change time CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 239 of 2438

Brake Warning Lamp may indicate reduced

braking ability. The following procedure should

be used to test drive an ABS complaint:(1) Ignition on. Turn the ignition to the ON position

without starting the car and wait until the Red Brake

Warning Lamp and Amber Anti-Lock Warning Lamp

turn off. This will allow the pump to charge the

accumulator to operating pressure. If the warning

lamp(s) do not turn off, go to step 3. (2) Ignition off for 15 seconds.

(3) Start car. Wait for displays to return to normal

operating mode before proceeding. (4) With Shift lever in PARK, slowly depress brake

pedal and release. (5) Drive vehicle a short distance. During this test

drive, be sure that the vehicle achieves at least 20 mph.

Then brake to at least one complete stop and accelerate

slowly back up to at least 20 mph. (6) If a functional problem with the A.B.S. system is

determined while test driving a vehicle. Refer to the

Bendix Anti-Lock 10 Diagnostics Manual for required

test procedures and proper use of the DRB II tester.

CAUTION: The following are general precautions that

should be observed when servicing and diagnosing

the ABS system and/or other vehicle systems. Failure

to observe these precautions may result in ABS

system damage.

(1) If welding work is to be performed on the vehicle

using an arc welder, the (CAB) should be disconnected

before the welding operation begins. (2) The (CAB) and hydraulic assembly 10 way con-

nectors should never be connected or disconnected with

the ignition on. (3) Some components of the ABS system are not

serviced separately and must be serviced as complete

assemblies. Do not disassemble any component which

is designated as non-serviceable. (4) Always de-pressurize the Hydraulic Accu-

mulator when performing any work that re-

quires disconnecting any hydraulic tube, flex

hose or fitting. The ABS system uses brake fluid

at high pressure. Failure to de-pressurize the

accumulator may result in personal injury

and/or damage to painted surfaces. Brake fluid will damage painted surfaces. If brake

fluid is spilled on any painted surfaces, wash off with

water immediately.

DE-PRESSURIZING HYDRAULIC ACCUMULA- TOR

The ABS pump/motor assembly keeps the hydraulic

accumulator charged between approximately 11,032

and 13,790 kPa (1600 and 2000 psi) anytime key is in the ON position. The pump/motor assembly

cannot run if the ignition is off or either battery ca-

ble is disconnected. Unless otherwise specified, the hydraulic accumu-

lator should be de-pressurized before disassembling

any portion of the hydraulic system. The following

procedure should be used to de-pressurize the hy-

draulic accumulator: (1) With ignition off, or either battery cable discon-

nected, pump the brake pedal a minimum of 40 times

using approximately 50 pounds of pedal force. A no-

ticeable change in pedal feel will occur when the ac-

cumulator becomes discharged. (2) When a definite increase in pedal effort is felt,

pump the pedal a few additional times. This will in-

sure removal of all hydraulic pressure from the

brake system.

WHEEL SPEED SENSOR CABLES

Proper installation of wheel speed sensor cables is

critical to continued ABS system operation. Be sure

that cables are installed and routed properly. Failure

to install cables in their retainers, as shown in Sec-

tion 3 of this manual. May result in contact with

moving parts or over extension of cables, resulting in

an open circuit.

MECHANICAL DIAGNOSTICS AND SERVICE

PROCEDURES

SPECIAL SERVICE TOOLS

Some diagnostic procedures in this section require

the use of special service tools. Each of these tools is

described below.

DRB II DIAGNOSTIC TESTER

Some of the diagnostic procedures that are ex-

plained in this section require the use of the DRB II

DIAGNOSTICS TESTER to insure that proper diag-

nostics are performed. Refer to those sections for

proper testing procedures and the DRB II manual for

its proper operational information.

MST-6163 PRESSURE TESTER

Some diagnostic procedures in this manual require

the use of the MST-6163 pressure gauge and adaptor

(Fig. 2). Pressure Gauge, Special Tool MST-6163 is

required to measure accumulator pressure during

certain phases of ABS operation. The pressure gauge

and adaptor should be installed as follows: (1) De-pressurize the accumulator by pumping the

brake pedal a minimum of 40 times with the ignition

off. The procedure is fully explained under De-Pres-

surizing Hydraulic Accumulator which is described

earlier in this System Diagnosis Section.

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 89

Page 243 of 2438

DRIVE-OFF CYCLE

The DRIVE-OFF CYCLE takes place when the ve-

hicle reaches about 3 miles per hour the first time af-

ter an ignition reset. During this test, the modulator

solenoid valves are activated briefly to test their

function. The DRIVE-OFF CYCLE will be bypassed

if you drive-off with the service brake pedal de-

pressed.

LATCHING VERSUS NON-LATCHING FAULTS

Some faults detected by the (CAB) are latching.

The fault is latched and (ABS) function is disabled

until the ignition switch is reset (turned OFF/ON).

Thus (ABS) function is disabled even if the original

fault has disappeared during the ignition cycle in

which it occurred. Other faults are non-latching; any

warning lights that are turned on are only on as long

as the fault condition exists. As soon as the condition

goes away. The Amber Anti-Lock Warning Light is

turned off. Although a fault code will be set in most

cases. (Example:low accumulator fault will not be

stored for a time of 2 minutes after the fault is de-

tected).

BENDIX ABS SYSTEMS DIAGNOSTICS

The Bendix Anti-Lock 10 Brake System diagnos-

tics. Beyond the basic mechanical diagnostics, sys-

tems and components covered earlier in this section,

is accomplished by using the DRB II diagnostic

tester. See testing procedures outlined in the Bendix

Anti-Lock 10 Diagnostics Manual for the 1993 M.Y. Please reference the above mentioned manual. For

any further diagnostic service procedures that are re-

quired on the Bendix Anti-Lock 10 Brake System, re-

quiring the use of the DRB II diagnostic tester.

ON CAR HYDRAULIC ABS COMPONENT SERVICE

WARNING: FAILURE TO FULLY DE-PRESSURIZE

THE HYDRAULIC ACCUMULATOR BEFORE PER-

FORMING HYDRAULIC SYSTEM SERVICE OPERA-

TIONS. COULD RESULT IN INJURY TO SERVICE

PERSONNEL AND OR DAMAGE TO PAINTED SUR-

FACES. SEE SECTION 2 FOR ADDITIONAL WARN-

INGS AND CAUTIONS.

GENERAL SERVICE PRECAUTIONS

The following are general precautions that should

be observed when servicing the Anti-Lock Brake Sys-

tem and/or other vehicle systems. Failure to observe

these precautions may result in Anti-Lock brake sys-

tem damage. If welding work is to be performed on the vehicle,

using an electric arc welder, the (CAB) connector

should be disconnected during the welding operation. The (CAB) or hydraulic assembly connector should

never be connected or disconnected with the ignition

switch in the ONposition.

Many components of the Anti-Lock brake system are

not serviceable and must be replaced as an assembly.

Do not attempt to disassemble any component

that is not designed to be a serviced component.

DE-PRESSURIZING HYDRAULIC ACCUMULA- TOR

The pump/motor assembly will keep the hydraulic

accumulator charged to approximately 11,032 and

13,790 kPa (1600 and 2000 psi) any time that the

ignition is in the ON position. The pump/motor assem-

bly cannot run if the ignition is off or if either battery

cable is disconnected. Unless otherwise specified, the hydraulic accumula-

tor should be de-pressurized before disassembling any

portion of the hydraulic system. The following proce-

dure should be used to relieve the pressure in the

hydraulic accumulator: (1) With ignition off, or either battery cable discon-

nected, pump the brake pedal a minimum of 40 times,

using approximately 222 N (50 lbs.) pedal force. A

noticeable change in pedal feel will occur, when the

accumulator is discharged. (2) When a definite increase in pedal effort is felt,

pump pedal a few additional times. This will insure

removal of all hydraulic pressure from the brake sys-

tem.

CHECKING BRAKE FLUID LEVEL

CAUTION: Use only brake fluid conforming to DOT 3

specifications such as Mopar Tor Equivalent. Do not

use any fluid in the brake hydraulic system, which

contains a petroleum base. Do not use a container

which has been used for petroleum based fluids or a

container that is wet with water. Petroleum based

fluids will cause swelling and distortion of rubber

parts in the hydraulic brake system and water will mix

with brake fluid, lowering the fluid boiling point. Keep

all brake fluid containers tightly capped to prevent

contamination.

The hydraulic assembly is equipped with a plastic

fluid reservoir, with a filter/strainer located in the filler

neck of each reservoir section. The Anti-Lock brake system requires that the hy-

draulic accumulator be de-pressurized when checking

the fluid level. To check the brake fluid level, the

following procedure should be used: (1) With the ignition off, de-pressurize the hydraulic

accumulator by applying the brake pedal approxi-

mately 40 times, using a pedal force of approximately

220 N (50 lbs.). A noticeable change in pedal feel will

occur when the accumulator is de-

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 93

Page 357 of 2438

-37ÉC (-35ÉF) to -59ÉC (-50ÉF). If it looses color or

becomes contaminated, drain, flush, and replace with

fresh properly mixed solution.

SERVICE

Coolant should be changed at 52,500 miles or three

years, whichever occurs first, then every two years or

30,000 miles.

ROUTINE LEVEL CHECK

Do not remove radiator cap for routine coolant

level inspections. The coolant reserve system provides a quick visual

method for determining the coolant level without re-

moving the radiator cap. Simply observe, with the

engine idling and warmed up to normal operating

temperature, that the level of the coolant in the reserve

tank (Figs. 5 and 6) is between the minimum and

maximum marks.

ADDING ADDITIONAL COOLANT

The radiator cap should not be removed. When

additional coolant is needed to maintain this level, it

should be added to the coolant reserve tank. Use only

50/50 concentration of ethylene glycol type antifreeze

and water.

SERVICE COOLANT LEVEL

The cooling system is closed and designed to main-

tain coolant level to the top of the radiator. When servicing requires a coolant level check in the

radiator, the engine must be offand notunder pres-

sure. Drain several ounces of coolant from the radiator

drain cock while observing the Coolant Recovery Sys-

tem (CRS) Tank. Coolant level in the CRS tank should

drop slightly. Then remove the radiator cap. The radia-

tor should be full to the top. If not, and the coolant level

in the CRS tank is at the MIN mark there is a air leak

in the CRS system. Check hose or hose connections to

the CRS tank, radiator filler neck or the pressure cap

seal to the radiator filler neck for leaks.

LOW COOLANT LEVEL AERATION

Low coolant level in a cross flow radiator will equal-

ize in both tanks with engine off. With engine at

running operating temperature the high pressure inlet

tank runs full and the low pressure outlet tank drops.

If this level drops below the top of the transmission oil

cooler, air will be sucked into the water pump:

² Transmission oil will become hotter.

² High reading shown on the temperature gauge.

² Air in the coolant will also cause loss of flow through

the heater.

² Exhaust gas leaks into the coolant can also cause the

same problems.

DEAERATION

Air can only be removed from the system by gather-

ing under the pressure cap. On the next heat up it will

be pushed past the pressure cap into the CRS tank by

thermal expansion of the coolant. It then escapes to the

atmosphere in the CRS tank and is replaced with solid

coolant on cool down.

COOLING SYSTEM DRAIN, CLEAN, FLUSH AND

REFILL

Drain, flush, and fill the cooling system at the

mileage or time intervals specified in the Maintenance

Schedule in this Group. If the solution is dirty or rusty

or contains a considerable amount of sediment, clean

and flush with a reliable cooling system cleaner. Care

should be taken in disposing of the used engine coolant

from your vehicle. Check governmental regulations for

disposal of used engine coolant.

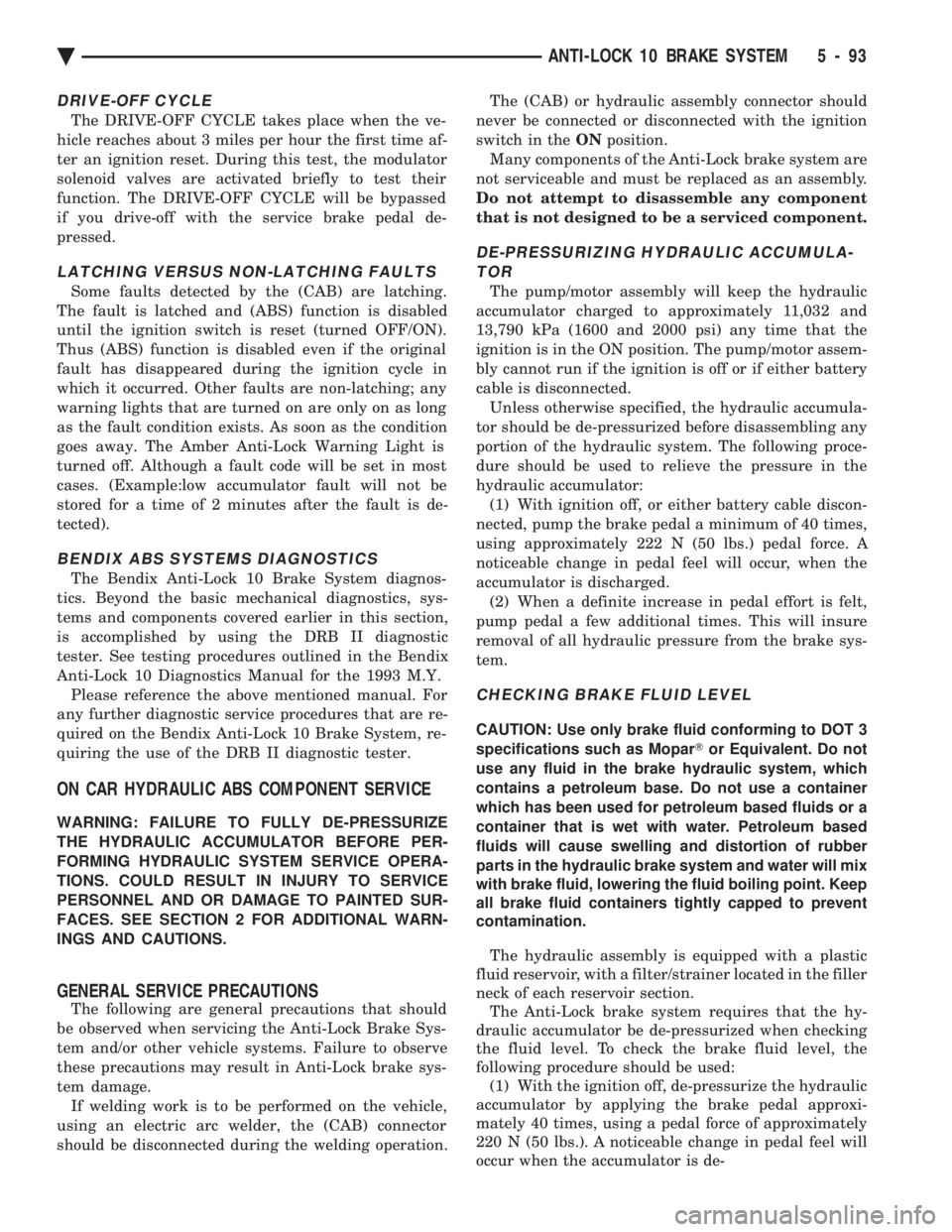

DRAINING

To drain cooling system move temperature selector

for heater to full heat with engine running (to provide

vacuum for actuation). Without removing radiator

pressure cap and with system not under pres-

sure, Shut engine off and open draincock. The coolant

reserve tank (Fig. 5) should empty first, then remove

radiator pressure cap. (if not, see Testing Cooling

System for leaks). To vent 2.2/2.5L engines remove the

plug above thermostat housing (Fig. 1). For Turbo III

engines remove coolant temperature sensor in the

thermostat housing (Fig. 2). For 3.3L /3.8L engine

remove the engine temperature sending unit (Fig. 3).

Removal of a plug or other component is required

because the thermostat has no air vent and prevents

air flow through it. This allows the coolant to drain

from the engine block.

Fig. 1 Thermostat Housing Drain/Fill PlugÐ2.2/2.5L Engines

Ä COOLING SYSTEM 7 - 15

Page 445 of 2438

When testing secondary cables for punctures and

cracks with an oscilloscope follow the equipment

manufacturers instructions. If an oscilloscope is not available, secondary cables

can be tested as follows:

CAUTION: Do not leave any one spark plug cable

disconnected any longer than necessary during test-

ing. Excessive heat could damage the catalytic con-

verter. Total test time must not exceed ten minutes.

(a) With the engine not running, connect one end

of a test probe to a good ground. Use a probe made of

insulated wire with insulated alligator clips on each

end. (b) With engine running, move test probe along

entire length of all cables (approximately 0 to 1/8

inch gap). If punctures or cracks are present there

will be a noticeable spark jump from the faulty area

to the probe. Check the coil cable the same way.

Replace cracked, leaking or faulty cables.

When replacing cables, install the new high

tension cable and nipple assembly over cap or

coil tower. When entering the terminal into the

tower, push lightly, then pinch the large diam-

eter of nipple to release air trapped between the

nipple and tower. Continue pushing on the cable

and nipple until cables are properly seated in the

cap towers. A snap should be heard as terminal

goes into place. Use the same procedure to install cable in coil tower.

Wipe the spark plug insulator clean before reinstalling

cable and cover. Use the following procedure when removing the high

tension cable from the spark plug. First, remove the

cable from the retaining bracket. Then grasp the ter-

minal as close as possible to the spark plug. Rotate the

cover and pull the cable straight back. Pulling on the

cable itself will damage the conductor and termi-

nal connection. Do not use pliers and do not pull

the cable at an angle. Doing so will damage the

insulation, cable terminal or the spark plug in-

sulator. Wipe spark plug insulator clean before

reinstalling cable and cover. Resistance type cable is identified by the words

Electronic Suppression printed on the cable jacket.

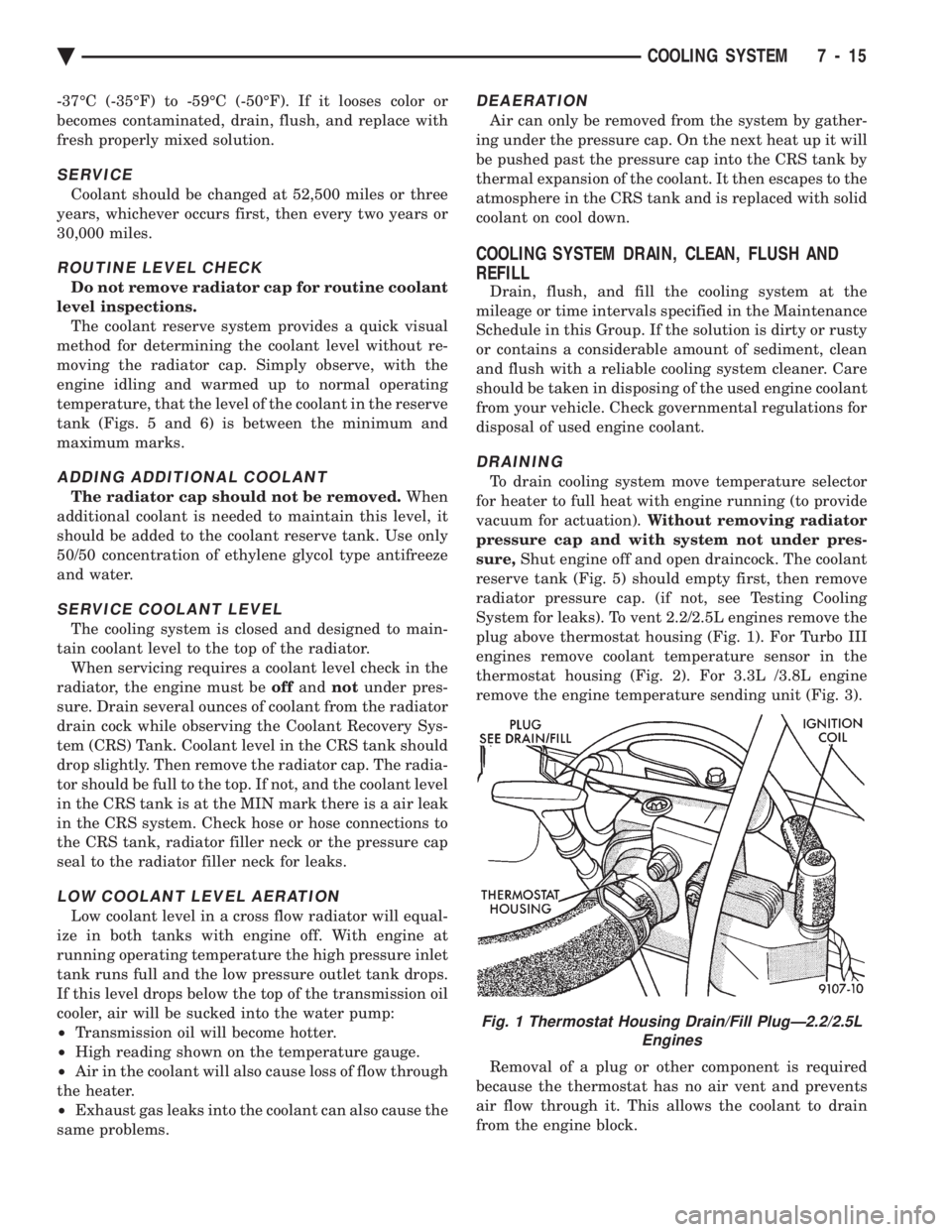

Use an ohmmeter to check resistance type cable for

open circuits, loose terminals or high resistance as

follows: (a) Remove cable from spark plug.

(b) Lift distributor cap from distributor with

cables intact. Do not remove cables from cap. The

cables must be removed from the spark plugs. (c) Connect the ohmmeter between spark plug end

terminal and the corresponding electrode inside the

cap, make sure ohmmeter probes are in good contact.

Resistance should be within tolerance shown in the cable resistance chart. If resistance is

not within tolerance, remove cable at cap tower

and check the cable. If resistance is still not within

tolerance, replace cable assembly. Test all spark

plug cables in same manner.

To test coil to distributor cap high tension cable,

remove distributor cap with the cable intact. Do not

remove cable from the cap. Connect the ohmmeter

between center contact in the cap and remove the ca-

ble at coil tower and check cable resistance. If resis-

tance is not within tolerance, replace the cable.

SPARK PLUGS

Resistor spark plugs are used in all engines and

have resistance values of 6,000 to 20,000 ohms when

checked with at least a 1000 volt tester. Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indi-

cates that a problem exists in the corresponding

cylinder. Replace spark plugs at the intervals recom-

mended in Group O. Undamaged low milage spark plugs can be cleaned

and reused. Refer to the Spark Plug Condition sec-

tion of this group. After cleaning, file the center elec-

trode flat with a small point file or jewelers file.

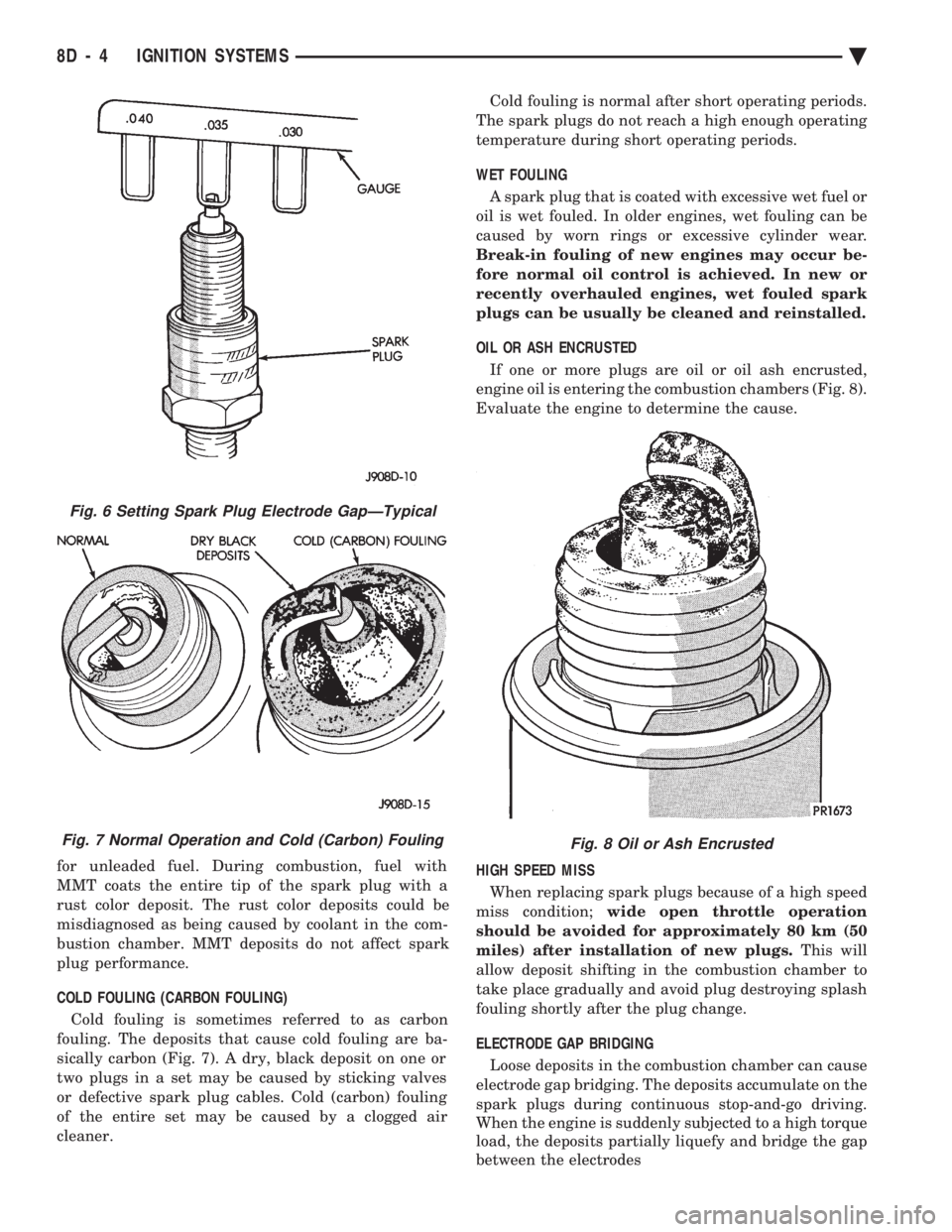

Adjust the gap between the electrodes (Fig. 6) to the

dimensions specified in the chart at the end of this

section. Always tighten spark plugs to the specified torque.

Over tightening can cause distortion and change

spark plug gap. Tighten spark plugs to 28 N Im (20 ft.

lbs.) torque.

SPARK PLUG CONDITION

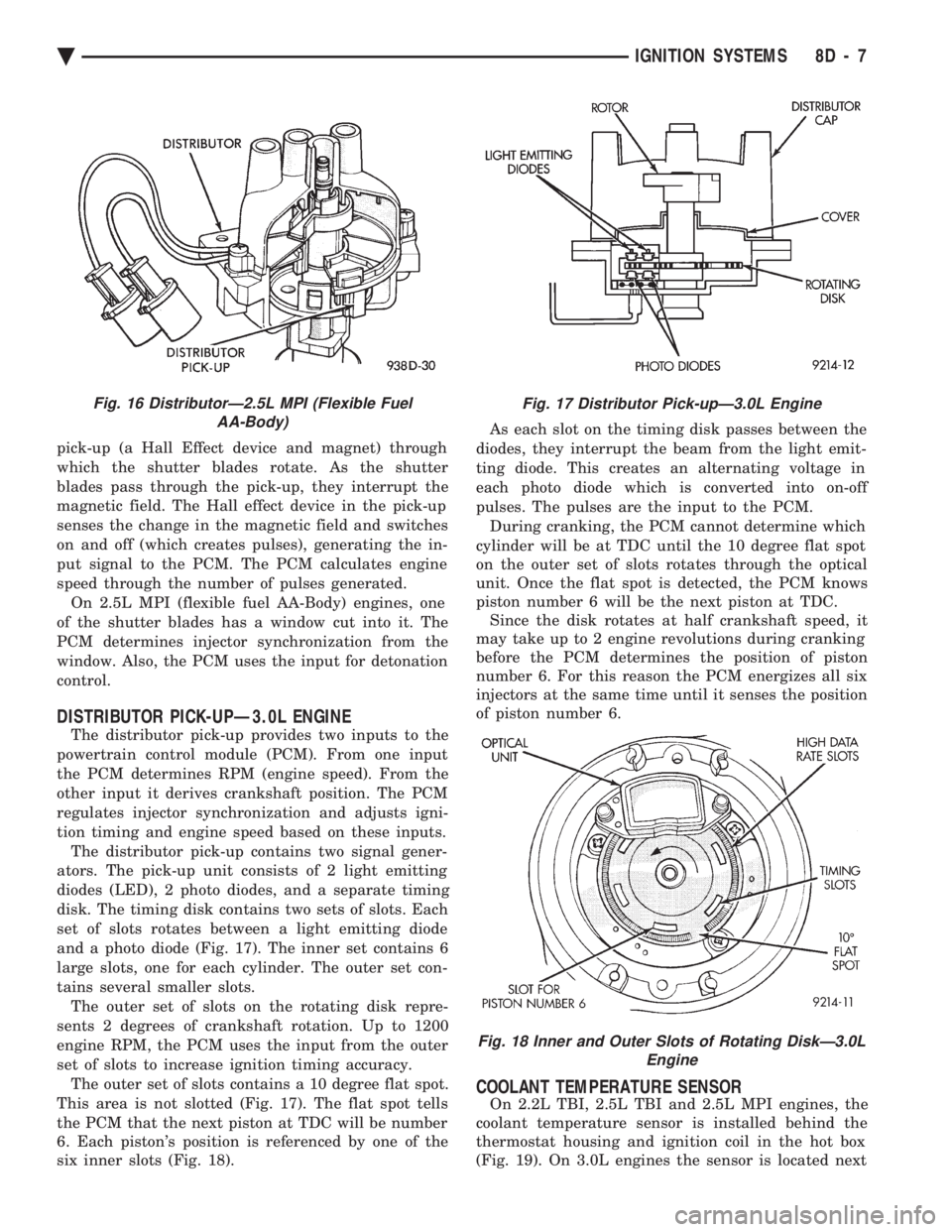

NORMAL OPERATING CONDITIONS

The few deposits present will be probably light tan

or slightly gray in color with most grades of commer-

cial gasoline (Fig. 7). There will not be evidence of

electrode burning. Gap growth will not average more

than approximately 0.025 mm (.001 in) per 1600 km

(1000 miles) of operation. Spark plugs that have nor-

mal wear can usually be cleaned, have the electrodes

filed and regapped, and then reinstalled. Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

CABLE RESISTANCE CHART

Ä IGNITION SYSTEMS 8D - 3

Page 446 of 2438

for unleaded fuel. During combustion, fuel with

MMT coats the entire tip of the spark plug with a

rust color deposit. The rust color deposits could be

misdiagnosed as being caused by coolant in the com-

bustion chamber. MMT deposits do not affect spark

plug performance.

COLD FOULING (CARBON FOULING)

Cold fouling is sometimes referred to as carbon

fouling. The deposits that cause cold fouling are ba-

sically carbon (Fig. 7). A dry, black deposit on one or

two plugs in a set may be caused by sticking valves

or defective spark plug cables. Cold (carbon) fouling

of the entire set may be caused by a clogged air

cleaner. Cold fouling is normal after short operating periods.

The spark plugs do not reach a high enough operating

temperature during short operating periods.

WET FOULING

A spark plug that is coated with excessive wet fuel or

oil is wet fouled. In older engines, wet fouling can be

caused by worn rings or excessive cylinder wear.

Break-in fouling of new engines may occur be-

fore normal oil control is achieved. In new or

recently overhauled engines, wet fouled spark

plugs can be usually be cleaned and reinstalled.

OIL OR ASH ENCRUSTED

If one or more plugs are oil or oil ash encrusted,

engine oil is entering the combustion chambers (Fig. 8).

Evaluate the engine to determine the cause.

HIGH SPEED MISS When replacing spark plugs because of a high speed

miss condition; wide open throttle operation

should be avoided for approximately 80 km (50

miles) after installation of new plugs. This will

allow deposit shifting in the combustion chamber to

take place gradually and avoid plug destroying splash

fouling shortly after the plug change.

ELECTRODE GAP BRIDGING

Loose deposits in the combustion chamber can cause

electrode gap bridging. The deposits accumulate on the

spark plugs during continuous stop-and-go driving.

When the engine is suddenly subjected to a high torque

load, the deposits partially liquefy and bridge the gap

between the electrodes

Fig. 6 Setting Spark Plug Electrode GapÐTypical

Fig. 7 Normal Operation and Cold (Carbon) FoulingFig. 8 Oil or Ash Encrusted

8D - 4 IGNITION SYSTEMS Ä

Page 449 of 2438

pick-up (a Hall Effect device and magnet) through

which the shutter blades rotate. As the shutter

blades pass through the pick-up, they interrupt the

magnetic field. The Hall effect device in the pick-up

senses the change in the magnetic field and switches

on and off (which creates pulses), generating the in-

put signal to the PCM. The PCM calculates engine

speed through the number of pulses generated. On 2.5L MPI (flexible fuel AA-Body) engines, one

of the shutter blades has a window cut into it. The

PCM determines injector synchronization from the

window. Also, the PCM uses the input for detonation

control.

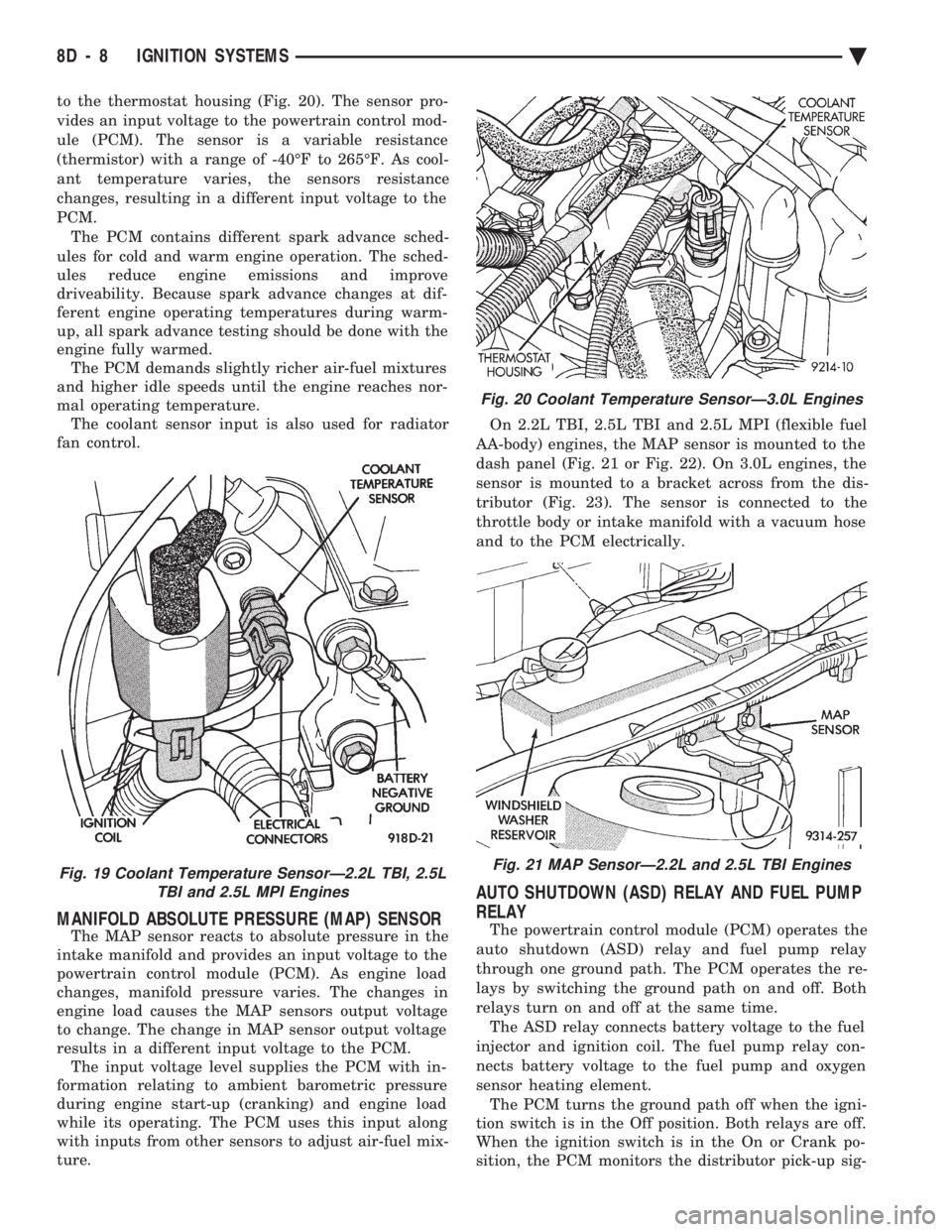

DISTRIBUTOR PICK-UPÐ3.0L ENGINE

The distributor pick-up provides two inputs to the

powertrain control module (PCM). From one input

the PCM determines RPM (engine speed). From the

other input it derives crankshaft position. The PCM

regulates injector synchronization and adjusts igni-

tion timing and engine speed based on these inputs. The distributor pick-up contains two signal gener-

ators. The pick-up unit consists of 2 light emitting

diodes (LED), 2 photo diodes, and a separate timing

disk. The timing disk contains two sets of slots. Each

set of slots rotates between a light emitting diode

and a photo diode (Fig. 17). The inner set contains 6

large slots, one for each cylinder. The outer set con-

tains several smaller slots. The outer set of slots on the rotating disk repre-

sents 2 degrees of crankshaft rotation. Up to 1200

engine RPM, the PCM uses the input from the outer

set of slots to increase ignition timing accuracy. The outer set of slots contains a 10 degree flat spot.

This area is not slotted (Fig. 17). The flat spot tells

the PCM that the next piston at TDC will be number

6. Each piston's position is referenced by one of the

six inner slots (Fig. 18). As each slot on the timing disk passes between the

diodes, they interrupt the beam from the light emit-

ting diode. This creates an alternating voltage in

each photo diode which is converted into on-off

pulses. The pulses are the input to the PCM. During cranking, the PCM cannot determine which

cylinder will be at TDC until the 10 degree flat spot

on the outer set of slots rotates through the optical

unit. Once the flat spot is detected, the PCM knows

piston number 6 will be the next piston at TDC. Since the disk rotates at half crankshaft speed, it

may take up to 2 engine revolutions during cranking

before the PCM determines the position of piston

number 6. For this reason the PCM energizes all six

injectors at the same time until it senses the position

of piston number 6.

COOLANT TEMPERATURE SENSOR

On 2.2L TBI, 2.5L TBI and 2.5L MPI engines, the

coolant temperature sensor is installed behind the

thermostat housing and ignition coil in the hot box

(Fig. 19). On 3.0L engines the sensor is located next

Fig. 16 DistributorÐ2.5L MPI (Flexible Fuel AA-Body)Fig. 17 Distributor Pick-upÐ3.0L Engine

Fig. 18 Inner and Outer Slots of Rotating DiskÐ3.0L Engine

Ä IGNITION SYSTEMS 8D - 7

Page 450 of 2438

to the thermostat housing (Fig. 20). The sensor pro-

vides an input voltage to the powertrain control mod-

ule (PCM). The sensor is a variable resistance

(thermistor) with a range of -40ÉF to 265ÉF. As cool-

ant temperature varies, the sensors resistance

changes, resulting in a different input voltage to the

PCM. The PCM contains different spark advance sched-

ules for cold and warm engine operation. The sched-

ules reduce engine emissions and improve

driveability. Because spark advance changes at dif-

ferent engine operating temperatures during warm-

up, all spark advance testing should be done with the

engine fully warmed. The PCM demands slightly richer air-fuel mixtures

and higher idle speeds until the engine reaches nor-

mal operating temperature. The coolant sensor input is also used for radiator

fan control.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

The MAP sensor reacts to absolute pressure in the

intake manifold and provides an input voltage to the

powertrain control module (PCM). As engine load

changes, manifold pressure varies. The changes in

engine load causes the MAP sensors output voltage

to change. The change in MAP sensor output voltage

results in a different input voltage to the PCM. The input voltage level supplies the PCM with in-

formation relating to ambient barometric pressure

during engine start-up (cranking) and engine load

while its operating. The PCM uses this input along

with inputs from other sensors to adjust air-fuel mix-

ture. On 2.2L TBI, 2.5L TBI and 2.5L MPI (flexible fuel

AA-body) engines, the MAP sensor is mounted to the

dash panel (Fig. 21 or Fig. 22). On 3.0L engines, the

sensor is mounted to a bracket across from the dis-

tributor (Fig. 23). The sensor is connected to the

throttle body or intake manifold with a vacuum hose

and to the PCM electrically.

AUTO SHUTDOWN (ASD) RELAY AND FUEL PUMP

RELAY

The powertrain control module (PCM) operates the

auto shutdown (ASD) relay and fuel pump relay

through one ground path. The PCM operates the re-

lays by switching the ground path on and off. Both

relays turn on and off at the same time. The ASD relay connects battery voltage to the fuel

injector and ignition coil. The fuel pump relay con-

nects battery voltage to the fuel pump and oxygen

sensor heating element. The PCM turns the ground path off when the igni-

tion switch is in the Off position. Both relays are off.

When the ignition switch is in the On or Crank po-

sition, the PCM monitors the distributor pick-up sig-

Fig. 19 Coolant Temperature SensorÐ2.2L TBI, 2.5L TBI and 2.5L MPI Engines

Fig. 20 Coolant Temperature SensorÐ3.0L Engines

Fig. 21 MAP SensorÐ2.2L and 2.5L TBI Engines

8D - 8 IGNITION SYSTEMS Ä

Page 469 of 2438

mal wear can usually be cleaned, have the electrodes

filed and regapped, and then reinstalled. Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with MMT

may coat the entire tip of the spark plug with a rust

colored deposit. The rust color deposits can be misdi-

agnosed as being caused by coolant in the combustion

chamber. Spark plug performance is not affected by

MMT deposits.

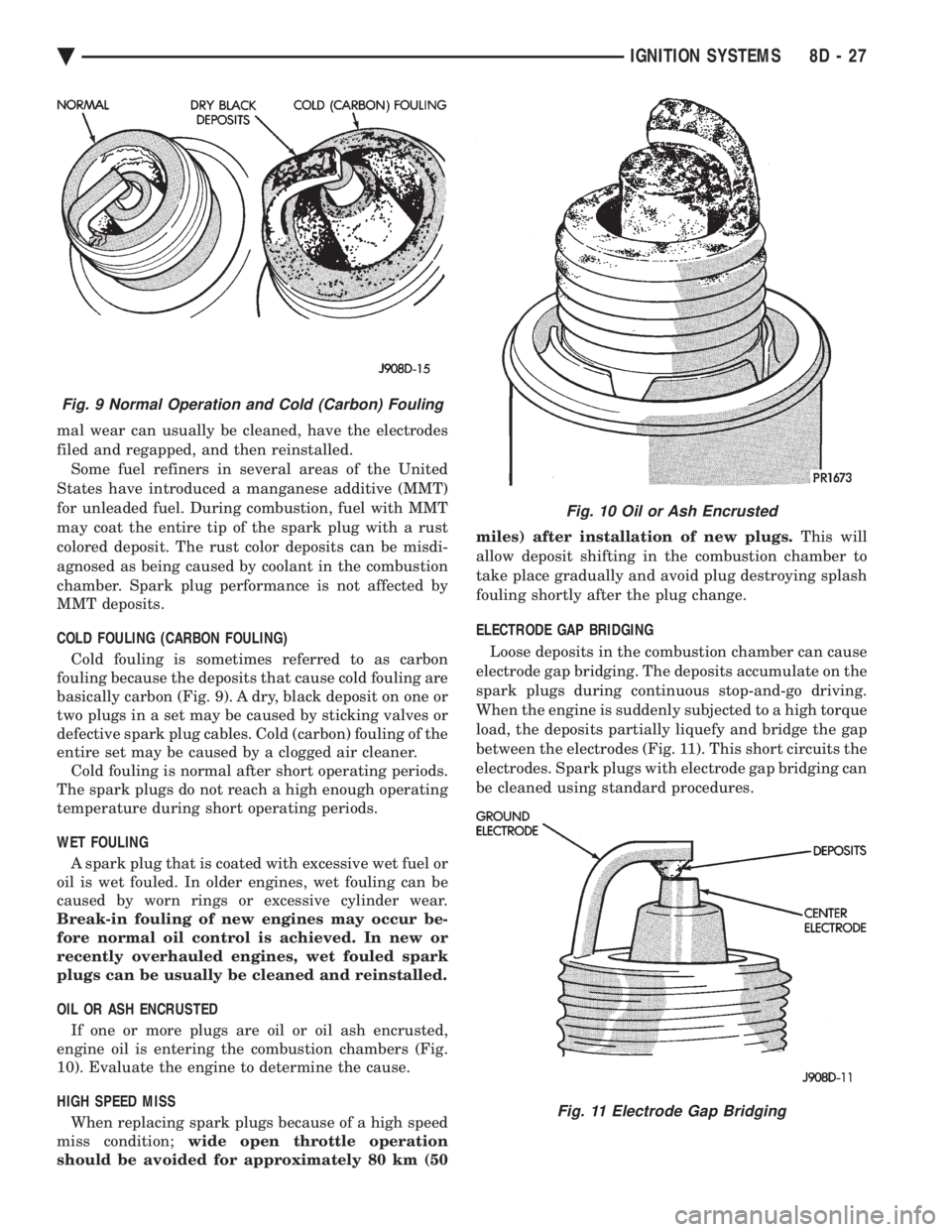

COLD FOULING (CARBON FOULING) Cold fouling is sometimes referred to as carbon

fouling because the deposits that cause cold fouling are

basically carbon (Fig. 9). A dry, black deposit on one or

two plugs in a set may be caused by sticking valves or

defective spark plug cables. Cold (carbon) fouling of the

entire set may be caused by a clogged air cleaner. Cold fouling is normal after short operating periods.

The spark plugs do not reach a high enough operating

temperature during short operating periods.

WET FOULING A spark plug that is coated with excessive wet fuel or

oil is wet fouled. In older engines, wet fouling can be

caused by worn rings or excessive cylinder wear.

Break-in fouling of new engines may occur be-

fore normal oil control is achieved. In new or

recently overhauled engines, wet fouled spark

plugs can be usually be cleaned and reinstalled.

OIL OR ASH ENCRUSTED If one or more plugs are oil or oil ash encrusted,

engine oil is entering the combustion chambers (Fig.

10). Evaluate the engine to determine the cause.

HIGH SPEED MISS When replacing spark plugs because of a high speed

miss condition; wide open throttle operation

should be avoided for approximately 80 km (50 miles) after installation of new plugs.

This will

allow deposit shifting in the combustion chamber to

take place gradually and avoid plug destroying splash

fouling shortly after the plug change.

ELECTRODE GAP BRIDGING

Loose deposits in the combustion chamber can cause

electrode gap bridging. The deposits accumulate on the

spark plugs during continuous stop-and-go driving.

When the engine is suddenly subjected to a high torque

load, the deposits partially liquefy and bridge the gap

between the electrodes (Fig. 11). This short circuits the

electrodes. Spark plugs with electrode gap bridging can

be cleaned using standard procedures.

Fig. 9 Normal Operation and Cold (Carbon) Fouling

Fig. 10 Oil or Ash Encrusted

Fig. 11 Electrode Gap Bridging

Ä IGNITION SYSTEMS 8D - 27

Page 474 of 2438

The coil's low primary resistance allows the PCM to

fully charge the coil for each firing.

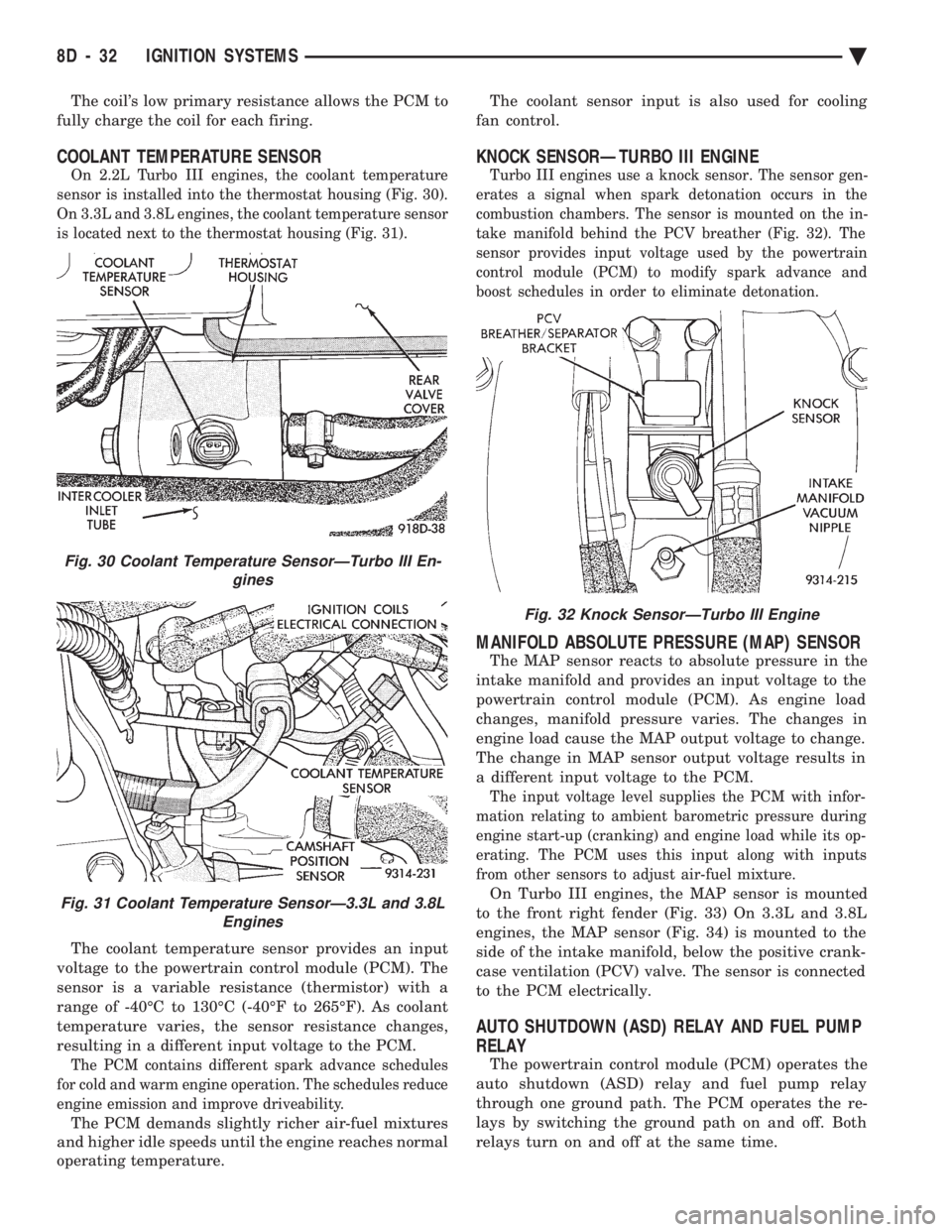

COOLANT TEMPERATURE SENSOR

On 2.2L Turbo III engines, the coolant temperature

sensor is installed into the thermostat housing (Fig. 30).

On 3.3L and 3.8L engines, the coolant temperature sensor

is located next to the thermostat housing (Fig. 31).

The coolant temperature sensor provides an input

voltage to the powertrain control module (PCM). The

sensor is a variable resistance (thermistor) with a

range of -40ÉC to 130ÉC (-40ÉF to 265ÉF). As coolant

temperature varies, the sensor resistance changes,

resulting in a different input voltage to the PCM.

The PCM contains different spark advance schedules

for cold and warm engine operation. The schedules reduce

engine emission and improve driveability.

The PCM demands slightly richer air-fuel mixtures

and higher idle speeds until the engine reaches normal

operating temperature. The coolant sensor input is also used for cooling

fan control.

KNOCK SENSORÐTURBO III ENGINE

Turbo III engines use a knock sensor. The sensor gen-

erates a signal when spark detonation occurs in the

combustion chambers. The sensor is mounted on the in-

take manifold behind the PCV breather (Fig. 32). The

sensor provides input voltage used by the powertrain

control module (PCM) to modify spark advance and

boost schedules in order to eliminate detonation.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

The MAP sensor reacts to absolute pressure in the

intake manifold and provides an input voltage to the

powertrain control module (PCM). As engine load

changes, manifold pressure varies. The changes in

engine load cause the MAP output voltage to change.

The change in MAP sensor output voltage results in

a different input voltage to the PCM.

The input voltage level supplies the PCM with infor-

mation relating to ambient barometric pressure during

engine start-up (cranking) and engine load while its op-

erating. The PCM uses this input along with inputs

from other sensors to adjust air-fuel mixture.

On Turbo III engines, the MAP sensor is mounted

to the front right fender (Fig. 33) On 3.3L and 3.8L

engines, the MAP sensor (Fig. 34) is mounted to the

side of the intake manifold, below the positive crank-

case ventilation (PCV) valve. The sensor is connected

to the PCM electrically.

AUTO SHUTDOWN (ASD) RELAY AND FUEL PUMP

RELAY

The powertrain control module (PCM) operates the

auto shutdown (ASD) relay and fuel pump relay

through one ground path. The PCM operates the re-

lays by switching the ground path on and off. Both

relays turn on and off at the same time.

Fig. 32 Knock SensorÐTurbo III Engine

Fig. 30 Coolant Temperature SensorÐTurbo III En- gines

Fig. 31 Coolant Temperature SensorÐ3.3L and 3.8LEngines

8D - 32 IGNITION SYSTEMS Ä

Page 605 of 2438

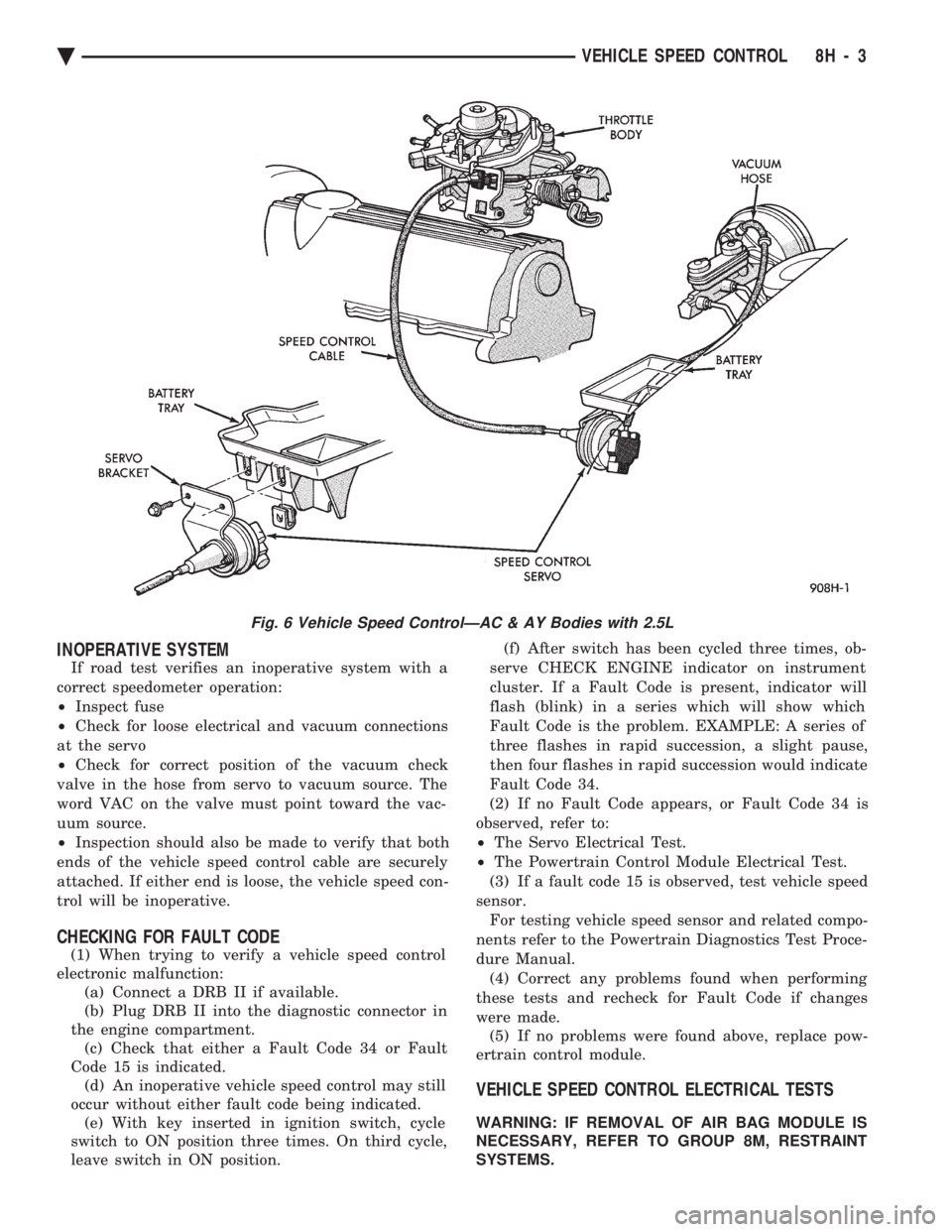

INOPERATIVE SYSTEM

If road test verifies an inoperative system with a

correct speedometer operation:

² Inspect fuse

² Check for loose electrical and vacuum connections

at the servo

² Check for correct position of the vacuum check

valve in the hose from servo to vacuum source. The

word VAC on the valve must point toward the vac-

uum source.

² Inspection should also be made to verify that both

ends of the vehicle speed control cable are securely

attached. If either end is loose, the vehicle speed con-

trol will be inoperative.

CHECKING FOR FAULT CODE

(1) When trying to verify a vehicle speed control

electronic malfunction: (a) Connect a DRB II if available.

(b) Plug DRB II into the diagnostic connector in

the engine compartment. (c) Check that either a Fault Code 34 or Fault

Code 15 is indicated. (d) An inoperative vehicle speed control may still

occur without either fault code being indicated. (e) With key inserted in ignition switch, cycle

switch to ON position three times. On third cycle,

leave switch in ON position. (f) After switch has been cycled three times, ob-

serve CHECK ENGINE indicator on instrument

cluster. If a Fault Code is present, indicator will

flash (blink) in a series which will show which

Fault Code is the problem. EXAMPLE: A series of

three flashes in rapid succession, a slight pause,

then four flashes in rapid succession would indicate

Fault Code 34.

(2) If no Fault Code appears, or Fault Code 34 is

observed, refer to:

² The Servo Electrical Test.

² The Powertrain Control Module Electrical Test.

(3) If a fault code 15 is observed, test vehicle speed

sensor. For testing vehicle speed sensor and related compo-

nents refer to the Powertrain Diagnostics Test Proce-

dure Manual. (4) Correct any problems found when performing

these tests and recheck for Fault Code if changes

were made. (5) If no problems were found above, replace pow-

ertrain control module.

VEHICLE SPEED CONTROL ELECTRICAL TESTS

WARNING: IF REMOVAL OF AIR BAG MODULE IS

NECESSARY, REFER TO GROUP 8M, RESTRAINT

SYSTEMS.

Fig. 6 Vehicle Speed ControlÐAC & AY Bodies with 2.5L

Ä VEHICLE SPEED CONTROL 8H - 3