service CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1948 of 2438

The Acustar tilt and standard column (Fig. 1) has

been designed to be serviced as an assembly; less wir-

ing, switches, shrouds, steering wheel, etc. Also, most

steering column components can be serviced without re-

moving the steering column from the vehicle.

CAUTION: Disconnect negative (ground) cable from

battery, before servicing any column component.

CAUTION: Do not attempt to remove the pivot pins

to disassemble the tilting mechanism. Damage will

occur.

STEERING COLUMN SERVICE PROCEDURES

To service the steering wheel and its components

or the air bag, refer to Group 8M, Restraint Systems.

Follow all WARNINGS. To service the switches, refer to the appropriate

section of Group 8, Electrical.

To replace the steering column assembly, refer to the

steering column removal procedure. For location of com-

ponents referred to in the procedure see (Fig. 1).

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM COMPONENT INSTALLATION OR RE-

MOVAL PROCEDURES. REMOVE AND ISOLATE

THE NEGATIVE (-) BATTERY CABLE (GROUND)

FROM THE VEHICLE BATTERY. THIS IS THE ONLY

SURE WAY TO DISABLE THE AIR BAG SYSTEM.

FAILURE TO DO THIS COULD RESULT IN ACCI-

DENTAL AIR BAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

STEERING COLUMN REMOVAL

(1) Make sure the front wheels of the vehicle are

in the straight ahead position.

(2) Disconnect the negative (ground) cable from

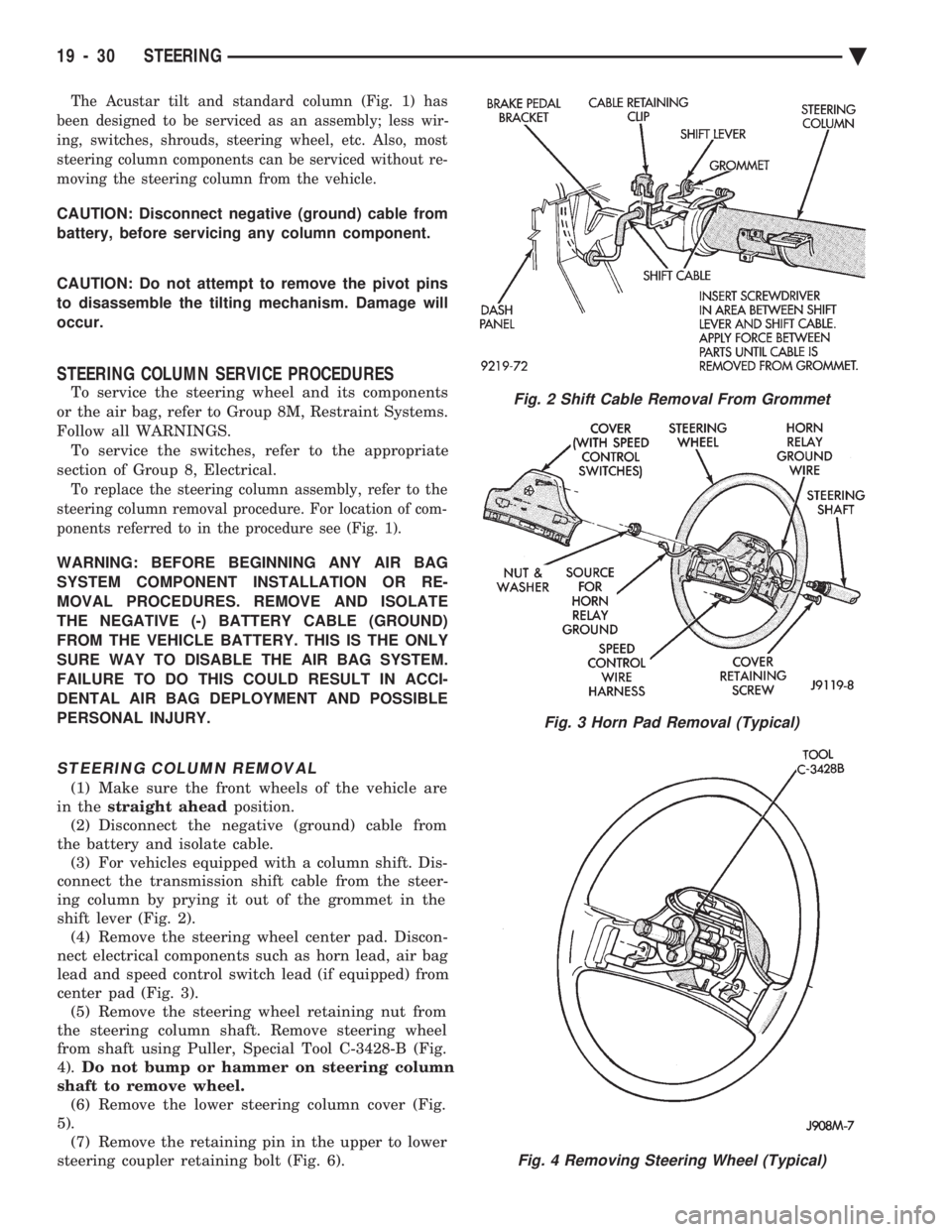

the battery and isolate cable. (3) For vehicles equipped with a column shift. Dis-

connect the transmission shift cable from the steer-

ing column by prying it out of the grommet in the

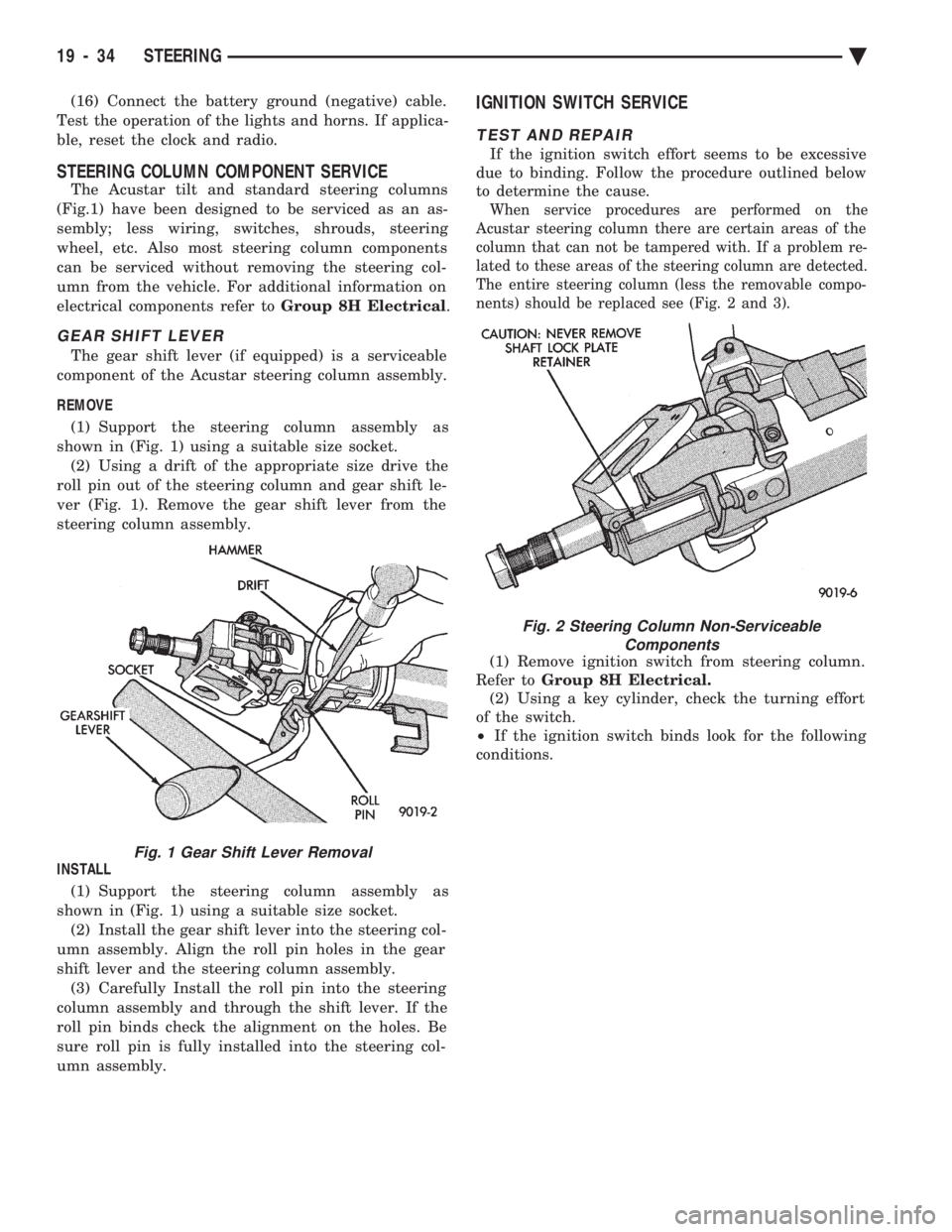

shift lever (Fig. 2). (4) Remove the steering wheel center pad. Discon-

nect electrical components such as horn lead, air bag

lead and speed control switch lead (if equipped) from

center pad (Fig. 3). (5) Remove the steering wheel retaining nut from

the steering column shaft. Remove steering wheel

from shaft using Puller, Special Tool C-3428-B (Fig.

4). Do not bump or hammer on steering column

shaft to remove wheel. (6) Remove the lower steering column cover (Fig.

5). (7) Remove the retaining pin in the upper to lower

steering coupler retaining bolt (Fig. 6).

Fig. 2 Shift Cable Removal From Grommet

Fig. 3 Horn Pad Removal (Typical)

Fig. 4 Removing Steering Wheel (Typical)

19 - 30 STEERING Ä

Page 1952 of 2438

(16) Connect the battery ground (negative) cable.

Test the operation of the lights and horns. If applica-

ble, reset the clock and radio.

STEERING COLUMN COMPONENT SERVICE

The Acustar tilt and standard steering columns

(Fig.1) have been designed to be serviced as an as-

sembly; less wiring, switches, shrouds, steering

wheel, etc. Also most steering column components

can be serviced without removing the steering col-

umn from the vehicle. For additional information on

electrical components refer to Group 8H Electrical.

GEAR SHIFT LEVER

The gear shift lever (if equipped) is a serviceable

component of the Acustar steering column assembly.

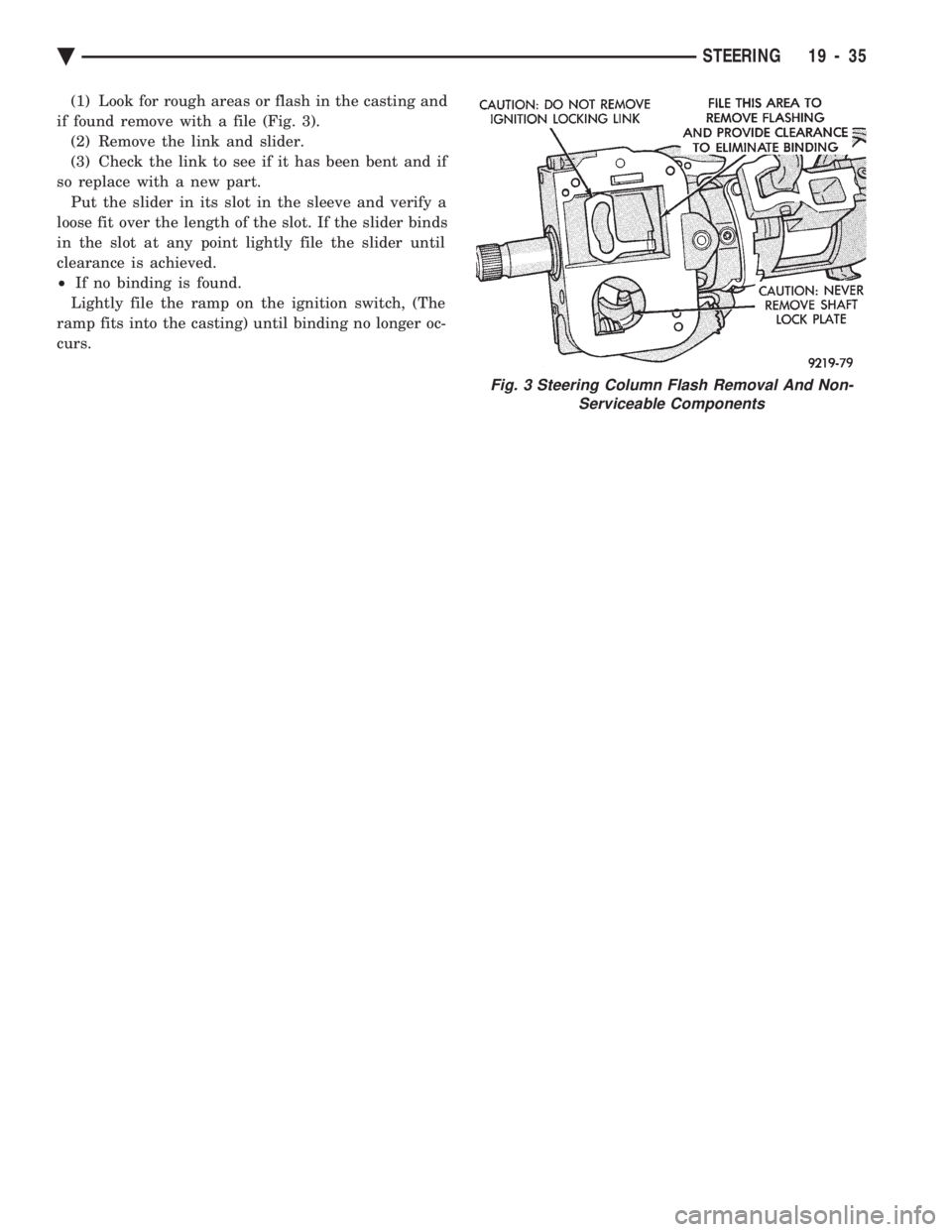

REMOVE (1) Support the steering column assembly as

shown in (Fig. 1) using a suitable size socket. (2) Using a drift of the appropriate size drive the

roll pin out of the steering column and gear shift le-

ver (Fig. 1). Remove the gear shift lever from the

steering column assembly.

INSTALL (1) Support the steering column assembly as

shown in (Fig. 1) using a suitable size socket. (2) Install the gear shift lever into the steering col-

umn assembly. Align the roll pin holes in the gear

shift lever and the steering column assembly. (3) Carefully Install the roll pin into the steering

column assembly and through the shift lever. If the

roll pin binds check the alignment on the holes. Be

sure roll pin is fully installed into the steering col-

umn assembly.

IGNITION SWITCH SERVICE

TEST AND REPAIR

If the ignition switch effort seems to be excessive

due to binding. Follow the procedure outlined below

to determine the cause.

When service procedures are performed on the

Acustar steering column there are certain areas of the

column that can not be tampered with. If a problem re-

lated to these areas of the steering column are detected.

The entire steering column (less the removable compo-

nents) should be replaced see (Fig. 2 and 3).

(1) Remove ignition switch from steering column.

Refer to Group 8H Electrical.

(2) Using a key cylinder, check the turning effort

of the switch.

² If the ignition switch binds look for the following

conditions.

Fig. 1 Gear Shift Lever Removal

Fig. 2 Steering Column Non-Serviceable Components

19 - 34 STEERING Ä

Page 1953 of 2438

(1) Look for rough areas or flash in the casting and

if found remove with a file (Fig. 3). (2) Remove the link and slider.

(3) Check the link to see if it has been bent and if

so replace with a new part. Put the slider in its slot in the sleeve and verify a

loose fit over the length of the slot. If the slider binds

in the slot at any point lightly file the slider until

clearance is achieved.

² If no binding is found.

Lightly file the ramp on the ignition switch, (The

ramp fits into the casting) until binding no longer oc-

curs.

Fig. 3 Steering Column Flash Removal And Non- Serviceable Components

Ä STEERING 19 - 35

Page 1954 of 2438

AUTOMATIC TRANSMISSION SHIFTER/IGNITION INTERLOCK INDEX

page page

General Information ....................... 36

Interlock System Adjustment ................ 37 Interlock System Operation Check

............ 36

Shifter/Ignition Interlock Cable ............... 38

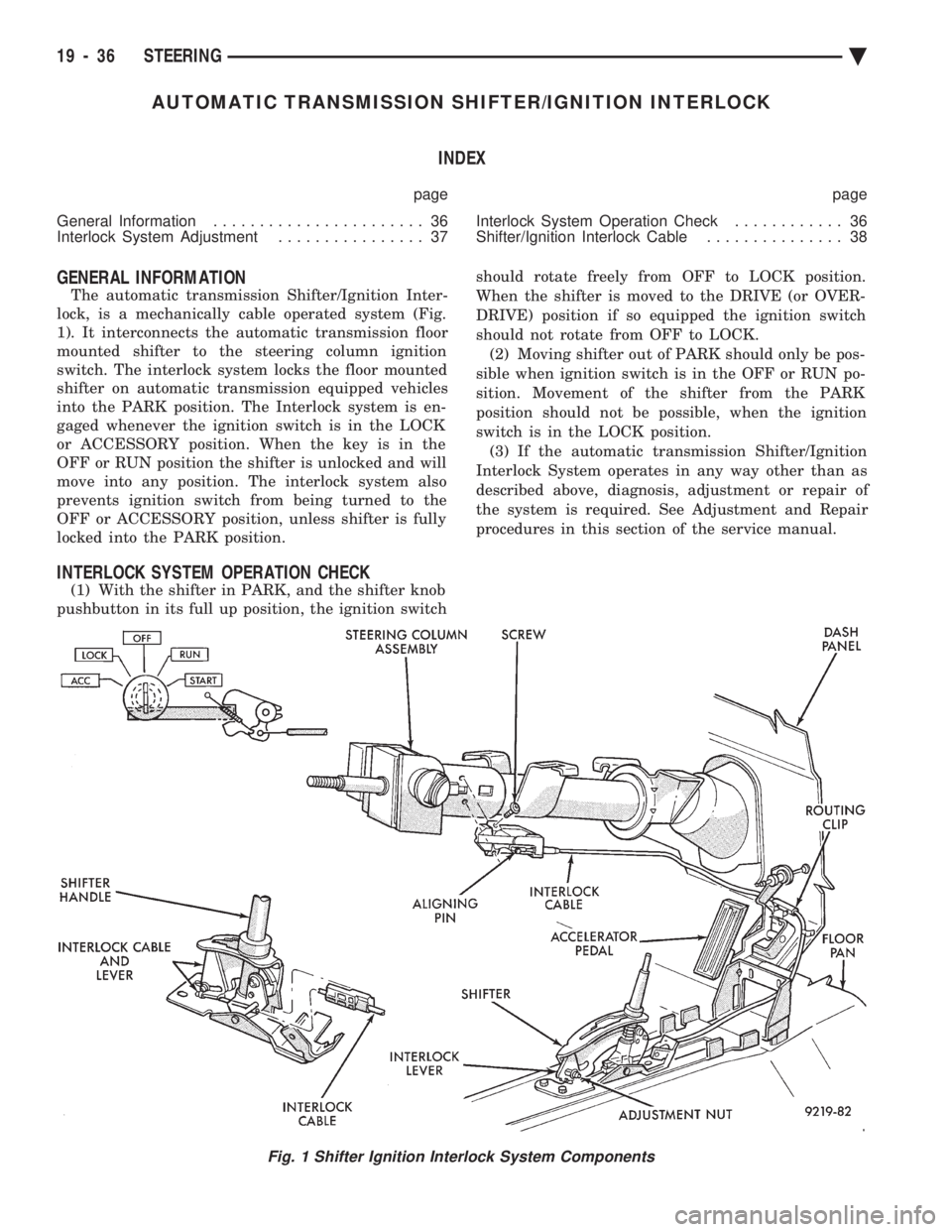

GENERAL INFORMATION

The automatic transmission Shifter/Ignition Inter-

lock, is a mechanically cable operated system (Fig.

1). It interconnects the automatic transmission floor

mounted shifter to the steering column ignition

switch. The interlock system locks the floor mounted

shifter on automatic transmission equipped vehicles

into the PARK position. The Interlock system is en-

gaged whenever the ignition switch is in the LOCK

or ACCESSORY position. When the key is in the

OFF or RUN position the shifter is unlocked and will

move into any position. The interlock system also

prevents ignition switch from being turned to the

OFF or ACCESSORY position, unless shifter is fully

locked into the PARK position.

INTERLOCK SYSTEM OPERATION CHECK

(1) With the shifter in PARK, and the shifter knob

pushbutton in its full up position, the ignition switch should rotate freely from OFF to LOCK position.

When the shifter is moved to the DRIVE (or OVER-

DRIVE) position if so equipped the ignition switch

should not rotate from OFF to LOCK. (2) Moving shifter out of PARK should only be pos-

sible when ignition switch is in the OFF or RUN po-

sition. Movement of the shifter from the PARK

position should not be possible, when the ignition

switch is in the LOCK position. (3) If the automatic transmission Shifter/Ignition

Interlock System operates in any way other than as

described above, diagnosis, adjustment or repair of

the system is required. See Adjustment and Repair

procedures in this section of the service manual.

Fig. 1 Shifter Ignition Interlock System Components

19 - 36 STEERING Ä

Page 1955 of 2438

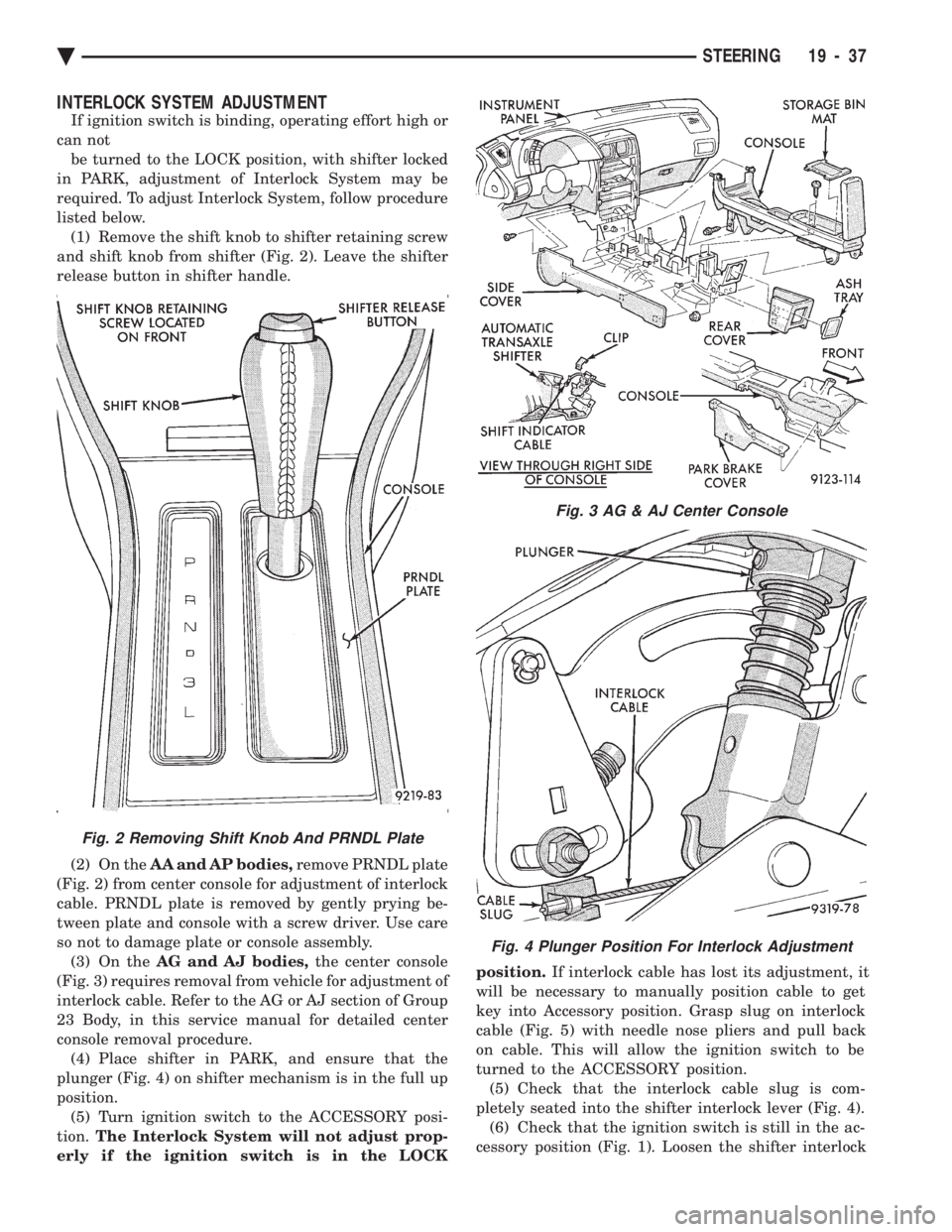

INTERLOCK SYSTEM ADJUSTMENT

If ignition switch is binding, operating effort high or

can not be turned to the LOCK position, with shifter locked

in PARK, adjustment of Interlock System may be

required. To adjust Interlock System, follow procedure

listed below. (1) Remove the shift knob to shifter retaining screw

and shift knob from shifter (Fig. 2). Leave the shifter

release button in shifter handle.

(2) On the AA and AP bodies, remove PRNDL plate

(Fig. 2) from center console for adjustment of interlock

cable. PRNDL plate is removed by gently prying be-

tween plate and console with a screw driver. Use care

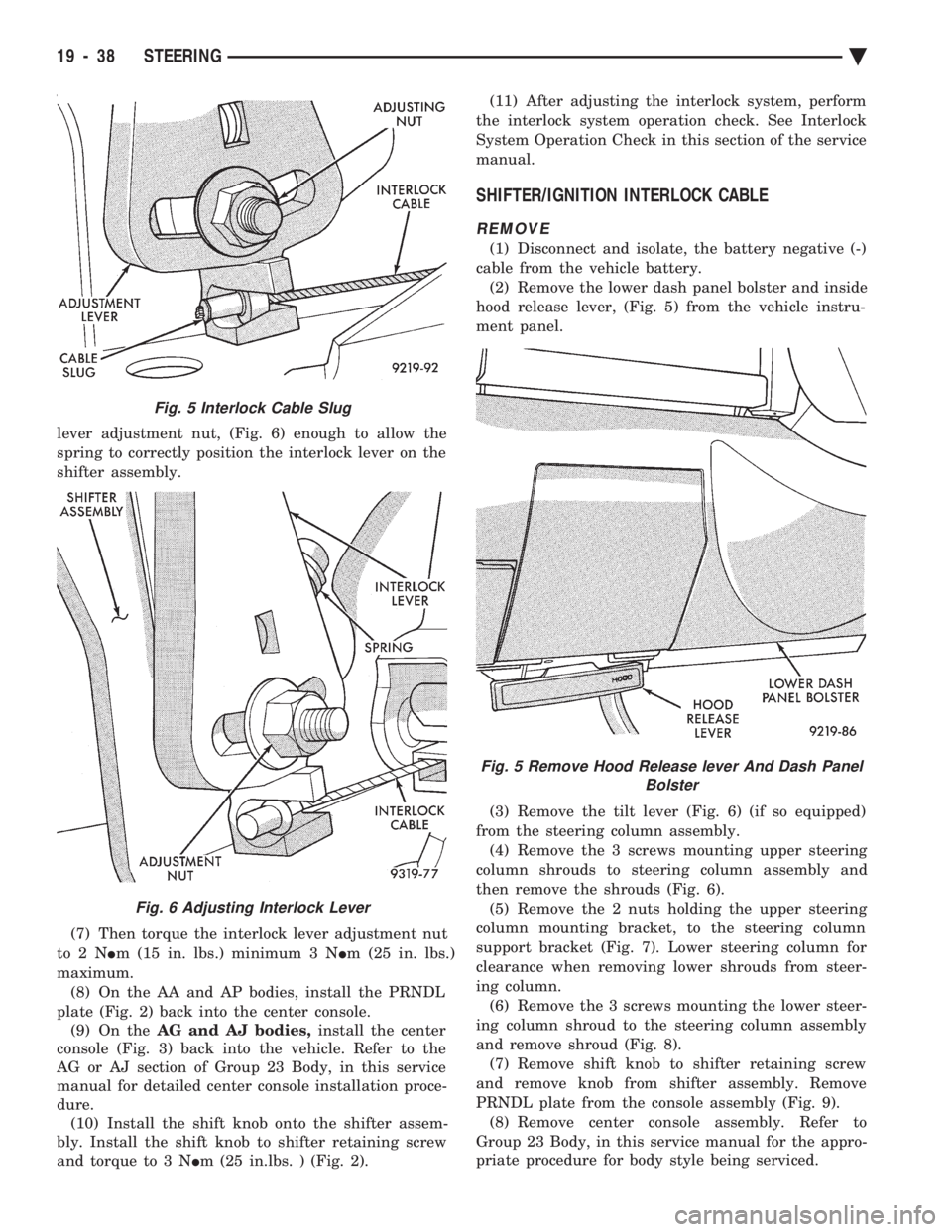

so not to damage plate or console assembly. (3) On the AG and AJ bodies, the center console

(Fig. 3) requires removal from vehicle for adjustment of

interlock cable. Refer to the AG or AJ section of Group

23 Body, in this service manual for detailed center

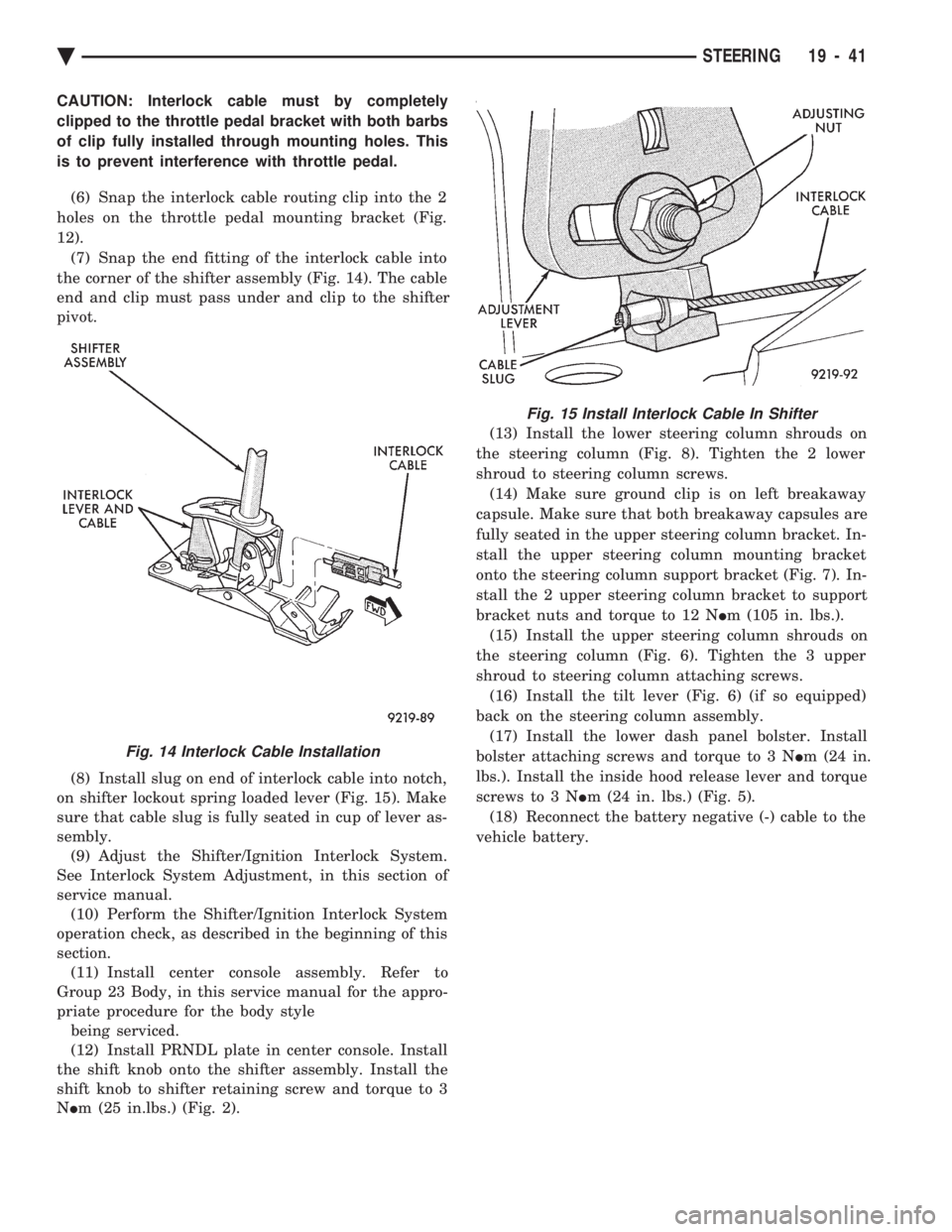

console removal procedure. (4) Place shifter in PARK, and ensure that the

plunger (Fig. 4) on shifter mechanism is in the full up

position. (5) Turn ignition switch to the ACCESSORY posi-

tion. The Interlock System will not adjust prop-

erly if the ignition switch is in the LOCK position.

If interlock cable has lost its adjustment, it

will be necessary to manually position cable to get

key into Accessory position. Grasp slug on interlock

cable (Fig. 5) with needle nose pliers and pull back

on cable. This will allow the ignition switch to be

turned to the ACCESSORY position. (5) Check that the interlock cable slug is com-

pletely seated into the shifter interlock lever (Fig. 4). (6) Check that the ignition switch is still in the ac-

cessory position (Fig. 1). Loosen the shifter interlock

Fig. 3 AG & AJ Center Console

Fig. 4 Plunger Position For Interlock Adjustment

Fig. 2 Removing Shift Knob And PRNDL Plate

Ä STEERING 19 - 37

Page 1956 of 2438

lever adjustment nut, (Fig. 6) enough to allow the

spring to correctly position the interlock lever on the

shifter assembly.

(7) Then torque the interlock lever adjustment nut

to2N Im (15 in. lbs.) minimum 3 N Im (25 in. lbs.)

maximum. (8) On the AA and AP bodies, install the PRNDL

plate (Fig. 2) back into the center console. (9) On the AG and AJ bodies, install the center

console (Fig. 3) back into the vehicle. Refer to the

AG or AJ section of Group 23 Body, in this service

manual for detailed center console installation proce-

dure. (10) Install the shift knob onto the shifter assem-

bly. Install the shift knob to shifter retaining screw

and torque to 3 N Im (25 in.lbs. ) (Fig. 2). (11) After adjusting the interlock system, perform

the interlock system operation check. See Interlock

System Operation Check in this section of the service

manual.

SHIFTER/IGNITION INTERLOCK CABLE

REMOVE

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery. (2) Remove the lower dash panel bolster and inside

hood release lever, (Fig. 5) from the vehicle instru-

ment panel.

(3) Remove the tilt lever (Fig. 6) (if so equipped)

from the steering column assembly. (4) Remove the 3 screws mounting upper steering

column shrouds to steering column assembly and

then remove the shrouds (Fig. 6). (5) Remove the 2 nuts holding the upper steering

column mounting bracket, to the steering column

support bracket (Fig. 7). Lower steering column for

clearance when removing lower shrouds from steer-

ing column. (6) Remove the 3 screws mounting the lower steer-

ing column shroud to the steering column assembly

and remove shroud (Fig. 8). (7) Remove shift knob to shifter retaining screw

and remove knob from shifter assembly. Remove

PRNDL plate from the console assembly (Fig. 9). (8) Remove center console assembly. Refer to

Group 23 Body, in this service manual for the appro-

priate procedure for body style being serviced.

Fig. 5 Interlock Cable Slug

Fig. 6 Adjusting Interlock Lever

Fig. 5 Remove Hood Release lever And Dash Panel Bolster

19 - 38 STEERING Ä

Page 1959 of 2438

CAUTION: Interlock cable must by completely

clipped to the throttle pedal bracket with both barbs

of clip fully installed through mounting holes. This

is to prevent interference with throttle pedal.

(6) Snap the interlock cable routing clip into the 2

holes on the throttle pedal mounting bracket (Fig.

12). (7) Snap the end fitting of the interlock cable into

the corner of the shifter assembly (Fig. 14). The cable

end and clip must pass under and clip to the shifter

pivot.

(8) Install slug on end of interlock cable into notch,

on shifter lockout spring loaded lever (Fig. 15). Make

sure that cable slug is fully seated in cup of lever as-

sembly. (9) Adjust the Shifter/Ignition Interlock System.

See Interlock System Adjustment, in this section of

service manual. (10) Perform the Shifter/Ignition Interlock System

operation check, as described in the beginning of this

section. (11) Install center console assembly. Refer to

Group 23 Body, in this service manual for the appro-

priate procedure for the body style being serviced.

(12) Install PRNDL plate in center console. Install

the shift knob onto the shifter assembly. Install the

shift knob to shifter retaining screw and torque to 3

N Im (25 in.lbs.) (Fig. 2). (13) Install the lower steering column shrouds on

the steering column (Fig. 8). Tighten the 2 lower

shroud to steering column screws. (14) Make sure ground clip is on left breakaway

capsule. Make sure that both breakaway capsules are

fully seated in the upper steering column bracket. In-

stall the upper steering column mounting bracket

onto the steering column support bracket (Fig. 7). In-

stall the 2 upper steering column bracket to support

bracket nuts and torque to 12 N Im (105 in. lbs.).

(15) Install the upper steering column shrouds on

the steering column (Fig. 6). Tighten the 3 upper

shroud to steering column attaching screws. (16) Install the tilt lever (Fig. 6) (if so equipped)

back on the steering column assembly. (17) Install the lower dash panel bolster. Install

bolster attaching screws and torque to 3 N Im (24 in.

lbs.). Install the inside hood release lever and torque

screws to 3 N Im (24 in. lbs.) (Fig. 5).

(18) Reconnect the battery negative (-) cable to the

vehicle battery.

Fig. 14 Interlock Cable Installation

Fig. 15 Install Interlock Cable In Shifter

Ä STEERING 19 - 41

Page 1962 of 2438

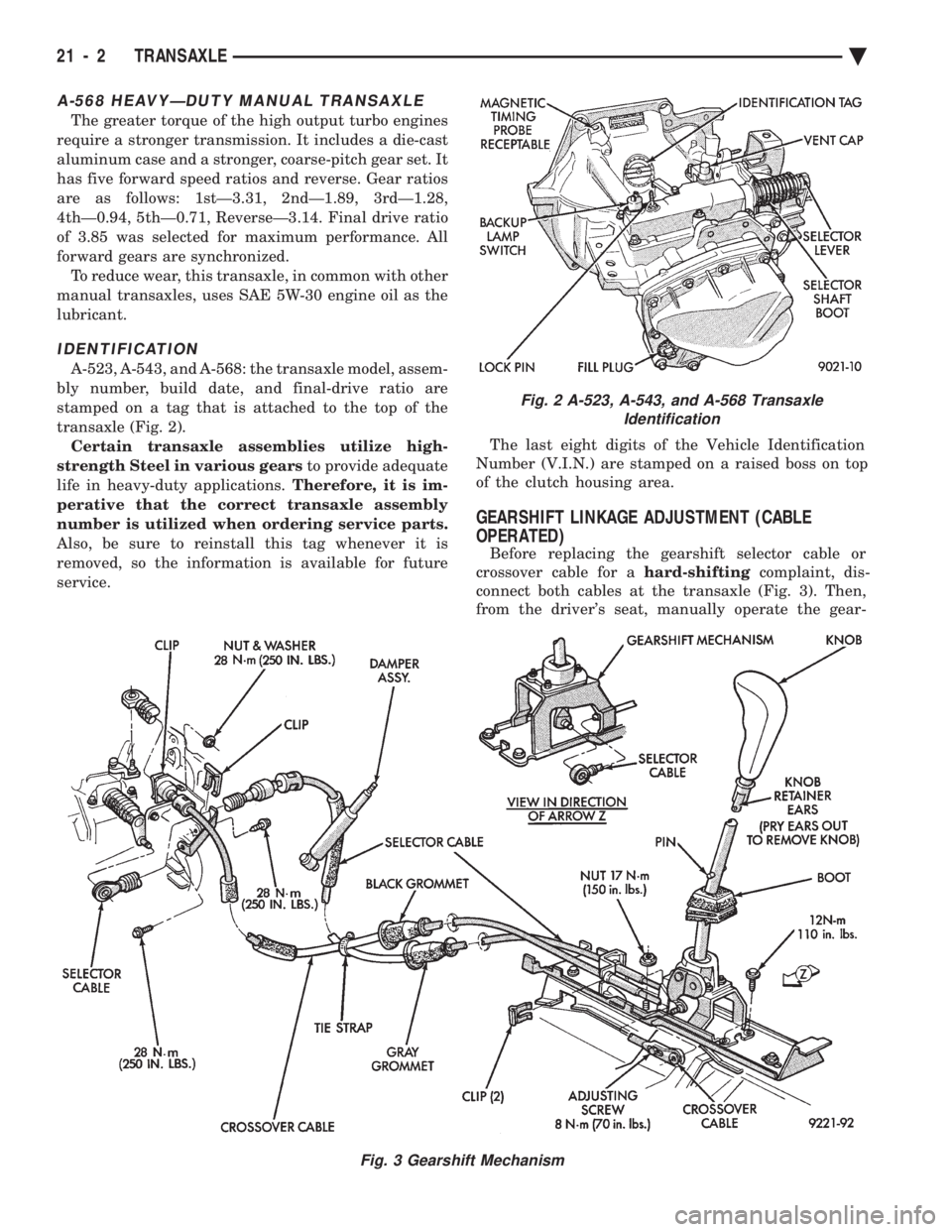

A-568 HEAVYÐDUTY MANUAL TRANSAXLE

The greater torque of the high output turbo engines

require a stronger transmission. It includes a die-cast

aluminum case and a stronger, coarse-pitch gear set. It

has five forward speed ratios and reverse. Gear ratios

are as follows: 1stÐ3.31, 2ndÐ1.89, 3rdÐ1.28,

4thÐ0.94, 5thÐ0.71, ReverseÐ3.14. Final drive ratio

of 3.85 was selected for maximum performance. All

forward gears are synchronized. To reduce wear, this transaxle, in common with other

manual transaxles, uses SAE 5W-30 engine oil as the

lubricant.

IDENTIFICATION

A-523, A-543, and A-568: the transaxle model, assem-

bly number, build date, and final-drive ratio are

stamped on a tag that is attached to the top of the

transaxle (Fig. 2). Certain transaxle assemblies utilize high-

strength Steel in various gears to provide adequate

life in heavy-duty applications. Therefore, it is im-

perative that the correct transaxle assembly

number is utilized when ordering service parts.

Also, be sure to reinstall this tag whenever it is

removed, so the information is available for future

service. The last eight digits of the Vehicle Identification

Number (V.I.N.) are stamped on a raised boss on top

of the clutch housing area.

GEARSHIFT LINKAGE ADJUSTMENT (CABLE

OPERATED)

Before replacing the gearshift selector cable or

crossover cable for a hard-shiftingcomplaint, dis-

connect both cables at the transaxle (Fig. 3). Then,

from the driver's seat, manually operate the gear-

Fig. 2 A-523, A-543, and A-568 Transaxle Identification

Fig. 3 Gearshift Mechanism

21 - 2 TRANSAXLE Ä

Page 1964 of 2438

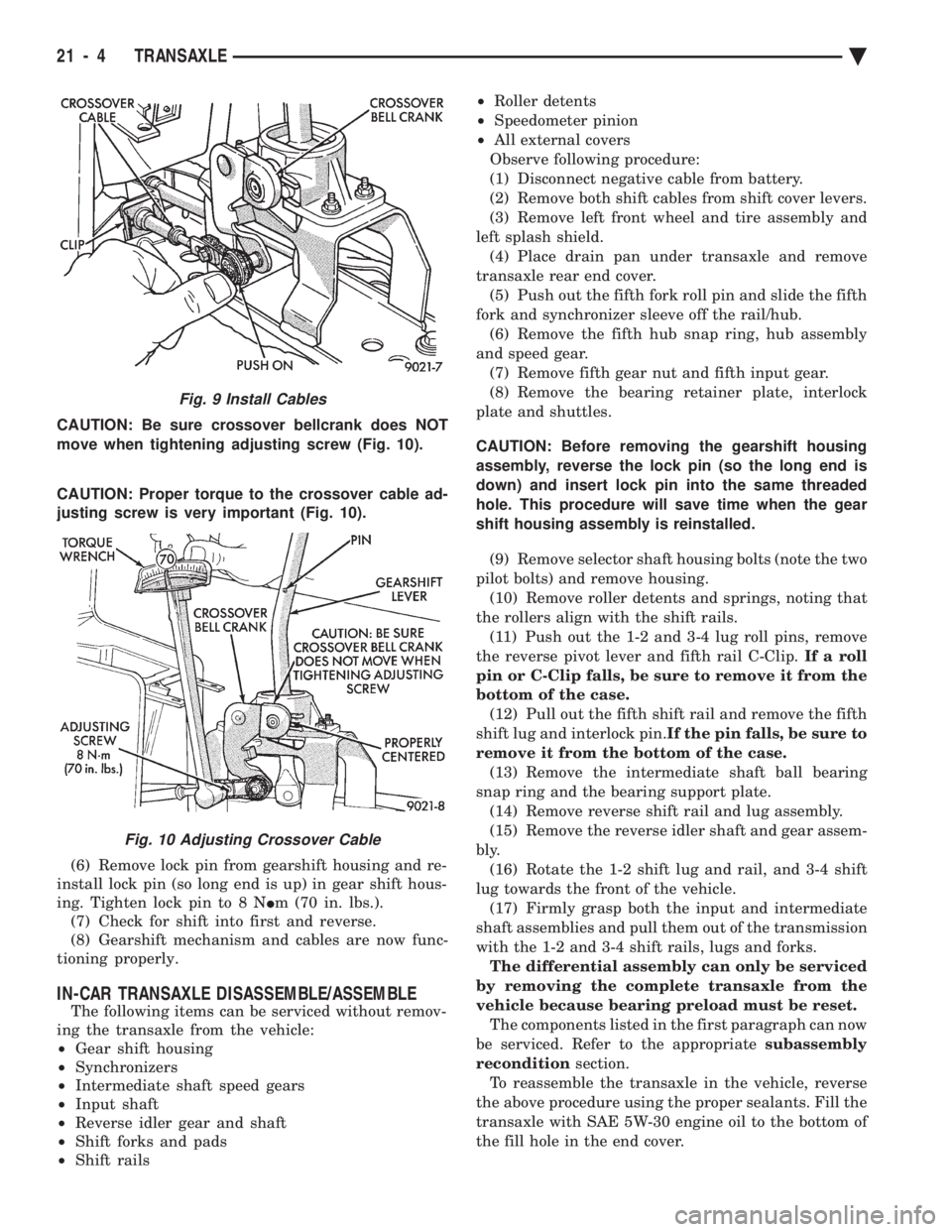

CAUTION: Be sure crossover bellcrank does NOT

move when tightening adjusting screw (Fig. 10).

CAUTION: Proper torque to the crossover cable ad-

justing screw is very important (Fig. 10).

(6) Remove lock pin from gearshift housing and re-

install lock pin (so long end is up) in gear shift hous-

ing. Tighten lock pin to 8 N Im (70 in. lbs.).

(7) Check for shift into first and reverse.

(8) Gearshift mechanism and cables are now func-

tioning properly.

IN-CAR TRANSAXLE DISASSEMBLE/ASSEMBLE

The following items can be serviced without remov-

ing the transaxle from the vehicle:

² Gear shift housing

² Synchronizers

² Intermediate shaft speed gears

² Input shaft

² Reverse idler gear and shaft

² Shift forks and pads

² Shift rails ²

Roller detents

² Speedometer pinion

² All external covers

Observe following procedure:

(1) Disconnect negative cable from battery.

(2) Remove both shift cables from shift cover levers.

(3) Remove left front wheel and tire assembly and

left splash shield. (4) Place drain pan under transaxle and remove

transaxle rear end cover. (5) Push out the fifth fork roll pin and slide the fifth

fork and synchronizer sleeve off the rail/hub. (6) Remove the fifth hub snap ring, hub assembly

and speed gear. (7) Remove fifth gear nut and fifth input gear.

(8) Remove the bearing retainer plate, interlock

plate and shuttles.

CAUTION: Before removing the gearshift housing

assembly, reverse the lock pin (so the long end is

down) and insert lock pin into the same threaded

hole. This procedure will save time when the gear

shift housing assembly is reinstalled. (9) Remove selector shaft housing bolts (note the two

pilot bolts) and remove housing. (10) Remove roller detents and springs, noting that

the rollers align with the shift rails. (11) Push out the 1-2 and 3-4 lug roll pins, remove

the reverse pivot lever and fifth rail C-Clip. If a roll

pin or C-Clip falls, be sure to remove it from the

bottom of the case. (12) Pull out the fifth shift rail and remove the fifth

shift lug and interlock pin. If the pin falls, be sure to

remove it from the bottom of the case. (13) Remove the intermediate shaft ball bearing

snap ring and the bearing support plate. (14) Remove reverse shift rail and lug assembly.

(15) Remove the reverse idler shaft and gear assem-

bly. (16) Rotate the 1-2 shift lug and rail, and 3-4 shift

lug towards the front of the vehicle. (17) Firmly grasp both the input and intermediate

shaft assemblies and pull them out of the transmission

with the 1-2 and 3-4 shift rails, lugs and forks. The differential assembly can only be serviced

by removing the complete transaxle from the

vehicle because bearing preload must be reset. The components listed in the first paragraph can now

be serviced. Refer to the appropriate subassembly

recondition section.

To reassemble the transaxle in the vehicle, reverse

the above procedure using the proper sealants. Fill the

transaxle with SAE 5W-30 engine oil to the bottom of

the fill hole in the end cover.

Fig. 9 Install Cables

Fig. 10 Adjusting Crossover Cable

21 - 4 TRANSAXLE Ä

Page 2000 of 2438

FLUID LEVEL AND CONDITION

The transmission and differential sump have a

common oil sump with a communicating opening

between the two. Before removing the dipstick, wipe all dirt off of the

protective disc and the dipstick handle. The torque converter will fill in both the PPark or N

Neutral positions. Place the selector lever in PPark to

check fluid level. Inspect fluid level on dipstick every six months.

Allow the engine to idle for at least one minute

with vehicle on level ground. This will assure

complete oil level stabilization between differen-

tial and transmission. A properly filled transaxle

will read near the addmark when fluid temperature is

21 degrees Celsius (70 degrees Fahrenheit). When the

transaxle reaches operating temperature the fluid

should be in the HOTregion.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with the

fluid. As in any hydraulic system, air bubbles make the

fluid spongy, therefore, pressures will be low and build

up slowly. Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the gears

churn up foam and cause the same conditions which

occur with a low fluid level. In either case, the air bubbles can cause overheating,

fluid oxidation, and varnishing, which can interfere

with normal valve, clutch, and servo operation. Foam-

ing can also result in fluid escaping from the transaxle

vent (dipstick handle) where it may be mistaken for a

leak. Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed. Be

sure to examine the fluid on the dipstick closely. If

there is any doubt about its condition, drain out a

sample for a double check. After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

SELECTION OF LUBRICANT

It is important that the proper lubricant be used in

these transmissions. MOPAR tATF PLUS (Automatic

Transmission Fluid-Type 7176) should be used to aid in

assuring optimum transmission performance. Fluids of

the type labeled DEXRON II Automatic Transmission

Fluid should be used only if the recommended fluid is

not available. It is important that the transmission

fluid be maintained at the prescribed level using the

recommended fluids.

SPECIAL ADDITIVES

Chrysler Corporation does not recommend the addi-

tion of any fluids to the transmission, other than the

automatic transmission fluid listed above. An ex- ception to this policy is the use of special dyes to aid in

detecting fluid leaks. The use of transmission sealers

should be avoided, since they may adversely affect

seals.

FLUID AND FILTER CHANGE

When the factory fill fluid is changed, only

fluids of the type labeled MOPAR tATF PLUS

(Automatic Transmission fluid) Type 7176 should

be used. A band adjustment and filter change

should be made at the time of the oil change. The

magnet (on the inside of the oil pan) should also

be cleaned with a clean, dry cloth. If the transaxle is disassembled for any reason,

the fluid and filter should be changed, and the

band(s) adjusted.

FLUID DRAIN AND REFILL

(1) Raise vehicle on a hoist (See Lubrication, Group

0). Place a drain container with a large opening, under

transaxle oil pan. (2) Loosen pan bolts and tap the pan at one corner to

break it loose allowing fluid to drain, then remove the

oil pan. (3) Install a new filter and gasket on bottom of the

valve body and tighten retaining screws to 5 N Im (40

in. lbs.). (4) Clean the oil pan and magnet. Reinstall pan

using new MOPAR tAdhesive sealant. Tighten oil pan

bolts to 19 N Im (165 in. lbs.).

(5) Pour four quarts of MOPAR tATF PLUS (Auto-

matic Transmission Fluid) Type 7176 through the

dipstick opening. (6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes ap-

plied, move selector lever momentarily to each posi-

tion, ending in the park or neutral position. (7) Add sufficient fluid to bring level to 1/8 inch

below the ADD mark. Recheck fluid level after transaxle is at normal

operating temperature. The level should be in the HOT

region (Fig. 1). To prevent dirt from entering transaxle, make cer-

tain that dipstick is full seated into the dipstick open-

ing.

TORQUE CONVERTER CLUTCH SOLENOID WIRING

CONNECTOR

If wiring connector is unplugged, the torque con-

verter clutch will not operate (Fig. 2).

ROAD TEST

Prior to performing a road test, be certain that the

fluid level and condition, and control cable adjustments

have been checked and approved. During the road test, the transaxle should be oper-

ated in each position to check for slipping and any

variation in shifting.

21 - 40 TRANSAXLE Ä