roof CHEVROLET DYNASTY 1993 Manual PDF

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2280 of 2438

(7) Install lower portion of rear window in position

on rear tack strip, align to the bottom center mark. (8) Staple the corners of the rear window valance

and carrier to the rear tack strip. Verify the edges

are even. (9) Position rear stay pads and suspender straps

over fourth roof bow and over the outboard ends of

the rear window fabric. (10) Stretch lower end of suspender straps to edge

of rear tack strip. (11) Staple lower end of suspender straps to rear

tack strip. (12) Staple lower end of rear stay pad to rear tack

strip. (13) Position top cover retainer channel on fourth

roof bow. (14) Rivet top cover retainer channel to fourth roof

bow with aluminum pop-rivets. (15) Position top cover over the fourth roof bow re-

tainer locating the centerline reference marks. (16) Slide feature strip insert into the fourth roof

bow retainer channel. (17) Position top cover on rear tack strip.

(18) Staple top cover to rear tack strip starting

from the outboard corner and stapling inward. (19) Position rear tack strip over the mounting

studs on inside of quarter panels. (20) Install nuts and bolts to hold rear tack strip to

the quarter panels an deck panel. (21) Install rear seat back.

(22) Remove protective materials that was applied

to the body during to removal operation.

TOP COVER

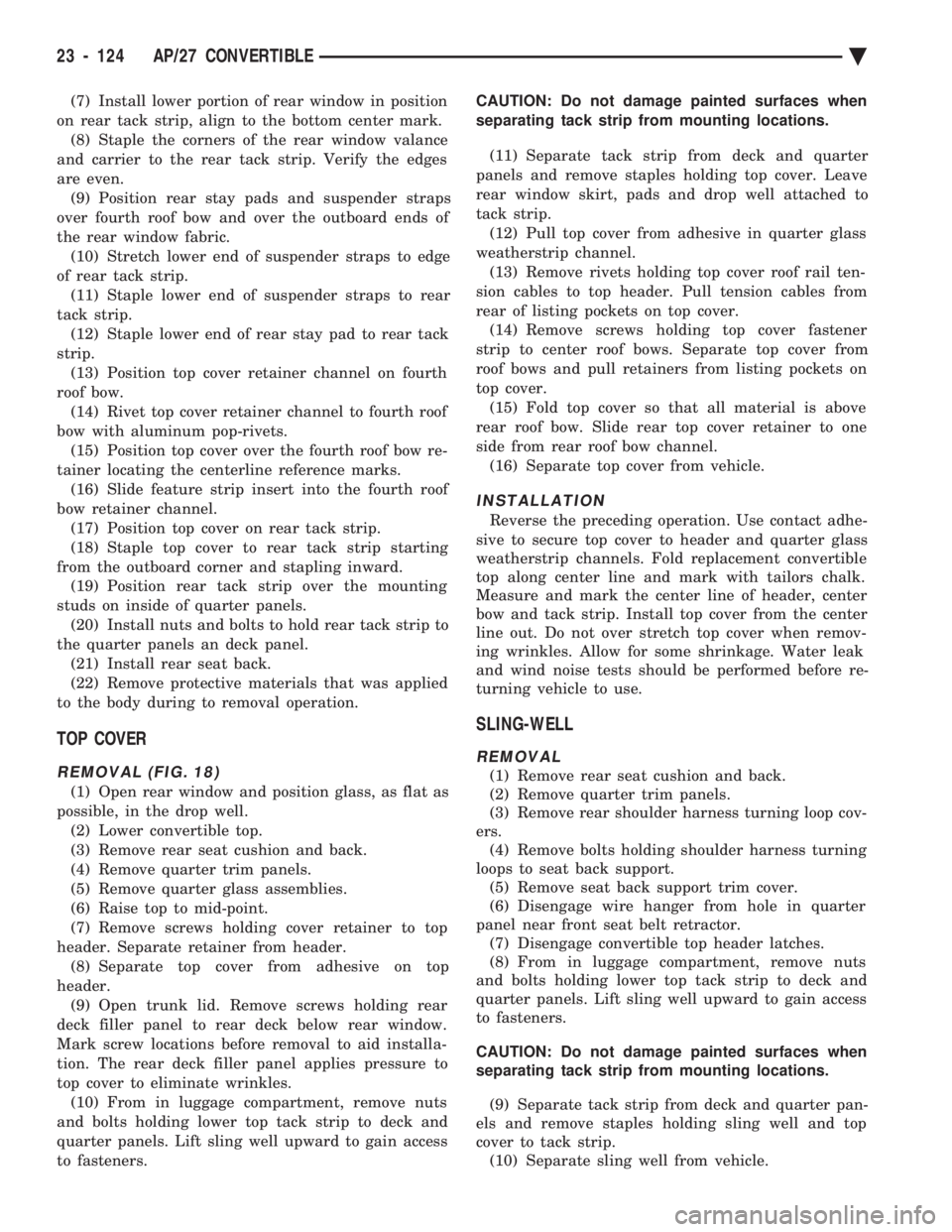

REMOVAL (FIG. 18)

(1) Open rear window and position glass, as flat as

possible, in the drop well. (2) Lower convertible top.

(3) Remove rear seat cushion and back.

(4) Remove quarter trim panels.

(5) Remove quarter glass assemblies.

(6) Raise top to mid-point.

(7) Remove screws holding cover retainer to top

header. Separate retainer from header. (8) Separate top cover from adhesive on top

header. (9) Open trunk lid. Remove screws holding rear

deck filler panel to rear deck below rear window.

Mark screw locations before removal to aid installa-

tion. The rear deck filler panel applies pressure to

top cover to eliminate wrinkles. (10) From in luggage compartment, remove nuts

and bolts holding lower top tack strip to deck and

quarter panels. Lift sling well upward to gain access

to fasteners. CAUTION: Do not damage painted surfaces when

separating tack strip from mounting locations.

(11) Separate tack strip from deck and quarter

panels and remove staples holding top cover. Leave

rear window skirt, pads and drop well attached to

tack strip. (12) Pull top cover from adhesive in quarter glass

weatherstrip channel. (13) Remove rivets holding top cover roof rail ten-

sion cables to top header. Pull tension cables from

rear of listing pockets on top cover. (14) Remove screws holding top cover fastener

strip to center roof bows. Separate top cover from

roof bows and pull retainers from listing pockets on

top cover. (15) Fold top cover so that all material is above

rear roof bow. Slide rear top cover retainer to one

side from rear roof bow channel. (16) Separate top cover from vehicle.

INSTALLATION

Reverse the preceding operation. Use contact adhe-

sive to secure top cover to header and quarter glass

weatherstrip channels. Fold replacement convertible

top along center line and mark with tailors chalk.

Measure and mark the center line of header, center

bow and tack strip. Install top cover from the center

line out. Do not over stretch top cover when remov-

ing wrinkles. Allow for some shrinkage. Water leak

and wind noise tests should be performed before re-

turning vehicle to use.

SLING-WELL

REMOVAL

(1) Remove rear seat cushion and back.

(2) Remove quarter trim panels.

(3) Remove rear shoulder harness turning loop cov-

ers. (4) Remove bolts holding shoulder harness turning

loops to seat back support. (5) Remove seat back support trim cover.

(6) Disengage wire hanger from hole in quarter

panel near front seat belt retractor. (7) Disengage convertible top header latches.

(8) From in luggage compartment, remove nuts

and bolts holding lower top tack strip to deck and

quarter panels. Lift sling well upward to gain access

to fasteners.

CAUTION: Do not damage painted surfaces when

separating tack strip from mounting locations.

(9) Separate tack strip from deck and quarter pan-

els and remove staples holding sling well and top

cover to tack strip. (10) Separate sling well from vehicle.

23 - 124 AP/27 CONVERTIBLE Ä

Page 2281 of 2438

INSTALLATION

Reverse the preceding operation. Use a suitable

contact adhesive to secure sling well to seat back

support and wherever necessary

TOP FRAME

REMOVAL

(1) Remove rear seat cushion and back.

(2) Remove quarter trim panels.

(3) Disengage convertible top header latches.

(4) From in luggage compartment, remove nuts

and bolts holding tack strip to deck and quarter pan-

els. Lift sling well upward to gain access to fasteners. (5) Separate sling well from seat back reinforce-

ment and wire hangers. (6) Lower convertible top.

(7) Remove bolts holding top frame to quarter

panel mounting supports. (8) Disconnect upper top lift assist cylinder mount-

ing. (9) Separate top frame from vehicle.

INSTALLATION

Reverse the preceding operation. Align top to

achieve proper sealing at roof rail and header weath-

erstrips.

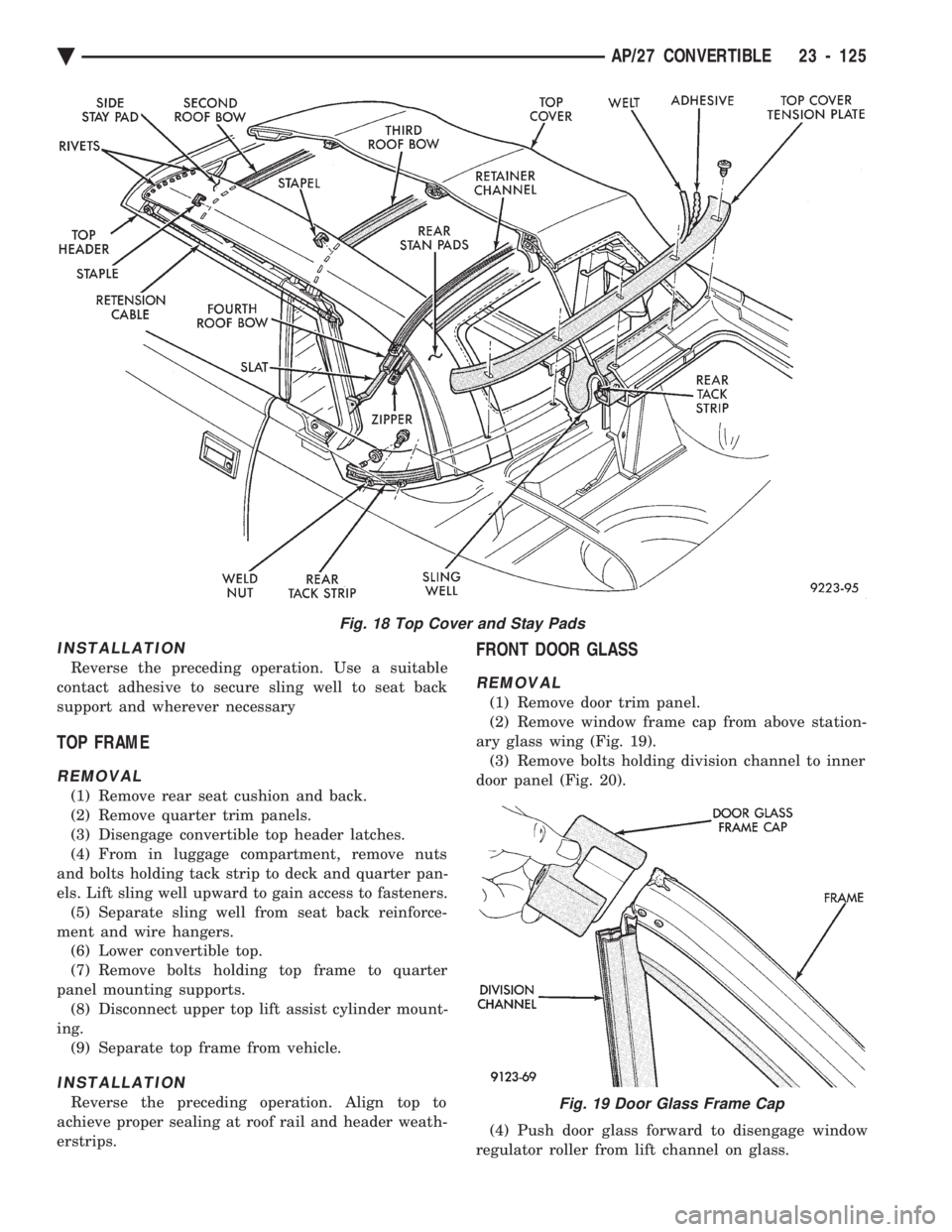

FRONT DOOR GLASS

REMOVAL

(1) Remove door trim panel.

(2) Remove window frame cap from above station-

ary glass wing (Fig. 19). (3) Remove bolts holding division channel to inner

door panel (Fig. 20).

(4) Push door glass forward to disengage window

regulator roller from lift channel on glass.

Fig. 18 Top Cover and Stay Pads

Fig. 19 Door Glass Frame Cap

Ä AP/27 CONVERTIBLE 23 - 125

Page 2287 of 2438

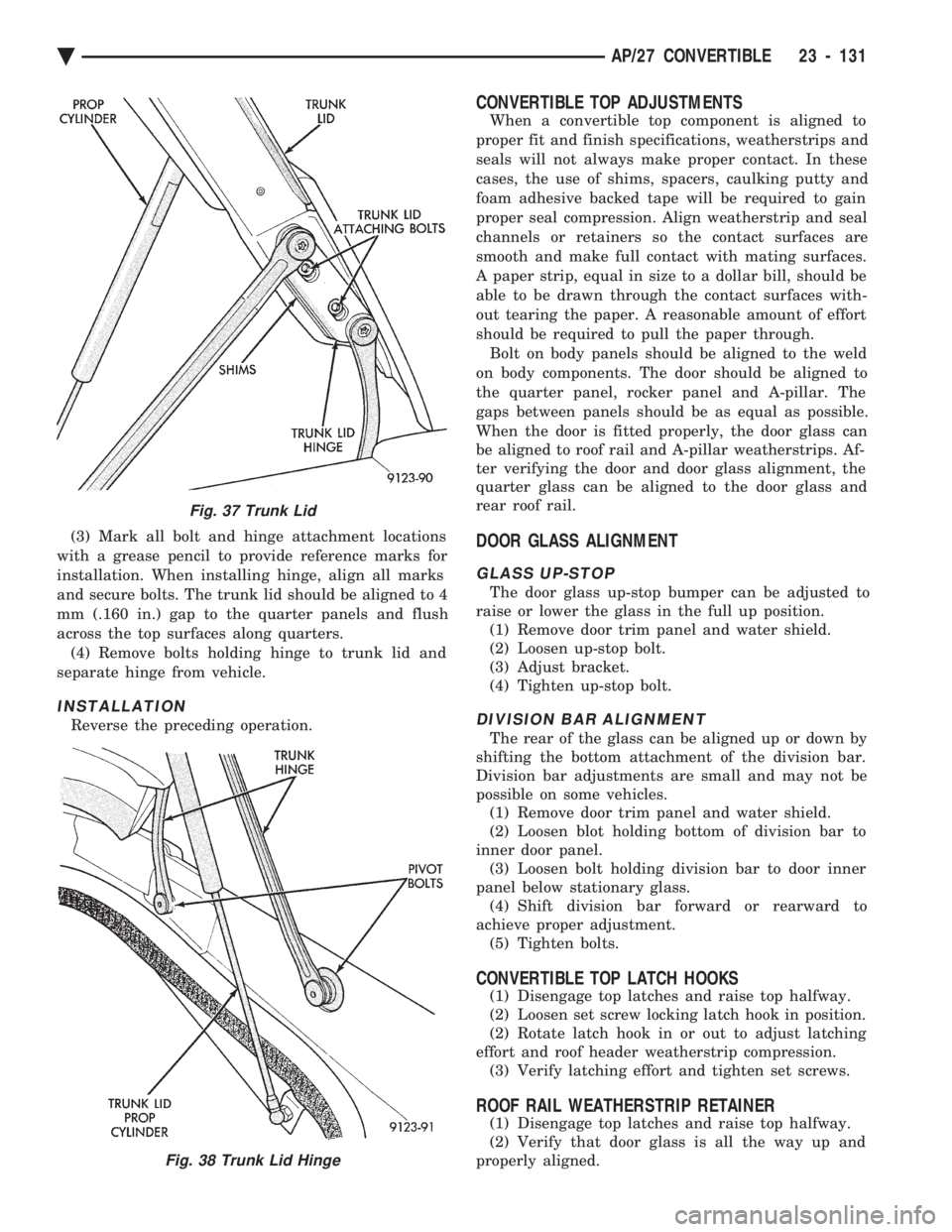

(3) Mark all bolt and hinge attachment locations

with a grease pencil to provide reference marks for

installation. When installing hinge, align all marks

and secure bolts. The trunk lid should be aligned to 4

mm (.160 in.) gap to the quarter panels and flush

across the top surfaces along quarters. (4) Remove bolts holding hinge to trunk lid and

separate hinge from vehicle.

INSTALLATION

Reverse the preceding operation.

CONVERTIBLE TOP ADJUSTMENTS

When a convertible top component is aligned to

proper fit and finish specifications, weatherstrips and

seals will not always make proper contact. In these

cases, the use of shims, spacers, caulking putty and

foam adhesive backed tape will be required to gain

proper seal compression. Align weatherstrip and seal

channels or retainers so the contact surfaces are

smooth and make full contact with mating surfaces.

A paper strip, equal in size to a dollar bill, should be

able to be drawn through the contact surfaces with-

out tearing the paper. A reasonable amount of effort

should be required to pull the paper through. Bolt on body panels should be aligned to the weld

on body components. The door should be aligned to

the quarter panel, rocker panel and A-pillar. The

gaps between panels should be as equal as possible.

When the door is fitted properly, the door glass can

be aligned to roof rail and A-pillar weatherstrips. Af-

ter verifying the door and door glass alignment, the

quarter glass can be aligned to the door glass and

rear roof rail.

DOOR GLASS ALIGNMENT

GLASS UP-STOP

The door glass up-stop bumper can be adjusted to

raise or lower the glass in the full up position. (1) Remove door trim panel and water shield.

(2) Loosen up-stop bolt.

(3) Adjust bracket.

(4) Tighten up-stop bolt.

DIVISION BAR ALIGNMENT

The rear of the glass can be aligned up or down by

shifting the bottom attachment of the division bar.

Division bar adjustments are small and may not be

possible on some vehicles. (1) Remove door trim panel and water shield.

(2) Loosen blot holding bottom of division bar to

inner door panel. (3) Loosen bolt holding division bar to door inner

panel below stationary glass. (4) Shift division bar forward or rearward to

achieve proper adjustment. (5) Tighten bolts.

CONVERTIBLE TOP LATCH HOOKS

(1) Disengage top latches and raise top halfway.

(2) Loosen set screw locking latch hook in position.

(2) Rotate latch hook in or out to adjust latching

effort and roof header weatherstrip compression. (3) Verify latching effort and tighten set screws.

ROOF RAIL WEATHERSTRIP RETAINER

(1) Disengage top latches and raise top halfway.

(2) Verify that door glass is all the way up and

properly aligned.

Fig. 37 Trunk Lid

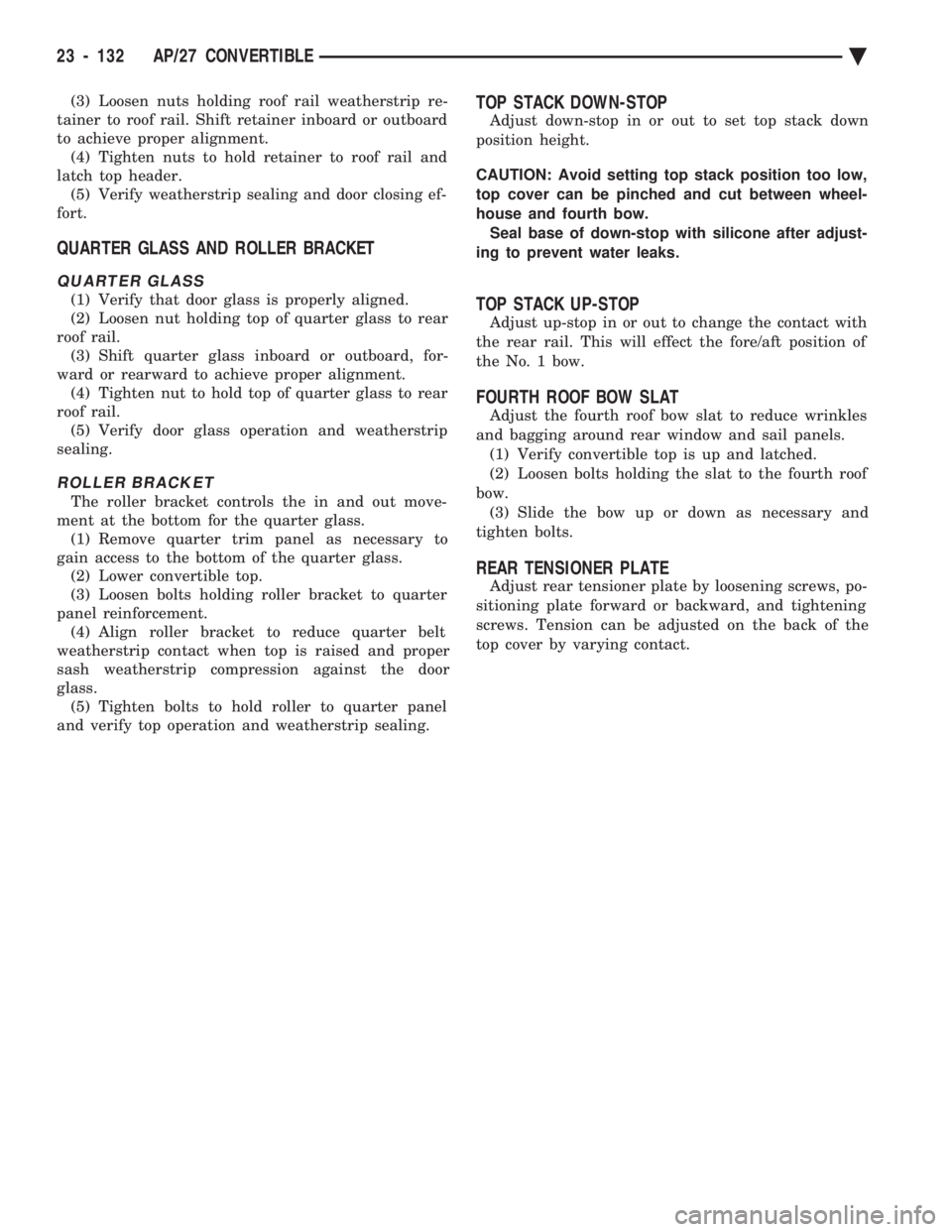

Fig. 38 Trunk Lid Hinge

Ä AP/27 CONVERTIBLE 23 - 131

Page 2288 of 2438

(3) Loosen nuts holding roof rail weatherstrip re-

tainer to roof rail. Shift retainer inboard or outboard

to achieve proper alignment. (4) Tighten nuts to hold retainer to roof rail and

latch top header. (5) Verify weatherstrip sealing and door closing ef-

fort.

QUARTER GLASS AND ROLLER BRACKET

QUARTER GLASS

(1) Verify that door glass is properly aligned.

(2) Loosen nut holding top of quarter glass to rear

roof rail. (3) Shift quarter glass inboard or outboard, for-

ward or rearward to achieve proper alignment. (4) Tighten nut to hold top of quarter glass to rear

roof rail. (5) Verify door glass operation and weatherstrip

sealing.

ROLLER BRACKET

The roller bracket controls the in and out move-

ment at the bottom for the quarter glass. (1) Remove quarter trim panel as necessary to

gain access to the bottom of the quarter glass. (2) Lower convertible top.

(3) Loosen bolts holding roller bracket to quarter

panel reinforcement. (4) Align roller bracket to reduce quarter belt

weatherstrip contact when top is raised and proper

sash weatherstrip compression against the door

glass. (5) Tighten bolts to hold roller to quarter panel

and verify top operation and weatherstrip sealing.

TOP STACK DOWN-STOP

Adjust down-stop in or out to set top stack down

position height.

CAUTION: Avoid setting top stack position too low,

top cover can be pinched and cut between wheel-

house and fourth bow. Seal base of down-stop with silicone after adjust-

ing to prevent water leaks.

TOP STACK UP-STOP

Adjust up-stop in or out to change the contact with

the rear rail. This will effect the fore/aft position of

the No. 1 bow.

FOURTH ROOF BOW SLAT

Adjust the fourth roof bow slat to reduce wrinkles

and bagging around rear window and sail panels. (1) Verify convertible top is up and latched.

(2) Loosen bolts holding the slat to the fourth roof

bow. (3) Slide the bow up or down as necessary and

tighten bolts.

REAR TENSIONER PLATE

Adjust rear tensioner plate by loosening screws, po-

sitioning plate forward or backward, and tightening

screws. Tension can be adjusted on the back of the

top cover by varying contact.

23 - 132 AP/27 CONVERTIBLE Ä

Page 2289 of 2438

AY-VEHICLE BODY COMPONENT SERVICE INDEX

page page

A-Pillar and Roof Rail Mouldings ............ 143

B-Pillar Trim Panel ...................... 143

Body Mouldings ......................... 146

Cowl Panel Trim and Scuff Plates ........... 143

Door Frame Trim Moulding ................ 137

Front Door and Hinge .................... 137

Front Door Glass ........................ 139

Front Door Latch ........................ 138

Front Door Silencer and Water Shield ........ 137

Front Door Trim Panel .................... 136

Front Door Window Regulator .............. 138

Front End Splash Shields ................. 136

Front Seat Belts ........................ 144

Front Seats ............................ 145

Grille AY/P Body ........................ 133

Grille AY/S Body ........................ 133

Grille Opening Panel AY/P Body ............ 134

Grille Opening Panel AY/S Body ............ 134

Head Lining ............................ 142

Hood and Hinges ....................... 134

Hood Latch and Release Cable ............. 135

Hood Ornament AY/P-S .................. 134

Outside Door Handle ..................... 138

Overhead Console ....................... 142 Quarter Trim Panel

...................... 143

Rear Deck Filler Panel ................... 146

Rear Door and Hinge .................... 140

Rear Door Fixed Glass Outer Cover ÐAY-S Body ......................... 141

Rear Door Fixed Window Module ........... 142

Rear Door Frame Trim Moulding ............ 139

Rear Door Glass ........................ 141

Rear Door Glass Lift Plate and Guide Bar ..... 141

Rear Door Latch ........................ 140

Rear Door Outer CoverÐAY-P Body ......... 141

Rear Door Outside Handle ................ 140

Rear Door Silencer and Water Shield ........ 140

Rear Door Trim Panel .................... 139

Rear Door Window Regulator .............. 141

Rear Seat Belts ......................... 144

Rear Seats ............................ 145

Rear Shelf Trim Panel .................... 144

Rear Window Glass ...................... 147

Side View Mirror Trim Cover ............... 137

Trunk Lid .............................. 147

Trunk Lid Hinge ........................ 147

Trunk Lid Torsion Bar .................... 148

Vinyl Roof Bonnet ....................... 146

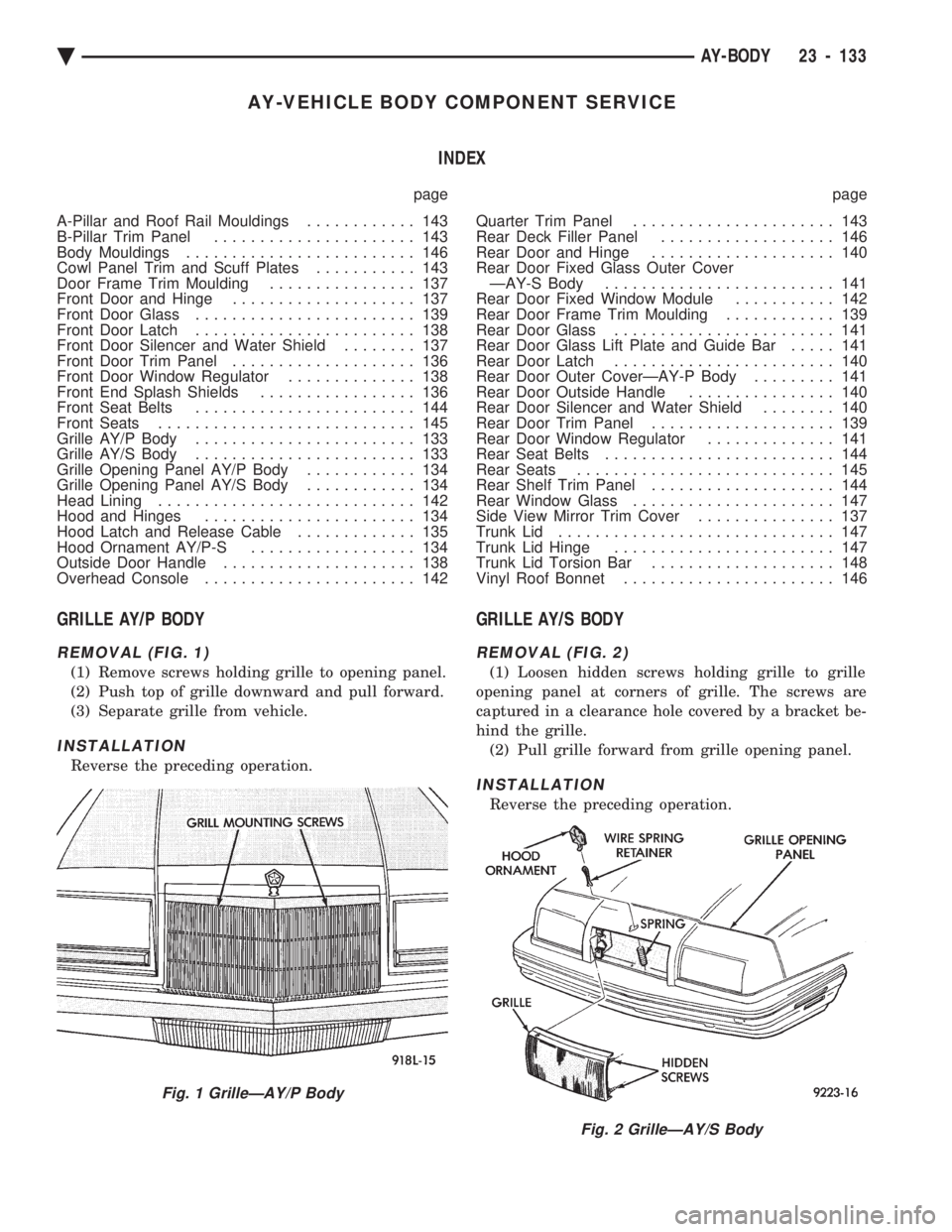

GRILLE AY/P BODY

REMOVAL (FIG. 1)

(1) Remove screws holding grille to opening panel.

(2) Push top of grille downward and pull forward.

(3) Separate grille from vehicle.

INSTALLATION

Reverse the preceding operation.

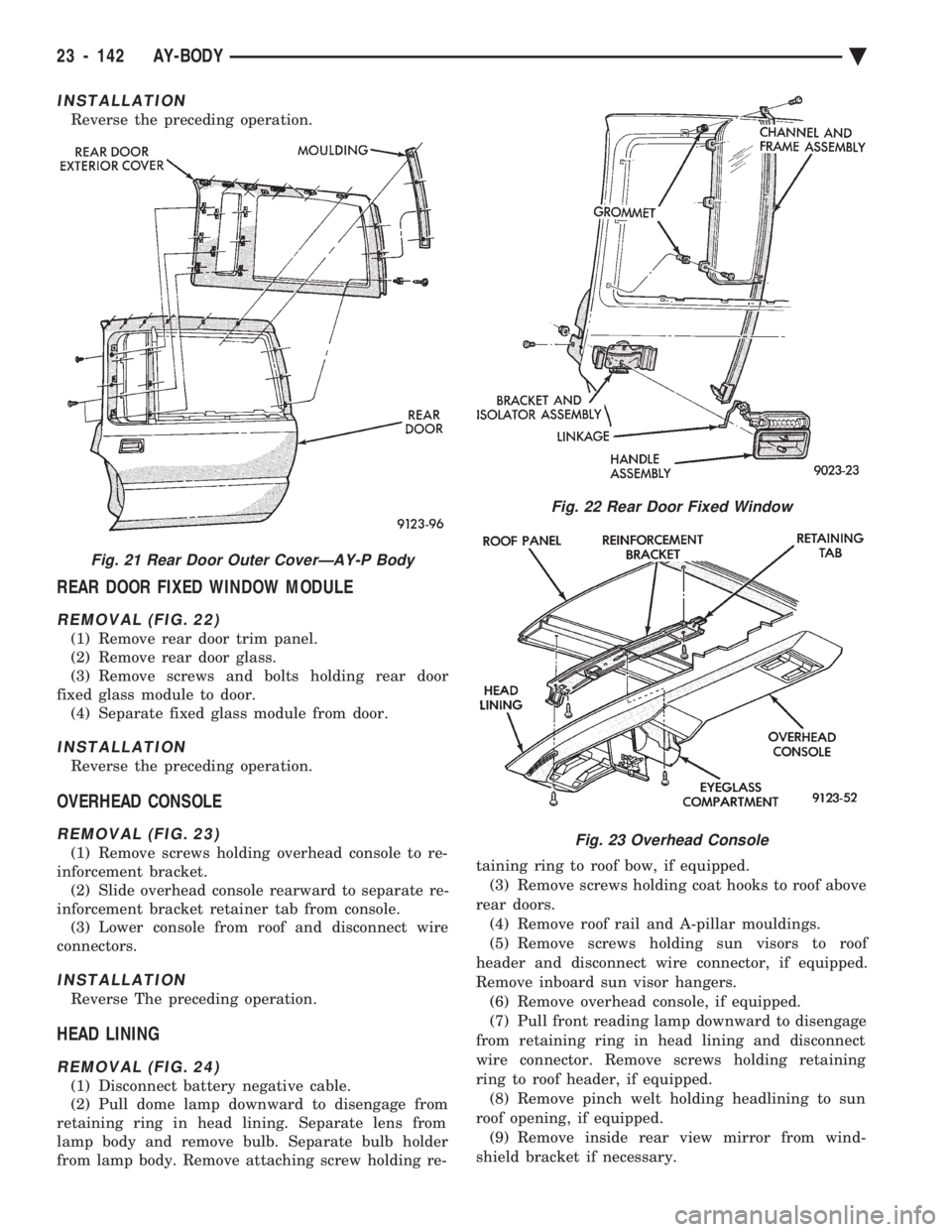

GRILLE AY/S BODY

REMOVAL (FIG. 2)

(1) Loosen hidden screws holding grille to grille

opening panel at corners of grille. The screws are

captured in a clearance hole covered by a bracket be-

hind the grille. (2) Pull grille forward from grille opening panel.

INSTALLATION

Reverse the preceding operation.

Fig. 1 GrilleÐAY/P Body

Fig. 2 GrilleÐAY/S Body

Ä AY-BODY 23 - 133

Page 2298 of 2438

INSTALLATION

Reverse the preceding operation.

REAR DOOR FIXED WINDOW MODULE

REMOVAL (FIG. 22)

(1) Remove rear door trim panel.

(2) Remove rear door glass.

(3) Remove screws and bolts holding rear door

fixed glass module to door. (4) Separate fixed glass module from door.

INSTALLATION

Reverse the preceding operation.

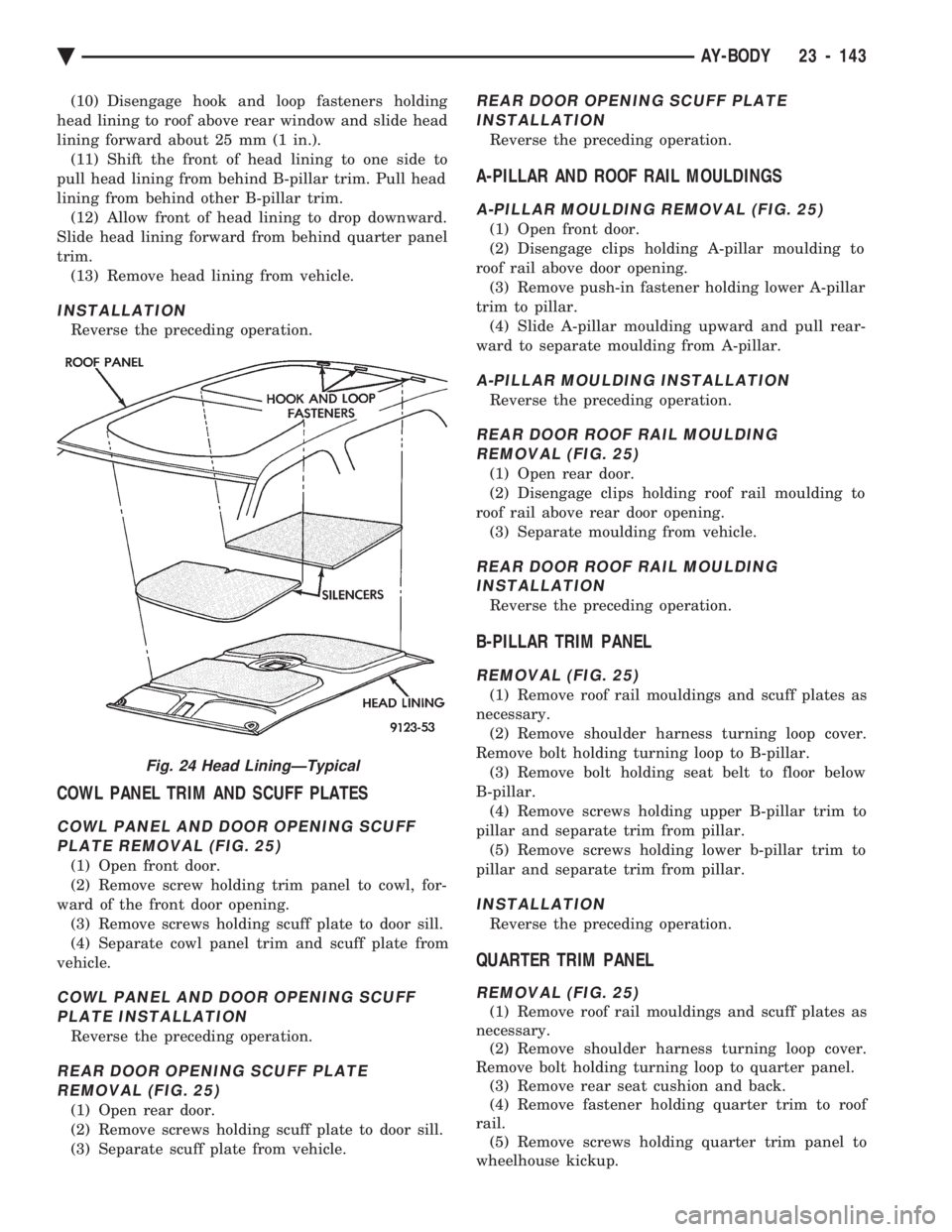

OVERHEAD CONSOLE

REMOVAL (FIG. 23)

(1) Remove screws holding overhead console to re-

inforcement bracket. (2) Slide overhead console rearward to separate re-

inforcement bracket retainer tab from console. (3) Lower console from roof and disconnect wire

connectors.

INSTALLATION

Reverse The preceding operation.

HEAD LINING

REMOVAL (FIG. 24)

(1) Disconnect battery negative cable.

(2) Pull dome lamp downward to disengage from

retaining ring in head lining. Separate lens from

lamp body and remove bulb. Separate bulb holder

from lamp body. Remove attaching screw holding re- taining ring to roof bow, if equipped.

(3) Remove screws holding coat hooks to roof above

rear doors. (4) Remove roof rail and A-pillar mouldings.

(5) Remove screws holding sun visors to roof

header and disconnect wire connector, if equipped.

Remove inboard sun visor hangers. (6) Remove overhead console, if equipped.

(7) Pull front reading lamp downward to disengage

from retaining ring in head lining and disconnect

wire connector. Remove screws holding retaining

ring to roof header, if equipped. (8) Remove pinch welt holding headlining to sun

roof opening, if equipped. (9) Remove inside rear view mirror from wind-

shield bracket if necessary.

Fig. 21 Rear Door Outer CoverÐAY-P Body

Fig. 22 Rear Door Fixed Window

Fig. 23 Overhead Console

23 - 142 AY-BODY Ä

Page 2299 of 2438

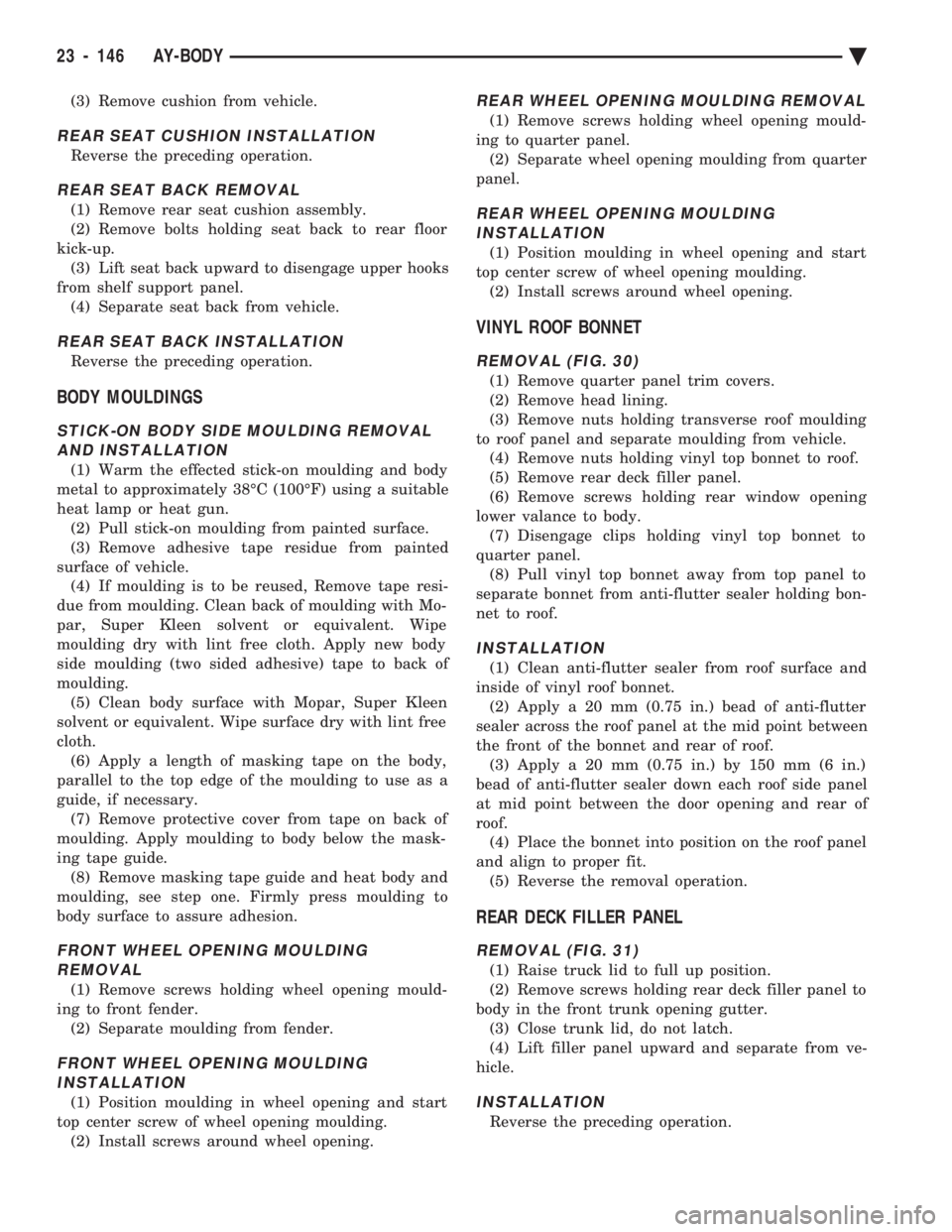

(10) Disengage hook and loop fasteners holding

head lining to roof above rear window and slide head

lining forward about 25 mm (1 in.). (11) Shift the front of head lining to one side to

pull head lining from behind B-pillar trim. Pull head

lining from behind other B-pillar trim. (12) Allow front of head lining to drop downward.

Slide head lining forward from behind quarter panel

trim. (13) Remove head lining from vehicle.

INSTALLATION

Reverse the preceding operation.

COWL PANEL TRIM AND SCUFF PLATES

COWL PANEL AND DOOR OPENING SCUFFPLATE REMOVAL (FIG. 25)

(1) Open front door.

(2) Remove screw holding trim panel to cowl, for-

ward of the front door opening. (3) Remove screws holding scuff plate to door sill.

(4) Separate cowl panel trim and scuff plate from

vehicle.

COWL PANEL AND DOOR OPENING SCUFF PLATE INSTALLATION

Reverse the preceding operation.

REAR DOOR OPENING SCUFF PLATEREMOVAL (FIG. 25)

(1) Open rear door.

(2) Remove screws holding scuff plate to door sill.

(3) Separate scuff plate from vehicle.

REAR DOOR OPENING SCUFF PLATEINSTALLATION

Reverse the preceding operation.

A-PILLAR AND ROOF RAIL MOULDINGS

A-PILLAR MOULDING REMOVAL (FIG. 25)

(1) Open front door.

(2) Disengage clips holding A-pillar moulding to

roof rail above door opening. (3) Remove push-in fastener holding lower A-pillar

trim to pillar. (4) Slide A-pillar moulding upward and pull rear-

ward to separate moulding from A-pillar.

A-PILLAR MOULDING INSTALLATION

Reverse the preceding operation.

REAR DOOR ROOF RAIL MOULDING REMOVAL (FIG. 25)

(1) Open rear door.

(2) Disengage clips holding roof rail moulding to

roof rail above rear door opening. (3) Separate moulding from vehicle.

REAR DOOR ROOF RAIL MOULDINGINSTALLATION

Reverse the preceding operation.

B-PILLAR TRIM PANEL

REMOVAL (FIG. 25)

(1) Remove roof rail mouldings and scuff plates as

necessary. (2) Remove shoulder harness turning loop cover.

Remove bolt holding turning loop to B-pillar. (3) Remove bolt holding seat belt to floor below

B-pillar. (4) Remove screws holding upper B-pillar trim to

pillar and separate trim from pillar. (5) Remove screws holding lower b-pillar trim to

pillar and separate trim from pillar.

INSTALLATION

Reverse the preceding operation.

QUARTER TRIM PANEL

REMOVAL (FIG. 25)

(1) Remove roof rail mouldings and scuff plates as

necessary. (2) Remove shoulder harness turning loop cover.

Remove bolt holding turning loop to quarter panel. (3) Remove rear seat cushion and back.

(4) Remove fastener holding quarter trim to roof

rail. (5) Remove screws holding quarter trim panel to

wheelhouse kickup.

Fig. 24 Head LiningÐTypical

Ä AY-BODY 23 - 143

Page 2302 of 2438

(3) Remove cushion from vehicle.

REAR SEAT CUSHION INSTALLATION

Reverse the preceding operation.

REAR SEAT BACK REMOVAL

(1) Remove rear seat cushion assembly.

(2) Remove bolts holding seat back to rear floor

kick-up. (3) Lift seat back upward to disengage upper hooks

from shelf support panel. (4) Separate seat back from vehicle.

REAR SEAT BACK INSTALLATION

Reverse the preceding operation.

BODY MOULDINGS

STICK-ON BODY SIDE MOULDING REMOVALAND INSTALLATION

(1) Warm the effected stick-on moulding and body

metal to approximately 38ÉC (100ÉF) using a suitable

heat lamp or heat gun. (2) Pull stick-on moulding from painted surface.

(3) Remove adhesive tape residue from painted

surface of vehicle. (4) If moulding is to be reused, Remove tape resi-

due from moulding. Clean back of moulding with Mo-

par, Super Kleen solvent or equivalent. Wipe

moulding dry with lint free cloth. Apply new body

side moulding (two sided adhesive) tape to back of

moulding. (5) Clean body surface with Mopar, Super Kleen

solvent or equivalent. Wipe surface dry with lint free

cloth. (6) Apply a length of masking tape on the body,

parallel to the top edge of the moulding to use as a

guide, if necessary. (7) Remove protective cover from tape on back of

moulding. Apply moulding to body below the mask-

ing tape guide. (8) Remove masking tape guide and heat body and

moulding, see step one. Firmly press moulding to

body surface to assure adhesion.

FRONT WHEEL OPENING MOULDING REMOVAL

(1) Remove screws holding wheel opening mould-

ing to front fender. (2) Separate moulding from fender.

FRONT WHEEL OPENING MOULDINGINSTALLATION

(1) Position moulding in wheel opening and start

top center screw of wheel opening moulding. (2) Install screws around wheel opening.

REAR WHEEL OPENING MOULDING REMOVAL

(1) Remove screws holding wheel opening mould-

ing to quarter panel. (2) Separate wheel opening moulding from quarter

panel.

REAR WHEEL OPENING MOULDING INSTALLATION

(1) Position moulding in wheel opening and start

top center screw of wheel opening moulding. (2) Install screws around wheel opening.

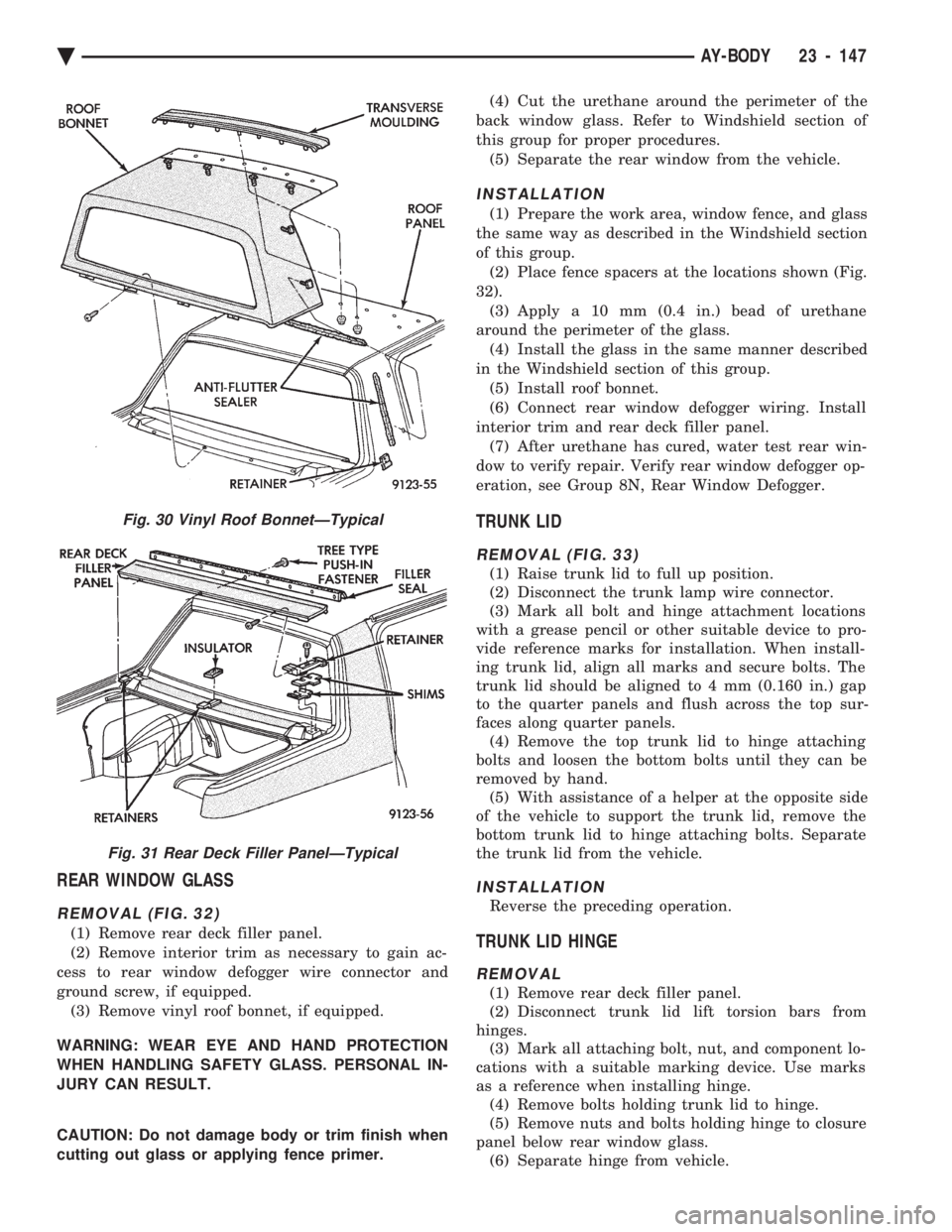

VINYL ROOF BONNET

REMOVAL (FIG. 30)

(1) Remove quarter panel trim covers.

(2) Remove head lining.

(3) Remove nuts holding transverse roof moulding

to roof panel and separate moulding from vehicle. (4) Remove nuts holding vinyl top bonnet to roof.

(5) Remove rear deck filler panel.

(6) Remove screws holding rear window opening

lower valance to body. (7) Disengage clips holding vinyl top bonnet to

quarter panel. (8) Pull vinyl top bonnet away from top panel to

separate bonnet from anti-flutter sealer holding bon-

net to roof.

INSTALLATION

(1) Clean anti-flutter sealer from roof surface and

inside of vinyl roof bonnet. (2) Apply a 20 mm (0.75 in.) bead of anti-flutter

sealer across the roof panel at the mid point between

the front of the bonnet and rear of roof. (3) Apply a 20 mm (0.75 in.) by 150 mm (6 in.)

bead of anti-flutter sealer down each roof side panel

at mid point between the door opening and rear of

roof. (4) Place the bonnet into position on the roof panel

and align to proper fit. (5) Reverse the removal operation.

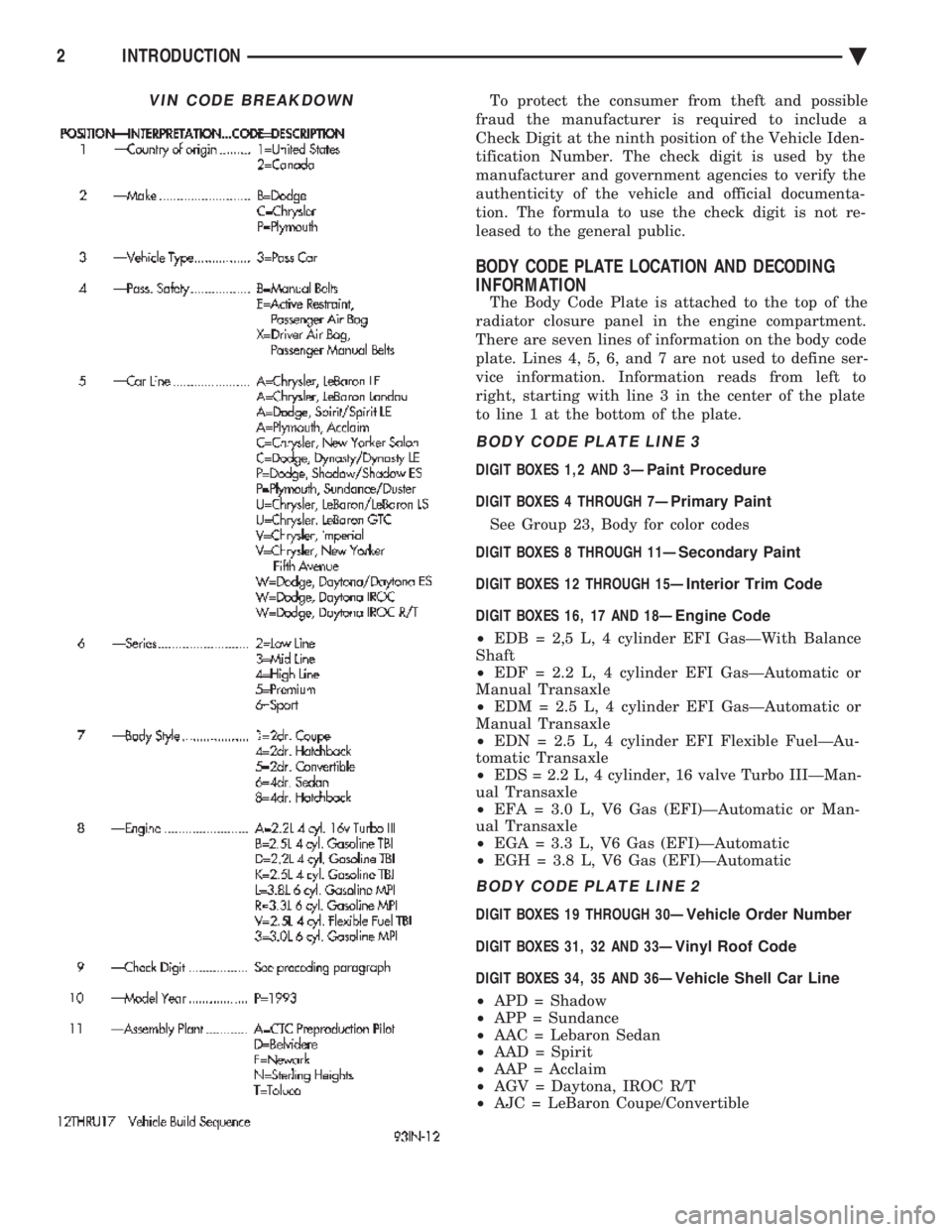

REAR DECK FILLER PANEL

REMOVAL (FIG. 31)

(1) Raise truck lid to full up position.

(2) Remove screws holding rear deck filler panel to

body in the front trunk opening gutter. (3) Close trunk lid, do not latch.

(4) Lift filler panel upward and separate from ve-

hicle.

INSTALLATION

Reverse the preceding operation.

23 - 146 AY-BODY Ä

Page 2303 of 2438

REAR WINDOW GLASS

REMOVAL (FIG. 32)

(1) Remove rear deck filler panel.

(2) Remove interior trim as necessary to gain ac-

cess to rear window defogger wire connector and

ground screw, if equipped. (3) Remove vinyl roof bonnet, if equipped.

WARNING: WEAR EYE AND HAND PROTECTION

WHEN HANDLING SAFETY GLASS. PERSONAL IN-

JURY CAN RESULT.

CAUTION: Do not damage body or trim finish when

cutting out glass or applying fence primer. (4) Cut the urethane around the perimeter of the

back window glass. Refer to Windshield section of

this group for proper procedures. (5) Separate the rear window from the vehicle.

INSTALLATION

(1) Prepare the work area, window fence, and glass

the same way as described in the Windshield section

of this group. (2) Place fence spacers at the locations shown (Fig.

32). (3) Apply a 10 mm (0.4 in.) bead of urethane

around the perimeter of the glass. (4) Install the glass in the same manner described

in the Windshield section of this group. (5) Install roof bonnet.

(6) Connect rear window defogger wiring. Install

interior trim and rear deck filler panel. (7) After urethane has cured, water test rear win-

dow to verify repair. Verify rear window defogger op-

eration, see Group 8N, Rear Window Defogger.

TRUNK LID

REMOVAL (FIG. 33)

(1) Raise trunk lid to full up position.

(2) Disconnect the trunk lamp wire connector.

(3) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When install-

ing trunk lid, align all marks and secure bolts. The

trunk lid should be aligned to 4 mm (0.160 in.) gap

to the quarter panels and flush across the top sur-

faces along quarter panels. (4) Remove the top trunk lid to hinge attaching

bolts and loosen the bottom bolts until they can be

removed by hand. (5) With assistance of a helper at the opposite side

of the vehicle to support the trunk lid, remove the

bottom trunk lid to hinge attaching bolts. Separate

the trunk lid from the vehicle.

INSTALLATION

Reverse the preceding operation.

TRUNK LID HINGE

REMOVAL

(1) Remove rear deck filler panel.

(2) Disconnect trunk lid lift torsion bars from

hinges. (3) Mark all attaching bolt, nut, and component lo-

cations with a suitable marking device. Use marks

as a reference when installing hinge. (4) Remove bolts holding trunk lid to hinge.

(5) Remove nuts and bolts holding hinge to closure

panel below rear window glass. (6) Separate hinge from vehicle.

Fig. 30 Vinyl Roof BonnetÐTypical

Fig. 31 Rear Deck Filler PanelÐTypical

Ä AY-BODY 23 - 147

Page 2417 of 2438

To protect the consumer from theft and possible

fraud the manufacturer is required to include a

Check Digit at the ninth position of the Vehicle Iden-

tification Number. The check digit is used by the

manufacturer and government agencies to verify the

authenticity of the vehicle and official documenta-

tion. The formula to use the check digit is not re-

leased to the general public.

BODY CODE PLATE LOCATION AND DECODING

INFORMATION

The Body Code Plate is attached to the top of the

radiator closure panel in the engine compartment.

There are seven lines of information on the body code

plate. Lines 4, 5, 6, and 7 are not used to define ser-

vice information. Information reads from left to

right, starting with line 3 in the center of the plate

to line 1 at the bottom of the plate.

BODY CODE PLATE LINE 3

DIGIT BOXES 1,2 AND 3Ð Paint Procedure

DIGIT BOXES 4 THROUGH 7Ð Primary Paint

See Group 23, Body for color codes

DIGIT BOXES 8 THROUGH 11Ð Secondary Paint

DIGIT BOXES 12 THROUGH 15Ð Interior Trim Code

DIGIT BOXES 16, 17 AND 18Ð Engine Code

² EDB = 2,5 L, 4 cylinder EFI GasÐWith Balance

Shaft

² EDF = 2.2 L, 4 cylinder EFI GasÐAutomatic or

Manual Transaxle

² EDM = 2.5 L, 4 cylinder EFI GasÐAutomatic or

Manual Transaxle

² EDN = 2.5 L, 4 cylinder EFI Flexible FuelÐAu-

tomatic Transaxle

² EDS = 2.2 L, 4 cylinder, 16 valve Turbo IIIÐMan-

ual Transaxle

² EFA = 3.0 L, V6 Gas (EFI)ÐAutomatic or Man-

ual Transaxle

² EGA = 3.3 L, V6 Gas (EFI)ÐAutomatic

² EGH = 3.8 L, V6 Gas (EFI)ÐAutomatic

BODY CODE PLATE LINE 2

DIGIT BOXES 19 THROUGH 30Ð Vehicle Order Number

DIGIT BOXES 31, 32 AND 33Ð Vinyl Roof Code

DIGIT BOXES 34, 35 AND 36Ð Vehicle Shell Car Line

² APD = Shadow

² APP = Sundance

² AAC = Lebaron Sedan

² AAD = Spirit

² AAP = Acclaim

² AGV = Daytona, IROC R/T

² AJC = LeBaron Coupe/Convertible

VIN CODE BREAKDOWN

2 INTRODUCTION Ä