engine oil CHEVROLET DYNASTY 1993 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 386 of 2438

STARTER FEED CIRCUIT RESISTANCE TEST

Before going on with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter, ac-

curate to 1/10 of a volt.

CAUTION: Ignition system also must be disabled to

prevent engine start while performing the following

tests.

(1) Disable ignition system as follows:

² VEHICLES WITH CONVENTIONAL DISTRIBU-

TORS: Disconnect the ignition coil cable from the

distributor cap. Connect a suitable jumper wire be-

tween the coil cable end-terminal and a good body

ground (Fig. 6).

² VEHICLES WITH DIRECT IGNITION SYSTEM:

Disconnect the ignition coils electrical connector (Fig.

7). (2) With all wiring harnesses and components

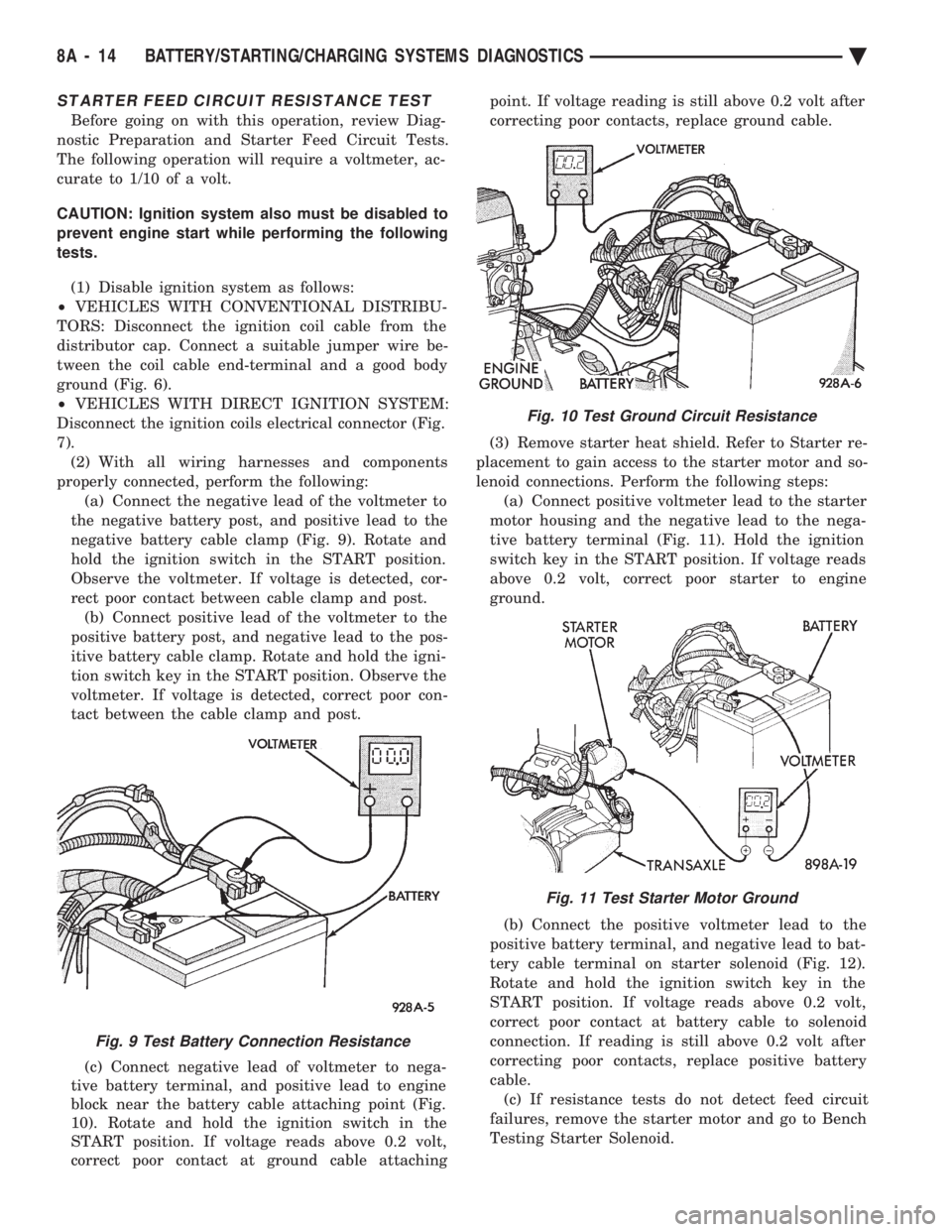

properly connected, perform the following: (a) Connect the negative lead of the voltmeter to

the negative battery post, and positive lead to the

negative battery cable clamp (Fig. 9). Rotate and

hold the ignition switch in the START position.

Observe the voltmeter. If voltage is detected, cor-

rect poor contact between cable clamp and post. (b) Connect positive lead of the voltmeter to the

positive battery post, and negative lead to the pos-

itive battery cable clamp. Rotate and hold the igni-

tion switch key in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between the cable clamp and post.

(c) Connect negative lead of voltmeter to nega-

tive battery terminal, and positive lead to engine

block near the battery cable attaching point (Fig.

10). Rotate and hold the ignition switch in the

START position. If voltage reads above 0.2 volt,

correct poor contact at ground cable attaching point. If voltage reading is still above 0.2 volt after

correcting poor contacts, replace ground cable.

(3) Remove starter heat shield. Refer to Starter re-

placement to gain access to the starter motor and so-

lenoid connections. Perform the following steps: (a) Connect positive voltmeter lead to the starter

motor housing and the negative lead to the nega-

tive battery terminal (Fig. 11). Hold the ignition

switch key in the START position. If voltage reads

above 0.2 volt, correct poor starter to engine

ground.

(b) Connect the positive voltmeter lead to the

positive battery terminal, and negative lead to bat-

tery cable terminal on starter solenoid (Fig. 12).

Rotate and hold the ignition switch key in the

START position. If voltage reads above 0.2 volt,

correct poor contact at battery cable to solenoid

connection. If reading is still above 0.2 volt after

correcting poor contacts, replace positive battery

cable. (c) If resistance tests do not detect feed circuit

failures, remove the starter motor and go to Bench

Testing Starter Solenoid.

Fig. 9 Test Battery Connection Resistance

Fig. 10 Test Ground Circuit Resistance

Fig. 11 Test Starter Motor Ground

8A - 14 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS Ä

Page 387 of 2438

STARTER CONTROL CIRCUIT TESTS

The starter control circuit has:

² Starter solenoid

² Starter relay (Fig. 2)

² Neutral starting and back-up switch with auto-

matic transmissions

² Clutch pedal mounted starter interlock switch

with manual transmissions

² Ignition switch

² Battery

² All related wiring and connections

CAUTION: Before performing any starter tests, the

ignition system must be disabled.

² VEHICLES EQUIPPED WITH A CONVEN-

TIONAL DISTRIBUTOR: Disconnect coil wire from

distributor cap center tower. Secure wire to a good

ground to prevent engine from starting (Fig. 6).

² VEHICLES EQUIPPED WITH DIRECT IGNI-

TION SYSTEM: Unplug the coils electrical connector

(Fig. 7).

STARTER SOLENOID TEST

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN PARK OR NEUTRAL WITH THE

PARKING BRAKE APPLIED

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests. (2) Perform this starter solenoid test BEFORE per-

forming the starter relay test. (3) Raise the vehicle.

(4) Perform a visual inspection of the starter/

starter solenoid for corrosion, loose connections or

faulty wiring. (5) Lower the vehicle.

(6) Locate the starter relay as follows:

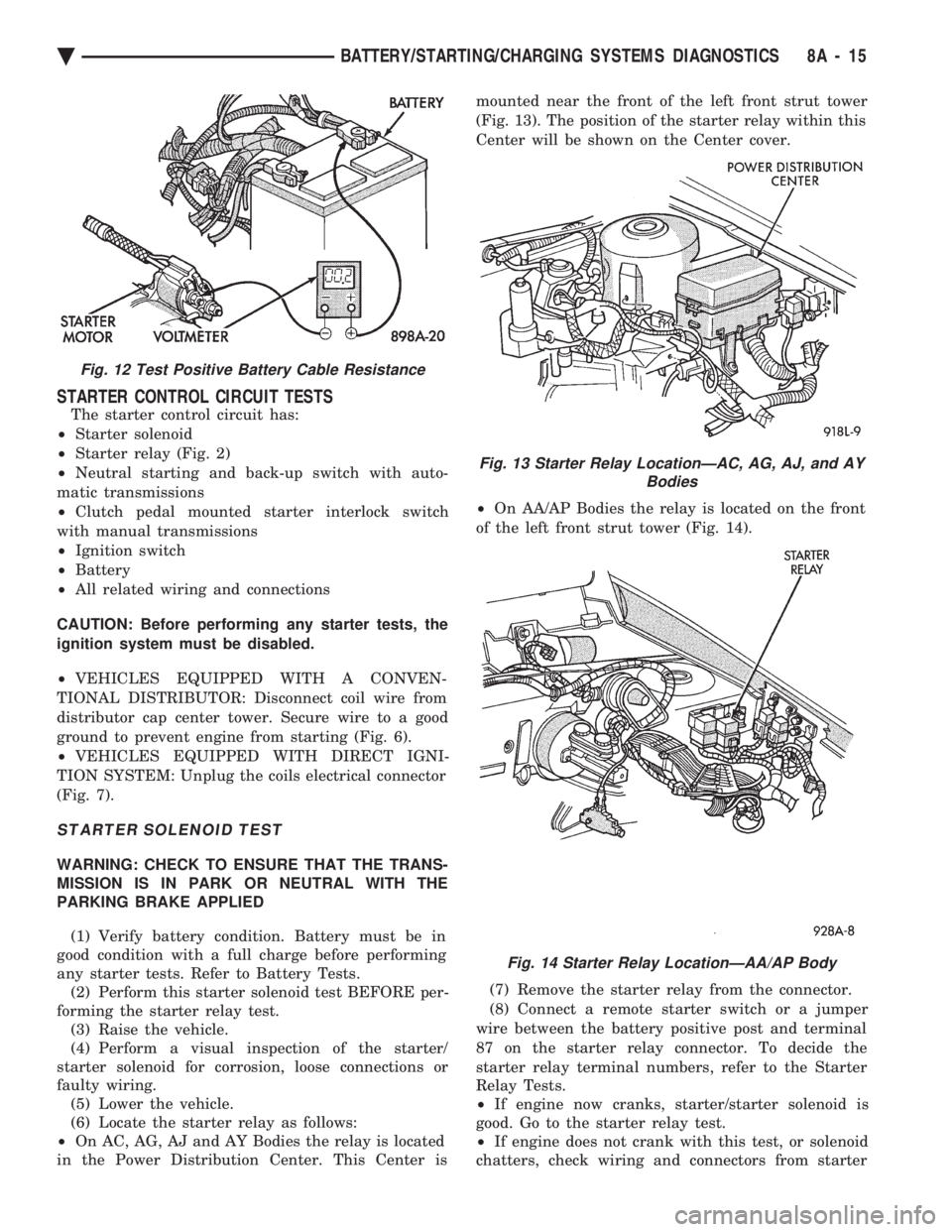

² On AC, AG, AJ and AY Bodies the relay is located

in the Power Distribution Center. This Center is mounted near the front of the left front strut tower

(Fig. 13). The position of the starter relay within this

Center will be shown on the Center cover.

² On AA/AP Bodies the relay is located on the front

of the left front strut tower (Fig. 14).

(7) Remove the starter relay from the connector.

(8) Connect a remote starter switch or a jumper

wire between the battery positive post and terminal

87 on the starter relay connector. To decide the

starter relay terminal numbers, refer to the Starter

Relay Tests.

² If engine now cranks, starter/starter solenoid is

good. Go to the starter relay test.

² If engine does not crank with this test, or solenoid

chatters, check wiring and connectors from starter

Fig. 12 Test Positive Battery Cable Resistance

Fig. 13 Starter Relay LocationÐAC, AG, AJ, and AY Bodies

Fig. 14 Starter Relay LocationÐAA/AP Body

Ä BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 15

Page 388 of 2438

relay to starter solenoid for loose or corroded connec-

tions. Particularly at starter terminals.

² Repeat test. If engine still fails to crank properly,

trouble is within starter or starter mounted solenoid,

and it must be removed for repairs. Refer to Group

8B, Battery/Starter/Generator Service, Starter re-

placement.

STARTER RELAY TEST

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN PARK OR NEUTRAL WITH THE

PARKING BRAKE APPLIED

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests. (2) Perform the preceding starter solenoid tests

BEFORE performing starter relay tests. Refer to

Starter Solenoid Test. (3) Locate and remove the starter relay. For

starter relay locations, refer to Starter Solenoid Test

(Fig. 13 or 14). (4) After the starter relay has been located and re-

moved, refer to Starter Relay Tests (Fig. 15).

NEUTRAL STARTING AND BACK-UP SWITCH

AUTOMATIC TRANSMISSION ONLY

For electrical diagnostics, when checking starter

circuits, refer to Starter Relay Tests (Fig. 15). For replacement of switch, refer to Group 21, Tran-

saxle, Neutral Starting and Switch Replacement.

STARTER INTERLOCK SWITCHÐCLUTCH PEDAL MOUNTED

MANUAL TRANSMISSION ONLY

For electrical diagnostics, refer to the Starter Relay

Tests. For replacement and/or adjustment of the switch,

refer to Group 6, Manual Transaxle Clutch, Manual

Transaxle Starter Interlock Switch.

IGNITION SWITCH TEST

After testing the starter solenoid and relay, test ig-

nition switch and wiring. Refer to Group 8D, Ignition

Systems, or the Front Wheel Drive Car Wiring Dia-

grams Service Manual. Check all wiring for opens or

shorts, and all connectors for being loose or corroded.

BENCH TESTING STARTER SOLENOID

(1) Disconnect field coil wire from field coil termi-

nal (Fig. 16 or 17). (2) Check for continuity between solenoid terminal

and field coil terminal with a continuity tester. Con-

tinuity should be detected (Fig. 18 or 19). (3) Check for continuity between solenoid terminal

and solenoid housing (Fig. 20 or 21). Continuity

should be detected. If continuity is detected, solenoid

is good. (4) If continuity is not detected in either test, sole-

noid has an open circuit and is defective. If equipped

with:

² BOSCH STARTER: Replace the solenoid.

² NIPPONDENSO STARTER: Replace the starter

assembly.

8A - 16 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS Ä

Page 406 of 2438

STARTER INDEX

page page

General Information ........................ 4

Neutral Starter and Back-Up Switch ........... 8

Starter Component Replacement .............. 5

Starter Interlock Switch: Clutch Pedal Mounted/ Manual Transmission Only ................. 7 Starter Motor Replacement

.................. 4

Starting System ........................... 4

Supply Circuit and Control Circuit ............. 4

GENERAL INFORMATION

This section will cover Starter replacement and

service procedures only. For starter diagnostic proce-

dures, refer to Group 8A, Battery/Starting/Charging

Systems Diagnostics.

STARTING SYSTEM

The starting system has:

² Ignition switch

² Starter relay

² Neutral starting and back-up switch with auto-

matic transmissions

² Clutch pedal mounted starter interlock switch

with manual transmissions

² Wiring harness

² Battery

² Starter motor with an integral solenoid

BOSCH STARTERS

²A Bosch permanent magnet starter motor is avail-

able on 2.2L, 2.5L and 3.0L engines on all vehicles.

A planetary gear train transmits power between

starter motor and pinion shaft. The fields consist of

six permanent magnets.

NIPPONDENSO STARTERS

² A Nippondenso reduction gear-field coil starter

motor is available on 3.0L, 3.3L and 3.8L engines.

SUPPLY CIRCUIT AND CONTROL CIRCUIT

Both starter systems consist of two separate cir-

cuits:

² A high amperage supply to feed the starter motor.

² A low amperage circuit to control the starter sole-

noid. For additional information on starter motor supply

and control circuits, refer to Group 8A, Battery/Start-

ing/Charging Systems Diagnostics.

STARTER MOTOR REPLACEMENT

BOSCH STARTERÐ2.2L/2.5L ENGINE

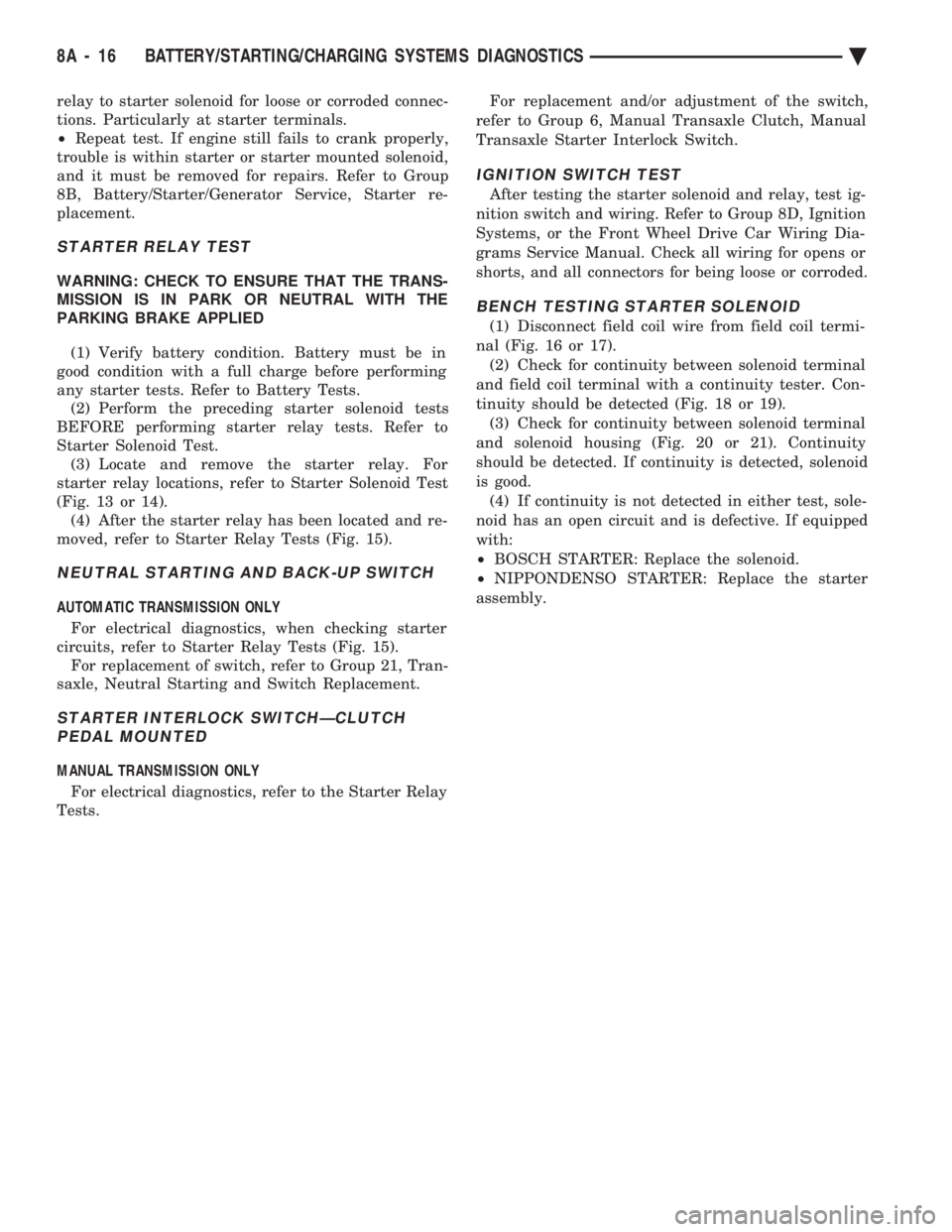

(1) Disconnect battery negative cable (Fig. 1).

(2) Raise vehicle. (3) Remove heat shield clip from the starter and

heat shield is clipped to starter (Fig. 2). For easier

servicing, do not remove the wiring from starter at

this time.

(4) Remove two bolts and one nut attaching starter

to engine (Fig. 3). (5) Remove starter/starter solenoid assembly from

engine. Position the starter to gain access to the wir-

ing connectors. (6) Disconnect the positive battery cable and wir-

ing at the starter. (7) Remove the starter from vehicle.

Fig. 1 Remove or Install Battery Cable

Fig. 2 Starter Heat ShieldÐ4 Cylinder Engines

8B - 4 BATTERY/STARTER/GENERATOR SERVICE Ä

Page 423 of 2438

² To set DAY of WEEK, press TIME button. An ar-

row will appear on the display and point to the Day.

Press and hold the SET button to move the day for-

ward or INFO button to move it backward.

² To set DAY of MONTH, press TIME button. The

arrow will point to Date. Press and hold the SET

button to advance the date or INFO button to move

it backwards.

² To set MONTH of YEAR, press TIME button. The

arrow will point to the Month. Press and hold the

SET button to advance the Month forward or INFO

button to move backward. TEMP button, pressing the Temp button will dis-

play:

² The temperature outside the vehicle

² Vehicle direction define by an eight point compass

If Compass has lost calibration or not receiving

good information from the engine compartment node,

an asterisk (*) will flash on the display and the word

calibrate will appear. Refer to Compass Calibration. FUEL BUTTON, WILL DISPLAY:

² Pressing FUEL button the first time will show, the

estimated number of miles that can be driven with

the remaining fuel. The destination to empty indica-

tion will vary every few seconds as the amount of

fuel and fuel efficiency is calculated. This function

can not be reset.

² Pressing the FUEL button second time; will dis-

play the fuel consumed.

²

Pressing the FUEL button third time; will display

the average fuel economy in miles per gallon since last

reset. The display will be updated every 16 seconds.

² Pressing the FUEL button forth time, the current

fuel economy will be displayed. The current fuel

economy will be up updated every two seconds.

² To reset Fuel consumed, press SET button until

the fuel consumed message is displayed and then

within five seconds press SET button.

² To reset AVERAGE FUEL ECONOMY, press the

FUEL button until average fuel economy is displayed

and within five seconds press SET button. TRIP RESET, press FUEL button and wait four

seconds press the SET button twice. This clears all

trip information and the message Trip Reset will be

displayed. This will occur only if a reset function is

currently being displayed. The reset functions:

² Fuel consumed

² Average fuel economy message

INFO button, will active a MONITORED SYS-

TEMS OK message on display if all monitored sys-

tems are operating properly. If a problem is detected,

the appropriate message will be displayed. SET button, will clear the various functions after

they have been displayed. It is used to enter the

clock set or compass variance modes. This button is

also used to reset certain trip computer functions and

the maintenance reminder message.

The EVIC display may be turned off by pressing the

TIME and SET buttons at the same time. Pressing the

buttons a second time will restore the display.

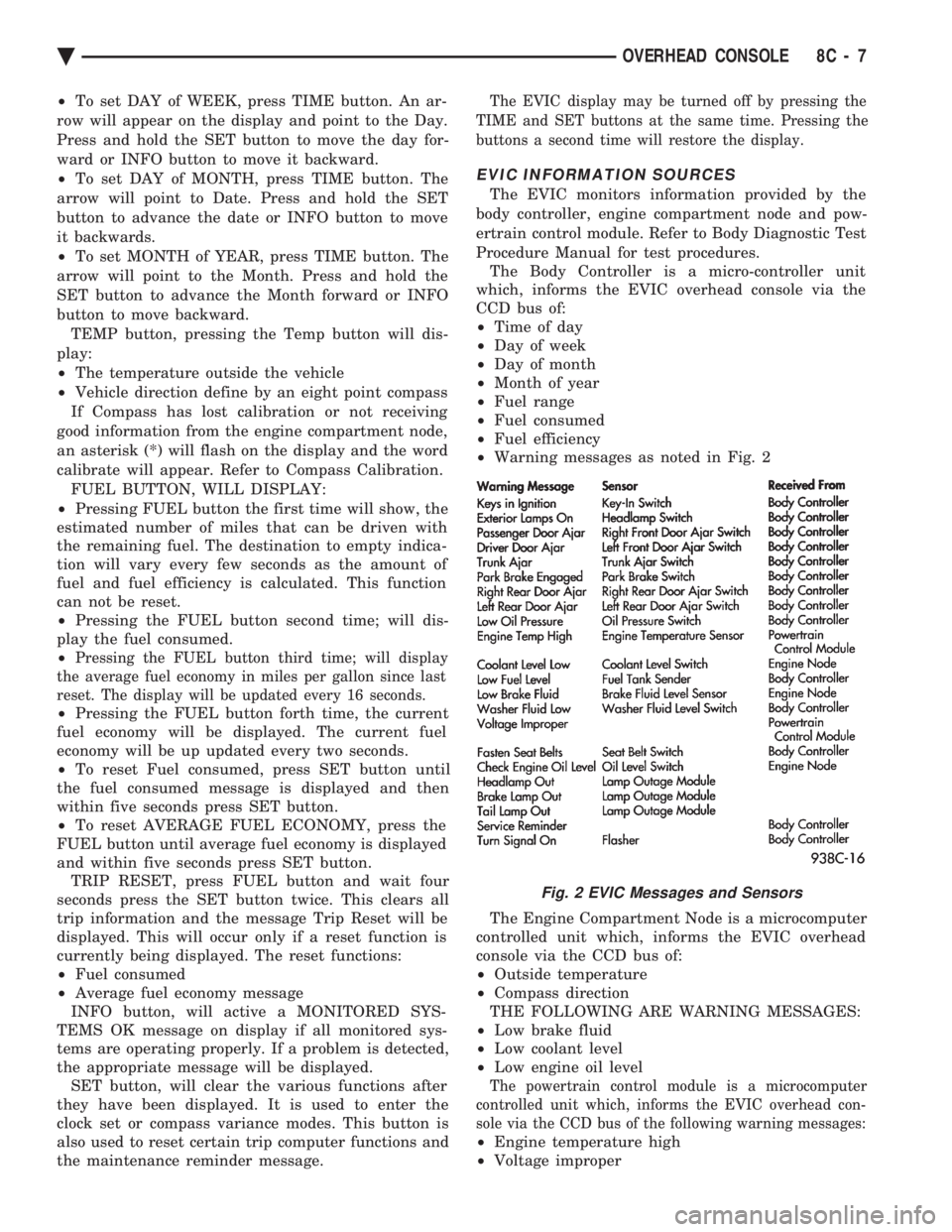

EVIC INFORMATION SOURCES

The EVIC monitors information provided by the

body controller, engine compartment node and pow-

ertrain control module. Refer to Body Diagnostic Test

Procedure Manual for test procedures. The Body Controller is a micro-controller unit

which, informs the EVIC overhead console via the

CCD bus of:

² Time of day

² Day of week

² Day of month

² Month of year

² Fuel range

² Fuel consumed

² Fuel efficiency

² Warning messages as noted in Fig. 2

The Engine Compartment Node is a microcomputer

controlled unit which, informs the EVIC overhead

console via the CCD bus of:

² Outside temperature

² Compass direction

THE FOLLOWING ARE WARNING MESSAGES:

² Low brake fluid

² Low coolant level

² Low engine oil level

The powertrain control module is a microcomputer

controlled unit which, informs the EVIC overhead con-

sole via the CCD bus of the following warning messages:

² Engine temperature high

² Voltage improper

Fig. 2 EVIC Messages and Sensors

Ä OVERHEAD CONSOLE 8C - 7

Page 424 of 2438

VISUAL MESSAGES

Following are the visual messages and the condi-

tions under which, the messages will be given:

² Keys in ignition

² Exterior lamps on

These messages will appear if the conditions are

present and the driver's door is open while the igni-

tion switch is in the OFF, LOCK, or ACC positions.

A tone will sound until the condition is corrected or

the door is closed.

² Passenger door ajar

² Driver door ajar

² Trunk ajar

² Park brake engaged

² Right rear door ajar

² Left rear door ajar

These messages will appear if a condition is de-

tected after the vehicle is in motion. When the con-

dition is corrected, a short tone will sound to

acknowledge the action. LOW OIL PRESSURE

If this message is displayed while the vehicle is at

cruising speeds, immediate attention is required. If

this message appears at idle speed, increase the idle

speed and the message should go off. If the message

remains on, immediate attention is required. ENGINE TEMP CRITICAL

This message appears when a sensor has determined

that the engine coolant is overheating. If this message

comes on and stays on, immediate action is required.

COOLANT LEVEL LOW

LOW FUEL LEVEL

LOW BRAKE FLUID

WASHER FLUID LOW

These messages will appear if a continuous warn-

ing condition is detected while the engine is running.

Inspection is required. To clear this message from

the display, after the condition is corrected, the igni-

tion switch must be turned OFF. CHECK TRANS

This message will appear if a continuous warning

condition is detected while the engine is running. Im-

mediate attention is recommended. To clear this mes-

sage from the display, after the condition has been

corrected, the ignition switch must be turned OFF. VOLTAGE IMPROPER

This message will appear if a continuous warning

condition is detected. Immediate attention is re-

quired. To clear this message from the display, after

the condition has been corrected, the ignition switch

must be turned OFF. TURN SIGNAL ON

This message will appear if the turn signal is left

on while vehicle speed is over 15 mph and the vehi-

cle has traveled over one-half mile. FASTEN SEAT BELTS An intermittent chime tone will sound for several

seconds if the seat belt is not fastened. CHK ENGINE OIL LEVEL

If this message is delivered, a check of the engine

oil dipstick is suggested. To clear this message, after

the condition is corrected, the ignition switch must

be turned OFF. HEADLAMP OUT

BRAKE LAMP OUT

TAIL LAMP OUT

These conditions are monitored only when the lamps

are on. The message will remain, even after the lamp is

replaced, until the lamp is turned on and operates.

SERVICE REMINDER

The maintenance reminder statement is programmed

to provide general information only. Refer to Group 0,

Lubrication & Maintenance for specific vehicle require-

ments.

The service reminder message is displayed at 7,500

miles or 12 months intervals, which ever comes first. MONITORED SYSTEMS OK

If there is no warning condition to report, the mes-

sage Monitored Systems OK is displayed (Fig. 2).

AUTOMATIC CALIBRATION SET PROCEDURE

The engine compartment node will continuously

and automatically recalibrate the compass under nor-

mal driving conditions. As long as the vehicle is

turning, the engine compartment node will record

new compass data. This new data will be used to

recalibrate the compass at a rate of at least once per

full (360 degree) turn of the vehicle. Automatic cali-

bration does not require operator interface.

MANUAL CALIBRATION SET PROCEDURE

Manual compass calibration has been replaced by

automatic calibration set procedure. The manual cal-

ibration set procedure is available, but no longer

serves any useful purpose.

EVIC SELF CHECK DIAGNOSTICS

Ignition switch ON, the EVIC not displaying any

message, may imply a system failure and not an

EVIC failure. Turn the ignition OFF, close all vehi-

cle doors and wait at least 60 seconds before begin-

ning test. Turn ignition switch to the ON position.

Pressing the TEMP, FUEL and INFO buttons at the

same time shall provide the visual message MOD-

ULE SELF CHECK for two seconds. Following at

two second interval there will be messages:

² E2-0 SELF CHECK

² E3-0 SELF CHECK

² END OF SELF CHECK

Showing the microcomputer is working properly.

When the self check mode and message shows:

² E2-1

² E3-2

This would show a fault exists in the EVIC's micro-

computer and the EVIC should be replaced (Fig. 3).

8C - 8 OVERHEAD CONSOLE Ä

Page 430 of 2438

dition exists. These messages are displayed on the

center of the instrument panel.For complete EVIC operating instructions, refer to

the Owners Manual provided with the vehicle.

EVIC BUTTON FUNCTIONS

TIME button will display:

² Time of day

² Day of week

² Day of month

² Month of year

² To set HOURS, press TIME button and within four

seconds press the SET button. An arrow will appear

on the display and point to the hours. Press and hold

the SET button to advance the hours or INFO button

to set back the hours.

² To set MINUTES, press TIME button. The arrow

will point to the minutes. Press and hold the SET

button to advance the minutes or INFO button to set

back the minutes.

² To set DAY of WEEK, press TIME button. An ar-

row will appear on the display and point to the Day.

Press and hold the SET button to move the day for-

ward or INFO button to move it backward.

² To set DAY of MONTH, press TIME button. The

arrow will point to Date. Press and hold the SET

button to advance the date or INFO button to move

it backwards.

² To set MONTH of YEAR, press TIME button. The

arrow will point to the Month. Press and hold the

SET button to advance the Month forward or INFO

button to move backward. TEMP button, pressing the Temp button will dis-

play:

² The temperature outside the vehicle

² Vehicle direction define by an eight point compass

If Compass has lost calibration or not receiving

good information from the engine compartment node,

an asterisk (*) will flash on the display and the word

calibrate will appear. Refer to Compass Calibration. FUEL BUTTON, WILL DISPLAY:

² Pressing FUEL button the first time will show, the

estimated number of miles that can be driven with

the remaining fuel. The destination to empty indica-

tion will vary every few seconds as the amount of

fuel and fuel efficiency is calculated. This function

can not be reset.

² Pressing the FUEL button second time; will dis-

play the fuel consumed.

² Pressing the FUEL button third time; will display

the average fuel economy in miles per gallon since

last reset. The display will be updated every 16 sec-

onds.

² Pressing the FUEL button forth time, the current

fuel economy will be displayed. The current fuel

economy will be up updated every two seconds. ²

To reset Fuel consumed, press SET button until

the fuel consumed message is displayed and then

within five seconds press SET button.

² To reset AVERAGE FUEL ECONOMY, press the

FUEL button until average fuel economy is displayed

and within five seconds press SET button. TRIP RESET, press FUEL button and wait four

seconds press the SET button twice. This clears all

trip information and the message Trip Reset will be

displayed. This will occur only if a reset function is

currently being displayed. The reset functions:

² Fuel consumed

² Average fuel economy message

INFO button, will active a MONITORED SYS-

TEMS OK message on display if all monitored sys-

tems are operating properly. If a problem is detected,

the appropriate message will be displayed. SET button, will clear the various functions after

they have been displayed. It is used to enter the

clock set or compass variance modes. This button is

also used to reset certain trip computer functions and

the maintenance reminder message. The EVIC display may be turned off by pressing

the TIME and SET buttons at the same time. Press-

ing the buttons a second time will restore the dis-

play.

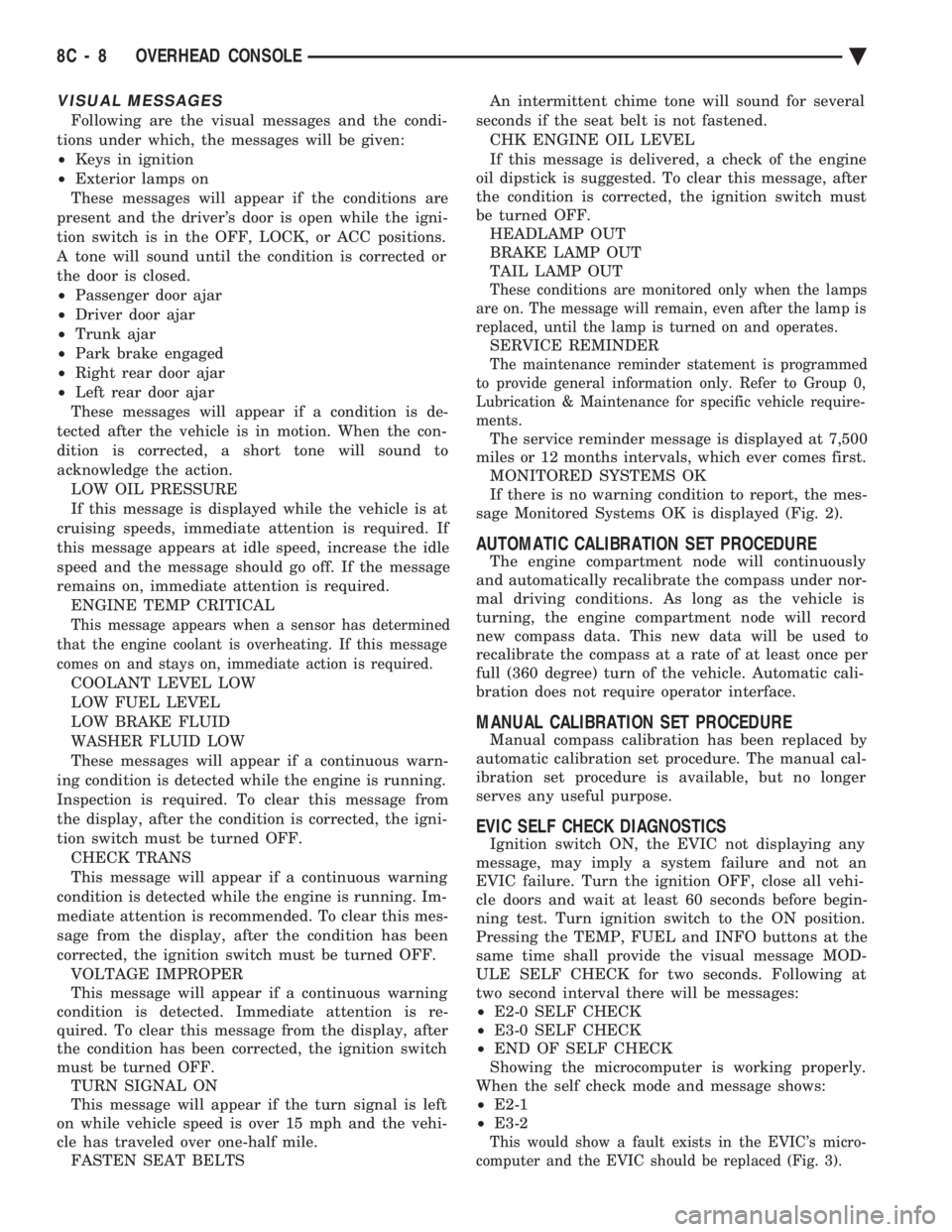

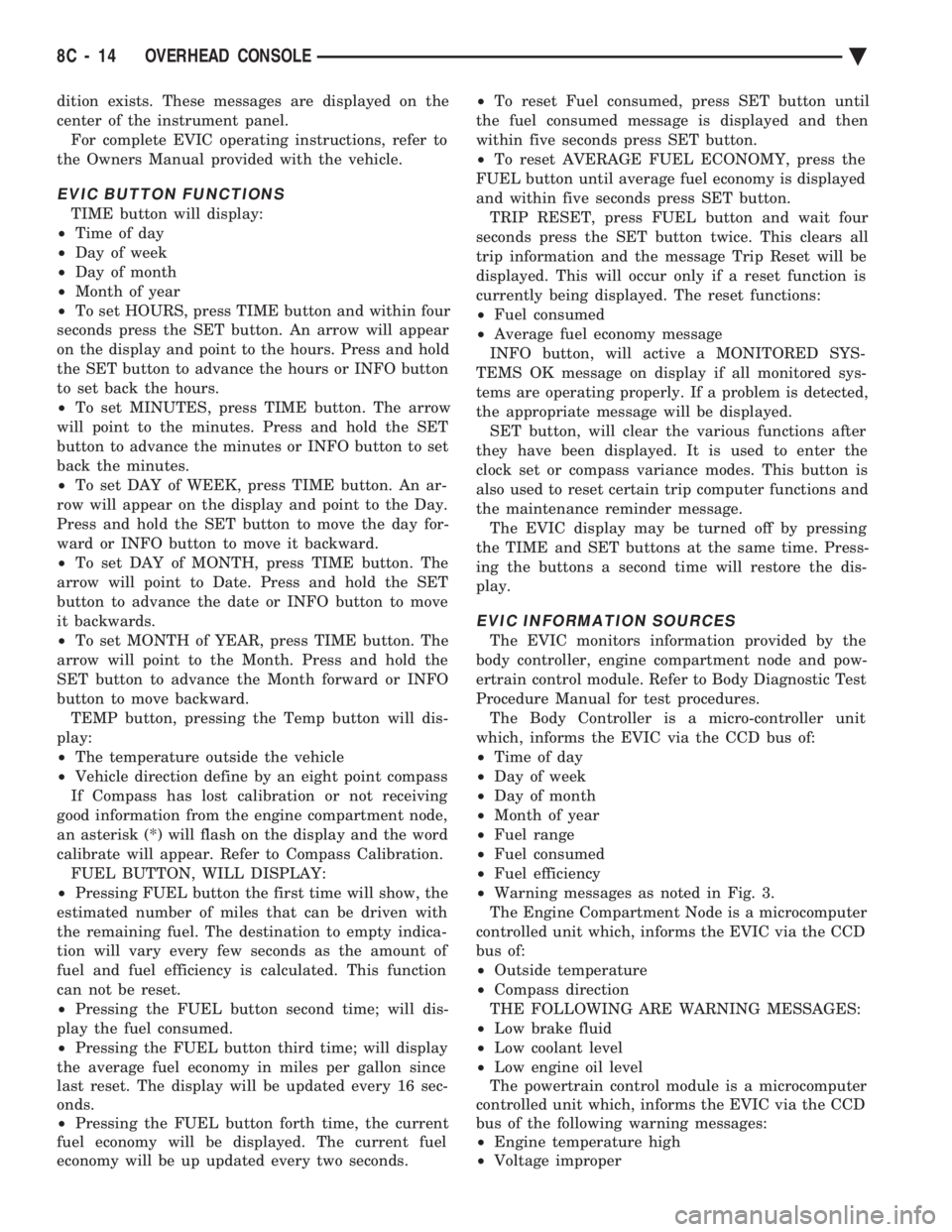

EVIC INFORMATION SOURCES

The EVIC monitors information provided by the

body controller, engine compartment node and pow-

ertrain control module. Refer to Body Diagnostic Test

Procedure Manual for test procedures. The Body Controller is a micro-controller unit

which, informs the EVIC via the CCD bus of:

² Time of day

² Day of week

² Day of month

² Month of year

² Fuel range

² Fuel consumed

² Fuel efficiency

² Warning messages as noted in Fig. 3.

The Engine Compartment Node is a microcomputer

controlled unit which, informs the EVIC via the CCD

bus of:

² Outside temperature

² Compass direction

THE FOLLOWING ARE WARNING MESSAGES:

² Low brake fluid

² Low coolant level

² Low engine oil level

The powertrain control module is a microcomputer

controlled unit which, informs the EVIC via the CCD

bus of the following warning messages:

² Engine temperature high

² Voltage improper

8C - 14 OVERHEAD CONSOLE Ä

Page 431 of 2438

VISUAL MESSAGES

Following are the visual messages and the condi-

tions under which, the messages will be given:

² Keys in ignition

² Exterior lamps on

These messages will appear if the conditions are

present and the driver's door is open while the igni-

tion switch is in the OFF, LOCK, or ACC positions.

A tone will sound until the condition is corrected or

the door is closed.

² Passenger door ajar

² Driver door ajar

² Trunk ajar

² Park brake engaged

² Right rear door ajar

² Left rear door ajar

These messages will appear if a condition is de-

tected after the vehicle is in motion. When the con-

dition is corrected, a short tone will sound to

acknowledge the action. LOW OIL PRESSURE

If this message is displayed while the vehicle is at

cruising speeds, immediate attention is required. If

this message appears at idle speed, increase the idle

speed and the message should go off. If the message

remains on, immediate attention is required. ENGINE TEMP CRITICAL

This message appears when a sensor has deter-

mined that the engine coolant is overheating. If this

message comes on and stays on, immediate action is

required. COOLANT LEVEL LOW

LOW FUEL LEVEL

LOW BRAKE FLUID WASHER FLUID LOW

These messages will appear if a continuous warn-

ing condition is detected while the engine is running.

Inspection is required. To clear this message from

the display, after the condition is corrected, the igni-

tion switch must be turned OFF. CHECK TRANS

This message will appear if a continuous warning

condition is detected while the engine is running. Im-

mediate attention is recommended. To clear this mes-

sage from the display, after the condition has been

corrected, the ignition switch must be turned OFF. VOLTAGE IMPROPER

This message will appear if a continuous warning

condition is detected. Immediate attention is re-

quired. To clear this message from the display, after

the condition has been corrected, the ignition switch

must be turned OFF. TURN SIGNAL ON

This message will appear if the turn signal is left

on while vehicle speed is over 15 mph and the vehi-

cle has traveled over one-half mile. FASTEN SEAT BELTS

An intermittent chime tone will sound for several

seconds if the seat belt is not fastened. CHK ENGINE OIL LEVEL

If this message is delivered, a check of the engine

oil dipstick is suggested. To clear this message, after

the condition is corrected, the ignition switch must

be turned OFF. HEADLAMP OUT

BRAKE LAMP OUT

TAIL LAMP OUT

These conditions are monitored only when the

lamps are on. The message will remain, even after

the lamp is replaced, until the lamp is turned on and

operates. SERVICE REMINDER

The maintenance reminder statement is pro-

grammed to provide general information only. Refer

to Group 0, Lubrication & Maintenance for specific

vehicle requirements. The service reminder message is displayed at 7,500

miles or 12 months intervals, which ever comes first. MONITORED SYSTEMS OK

If there is no warning condition to report, the mes-

sage Monitored Systems OK is displayed (Fig. 3).

ENGINE COMPARTMENT NODE (ECN)

The Engine Compartment Node is a microcomputer

controlled unit which, informs the Electronic Vehicle

Information Center (EVIC) via the CCD bus of:

² Outside temperature

² Compass direction

and the following warning messages:

² Low Brake Fluid

² Low Coolant Level

² Low Engine Oil Level

Fig. 3 EVIC Messages and Sensors

Ä OVERHEAD CONSOLE 8C - 15

Page 443 of 2438

IGNITION SYSTEMS

CONTENTS

page page

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐDIAGNOSTIC PROCEDURES

..... 11

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNI- TION SYSTEMSÐSERVICE PROCEDURES . 14

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNI- TION SYSTEMSÐSYSTEM OPERATION .... 1

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMÐDIAGNOSTIC PROCEDURES

.... 35

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMÐSYSTEM OPERATION ......... 24

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMSÐSERVICE PROCEDURES ...... 39

IGNITION SWITCH ...................... 45

SPECIFICATIONS ....................... 47

GENERAL INFORMATION

Throughout this group, references are made to par-

ticular vehicles by letter designation. A chart ex-

plaining the designations appears in the Introduction

Section of this manual.

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐSYSTEM OPERATION

INDEX

page page

Auto Shutdown (ASD) Relay and Fuel Pump Relay . 8

Coolant Temperature Sensor ................. 7

Distributor Cap ........................... 1

Distributor Pick-UpÐ3.0L Engine .............. 7

Distributor Pick-UpÐPCM Input ............... 6

General Information ........................ 1 Ignition Coil

.............................. 9

Manifold Absolute Pressure (MAP) Sensor ...... 8

Powertrain Control Module (PCM) ............. 6

Rotor .................................. 2

Spark Plug Cables ........................ 2

Spark Plugs ............................. 3

GENERAL INFORMATION

This section describes the ignition systems of the

2.2L TBI, 2.5L TBI, 2.5L MPI (flexible fuel AA-body)

and 3.0L engines. The Fuel Injection sections of Group 14 explain On

Board Diagnostics. Group 0, Lubrication and Maintenance, contains

general maintenance information for ignition related

items. The Owner's Manual also contains mainte-

nance information.

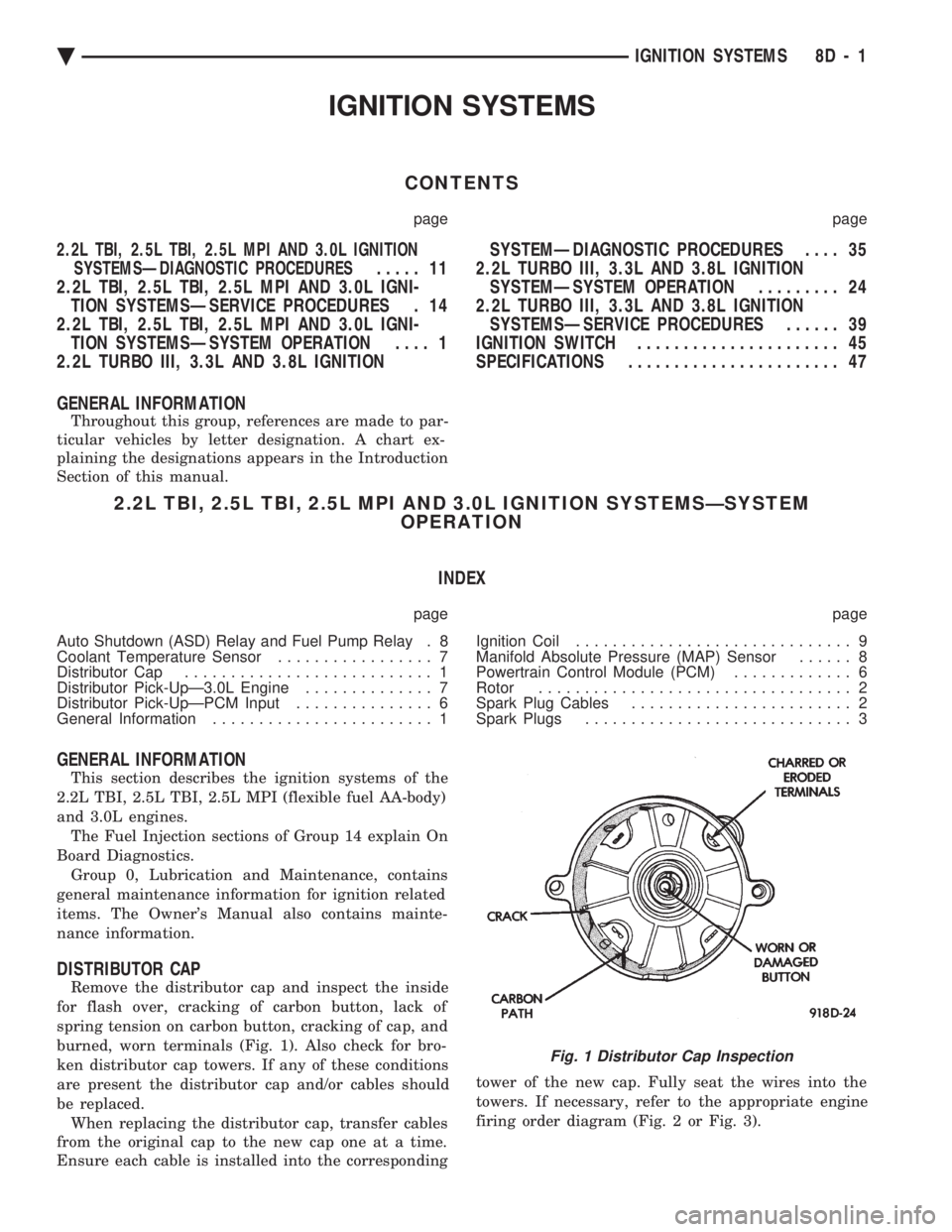

DISTRIBUTOR CAP

Remove the distributor cap and inspect the inside

for flash over, cracking of carbon button, lack of

spring tension on carbon button, cracking of cap, and

burned, worn terminals (Fig. 1). Also check for bro-

ken distributor cap towers. If any of these conditions

are present the distributor cap and/or cables should

be replaced. When replacing the distributor cap, transfer cables

from the original cap to the new cap one at a time.

Ensure each cable is installed into the corresponding tower of the new cap. Fully seat the wires into the

towers. If necessary, refer to the appropriate engine

firing order diagram (Fig. 2 or Fig. 3).

Fig. 1 Distributor Cap Inspection

Ä

IGNITION SYSTEMS 8D - 1

Page 444 of 2438

Light scaling of the terminals can be cleaned with

a sharp knife. If the terminals are heavily scaled, re-

place the distributor cap. A cap that is greasy, dirty or has a powder-like

substance on the inside should be cleaned with a so-

lution of warm water and a mild detergent. Scrub

the cap with a soft brush. Thoroughly rinse the cap

and dry it with a clean soft cloth.

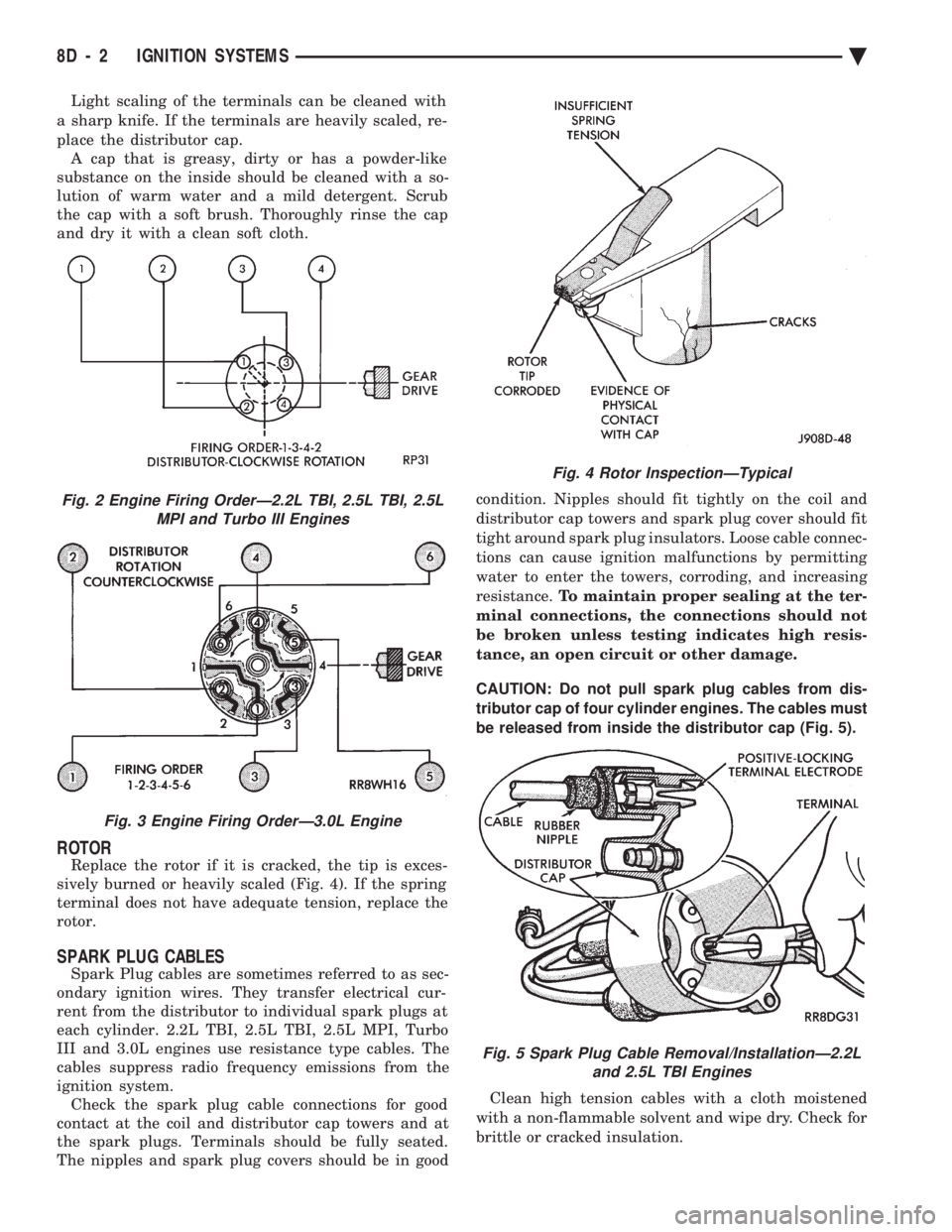

ROTOR

Replace the rotor if it is cracked, the tip is exces-

sively burned or heavily scaled (Fig. 4). If the spring

terminal does not have adequate tension, replace the

rotor.

SPARK PLUG CABLES

Spark Plug cables are sometimes referred to as sec-

ondary ignition wires. They transfer electrical cur-

rent from the distributor to individual spark plugs at

each cylinder. 2.2L TBI, 2.5L TBI, 2.5L MPI, Turbo

III and 3.0L engines use resistance type cables. The

cables suppress radio frequency emissions from the

ignition system. Check the spark plug cable connections for good

contact at the coil and distributor cap towers and at

the spark plugs. Terminals should be fully seated.

The nipples and spark plug covers should be in good condition. Nipples should fit tightly on the coil and

distributor cap towers and spark plug cover should fit

tight around spark plug insulators. Loose cable connec-

tions can cause ignition malfunctions by permitting

water to enter the towers, corroding, and increasing

resistance. To maintain proper sealing at the ter-

minal connections, the connections should not

be broken unless testing indicates high resis-

tance, an open circuit or other damage.

CAUTION: Do not pull spark plug cables from dis-

tributor cap of four cylinder engines. The cables must

be released from inside the distributor cap (Fig. 5).

Clean high tension cables with a cloth moistened

with a non-flammable solvent and wipe dry. Check for

brittle or cracked insulation.

Fig. 2 Engine Firing OrderÐ2.2L TBI, 2.5L TBI, 2.5L MPI and Turbo III Engines

Fig. 3 Engine Firing OrderÐ3.0L Engine

Fig. 4 Rotor InspectionÐTypical

Fig. 5 Spark Plug Cable Removal/InstallationÐ2.2L and 2.5L TBI Engines

8D - 2 IGNITION SYSTEMS Ä