tow CHEVROLET DYNASTY 1993 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 444 of 2438

Light scaling of the terminals can be cleaned with

a sharp knife. If the terminals are heavily scaled, re-

place the distributor cap. A cap that is greasy, dirty or has a powder-like

substance on the inside should be cleaned with a so-

lution of warm water and a mild detergent. Scrub

the cap with a soft brush. Thoroughly rinse the cap

and dry it with a clean soft cloth.

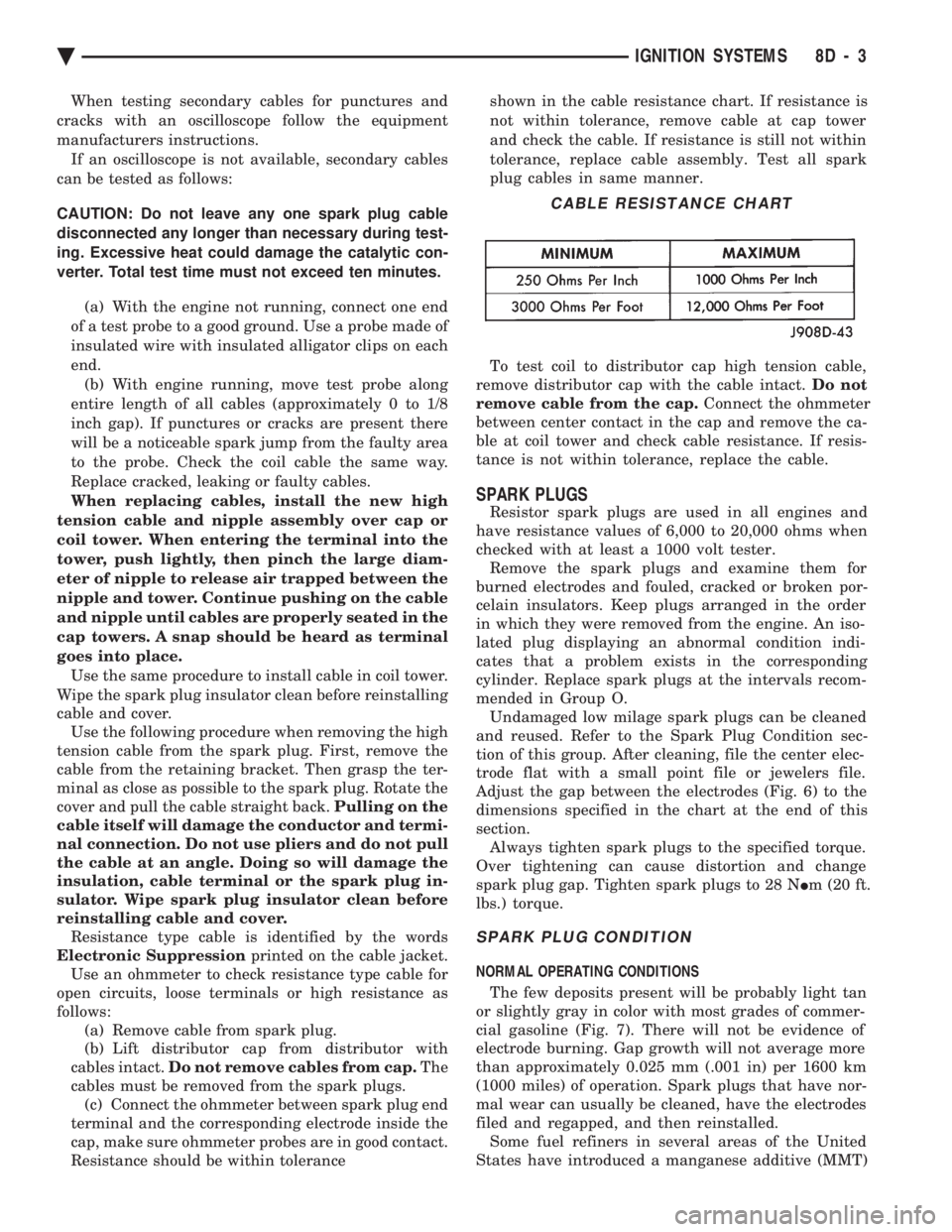

ROTOR

Replace the rotor if it is cracked, the tip is exces-

sively burned or heavily scaled (Fig. 4). If the spring

terminal does not have adequate tension, replace the

rotor.

SPARK PLUG CABLES

Spark Plug cables are sometimes referred to as sec-

ondary ignition wires. They transfer electrical cur-

rent from the distributor to individual spark plugs at

each cylinder. 2.2L TBI, 2.5L TBI, 2.5L MPI, Turbo

III and 3.0L engines use resistance type cables. The

cables suppress radio frequency emissions from the

ignition system. Check the spark plug cable connections for good

contact at the coil and distributor cap towers and at

the spark plugs. Terminals should be fully seated.

The nipples and spark plug covers should be in good condition. Nipples should fit tightly on the coil and

distributor cap towers and spark plug cover should fit

tight around spark plug insulators. Loose cable connec-

tions can cause ignition malfunctions by permitting

water to enter the towers, corroding, and increasing

resistance. To maintain proper sealing at the ter-

minal connections, the connections should not

be broken unless testing indicates high resis-

tance, an open circuit or other damage.

CAUTION: Do not pull spark plug cables from dis-

tributor cap of four cylinder engines. The cables must

be released from inside the distributor cap (Fig. 5).

Clean high tension cables with a cloth moistened

with a non-flammable solvent and wipe dry. Check for

brittle or cracked insulation.

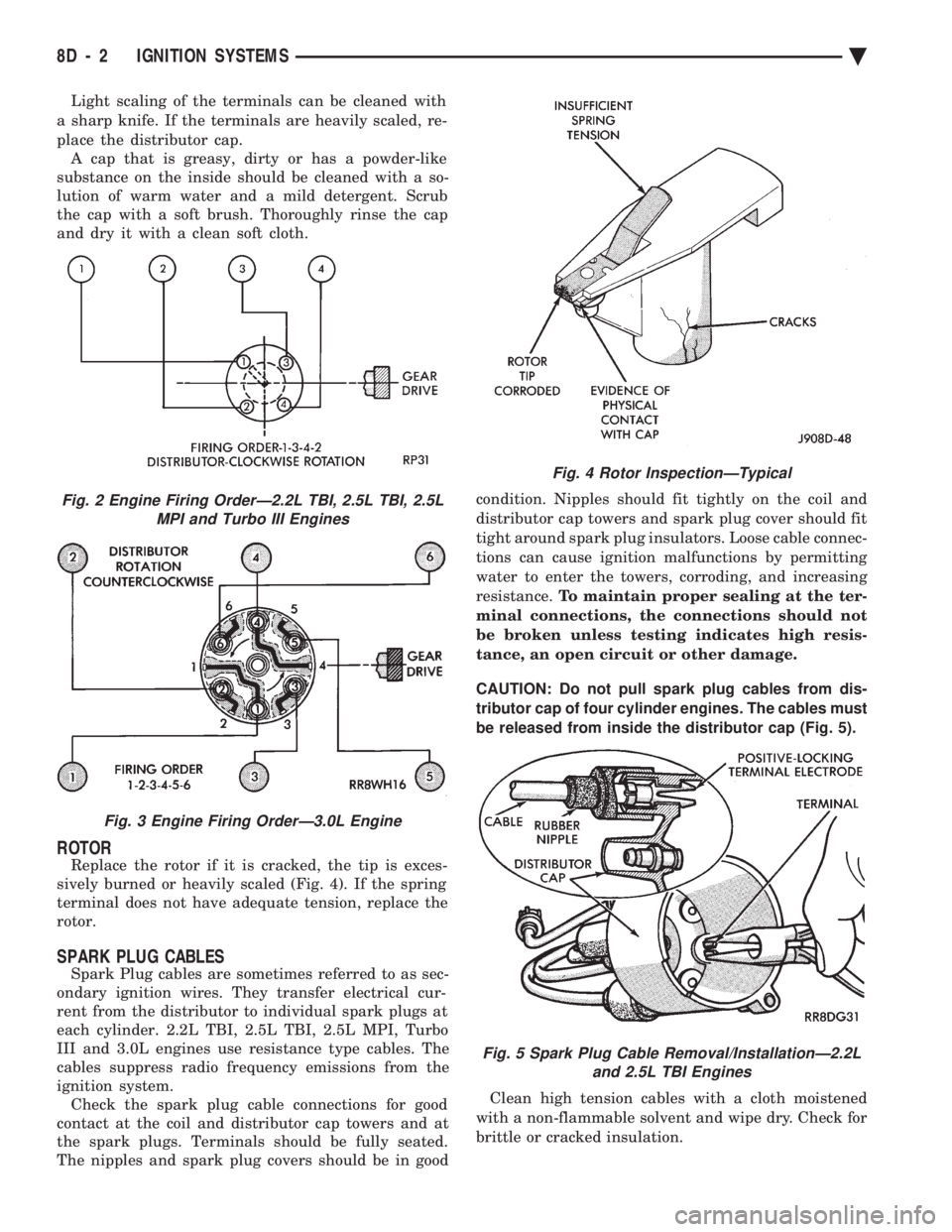

Fig. 2 Engine Firing OrderÐ2.2L TBI, 2.5L TBI, 2.5L MPI and Turbo III Engines

Fig. 3 Engine Firing OrderÐ3.0L Engine

Fig. 4 Rotor InspectionÐTypical

Fig. 5 Spark Plug Cable Removal/InstallationÐ2.2L and 2.5L TBI Engines

8D - 2 IGNITION SYSTEMS Ä

Page 445 of 2438

When testing secondary cables for punctures and

cracks with an oscilloscope follow the equipment

manufacturers instructions. If an oscilloscope is not available, secondary cables

can be tested as follows:

CAUTION: Do not leave any one spark plug cable

disconnected any longer than necessary during test-

ing. Excessive heat could damage the catalytic con-

verter. Total test time must not exceed ten minutes.

(a) With the engine not running, connect one end

of a test probe to a good ground. Use a probe made of

insulated wire with insulated alligator clips on each

end. (b) With engine running, move test probe along

entire length of all cables (approximately 0 to 1/8

inch gap). If punctures or cracks are present there

will be a noticeable spark jump from the faulty area

to the probe. Check the coil cable the same way.

Replace cracked, leaking or faulty cables.

When replacing cables, install the new high

tension cable and nipple assembly over cap or

coil tower. When entering the terminal into the

tower, push lightly, then pinch the large diam-

eter of nipple to release air trapped between the

nipple and tower. Continue pushing on the cable

and nipple until cables are properly seated in the

cap towers. A snap should be heard as terminal

goes into place. Use the same procedure to install cable in coil tower.

Wipe the spark plug insulator clean before reinstalling

cable and cover. Use the following procedure when removing the high

tension cable from the spark plug. First, remove the

cable from the retaining bracket. Then grasp the ter-

minal as close as possible to the spark plug. Rotate the

cover and pull the cable straight back. Pulling on the

cable itself will damage the conductor and termi-

nal connection. Do not use pliers and do not pull

the cable at an angle. Doing so will damage the

insulation, cable terminal or the spark plug in-

sulator. Wipe spark plug insulator clean before

reinstalling cable and cover. Resistance type cable is identified by the words

Electronic Suppression printed on the cable jacket.

Use an ohmmeter to check resistance type cable for

open circuits, loose terminals or high resistance as

follows: (a) Remove cable from spark plug.

(b) Lift distributor cap from distributor with

cables intact. Do not remove cables from cap. The

cables must be removed from the spark plugs. (c) Connect the ohmmeter between spark plug end

terminal and the corresponding electrode inside the

cap, make sure ohmmeter probes are in good contact.

Resistance should be within tolerance shown in the cable resistance chart. If resistance is

not within tolerance, remove cable at cap tower

and check the cable. If resistance is still not within

tolerance, replace cable assembly. Test all spark

plug cables in same manner.

To test coil to distributor cap high tension cable,

remove distributor cap with the cable intact. Do not

remove cable from the cap. Connect the ohmmeter

between center contact in the cap and remove the ca-

ble at coil tower and check cable resistance. If resis-

tance is not within tolerance, replace the cable.

SPARK PLUGS

Resistor spark plugs are used in all engines and

have resistance values of 6,000 to 20,000 ohms when

checked with at least a 1000 volt tester. Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indi-

cates that a problem exists in the corresponding

cylinder. Replace spark plugs at the intervals recom-

mended in Group O. Undamaged low milage spark plugs can be cleaned

and reused. Refer to the Spark Plug Condition sec-

tion of this group. After cleaning, file the center elec-

trode flat with a small point file or jewelers file.

Adjust the gap between the electrodes (Fig. 6) to the

dimensions specified in the chart at the end of this

section. Always tighten spark plugs to the specified torque.

Over tightening can cause distortion and change

spark plug gap. Tighten spark plugs to 28 N Im (20 ft.

lbs.) torque.

SPARK PLUG CONDITION

NORMAL OPERATING CONDITIONS

The few deposits present will be probably light tan

or slightly gray in color with most grades of commer-

cial gasoline (Fig. 7). There will not be evidence of

electrode burning. Gap growth will not average more

than approximately 0.025 mm (.001 in) per 1600 km

(1000 miles) of operation. Spark plugs that have nor-

mal wear can usually be cleaned, have the electrodes

filed and regapped, and then reinstalled. Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

CABLE RESISTANCE CHART

Ä IGNITION SYSTEMS 8D - 3

Page 451 of 2438

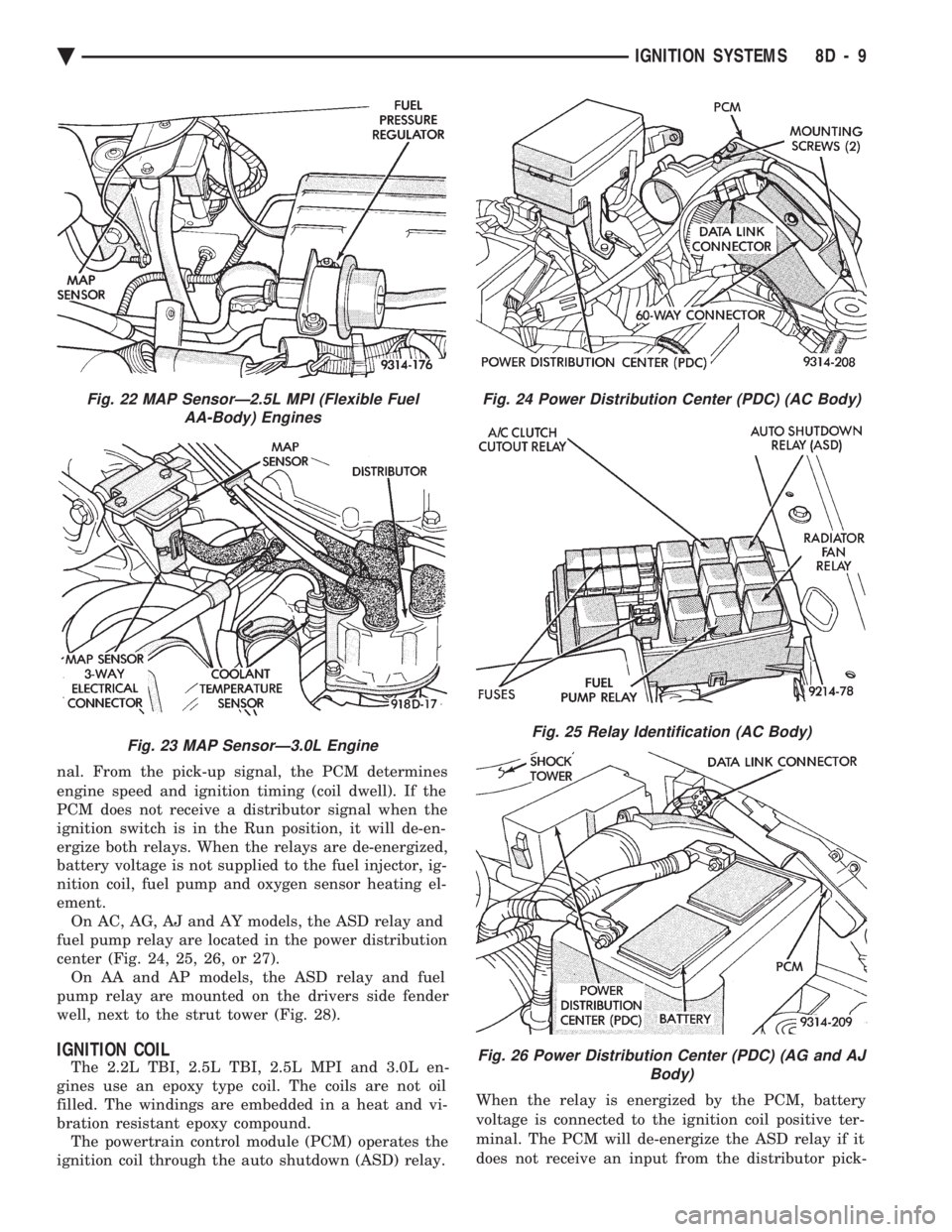

nal. From the pick-up signal, the PCM determines

engine speed and ignition timing (coil dwell). If the

PCM does not receive a distributor signal when the

ignition switch is in the Run position, it will de-en-

ergize both relays. When the relays are de-energized,

battery voltage is not supplied to the fuel injector, ig-

nition coil, fuel pump and oxygen sensor heating el-

ement. On AC, AG, AJ and AY models, the ASD relay and

fuel pump relay are located in the power distribution

center (Fig. 24, 25, 26, or 27). On AA and AP models, the ASD relay and fuel

pump relay are mounted on the drivers side fender

well, next to the strut tower (Fig. 28).

IGNITION COIL

The 2.2L TBI, 2.5L TBI, 2.5L MPI and 3.0L en-

gines use an epoxy type coil. The coils are not oil

filled. The windings are embedded in a heat and vi-

bration resistant epoxy compound. The powertrain control module (PCM) operates the

ignition coil through the auto shutdown (ASD) relay. When the relay is energized by the PCM, battery

voltage is connected to the ignition coil positive ter-

minal. The PCM will de-energize the ASD relay if it

does not receive an input from the distributor pick-

Fig. 22 MAP SensorÐ2.5L MPI (Flexible Fuel AA-Body) Engines

Fig. 23 MAP SensorÐ3.0L Engine

Fig. 24 Power Distribution Center (PDC) (AC Body)

Fig. 25 Relay Identification (AC Body)

Fig. 26 Power Distribution Center (PDC) (AG and AJ Body)

Ä IGNITION SYSTEMS 8D - 9

Page 453 of 2438

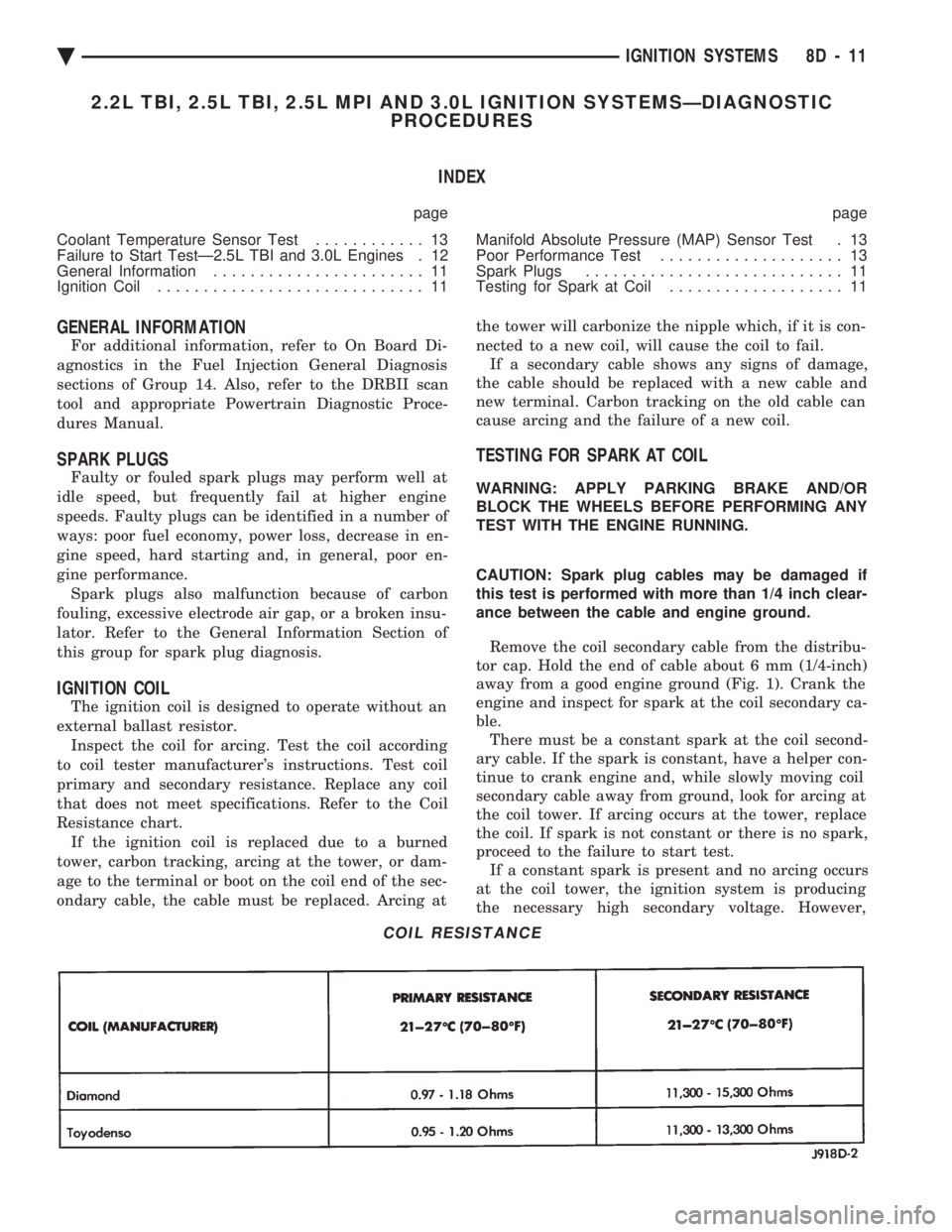

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐDIAGNOSTIC PROCEDURES

INDEX

page page

Coolant Temperature Sensor Test ............ 13

Failure to Start TestÐ2.5L TBI and 3.0L Engines . 12

General Information ....................... 11

Ignition Coil ............................. 11 Manifold Absolute Pressure (MAP) Sensor Test . 13

Poor Performance Test .................... 13

Spark Plugs ............................ 11

Testing for Spark at Coil ................... 11

GENERAL INFORMATION

For additional information, refer to On Board Di-

agnostics in the Fuel Injection General Diagnosis

sections of Group 14. Also, refer to the DRBII scan

tool and appropriate Powertrain Diagnostic Proce-

dures Manual.

SPARK PLUGS

Faulty or fouled spark plugs may perform well at

idle speed, but frequently fail at higher engine

speeds. Faulty plugs can be identified in a number of

ways: poor fuel economy, power loss, decrease in en-

gine speed, hard starting and, in general, poor en-

gine performance. Spark plugs also malfunction because of carbon

fouling, excessive electrode air gap, or a broken insu-

lator. Refer to the General Information Section of

this group for spark plug diagnosis.

IGNITION COIL

The ignition coil is designed to operate without an

external ballast resistor. Inspect the coil for arcing. Test the coil according

to coil tester manufacturer's instructions. Test coil

primary and secondary resistance. Replace any coil

that does not meet specifications. Refer to the Coil

Resistance chart. If the ignition coil is replaced due to a burned

tower, carbon tracking, arcing at the tower, or dam-

age to the terminal or boot on the coil end of the sec-

ondary cable, the cable must be replaced. Arcing at the tower will carbonize the nipple which, if it is con-

nected to a new coil, will cause the coil to fail. If a secondary cable shows any signs of damage,

the cable should be replaced with a new cable and

new terminal. Carbon tracking on the old cable can

cause arcing and the failure of a new coil.

TESTING FOR SPARK AT COIL

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK THE WHEELS BEFORE PERFORMING ANY

TEST WITH THE ENGINE RUNNING.

CAUTION: Spark plug cables may be damaged if

this test is performed with more than 1/4 inch clear-

ance between the cable and engine ground.

Remove the coil secondary cable from the distribu-

tor cap. Hold the end of cable about 6 mm (1/4-inch)

away from a good engine ground (Fig. 1). Crank the

engine and inspect for spark at the coil secondary ca-

ble. There must be a constant spark at the coil second-

ary cable. If the spark is constant, have a helper con-

tinue to crank engine and, while slowly moving coil

secondary cable away from ground, look for arcing at

the coil tower. If arcing occurs at the tower, replace

the coil. If spark is not constant or there is no spark,

proceed to the failure to start test. If a constant spark is present and no arcing occurs

at the coil tower, the ignition system is producing

the necessary high secondary voltage. However,

COIL RESISTANCE

Ä IGNITION SYSTEMS 8D - 11

Page 459 of 2438

Fig. 10). Turn distributor housing to adjust timing.

Tighten the hold-down arm screw and recheck timing.

(8) Turn the engine off. Remove timing light or

magnetic timing unit and tachometer. If the coolant

temperature sensor was disconnected, connect the sen-

sor and erase fault codes using the Erase Fault

Code Mode on the DRBII scan tool.

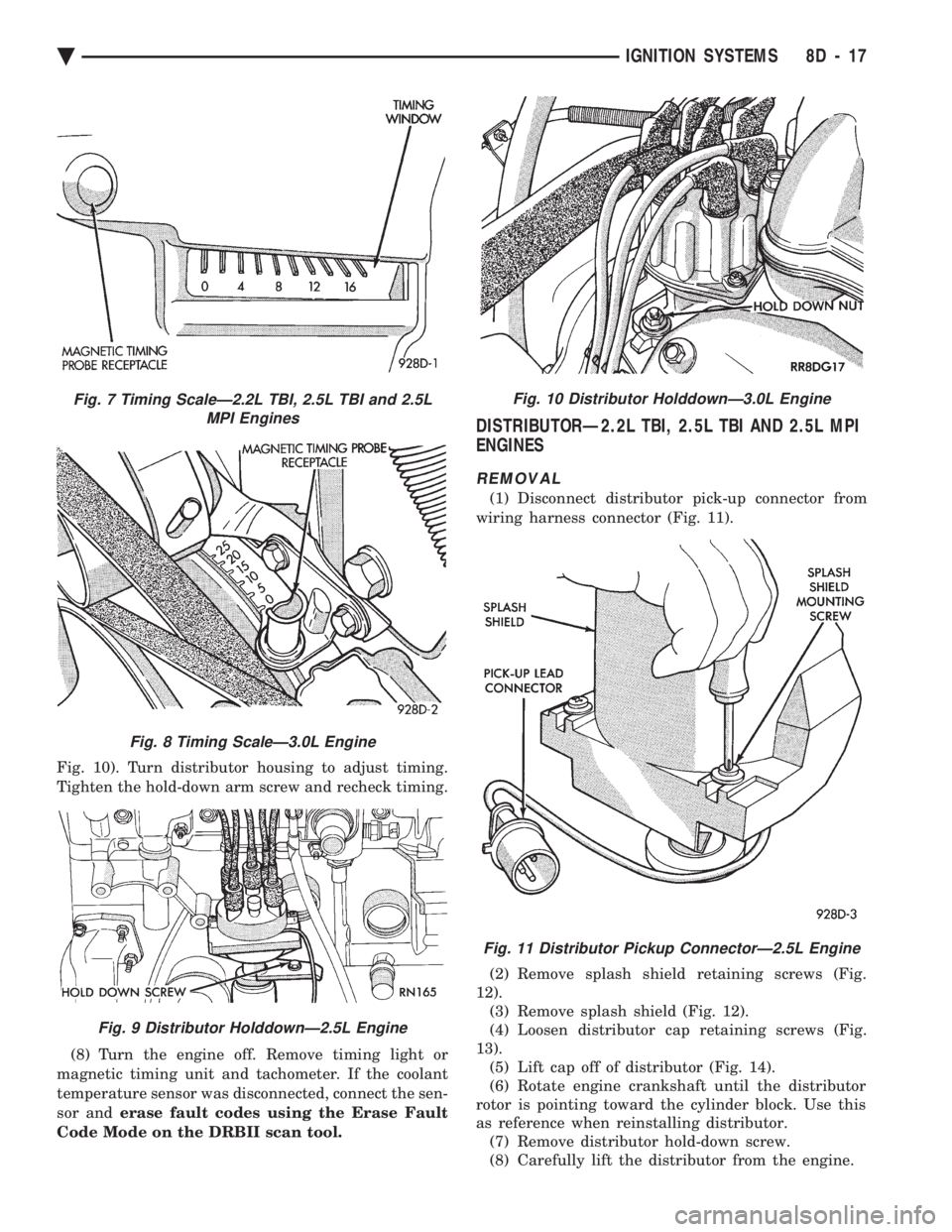

DISTRIBUTORÐ2.2L TBI, 2.5L TBI AND 2.5L MPI

ENGINES

REMOVAL

(1) Disconnect distributor pick-up connector from

wiring harness connector (Fig. 11).

(2) Remove splash shield retaining screws (Fig.

12). (3) Remove splash shield (Fig. 12).

(4) Loosen distributor cap retaining screws (Fig.

13). (5) Lift cap off of distributor (Fig. 14).

(6) Rotate engine crankshaft until the distributor

rotor is pointing toward the cylinder block. Use this

as reference when reinstalling distributor. (7) Remove distributor hold-down screw.

(8) Carefully lift the distributor from the engine.

Fig. 10 Distributor HolddownÐ3.0L Engine

Fig. 11 Distributor Pickup ConnectorÐ2.5L Engine

Fig. 7 Timing ScaleÐ2.2L TBI, 2.5L TBI and 2.5L MPI Engines

Fig. 8 Timing ScaleÐ3.0L Engine

Fig. 9 Distributor HolddownÐ2.5L Engine

Ä IGNITION SYSTEMS 8D - 17

Page 460 of 2438

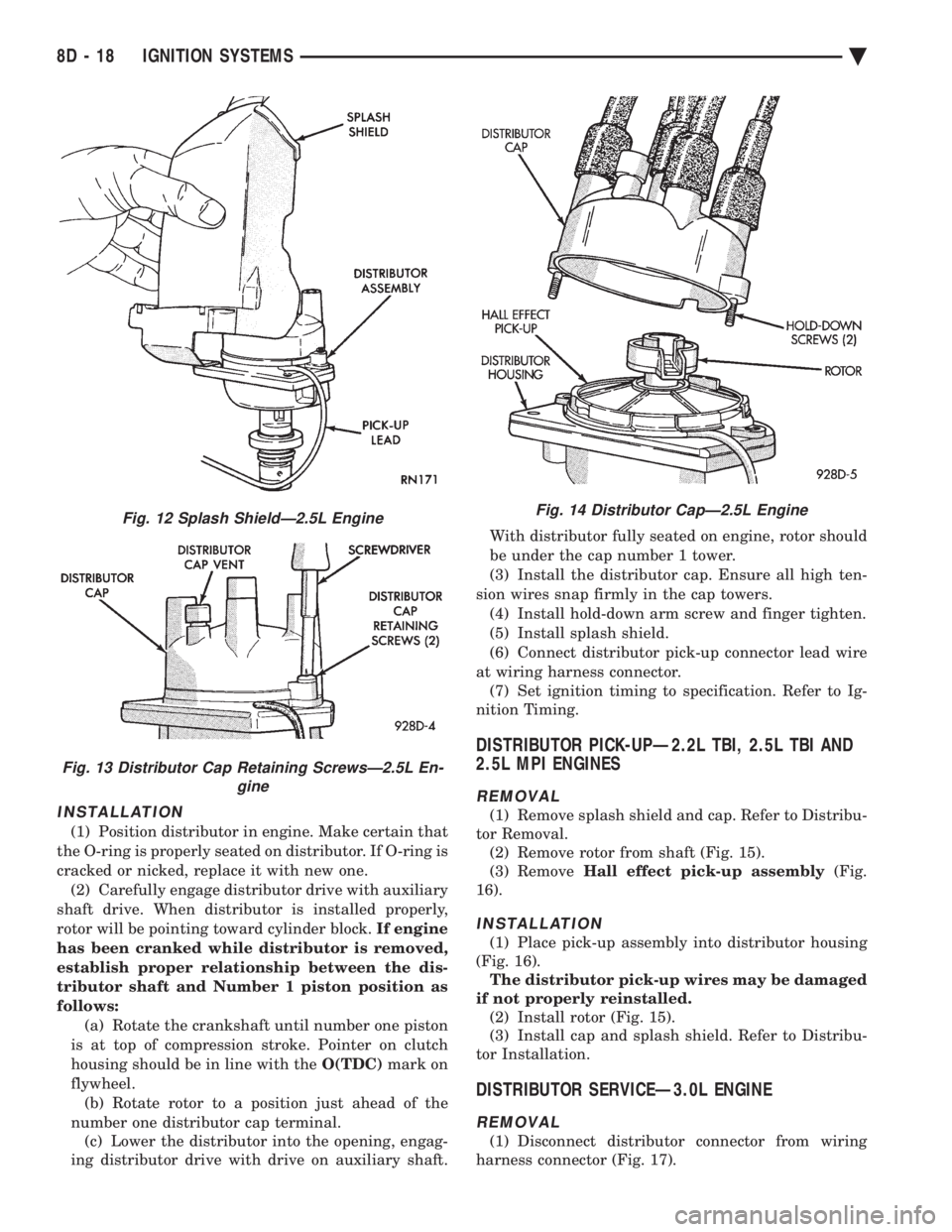

INSTALLATION

(1) Position distributor in engine. Make certain that

the O-ring is properly seated on distributor. If O-ring is

cracked or nicked, replace it with new one. (2) Carefully engage distributor drive with auxiliary

shaft drive. When distributor is installed properly,

rotor will be pointing toward cylinder block. If engine

has been cranked while distributor is removed,

establish proper relationship between the dis-

tributor shaft and Number 1 piston position as

follows: (a) Rotate the crankshaft until number one piston

is at top of compression stroke. Pointer on clutch

housing should be in line with the O(TDC)mark on

flywheel. (b) Rotate rotor to a position just ahead of the

number one distributor cap terminal. (c) Lower the distributor into the opening, engag-

ing distributor drive with drive on auxiliary shaft. With distributor fully seated on engine, rotor should

be under the cap number 1 tower.

(3) Install the distributor cap. Ensure all high ten-

sion wires snap firmly in the cap towers. (4) Install hold-down arm screw and finger tighten.

(5) Install splash shield.

(6) Connect distributor pick-up connector lead wire

at wiring harness connector. (7) Set ignition timing to specification. Refer to Ig-

nition Timing.

DISTRIBUTOR PICK-UPÐ2.2L TBI, 2.5L TBI AND

2.5L MPI ENGINES

REMOVAL

(1) Remove splash shield and cap. Refer to Distribu-

tor Removal. (2) Remove rotor from shaft (Fig. 15).

(3) Remove Hall effect pick-up assembly (Fig.

16).

INSTALLATION

(1) Place pick-up assembly into distributor housing

(Fig. 16). The distributor pick-up wires may be damaged

if not properly reinstalled. (2) Install rotor (Fig. 15).

(3) Install cap and splash shield. Refer to Distribu-

tor Installation.

DISTRIBUTOR SERVICEÐ3.0L ENGINE

REMOVAL

(1) Disconnect distributor connector from wiring

harness connector (Fig. 17).

Fig. 12 Splash ShieldÐ2.5L Engine

Fig. 13 Distributor Cap Retaining ScrewsÐ2.5L En- gine

Fig. 14 Distributor CapÐ2.5L Engine

8D - 18 IGNITION SYSTEMS Ä

Page 462 of 2438

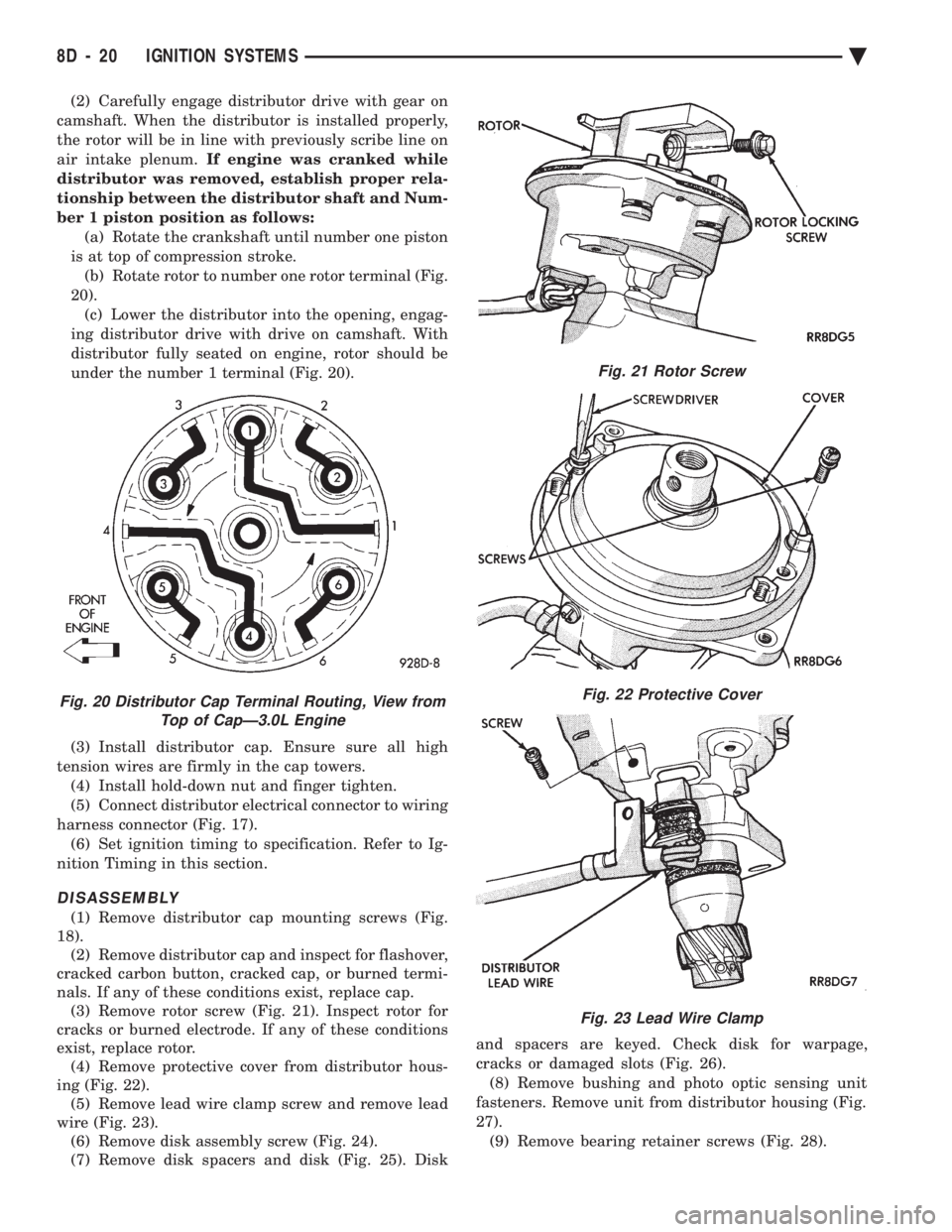

(2) Carefully engage distributor drive with gear on

camshaft. When the distributor is installed properly,

the rotor will be in line with previously scribe line on

air intake plenum. If engine was cranked while

distributor was removed, establish proper rela-

tionship between the distributor shaft and Num-

ber 1 piston position as follows: (a) Rotate the crankshaft until number one piston

is at top of compression stroke. (b) Rotate rotor to number one rotor terminal (Fig.

20). (c) Lower the distributor into the opening, engag-

ing distributor drive with drive on camshaft. With

distributor fully seated on engine, rotor should be

under the number 1 terminal (Fig. 20).

(3) Install distributor cap. Ensure sure all high

tension wires are firmly in the cap towers. (4) Install hold-down nut and finger tighten.

(5) Connect distributor electrical connector to wiring

harness connector (Fig. 17). (6) Set ignition timing to specification. Refer to Ig-

nition Timing in this section.

DISASSEMBLY

(1) Remove distributor cap mounting screws (Fig.

18). (2) Remove distributor cap and inspect for flashover,

cracked carbon button, cracked cap, or burned termi-

nals. If any of these conditions exist, replace cap. (3) Remove rotor screw (Fig. 21). Inspect rotor for

cracks or burned electrode. If any of these conditions

exist, replace rotor. (4) Remove protective cover from distributor hous-

ing (Fig. 22). (5) Remove lead wire clamp screw and remove lead

wire (Fig. 23). (6) Remove disk assembly screw (Fig. 24).

(7) Remove disk spacers and disk (Fig. 25). Disk and spacers are keyed. Check disk for warpage,

cracks or damaged slots (Fig. 26). (8) Remove bushing and photo optic sensing unit

fasteners. Remove unit from distributor housing (Fig.

27). (9) Remove bearing retainer screws (Fig. 28).

Fig. 21 Rotor Screw

Fig. 22 Protective Cover

Fig. 23 Lead Wire Clamp

Fig. 20 Distributor Cap Terminal Routing, View from Top of CapÐ3.0L Engine

8D - 20 IGNITION SYSTEMS Ä

Page 468 of 2438

tance. The cables provide suppression of radio fre-

quency emissions from the ignition system.Check the spark plug cable connections for good

contact at the coil and distributor cap towers and at

the spark plugs. Terminals should be fully seated.

The nipples and spark plug covers should be in good

condition. Nipples should fit tightly on the coil and

distributor cap towers and spark plug cover should

fit tight around spark plug insulators. Loose cable

connections can cause ignition malfunctions by per-

mitting water to enter the towers, corroding, and in-

creasing resistance.

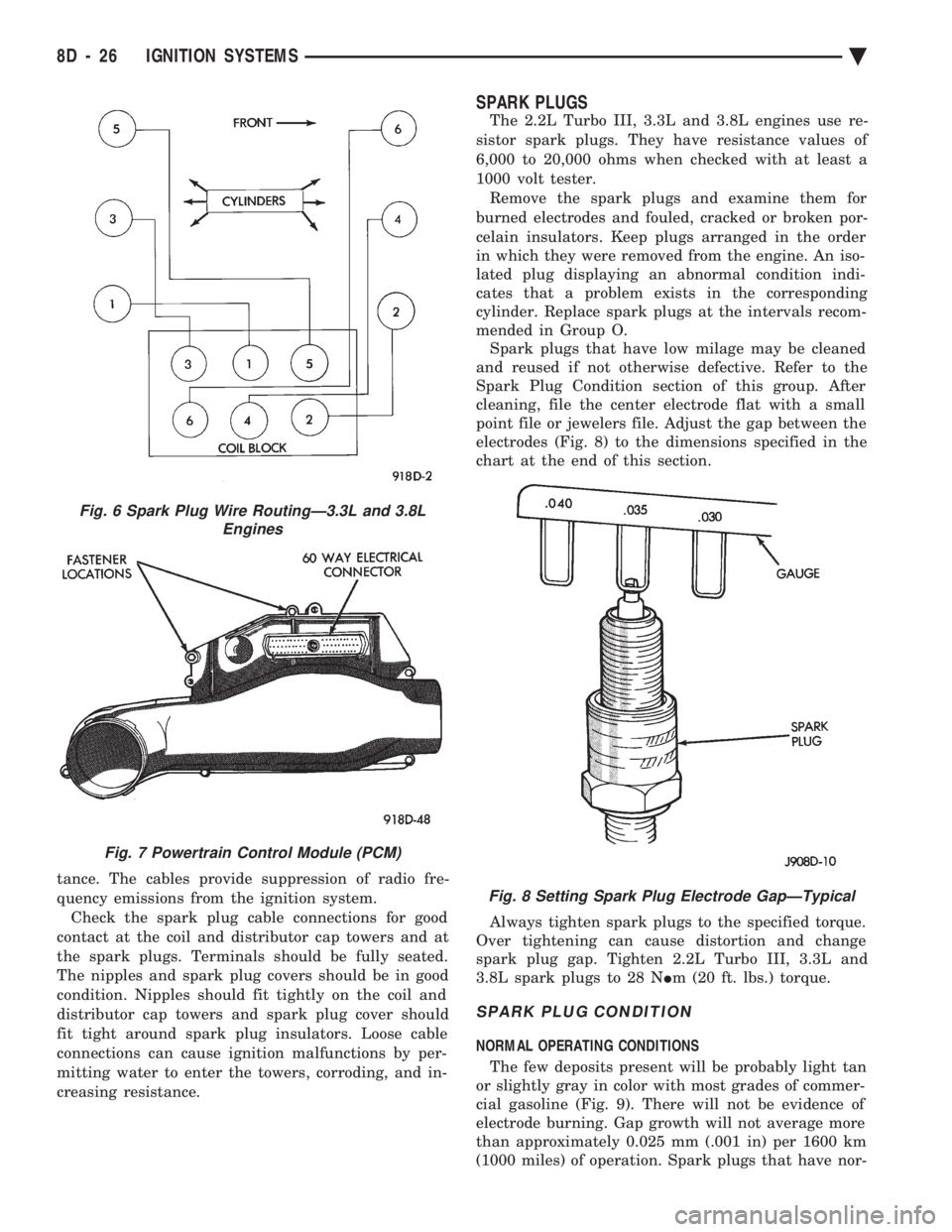

SPARK PLUGS

The 2.2L Turbo III, 3.3L and 3.8L engines use re-

sistor spark plugs. They have resistance values of

6,000 to 20,000 ohms when checked with at least a

1000 volt tester. Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indi-

cates that a problem exists in the corresponding

cylinder. Replace spark plugs at the intervals recom-

mended in Group O. Spark plugs that have low milage may be cleaned

and reused if not otherwise defective. Refer to the

Spark Plug Condition section of this group. After

cleaning, file the center electrode flat with a small

point file or jewelers file. Adjust the gap between the

electrodes (Fig. 8) to the dimensions specified in the

chart at the end of this section.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion and change

spark plug gap. Tighten 2.2L Turbo III, 3.3L and

3.8L spark plugs to 28 N Im (20 ft. lbs.) torque.

SPARK PLUG CONDITION

NORMAL OPERATING CONDITIONS

The few deposits present will be probably light tan

or slightly gray in color with most grades of commer-

cial gasoline (Fig. 9). There will not be evidence of

electrode burning. Gap growth will not average more

than approximately 0.025 mm (.001 in) per 1600 km

(1000 miles) of operation. Spark plugs that have nor-

Fig. 6 Spark Plug Wire RoutingÐ3.3L and 3.8L Engines

Fig. 7 Powertrain Control Module (PCM)

Fig. 8 Setting Spark Plug Electrode GapÐTypical

8D - 26 IGNITION SYSTEMS Ä

Page 475 of 2438

The ASD relay connects battery voltage to the fuel

injector and ignition coil. The fuel pump relay con-

nects battery voltage to the fuel pump and oxygen

sensor heating element. The PCM turns the ground path off when the igni-

tion switch is in the Off position. Both relays are off.

When the ignition switch is in the On or Crank po-

sition, the PCM monitors the camshaft position sen-

sor and crankshaft position sensor signals. From

these inputs, the PCM determines engine speed and

ignition timing (coil dwell). If the PCM does not re-

ceive a camshaft position sensor signal when the ig-

nition switch is in the Run position, it will de-

energize both relays. When the relays are de-

energized, battery voltage is not supplied to the fuel

injector, ignition coil, fuel pump and oxygen sensor

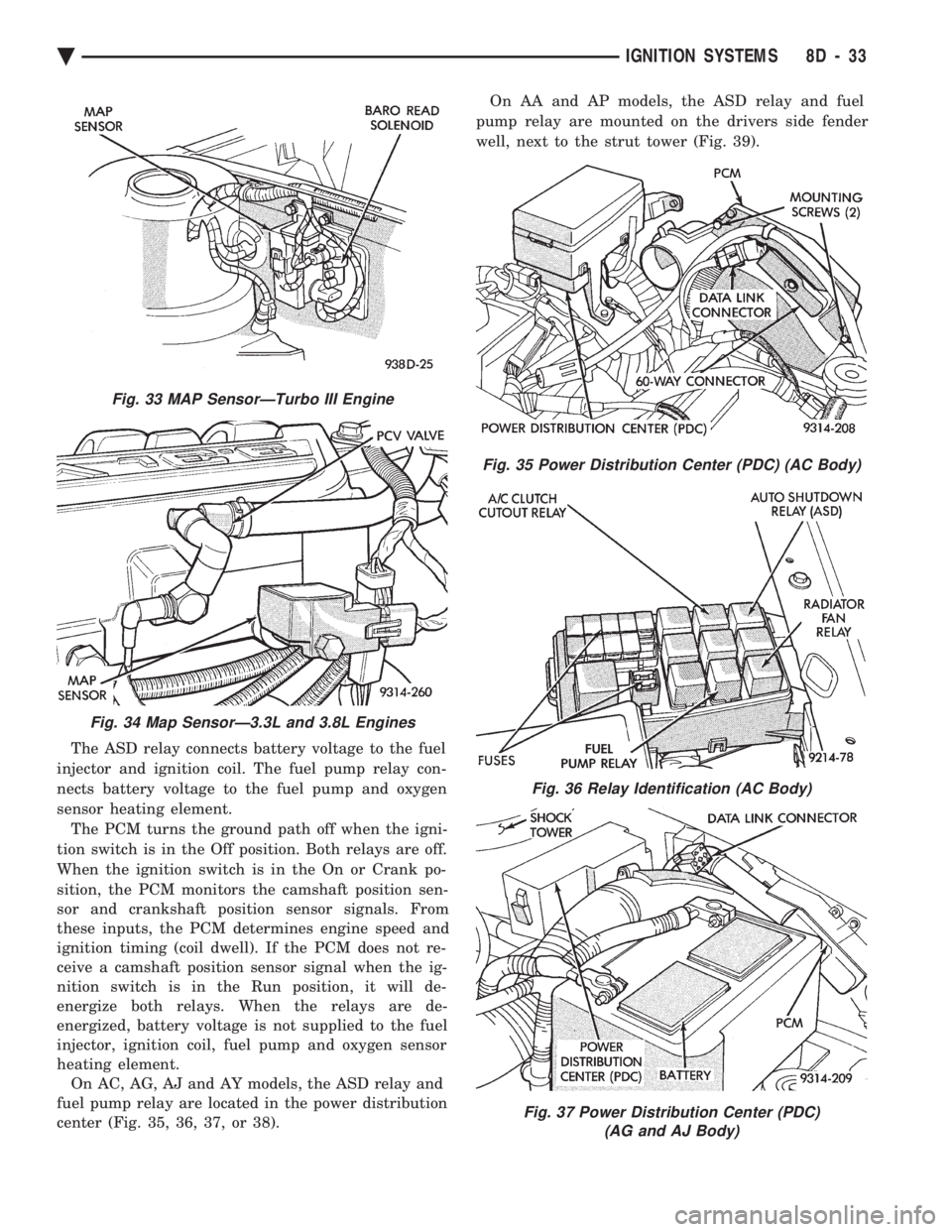

heating element. On AC, AG, AJ and AY models, the ASD relay and

fuel pump relay are located in the power distribution

center (Fig. 35, 36, 37, or 38). On AA and AP models, the ASD relay and fuel

pump relay are mounted on the drivers side fender

well, next to the strut tower (Fig. 39).

Fig. 33 MAP SensorÐTurbo III Engine

Fig. 34 Map SensorÐ3.3L and 3.8L Engines

Fig. 35 Power Distribution Center (PDC) (AC Body)

Fig. 36 Relay Identification (AC Body)

Fig. 37 Power Distribution Center (PDC) (AG and AJ Body)

Ä IGNITION SYSTEMS 8D - 33

Page 477 of 2438

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMÐDIAGNOSTIC PROCEDURES INDEX

page page

Check Coil TestÐ3.3L and 3.8L Engines ...... 36

Check Coil TestÐTurbo III Engine ........... 35

Coolant Temperature Sensor Test ............ 38

Crankshaft Position Sensor and Camshaft Position Sensor Tests .......................... 38 Failure to Start Test

...................... 37

Failure to Start TestÐTurbo III Engine ........ 36

Manifold Absolute Pressure (MAP) Sensor Test . 38

Testing for Spark at CoilÐ3.3L and 3.8L Engines . 36

Testing for Spark at CoilÐTurbo III Engine ..... 35

TESTING FOR SPARK AT COILÐTURBO III ENGINE

WARNING: THE DIRECT IGNITION SYSTEM GENER-

ATES APPROXIMATELY 40,000 VOLTS. PERSONAL

INJURY COULD RESULT FROM CONTACT WITH

THIS SYSTEM.

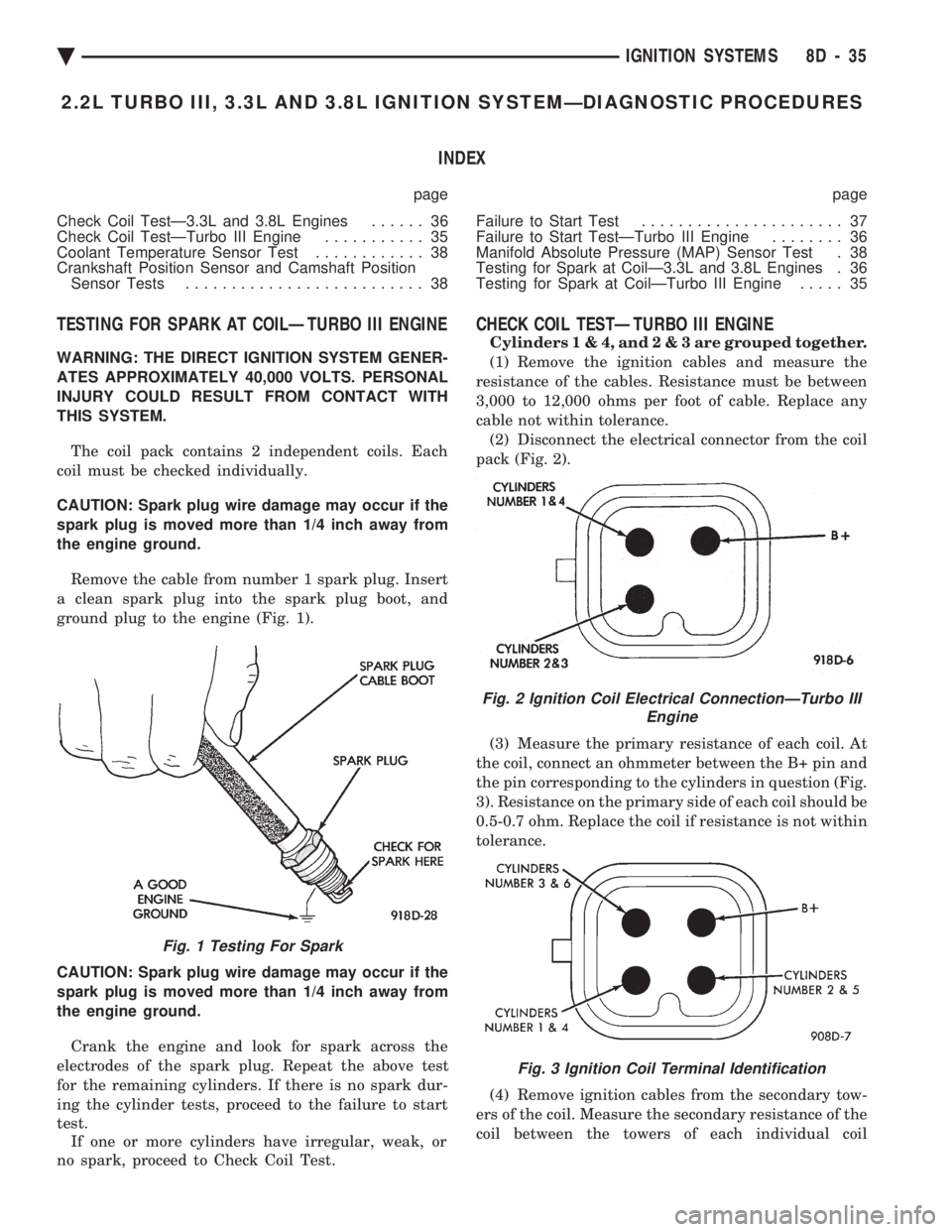

The coil pack contains 2 independent coils. Each

coil must be checked individually.

CAUTION: Spark plug wire damage may occur if the

spark plug is moved more than 1/4 inch away from

the engine ground.

Remove the cable from number 1 spark plug. Insert

a clean spark plug into the spark plug boot, and

ground plug to the engine (Fig. 1).

CAUTION: Spark plug wire damage may occur if the

spark plug is moved more than 1/4 inch away from

the engine ground. Crank the engine and look for spark across the

electrodes of the spark plug. Repeat the above test

for the remaining cylinders. If there is no spark dur-

ing the cylinder tests, proceed to the failure to start

test. If one or more cylinders have irregular, weak, or

no spark, proceed to Check Coil Test.

CHECK COIL TESTÐTURBO III ENGINE

Cylinder s1&4,and2&3are grouped together.

(1) Remove the ignition cables and measure the

resistance of the cables. Resistance must be between

3,000 to 12,000 ohms per foot of cable. Replace any

cable not within tolerance. (2) Disconnect the electrical connector from the coil

pack (Fig. 2).

(3) Measure the primary resistance of each coil. At

the coil, connect an ohmmeter between the B+ pin and

the pin corresponding to the cylinders in question (Fig.

3). Resistance on the primary side of each coil should be

0.5-0.7 ohm. Replace the coil if resistance is not within

tolerance.

(4) Remove ignition cables from the secondary tow-

ers of the coil. Measure the secondary resistance of the

coil between the towers of each individual coil

Fig. 1 Testing For Spark

Fig. 2 Ignition Coil Electrical ConnectionÐTurbo III Engine

Fig. 3 Ignition Coil Terminal Identification

Ä IGNITION SYSTEMS 8D - 35