ad blue CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 171 of 2438

If old springs have overheated or are damaged, re-

place. Overheating indications are paint discoloration

or distorted end coils. Varga brake springs are not

painted but overheating of the brake springs will be

noted by any Blueing of the springs.

BRAKE SHOE INSTALLATION

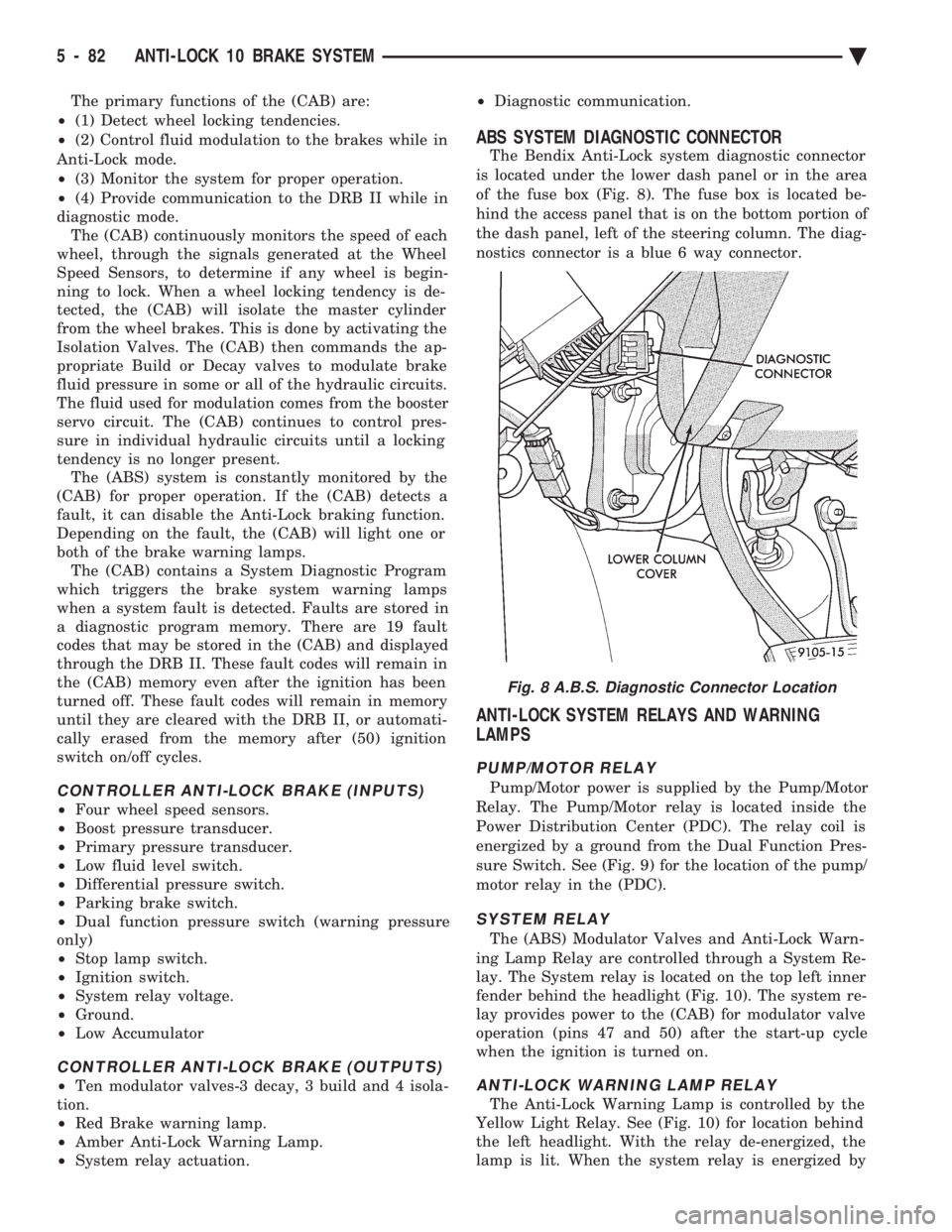

Lubricate the eight shoe contact areas on the sup-

port plate and anchor using Mopar Multi-Purpose

Lubricant or equivalent (Fig. 11).

KELSEY HAYES REASSEMBLE

Assemble the park brake lever and wave washer to

the new replacement shoe (Fig. 9). Attach upper return spring between the two new

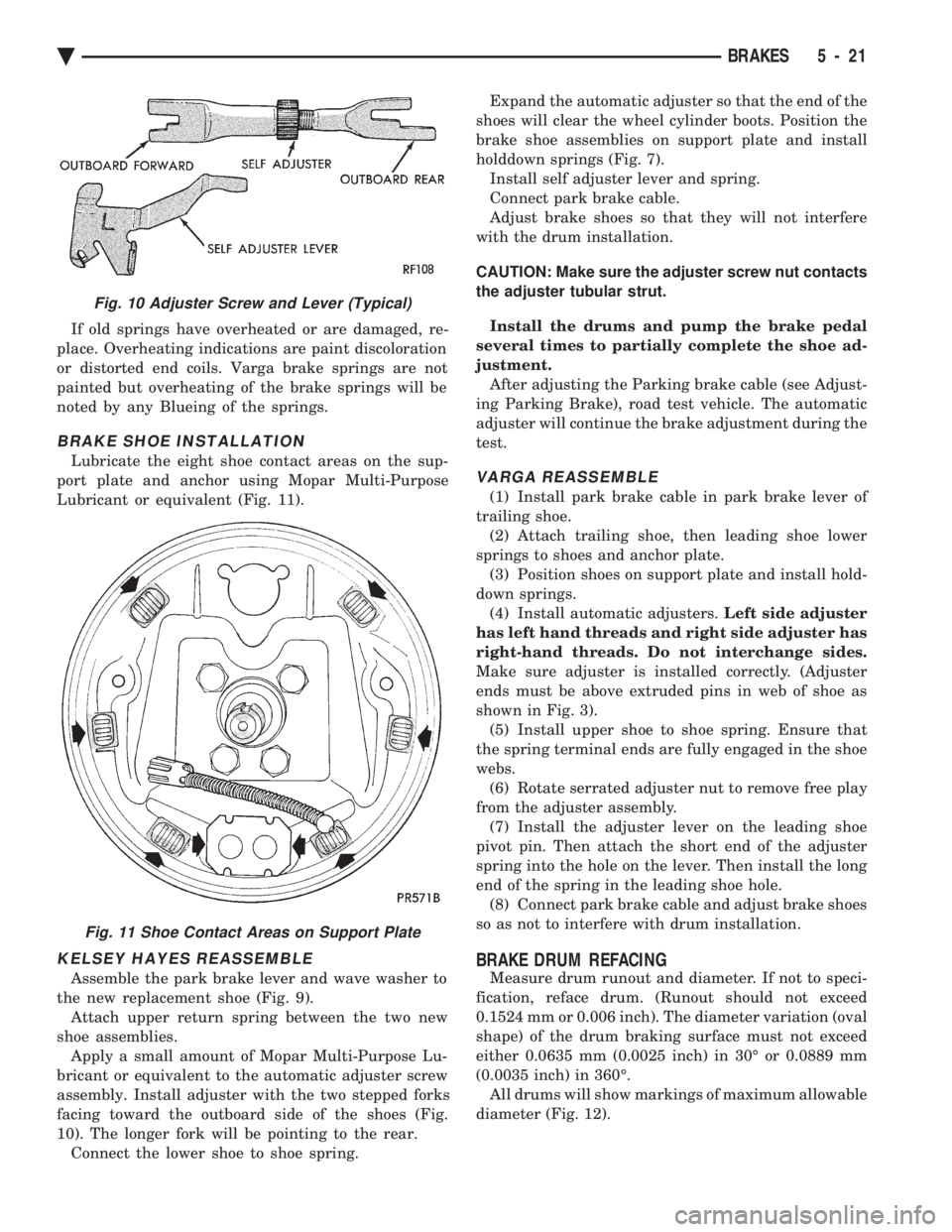

shoe assemblies. Apply a small amount of Mopar Multi-Purpose Lu-

bricant or equivalent to the automatic adjuster screw

assembly. Install adjuster with the two stepped forks

facing toward the outboard side of the shoes (Fig.

10). The longer fork will be pointing to the rear. Connect the lower shoe to shoe spring. Expand the automatic adjuster so that the end of the

shoes will clear the wheel cylinder boots. Position the

brake shoe assemblies on support plate and install

holddown springs (Fig. 7). Install self adjuster lever and spring.

Connect park brake cable.

Adjust brake shoes so that they will not interfere

with the drum installation.

CAUTION: Make sure the adjuster screw nut contacts

the adjuster tubular strut.

Install the drums and pump the brake pedal

several times to partially complete the shoe ad-

justment. After adjusting the Parking brake cable (see Adjust-

ing Parking Brake), road test vehicle. The automatic

adjuster will continue the brake adjustment during the

test.

VARGA REASSEMBLE

(1) Install park brake cable in park brake lever of

trailing shoe. (2) Attach trailing shoe, then leading shoe lower

springs to shoes and anchor plate. (3) Position shoes on support plate and install hold-

down springs. (4) Install automatic adjusters. Left side adjuster

has left hand threads and right side adjuster has

right-hand threads. Do not interchange sides.

Make sure adjuster is installed correctly. (Adjuster

ends must be above extruded pins in web of shoe as

shown in Fig. 3). (5) Install upper shoe to shoe spring. Ensure that

the spring terminal ends are fully engaged in the shoe

webs. (6) Rotate serrated adjuster nut to remove free play

from the adjuster assembly. (7) Install the adjuster lever on the leading shoe

pivot pin. Then attach the short end of the adjuster

spring into the hole on the lever. Then install the long

end of the spring in the leading shoe hole. (8) Connect park brake cable and adjust brake shoes

so as not to interfere with drum installation.

BRAKE DRUM REFACING

Measure drum runout and diameter. If not to speci-

fication, reface drum. (Runout should not exceed

0.1524 mm or 0.006 inch). The diameter variation (oval

shape) of the drum braking surface must not exceed

either 0.0635 mm (0.0025 inch) in 30É or 0.0889 mm

(0.0035 inch) in 360É. All drums will show markings of maximum allowable

diameter (Fig. 12).

Fig. 10 Adjuster Screw and Lever (Typical)

Fig. 11 Shoe Contact Areas on Support Plate

Ä BRAKES 5 - 21

Page 232 of 2438

The primary functions of the (CAB) are:

² (1) Detect wheel locking tendencies.

² (2) Control fluid modulation to the brakes while in

Anti-Lock mode.

² (3) Monitor the system for proper operation.

² (4) Provide communication to the DRB II while in

diagnostic mode. The (CAB) continuously monitors the speed of each

wheel, through the signals generated at the Wheel

Speed Sensors, to determine if any wheel is begin-

ning to lock. When a wheel locking tendency is de-

tected, the (CAB) will isolate the master cylinder

from the wheel brakes. This is done by activating the

Isolation Valves. The (CAB) then commands the ap-

propriate Build or Decay valves to modulate brake

fluid pressure in some or all of the hydraulic circuits.

The fluid used for modulation comes from the booster

servo circuit. The (CAB) continues to control pres-

sure in individual hydraulic circuits until a locking

tendency is no longer present. The (ABS) system is constantly monitored by the

(CAB) for proper operation. If the (CAB) detects a

fault, it can disable the Anti-Lock braking function.

Depending on the fault, the (CAB) will light one or

both of the brake warning lamps. The (CAB) contains a System Diagnostic Program

which triggers the brake system warning lamps

when a system fault is detected. Faults are stored in

a diagnostic program memory. There are 19 fault

codes that may be stored in the (CAB) and displayed

through the DRB II. These fault codes will remain in

the (CAB) memory even after the ignition has been

turned off. These fault codes will remain in memory

until they are cleared with the DRB II, or automati-

cally erased from the memory after (50) ignition

switch on/off cycles.

CONTROLLER ANTI-LOCK BRAKE (INPUTS)

² Four wheel speed sensors.

² Boost pressure transducer.

² Primary pressure transducer.

² Low fluid level switch.

² Differential pressure switch.

² Parking brake switch.

² Dual function pressure switch (warning pressure

only)

² Stop lamp switch.

² Ignition switch.

² System relay voltage.

² Ground.

² Low Accumulator

CONTROLLER ANTI-LOCK BRAKE (OUTPUTS)

²Ten modulator valves-3 decay, 3 build and 4 isola-

tion.

² Red Brake warning lamp.

² Amber Anti-Lock Warning Lamp.

² System relay actuation. ²

Diagnostic communication.

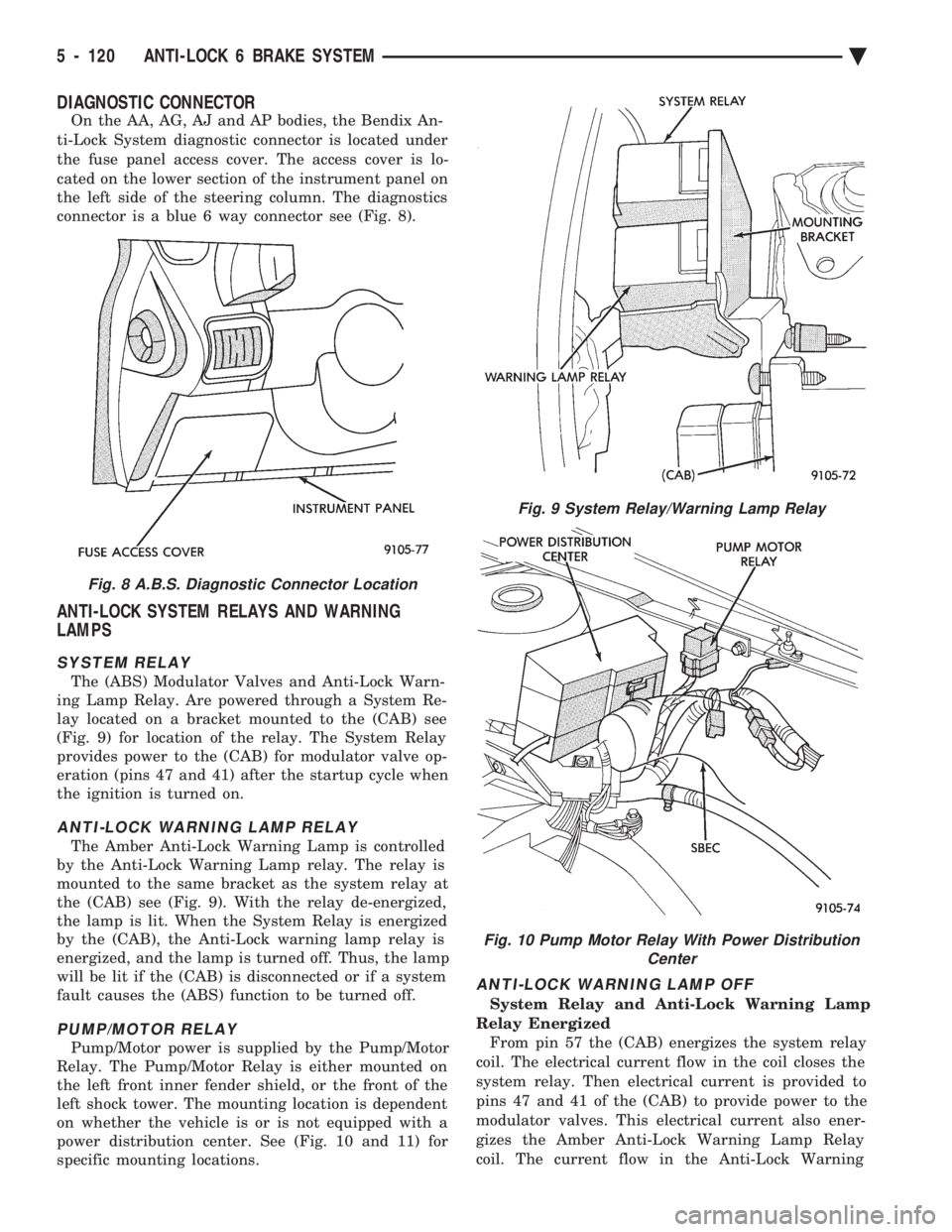

ABS SYSTEM DIAGNOSTIC CONNECTOR

The Bendix Anti-Lock system diagnostic connector

is located under the lower dash panel or in the area

of the fuse box (Fig. 8). The fuse box is located be-

hind the access panel that is on the bottom portion of

the dash panel, left of the steering column. The diag-

nostics connector is a blue 6 way connector.

ANTI-LOCK SYSTEM RELAYS AND WARNING

LAMPS

PUMP/MOTOR RELAY

Pump/Motor power is supplied by the Pump/Motor

Relay. The Pump/Motor relay is located inside the

Power Distribution Center (PDC). The relay coil is

energized by a ground from the Dual Function Pres-

sure Switch. See (Fig. 9) for the location of the pump/

motor relay in the (PDC).

SYSTEM RELAY

The (ABS) Modulator Valves and Anti-Lock Warn-

ing Lamp Relay are controlled through a System Re-

lay. The System relay is located on the top left inner

fender behind the headlight (Fig. 10). The system re-

lay provides power to the (CAB) for modulator valve

operation (pins 47 and 50) after the start-up cycle

when the ignition is turned on.

ANTI-LOCK WARNING LAMP RELAY

The Anti-Lock Warning Lamp is controlled by the

Yellow Light Relay. See (Fig. 10) for location behind

the left headlight. With the relay de-energized, the

lamp is lit. When the system relay is energized by

Fig. 8 A.B.S. Diagnostic Connector Location

5 - 82 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 270 of 2438

DIAGNOSTIC CONNECTOR

On the AA, AG, AJ and AP bodies, the Bendix An-

ti-Lock System diagnostic connector is located under

the fuse panel access cover. The access cover is lo-

cated on the lower section of the instrument panel on

the left side of the steering column. The diagnostics

connector is a blue 6 way connector see (Fig. 8).

ANTI-LOCK SYSTEM RELAYS AND WARNING

LAMPS

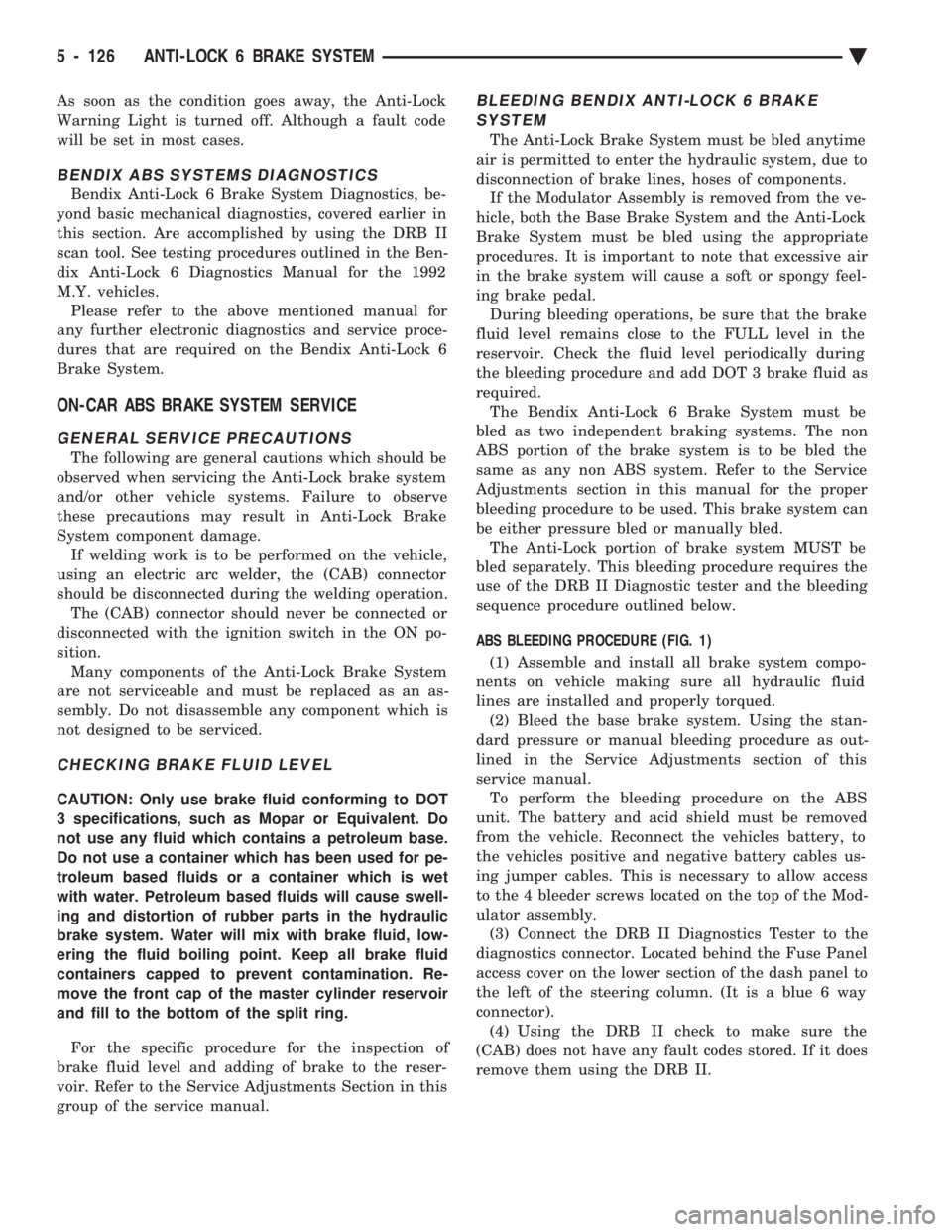

SYSTEM RELAY

The (ABS) Modulator Valves and Anti-Lock Warn-

ing Lamp Relay. Are powered through a System Re-

lay located on a bracket mounted to the (CAB) see

(Fig. 9) for location of the relay. The System Relay

provides power to the (CAB) for modulator valve op-

eration (pins 47 and 41) after the startup cycle when

the ignition is turned on.

ANTI-LOCK WARNING LAMP RELAY

The Amber Anti-Lock Warning Lamp is controlled

by the Anti-Lock Warning Lamp relay. The relay is

mounted to the same bracket as the system relay at

the (CAB) see (Fig. 9). With the relay de-energized,

the lamp is lit. When the System Relay is energized

by the (CAB), the Anti-Lock warning lamp relay is

energized, and the lamp is turned off. Thus, the lamp

will be lit if the (CAB) is disconnected or if a system

fault causes the (ABS) function to be turned off.

PUMP/MOTOR RELAY

Pump/Motor power is supplied by the Pump/Motor

Relay. The Pump/Motor Relay is either mounted on

the left front inner fender shield, or the front of the

left shock tower. The mounting location is dependent

on whether the vehicle is or is not equipped with a

power distribution center. See (Fig. 10 and 11) for

specific mounting locations.

ANTI-LOCK WARNING LAMP OFF

System Relay and Anti-Lock Warning Lamp

Relay Energized From pin 57 the (CAB) energizes the system relay

coil. The electrical current flow in the coil closes the

system relay. Then electrical current is provided to

pins 47 and 41 of the (CAB) to provide power to the

modulator valves. This electrical current also ener-

gizes the Amber Anti-Lock Warning Lamp Relay

coil. The current flow in the Anti-Lock Warning

Fig. 8 A.B.S. Diagnostic Connector Location

Fig. 9 System Relay/Warning Lamp Relay

Fig. 10 Pump Motor Relay With Power Distribution Center

5 - 120 ANTI-LOCK 6 BRAKE SYSTEM Ä

Page 276 of 2438

As soon as the condition goes away, the Anti-Lock

Warning Light is turned off. Although a fault code

will be set in most cases.

BENDIX ABS SYSTEMS DIAGNOSTICS

Bendix Anti-Lock 6 Brake System Diagnostics, be-

yond basic mechanical diagnostics, covered earlier in

this section. Are accomplished by using the DRB II

scan tool. See testing procedures outlined in the Ben-

dix Anti-Lock 6 Diagnostics Manual for the 1992

M.Y. vehicles. Please refer to the above mentioned manual for

any further electronic diagnostics and service proce-

dures that are required on the Bendix Anti-Lock 6

Brake System.

ON-CAR ABS BRAKE SYSTEM SERVICE

GENERAL SERVICE PRECAUTIONS

The following are general cautions which should be

observed when servicing the Anti-Lock brake system

and/or other vehicle systems. Failure to observe

these precautions may result in Anti-Lock Brake

System component damage. If welding work is to be performed on the vehicle,

using an electric arc welder, the (CAB) connector

should be disconnected during the welding operation. The (CAB) connector should never be connected or

disconnected with the ignition switch in the ON po-

sition. Many components of the Anti-Lock Brake System

are not serviceable and must be replaced as an as-

sembly. Do not disassemble any component which is

not designed to be serviced.

CHECKING BRAKE FLUID LEVEL

CAUTION: Only use brake fluid conforming to DOT

3 specifications, such as Mopar or Equivalent. Do

not use any fluid which contains a petroleum base.

Do not use a container which has been used for pe-

troleum based fluids or a container which is wet

with water. Petroleum based fluids will cause swell-

ing and distortion of rubber parts in the hydraulic

brake system. Water will mix with brake fluid, low-

ering the fluid boiling point. Keep all brake fluid

containers capped to prevent contamination. Re-

move the front cap of the master cylinder reservoir

and fill to the bottom of the split ring.

For the specific procedure for the inspection of

brake fluid level and adding of brake to the reser-

voir. Refer to the Service Adjustments Section in this

group of the service manual.

BLEEDING BENDIX ANTI-LOCK 6 BRAKE SYSTEM

The Anti-Lock Brake System must be bled anytime

air is permitted to enter the hydraulic system, due to

disconnection of brake lines, hoses of components. If the Modulator Assembly is removed from the ve-

hicle, both the Base Brake System and the Anti-Lock

Brake System must be bled using the appropriate

procedures. It is important to note that excessive air

in the brake system will cause a soft or spongy feel-

ing brake pedal. During bleeding operations, be sure that the brake

fluid level remains close to the FULL level in the

reservoir. Check the fluid level periodically during

the bleeding procedure and add DOT 3 brake fluid as

required. The Bendix Anti-Lock 6 Brake System must be

bled as two independent braking systems. The non

ABS portion of the brake system is to be bled the

same as any non ABS system. Refer to the Service

Adjustments section in this manual for the proper

bleeding procedure to be used. This brake system can

be either pressure bled or manually bled. The Anti-Lock portion of brake system MUST be

bled separately. This bleeding procedure requires the

use of the DRB II Diagnostic tester and the bleeding

sequence procedure outlined below.

ABS BLEEDING PROCEDURE (FIG. 1)

(1) Assemble and install all brake system compo-

nents on vehicle making sure all hydraulic fluid

lines are installed and properly torqued. (2) Bleed the base brake system. Using the stan-

dard pressure or manual bleeding procedure as out-

lined in the Service Adjustments section of this

service manual. To perform the bleeding procedure on the ABS

unit. The battery and acid shield must be removed

from the vehicle. Reconnect the vehicles battery, to

the vehicles positive and negative battery cables us-

ing jumper cables. This is necessary to allow access

to the 4 bleeder screws located on the top of the Mod-

ulator assembly. (3) Connect the DRB II Diagnostics Tester to the

diagnostics connector. Located behind the Fuse Panel

access cover on the lower section of the dash panel to

the left of the steering column. (It is a blue 6 way

connector). (4) Using the DRB II check to make sure the

(CAB) does not have any fault codes stored. If it does

remove them using the DRB II.

5 - 126 ANTI-LOCK 6 BRAKE SYSTEM Ä

Page 305 of 2438

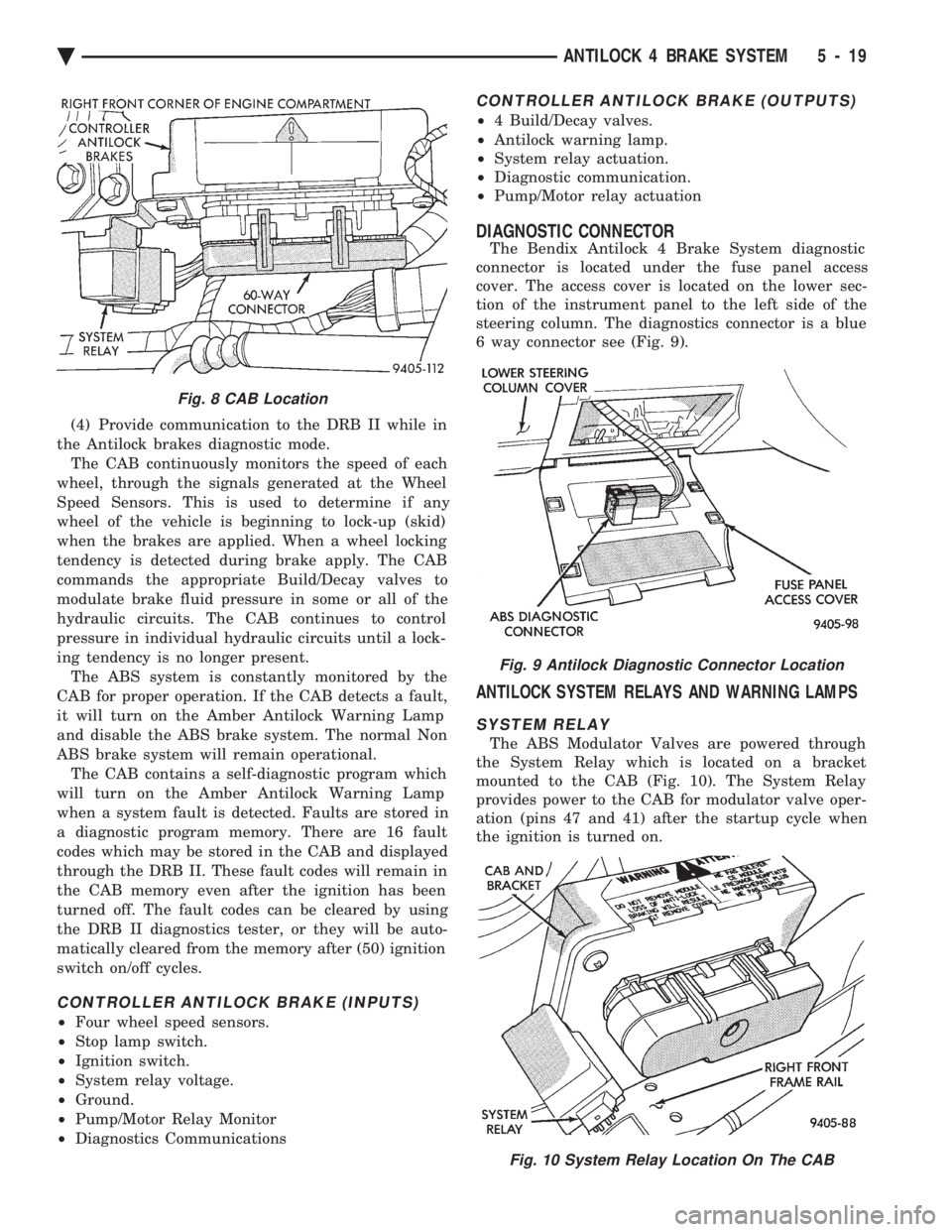

(4) Provide communication to the DRB II while in

the Antilock brakes diagnostic mode. The CAB continuously monitors the speed of each

wheel, through the signals generated at the Wheel

Speed Sensors. This is used to determine if any

wheel of the vehicle is beginning to lock-up (skid)

when the brakes are applied. When a wheel locking

tendency is detected during brake apply. The CAB

commands the appropriate Build/Decay valves to

modulate brake fluid pressure in some or all of the

hydraulic circuits. The CAB continues to control

pressure in individual hydraulic circuits until a lock-

ing tendency is no longer present. The ABS system is constantly monitored by the

CAB for proper operation. If the CAB detects a fault,

it will turn on the Amber Antilock Warning Lamp

and disable the ABS brake system. The normal Non

ABS brake system will remain operational. The CAB contains a self-diagnostic program which

will turn on the Amber Antilock Warning Lamp

when a system fault is detected. Faults are stored in

a diagnostic program memory. There are 16 fault

codes which may be stored in the CAB and displayed

through the DRB II. These fault codes will remain in

the CAB memory even after the ignition has been

turned off. The fault codes can be cleared by using

the DRB II diagnostics tester, or they will be auto-

matically cleared from the memory after (50) ignition

switch on/off cycles.

CONTROLLER ANTILOCK BRAKE (INPUTS)

² Four wheel speed sensors.

² Stop lamp switch.

² Ignition switch.

² System relay voltage.

² Ground.

² Pump/Motor Relay Monitor

² Diagnostics Communications

CONTROLLER ANTILOCK BRAKE (OUTPUTS)

²4 Build/Decay valves.

² Antilock warning lamp.

² System relay actuation.

² Diagnostic communication.

² Pump/Motor relay actuation

DIAGNOSTIC CONNECTOR

The Bendix Antilock 4 Brake System diagnostic

connector is located under the fuse panel access

cover. The access cover is located on the lower sec-

tion of the instrument panel to the left side of the

steering column. The diagnostics connector is a blue

6 way connector see (Fig. 9).

ANTILOCK SYSTEM RELAYS AND WARNING LAMPS

SYSTEM RELAY

The ABS Modulator Valves are powered through

the System Relay which is located on a bracket

mounted to the CAB (Fig. 10). The System Relay

provides power to the CAB for modulator valve oper-

ation (pins 47 and 41) after the startup cycle when

the ignition is turned on.

Fig. 8 CAB Location

Fig. 9 Antilock Diagnostic Connector Location

Fig. 10 System Relay Location On The CAB

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 19

Page 312 of 2438

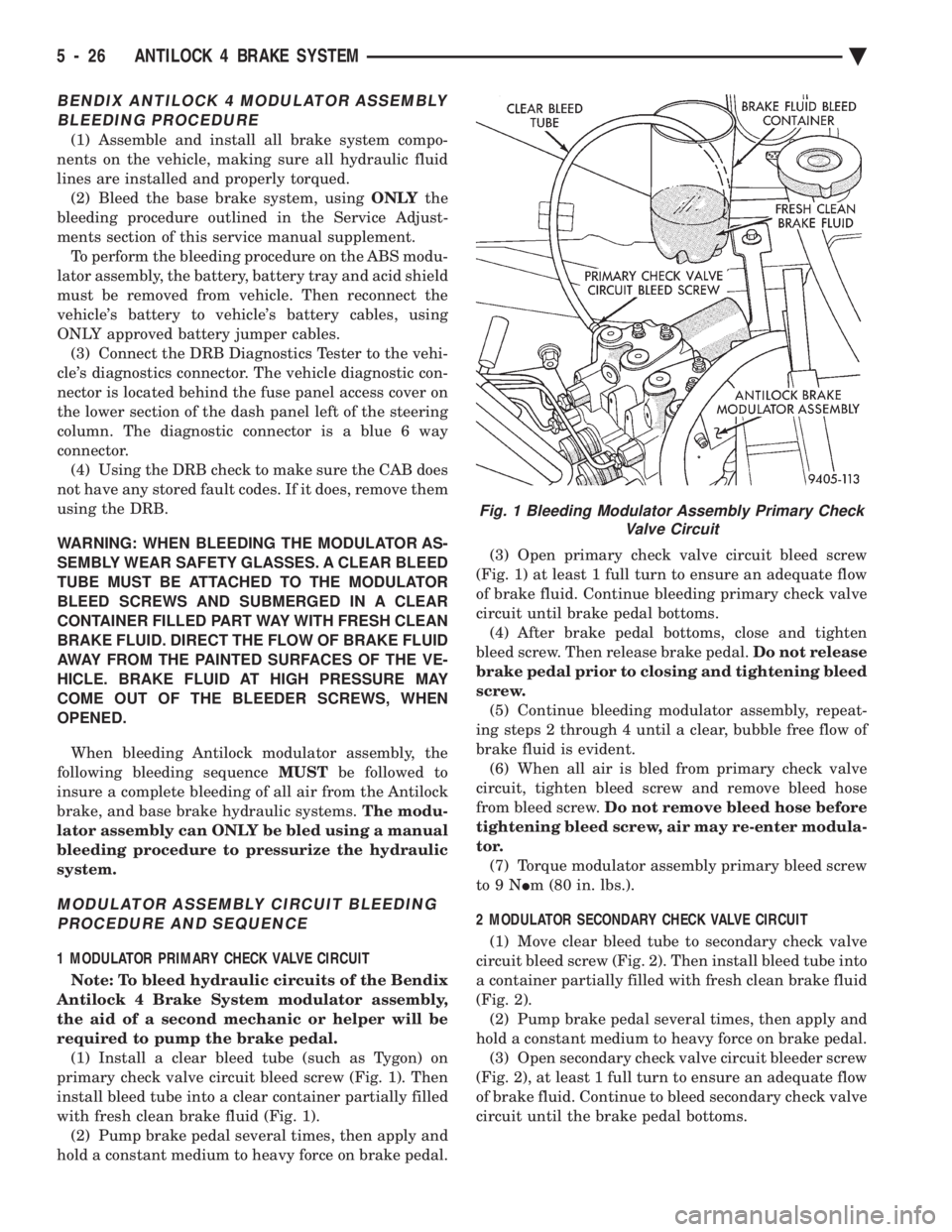

BENDIX ANTILOCK 4 MODULATOR ASSEMBLY BLEEDING PROCEDURE

(1) Assemble and install all brake system compo-

nents on the vehicle, making sure all hydraulic fluid

lines are installed and properly torqued. (2) Bleed the base brake system, using ONLYthe

bleeding procedure outlined in the Service Adjust-

ments section of this service manual supplement. To perform the bleeding procedure on the ABS modu-

lator assembly, the battery, battery tray and acid shield

must be removed from vehicle. Then reconnect the

vehicle's battery to vehicle's battery cables, using

ONLY approved battery jumper cables. (3) Connect the DRB Diagnostics Tester to the vehi-

cle's diagnostics connector. The vehicle diagnostic con-

nector is located behind the fuse panel access cover on

the lower section of the dash panel left of the steering

column. The diagnostic connector is a blue 6 way

connector. (4) Using the DRB check to make sure the CAB does

not have any stored fault codes. If it does, remove them

using the DRB.

WARNING: WHEN BLEEDING THE MODULATOR AS-

SEMBLY WEAR SAFETY GLASSES. A CLEAR BLEED

TUBE MUST BE ATTACHED TO THE MODULATOR

BLEED SCREWS AND SUBMERGED IN A CLEAR

CONTAINER FILLED PART WAY WITH FRESH CLEAN

BRAKE FLUID. DIRECT THE FLOW OF BRAKE FLUID

AWAY FROM THE PAINTED SURFACES OF THE VE-

HICLE. BRAKE FLUID AT HIGH PRESSURE MAY

COME OUT OF THE BLEEDER SCREWS, WHEN

OPENED.

When bleeding Antilock modulator assembly, the

following bleeding sequence MUSTbe followed to

insure a complete bleeding of all air from the Antilock

brake, and base brake hydraulic systems. The modu-

lator assembly can ONLY be bled using a manual

bleeding procedure to pressurize the hydraulic

system.

MODULATOR ASSEMBLY CIRCUIT BLEEDING PROCEDURE AND SEQUENCE

1 MODULATOR PRIMARY CHECK VALVE CIRCUIT

Note: To bleed hydraulic circuits of the Bendix

Antilock 4 Brake System modulator assembly,

the aid of a second mechanic or helper will be

required to pump the brake pedal. (1) Install a clear bleed tube (such as Tygon) on

primary check valve circuit bleed screw (Fig. 1). Then

install bleed tube into a clear container partially filled

with fresh clean brake fluid (Fig. 1). (2) Pump brake pedal several times, then apply and

hold a constant medium to heavy force on brake pedal. (3) Open primary check valve circuit bleed screw

(Fig. 1) at least 1 full turn to ensure an adequate flow

of brake fluid. Continue bleeding primary check valve

circuit until brake pedal bottoms. (4) After brake pedal bottoms, close and tighten

bleed screw. Then release brake pedal. Do not release

brake pedal prior to closing and tightening bleed

screw. (5) Continue bleeding modulator assembly, repeat-

ing steps 2 through 4 until a clear, bubble free flow of

brake fluid is evident. (6) When all air is bled from primary check valve

circuit, tighten bleed screw and remove bleed hose

from bleed screw. Do not remove bleed hose before

tightening bleed screw, air may re-enter modula-

tor. (7) Torque modulator assembly primary bleed screw

to9N Im (80 in. lbs.).

2 MODULATOR SECONDARY CHECK VALVE CIRCUIT (1) Move clear bleed tube to secondary check valve

circuit bleed screw (Fig. 2). Then install bleed tube into

a container partially filled with fresh clean brake fluid

(Fig. 2). (2) Pump brake pedal several times, then apply and

hold a constant medium to heavy force on brake pedal. (3) Open secondary check valve circuit bleeder screw

(Fig. 2), at least 1 full turn to ensure an adequate flow

of brake fluid. Continue to bleed secondary check valve

circuit until the brake pedal bottoms.

Fig. 1 Bleeding Modulator Assembly Primary Check Valve Circuit

5 - 26 ANTILOCK 4 BRAKE SYSTEM Ä

Page 626 of 2438

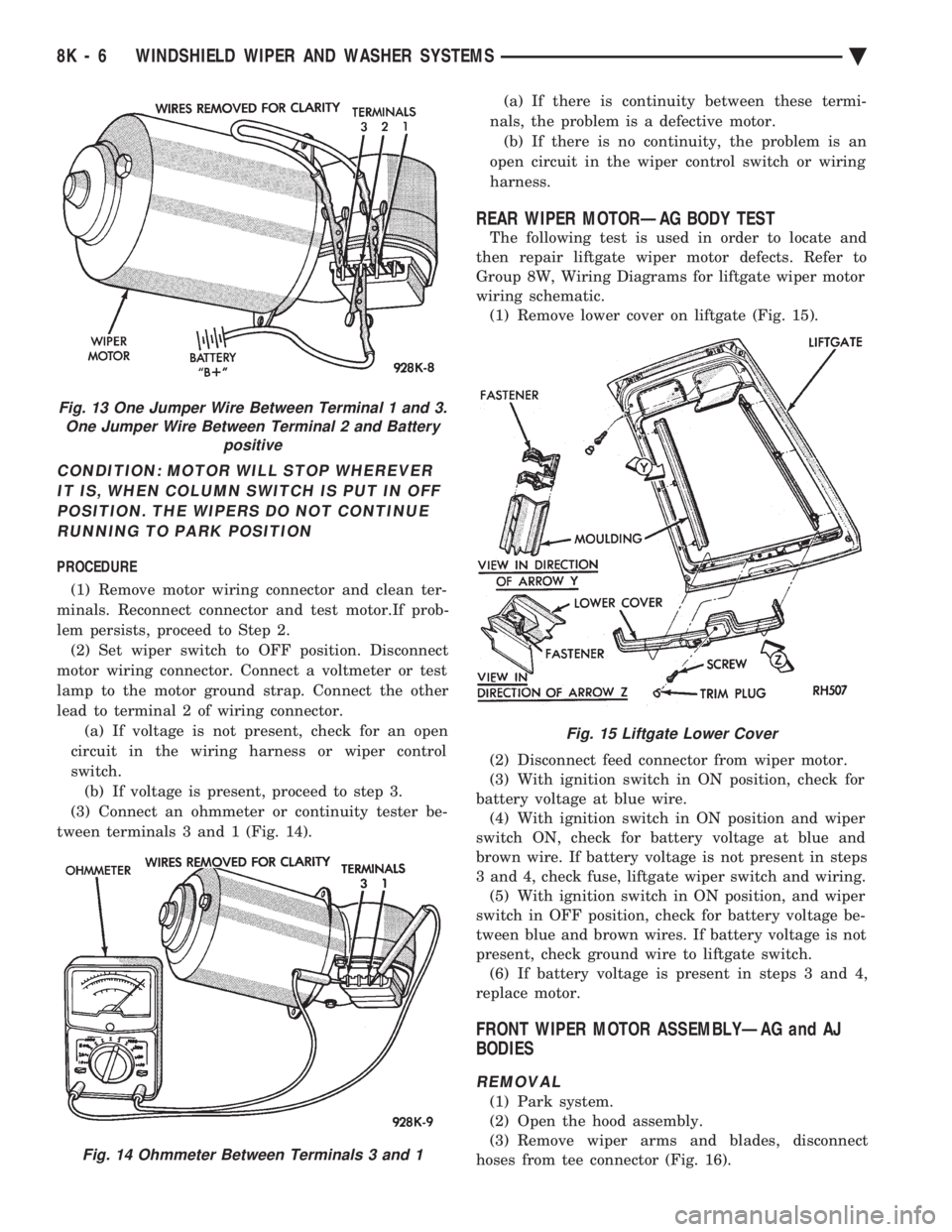

CONDITION: MOTOR WILL STOP WHEREVER IT IS, WHEN COLUMN SWITCH IS PUT IN OFFPOSITION. THE WIPERS DO NOT CONTINUERUNNING TO PARK POSITION

PROCEDURE

(1) Remove motor wiring connector and clean ter-

minals. Reconnect connector and test motor.If prob-

lem persists, proceed to Step 2. (2) Set wiper switch to OFF position. Disconnect

motor wiring connector. Connect a voltmeter or test

lamp to the motor ground strap. Connect the other

lead to terminal 2 of wiring connector. (a) If voltage is not present, check for an open

circuit in the wiring harness or wiper control

switch. (b) If voltage is present, proceed to step 3.

(3) Connect an ohmmeter or continuity tester be-

tween terminals 3 and 1 (Fig. 14). (a) If there is continuity between these termi-

nals, the problem is a defective motor. (b) If there is no continuity, the problem is an

open circuit in the wiper control switch or wiring

harness.

REAR WIPER MOTORÐAG BODY TEST

The following test is used in order to locate and

then repair liftgate wiper motor defects. Refer to

Group 8W, Wiring Diagrams for liftgate wiper motor

wiring schematic. (1) Remove lower cover on liftgate (Fig. 15).

(2) Disconnect feed connector from wiper motor.

(3) With ignition switch in ON position, check for

battery voltage at blue wire. (4) With ignition switch in ON position and wiper

switch ON, check for battery voltage at blue and

brown wire. If battery voltage is not present in steps

3 and 4, check fuse, liftgate wiper switch and wiring. (5) With ignition switch in ON position, and wiper

switch in OFF position, check for battery voltage be-

tween blue and brown wires. If battery voltage is not

present, check ground wire to liftgate switch. (6) If battery voltage is present in steps 3 and 4,

replace motor.

FRONT WIPER MOTOR ASSEMBLYÐAG and AJ

BODIES

REMOVAL

(1) Park system.

(2) Open the hood assembly.

(3) Remove wiper arms and blades, disconnect

hoses from tee connector (Fig. 16).

Fig. 13 One Jumper Wire Between Terminal 1 and 3. One Jumper Wire Between Terminal 2 and Battery positive

Fig. 14 Ohmmeter Between Terminals 3 and 1

Fig. 15 Liftgate Lower Cover

8K - 6 WINDSHIELD WIPER AND WASHER SYSTEMS Ä

Page 632 of 2438

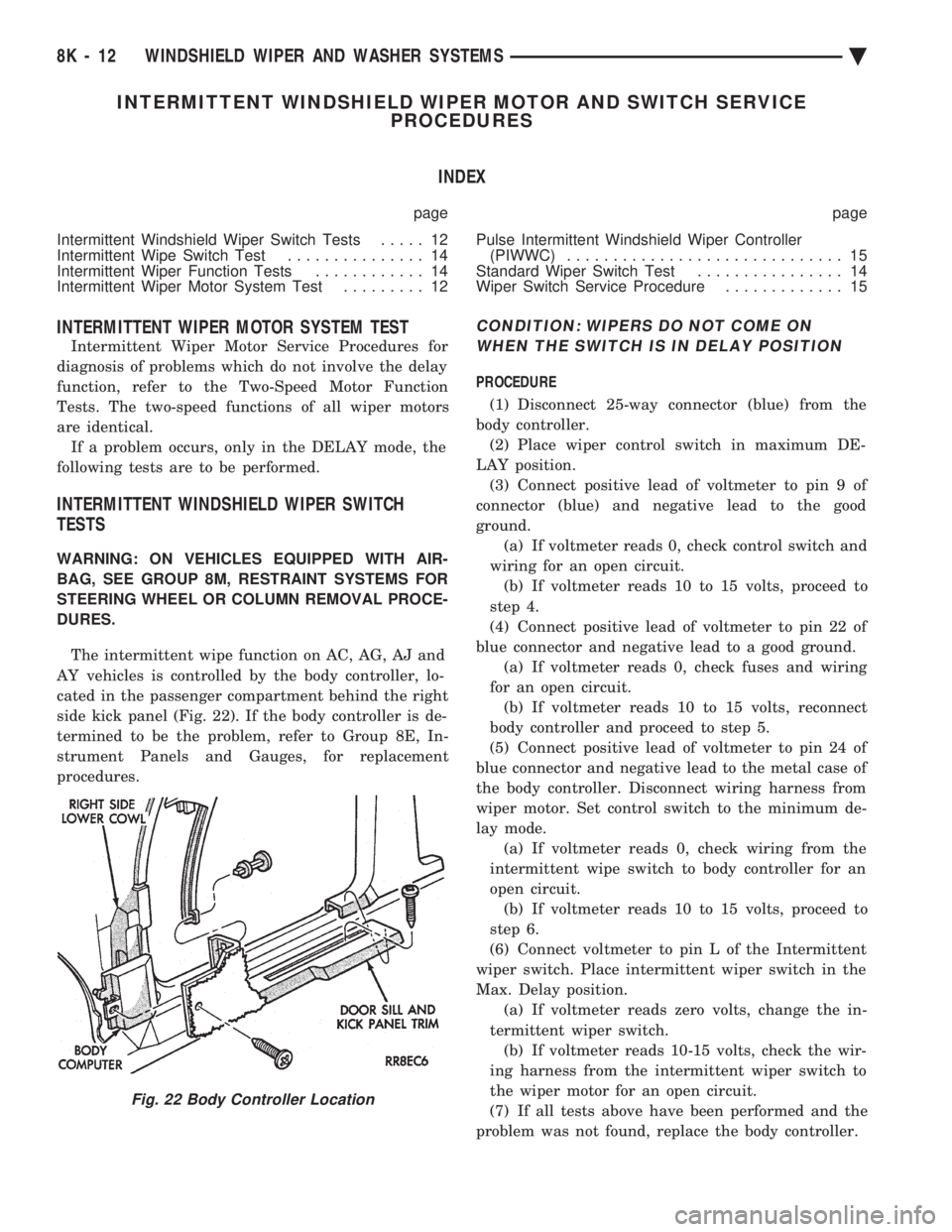

INTERMITTENT WINDSHIELD WIPER MOTOR AND SWITCH SERVICE PROCEDURES

INDEX

page page

Intermittent Windshield Wiper Switch Tests ..... 12

Intermittent Wipe Switch Test ............... 14

Intermittent Wiper Function Tests ............ 14

Intermittent Wiper Motor System Test ......... 12 Pulse Intermittent Windshield Wiper Controller

(PIWWC) .............................. 15

Standard Wiper Switch Test ................ 14

Wiper Switch Service Procedure ............. 15

INTERMITTENT WIPER MOTOR SYSTEM TEST

Intermittent Wiper Motor Service Procedures for

diagnosis of problems which do not involve the delay

function, refer to the Two-Speed Motor Function

Tests. The two-speed functions of all wiper motors

are identical. If a problem occurs, only in the DELAY mode, the

following tests are to be performed.

INTERMITTENT WINDSHIELD WIPER SWITCH

TESTS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

The intermittent wipe function on AC, AG, AJ and

AY vehicles is controlled by the body controller, lo-

cated in the passenger compartment behind the right

side kick panel (Fig. 22). If the body controller is de-

termined to be the problem, refer to Group 8E, In-

strument Panels and Gauges, for replacement

procedures.

CONDITION: WIPERS DO NOT COME ON WHEN THE SWITCH IS IN DELAY POSITION

PROCEDURE

(1) Disconnect 25-way connector (blue) from the

body controller. (2) Place wiper control switch in maximum DE-

LAY position. (3) Connect positive lead of voltmeter to pin 9 of

connector (blue) and negative lead to the good

ground. (a) If voltmeter reads 0, check control switch and

wiring for an open circuit. (b) If voltmeter reads 10 to 15 volts, proceed to

step 4.

(4) Connect positive lead of voltmeter to pin 22 of

blue connector and negative lead to a good ground. (a) If voltmeter reads 0, check fuses and wiring

for an open circuit. (b) If voltmeter reads 10 to 15 volts, reconnect

body controller and proceed to step 5.

(5) Connect positive lead of voltmeter to pin 24 of

blue connector and negative lead to the metal case of

the body controller. Disconnect wiring harness from

wiper motor. Set control switch to the minimum de-

lay mode. (a) If voltmeter reads 0, check wiring from the

intermittent wipe switch to body controller for an

open circuit. (b) If voltmeter reads 10 to 15 volts, proceed to

step 6.

(6) Connect voltmeter to pin L of the Intermittent

wiper switch. Place intermittent wiper switch in the

Max. Delay position. (a) If voltmeter reads zero volts, change the in-

termittent wiper switch. (b) If voltmeter reads 10-15 volts, check the wir-

ing harness from the intermittent wiper switch to

the wiper motor for an open circuit.

(7) If all tests above have been performed and the

problem was not found, replace the body controller.

Fig. 22 Body Controller Location

8K - 12 WINDSHIELD WIPER AND WASHER SYSTEMS Ä

Page 633 of 2438

CONDITION: WIPERS START TO WIPE, BUT STOP BEFORE ONE COMPLETE CYCLE ANDDO NOT RETURN TO PARK POSITION

PROCEDURE

(1) Verify that motor will park when the column

switch is put in the OFF position. (2) Set wiper control switch to maximum DELAY

and allow motor to run until it stops during the wipe

cycle. When motor stops, disconnect 25-way blue con-

nector from the body controller. (3) Connect positive lead of voltmeter to pin 20 of

blue connector and negative lead to the metal case of

the body controller. (a) If voltmeter reads 0, check wiring for an open

circuit. (b) If voltmeter reads 10 to 15 volts, proceed to

step 4.

(4) Using an ohmmeter or continuity tester; (a) Check for continuity between pins 20 and 24

of blue connector of the body controller. (b) Reverse ohmmeter leads on pins 20 and 24,

again checking for continuity. (c) If continuity between pins 20 and 24 is not

observed in both steps a and b, replace the body

controller.

CONDITION: EXCESSIVE DELAY OF MORE THAN 30 SECONDS OR INADEQUATEVARIATION IN DELAY

PROCEDURE

(1) Variations in delay should be as follows: (a) Minimum delay control to extreme counter-

clockwise position before first detent of 1/2 to 2 sec-

onds. (b) Maximum delay control to extreme clockwise

position before OFF detent of 15 to 25 seconds.

(2) If there is excessive delay or no variations in

delay, remove the wiper motor wiring harness while

the motor is parked in the OFF position. (3) Remove 25-way blue connector from the body

controller. (4) Set wiper control switch to maximum DELAY

position. (5) With ignition switch in ON position, measure

voltage between pin 9 of black connector and a good

ground. (a) If voltmeter reads 0, proceed to step 6.

(b) If voltmeter reads 10 to 15 volts, proceed to

step 7.

(6) Set wiper control switch to minimum DELAY

position and measure voltage between pin 9 of blue

connector and a good ground. If voltmeter reads 0,

check for an open circuit in the intermittent wipe

wiring harness. (7) Remove wiper motor circuit fuse. (8) Using an ohmmeter, measure the resistance be-

tween pins 9 and 22 of the body controller 25-way

black connector. Set the wiper control switch first to

minimum DELAY and then maximum DELAY. (a) If resistance reading at minimum DELAY

setting is between 0 and 15 ohms, and at maxi-

mum DELAY setting the resistance is between

240,000 and 400,000 ohms, replace the body con-

troller. (b) If the resistance values above are not ob-

tained, replace the wiper control switch.

CONDITION: WIPERS DO NOT RUN CONTINUALLY WHEN WASH CONTROL ISOPERATED DURING DELAY MODE

PROCEDURE

(1) Disconnect 25-way blue connector from the

body controller (2) Using a voltmeter, connect the positive lead to

pin 10 of the (Black) connector. Connect negative

lead to the body computer metal case. (3) Set wiper control switch to DELAY position.

(4) Depress wash switch.

(5) If voltage reads 0, check switch relay and wir-

ing. (6) If voltage is between 10 and 15 volts, the prob-

lem is in the body controller.

CONDITION: IN DELAY MODE, WIPERS RUN CONTINUALLY WHEN WASH IS OPERATEDBUT DO NOT PROVIDE FOUR EXTRA WIPESWHEN WASH CONTROL IS RELEASED

PROCEDURE

Replace body controller.

CONDITION: WIPERS START ERRATICALLY DURING DELAY MODE

PROCEDURE

(1) Verify that the ground connection at the in-

strument panel is making a good connection, free

from paint and is tight. (2) Verify that the motor ground strap is making

good contact and that the motor mounting bolts are

tight. (3) Verify that the wiring connections to the body

controller, wiper motor, and wiper motor switch are

tight and free of corrosion. (4) If condition is not corrected, problem is with

the body controller

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 13

Page 718 of 2438

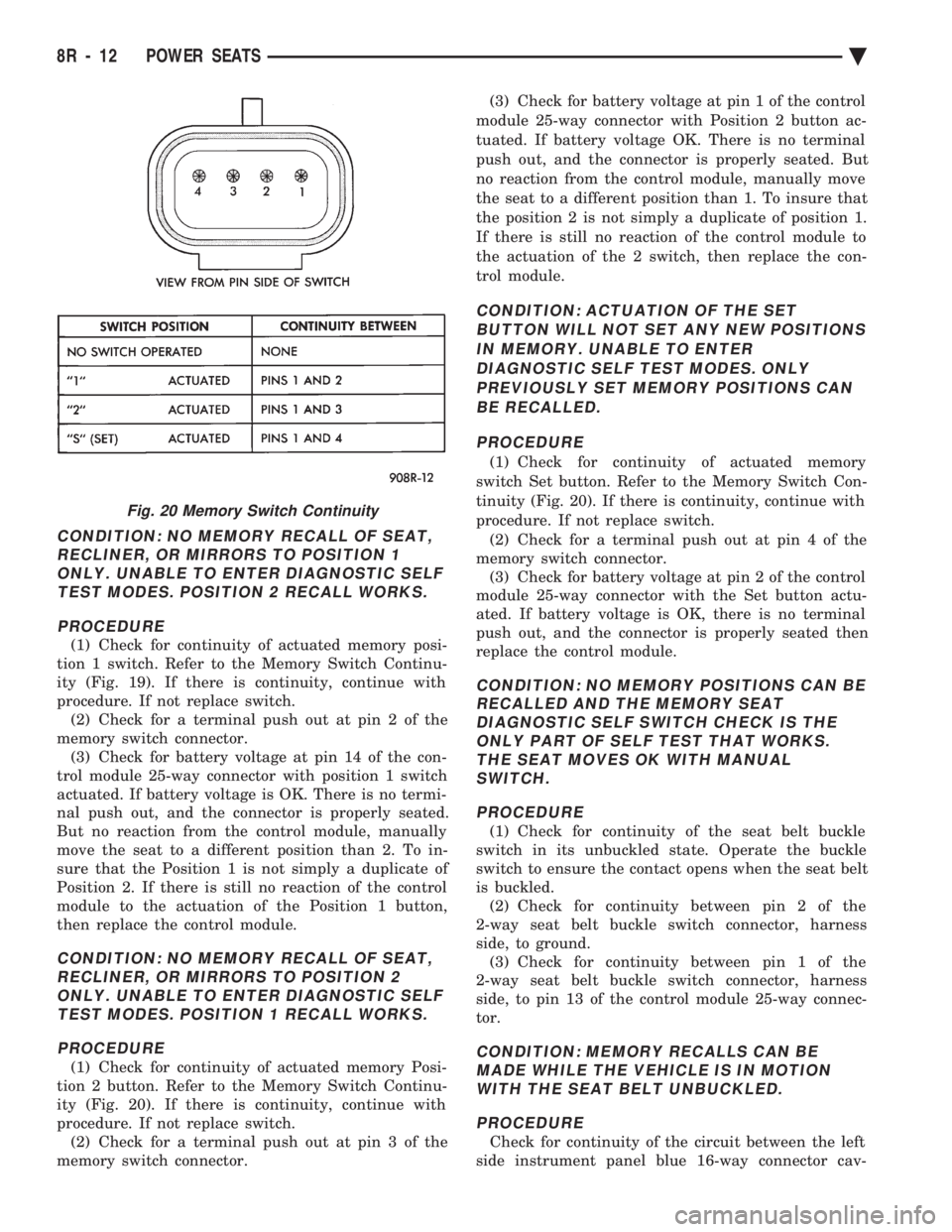

CONDITION: NO MEMORY RECALL OF SEAT, RECLINER, OR MIRRORS TO POSITION 1ONLY. UNABLE TO ENTER DIAGNOSTIC SELFTEST MODES. POSITION 2 RECALL WORKS.

PROCEDURE

(1) Check for continuity of actuated memory posi-

tion 1 switch. Refer to the Memory Switch Continu-

ity (Fig. 19). If there is continuity, continue with

procedure. If not replace switch. (2) Check for a terminal push out at pin 2 of the

memory switch connector. (3) Check for battery voltage at pin 14 of the con-

trol module 25-way connector with position 1 switch

actuated. If battery voltage is OK. There is no termi-

nal push out, and the connector is properly seated.

But no reaction from the control module, manually

move the seat to a different position than 2. To in-

sure that the Position 1 is not simply a duplicate of

Position 2. If there is still no reaction of the control

module to the actuation of the Position 1 button,

then replace the control module.

CONDITION: NO MEMORY RECALL OF SEAT, RECLINER, OR MIRRORS TO POSITION 2ONLY. UNABLE TO ENTER DIAGNOSTIC SELFTEST MODES. POSITION 1 RECALL WORKS.

PROCEDURE

(1) Check for continuity of actuated memory Posi-

tion 2 button. Refer to the Memory Switch Continu-

ity (Fig. 20). If there is continuity, continue with

procedure. If not replace switch. (2) Check for a terminal push out at pin 3 of the

memory switch connector. (3) Check for battery voltage at pin 1 of the control

module 25-way connector with Position 2 button ac-

tuated. If battery voltage OK. There is no terminal

push out, and the connector is properly seated. But

no reaction from the control module, manually move

the seat to a different position than 1. To insure that

the position 2 is not simply a duplicate of position 1.

If there is still no reaction of the control module to

the actuation of the 2 switch, then replace the con-

trol module.

CONDITION: ACTUATION OF THE SET BUTTON WILL NOT SET ANY NEW POSITIONSIN MEMORY. UNABLE TO ENTERDIAGNOSTIC SELF TEST MODES. ONLYPREVIOUSLY SET MEMORY POSITIONS CANBE RECALLED.

PROCEDURE

(1) Check for continuity of actuated memory

switch Set button. Refer to the Memory Switch Con-

tinuity (Fig. 20). If there is continuity, continue with

procedure. If not replace switch. (2) Check for a terminal push out at pin 4 of the

memory switch connector. (3) Check for battery voltage at pin 2 of the control

module 25-way connector with the Set button actu-

ated. If battery voltage is OK, there is no terminal

push out, and the connector is properly seated then

replace the control module.

CONDITION: NO MEMORY POSITIONS CAN BE RECALLED AND THE MEMORY SEATDIAGNOSTIC SELF SWITCH CHECK IS THEONLY PART OF SELF TEST THAT WORKS.THE SEAT MOVES OK WITH MANUALSWITCH.

PROCEDURE

(1) Check for continuity of the seat belt buckle

switch in its unbuckled state. Operate the buckle

switch to ensure the contact opens when the seat belt

is buckled. (2) Check for continuity between pin 2 of the

2-way seat belt buckle switch connector, harness

side, to ground. (3) Check for continuity between pin 1 of the

2-way seat belt buckle switch connector, harness

side, to pin 13 of the control module 25-way connec-

tor.

CONDITION: MEMORY RECALLS CAN BE MADE WHILE THE VEHICLE IS IN MOTIONWITH THE SEAT BELT UNBUCKLED.

PROCEDURE

Check for continuity of the circuit between the left

side instrument panel blue 16-way connector cav-

Fig. 20 Memory Switch Continuity

8R - 12 POWER SEATS Ä