodynamic oil

seal is used for oil control at the front of the cam-

shaft. ACCESSORY SHAFT: The iron accessory shaft

has two bearing journals and is housed in the for-

ward facing side of the block. A hydrodynamic seal,

installed in an aluminum housing attached to the

block, provides retention, shaft thrust, and oil con-

trol. The accessory shaft is driven by the timing belt

through a sintered iron (TBI engine and steel billet

Turbo III engines) sprocket mounted on the nose of

the accessory shaft. The accessory shaft in turn

drives the oil pump and distributor on 2.2/2.5L and

2.5L FFV and the oil pump only on Turbo III. VALVES: The valves are actuated by roller cam

followers which pivot on stationary hydraulic lash

adjusters. The valve train with 40.6 mm (1.60 inch)

diameter intake valves and 35.4 mm (1.39 inch) di-

ameter exhaust valves employ viton rubber valve

stem seals except 2.5L FFv . the 2.5L FFV valve

stem seals are made of special rubber compound

which resist the deteriorating effects of methanol

fuel by-products that enter the oil during combus-

tion. Valve springs, spring retainers, and locks are

conventional. For Turbo III engines the valves are

actuated by roller tipped rocker arms with hydraulic

lash adjusters which pivot on a shaft. The valve train

with 33.88 mm (1.33 in.) diameter intake valves are

arranged in line opposite of the 29.26 mm (1.15 in.)

diameter exhaust valves employ locking valve stem

seals. Valve springs, spring retainers, and locks are

not interchangeable with other engines. BALANCE SHAFTS: 2.2 Turbo III and 2.5L en-

gines are equipped with two counter rotating balance

shafts installed in a carrier attached to the lower

crankcase. The shafts are interconnect through

gears. These gears are driven by a short chain from

the crankshaft, to rotate at two times crankshaft

speed. This counterbalances certain engine recipro-

cating forces. INTAKE MANIFOLDS:

All intake manifolds are

aluminum castings, attached to the cylinder head

with eight bolts. N.A. engines use a four branch de-

sign. This long branch fan design enhances low and

midspeed torque. It also features an integrally cast

water crossover passage to warm incoming fuel/air

mixture, plus an EGR mounting boss and PCV inlet. The Turbo III engine intake manifold is a log type

with tuned runners. The manifold is machined to ac-

cept fuel injectors near the ports of each cylinder. EXHAUST MANIFOLDS: The exhaust manifolds

are made of nodular cast iron for strength and high

temperatures. All naturally aspirated (N.A.) and tur-

bocharged engines exit exhaust gasses through a ma-

chined, articulated joint connection to the exhaust

pipe. 2.2/2.5L and 2.5L FFV manifolds intermesh

with the intake manifold at the cylinder head. N.A. engines use a four branch design with cylin-

ders one and four joined and cylinder two and three

joined to exit at the outlet. The Turbo III engine exhaust manifold also carries

the turbocharger. This manifold has a modified log

type collector with exhaust gasses directed to and

through the turbocharger to exit the conical (articu-

lated joint) outlet machined into the turbocharger ex-

haust elbow. ENGINE LUBRICATION: Refer to Group 0 Lu-

brication and Maintenance for recommended oil to be

used in various engine application. System is full

flow filtration, pressure feed type. The oil pump is

mounted within the crankcase and driven by the ac-

cessory shaft. Pressurized oil is then routed through

the main oil gallery, running the length of the cylin-

der block, supplying main and rod bearings with fur-

ther routing (for 2.2L turbo III and 2.5L engines) to

the lower balance shaft assemblies. Pistons are lubri-

cated from directed holes in the connecting rod as-

semblies. Camshaft and valve mechanisms are

lubricated from a full-length cylinder head oil gallery

supplied from the crankcase main oil gallery.

9 - 10 2.2/2.5L ENGINE Ä

Page 1609 of 2438

CRANKSHAFT SERVICE

CRANKSHAFT MAIN BEARINGS

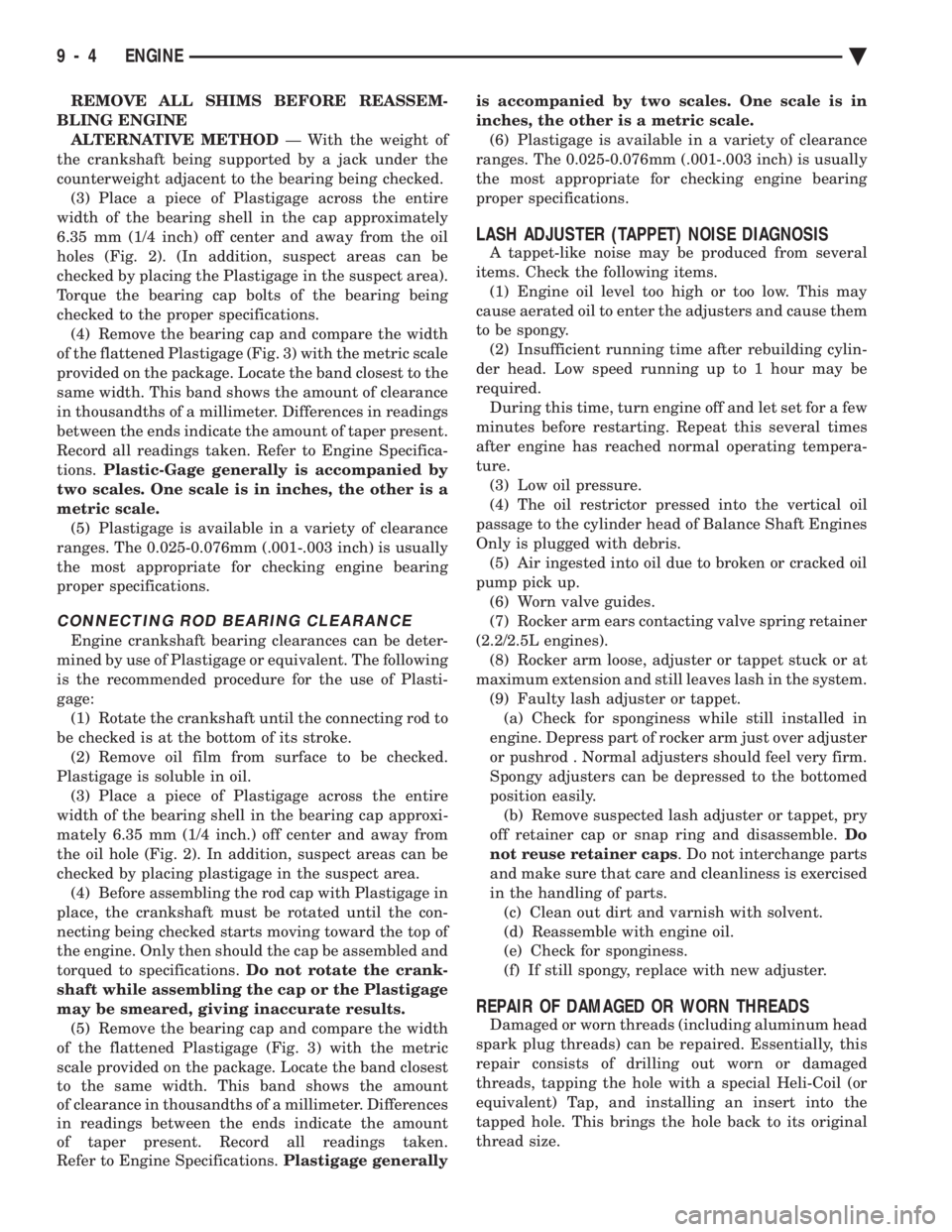

Bearing caps are not interchangeable and should

be marked at removal to insure correct assembly.

Upper and lower bearing halves are NOT inter-

changeable. Lower main bearing halves of 1, 2, 4 and

5 are interchangeable. Upper main bearing halves of

1, 2, 4 and 5 are interchangeable (Fig. 7).

CRANKSHAFT MAIN JOURNALS

The crankshaft journals should be checked for ex-

cessive wear, taper and scoring. Limits of taper or

out-of-round on any crankshaft journals should be

held to .025mm (.001 inch). Journal grinding should

not exceed .305mm (.012 inch) under the standard

journal diameter. Do NOT grind thrust faces of Num-

ber 3 main bearing. Do NOT nick crank pin or bear-

ing fillets. After grinding, remove rough edges from

crankshaft oil holes and clean out all passages.

CAUTION: With the nodular cast iron crankshafts

used it is important that the final paper or cloth pol-

ish after any journal regrind be in the same direc-

tion as normal rotation in the engine.

Upper and lower Number 3 bearing halves are

flanged to carry the crankshaft thrust loads and are

NOT interchangeable with any other bearing halves

in the engine (Fig. 7). All bearing cap bolts removed

during service procedures are to be cleaned and oiled

before installation. Bearing shells are available in

standard and the following undersized: 0.025mm

(.001 inch), .051mm (.002 inch), .076mm (.003 inch),

.254mm (.010 inch), and .305mm (.012 inch). Never

install an undersize bearing that will reduce clear-

ance below specifications.

MAIN BEARING SERVICEÐCRANKSHAFT NOT REMOVED

REMOVAL

(1) Remove oil pan and identify bearing caps before

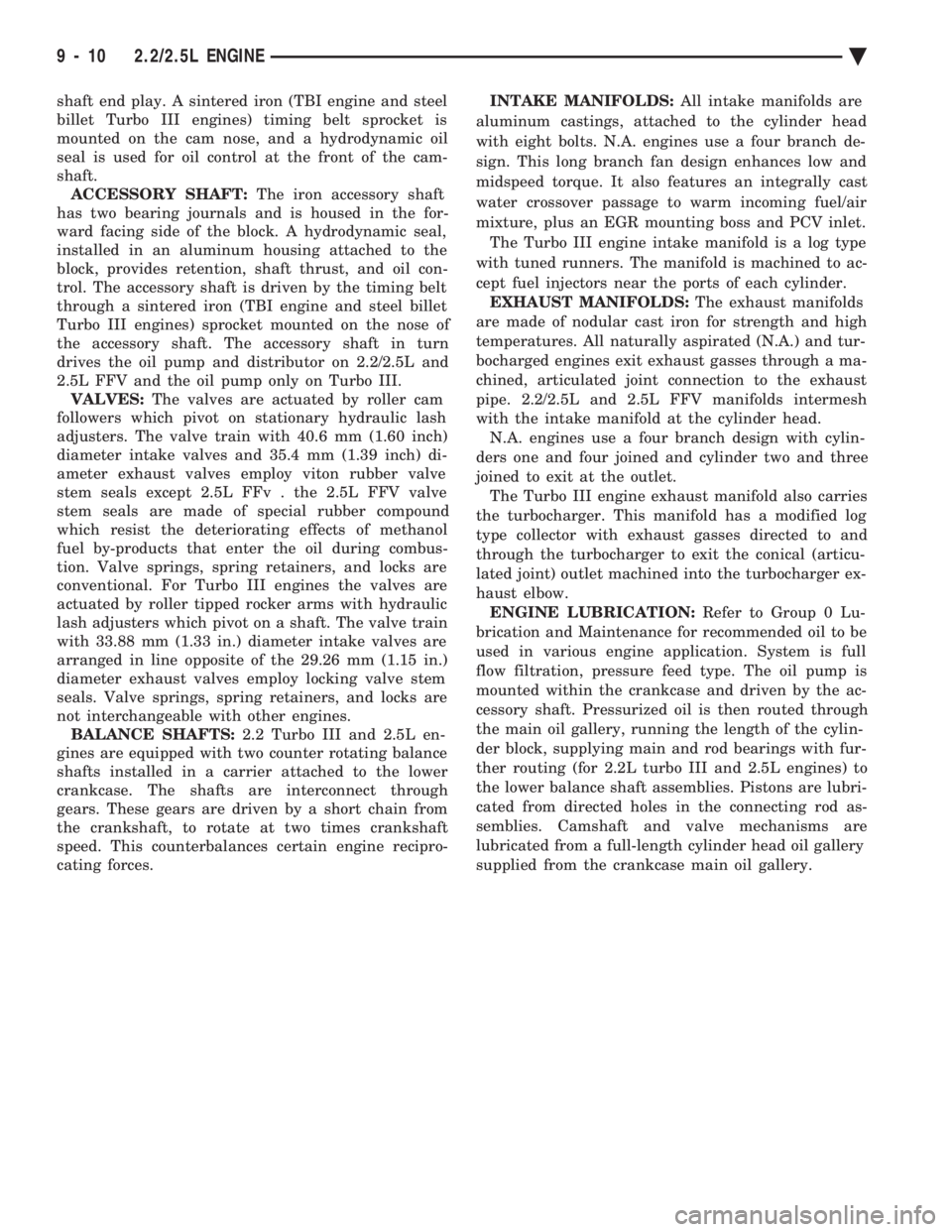

removal. (2) Remove bearing caps one at a time. Remove

upper half of bearing by inserting Special Main Bear-

ing Tool C-3059 (Fig. 8) into the oil hole of crankshaft. (3) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

INSTALLATION Only one main bearing should be selectively

fitted while all other main bearing caps are prop-

erly tightened. When installing a new upper bearing shell, slightly

chamfer the sharp edges from the plain side. (1) Start bearing in place, and insert Main Bearing

Tool C-3059 into oil hole of crankshaft (Fig. 8). (2) Slowly rotate crankshaft counter-clockwise slid-

ing the bearing into position. Remove Special Main

Bearing Tool C-3059.

CHECKING CRANKSHAFT END PLAY

(1) Mount a dial indicator to front of engine, locating

probe on nose of crankshaft (Fig. 9). (2) Move crankshaft all the way to the rear of its

travel. (3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and read

the dial indicator. Refer to (Fig. 10) for specifications.

OPTIONAL CRANKSHAFT END PLAY CHECK

(1) Move crankshaft all the way to the rear of its

travel using a lever inserted between a main bearingFig. 7 Main Bearing Identification

Fig. 8 Removing and Installing Upper Main Bearing With Special Tool C-3059

Ä 2.2/2.5L ENGINE 9 - 43

Page 1620 of 2438

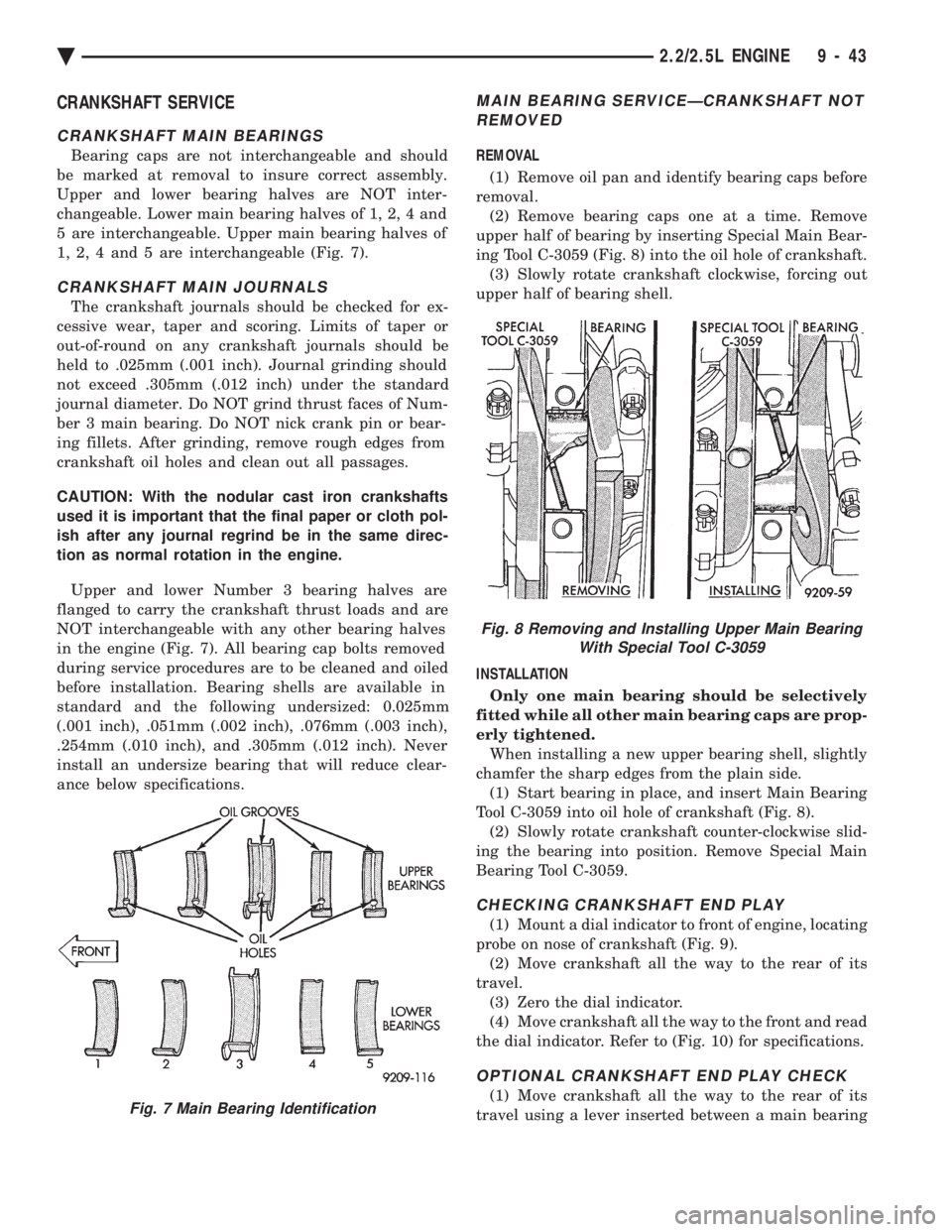

firmly and press down the portion to be installed un-

til side rail is in position. Do not use a piston ring

expander. (Fig. 19).

(3) Install upper side rail first and then the lower

side rail. (4) Install No. 2 piston ring and then No. 1 piston

ring (Fig. 8). (5) Position piston ring end gaps as shown in (Fig.

19). (6) Position oil ring expander gap at least 45É from

the side rail gaps but noton the piston pin center or

on the thrust direction. Staggering ring gap is impor-

tant for oil control.

PISTON AND CONNECTING ROD ASSEMBLY INSTALLATION

(1) Before installing pistons and connecting rod as-

semblies into the bore, besure that compression ring

gaps are staggered so that neither is in line with oil

ring rail gap. (2) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located as shown in (Fig. 19).

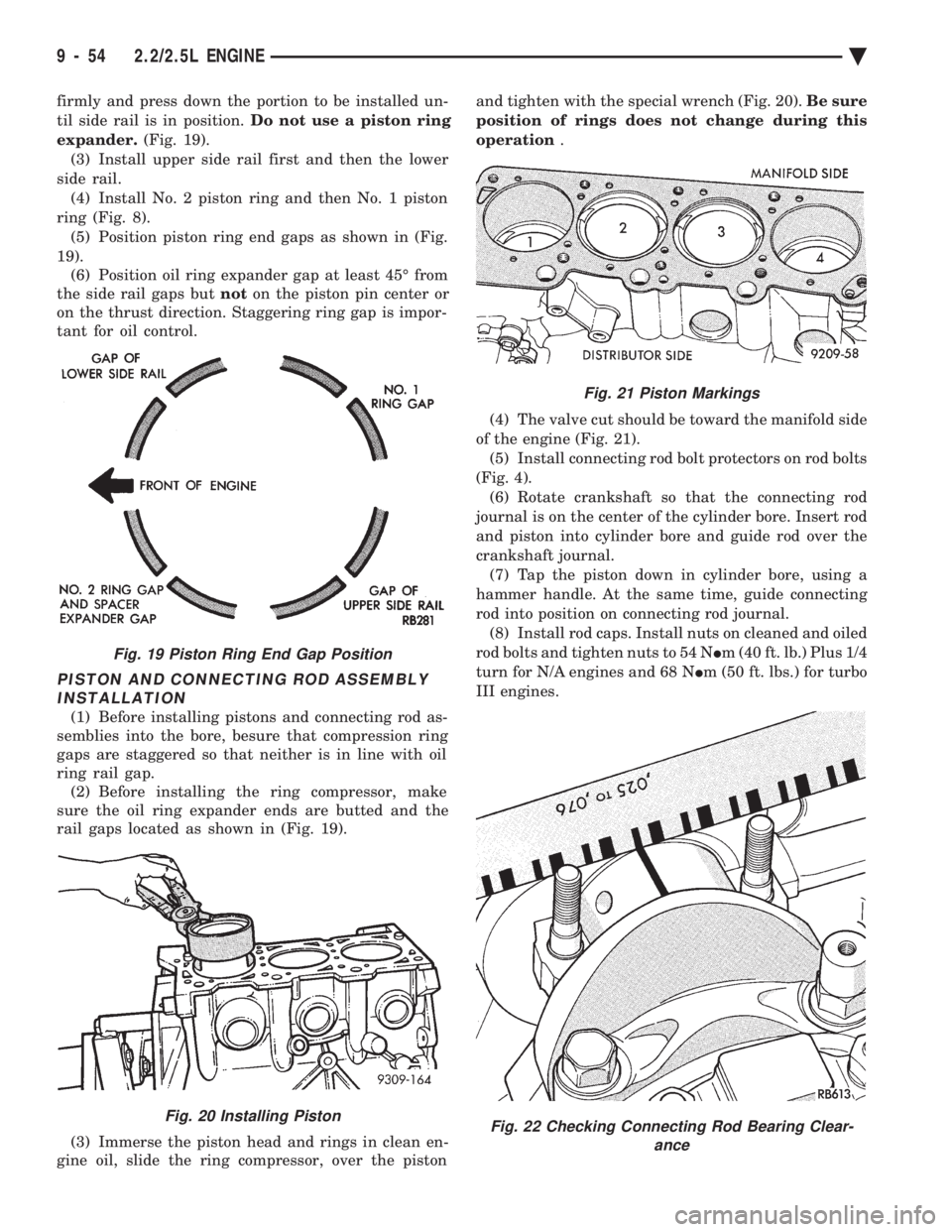

(3) Immerse the piston head and rings in clean en-

gine oil, slide the ring compressor, over the piston and tighten with the special wrench (Fig. 20).

Be sure

position of rings does not change during this

operation .

(4) The valve cut should be toward the manifold side

of the engine (Fig. 21). (5) Install connecting rod bolt protectors on rod bolts

(Fig. 4). (6) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Insert rod

and piston into cylinder bore and guide rod over the

crankshaft journal. (7) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal. (8) Install rod caps. Install nuts on cleaned and oiled

rod bolts and tighten nuts to 54 N Im (40 ft. lb.) Plus 1/4

turn for N/A engines and 68 N Im (50 ft. lbs.) for turbo

III engines.

Fig. 19 Piston Ring End Gap Position

Fig. 20 Installing Piston

Fig. 21 Piston Markings

Fig. 22 Checking Connecting Rod Bearing Clear- ance

9 - 54 2.2/2.5L ENGINE Ä

Page 1674 of 2438

(15) Install rocker arm covers tighten screws to 14

N Im (120 in. lbs.) and connector to ignition coils.

(16) Install Intake Manifold; Refer to Intake Mani-

fold Installation 3.3/3.8L Engine, Group 11 Exhaust

System and Intake Manifold.

HYDRAULIC TAPPETS

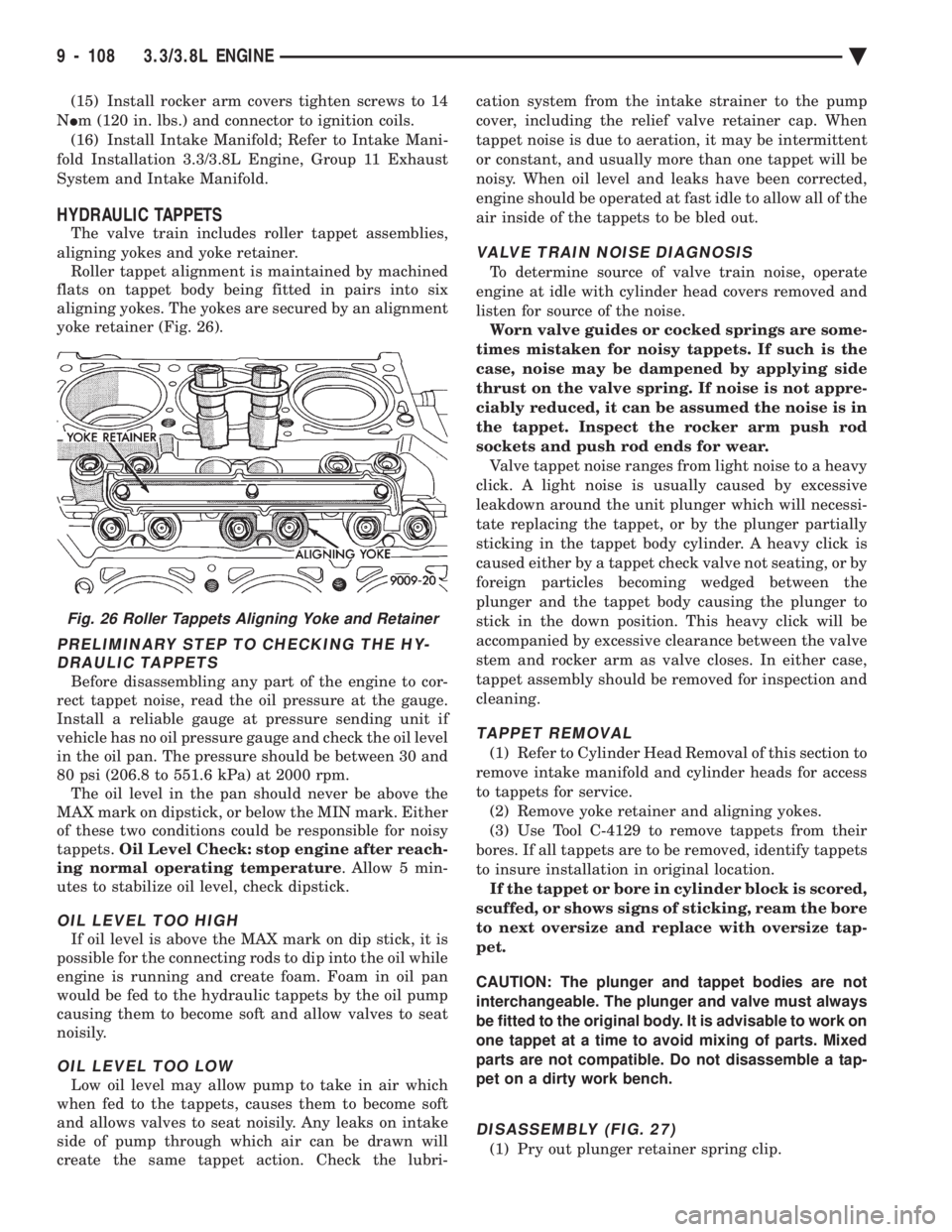

The valve train includes roller tappet assemblies,

aligning yokes and yoke retainer. Roller tappet alignment is maintained by machined

flats on tappet body being fitted in pairs into six

aligning yokes. The yokes are secured by an alignment

yoke retainer (Fig. 26).

PRELIMINARY STEP TO CHECKING THE HY- DRAULIC TAPPETS

Before disassembling any part of the engine to cor-

rect tappet noise, read the oil pressure at the gauge.

Install a reliable gauge at pressure sending unit if

vehicle has no oil pressure gauge and check the oil level

in the oil pan. The pressure should be between 30 and

80 psi (206.8 to 551.6 kPa) at 2000 rpm. The oil level in the pan should never be above the

MAX mark on dipstick, or below the MIN mark. Either

of these two conditions could be responsible for noisy

tappets. Oil Level Check: stop engine after reach-

ing normal operating temperature . Allow 5 min-

utes to stabilize oil level, check dipstick.

OIL LEVEL TOO HIGH

If oil level is above the MAX mark on dip stick, it is

possible for the connecting rods to dip into the oil while

engine is running and create foam. Foam in oil pan

would be fed to the hydraulic tappets by the oil pump

causing them to become soft and allow valves to seat

noisily.

OIL LEVEL TOO LOW

Low oil level may allow pump to take in air which

when fed to the tappets, causes them to become soft

and allows valves to seat noisily. Any leaks on intake

side of pump through which air can be drawn will

create the same tappet action. Check the lubri- cation system from the intake strainer to the pump

cover, including the relief valve retainer cap. When

tappet noise is due to aeration, it may be intermittent

or constant, and usually more than one tappet will be

noisy. When oil level and leaks have been corrected,

engine should be operated at fast idle to allow all of the

air inside of the tappets to be bled out.

VALVE TRAIN NOISE DIAGNOSIS

To determine source of valve train noise, operate

engine at idle with cylinder head covers removed and

listen for source of the noise. Worn valve guides or cocked springs are some-

times mistaken for noisy tappets. If such is the

case, noise may be dampened by applying side

thrust on the valve spring. If noise is not appre-

ciably reduced, it can be assumed the noise is in

the tappet. Inspect the rocker arm push rod

sockets and push rod ends for wear. Valve tappet noise ranges from light noise to a heavy

click. A light noise is usually caused by excessive

leakdown around the unit plunger which will necessi-

tate replacing the tappet, or by the plunger partially

sticking in the tappet body cylinder. A heavy click is

caused either by a tappet check valve not seating, or by

foreign particles becoming wedged between the

plunger and the tappet body causing the plunger to

stick in the down position. This heavy click will be

accompanied by excessive clearance between the valve

stem and rocker arm as valve closes. In either case,

tappet assembly should be removed for inspection and

cleaning.

TAPPET REMOVAL

(1) Refer to Cylinder Head Removal of this section to

remove intake manifold and cylinder heads for access

to tappets for service. (2) Remove yoke retainer and aligning yokes.

(3) Use Tool C-4129 to remove tappets from their

bores. If all tappets are to be removed, identify tappets

to insure installation in original location. If the tappet or bore in cylinder block is scored,

scuffed, or shows signs of sticking, ream the bore

to next oversize and replace with oversize tap-

pet.

CAUTION: The plunger and tappet bodies are not

interchangeable. The plunger and valve must always

be fitted to the original body. It is advisable to work on

one tappet at a time to avoid mixing of parts. Mixed

parts are not compatible. Do not disassemble a tap-

pet on a dirty work bench.

DISASSEMBLY (FIG. 27)

(1) Pry out plunger retainer spring clip.

Fig. 26 Roller Tappets Aligning Yoke and Retainer

9 - 108 3.3/3.8L ENGINE Ä

Page 1683 of 2438

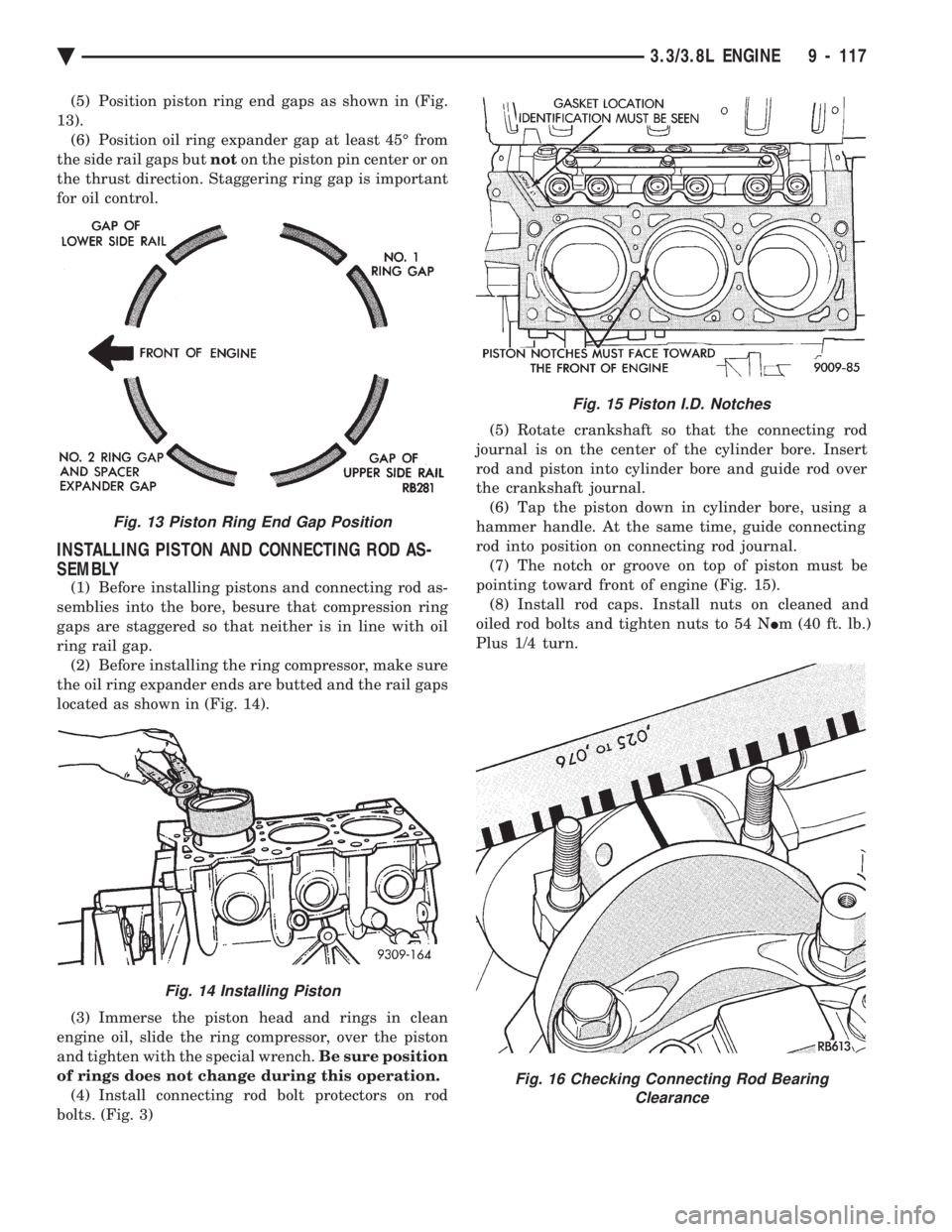

(5) Position piston ring end gaps as shown in (Fig.

13). (6) Position oil ring expander gap at least 45É from

the side rail gaps but noton the piston pin center or on

the thrust direction. Staggering ring gap is important

for oil control.

INSTALLING PISTON AND CONNECTING ROD AS-

SEMBLY

(1) Before installing pistons and connecting rod as-

semblies into the bore, besure that compression ring

gaps are staggered so that neither is in line with oil

ring rail gap. (2) Before installing the ring compressor, make sure

the oil ring expander ends are butted and the rail gaps

located as shown in (Fig. 14).

(3) Immerse the piston head and rings in clean

engine oil, slide the ring compressor, over the piston

and tighten with the special wrench. Be sure position

of rings does not change during this operation. (4) Install connecting rod bolt protectors on rod

bolts. (Fig. 3) (5) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Insert

rod and piston into cylinder bore and guide rod over

the crankshaft journal. (6) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal. (7) The notch or groove on top of piston must be

pointing toward front of engine (Fig. 15). (8) Install rod caps. Install nuts on cleaned and

oiled rod bolts and tighten nuts to 54 N Im (40 ft. lb.)

Plus 1/4 turn.

Fig. 15 Piston I.D. Notches

Fig. 16 Checking Connecting Rod Bearing Clearance

Fig. 13 Piston Ring End Gap Position

Fig. 14 Installing Piston

Ä 3.3/3.8L ENGINE 9 - 117