air bleeding CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 156 of 2438

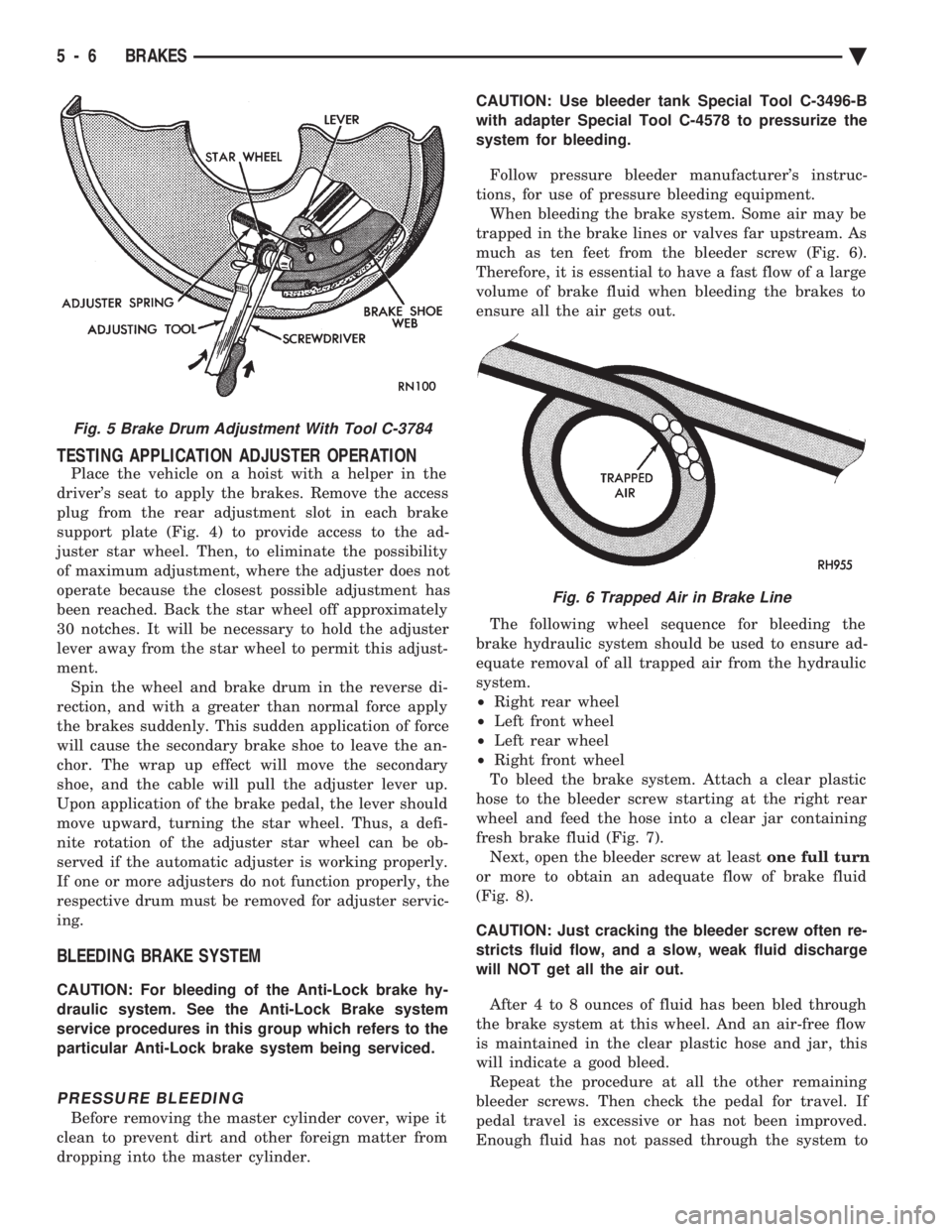

TESTING APPLICATION ADJUSTER OPERATION

Place the vehicle on a hoist with a helper in the

driver's seat to apply the brakes. Remove the access

plug from the rear adjustment slot in each brake

support plate (Fig. 4) to provide access to the ad-

juster star wheel. Then, to eliminate the possibility

of maximum adjustment, where the adjuster does not

operate because the closest possible adjustment has

been reached. Back the star wheel off approximately

30 notches. It will be necessary to hold the adjuster

lever away from the star wheel to permit this adjust-

ment. Spin the wheel and brake drum in the reverse di-

rection, and with a greater than normal force apply

the brakes suddenly. This sudden application of force

will cause the secondary brake shoe to leave the an-

chor. The wrap up effect will move the secondary

shoe, and the cable will pull the adjuster lever up.

Upon application of the brake pedal, the lever should

move upward, turning the star wheel. Thus, a defi-

nite rotation of the adjuster star wheel can be ob-

served if the automatic adjuster is working properly.

If one or more adjusters do not function properly, the

respective drum must be removed for adjuster servic-

ing.

BLEEDING BRAKE SYSTEM

CAUTION: For bleeding of the Anti-Lock brake hy-

draulic system. See the Anti-Lock Brake system

service procedures in this group which refers to the

particular Anti-Lock brake system being serviced.

PRESSURE BLEEDING

Before removing the master cylinder cover, wipe it

clean to prevent dirt and other foreign matter from

dropping into the master cylinder. CAUTION: Use bleeder tank Special Tool C-3496-B

with adapter Special Tool C-4578 to pressurize the

system for bleeding.

Follow pressure bleeder manufacturer's instruc-

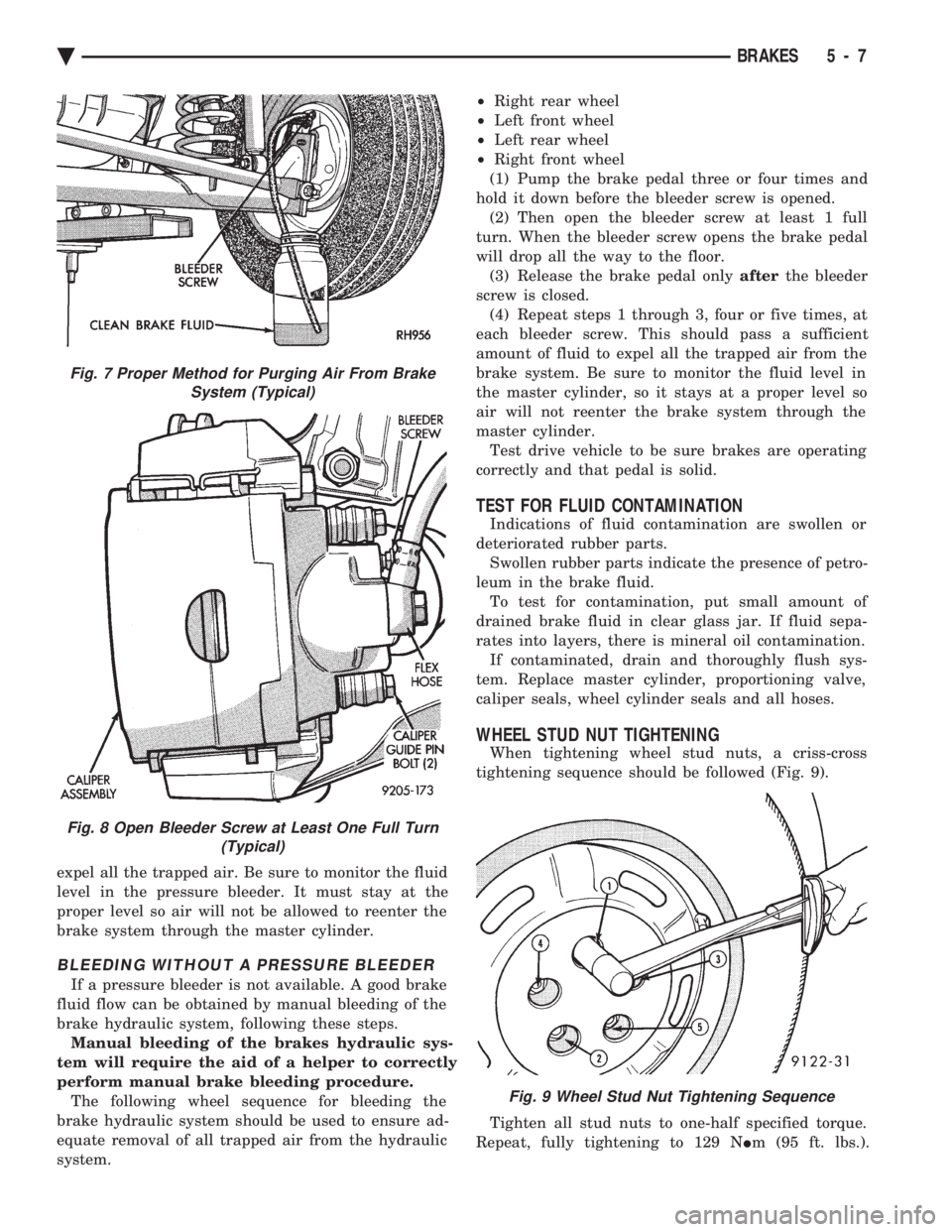

tions, for use of pressure bleeding equipment. When bleeding the brake system. Some air may be

trapped in the brake lines or valves far upstream. As

much as ten feet from the bleeder screw (Fig. 6).

Therefore, it is essential to have a fast flow of a large

volume of brake fluid when bleeding the brakes to

ensure all the air gets out.

The following wheel sequence for bleeding the

brake hydraulic system should be used to ensure ad-

equate removal of all trapped air from the hydraulic

system.

² Right rear wheel

² Left front wheel

² Left rear wheel

² Right front wheel

To bleed the brake system. Attach a clear plastic

hose to the bleeder screw starting at the right rear

wheel and feed the hose into a clear jar containing

fresh brake fluid (Fig. 7). Next, open the bleeder screw at least one full turn

or more to obtain an adequate flow of brake fluid

(Fig. 8).

CAUTION: Just cracking the bleeder screw often re-

stricts fluid flow, and a slow, weak fluid discharge

will NOT get all the air out.

After 4 to 8 ounces of fluid has been bled through

the brake system at this wheel. And an air-free flow

is maintained in the clear plastic hose and jar, this

will indicate a good bleed. Repeat the procedure at all the other remaining

bleeder screws. Then check the pedal for travel. If

pedal travel is excessive or has not been improved.

Enough fluid has not passed through the system to

Fig. 5 Brake Drum Adjustment With Tool C-3784

Fig. 6 Trapped Air in Brake Line

5 - 6 BRAKES Ä

Page 157 of 2438

expel all the trapped air. Be sure to monitor the fluid

level in the pressure bleeder. It must stay at the

proper level so air will not be allowed to reenter the

brake system through the master cylinder.

BLEEDING WITHOUT A PRESSURE BLEEDER

If a pressure bleeder is not available. A good brake

fluid flow can be obtained by manual bleeding of the

brake hydraulic system, following these steps. Manual bleeding of the brakes hydraulic sys-

tem will require the aid of a helper to correctly

perform manual brake bleeding procedure. The following wheel sequence for bleeding the

brake hydraulic system should be used to ensure ad-

equate removal of all trapped air from the hydraulic

system. ²

Right rear wheel

² Left front wheel

² Left rear wheel

² Right front wheel

(1) Pump the brake pedal three or four times and

hold it down before the bleeder screw is opened. (2) Then open the bleeder screw at least 1 full

turn. When the bleeder screw opens the brake pedal

will drop all the way to the floor. (3) Release the brake pedal only afterthe bleeder

screw is closed. (4) Repeat steps 1 through 3, four or five times, at

each bleeder screw. This should pass a sufficient

amount of fluid to expel all the trapped air from the

brake system. Be sure to monitor the fluid level in

the master cylinder, so it stays at a proper level so

air will not reenter the brake system through the

master cylinder. Test drive vehicle to be sure brakes are operating

correctly and that pedal is solid.

TEST FOR FLUID CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts. Swollen rubber parts indicate the presence of petro-

leum in the brake fluid. To test for contamination, put small amount of

drained brake fluid in clear glass jar. If fluid sepa-

rates into layers, there is mineral oil contamination. If contaminated, drain and thoroughly flush sys-

tem. Replace master cylinder, proportioning valve,

caliper seals, wheel cylinder seals and all hoses.

WHEEL STUD NUT TIGHTENING

When tightening wheel stud nuts, a criss-cross

tightening sequence should be followed (Fig. 9).

Tighten all stud nuts to one-half specified torque.

Repeat, fully tightening to 129 N Im (95 ft. lbs.).

Fig. 9 Wheel Stud Nut Tightening Sequence

Fig. 7 Proper Method for Purging Air From Brake

System (Typical)

Fig. 8 Open Bleeder Screw at Least One Full Turn (Typical)

Ä BRAKES 5 - 7

Page 174 of 2438

cylinder bore and piston for scoring and pitting. (Do

not use a rag as lint from the rag will stick to bore

surfaces.) Wheel cylinder bores and pistons that are scored or

pitted in any way should be replaced. Cylinder walls

that have light scratches, or show signs of corrosion,

can usually be cleaned with crocus cloth, using a cir-

cular motion. Black stains on the cylinder walls are

caused by piston cups and will not impair operation

of cylinder.

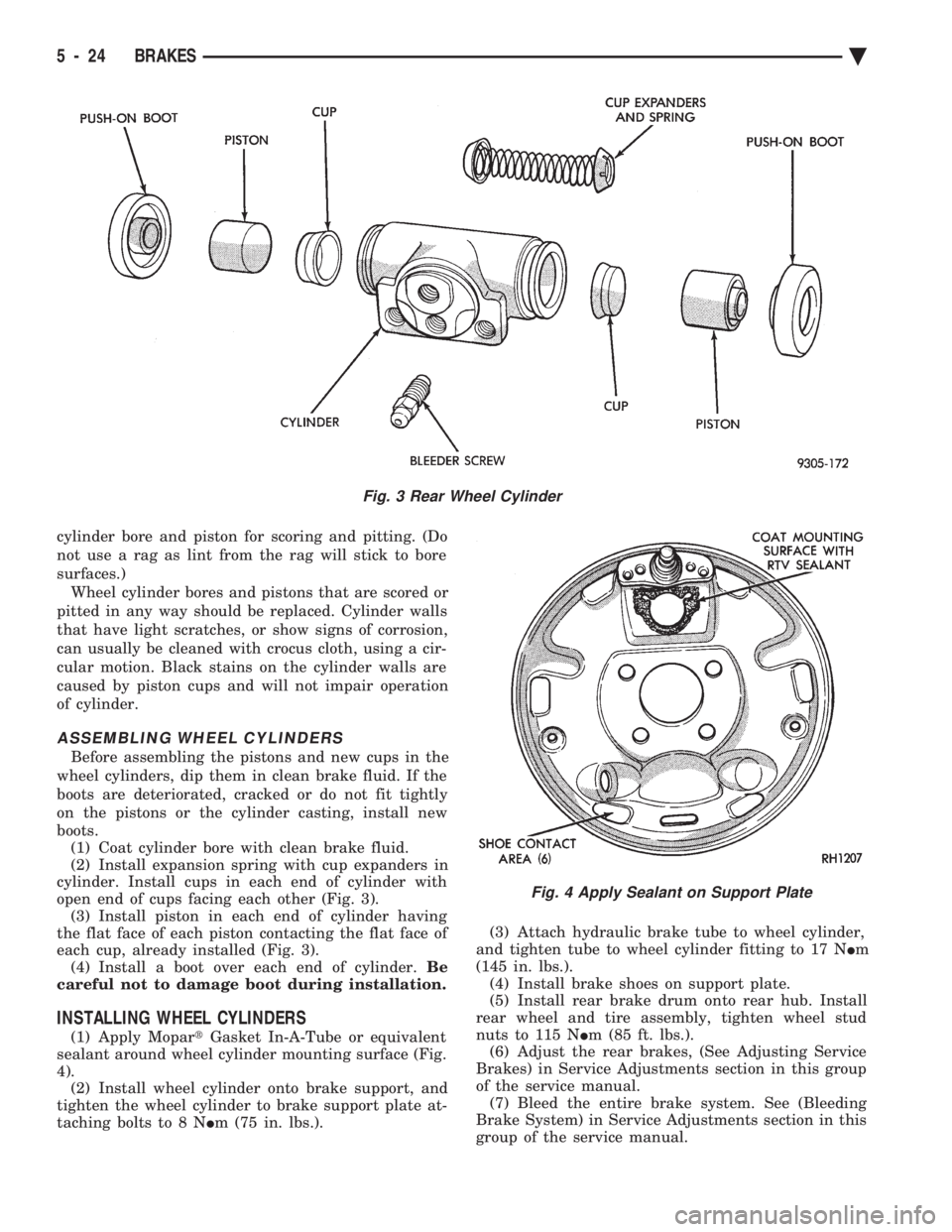

ASSEMBLING WHEEL CYLINDERS

Before assembling the pistons and new cups in the

wheel cylinders, dip them in clean brake fluid. If the

boots are deteriorated, cracked or do not fit tightly

on the pistons or the cylinder casting, install new

boots. (1) Coat cylinder bore with clean brake fluid.

(2) Install expansion spring with cup expanders in

cylinder. Install cups in each end of cylinder with

open end of cups facing each other (Fig. 3). (3) Install piston in each end of cylinder having

the flat face of each piston contacting the flat face of

each cup, already installed (Fig. 3). (4) Install a boot over each end of cylinder. Be

careful not to damage boot during installation.

INSTALLING WHEEL CYLINDERS

(1) Apply Mopar tGasket In-A-Tube or equivalent

sealant around wheel cylinder mounting surface (Fig.

4). (2) Install wheel cylinder onto brake support, and

tighten the wheel cylinder to brake support plate at-

taching bolts to 8 N Im (75 in. lbs.). (3) Attach hydraulic brake tube to wheel cylinder,

and tighten tube to wheel cylinder fitting to 17 N Im

(145 in. lbs.). (4) Install brake shoes on support plate.

(5) Install rear brake drum onto rear hub. Install

rear wheel and tire assembly, tighten wheel stud

nuts to 115 N Im (85 ft. lbs.).

(6) Adjust the rear brakes, (See Adjusting Service

Brakes) in Service Adjustments section in this group

of the service manual. (7) Bleed the entire brake system. See (Bleeding

Brake System) in Service Adjustments section in this

group of the service manual.

Fig. 3 Rear Wheel Cylinder

Fig. 4 Apply Sealant on Support Plate

5 - 24 BRAKES Ä

Page 177 of 2438

to the rear will be lower than the front brakes. This will

prevent premature rear wheel lock-up and skid. If

hydraulic pressure is lost in one half of the diagonally

split system, the operation of the proportioning valve

in the remaining half is not effected.

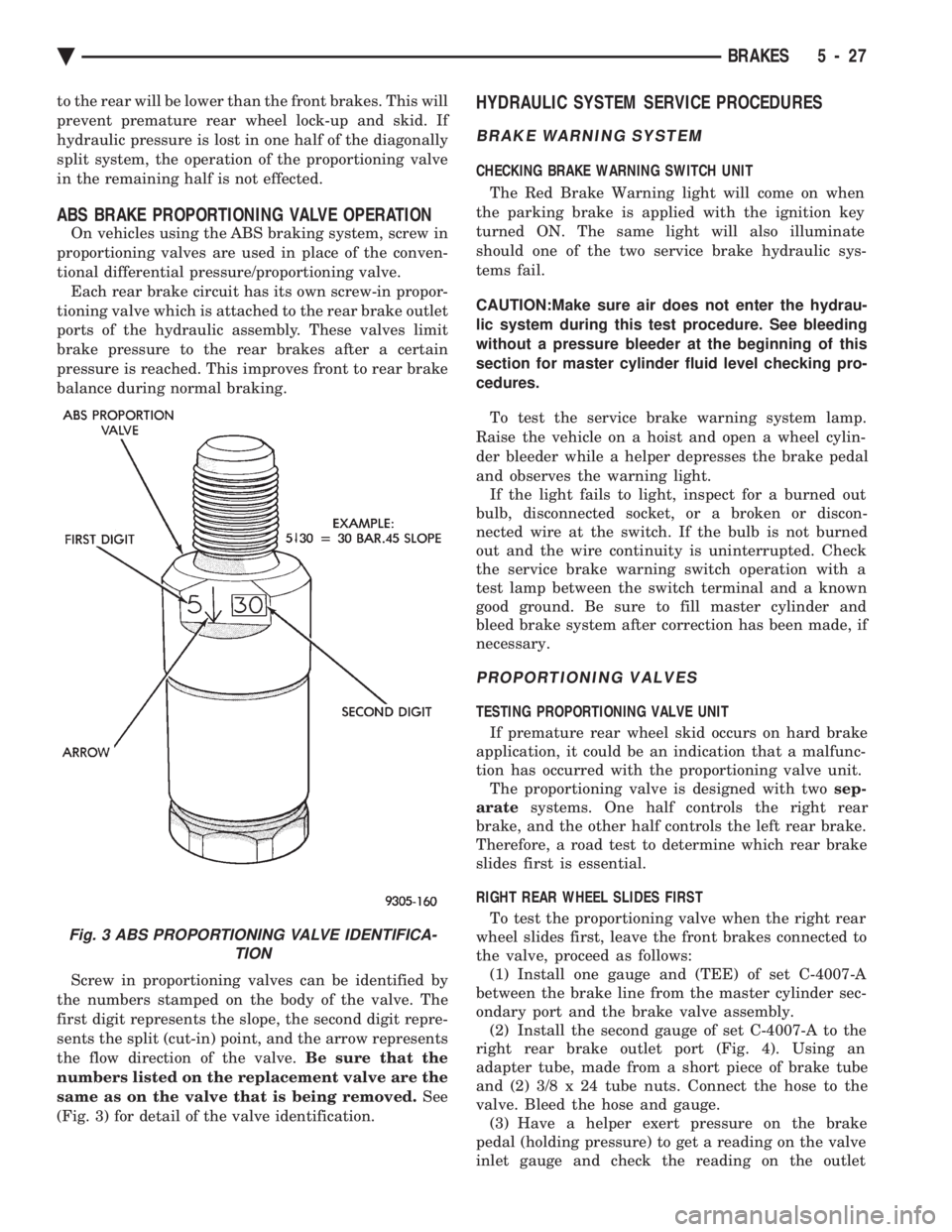

ABS BRAKE PROPORTIONING VALVE OPERATION

On vehicles using the ABS braking system, screw in

proportioning valves are used in place of the conven-

tional differential pressure/proportioning valve. Each rear brake circuit has its own screw-in propor-

tioning valve which is attached to the rear brake outlet

ports of the hydraulic assembly. These valves limit

brake pressure to the rear brakes after a certain

pressure is reached. This improves front to rear brake

balance during normal braking.

Screw in proportioning valves can be identified by

the numbers stamped on the body of the valve. The

first digit represents the slope, the second digit repre-

sents the split (cut-in) point, and the arrow represents

the flow direction of the valve. Be sure that the

numbers listed on the replacement valve are the

same as on the valve that is being removed. See

(Fig. 3) for detail of the valve identification.

HYDRAULIC SYSTEM SERVICE PROCEDURES

BRAKE WARNING SYSTEM

CHECKING BRAKE WARNING SWITCH UNIT

The Red Brake Warning light will come on when

the parking brake is applied with the ignition key

turned ON. The same light will also illuminate

should one of the two service brake hydraulic sys-

tems fail.

CAUTION:Make sure air does not enter the hydrau-

lic system during this test procedure. See bleeding

without a pressure bleeder at the beginning of this

section for master cylinder fluid level checking pro-

cedures.

To test the service brake warning system lamp.

Raise the vehicle on a hoist and open a wheel cylin-

der bleeder while a helper depresses the brake pedal

and observes the warning light. If the light fails to light, inspect for a burned out

bulb, disconnected socket, or a broken or discon-

nected wire at the switch. If the bulb is not burned

out and the wire continuity is uninterrupted. Check

the service brake warning switch operation with a

test lamp between the switch terminal and a known

good ground. Be sure to fill master cylinder and

bleed brake system after correction has been made, if

necessary.

PROPORTIONING VALVES

TESTING PROPORTIONING VALVE UNIT

If premature rear wheel skid occurs on hard brake

application, it could be an indication that a malfunc-

tion has occurred with the proportioning valve unit. The proportioning valve is designed with two sep-

arate systems. One half controls the right rear

brake, and the other half controls the left rear brake.

Therefore, a road test to determine which rear brake

slides first is essential.

RIGHT REAR WHEEL SLIDES FIRST To test the proportioning valve when the right rear

wheel slides first, leave the front brakes connected to

the valve, proceed as follows: (1) Install one gauge and (TEE) of set C-4007-A

between the brake line from the master cylinder sec-

ondary port and the brake valve assembly. (2) Install the second gauge of set C-4007-A to the

right rear brake outlet port (Fig. 4). Using an

adapter tube, made from a short piece of brake tube

and (2) 3/8 x 24 tube nuts. Connect the hose to the

valve. Bleed the hose and gauge. (3) Have a helper exert pressure on the brake

pedal (holding pressure) to get a reading on the valve

inlet gauge and check the reading on the outlet

Fig. 3 ABS PROPORTIONING VALVE IDENTIFICA- TION

Ä BRAKES 5 - 27

Page 217 of 2438

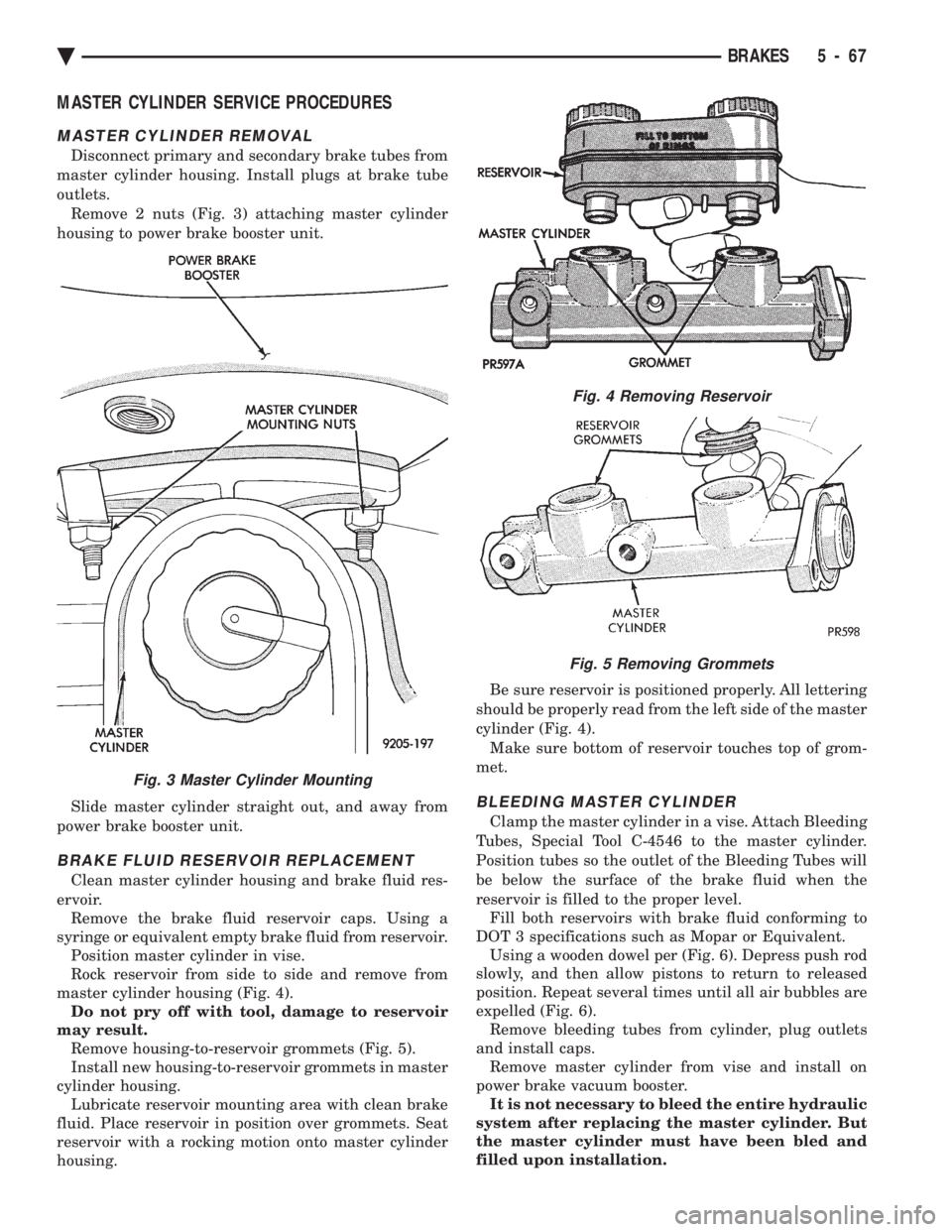

MASTER CYLINDER SERVICE PROCEDURES

MASTER CYLINDER REMOVAL

Disconnect primary and secondary brake tubes from

master cylinder housing. Install plugs at brake tube

outlets. Remove 2 nuts (Fig. 3) attaching master cylinder

housing to power brake booster unit.

Slide master cylinder straight out, and away from

power brake booster unit.

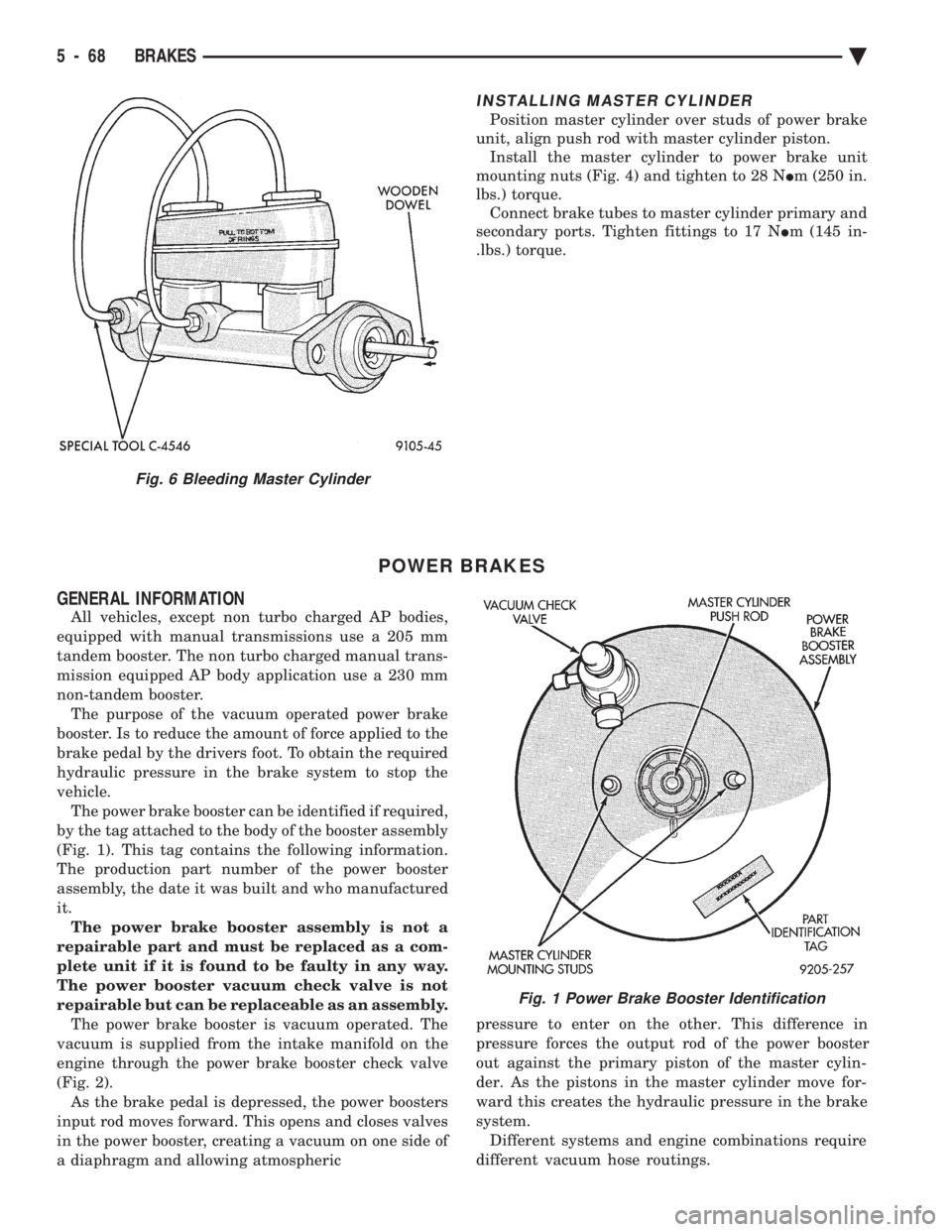

BRAKE FLUID RESERVOIR REPLACEMENT

Clean master cylinder housing and brake fluid res-

ervoir. Remove the brake fluid reservoir caps. Using a

syringe or equivalent empty brake fluid from reservoir. Position master cylinder in vise.

Rock reservoir from side to side and remove from

master cylinder housing (Fig. 4). Do not pry off with tool, damage to reservoir

may result. Remove housing-to-reservoir grommets (Fig. 5).

Install new housing-to-reservoir grommets in master

cylinder housing. Lubricate reservoir mounting area with clean brake

fluid. Place reservoir in position over grommets. Seat

reservoir with a rocking motion onto master cylinder

housing. Be sure reservoir is positioned properly. All lettering

should be properly read from the left side of the master

cylinder (Fig. 4). Make sure bottom of reservoir touches top of grom-

met.

BLEEDING MASTER CYLINDER

Clamp the master cylinder in a vise. Attach Bleeding

Tubes, Special Tool C-4546 to the master cylinder.

Position tubes so the outlet of the Bleeding Tubes will

be below the surface of the brake fluid when the

reservoir is filled to the proper level. Fill both reservoirs with brake fluid conforming to

DOT 3 specifications such as Mopar or Equivalent. Using a wooden dowel per (Fig. 6). Depress push rod

slowly, and then allow pistons to return to released

position. Repeat several times until all air bubbles are

expelled (Fig. 6). Remove bleeding tubes from cylinder, plug outlets

and install caps. Remove master cylinder from vise and install on

power brake vacuum booster. It is not necessary to bleed the entire hydraulic

system after replacing the master cylinder. But

the master cylinder must have been bled and

filled upon installation.

Fig. 4 Removing Reservoir

Fig. 5 Removing Grommets

Fig. 3 Master Cylinder Mounting

Ä BRAKES 5 - 67

Page 218 of 2438

INSTALLING MASTER CYLINDER

Position master cylinder over studs of power brake

unit, align push rod with master cylinder piston. Install the master cylinder to power brake unit

mounting nuts (Fig. 4) and tighten to 28 N Im (250 in.

lbs.) torque. Connect brake tubes to master cylinder primary and

secondary ports. Tighten fittings to 17 N Im (145 in-

.lbs.) torque.

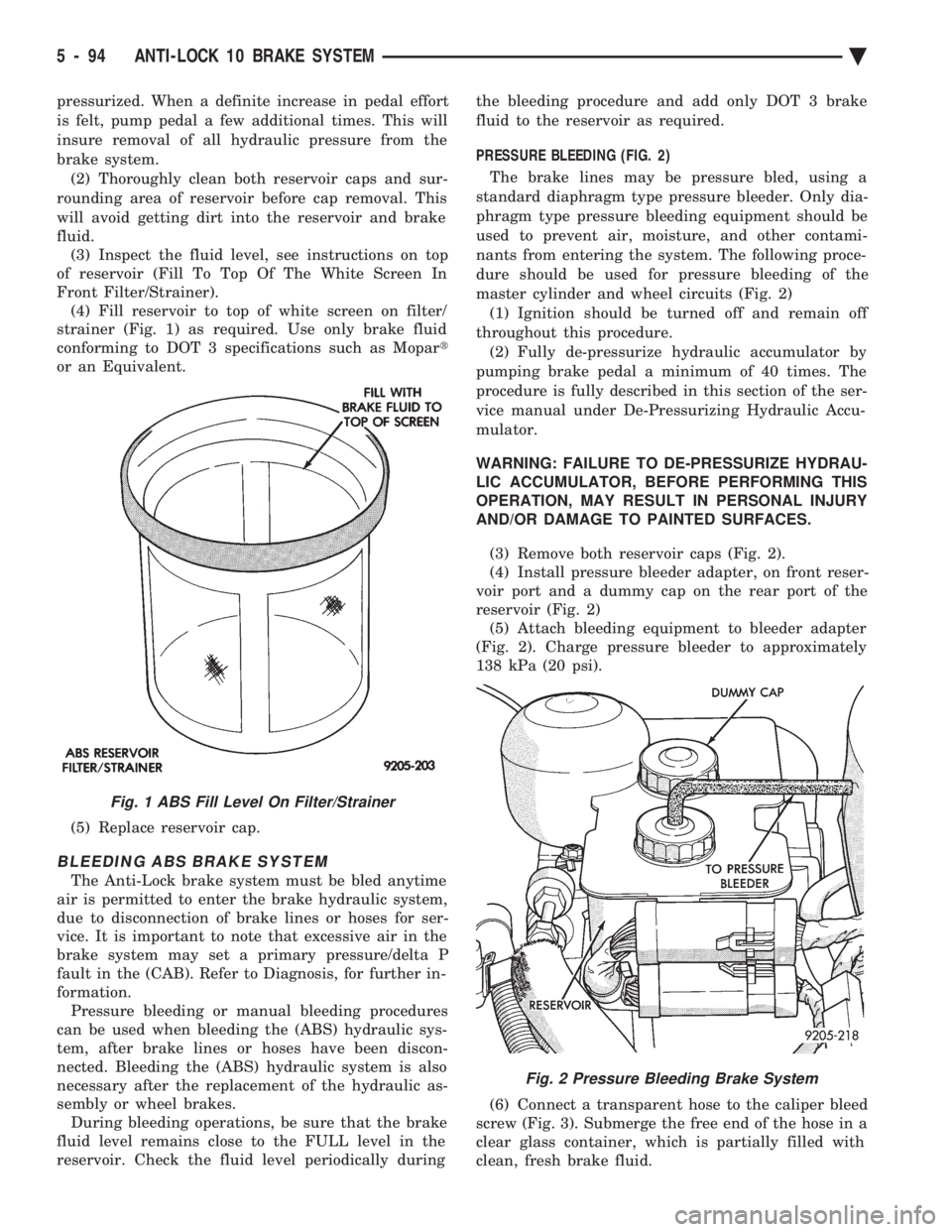

POWER BRAKES

GENERAL INFORMATION

All vehicles, except non turbo charged AP bodies,

equipped with manual transmissions use a 205 mm

tandem booster. The non turbo charged manual trans-

mission equipped AP body application use a 230 mm

non-tandem booster. The purpose of the vacuum operated power brake

booster. Is to reduce the amount of force applied to the

brake pedal by the drivers foot. To obtain the required

hydraulic pressure in the brake system to stop the

vehicle. The power brake booster can be identified if required,

by the tag attached to the body of the booster assembly

(Fig. 1). This tag contains the following information.

The production part number of the power booster

assembly, the date it was built and who manufactured

it. The power brake booster assembly is not a

repairable part and must be replaced as a com-

plete unit if it is found to be faulty in any way.

The power booster vacuum check valve is not

repairable but can be replaceable as an assembly. The power brake booster is vacuum operated. The

vacuum is supplied from the intake manifold on the

engine through the power brake booster check valve

(Fig. 2). As the brake pedal is depressed, the power boosters

input rod moves forward. This opens and closes valves

in the power booster, creating a vacuum on one side of

a diaphragm and allowing atmospheric pressure to enter on the other. This difference in

pressure forces the output rod of the power booster

out against the primary piston of the master cylin-

der. As the pistons in the master cylinder move for-

ward this creates the hydraulic pressure in the brake

system. Different systems and engine combinations require

different vacuum hose routings.

Fig. 6 Bleeding Master Cylinder

Fig. 1 Power Brake Booster Identification

5 - 68 BRAKES Ä

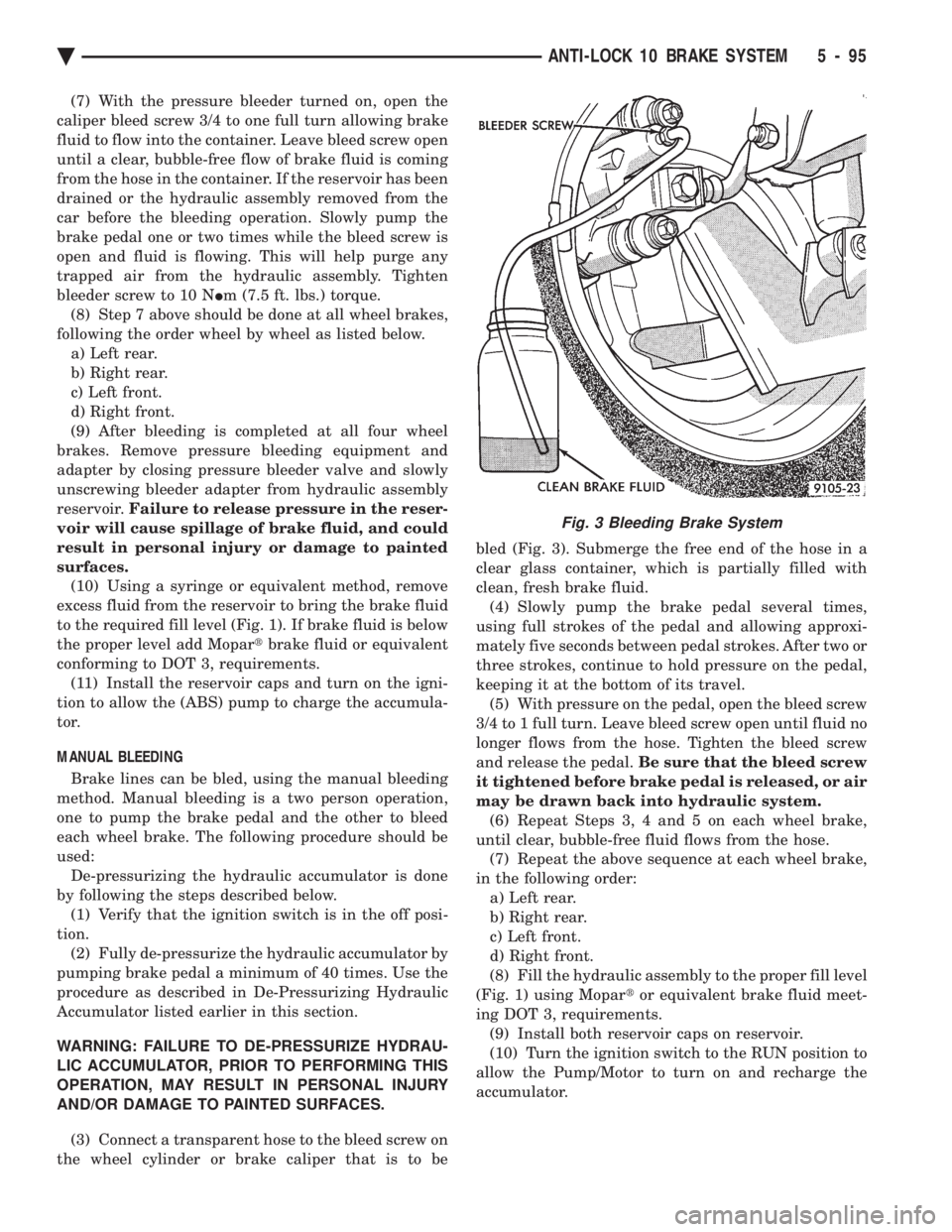

Page 244 of 2438

pressurized. When a definite increase in pedal effort

is felt, pump pedal a few additional times. This will

insure removal of all hydraulic pressure from the

brake system.(2) Thoroughly clean both reservoir caps and sur-

rounding area of reservoir before cap removal. This

will avoid getting dirt into the reservoir and brake

fluid. (3) Inspect the fluid level, see instructions on top

of reservoir (Fill To Top Of The White Screen In

Front Filter/Strainer). (4) Fill reservoir to top of white screen on filter/

strainer (Fig. 1) as required. Use only brake fluid

conforming to DOT 3 specifications such as Mopar t

or an Equivalent.

(5) Replace reservoir cap.

BLEEDING ABS BRAKE SYSTEM

The Anti-Lock brake system must be bled anytime

air is permitted to enter the brake hydraulic system,

due to disconnection of brake lines or hoses for ser-

vice. It is important to note that excessive air in the

brake system may set a primary pressure/delta P

fault in the (CAB). Refer to Diagnosis, for further in-

formation. Pressure bleeding or manual bleeding procedures

can be used when bleeding the (ABS) hydraulic sys-

tem, after brake lines or hoses have been discon-

nected. Bleeding the (ABS) hydraulic system is also

necessary after the replacement of the hydraulic as-

sembly or wheel brakes. During bleeding operations, be sure that the brake

fluid level remains close to the FULL level in the

reservoir. Check the fluid level periodically during the bleeding procedure and add only DOT 3 brake

fluid to the reservoir as required.

PRESSURE BLEEDING (FIG. 2)

The brake lines may be pressure bled, using a

standard diaphragm type pressure bleeder. Only dia-

phragm type pressure bleeding equipment should be

used to prevent air, moisture, and other contami-

nants from entering the system. The following proce-

dure should be used for pressure bleeding of the

master cylinder and wheel circuits (Fig. 2) (1) Ignition should be turned off and remain off

throughout this procedure. (2) Fully de-pressurize hydraulic accumulator by

pumping brake pedal a minimum of 40 times. The

procedure is fully described in this section of the ser-

vice manual under De-Pressurizing Hydraulic Accu-

mulator.

WARNING: FAILURE TO DE-PRESSURIZE HYDRAU-

LIC ACCUMULATOR, BEFORE PERFORMING THIS

OPERATION, MAY RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES.

(3) Remove both reservoir caps (Fig. 2).

(4) Install pressure bleeder adapter, on front reser-

voir port and a dummy cap on the rear port of the

reservoir (Fig. 2) (5) Attach bleeding equipment to bleeder adapter

(Fig. 2). Charge pressure bleeder to approximately

138 kPa (20 psi).

(6) Connect a transparent hose to the caliper bleed

screw (Fig. 3). Submerge the free end of the hose in a

clear glass container, which is partially filled with

clean, fresh brake fluid.

Fig. 1 ABS Fill Level On Filter/Strainer

Fig. 2 Pressure Bleeding Brake System

5 - 94 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 245 of 2438

(7) With the pressure bleeder turned on, open the

caliper bleed screw 3/4 to one full turn allowing brake

fluid to flow into the container. Leave bleed screw open

until a clear, bubble-free flow of brake fluid is coming

from the hose in the container. If the reservoir has been

drained or the hydraulic assembly removed from the

car before the bleeding operation. Slowly pump the

brake pedal one or two times while the bleed screw is

open and fluid is flowing. This will help purge any

trapped air from the hydraulic assembly. Tighten

bleeder screw to 10 N Im (7.5 ft. lbs.) torque.

(8) Step 7 above should be done at all wheel brakes,

following the order wheel by wheel as listed below. a) Left rear.

b) Right rear.

c) Left front.

d) Right front.

(9) After bleeding is completed at all four wheel

brakes. Remove pressure bleeding equipment and

adapter by closing pressure bleeder valve and slowly

unscrewing bleeder adapter from hydraulic assembly

reservoir. Failure to release pressure in the reser-

voir will cause spillage of brake fluid, and could

result in personal injury or damage to painted

surfaces. (10) Using a syringe or equivalent method, remove

excess fluid from the reservoir to bring the brake fluid

to the required fill level (Fig. 1). If brake fluid is below

the proper level add Mopar tbrake fluid or equivalent

conforming to DOT 3, requirements. (11) Install the reservoir caps and turn on the igni-

tion to allow the (ABS) pump to charge the accumula-

tor.

MANUAL BLEEDING

Brake lines can be bled, using the manual bleeding

method. Manual bleeding is a two person operation,

one to pump the brake pedal and the other to bleed

each wheel brake. The following procedure should be

used: De-pressurizing the hydraulic accumulator is done

by following the steps described below. (1) Verify that the ignition switch is in the off posi-

tion. (2) Fully de-pressurize the hydraulic accumulator by

pumping brake pedal a minimum of 40 times. Use the

procedure as described in De-Pressurizing Hydraulic

Accumulator listed earlier in this section.

WARNING: FAILURE TO DE-PRESSURIZE HYDRAU-

LIC ACCUMULATOR, PRIOR TO PERFORMING THIS

OPERATION, MAY RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES.

(3) Connect a transparent hose to the bleed screw on

the wheel cylinder or brake caliper that is to be bled (Fig. 3). Submerge the free end of the hose in a

clear glass container, which is partially filled with

clean, fresh brake fluid.

(4) Slowly pump the brake pedal several times,

using full strokes of the pedal and allowing approxi-

mately five seconds between pedal strokes. After two or

three strokes, continue to hold pressure on the pedal,

keeping it at the bottom of its travel. (5) With pressure on the pedal, open the bleed screw

3/4 to 1 full turn. Leave bleed screw open until fluid no

longer flows from the hose. Tighten the bleed screw

and release the pedal. Be sure that the bleed screw

it tightened before brake pedal is released, or air

may be drawn back into hydraulic system. (6) Repeat Steps 3, 4 and 5 on each wheel brake,

until clear, bubble-free fluid flows from the hose. (7) Repeat the above sequence at each wheel brake,

in the following order: a) Left rear.

b) Right rear.

c) Left front.

d) Right front.

(8) Fill the hydraulic assembly to the proper fill level

(Fig. 1) using Mopar tor equivalent brake fluid meet-

ing DOT 3, requirements. (9) Install both reservoir caps on reservoir.

(10) Turn the ignition switch to the RUN position to

allow the Pump/Motor to turn on and recharge the

accumulator.

Fig. 3 Bleeding Brake System

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 95

Page 246 of 2438

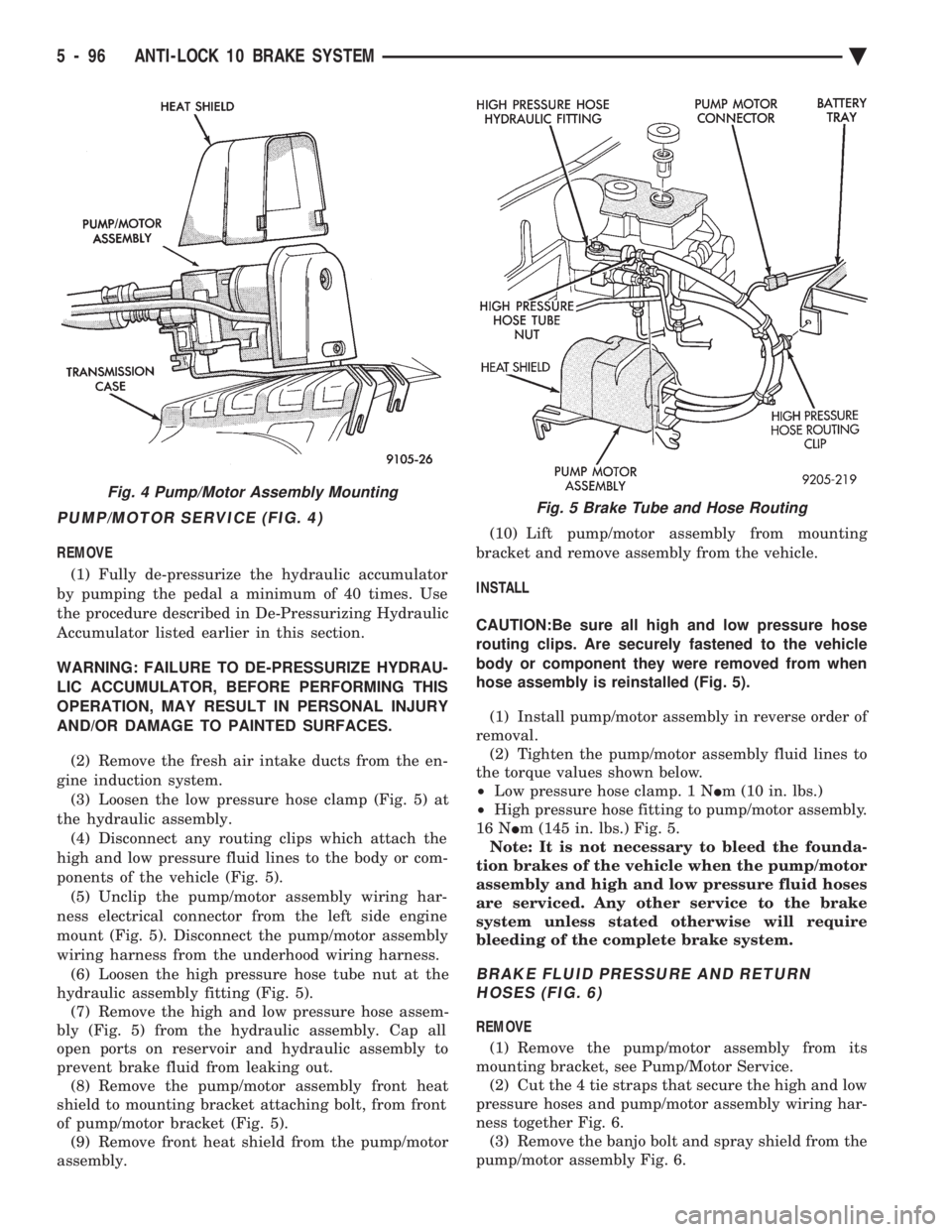

PUMP/MOTOR SERVICE (FIG. 4)

REMOVE (1) Fully de-pressurize the hydraulic accumulator

by pumping the pedal a minimum of 40 times. Use

the procedure described in De-Pressurizing Hydraulic

Accumulator listed earlier in this section.

WARNING: FAILURE TO DE-PRESSURIZE HYDRAU-

LIC ACCUMULATOR, BEFORE PERFORMING THIS

OPERATION, MAY RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES.

(2) Remove the fresh air intake ducts from the en-

gine induction system. (3) Loosen the low pressure hose clamp (Fig. 5) at

the hydraulic assembly. (4) Disconnect any routing clips which attach the

high and low pressure fluid lines to the body or com-

ponents of the vehicle (Fig. 5). (5) Unclip the pump/motor assembly wiring har-

ness electrical connector from the left side engine

mount (Fig. 5). Disconnect the pump/motor assembly

wiring harness from the underhood wiring harness. (6) Loosen the high pressure hose tube nut at the

hydraulic assembly fitting (Fig. 5). (7) Remove the high and low pressure hose assem-

bly (Fig. 5) from the hydraulic assembly. Cap all

open ports on reservoir and hydraulic assembly to

prevent brake fluid from leaking out. (8) Remove the pump/motor assembly front heat

shield to mounting bracket attaching bolt, from front

of pump/motor bracket (Fig. 5). (9) Remove front heat shield from the pump/motor

assembly. (10) Lift pump/motor assembly from mounting

bracket and remove assembly from the vehicle.

INSTALL

CAUTION:Be sure all high and low pressure hose

routing clips. Are securely fastened to the vehicle

body or component they were removed from when

hose assembly is reinstalled (Fig. 5).

(1) Install pump/motor assembly in reverse order of

removal. (2) Tighten the pump/motor assembly fluid lines to

the torque values shown below.

² Low pressure hose clamp. 1 N Im (10 in. lbs.)

² High pressure hose fitting to pump/motor assembly.

16 N Im (145 in. lbs.) Fig. 5.

Note: It is not necessary to bleed the founda-

tion brakes of the vehicle when the pump/motor

assembly and high and low pressure fluid hoses

are serviced. Any other service to the brake

system unless stated otherwise will require

bleeding of the complete brake system.

BRAKE FLUID PRESSURE AND RETURN HOSES (FIG. 6)

REMOVE

(1) Remove the pump/motor assembly from its

mounting bracket, see Pump/Motor Service. (2) Cut the 4 tie straps that secure the high and low

pressure hoses and pump/motor assembly wiring har-

ness together Fig. 6. (3) Remove the banjo bolt and spray shield from the

pump/motor assembly Fig. 6.

Fig. 4 Pump/Motor Assembly MountingFig. 5 Brake Tube and Hose Routing

5 - 96 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 249 of 2438

(7) Install high pressure hose to hydraulic assem-

bly (Fig. 7). Tighten the hose, to hydraulic assembly

fitting to 16 N Im (145 in. lbs)

(8) Fill hydraulic assembly brake fluid reservoir to

top of screen on the reservoir filter/strainer Fig. 9.

(9) Connect all electrical connectors to the hydrau-

lic assembly. (10) Bleed the entire brake system, see Bleeding

Brake System in this section of the Service Manual. (11) Replace all fresh air intake ducts, air cleaner

and washer bottle. (12) Check that the brake fluid in the hydraulic

assembly is at the correct level before moving vehicle

(Fig. 9). (See Checking Brake Fluid Level in this sec-

tion of the service manual).

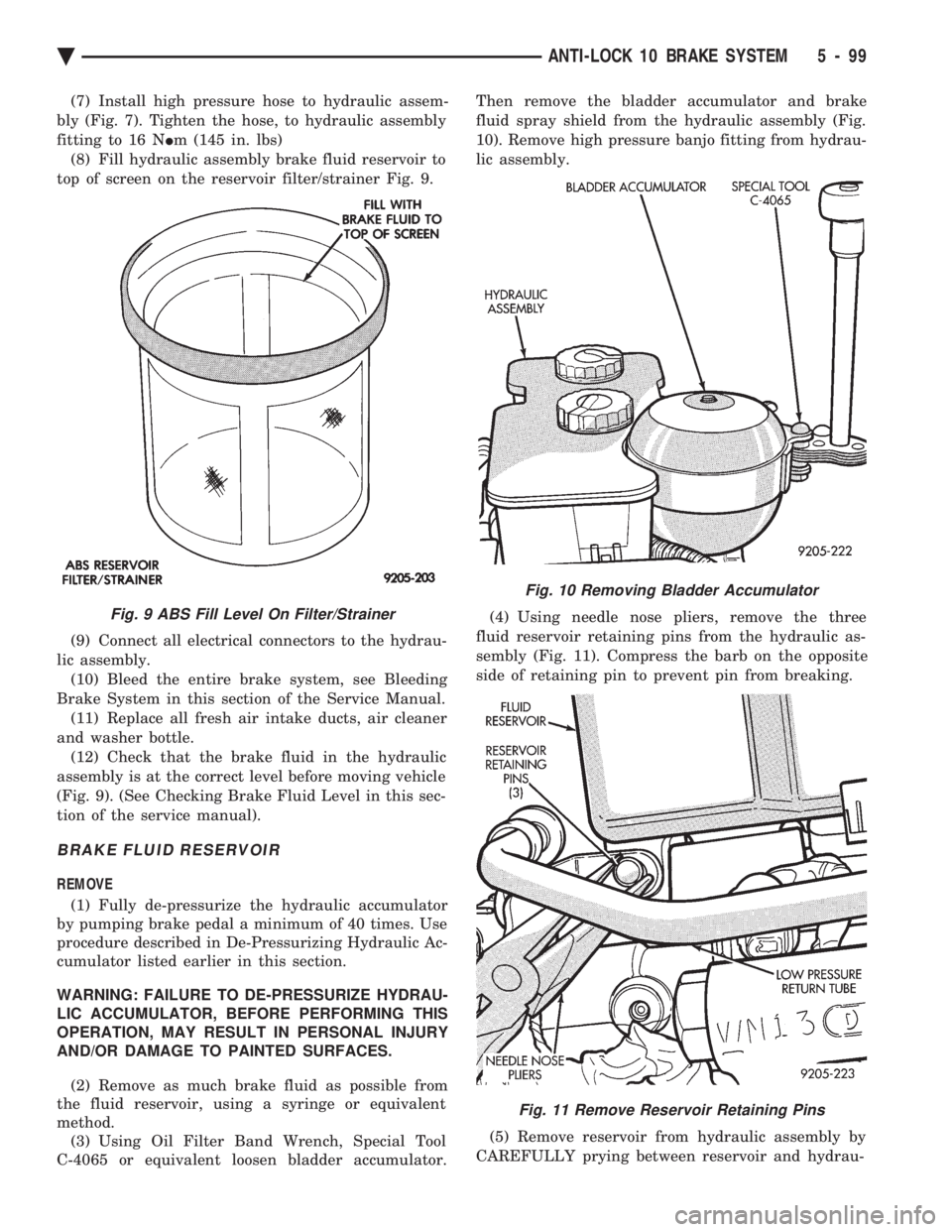

BRAKE FLUID RESERVOIR

REMOVE

(1) Fully de-pressurize the hydraulic accumulator

by pumping brake pedal a minimum of 40 times. Use

procedure described in De-Pressurizing Hydraulic Ac-

cumulator listed earlier in this section.

WARNING: FAILURE TO DE-PRESSURIZE HYDRAU-

LIC ACCUMULATOR, BEFORE PERFORMING THIS

OPERATION, MAY RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES.

(2) Remove as much brake fluid as possible from

the fluid reservoir, using a syringe or equivalent

method. (3) Using Oil Filter Band Wrench, Special Tool

C-4065 or equivalent loosen bladder accumulator. Then remove the bladder accumulator and brake

fluid spray shield from the hydraulic assembly (Fig.

10). Remove high pressure banjo fitting from hydrau-

lic assembly.

(4) Using needle nose pliers, remove the three

fluid reservoir retaining pins from the hydraulic as-

sembly (Fig. 11). Compress the barb on the opposite

side of retaining pin to prevent pin from breaking.

(5) Remove reservoir from hydraulic assembly by

CAREFULLY prying between reservoir and hydrau-

Fig. 9 ABS Fill Level On Filter/Strainer

Fig. 10 Removing Bladder Accumulator

Fig. 11 Remove Reservoir Retaining Pins

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 99